FEATURES

■

High Efficiency Over Wide Load Current Range

■

±0.8% Output Voltage Accuracy

■

Dual N-Channel MOSFET Synchronous Drivers

■

Pulse Transformer Synchronization

■

Optocoupler Feedback Driver

■

Programmable Current Limit Protection

■

±5% Margin Output Voltage Adjustment

■

Adjustable Overvoltage Fault Protection

■

Power Good Flag

■

Auxiliary 3.3V Logic Supply

■

Available in 16-Lead SSOP and SO Packages

U

APPLICATIO S

■

48V Input Isolated DC/DC Converters

■

Isolated Telecommunication Power Systems

■

Distributed Power Step-Down Converters

■

Industrial Control Systems

■

Automotive and Heavy Equipment

LTC1698

Isolated Secondary

Synchronous Rectifier Controller

U

DESCRIPTIO

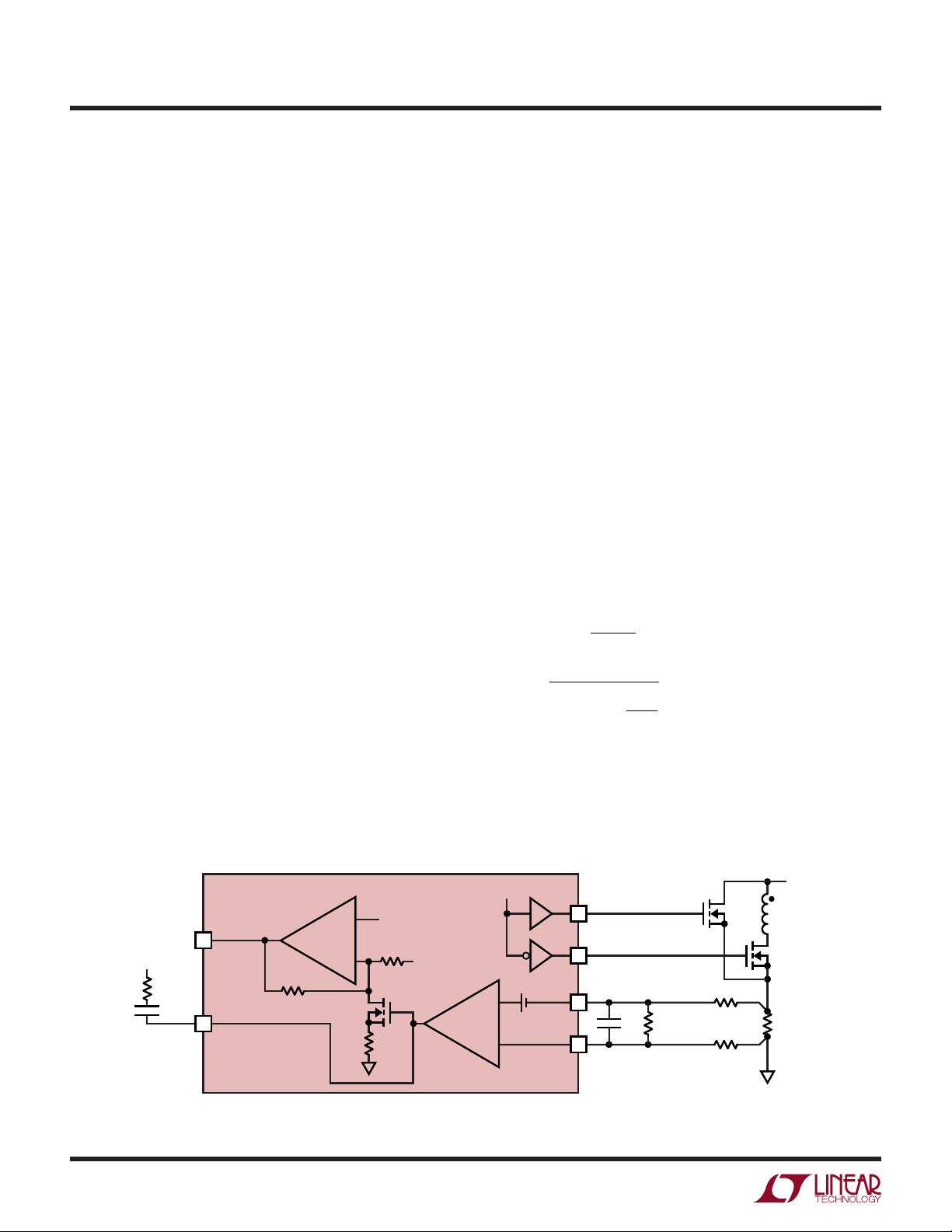

The LTC®1698 is a precision secondary-side forward

converter controller that synchronously drives external

N-channel MOSFETs. It is designed for use with the

LT®3781 primary-side synchronous forward converter

controller to create a completely isolated power supply.

The LT3781 synchronizes the LTC1698 through a small

pulse transformer and the LTC1698 drives a feedback

optocoupler to close the feedback loop. Output accuracy

of ±0.8% and high efficiency over a wide range of load

currents are obtained.

The LTC1698 provides accurate secondary-side current

limit using an external current sense resistor. The input

voltage at the MARGIN pin provides ±5% output voltage

adjustment. A power good flag and overvoltage input are

provided to ensure proper power supply conditions. An

auxiliary 3.3V logic supply is included that supplies up to

10mA of output current.

, LTC and LT are registered trademarks of Linear Technology Corporation.

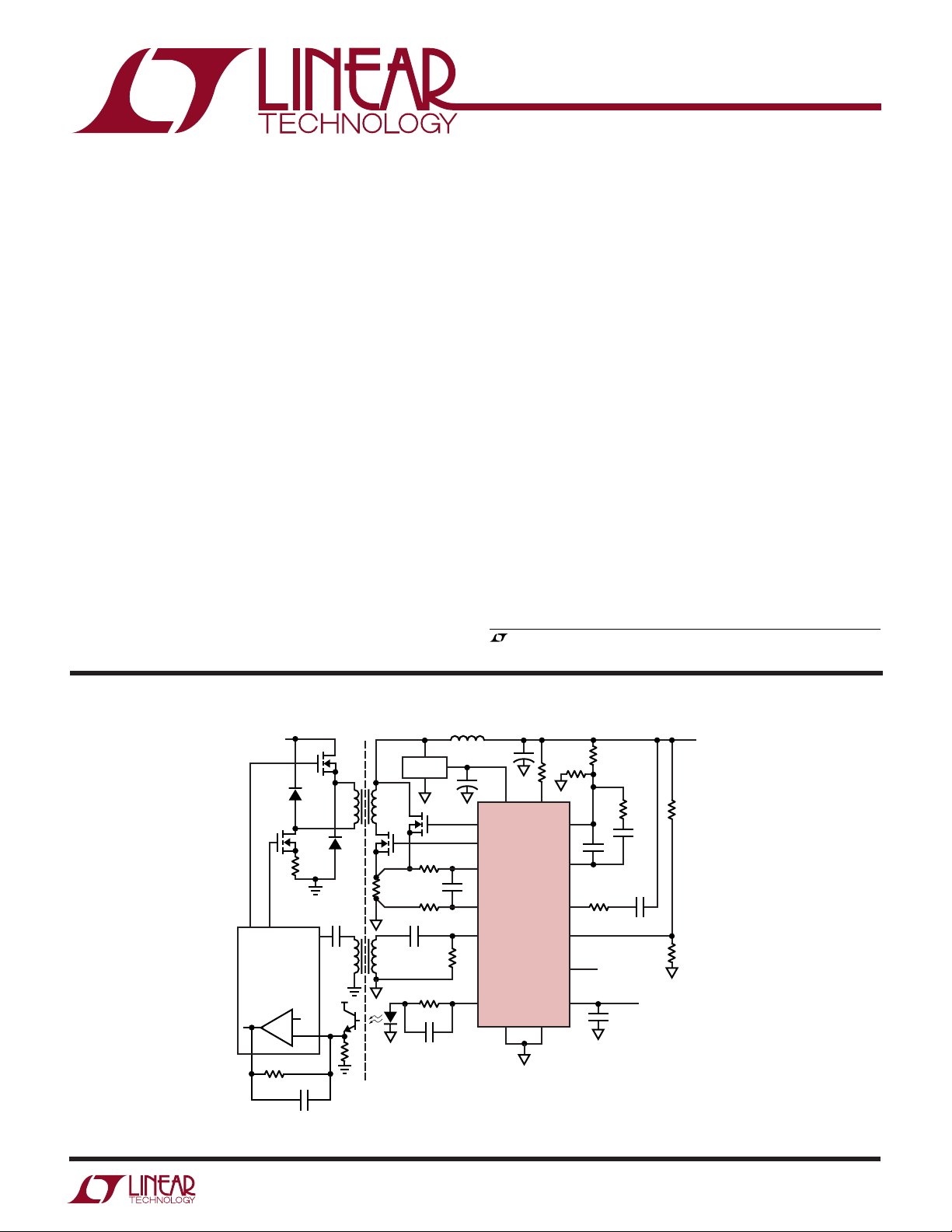

TYPICAL APPLICATIO

V

IN

36V to 72V

TG BG

LT3781

+

–

V

C

R

F

U

L1

+

C

OUT

+

110

V

PWRGD

DD

28

CG

16

FG

12

I

SNS

11

I

SNSGND

15

SYNC

5

OPTODRV

PGND GND

V

LTC1698

V

COMP

I

COMP

OVPIN

MARGIN V

V

AUX

34

Q2

R

REF

C

D1

PRISEN

SG

V

FB

F

Q1

T1

C

SG

T2

•

D2

•

R

E

ISOLATION

BOUNDARY

•

R

•

Q4

Q3

SECSEN

VDD BIAS

C

SYNC

R

SYNC

R

K

C

K

PLEASE REFER TO FIGURE 12 IN THE TYPICAL APPLICATIONS

SECTION FOR THE COMPLETE 3.3V/15A APPLICATION SCHEMATIC

Figure 1. Simplified 2-Transistor Isolated Forward Converter

R2

R1

R

FB

6

13

9

7

14

C

C

C

C

FB

C

CILM

R

CILM

MARGIN

V

AUX

3.3V

10mA

O.1µF

1681 F01

V

OUT

R5

R4

1698f

1

LTC1698

WW

W

ABSOLUTE MAXIMUM RATINGS

U

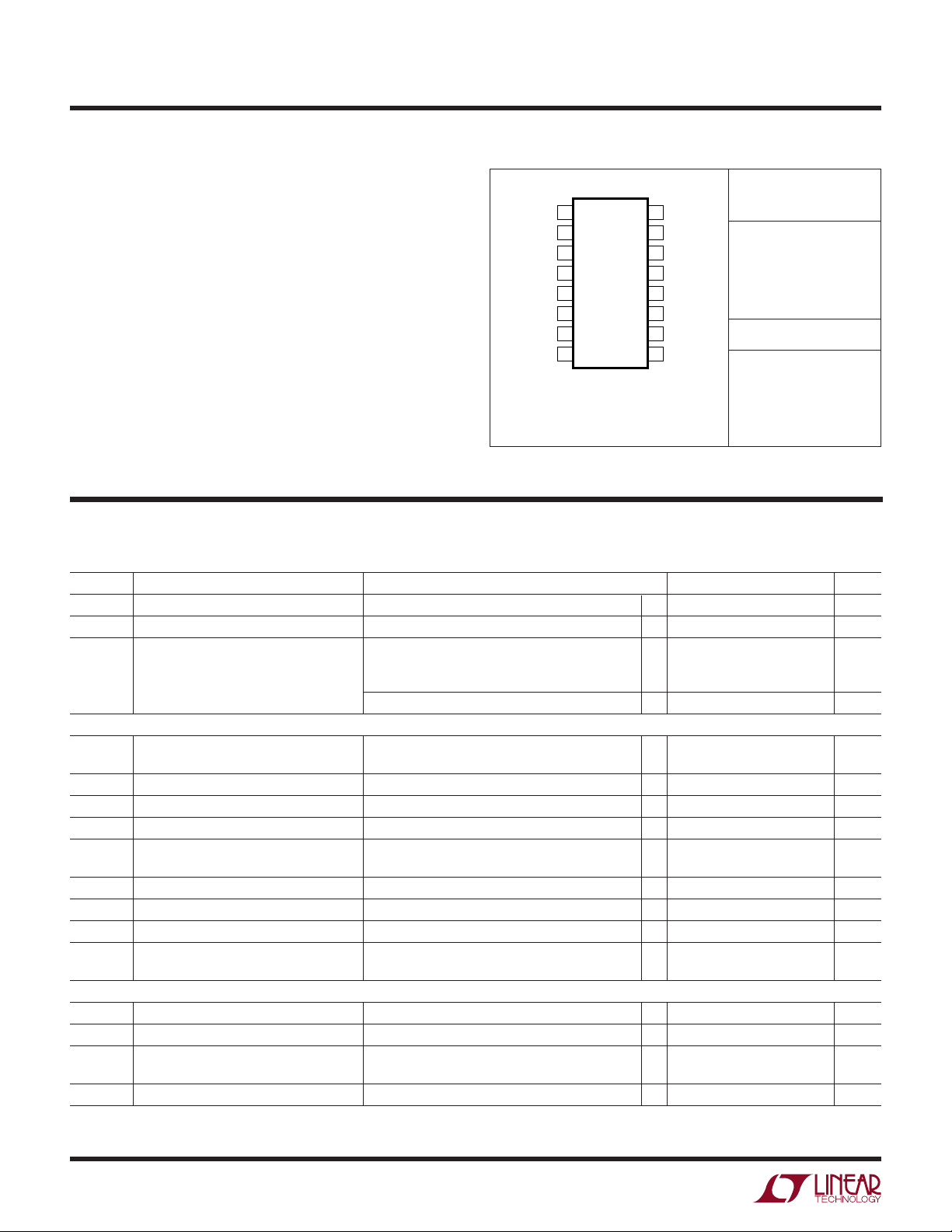

PACKAGE/ORDER INFORMATION

(Note 1)

VDD, PWRGD ....................................................... 13.2V

Input Voltage

MARGIN, VFB, OVPIN, I

SNSGND

, I

... –0.3V to 5.3V

SNS

SYNC ..................................................... –14V to 14V

Output Voltage

V

COMP

, I

(Note 2)......................... – 0.3V to 5.3V

COMP

Power Dissipation.............................................. 500mW

Operating Temperature Range

LTC1698E (Note 3)............................ –40°C to 85°C

LTC1698I........................................... – 40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ELECTRICAL CHARACTERISTICS

The ● indicates specifications which apply over the full operating

V

DD

CG

PGND

GND

OPTODRV

V

COMP

MARGIN

V

FB

GN PACKAGE

16-LEAD PLASTIC SSOP

T

JMAX

T

JMAX

Consult LTC Marketing for parts specified with wider operating temperature ranges.

TOP VIEW

1

2

3

4

5

6

7

8

16-LEAD PLASTIC SO

= 125°C, θJA = 130°C/W (GN)

= 125°C, θJA = 110°C/W (SO)

FG

16

SYNC

15

V

14

I

13

I

12

I

11

PWRGD

10

OVPIN

9

S PACKAGE

AUX

COMP

SNS

SNSGND

temperature range, otherwise specifications are at TA = 25°C. VDD = 8V, unless otherwise noted. (Note 4)

U

W

ORDER PART

NUMBER

LTC1698EGN

LTC1698ES

LTC1698IGN

LTC1698IS

GN PART MARKING

1698

1698I

U

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

DD

V

UVLO

I

VDD

MARGIN and Error Amplifier

V

FB

I

VFB

V

MARGIN

R

MARGIN

∆V

FB

G

ERR

BW

ERR

V

CLAMP

I

VCOMP

OPTODRV

G

OPTO

BW

OPTO

V

OPTOHIGH

I

OPTOSC

Supply Voltage ● 6 8 12.6 V

Undervoltage Lockout 4V

VDD Supply Current VFB, OVPIN, V

C

= CCG = 1000pF, C

FG

V

= 0V ● 1.8 4 mA

SYNC

f

= 100kHz (Note 5) 5.0 mA

SYNC

Feedback Voltage MARGIN = Open, V

Feedback Input Current VFB = 1.233V ● 0.05 1 µA

MARGIN Voltage MARGIN = Open 1.65 V

MARGIN Input Resistance 16.5 kΩ

Feedback Voltage Adjustment V

Error Amplifier Open-Loop DC Gain V

Error Amplifier Unity-Gain Bandwidth No Load (Note 6) 2 MHz

Error Amplifier Output Clamp Voltage VFB = 0V 2 V

Error Amplifier Source Current VFB = 0V ● –25 –10 mA

Error Amplifier Sink Current V

Opto Driver DC Gain OVPIN, V

Opto Driver Unity-Gain Bandwidth No Load (Note 6) 1 MHz

Opto Driver Output High Voltage VFB, OVPIN, V

Opto Driver Output Short-Circuit Current OVPIN, V

= 3.3V ● 456 %

MARGIN

V

= 0V ● –6 –5 –4 %

MARGIN

= 0.8V to 1.2V, Load = 2kΩ, 100pF ● 65 90 dB

COMP

= 5V, V

FB

I

= –10mA ● 45 V

OPTODRV

, V

ISNS

COMP

= 1.233V ● 37 mA

COMP

, V

ISNS

ISNSGND

ISNSGND

, V

ISNSGND

ISNS

= 0V,

ISNSGND

= 0.1µF,

VAUX

= 1V (Note 7) 1.223 1.233 1.243 V

● 1.215 1.233 1.251 V

= 0V ● 4.75 5 5.25 V/V

= 0V, V

= 0V, VFB = 1.233V ● –50 –25 –10 mA

= –50mV,

ISNS

2

1698f

LTC1698

ELECTRICAL CHARACTERISTICS

The ● indicates specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VDD = 8V, unless otherwise noted. (Note 4)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

AUX

V

AUX

Current Limit Amplifier

I

ISNSGNDISNSGND

I

ISNS

V

ILIMTH

I

ICOMPICOMP

g

mILIM

G

ICOMP

PWRGD and OVP Comparators

V

PWRGD

I

PWRGD

V

OL

V

OVPREF

I

OVPIN

t

PWRGD

t

OVP

SYNC and Drivers

V

PT

V

NT

I

SYNC

f

SYNC

t

d

t

SYNC

tr, t

t

DDIS

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired. All voltages refer to GND.

Note 2: The LTC1698 incorporates a 5V linear regulator to power internal

circuitry. Driving these pins above 5.3V may cause excessive current flow.

Guaranteed by design and not subject to test.

Note 3: The LTC1698E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls. For guaranteed performance to

specifications over the –40°C to 85°C range, the LTC1698I is available.

Note 4: All currents into device pins are positive; all currents out of the

device pins are negative. All voltages are referenced to ground unless

otherwise specified. For applications with V

Performance Characteristics.

Auxiliary Supply Voltage C

Input Current V

I

Input Current V

SNS

Current Limit Threshold V

(V

ISNS

– V

) ● –27.5 –25 –22.5 mV

ISNSGND

Source Current V

I

Sink Current V

COMP

Current Limit Amplifier V

= 0.1µF, I

VAUX

= 0V ● 0.05 1 µA

ISNSGND

= 0V ● 0.05 1 µA

ISNS

= 2.5V, V

ICOMP

= 0V, V

ISNSGND

= 0V, V

ISNSGND

= 0V, V

ISNSGND

= 0mA to 10mA, VDD = 7V to 12.6V ● 3.135 3.320 3.465 V

LOAD

= 0V –27.0 –25 –23.0 mV

ISNSGND

= –0.3V, V

ISNS

= 0.3V, V

ISNS

ICOMP

= 2.5V, I

= 2.5V (Note 8) –280 –200 – 120 µA

ICOMP

= 2.5V (Note 8) 120 200 280 µA

ICOMP

= ±10µA ● 2.2 3.5 5 millimho

ICOMP

● –370 – 200 – 80 µA

● 80 200 370 µA

Transconductance

Current Limit Amplifier V

= 2.5V, No Load ● 48 60 dB

ICOMP

Open-Loop DC Gain

Percent Below V

FB

V

↓, MARGIN = Open (Note 9) ● –9 –6 –3 %

FB

Power Good Sink Current VFB = 2V ● 10 µA

VFB = 0V ● 10 mA

Power Good Output Low Voltage I

OVPIN Threshold VFB = V

OVPIN Input Bias Current V

= 3mA, VFB = 0V ● 0.4 V

PWRGD

= V

ISNS

= 1.233V ● 0.1 1 µA

OVPIN

= 0V, OVPIN ↑ (Note 9) ● 1.18 1.233 1.28 V

ISNSGND

Power Good Response Time VFB ↑ ● 125 ms

Power Bad Response Time VFB ↓ ● 0.5 1 2.5 ms

Overvoltage Response Time V

OVPIN

↑, C

= 0.1µF ● 520 µs

OPTODRV

SYNC Input Positive Threshold ● 1 1.6 2.2 V

SYNC Input Negative Threshold ● – 2.2 –1.6 –1 V

SYNC Input Current V

SYNC Frequency Range CFG = CCG = 1000pF, V

SYNC Input to Driver Output Delay CFG = CCG = 1000pF, f

Minimum SYNC Pulse Width f

Driver Rise and Fall Time CFG = CCG = 1000pF, f

f

= ±10V ● 150 µA

SYNC

= ±5V ● 50 400 kHz

SYNC

= 100kHz, V

SYNC

= 100kHz, V

SYNC

= ±10V (Note 6) ● 75 ns

SYNC

= 100kHz, V

SYNC

= ±5V ● 40 90 ns

SYNC

= ±5V, ● 10 40 ns

SYNC

10% to 90%

Driver Disable Time-Out CFG = CCG = 1000pF, f

= 100kHz, V

SYNC

SYNC

= ±5V

Measured from CG ↑ (Note 10) ● 10 15 20 µs

Note 5: Supply current in active operation is dominated by the current

needed to charge and discharge the external FET gates. This will vary with

the LTC1698 operating frequency, supply voltage and the external FETs

used.

Note 6: This parameter is guaranteed by correlation and is not tested.

Note 7: VFB is tested in an op amp feedback loop which servos VFB to the

internal bandgap voltage.

Note 8: The current comparator output current varies linearly with

temperature.

Note 9: The PWRGD and OVP comparators incorporate 10mV of

hysteresis.

< 7V, refer to the Typical

DD

Note 10: The driver disable time-out is proportional to the SYNC period

within the frequency synchronization range.

1698f

3

LTC1698

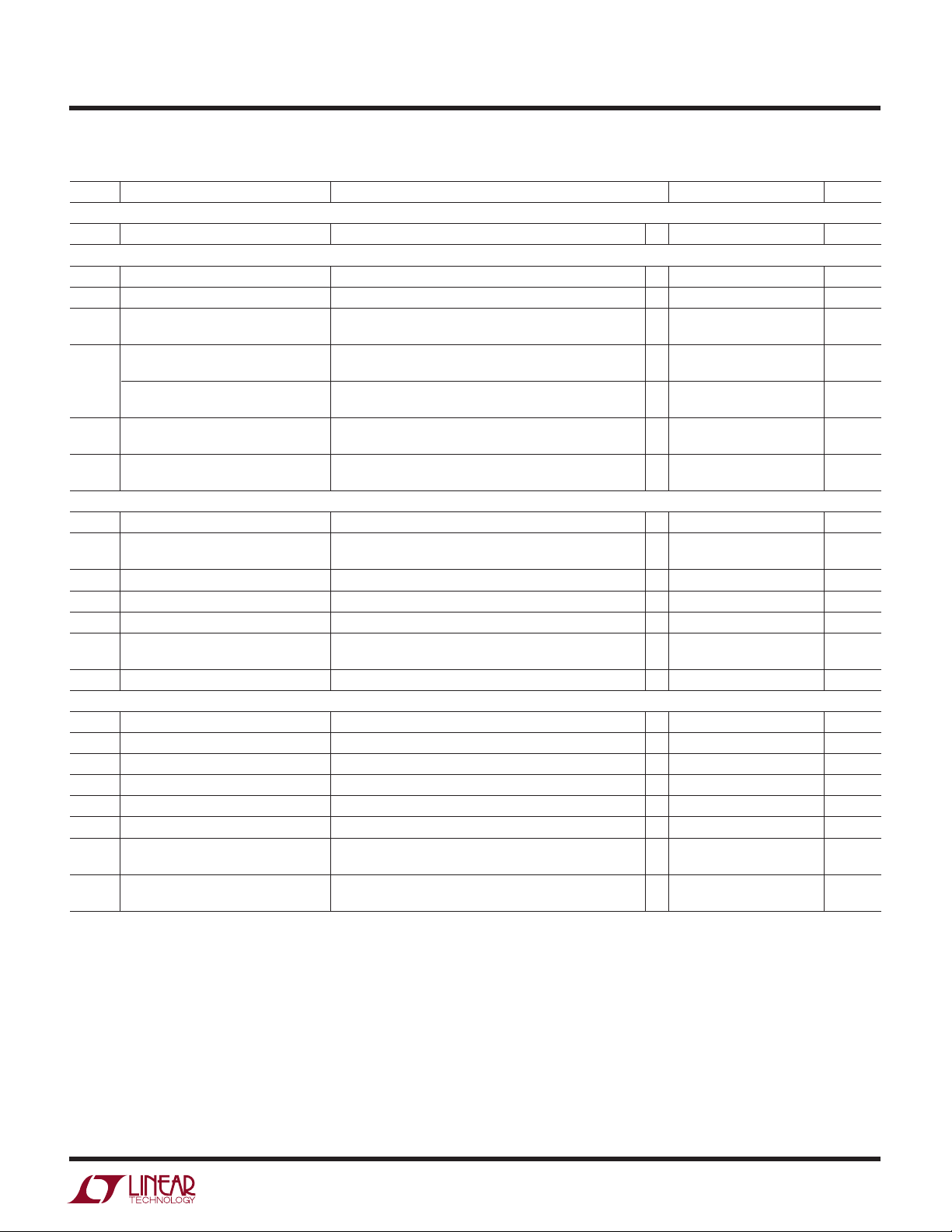

TEMPERATURE (°C)

–50

g

mILIM

(millimho)

3.8

4.2

4.6

100 125

1698 G06

3.4

3.0

–25 250 50 75 150

2.6

2.2

5.0

VDD = 8V

UW

TYPICAL PERFOR A CE CHARACTERISTICS

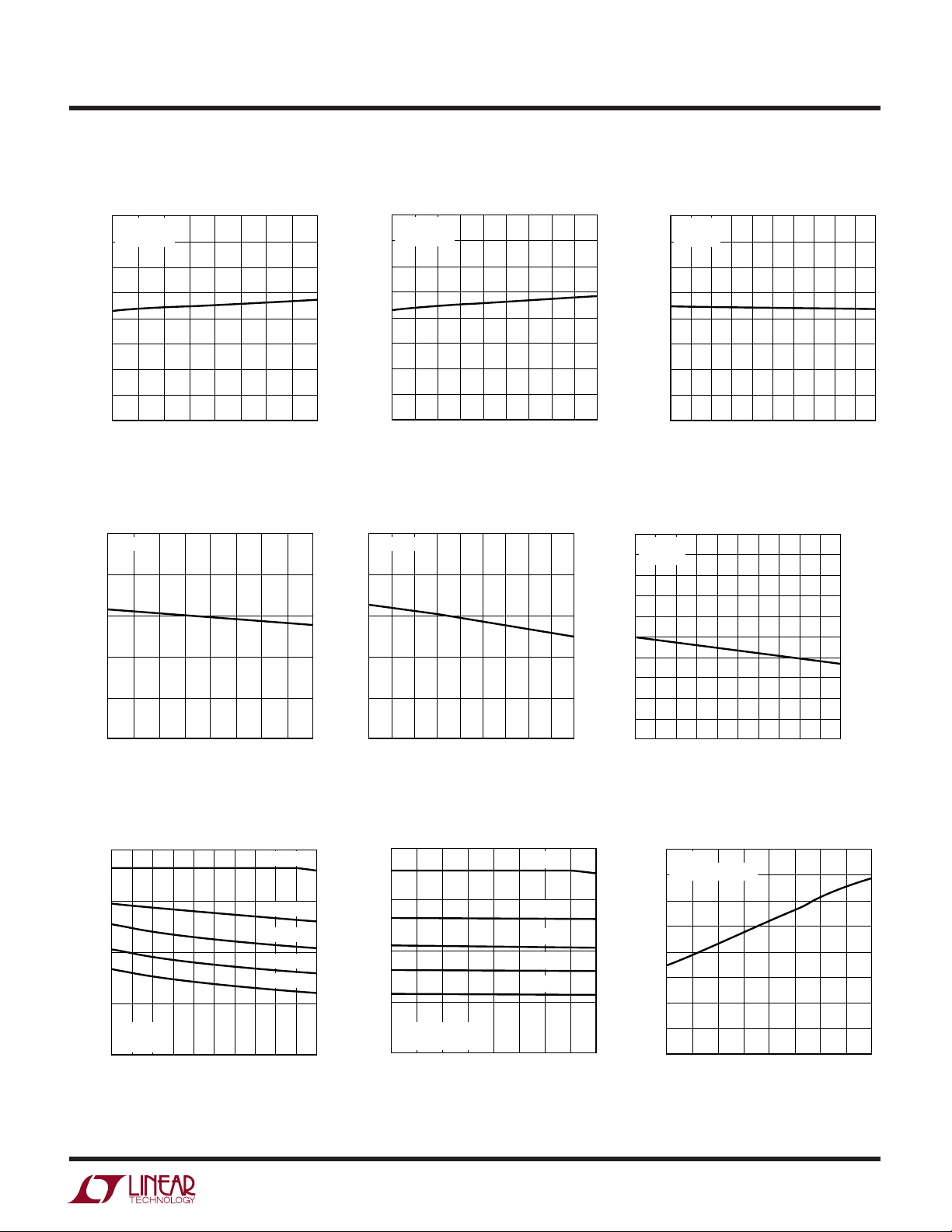

VFB vs Temperature

1.248

VDD = 8V

1.242

1.236

(V)

FB

V

1.230

1.224

1.218

–50

–25 0

I

Threshold vs Temperature I

SNS

–22.5

VDD = 8V

–23.0

–23.5

–24.0

–24.5

–25.0

–25.5

THRESHOLD (mV)

–26.0

SNS

I

–26.5

–27.0

–27.5

–50

–25 25

50

25 75 150

TEMPERATURE (°C)

0

50

TEMPERATURE (°C)

75

100 125

100

1698 G01

125

1698 G04

150

VFB vs V

1.248

TA = 25°C

1.242

1.236

(V)

FB

V

1.230

1.224

1.218

5

–22.5

–23.0

–23.5

–24.0

–24.5

–25.0

–25.5

THRESHOLD (mV)

–26.0

SNS

I

–26.5

–27.0

–27.5

DD

68

7

Threshold vs V

SNS

TA = 25°C

5

69

10 14

9

VDD (V)

87

VDD (V)

VFB vs V

1.295

1.282

1.270

1.258

1.245

(V)

1.233

FB

V

1.221

1.208

1.196

1.184

13

1698 G05

1.171

0

14

12

11

13

1698 G02

DD

12

10

11

MARGIN

VDD = 8V

= 25°C

T

A

0.660.33

1.320.99

V

MARGIN

1.65

1.98 2.31 2.97

(V)

Current Limit Amplifier g

vs Temperature

2.64

1698 G03

m

3.3

5

4

3

2

∆V

1

FB

(%)

0

–1

–2

–3

–4

–5

OVPIN Threshold vs Temperature OVPIN Threshold vs V

1.28

VDD = 8V

1.26

1.24

1.22

OVPIN THRESHOLD (V)

1.20

1.18

–50

–25 0

4

50

25 75 150

TEMPERATURE (°C)

100 125

1698 G07

1.28

TA = 25°C

1.26

1.24

1.22

OVPIN THRESHOLD (V)

1.20

1.18

68

7

5

DD

12

10 14

11

9

VDD (V)

13

1698 G08

Power Good Threshold

vs Temperature

1.196

VDD = 8V

1.181

1.166

1.152

1.137

POWER GOOD THRESHOLD (V)

1.122

–50

–25 0

25 75 150

TEMPERATURE (°C)

–3.0

–4.2

∆V

–5.4

FB

(%)

–6.6

–7.8

50

100 125

–9.0

1698 G09

1698f

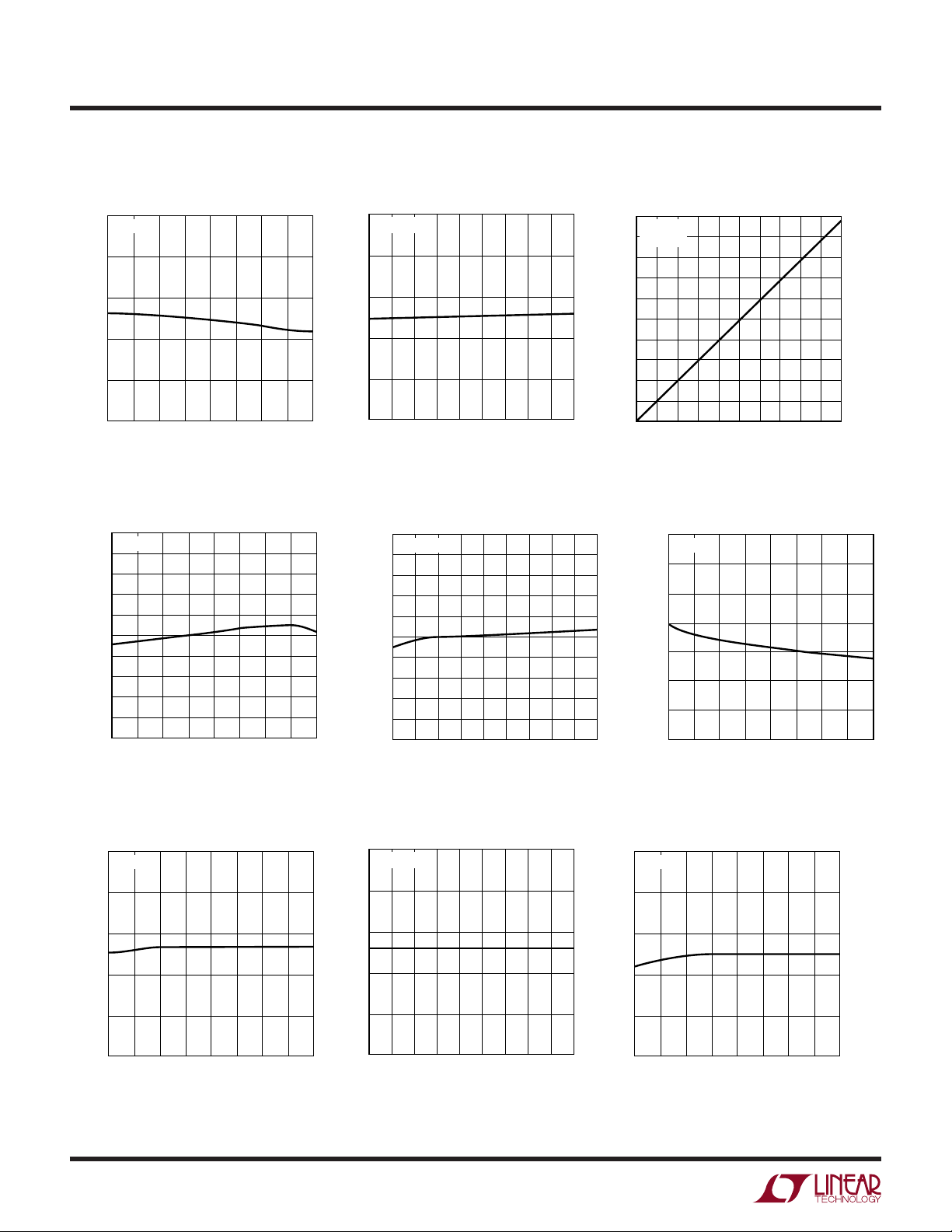

UW

TYPICAL PERFOR A CE CHARACTERISTICS

V

vs Temperature V

AUX

3.465

VDD = 8V

= 0mA

I

LOAD

3.424

3.383

3.341

(V)

3.300

AUX

V

3.259

3.218

3.176

3.135

–25

–50

V

0

Short-Circuit Current

AUX

50

25

TEMPERATURE (°C)

vs Temperature

0

VDD = 8V

–10

–20

–30

SHORT-CIRCUIT CURRENT (mA)

–40

AUX

V

–50

–50

–25 0

50

25 75 150

TEMPERATURE (°C)

75

100

125

100 125

1698 G10

1698 G13

3.465

3.424

3.383

3.341

(V)

3.300

AUX

V

3.259

3.218

3.176

150

3.135

V

AUX

vs V

0

TA = 25°C

–10

–20

–30

SHORT-CIRCUIT CURRENT (mA)

–40

AUX

V

–50

5

vs Line Voltage V

AUX

VDD = 8V

= 0mA

I

LOAD

10

6

5

78

9

VDD (V)

11

12

Short-Circuit Current

DD

9

67

810 14

11 12 13

VDD (V)

1698 G14

AUX

3.465

VDD = 8V

= 25°C

T

A

3.424

3.383

3.341

(V)

3.300

AUX

V

3.259

3.218

3.176

13

1698 G11

14

3.135

0

Opto Driver Load Regulation

3.030

VDD = 8V

3.024

= 25°C

T

A

3.018

3.012

3.006

3.000

2.994

2.988

2.982

OPTO DRIVER OUTPUT VOLTAGE (V)

2.976

2.970

21

0

vs Load Current

1

23

4

LOAD CURRENT (mA)

67 9

43

5

LOAD CURRENT (mA)

LTC1698

5

6

7

8

1698 G12

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

–0.8

1698 G15

–1.0

10

8

109

PERCENT (%)

Maximum OPTO Driver Output

Voltage vs Load Current

8

6

4

2

TA = 25°C

V

= 0V

COMP

MAXIMUM OPTO DRIVER OUTPUT VOLTAGE (V)

0

2

1

0

5

4

3

LOAD CURRENT (mA)

6

VDD = 10V

VDD = 8V

VDD = 7V

VDD = 6V

VDD = 5V

7

8

9

1698 G22

Maximum OPTO Driver Output

Voltage vs Temperature

8

6

4

2

= 0V

V

COMP

I

= –10mA

OPTODRV

MAXIMUM OPTO DRIVER OUTPUT VOLTAGE (V)

0

–50

10

–25 0 25 50

TEMPERATURE (°C)

VDD = 10V

VDD = 8V

VDD = 7V

VDD = 6V

VDD = 5V

75 100 125 150

1698 G23

Opto Driver Short-Circuit Current

vs Temperature

–10

VDD = 8V

= 1.233V

V

OPTODRV

–15

–20

–25

–30

–35

–40

–45

OPTO DRIVER SHORT-CIRCUIT CURRENT (mA)

–50

–50

–25

0

50

25

TEMPERATURE (°C)

75

100

125

1698 G16

150

1698f

5

LTC1698

VDD (V)

5

1.00

SYNC POSITIVE THRESHOLD (V)

1.24

1.72

1.96

2.20

7

9

10 14

1698 G21

1.48

68

11

12

13

TA = 25°C

UW

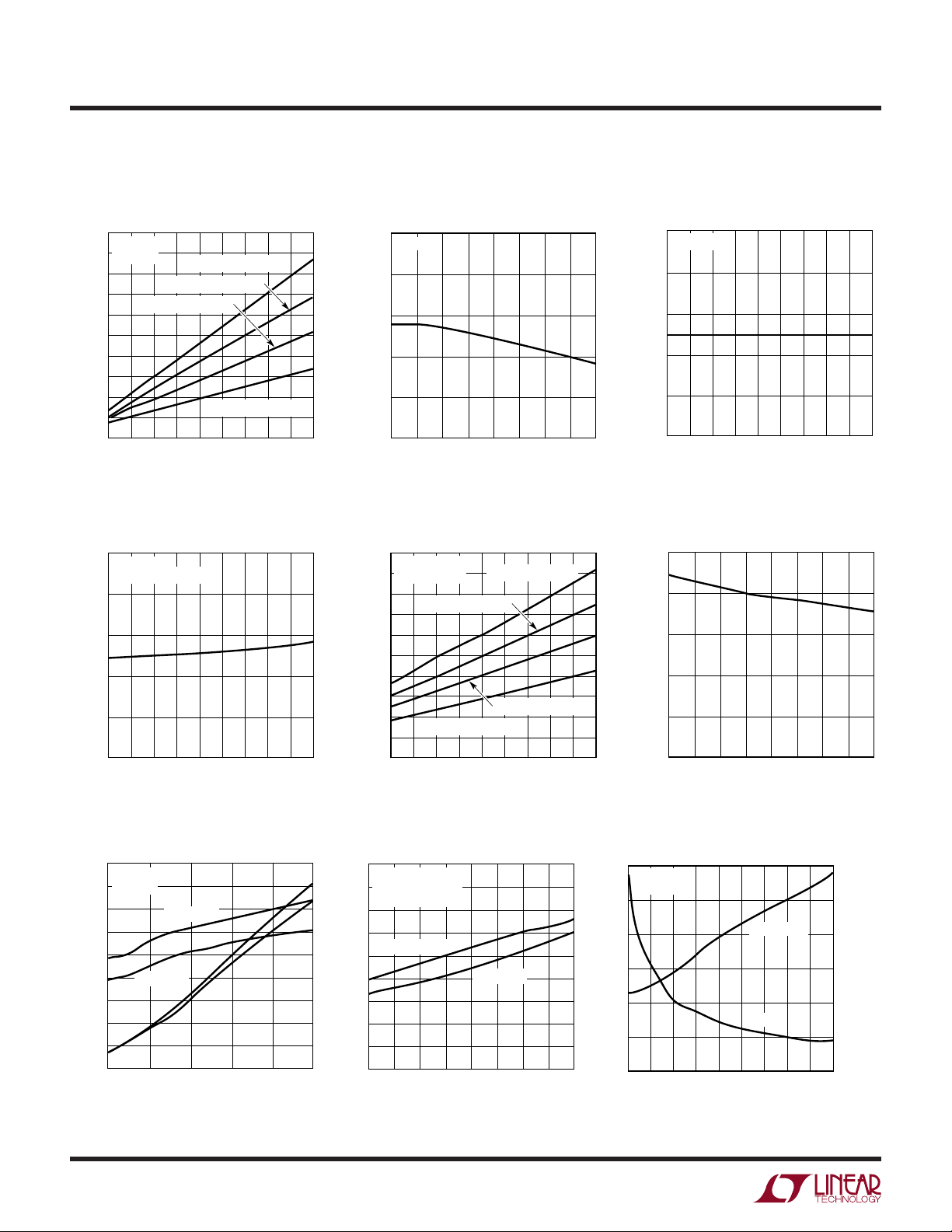

TYPICAL PERFOR A CE CHARACTERISTICS

I

vs SYNC Frequency

VDD

50

VDD = 8V

45

T

= 25°C

(mA)

VDD

I

A

40

35

30

25

20

15

10

5

0

50

CFG = CCG = 2200pF

150100

CFG = CCG = 4700pF

CFG = CCG = 3300pF

CFG = CCG = 1000pF

350 400

250200

300

f

(kHz)

SYNC

Opto Driver Short-Circuit Current

vs V

DD

0

TA = 25°C

= 1.233V

V

OPTODRV

–10

–20

–30

–40

OPTO DRIVER SHORT-CIRCUIT CURRENT (mA)

–50

5

67

9

810 14

11 12 13

VDD (V)

450

1698 G19

1698 G17

500

SYNC Positive Threshold

vs Temperature

2.25

VDD = 8V

2.00

1.75

1.50

1.25

SYNC POSITIVE THRESHOLD (V)

1.00

(mA)

VDD

I

20

18

16

14

12

10

8

6

4

2

0

–50

I

VDD

TA = 25°C

f

SYNC

5

–25 0

vs V

= 100kHz

CFG = CCG = 3300pF

CFG = CCG = 1000pF

76

50

25 75 150

TEMPERATURE (°C)

DD

CFG = CCG = 4700pF

98

VDD (V)

100 125

1698 G20

CFG = CCG = 2200pF

11 12

10

13

1698 G18

SYNC Positive Threshold

vs V

DD

Undervoltage Lockout Threshold

vs Temperature

5

4

3

(V)

UVLO

V

2

1

0

–50

14

–25 0

50

25 75 150

TEMPERATURE (°C)

100 125

1698 G24

Driver Rise, Fall and Propagation

Delay vs Driver Load

90

VDD = 8V

= 25°C

T

80

A

70

60

50

40

TIME (ns)

30

20

10

0

0

6

CG, FG t

2000 6000

CG, FG t

PLH

t

f

PHL

4000

DRIVER LOAD (pF)

t

SYNC Input to Driver Output Delay

vs Temperature

90

VDD = 8V

C

= CFG = 1000pF

80

CG

= 100kHz

f

SYNC

70

60

CG, FG t

r

10000

8000

1698 G25

50

(ns)

d

t

40

30

20

10

0

–50 –25 0 25 50 75 100 125 150

PLH

CG, FG t

TEMPERATURE (°C)

PHL

1698 G26

Driver Disable Time-Out vs SYNC

Frequency

30

VDD = 8V

= 25°C

T

A

25

(µs)

DISS

20

15

10

5

DRIVER DISABLE TIME-OUT t

0

100 200

150

50

t

DISS

t

DISS

300 500

350

250

f

(kHz)

SYNC

2.2

NORMALIZED DRIVER DISABLE TIME-OUT

2.0

× f

SYNC

400

450

1698 G27

1.8

1.6

1.4

1.2

1.0

t

DISS

× f

SYNC

1698f

LTC1698

U

UU

PI FU CTIO S

VDD (Pin 1): Power Supply Input. For isolated applications, a simple rectifier from the power transformer is

used to power the chip. This pin powers the opto driver,

the V

regulator powers the remaining circuitry. VDD requires an

external 4.7µF bypass capacitor.

CG (Pin 2): Catch Gate Driver. If SYNC slews positive, CG

pulls high to drive an external N-channel MOSFET. CG

draws power from the VDD pin and swings between V

and PGND.

PGND (Pin 3): Power Ground. Connect PGND to a low

impedance ground plane in close proximity to the ground

terminal of the external current sensing resistor.

GND (Pin 4): Logic and Signal Ground. GND is referenced

to the internal low power circuitry. Careful board layout

techniques must be used to prevent corruption of signal

ground reference. Connect GND and PGND together directly at the LTC1698.

OPTODRV (Pin 5): Optocoupler Driver Output. This pin

drives a ground referenced optocoupler through an external resistor. If VFB is low, OPTODRV pulls low. If VFB is

high, OPTODRV pulls high. This optocoupler driver has a

DC gain of 5. During overvoltage or overcurrent conditions, OPTODRV pulls high. The output is capable of

sourcing 10mA of current and will drive an external 0.1µF

capacitive load and is short-circuit protected.

V

COMP

is able to drive more than 2kΩ and 100pF of load. The

internal diode connected from VFB to V

OPTODRV recovery time under start-up conditions.

MARGIN (Pin 7): Current Input to Adjust the Output

Voltage Linearly. The MARGIN pin connects to an internal

16.5k resistor. The other end of this resistor is regulated

to 1.65V. Connecting MARGIN to a 3.3V logic supply

sources 100µA of current into the chip and moves the

output voltage 5% higher. Connecting MARGIN to 0V

sinks 100µA out of the pin and moves the regulated output

voltage 5% lower. The MARGIN pin voltage does not affect

the PWRGD and OVPIN trip points.

VFB (Pin 8): Feedback Voltage. VFB senses the regulated

output voltage through an external resistor divider. The

VFB pin is servoed to the reference voltage of 1.233V under

closed-loop conditions. An RC network from VFB to V

supply and the FG and CG drivers. An internal 5V

AUX

DD

(Pin 6): Error Amplifier Output. This error amplifier

reduces

COMP

COMP

compensates the feedback loop. If VFB goes low, V

pulls high and OPTODRV goes low.

OVPIN (Pin 9): Overvoltage Input. OVPIN is a high impedance input to an internal comparator. The threshold of this

comparator is set to 1.233V. If the OVPIN potential is

higher than the threshold voltage, OPTODRV pulls high

immediately. Use an external RC lowpass filter to prevent

noisy signals from triggering this comparator.

PWRGD (Pin 10): Power Good Output. This is an opendrain output. PWRGD floats if VFB is above 94% of the

nominal value for more than 2ms. PWRGD pulls low if V

is below 94% of the nominal value for more than 1ms. The

PWRGD threshold is independent of the MARGIN pin

potential.

I

SNSGND

positive side of the sense resistor, normally grounded.

I

SNS

tive side of the sense resistor through an external RC

lowpass filter. This pin normally sees a negative voltage,

which is proportional to the average load current. If

current limit is exceeded, OPTODRV pulls high.

I

COMP

at this pin compensates the current limit feedback loop.

Referencing the RC to V

shoot on start-up. This pin can float if current limit loop

compensation is not required.

V

AUX

requires a 0.1µF or greater bypass capacitor. This auxiliary

power supply can power external devices and sources

10mA of current. Internal current limiting is provided.

SYNC (Pin 15): Drivers Synchronization Input. A negative

voltage slew at SYNC forces FG to pull high and CG to pull

low. A positive voltage slew at SYNC resets the FG pin and

CG pulls high. If SYNC loses its synchronization signal for

more than the driver disable time-out interval, both the

forward and catch drivers output are forced low. The SYNC

circuit accepts pulse and square wave signals. The minimum pulse width is 75ns. The synchronization frequency

range is between 50kHz to 400kHz.

FG (Pin 16): Forward Gate Driver. If SYNC slews negative,

FG goes high. FG draws power from VDD and swings

between VDD and PGND.

(Pin 11): Current Sense Ground. Connect to the

(Pin 12): Current Sense Input. Connect to the nega-

(Pin 13): Current Amplifier Output. An RC network

controls output voltage over-

OUT

(Pin 14): Auxiliary 3.3V Logic Supply. This pin

COMP

FB

1698f

7

LTC1698

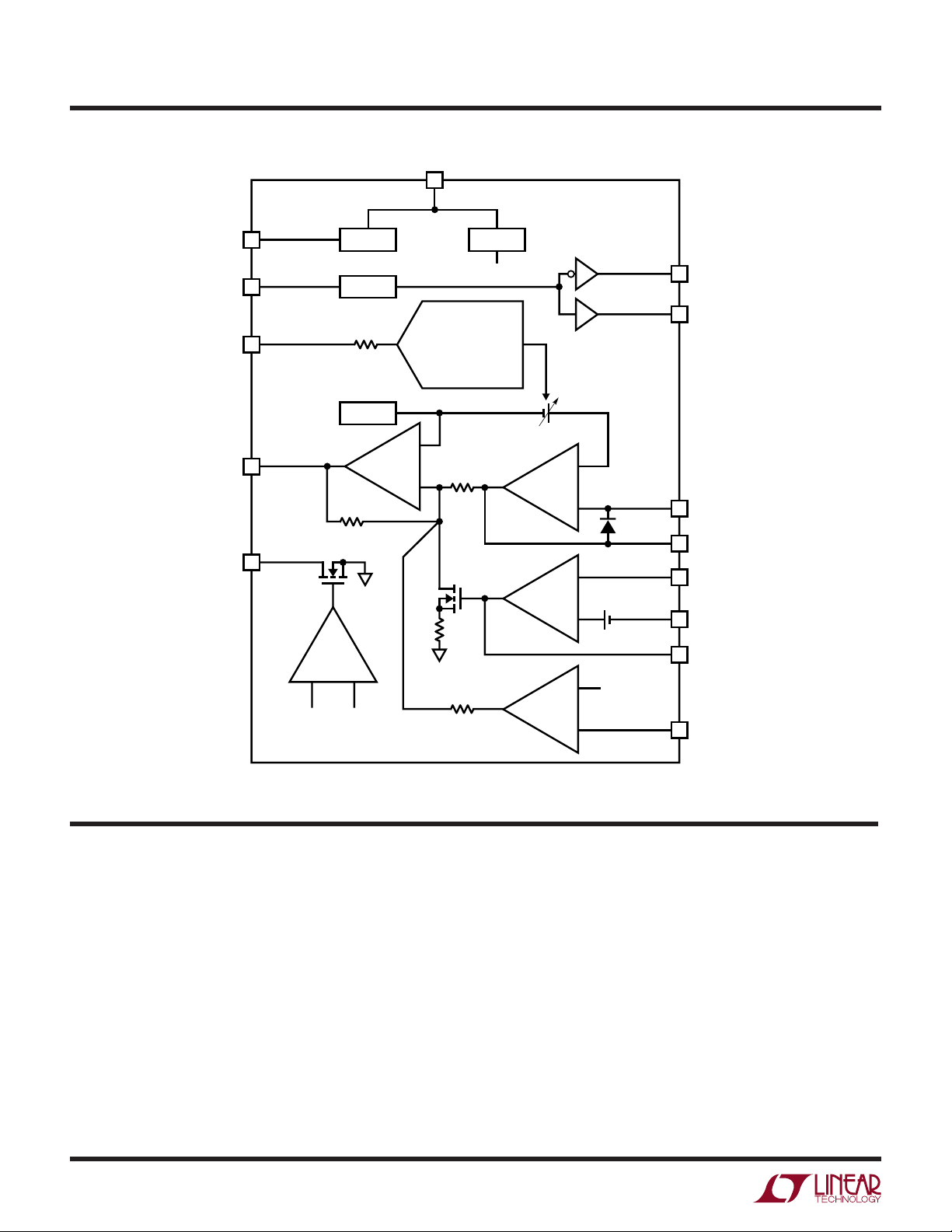

BLOCK DIAGRA

V

14

SYNC

15

MARGIN

7

W

AUX

1

V

DD

AUX GEN VCC GEN

V

SYNC IN

R

MARGIN

I-TO-V CONVERTER

CC

CG

FG

16

2

OPERATIO

OPTODRV

5

PWRGD

10

–

V

U

(Refer to Block Diagram)

M

PWRGD

PWRGD

FB

BANDGAP

100k

+

0.94V

REF

OPTO

V

REF

±5% V

REF

+

20k

–

M

ILIM

R

ILIM

3k

R

OVP

3k

+

ERR

–

+

I

LIM 25mV

+

–

+

OVP

–

V

FB

8

V

COMP

6

I

SNSGND

11

I

SNS

12

I

COMP

13

V

REF

OVPIN

9

1698 BD

The LTC1698 is a secondary-side synchronous rectifier

controller designed to work with the LT3781 primary-side

synchronous controller chip to form an isolated synchronous forward converter. This chip set uses a dual transistor forward topology that is predominantly used in distributed power supply systems where isolated low voltages

are needed to power complex electronic equipment. The

primary stage is a current mode, fixed frequency forward

converter and provides the typical PWM operation. A

power transformer is used to provide the functions of

input/output isolation and voltage step-down to achieve

the required low output voltage. Instead of using typical

8

Schottky diodes, synchronous rectification on the secondary offers isolation with high efficiency. It supplies

high power without the need of bulky heat sinks, which is

often a problem in any space constrained application.

The LTC1698 not only provides synchronous drivers for

the external MOSFETs, it comes with other housekeeping

functions performed on the secondary side of the power

supply, all within a single integrated controller. Figure 1

shows the typical chip-set application. Upon power up, the

LTC1698’s VDD input is low, the gate drivers TG and BG are

both at the ground potential. The secondary forward and

1698f

OPERATIO

LTC1698

U

(Refer to Block Diagram)

catch MOSFETs Q3 and Q4 are off. As soon as transistors

Q1 and Q2 turn on, the flux in the power transformer T1

forces the body diodes of Q3 and Q4 to conduct, and the

whole circuit starts like a conventional forward converter.

At the same time, the LTC1698 VDD potential ramps up

quickly through the VDD bias circuitry. Once the V

DD

voltage exceeds 4.0V, the LTC1698 enables its drivers and

enters synchronous operation.

The pulse transformer T2 synchronizes the primary and

secondary MOSFET drivers. In a typical conversion cycle,

the primary MOSFETs Q1 and Q2 turn on simultaneously.

SG goes low and generates a negative spike at the LTC1698

SYNC input through the pulse transformer. The LTC1698

forces FG to turn on and CG to turn off. Power is delivered

to the load through the transformer T1 and the inductor L1.

At the beginning of the next phase in which Q1 and Q2 turn

off, SG goes high, SYNC sees a positive spike, the MOSFET

Q3 shuts off, Q4 conducts and allows continuous current

to flow through the inductor L1. The capacitor C

OUT

filters

the switching waveform to provide a steady DC output

voltage for the load.

The LTC1698 error amplifier ERR senses the output voltage through an external resistor divider and regulates the

VFB pin potential to the 1.233V internal bandgap voltage.

An external RC network across the VFB and V

COMP

pins

frequency compensates the error amplifier feedback. The

opto driver amplifies the voltage difference between the

V

pin and the bandgap potential, driving the external

COMP

optocoupler diode with an inverting gain of 5. The

optocoupler feeds the amplified output error signal to the

primary controller and closes the forward converter voltage feedback loop. Under start-up conditions, the internal

diode across the LTC1698 error amplifier clamps the

V

pin. This speeds up the opto driver recovery time by

COMP

reducing the negative slew rate excursion at the COMP pin.

The forward converter output voltage can be easily ad-

justed. The potential at the MARGIN pin is capable of

forcing the error amplifier reference voltage to move

linearly by ±5%. The internal R

MARGIN

resistor converts

the MARGIN voltage to a current and linearly controls the

offset of the error amplifier. Connecting the MARGIN pin

to 3.3V increases the VFB voltage by 5%, and connecting

the MARGIN pin to 0V reduces VFB by 5%. With the

MARGIN pin floating, the VFB voltage is regulated to the

internal bandgap voltage.

The current limit transconductance amplifier I

provides

LIM

the secondary side average current limit function. The

average voltage drops across the R

SECSEN

resistor is

sensed and compared to the –25mV threshold set by the

internal I

amplifier. Once I

LIM

detects high output

LIM

current, the current amplifier output pulls high, overrides

the error amplifier, injects more current into the photo

diode and forces a lower duty cycle. An RC network

connected to the I

pin is used to stabilize the second-

COMP

ary current limit loop. Alternatively, if only overcurrent

fault protection is required, I

COMP

can float.

If under abnormal conditions the feedback path is broken,

OVPIN provides another route for overvoltage fault protection. If the voltage at OVPIN is higher than the bandgap

voltage, the OVP comparator forces OPTODRV high immediately. A simple external RC filter prevents a momentary overshoot at OVPIN from triggering the OVP

comparator. Short OVPIN to ground if this pin is not used.

The LTC1698 provides an open-drain PWRGD output. If

VFB is less than 94% of its nominal value for more than

1ms, the PWRGD comparator pulls the PWRGD pin low.

If VFB is higher than 94% of its nominal value for more than

2ms, the transistor M

shuts off, and an external

PWRGD

resistor pulls the PWRGD pin high.

The LTC1698 provides an auxiliary 3.3V logic power

supply. This auxiliary power supply is externally compensated with a minimum 0.1µF bypass capacitor. It supplies

up to 10mA of current to any external devices.

1698f

9

LTC1698

WUUU

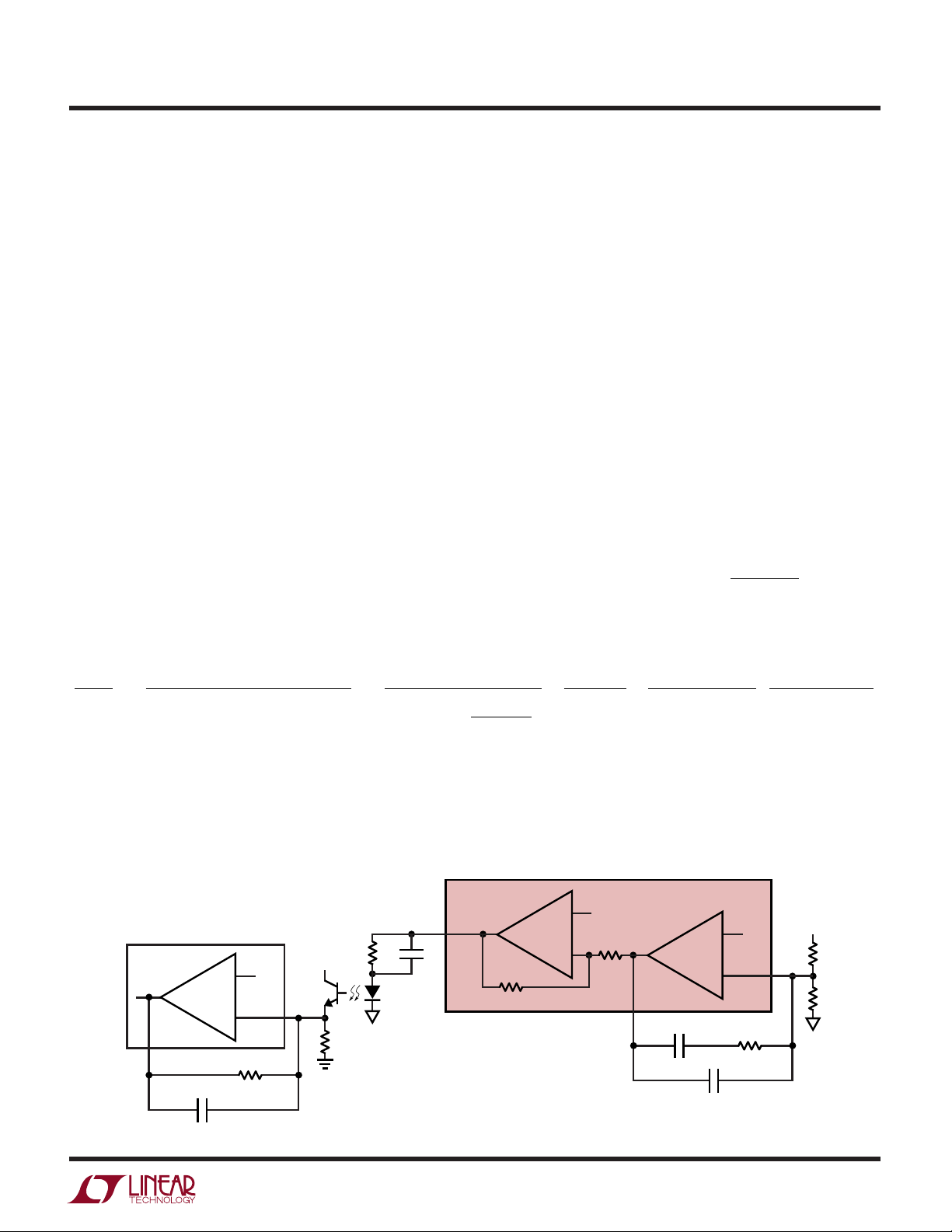

APPLICATIO S I FOR ATIO

Undervoltage Lockout

In UVLO (low VDD voltage) the drivers FG and CG are shut

off and the pins OPTODRV, V

, PWRGD and I

AUX

COMP

are

forced low. The LTC1698 allows the bandgap and the

internal bias currents to reach their steady-state values

before releasing UVLO. Typically, this happens when V

DD

reaches approximately 4.0V. Beyond this threshold, the

drivers start switching. The OPTODRV, V

I

pins return to their normal values and the chip is

COMP

, PWRGD and

AUX

fully functional. However, if the VDD voltage is less than 7V,

the OPTODRV and V

current sourcing capabilities are

AUX

limited. See the OPTO driver graphs in the Typical Performance Characteristics section.

VDD Regulator

The bias supply for the LTC1698 is generated by peak

rectifying the isolated transformer secondary winding. As

shown in Figure 2, the zener diode Z1 is connected from

base of Q5 to ground such that the emitter of Q5 is

regulated to one diode drop below the zener voltage. RZ is

selected to bring Z1 into conduction and also provide base

current to Q5. A resistor (on the order of a few hundred

ohms), in series with the base of Q5, may be required to

surpress high frequency oscillations depending on Q5’s

selection. A power MOSFET can also be used by increasing

the zener diode value to offset the drop of the gate-tosource voltage. VDD supply current varies linearly with the

supply voltage, driver load and clock frequency. A 4.7µF

bypass capacitor for the VDD supply is sufficient for most

applications. This capacitor must be large enough to

provide a stable DC voltage to meet the LTC1698 V

DD

supply requirement. Under start-up conditions, it must be

small enough to power up instantaneously, enabling the

LTC1698 to regulate the feedback loop. Using a larger

capacitor requires evaluation of the start-up performance.

SYNC Input

Figure 3 shows the synchronous forward converter application. The primary controller LT3781 runs at a fixed

frequency and controls MOSFETs Q1 and Q2. The secondary controller LTC1698 controls MOSFETs Q3 and Q4. An

inexpensive, small-size pulse transformer T2 synchronizes the primary and the secondary controllers. Figure 4

shows the pulse transformer timing waveforms. When the

LT3781 synchronization output SG goes low, MOSFET

V

IN

PRIMARY

CONTROLLER

LT3781

SG

TG

BG

Q1

D1

Q2 Q3

C

SG

ISOLATION BARRIER

••

D2

••

T2

Q4

T1

C

SYNC

R

CG

FG

SYNC

Figure 3. Synchronization Using Pulse Transformer

L1

SECONDARY

CONTROLLER

LTC1698

SYNC

1698 F03

SECONDARYPRIMARY

V

OUT

C

OUT

10

V

SECONDARY

1Ω

D3

0.47µF

*RB IS OPTIONAL, SEE TEXT

Figure 2. VDD Regulator

TG

BG

SG

R

Z

2k

*

R

B

Q5

FZT690

Z1

10V

4.7µF

1698 F02

V

DD

SYNC

FG

CG

1698 F04

Figure 4. Primary Side and Secondary Side

Synchronization Waveforms

1698f

WUUU

APPLICATIO S I FOR ATIO

LTC1698

drivers TG and BG go high. The pulse transformer T2

generates a negative slew at the SYNC pin and forces the

secondary MOSFET driver FG to go high and CG to go low.

When TG and BG go low, SG goes high and the secondary

controller forces CG high and FG low.

For a given pulse transformer, a bigger capacitor C

SG

generates a higher and wider SYNC pulse. The peak of this

pulse should be much higher than the SYNC threshold.

Amplitudes greater than ±5V help to speed up the SYNC

comparator and reduce the SYNC to FG and CG drivers

propagation delay. The minimum pulse width is 75ns.

Overshoot during the pulse transformer reset interval

must be minimized and kept below the minimum comparator thresholds of ±1V. The amount of overshoot can

be reduced by having a smaller reset resistor R

SYNC

. For

nonisolated applications, the SYNC input can be driven

directly by a square pulse. To reduce the propagation

delay, make the positive and negative magnitude of the

square wave much greater than the ±2.2V maximum

threshold.

In addition to the simple driver synchronization, the secondary controller requires a driver disable signal. Loss of

synchronization while CG is high will cause Q4 to discharge the output capacitor. This produces a negative

output voltage transient and possible damage to the load

circuitry connected to V

. To overcome this problem,

OUT

the LTC1698 comes with a unique adaptive time-out

circuit. It works well within the 50kHz to 400kHz frequency

range. At every positive SYNC pulse, the internal timer

resets. If the SYNC signal is missing, the internal timer

loses its reset command, and eventually exceeds the

internal time-out limit. This forces both the FG and CG

drivers to go low immediately.

The time-out duration varies linearly with the LT3781

primary controller clocking frequency. Upon power up,

the time-out circuitry takes a few clock cycles to adapt to

the input clock frequency. During this time interval, the

drivers pulse width might be prematurely terminated, and

the inductor current flows through the MOSFETs body

diode. Once the LTC1698 timer locks to the clocking

frequency, the LTC1698 drivers follow the SYNC signal

without fail. Figure 5 shows the SYNC time-out wave-

SG

SYNC

FG

CG

RESET

(INTERNAL)

DISDRI

(INTERNAL)

Figure 5. SYNC Time-Out Waveforms

1698 F05

forms. The time-out circuit guarantees that if the SYNC

pulse is missing for more than one period, both the

drivers will be shut down preventing the output voltage

from going below ground. The wide synchronization

frequency range adds flexibility to the forward converter

and allows this converter chip set to meet different

application requirements.

Under normal operating conditions, the time-out circuitry

adapts to the switching frequency within a few cycles.

Once synchronized, internal circuitry ensures the maximum time that the Catch FET (Q4) could be left turned on

is typically just over one switching period. This is particularly important with high output voltages that can generate

significant negative output inductor currents if the Catch

FET Q4 is left on. Poor feedback loop performance including output voltage overshoot can cause the primary controller to interrupt the synchronization pulse train. While

this generally is not a problem, it is possible that low

frequency interruptions could lead to a time-out period

longer than a switching period, limited only by the internal

timer clamp (50µs typical).

Output Voltage Programming

The switching regulator output voltage is programmed

through a resistor feedback network (R1 and R2 in

Figure 1) connected to VFB. If the output is at its nominal

value, the divider output is regulated to the error amplifier

threshold of 1.233V.

The output voltage is thus set according to the relation:

V

= 1.233 • (1 + R2/R1)

OUT

1698f

11

LTC1698

WUUU

APPLICATIO S I FOR ATIO

MARGIN Adjustment

The MARGIN input is used for adjusting the programmed

output voltage linearly by varying the current flowing into

and out of the pin. Forcing 100µA into the pin moves the

output voltage 5% higher. Forcing 100µA out of the pin

moves the output voltage 5% lower. With the MARGIN pin

floating, the VFB pin is regulated to the bandgap voltage of

1.233V. The MARGIN pin is a high impedance input. It is

important to keep this pin away from any noise source like

the inductor switching node. Any stray signal coupled to

the MARGIN pin can affect the switching regulator output

voltage.

This pin is internally connected to a 16.5k resistor that

feeds the I-V converter. The I-V converter output linearly

controls the error amplifier offset voltage. The input of the

I-V converter is biased at 1.65V. This allows the ±100µA

current to be obtained by connecting the MARGIN pin to

the V

3.3V supply (+5%) or GND (– 5%). For output

AUX

voltage adjustment smaller than ±5%, an external resistor

R

as shown in Figure 6 is added in series with the

EXT

internal resistor to lower the current flowing into or out of

the MARGIN pin. The value of R

R

=

EXT

5

%

REQUIRED

%

is calculated as follow:

EXT

1165

–•.

k

VFB loop causes the error amplifier to drive the OPTODRV

pin low, forcing the primary controller to increase the duty

cycle. This causes the output voltage to increase to a

dangerously high level. To eliminate this fault condition,

the OVP comparator monitors the output voltage with a

resistive divider at OVPIN. A voltage at OVPIN higher than

the V

potential forces the OPTODRV pin high and

REF

reduces the duty cycle, thus preventing the output voltage

from increasing further.

The OVPIN senses the output voltage through a resistor

divider network (R4 and R5 in Figure 1). The divider is

ratioed such that the voltage at OVPIN equals 1.233V when

the output voltage rises to the overvoltage level. The

overvoltage level is set following the relation:

V

OVERVOLTAGE

= 1.233 • (1 + R5/R4)

The OVP comparator is designed to respond quickly to an

overvoltage condition. A small capacitor from OVPIN to

ground keeps any noise spikes from coupling to the OVP

pin. This simple RC filter prevents a momentary overshoot

from triggering the OVP comparator.

The OVP comparator threshold is independent of the

potential at the MARGIN pin. If the OVP function is not

used, connect OVPIN to ground.

Power Good

R

REDUCE

V

FB

V

AUX

3.3V

EXT

(OPTIONAL)

INCREASE

V

FB

0.1µF

Figure 6. Output Voltage Adjustment

7

14

MARGIN

V

AUX

R

MARGIN

V

AUX GEN

DD

I-V CONVERTER

BANDGAP

ERR

V

REF

±5% V

REF

+

V

FB

V

COMP

8

6

1698 F06

–

Overvoltage Function

The OVPIN is used for overvoltage protection and is

designed to protect against an open VFB loop. Opening the

12

The PWRGD pin is an open-drain output for power good

indication. PWRGD floats if VFB is above 94% of the

nominal value for more than 2ms. An external pull-up

resistor is required for PWRGD to swing high. PWRGD

pulls low if VFB drops below 94% of the nominal value for

more than 1ms. The PWRGD threshold is referenced to the

1.233V bandgap voltage, which remains unchanged if the

MARGIN pin is exercised.

Opto Feedback and Frequency Compensation

For a forward converter to obtain good load and line

regulation, the output voltage must be sensed and compared to an accurate reference potential. Any error voltage

must be amplified and fed back to the supply’s control

circuitry where the sensed error can be corrected. In an

isolated supply, the control circuitry is frequently located

on the primary. The output error signal in this type of

1698f

WUUU

APPLICATIO S I FOR ATIO

LTC1698

supply must cross the isolation boundary. Coupling this

signal requires an element that will withstand the isolation

potentials and still transfer the loop error signal.

Optocouplers are widely used for this function due to their

ability to couple DC signals. To properly apply them, a

number of factors must be considered. The gain, or

current transfer ratio (CTR) through an optocoupler is

loosely specified and is a strong function of the input

current through the diode. It changes considerably as a

function of time (aging) and temperature. The amount of

aging accelerates with higher operating current. This

variation directly affects the overall loop gain of the system. To be an effective optical detector, the output transistor of the optocoupler must have a large base area to

collect the light energy. This gives it a large collector to

base capacitance which can introduce a pole into the

feedback loop. This pole varies considerably with the

current and interacts with the overall loop frequency

compensation network.

The common collector optocoupler configuration removes

the miller effect due to the parasitic capacitance and

increases the frequency response. Figure 7 shows the

optocoupler feedback circuitry using the common collector approach. Note that the terms RD, CTR, CDE and rπ vary

from part to part. They also change with bias current. The

dominant pole of the opto feedback is due to RF and CF. The

feedforward capacitor CK at the optocoupler creates a low

frequency zero. This zero should be chosen to provide a

phase boost at the loop crossover frequency. The parallel

combination of RK and RD form a high frequency pole with

CK. For most optocouplers, RD is 50Ω at a DC bias of 1mA,

and 25Ω at a DC bias of 2mA. The CTR term is the small

signal AC current transfer ratio. For the QT Optoelectronics MOC207 optocoupler used here, the AC CTR is around

1, even though the DC CTR is much lower when biased at

1mA or 2mA. The first denominator term in the VC/V

OUT

equation has been simplified and assumes that CFB<<CC.

The actual term is:

sR C C sR

••( )• ••

21++

CFB C

CC

CFB

CC

CFB

•

+

+

(••)

V

C

=

–

V

OUT

wherewhere

R Optocoupler diode equivalentsmall signalresis ce

D

CTR Optocoupler current transferratio

C Optocoupler nonlinearcapacitor acrossbase to emitter

DE

r Optocoupler small signalresis ce across the base emitter

π

(••)•( •• )

sR C sR C

:

=−

=

=

=−

LT3781

1

sC R

21

CCFB

+

–

V

C

C

F

CC

+

V

REF

V

FB

R

F

••

5

tan

V

CC

R

E

+

(••)

1

sR C

KK

+

••

1

sC

C

K

K

RR

OPTODRV

R

K

MOC207

•

RR

KD

+

KD

tan

100k

R CTR

•

RR srC sRC

+

–

•

F

+

DK DE FF

•

(••)•(••)

V

REF

20k

V

COMP

1

++

1

π

LTC1698

V

+

REF

V

FB

–

C

C

R

C

C

FB

1698 F07

1

1

V

OUT

R2

R1

Figure 7. Error Signal Feedback

1698f

13

LTC1698

WUUU

APPLICATIO S I FOR ATIO

A series RC network can be added in parallel with R2

(Figure 7) to provide a zero for the feedback loop frequency compensation.

The opto driver will drive a capacitive load up to 0.1µF. For

optocouplers with a base pin, switching signal noise can

get into this high impedance node. Connect a large resistor, 1M or 2M between the base and the emitter. This

increases the diode current and the overall feedback

bandwidth slightly, and decreases the optocoupler gain.

When designing the resistor in series with the optocoupler

diode, it is important to consider the part to part variations

in the current transfer ratio and its reduction over temperature and aging. The bigger the biasing current, the

faster the aging. The LTC1698 opto driver is designed to

source up to 10mA of current and swing between 0.4V to

(V

– 2.5V). This should meet the design consideration

DD

of most optocouplers.

Besides the voltage feedback function, the LTC1698 opto

driver couples fault signals to the primary controller and

prevents catastrophic damage to the circuit. Upon current

limit or an overvoltage fault, the I

or OVP comparator

LIM

overrides the error amplifier output and forces the

OPTODRV pin high. This sources maximum current into

the external optodiode and reduces the forward converter

duty cycle.

Average Current Limit

The secondary current limit function is implemented by

measuring the negative voltage across the current sense

resistor R

SECSEN

. The current limit transconductance

amplifier I

Figure 8, if the secondary current is small, the I

goes low and the transistor M

at V

COMP

ary current is large, I

sistor M

has a –25mV threshold. As shown in

LIM

pin

COMP

shuts off. The potential

ILIM

determines the OPTODRV output. If the second-

pulls high and forces the tran-

COMP

to turn on hard. Thus the current limit circuit

ILIM

overrides the voltage feedback and forces OPTODRV high

and injects maximum current into the external optocoupler.

The R

resistor provides a linear relationship between

ILIM

the current sensed and the OPTODRV output.

The I

SNS

and I

SNSGND

pins allow a true Kelvin current

sense measurement and offer true differential measurement across the sense resistor. A differential lowpass

filter formed by R6 and C2 removes the pulse-to-pulse

inductor current ripple and generates the average secondary current which is equal to the load current. The

lowpass corner frequency is typically set to 1 to 2 orders

of magnitude below the switching frequency and follows

the relationship:

mV

R

SECSEN

6

R

=

25

=

I

LMAX

1

f

π

22

•• •

SW

C

10

where:

R

I

LMAX

f

SW

= Secondary current sense resistor

SECSEN

= Maximum allowed secondary current

= Forward converter switching frequency

14

DRIVE

V

+

OPTODRV

5

V

OUT

R

CILM

C

CILM

I

COMP

13

LTC1698

OPTO

100k

M

REF

20k

–

ILIM

Figure 8. Secondary Average Current Limit

V

COMP

–

I

LIM

R

ILIM

3k

+

25mV

+

I

I

SNSGND

CG

SNS

2

FG

16

12

11

C2

R

DIV

(OPTIONAL)

R6

R6

T1

Q4

Q3

R

SECSEN

1698 F08

1698f

WUUU

APPLICATIO S I FOR ATIO

LTC1698

If the application generates a bigger current sense voltage,

a potential divider can be easily obtained by adding a

resistor across C2. With this additional resistor, the voltage sensed by the current comparator becomes:

R

DIV

+(• )

RR

DIV

26

An RC network formed by R

and V

can be used to stabilize the current limit loop.

OUT

Connecting the compensation network to V

•

V

RSENSE

CILM

and C

between I

CILM

minimizes

OUT

COMP

output overshoot during start-up or short-circuit recovery. The R

CILM

and C

zero should be chosen to be well

CILM

within the closed-loop crossover frequency. This pin can

be left floating if current loop compensation is not required. The forward converter secondary current limit function can be disabled by shorting I

SNS

and I

SNSGND

to ground.

Auxiliary 3.3V Logic Power Supply

An internal P-channel LDO (low dropout regulator) produces the 3.3V auxiliary supply that can power external

devices or drive the MARGIN pin. This supply can source

up to 10mA of current and the current limit is provided

internally. The pin requires at least a 0.1µF bypass

capacitor.

MOSFET Selection

Two logic-level N-channel power MOSFETs (Q3 and Q4 in

Figure 1) are required for most LTC1698 circuits. They are

selected based primarily on the on-resistance and body

diode considerations. The required MOSFET R

DS(ON)

should

be determined based on input and output voltage, allowable power dissipation and maximum required output

current.

The average inductor (L1) current is equal to the output

load current. This current is always flowing through either

Q3 or Q4 with the power dissipation split up according to

the duty cycle:

DC Q

() •

() – •

DC Q

V

3

=

41

=

N

OUTINP

V

N

V

OUTINP

V

S

N

N

S

The R

required for a given conduction loss can now

DS(ON)

be calculated by rearranging the relation P = I2R.

PIRDCQ

MAX Q MAX DS ON Q

⇒=

PIRDCQ

MAX Q MAX DS ON Q

⇒=

where I

=

() ()

3

R

()

DS ON Q

=

() ()

4

R

()

DS ON Q

is the maximum load current and P

MAX

2

••()

P

3

4

MAX Q

2

IDCQ

MAX

2

••()

P

MAX Q

2

IDCQ

MAX

3

()

3

•()

•()

4

()

4

3

4

3

4

is the

MAX

allowable conduction loss.

In a typical 2-transistor forward converter circuit, the duty

cycle is less than 50% to prevent the transformer core

from saturating. This results in the duty cycle of Q4 being

greater than that of Q3. Q4 will dissipate more power due

to the higher duty cycle. A lower R

MOSFET can be

DS(ON)

used for Q4. This will slow down the turn-on time of Q4

since a lower R

MOSFET will have a larger gate

DS(ON)

capacitance.

The next consideration for the MOSFET is the characteris-

tic of the body diode. The body diodes conduct during the

power-up phase, when the LTC1698 VDD supply is ramping up and the time-out circuit is adapting to the SYNC

input frequency. The CG and FG signals terminate prematurely and the inductor current flows through the body

diodes. The body diodes must be able to take the comparable amount of current as the MOSFETs. Most power

MOSFETs have the same current rating for the body diode

and the MOSFET itself.

The LTC1698 CG and FG MOSFET drivers will dissipate

power. This will increase with higher switching frequency,

higher VDD or larger MOSFETs. To calculate the driver

dissipation, the total gate charge Qg is used. This parameter is found on the MOSFET manufacturers data sheet.

The power dissipated in each LTC1698 MOSFET driver is:

P

DRIVER

= Qg • VDD • f

SW

where fSW is the switching frequency of the converter.

where NP/NS is the turns ratio of the transformer T1.

1698f

15

LTC1698

t

DC MIN

f

OFF MAXSW()

–()

=

()

1

DC MIN

N

NVV

P

S

OUT

IN MAX

() •

()

=

WUUU

APPLICATIO S I FOR ATIO

Power Transformer Selection

The forward transformer provides DC isolation and delivers energy from the primary to the secondary. Unlike the

flyback topology, the transformer in the forward converter

is not an energy storage device. As such, ungapped ferrite

material is typically used. Select a power material rated

with low loss at the switching frequency. Many core

manufacturers have selection guides and application notes

for transformer design. A brief overview of the more

important design considerations is presented here.

For operating frequencies greater than 100kHz, the flux

in the core is usually limited by core loss, not saturation.

It is important to review both criteria when selecting the

trans

former. The AC operating flux density for core loss is

given by:

VDC

••

B

AC

IN

=

NAf

•••

2

PeSW

10

8

where:

BAC is the AC operating flux density (gauss)

The core must be sized to provide sufficient window area

for the amount of wire and insulation needed. The best

performance is achieved by making each winding a single

layer evenly distributed across the width of the bobbin.

Multiple layers may be used to increase the copper area.

Interleaving the primary and secondary windings will

decrease the leakage inductance.

In a single-ended forward converter, much of the energy

stored in the leakage inductance is dissipated in the

primary-side MOSFET during turn-off. It is good design

practice to sandwich the secondary winding between two

primary windings.

For the 2-transistor forward converter shown in Figure 1,

energy stored in the leakage inductance is returned to the

input by diodes D1 and D2. With this topology, additional

insulation for higher isolation can be used without significant penalty.

For a more detailed discussion on transformer core and

winding losses, see Application Note AN19.

Inductor Selection

DC is the operating duty cycle

Ae is the effective cross sectional core area (cm2)

fSW is the switching frequency

To prevent core saturation during a transient condition,

the peak flux density is:

V DC MAX

=

IN MAX

B

PK

•( )•

()

NAf

••

PeSW

10

8

The minimum secondary turns count is:

VV

+

NN

S MIN P

()

•

=

OUT D

V DC MAX

IN MIN

()

•( )

where:

V

is the secondary output voltage

OUT

VD is the voltage drop across the rectifier in the secondary

V

is the minimum input voltage

IN(MIN)

DC(MAX) is the maximum duty cycle

The output inductor in a typical LTC1698 circuit is chosen

for inductance value and saturation current rating. The

output inductor in a forward converter operates the same

as in a buck regulator. The inductance sets the ripple

current, which is commonly chosen to be 40% of the full

load current. Ripple current is set by:

Vt

•

I

RIPPLE

OUT OFF MAX

=

()

L

where:

and DC(MIN) is calculated based on the maximum input

voltage.

16

1698f

WUUU

APPLICATIO S I FOR ATIO

LTC1698

Once the value of the inductor has been determined, an

inductor with sufficient DC current rating is selected. Core

saturation must be avoided under all operating conditions.

Under start-up conditions, the converter sees a short

circuit while charging the output capacitor. If the inductor

saturates, the peak current will dramatically increase. The

current will be limited only by the primary controller

minimum on time and the circuit impedances.

High efficiency converters generally cannot afford the core

loss found in low cost iron powder cores, forcing the use

of more expensive ferrite, molypermalloy, or Kool Mµ

®

cores. As inductance increases, core loss goes down.

Increased inductance requires more turns of wire so

copper losses will increase. The optimum inductor will

have equal core and copper loss.

Ferrite designs have very low core losses and are preferred

at higher switching frequencies. Therefore, design goals

concentrate on minimizing copper loss and preventing

saturation. Kool Mµ is a very good, low-loss powder

material with a “soft” saturation characteristic.

Molypermalloy is more efficient at higher switching frequencies, but is also more expensive. Surface mount

designs are available from many manufacturers using all

of these materials.

Output Capacitor Selection

The output capacitor selection is primarily determined by

the effective series resistance (ESR) to minimize voltage

ripple. In a forward converter application, the inductor

current is constantly flowing to the output capacitor,

therefore, the ripple current at the output capacitor is

small. The output ripple voltage is approximately given by:

V I ESR

RIPPLE RIPPLE

≈+

•

fC

••

8

SW OUT

1

The output ripple is highest at maximum input voltage

since I

the ESR requirement for C

increases with input voltage. Typically, once

RIPPLE

has been satisfied the

OUT

capacitance is adequate for filtering and has the required

RMS current rating.

Fast load current transitions at the output will appear as a

voltage across the ESR of the output capacitor until the

feedback loop can change the inductor current to match

the new load current value. As an example: at 3.3V out, a

10A load step with a 0.01Ω ESR output capacitor would

experience a 100mV step at the output, a 3% output

change. In surface mount applications, multiple capacitors may have to be placed in parallel to meet the ESR

requirement.

PC Board Layout Checklist

When laying out the printed circuit board, the following

checklist should be used to ensure proper operation of the

LTC1698. These items are also illustrated graphically in

Figure 9. Check the following for your layout:

1. Keep the power circuit and the signal circuit segregated. Place the power circuit, shown in bold, so that

the two MOSFET drain connections are made directly at

the transformer. The two MOSFET sources should be as

close together as possible.

2. Connect PGND directly to the sense resistor with as

short a path as possible. The MOSFET gate drive return

currents flow through this connection.

3. Connect the 4.7µF ceramic capacitor directly between

VDD and PGND. This supplies the FG and CG drivers and

must supply the gate drive current.

4. Bypass the V

supply with a 0.1µF ceramic capacitor

AUX

returned to GND.

5. Place all signal components in close proximity to their

associated LTC1698 pins. Return all signal component

grounds directly to the GND pin. One common connection can be made to V

+

from R2, R5 and C

OUT

CILM

.

6. Make the connection between GND and PGND right at

the LTC1698 pins.

7. Use a Kelvin-sense connection from the I

SNS

and I

SNSGND

pins to the secondary-side current-limit resistor

R

Kool Mµ is a registered trademark of Magnetics, Inc.

SECSEN

.

1698f

17

LTC1698

WUUU

APPLICATIO S I FOR ATIO

T1

•

•

Q3

MOC207

Q4

C4

T2

•

•

BOLD LINES INDICATE HIGH CURRENT PATHS

1Ω

R

D3

R2R7

R

K

R1

C

K

R

Figure 9. LTC1698 Layout Diagram

L1

SECSEN

C

4.7µF

C

+

V

OUT

+

C

OUT

–

V

OUT

SYNC

V

I

COMP

I

SENSGND

PWRGD

OVPIN

16

FG

15

14

AUX

13

12

I

SNS

11

10

9

0.1µF

R

C

CILM

CILM

0.1µF

0.1µF

R5

1k

1k

R4

1698 F09

1

V

DD

LTC1698

2

CG

3

PGND

GND

4

5

OPTODRV

6

V

COMP

C

7

C

MARGIN

FB

8

V

FB

36V

TO 72V

+

220Ω

V

OUT1

3.3V

AT 10A

V

OUT2

1.8V

AT 10A

C

OUT2

1698 F10

L1

V

IN

••

BG

TG

V

C

LT3781

SG

V

REF

+

V

FB

–

ISOLATION

BOUNDARY

••

V

BIAS

CC

V

DD

V

CG

FG

I

SNS

LTC1698

SYNC

OPTODRV

GND

COMP

10k

V

BOOST

GBIAS

SW

VA

OUT

V

CMDSH-3

4.7µF

L2

TG

0.1µF

BG

3.3k

33nF

FB

+

Q1

1.8µH

Q2 B340A

0.006Ω

4700pF

3.01k

2.32k

CC

10pF

V

FB

180pF

680pF

10k

C

OUT2

L2: SUMIDA CEP125-IR8MC-H

Q1, Q2: SILICONIX Si7440DP

SYNC

CSET

C

S

ILCOMP

SS

0.01µF

BGS

PGND

CL–CL

: POSCAP, 680µF/4V

LT3710

Figure 10. Simplified Single Secondary Winding 3.3V and 1.8V Output Isolated DC/DC Converter

18

1698f

TYPICAL APPLICATIO S

V

CC

13

2

1

5

1µF

0.01µF

82pF

OVLO

SHDN

1.24k

1%

10k

4.7µF

16V

1000pF

5V

REF

6

F

SET

0.1µF

8

SS

10

12

T2

PULSE ENG

P2033

BAS21

BAS21

BAT54

BAT54S

ZVN3310F

9

V

C

PGND

14

V

FB

37

4

THERM

LT3781

SYNC SGND

52.3k

1%

10Ω

1k

3k

1k

3.3k

FZT690B

0.22µF

50V

1

10k

220pF

MOC207

143

1

4

8

7

5

14

15

8

5

6

7

2

3300pF

2200pF

4700pF

5V

REF

5V

REF

SG

11

SENSE

15

BG

18

BSTREF

19

TG

20

BAS21

0.1µF

100V

1mH

DO1608C-105

COILCRAFT

V

BST

1.5µF

100V

1.5µF

100V

0.56µH

DO1813P-561HC

0.022µF

1000pF

••

SYNC V

FB

OVPIN

MARGIN

I

COMP

V

DD

OPTODRV

V

AUX

0.1µF

1612 11

I

SNS

I

SNSGND

FG

2

CG

PGND GND

LTC1698

PWRGD

6

8

9

7

13

1.24k

1%

976Ω

1%

4.22k

1%

3.01k

1%

1043

V

COMP

1698 F11

MMBZ5240B

0.008Ω

1%, 1W

1000pF

100V

2200pF

250V

AC

•

•••

T1

PULSE

PA0285

PULSE

PA0265

100Ω

10Ω

V

IN

+

36V TO 72V

V

IN

–

V

OUT

+

5V /30A

V

OUT

–

RTN

10Ω

1/4W

1000pF

100V

10Ω

1/4W

330pF

+

+

+

+

3.3Ω

V

IN

V

IN

V

CC

V

CC

V

OUT

V

CC

V

OUT

V

CC

V

IN

V

CC

0Ω

2.43k

1%

RT1

100k

1µF

ON/OFF

V

OUT

TRIM

4.7µF

16V

470Ω

V

OUT

FZT853

B0540W

100Ω

0.25W

2k

0.25W

5241B

11V

20k

FMMT619

FMMT718

Si7456DP

Si7456DP

Si7456DP

Si7884DP Si7884DP Si7884DP Si7884DP Si7884DP

Si7456DP

0.047µF

B2100

B2100

470µF

6.3V

POSCAP

470µF

6.3V

POSCAP

470µF

6.3V

POSCAP

470µF

6.3V

POSCAP

22µF

6.3V

1µF

16V

0Ω

B0540W

MMBD4148

0Ω

270k

0.25W

73.2k

1%

1

2

3

4

5

7

LTC1698

U

to 5V/30A Isolated Synchronous Forward Converter

IN

-72V

IN

Figure 11. 36V

1698f

19

LTC1698

V

CC

13

2

1

5

1µF

0.01µF

82pF

OVLO

SHDN

1.24k

1%

10k

270k

1/4W

100µF

20V

1000pF

5V

REF

6

F

SET

4700pF

8

SS

10

BAT54

BAT54

PULSE ENG

PA0184

BAS21

BAS21

BAT54

ZETEX

ZVN3310F

9

V

C

PGND

12

V

FB

37 4

THERM

LT3781

SYNC SGND

52.3k

1%

10Ω

1k

3k

1k

1k

2k

FZT690B

4.7µF

0.22µF

1

10k

5V

REF

MOC207

7

143

8

1

5

4

5

14

15

6

5

8

2

3300pF

4700pF

220pF

5V

REF

14

SG

+

11

SENSEBG

18

BSTREF

19 1617

TG NC NC

15 20

BAS21

0.1µF

1mH

DO1608C-105

COILCRAFT

V

BST

3.3µH

D01608C-332

COILCRAFT

0.022µF

1000pF

••

SYNC V

FB

OVPIN

MARGIN

I

COMP

V

DD

OPTODRV

V

AUX

0.1µF

1612 11

FG

2

CG

PGND GND

LTC1698

PWRGD

6

8

9

7

13

1.78k

1%

1.24k

1%

3.01k

1%

2.43k

1%

3410

V

COMP

1698 F12

1k

0.22µF

MBR0540

0.03Ω

Si7456DP

Si7456DP

1000pF

100V

1000pF

100V

2200pF

250V

MURS120

MURS120

10Ω

•

••

T1

38431

SCHOTT

10Ω

MMBT3906

MMBD914

MMBT3906

V

IN

+

V

IN

–

0.82µF

100V

0.82µF

100V

×2

V

OUT

+

V

OUT

–

330pF

+

+

+

330µF

6.3V

KEMET

T520

330µF

6.3V

KEMET

T520

330µF

6.3V

KEMET

T520

330µF

6.3V

KEMET

T520

+

3.3Ω

V

CC

V

IN

V

CC

V

CC

10k

2.43k

1%

RT1

100k

0.1µF

ON/OFF

TRIM

V

OUT

+

4.7Ω

10V

MMBZ5240B

470Ω

–

+

3.01k

1%

3.01k

1%

3.01k

1%

3.01k

1%

100Ω

1/4W

100Ω

1/4W

9V

V

OUT

V

OUT

+

3

4

2

1

LT1783CS5

+SENSE

–SENSE

OPTIONAL DIFFERENTIAL SENSE**

V

CC

V

IN

5V

REF

FQT7N10L

100Ω

1/4W

100Ω

1/4W

47k

62k

1/4W

4.7µF

MMBT3904

OPTIONAL FAST START*

V

IN

18V

MMBZ5248B

•

0.1µF

100Ω

9V

5

I

SNS

I

SNSGND

0.1µF

1k

1k

Si7892DP

Si7892DP Si7892DP Si7892DP

10Ω

1/4W

10Ω

1/4W

R

OUT

(OPTIONAL)

73.2k

1%

3300pF

R

IN

(OPTIONAL)

1

2

3

4

5

6

78

TYPICAL APPLICATIO S

U

20

to 3.3V/15A Isolated Synchronous Forward Converter-Quarter Brick

IN

-72V

IN

Figure 12. LT3781/LTC1698 36V

1698f

TYPICAL APPLICATIO S

V

CC

14

2

1

5

1µF

25V

82pF

OVLO

SHDN

1.24k

1%

73.2k

1%

24k

10k

270k

0.25W

68µF

25V

1000pF

56k

5V

REF

6

F

SET

4700pF

8

SS

10

13

BAT54

BAT54

T2

MIDCOM, INC

31264R

BAS21LT1

BAS21LT1

BAT54

ZVN3310F

9

V

C

PGND

12

I

MAX

V

FB

37 4

THERM

LT3781

SYNC SGND

52.3k

1%

10Ω

1k

3k

1k

3.3k

20k

0.25W

100Ω

0.25W

FZT603

ZETEX

4.7µF

16V

0.22µF

50V

1

10k

5V

REF

ISO1

MOC207

7

143

3

1

4

6

5

14

15

6

5

8

2

3300pF

4700pF

47Ω

0.01µF

50V

5V

REF

15

SG

+

11

SENSE

16

BG

18

BSTREF

19

TG

17 20

BAS21LT1

0.1µF

100V

1mH

DO1608C-105

COILCRAFT

BLKSENS

V

BST

220pF

1.5µF

100V

4.7µH

DO1608C-472

COILCRAFT

0.022µF

1000pF

•

•

SYNC V

FB

OVPIN

MARGIN

I

COMP

V

DD

OPTODRV

V

AUX

0.1µF

50V

0.1µF

50V

16

I

SNS

I

SNSGND

FG

2

CG

PGND GND

LTC1698

PWRGD

6

8

9

7

13

909Ω

0.1%

8.25k

0.1%

3411 1012

V

COMP

1698 F13

1k

0.01µF

MURS120T3

0.025Ω

1/2W

3

675

4

SUD40N10-25

SUD40N10-25

SUD40N10-25

470pF

100V

470pF

100V

2200pF

250V

MURS120T3

MURS120T3

10Ω

1

8

11

12

10

9

•

••

2

T1

EFD25

10Ω

V

IN

+

V

IN

–

1.5µF

100V

1.5µF

100V

V

OUT

+

V

OUT

–

68µF

25V

AVX

68µF

25V

AVX

68µF

25V

AVX

68µF

25V

AVX

22Ω

0.25W

22Ω

0.25W

25µH

MAG INC CORE

55380-A2 18T #18AWG

330pF