Application Note 64

Using the LTC1325 Battery Management IC

Anthony Ng, Peter Schwartz, Robert Reay,

Richard Markell

INTRODUCTION

August 1996

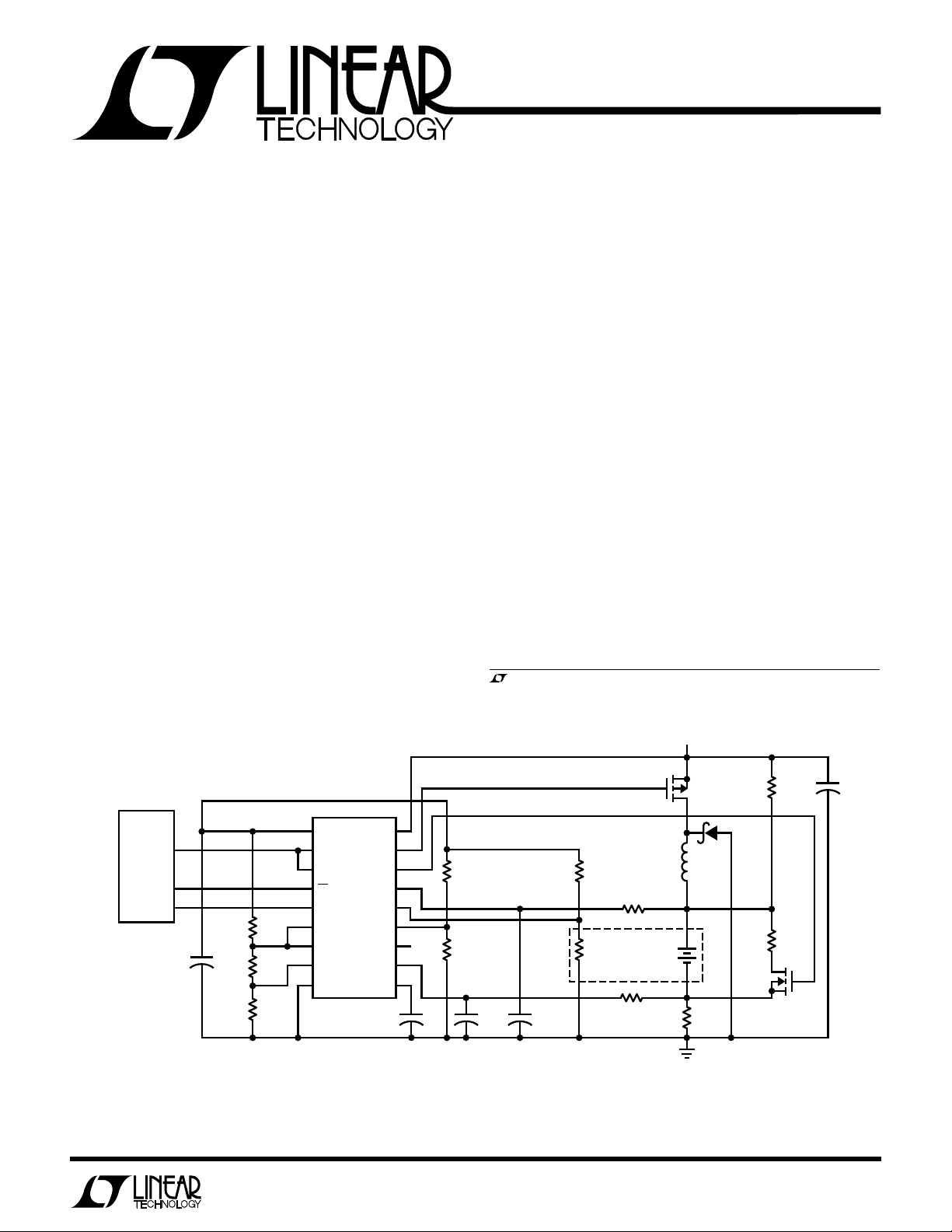

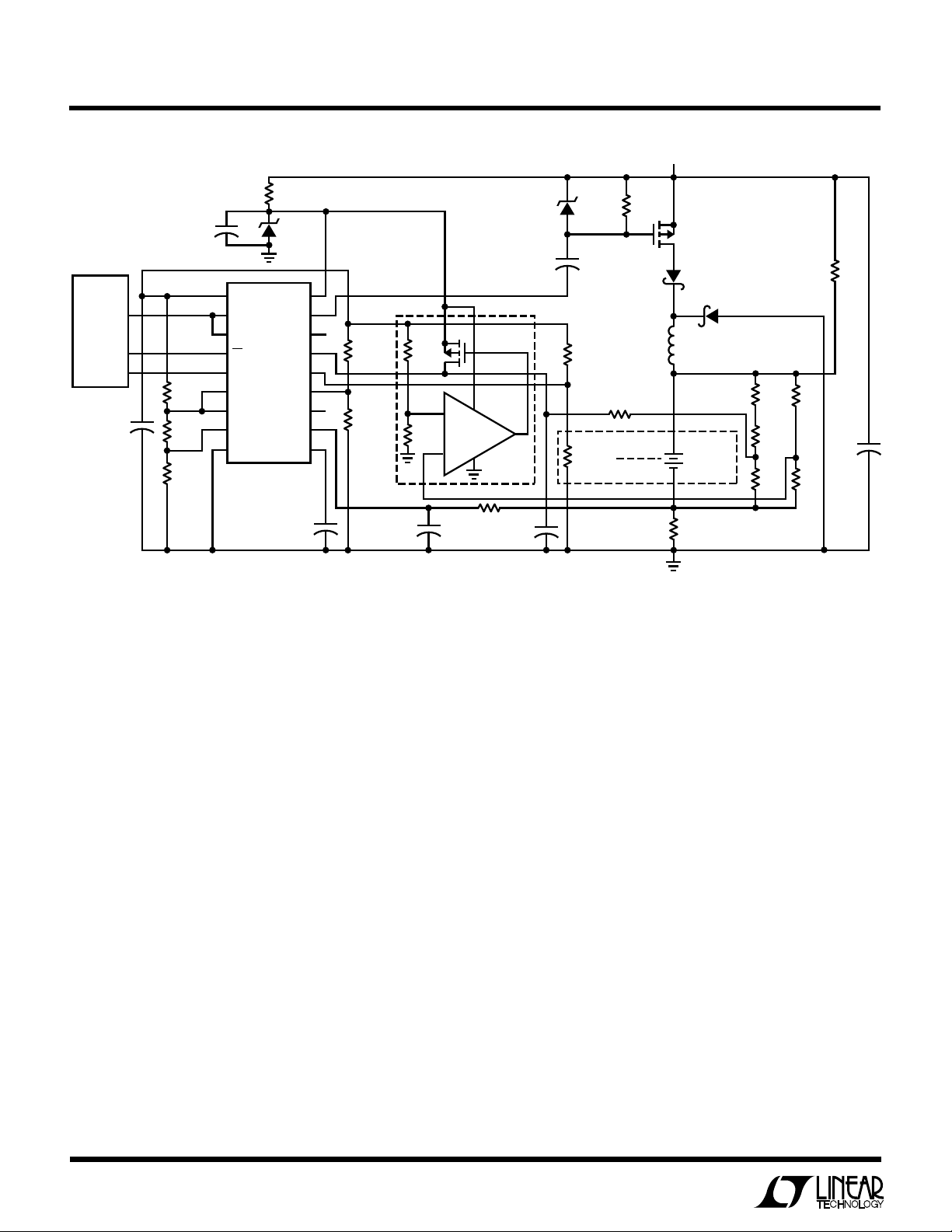

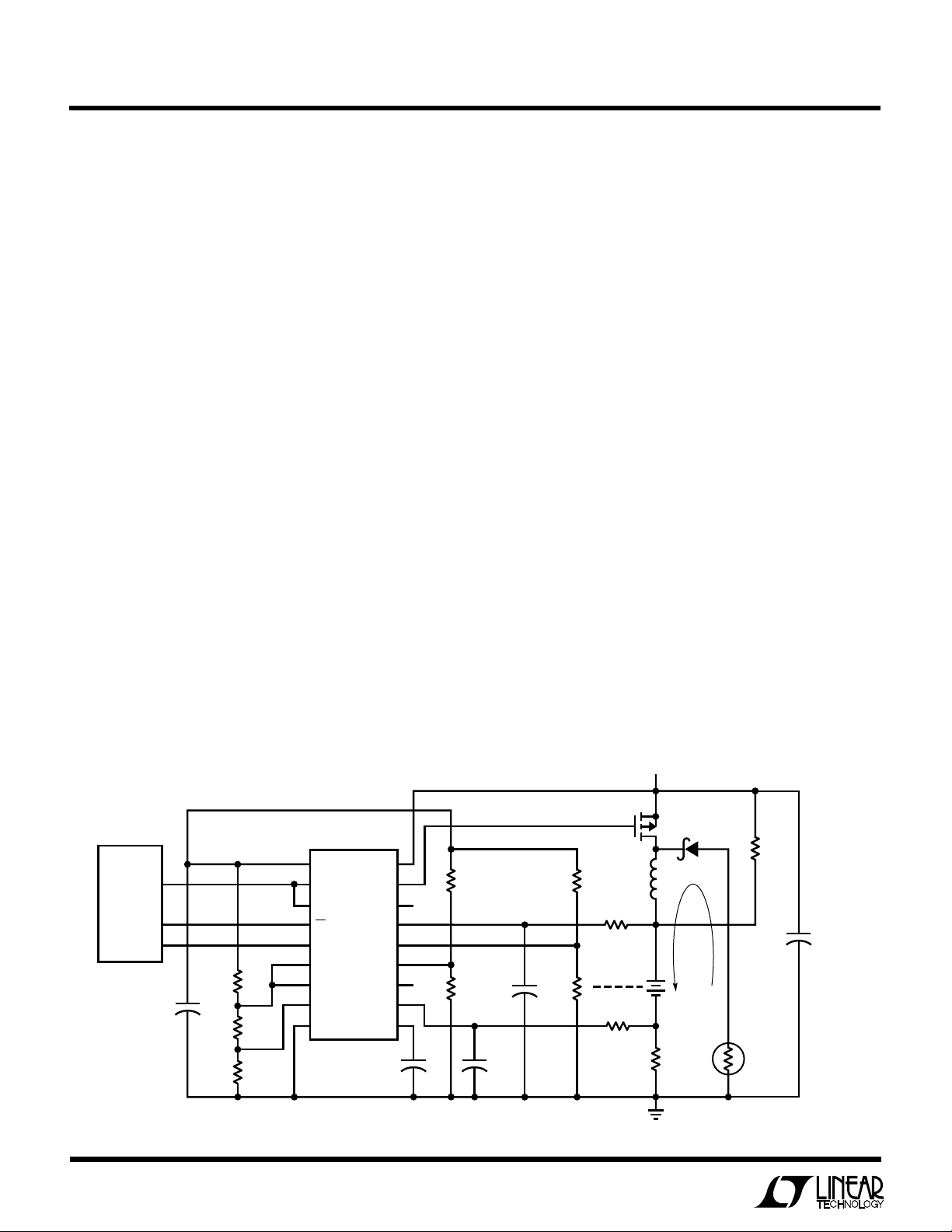

For a variety of reasons, it is desirable to charge batteries

as rapidly as possible. At the same time, overcharging

must be limited to prolong battery life. Such limitation of

overcharging depends on factors such as the choice of

charge termination technique and the use of multi-rate/

multi-stage charging schemes. The majority of battery

charger ICs available today lock the user into one fixed

charging regimen, with at best a limited number of

customization options to suit a variety of application needs

or battery types. The LTC®1325 addresses these shortcomings by providing the user with all the functional

blocks needed to implement a simple but highly flexible

battery charger (see Figure 1) which not only addresses

the issue of charging batteries but also those of battery

conditioning and capacity monitoring. A microprocessor

interacts with the LTC1325 through a serial interface to

control the operation of its functional blocks, allowing

software to expand the scope and flexibility of the charger

circuit.

MPU

(e.g. 8051)

p1.4

p1.3

p1.2

REG

D

OUT

D

IN

CS

R1

10k

1%

C

REG

+

NOTE 1: THERMISTORS 1 AND 2 ARE PANASONIC ERT-D2FHL103S NTC THERMISTORS OR EQUIVALENT.

NOTE 2: V

NOTE 3: CHOOSE FOR C/20 TRICKLE CHARGE RATE.

NOTE 4: 2.0k AND 47µF FOR COMPATIBILITY WITH LITHIUM-ION AND LEAD-ACID

4.7µF

TANT

25V

R2

10k

1%

R3

10k

1%

= 160mV, R

REF

CLK

LTF

MCV

HTF

GND

SENSE

VDD

PGATE

DIS

LTC1325

V

BAT

T

BAT

T

AMB

V

IN

SENSE

FILTER

+

= 1 FOR C/3 CHARGE RATE (160mA).

C

1µF

F

R4

7.5k

1%

THERM 2

10k

NOTE 1

+ +

This Application Note was written with the following

objectives in mind :

• Provide users with an insight into the architecture and

operation of the LTC1325.

• Outline basic techniques for charging various battery

types.

• Present a variety of useful, tried and tested charging

circuits.

• Give an overview of the most common battery types

and their characteristics.

• Clarify specialized and application-specific terminology. Definitions are provided in the text, as well as in

Appendix C.

, LTC and LT are registered trademarks of Linear Technology Corporation.

V

DC

16V MAX

C2

+

R

AN64 F01

10µF

TANT

25V

500pF

3.3µF

(NOTE 4)

COILTRONICS

R5

7.5k

1%

100Ω (NOTE 4)

THERM 1

10k

NOTE 1

100Ω

CTX100-1-52

100µH

V

BAT

8 CELLS

500mA HR

C/3 RATE

P1

IRF9531

L1

D1

1N5818

IRF510

R

SENSE

1Ω

TRK

NOTE 3

R

DIS

N1

Figure 1. Complete LTC1325 Battery Management System

AN64-1

Application Note 64

LTC1325 PRIMER

The main features of the LTC1325 may be summarized as

follows:

• It has all the functional blocks needed to build a charger:

a 10-bit Analog-to-Digital Converter (ADC), fault detection circuitry, a switching regulator controller with a

MOSFET driver, a programmable timer, a precision

3.072V regulator for powering external temperature

sensors, and a programmable battery voltage divider.

• The functional blocks are placed under the control of an

external microprocessor for ready adaptability to

different charging algorithms, battery chemistries, or

charge rates.

• Communication with the microprocessor is via a simple

serial interface, configurable for 3-wire or 4-wire operation.

• It has autonomous fault detection circuitry to protect

the battery against temperature or voltage extremes.

• In addition to charging, the part can discharge batteries

for battery conditioning purposes.

• It includes on-chip circuitry for an accurate battery

capacity monitor (Gas Gauge).

• It charges batteries using a switching buck regulator for

highest efficiency and lowest power dissipation.

• The wide supply voltage range (VDD) of 4.5V to 16V

allows the battery charger to be powered from the

charging supply while charging batteries of up to 8 cells

in series.

• It can charge batteries which require charging voltages

greater than VDD.

Charging Circuit

Unlike most other charger ICs which employ a linear

regulator, the LTC1325 charges batteries using a switching buck regulator. This approach simultaneously maximizes efficiency and minimizes power dissipation. The

only external power components needed are an inductor,

a P-channel MOSFET switch, a sense resistor and a catch

diode (see Figure 1). An internal, programmable battery

voltage divider which accommodates 1 to 16 cells removes the need for an external resistive divider (for

batteries with voltages below the maximum VDD of 16V).

All the circuits needed for controlling the loop are integrated on-chip and no external ICs are required. The

LTC1325 operates from 4.5V to 16V so that it can be

powered directly from the charging supply. The wide

supply range makes it possible to charge up to 8 cells

without the need for an external regulator to drop the

charging supply down to the supply range of the LTC1325.

These features make the LTC1325 easy to use. When

charging is completed and the charging supply is removed, the chip does not load down other system supplies. If the LTC1325 is powered from a system supply, the

microprocessor can program it into shutdown mode in

which the quiescent current drops to 30µA. In shutdown

mode the digital inputs stay alive to await the wake-up

signal from the microprocessor.

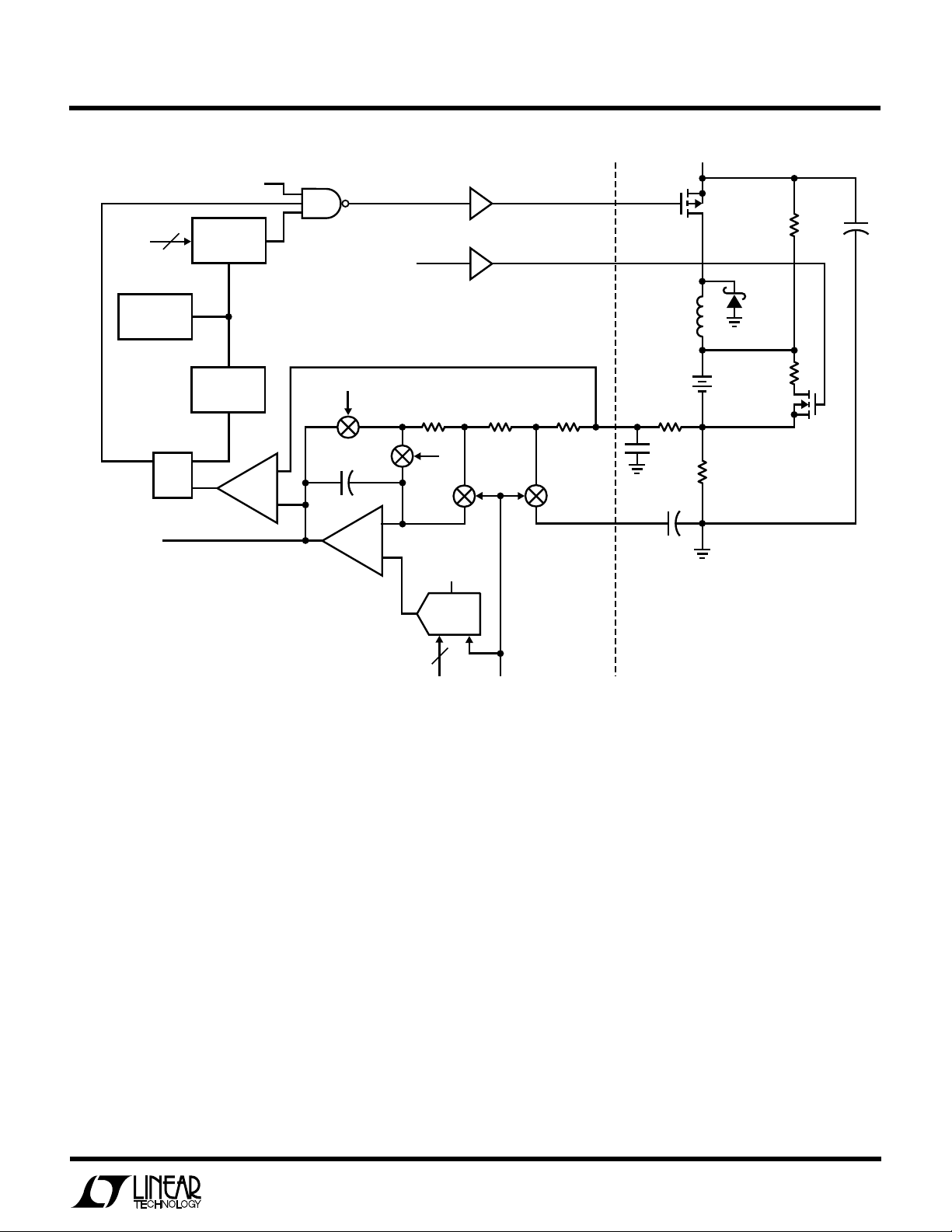

The buck regulator control circuit maintains the average

voltage across the sense resistor (R

SENSE

) at V

DAC

(see

Figure 2). In addition, a programmable duty cycle can

modulate the P-channel MOSFET driver output (PGATE)

to reduce average charging current. The average charging

current is given by:

I

CHRG

= V

(duty cycle)/Rsense

DAC

• It can charge batteries from charging supplies greater

than VDD.

• A shutdown mode drops the supply current to 30µA.

AN64-2

The microprocessor can set V

to one of four values,

DAC

and the duty cycle to one of five values, giving 20 possible

I

values with a single R

CHRG

SENSE

resistor.

Application Note 64

V

DD

16V

111kHz

OSCILLATOR

TO ADC MUX

3

QS

R

CHARGE

DUTY RATIO

GENERATOR

ONE SHOT

PGATE

DISCHARGE

GG

R1

S1

C1

S2

+

A2

–

16pF

+

500k

CL

S3 S4

R2

125k

R

F

1k

–

A1

+

V

DAC

REG

3.072V

DAC

DIS

SENSE

FILTER

BATTERY

100Ω

500pF

+

CF

1µF

P1

IRF9531

L1

R

SENSE

1Ω

D1

1N5818

NOTE 2

R

TRK

R

DIS

C

10µF

SPLY

AN64 F02

+

2

V

GAS GAUGE (GG)

R0, VR1

Figure 2. LTC1325 Charge, Discharge and Gas Gauge Circuit

Charge Termination

Virtually any known charge termination technique can be

implemented with the LTC1325. The most common of

these are based on battery temperature (T

(V

), time (t), ambient temperature (T

CELL

), cell voltage

BAT

), or a com-

AMB

bination of these parameters. Unlike other fast charging

ICs, the LTC1325 does not lock the user into a particular

termination technique and any shortcomings of that technique. Instead, it provides the microprocessor a means to

measure T

BAT

, T

AMB

and V

. By keeping track of

CELL

elapsed time, the microprocessor has the means to calculate all existing termination techniques (including dT

dt and d2V

/dt2), and perform averaging to reduce the

BAT

BAT

/

probability of false termination. This flexibility also means

CHIP BOUNDARY

that a single circuit can charge Nickel-Cadmium, NickelMetal Hydride, Sealed Lead-Acid, and Lithium-Ion batteries. The LTC1325 has an on-chip 10-bit successive approximation ADC with a 5-channel input multiplexer. Three

channels are dedicated to T

BAT

, V

and the Gas Gauge

CELL

(see section on Capacity Monitoring); the other two channels can be used for other purposes such as sensing T

AMB

or another external sensor. The LTC1325 can be programmed into Idle mode in which the charge loop is turned

off. This permits measurements to be made without the

switching noise that is present across the battery during

charging.

AN64-3

Application Note 64

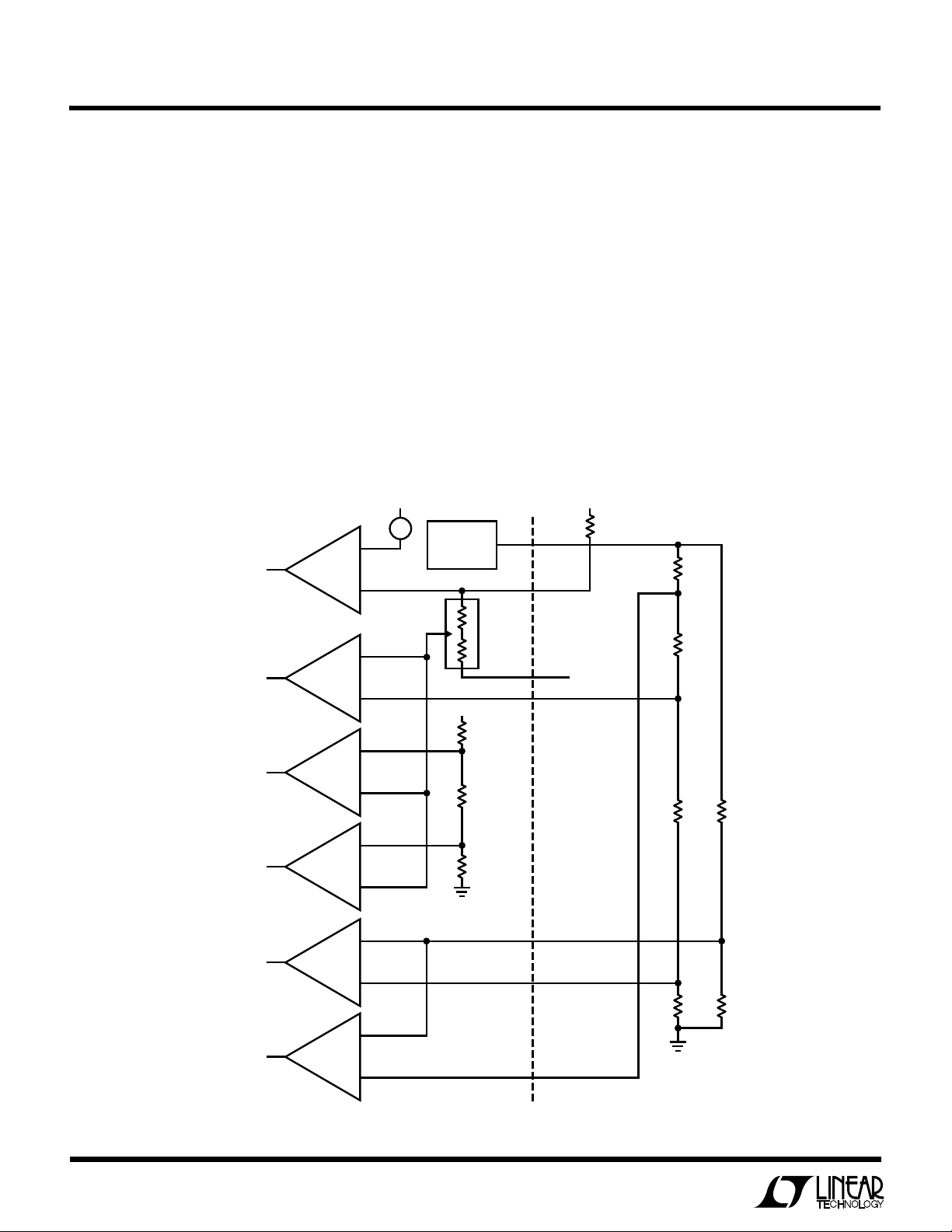

Fault Protection

The LTC1325 monitors battery temperature, cell voltage

and elapsed time for faults and prevents the initiation or

the continuation of charging should a fault arise. The fault

detection circuit (see Figure 3) consists of comparators

which monitor T

BAT

and V

to detect low temperature

CELL

faults (LTF), high temperature faults (HTF), low cell voltages (BATR, EDV) and high cell voltages (MCV). The LTF,

HTF and MCV thresholds are set by an external resistor

divider (R1 to R4) to maximize flexibility. The LTC1325

also includes a timer that permits the microprocessor to

set charging time before a timer fault occurs to one of eight

values: 5, 10, 20, 40, 80, 160, 320 minutes or no time-out.

Selecting “no time-out” disables timer faults (the time-out

period is in effect set to infinity).

V

DD

+

BATP

MCV

1.6V

–

+

C1

–

BATTERY

+

C2

–

DIVIDER

3.072V

LINEAR

REGULATOR

REG

Battery Conditioning

Under some operating or storage conditions, certain battery types (most notably NiCd) lose their full capacity. It is

often necessary to subject such batteries to deep discharge and charge cycles to restore the lost capacity. The

LTC1325 can be programmed into Discharge mode in

which it automatically discharges each cell to 0.9V. This

voltage is defined as the End-of-Discharge Voltage (EDV).

Fault protection remains active in Discharge mode to

protect the battery against temperature extremes (LTF,

HTF) and to detect the EDV discharge termination point.

V

DD

R

REG

V

BAT

MCV

TRK

R1

R2

SENSE

+

C3EDV

900mV

–

+

C4BATR

100mV

–

–

C5HTF

+

T

HTF

BAT

+

C6LTF

–

LTF

Figure 3. LTC1325 Fault Detection Circuitry

AN64 • F03

R3 R

R4 R

L

T

AN64-4

Application Note 64

Capacity Monitoring

The LTC1325 may be programmed into Gas Gauge mode

(GG = 1 in Figure 2). In this mode, the sense resistor is

used to sense the battery load current. The battery load is

connected between V

and ground so that the load

BAT

current passes through the sense resistor, producing a

negative voltage at the Sense pin. The Sense pin voltage

is filtered by a 1kΩ × CF lowpass filter and multiplied by a

gain of –4 via amplifier A1. The output of A1 is converted

by the ADC whenever the gas gauge channel is selected by

the microprocessor. By accumulating gas gauge measurements over time, the microprocessor can determine

how much charge has left the battery and what capacity

remains.

APPLICATIONS CIRCUITS

Charging Nickel Cadmium and Nickel Metal Hydride

Batteries

It is desirable to charge batteries as fully and rapidly as

possible. At the same time it is necessary to limit overcharging, which can adversely affect battery life. To meet

these requirements, multi-stage charging algorithms are

recommended for NiCd and NiMH batteries. Multi-stage

charging algorithms consist of 2 or 3 stages:

2-Stage: Fast Charge

Trickle Charge

3-Stage: Fast Charge

Top-Off Charge

Trickle Charge

During Fast Charge, the battery is charged at the maximum

permitted rate to near full capacity. In Top-Off the battery

is charged at a lower rate to bring it to full capacity thus

minimizing overcharge. Finally, during Trickle Charge, the

battery is charged at a rate that just compensates for self-

discharge to maintain it at full capacity. Recommendations of the battery manufacturer determine which algorithm to use. In general, the best way to limit overcharge

is to use a primary charge termination technique and

several secondary techniques for redundancy. Regardless

of the algorithm, the basic circuit to charge up to 8 NiCd or

NiMH cells is shown in Figure 1.

Examples of Charging Algorithms

2-Stage NiCd

Fast Charge C/1 rate, –∆V (15mV) primary termination

Time-out secondary termination (80 minutes)

Trickle Charge C/10 rate, no termination needed

2-Stage NiCd

Fast Charge C/1 rate, TCO (45°C) primary termination

Time-out secondary termination (80 minutes)

Trickle Charge C/10 rate, no termination needed.

3-Stage NiMH

Fast Charge C/1 rate, ∆TCO (10°C) primary termination

Top-Off Charge C/10 until secondary termination at

180 minutes (160 min + 20 min)

Trickle Charge C/40 rate, no termination

3-Stage NiMH

Quick Charge C/3 rate, 120 minute (80 min + 40 min) to

160 minute time-out

TCO (40°C) secondary termination

Top-Off Charge C/10 rate until V

Trickle Charge C/40 rate, no termination

CELL

= 1.5V

All these algorithms may be realized with the circuit in

Figure 1. Only the software and perhaps some component

values change.

AN64-5

Application Note 64

Conditioning Batteries

When overcharged for extended periods of time, some

NiCd batteries exhibit what is commonly called the “memory

effect,” The voltage per cell drops 150mV which may lead

the user to conclude that the battery is at the end of its

discharge curve. This condition may be reversed by deeply

discharging and recharging the battery. The LTC1325 can

be programmed to discharge a battery until its per cell

voltage falls below 0.9V (EDV). As shown in Figure 1, the

external N-channel MOSFET N1 is turned on to discharge

the battery. R

current, V

BAT/RDIS

is selected such that the discharge

DIS

, is within the allowable limits set by the

battery manufacturer. Discharge currents can be large

with high capacity batteries. The power rating of R

should be greater than I

be terminated to the top of R

ground. The former is preferred since the V

DIS

2

× R

. The source of N1 may

DIS

(as in Figure 1) or to

SENSE

BAT

pin moni-

DIS

tors the battery voltage for EDV and not the battery voltage

plus the drop across R

. If desired it is possible to

SENSE

adjust the EDV voltage via the internal battery divider

setting as outlined in the next section.

Using the End-of-Discharge Voltage Fail-Safe

The LTC1325, when commanded to do so, will discharge

a battery until its cell voltage goes below 900mV nominal,

at which point an EDV fail-safe occurs and the DIS pin is

taken low to stop discharge. This function of the IC is most

commonly used for the protection and conditioning of

NiCd and NiMH batteries, but may also be used to condition a Lead-Acid battery or to reset the Gas Guage to a

known point (remaining battery capacity equals zero) for

any battery type. Immediately following discharge, the

voltage per cell for NiCd and NiMH batteries will typically

“rebound” by 100mV to 200mV. The controlling software

will need to take this rebound into account to prevent a

possible oscillation in which the ADC would be read, the

EDV and fail-safe bits reset, and the battery discharged for

a few more seconds before again indicating EDV and

stopping the discharge.

If desired, the battery divider can be programmed to divide

by a factor that is less than the number of cells in the

battery. For example, if the divider is programmed to

divide-by-5 when the number of cells in the battery is six,

the EDV fault occurs at (5 × 0.9)/6 or 0.75V. Similarly,

programming the divider to divide-by-6 with a three-cell

Lead-Acid battery would give an EDV of (6 × 0.9)/3 = 1.8V

per cell at termination of discharge.

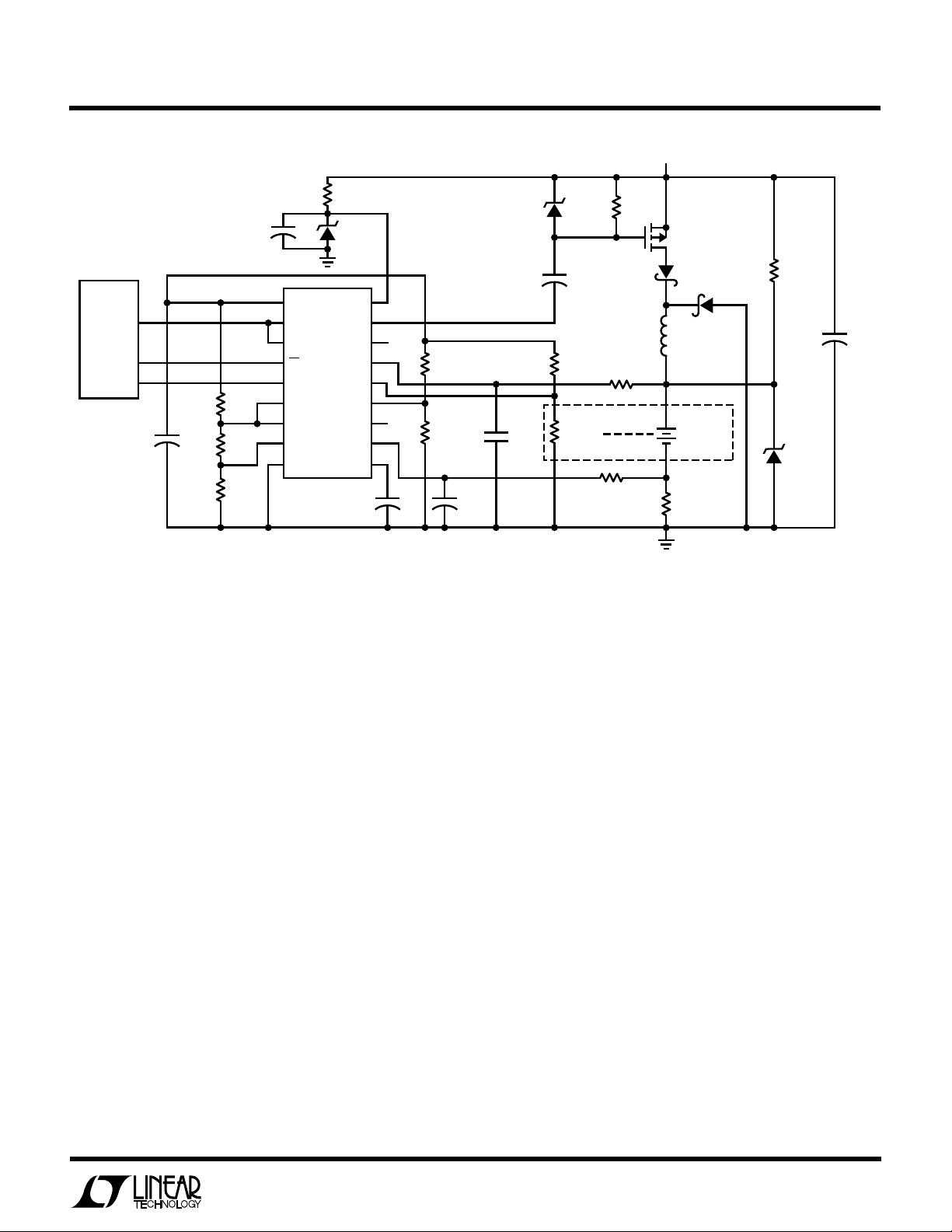

Operating from Charging Power Supplies of

Above 16V

The LTC1325 has a maximum VDD range of 16V. To

operate from a higher supply voltage, it is necessary to do

two things: add a regulator to drop the higher supply (VDC)

down to the supply range of the LTC1325 and add a level

shifter between the PGATE pin and the gate of the external

P-channel MOSFET. The level shifter ensures that the

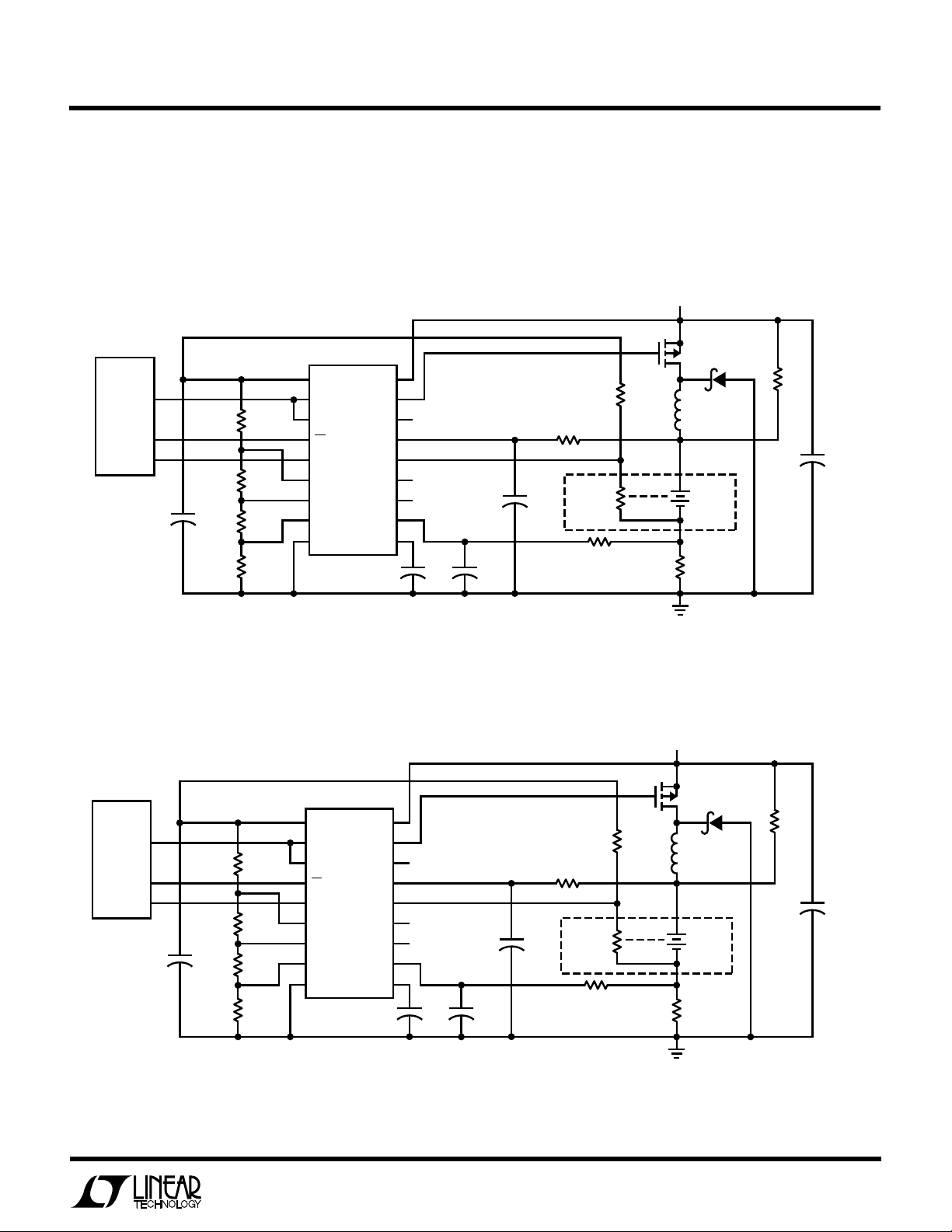

P-channel MOSFET can be switched off completely. Figure

4 shows a low cost circuit that will charge up to 8 cells from

a 25V supply at 160mA. For 2A charge current, L1 and

R

tively. V

should be changed to 15µH and 0.08Ω respec-

SENSE

is set to 160mV in both cases for best

DAC

accuracy. The number of cells that can be charged is

affected by any series resistance in the charge path. At

high charging currents low resistance inter-cell connections such as solder tabs are recommended.

The zener diode D3 is used to drop the 25V VDC down to

16V to serve as VDD supply to the LTC1325. R7 should not

be greater than 220Ω. Alternatively, a 3-terminal regulator

(such as the LT®1086-12 or LT1085-12) may replace D3,

C1 and R7. The regulator output voltage (VDD) fixes the

number of cells that can be charged with the circuit to

about VDD/VEC where VEC is the maximum cell voltage

expected.

When the battery is removed, R

towards VDC. D4 acts as a clamp to prevent V

pulls the V

TRK

BAT

BAT

pin

from

rising above the VDD supply voltage. D2, C2 and R11 form

a simple level shifter. During charging, D2 clamps the

voltage at the gate of P1 between V

– VZ and V

DC

+ 0.7V,

DC

where VZ is the reverse breakdown voltage of D2. VZ is

selected to limit the VGS of P1 to within its maximum

rating. For logic-level P-channel MOSFETs with a maximum VGS of ± 8V, D2 may be a 3.9V zener such as the

1N4730A. For standard MOSFETs (± 20V VGS rating), a

1N4740A 10V zener may be used. When power (VDC) is

first applied, VDD takes a finite time to charge up to 16V so

that the voltage on the PGATE pin is initially 0 and P1 is

turned on. D2 breaks down, charging C2 quickly to one

zener drop below VDC. Then as PGATE rises, D2 forward

AN64-6

MPU

(e.g. 8051)

p1.4

p1.3

p1.2

R7

220Ω

1/2W

+

C1

1µF

35V

REG

D

OUT

D

IN

CS

R1

10k

1%

C

+

REG

R2

4.7µF

10k

35V

1%

R3

10k

1%

NOTE 1: THERMISTORS ARE PANASONIC ERT-D2FHL103S NTC THERMISTORS OR EQUIVALENT.

CLK

LTF

MCV

HTF

GND

LTC1325

D3

16V

1N4745A

VDD

PGATE

DIS

V

BAT

T

BAT

T

AMB

V

SENSE

FILTER

IN

+ +

C

1µF

CER

F

R4

7.5k

1%

10k

THERM 2

NOTE 1

3.3µF

500pF

+

D2

10V

1N4740A

C2

0.1µF

35V

R5

7.5k

1%

10k

THERM 1

NOTE 1

Application Note 64

V

DC

25V

R11

100k

P1

100µH

COILTRONICS

CTX100-1-52

100Ω

100Ω

IRF9531

D5

1N5818

L1

D1

1N5818

V

BAT

8 CELLS

500mA HR

C/3 RATE

R

SENSE

1Ω

1%

R

TRK

487Ω

C/20

TRICKLE

D4

16V

1N4745A

+

AN64 F04

C

SPLY

10µF

Figure 4. Charging from a 25V Supply

biases and the gate of P1 rises to one diode drop above V

and P1 shuts off. R11 serves to hold P1 off if the V

DC

DD

supply should go away for some reason. In this situation,

it takes several milliseconds for R11 to shut P1 off completely which means that P1, L1 and R

to withstand a brief current pulse of (V

R is the total of the R

DS(ON)

of P1, R

must be able

SENSE

– V

DC

BAT

and inductor

SENSE

)/R, where

winding resistance. Diode D5 prevents battery discharge

if the VDC supply is removed.

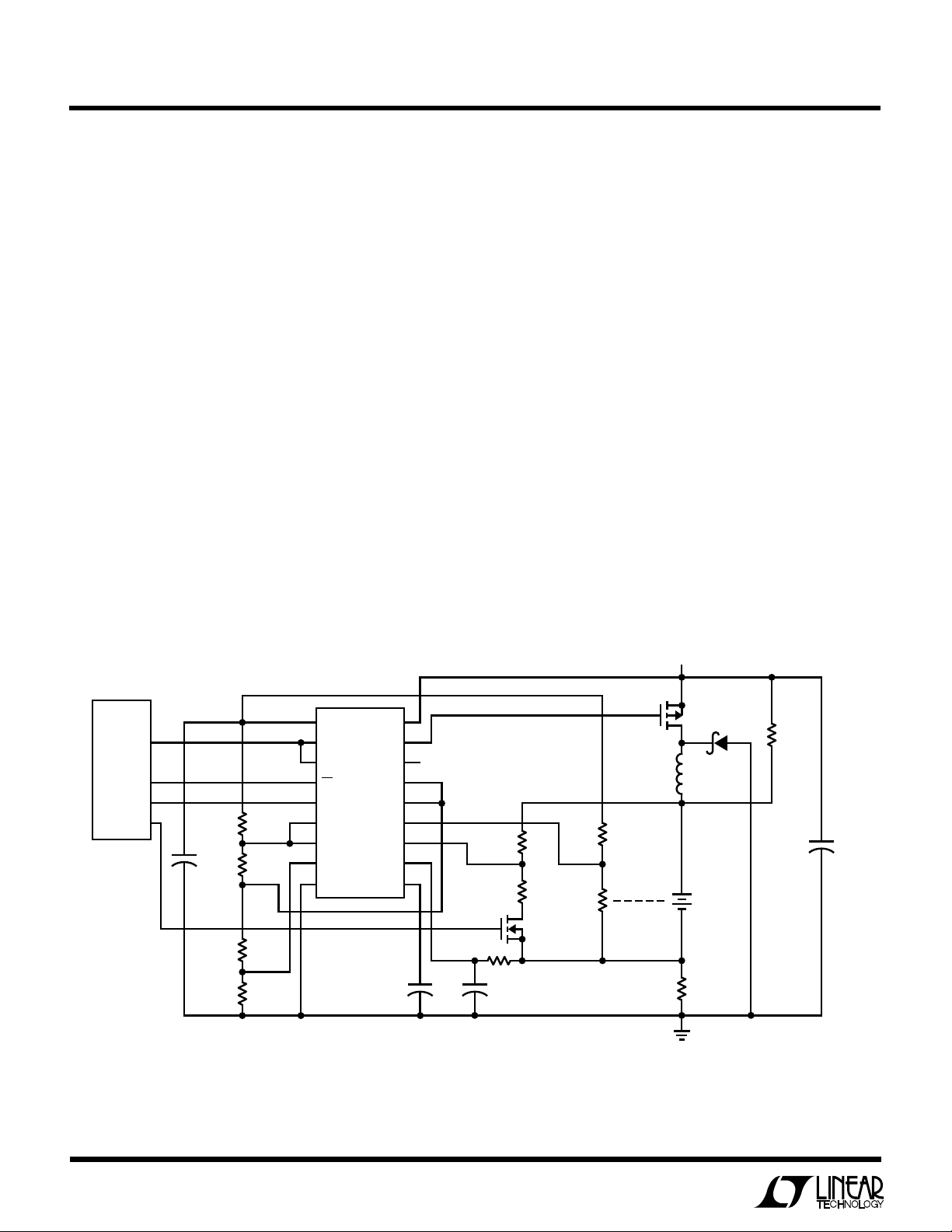

Charging “Tall” Batteries (> 8 cells)

To charge more than 8 cells, the charging supply (VDC)

must be greater than 16V (assuming 2V per cell at the end

of charge). Since VDC is above 16V, a regulator and level

shifter are required, as explained in the previous application. Figure 5 shows a circuit that will charge batteries with

more than 8 cells in series. In addition, an external battery

divider is added to limit the voltage seen at the V

BAT

pin to

below VDD. The values of R8, R9 and R10 are selected such

that R10/(R8 + R9 + R10) is the number of cells in the

battery. The battery divider in the LTC1325 is programmed

to divide by one. V

the charging current is 160mV/R

charges the 10 cell 500mA Hr stack at a C/3 rate. R

is programmed for 160mV so that

DAC

or 160mA. This

SENSE

TRK

is

selected to trickle charge the battery at C/20. The same

circuit will charge batteries at 2A if L1 and R

SENSE

are

changed to 15µH and 0.08Ω respectively.

Without R11 to R14, P2 and A1 in Figure 5, the BATP status

flag will always be high regardless of whether the battery

is present or not. It is therefore possible to start the charge

loop when the battery is not present. The current through

the charge loop will be low (typically in the milliampere

range). If this is undesirable, R11 to R14, P2 and A1 may

be added to ensure proper operation of the BATP flag. R11

and R12 are selected such that R12/(R11+R12) is the

number of cells in the battery. Op amp A1 compares the

cell voltage against a threshold set by R13 and R14. When

the battery is absent, A1 trips to turn on P2 which then

pulls V

up to VDD. This causes the BATP flag to go low

BAT

to indicate the absence of the battery.

AN64-7

Application Note 64

V

25V

DC

MPU

(e.g. 8051)

p1.4

p1.3

p1.2

C

REG

4.7µF

R7

220Ω

C2

1µF

35V

REG

D

D

CS

R1

10k

1%

+

R2

10k

1%

R3

10k

1%

NOTE 1: PANASONIC ERT-D2FHL103S NTC THERMISTORS OR EQUIVALENT.

CLK

LTF

MCV

HTF

GND

+

OUT

IN

LTC1325

D4

16V

1N4745A

VDD

PGATE

DIS

V

BAT

T

BAT

T

AMB

V

SENSE

FILTER

1µF

R4

IN

C

F

7.5k

1%

THERM 2

NOTE 1

+

R13

10k

R14

5.1k

+

Figure 5. Charging More Than 8 Cells

32V

2

500pF

+

LT1006

–

A1

P2

BS250

7

4

100Ω

6

3.3µF

+

+

D3

10V

1N4740A

C2

0.1µF

35V

R5

7.5k

1%

THERM 1

NOTE 1

R16

100k

COILTRONICS

CTX100-1-52

100µH

100Ω

P1

IRF9531

D2

1N5818

L1

D1

1N5818

V

BAT

10 CELLS

500mA HR

C/3 RATE

R

SENSE

1Ω

C/20 TRICKLE

R8

11.3k

1%

R9

78.7k

1%

R10

10k

1%

R

TRK

200Ω

1/4W

R11

91k

R12

10k

C

SPLY

10µF

AN64 F05

+

Hardwired Charge Termination Using Thermistors

Termination Using Positive Temperature Coefficient

(PTC) Thermistors: The resistance of a PTC thermistor

increases sharply when its temperature rises above a

specified setpoint (TS). This rapid change may be exploited to implement hardwired TCO charge termination.

In Figure 6, fixed resistor R4 is connected from REG to the

T

input, and the PTC thermistor R5 is connected

BAT

between the T

input and Sense. Hence R5 is the

BAT

controlling element of a temperature-dependent voltage

divider. The PTC is mounted on the battery to sense its

temperature. R4 is selected such that when the battery

temperature is below TS, the divider output voltage is

between the voltages at the LTF and HTF pins. When the

battery temperature rises above TS, the rapid increase in

the resistance of the PTC device causes the divider output

(i.e. the voltage at the T

pin) to rise above the voltage

BAT

set by R1, R2 and R3 at the LTF pin. The LTC1325 detects

a temperature fail-safe (LTF = 1, FS = 1) and stops charging

by taking the PGATE pin to VDD. A typical value for TCO is

45°C. TS and R

THERM1

have typical tolerances of ±5°C and

±40% respectively. The PTC shown in Figure 6 has a TS of

50°C ±5°C, so charging will terminate when the battery

temperature reaches a value between 45°C and 55°C. The

series resistance of PTC thermistor and R4 should be in

the kΩ range to minimize loading on the REG pin of the

LTC1325.

In principle, it is possible to implement hardwired ∆TCO

termination by replacing R4 with another PTC with a

resistance vs temperature characteristic that matches that

of R5 as shown in Figure 7. If both PTCs match closely, the

divider output will now respond to the difference between

AN64-8

Application Note 64

battery and ambient temperature. In practice, matched

PTCs are not generally available as standard items from

thermistor manufacturers and are therefore not recommended for such use. If hardware ∆TCO termination is

desired, standard NTCs such as those matched over a

MPU

(e.g. 8051)

p1.4

p1.3

p1.2

REG

D

OUT

R1

R2

+

C

REG

4.7µF

R3

R4

D

IN

CS

CLK

LTF

MCV

HTF

GND

LTC1325

VDD

PGATE

DIS

V

BAT

T

BAT

T

AMB

V

SENSE

FILTER

IN

+ +

C

1µF

F

specified temperature range may be used. With NTCs, the

divider output will drop as the battery heats up and when

the voltage drops below the voltage at the HTF pin, the

LTC1325 will detect a temperature fail-safe (HTF = 1,

FS = 1) and terminate charging.

V

DC

16V MAX

P1

D1

R

TRK

AN64 F06

+

C

SPLY

10µF

500pF

R4

100Ω

+

3.3µF

PTC

THERM 1

100Ω

L1

V

8 CELLS

MAX

R

SENSE

BAT

MPU

(e.g. 8051)

p1.4

p1.3

p1.2

Figure 6. Hardwired TCO Termination

V

DC

12V

P1

D1

R

TRK

AN64 F07

+

C

SPLY

10µF

LTC1325

VDD

PGATE

DIS

V

BAT

T

BAT

T

AMB

V

SENSE

FILTER

IN

+ +

C

1µF

THERM 1

100Ω

+

F

500pF

3.3µF

THERM 2

100Ω

L1

V

BAT

8 CELLS

MAX

R

SENSE

REG

D

OUT

R1

R2

+

C

REG

4.7µF

R3

R4

D

IN

CS

CLK

LTF

MCV

HTF

GND

Figure 7. Hardwired ∆TCO Termination

AN64-9

Application Note 64

Termination Using Negative Temperature Coefficient

(NTC) Thermistor: It is common for the thermistor in the

battery pack to be terminated at the negative terminal of

the battery. During charging, the Sense pin will exhibit a

switching waveform with peaks of 200mV to 300mV when

V

is programmed for 160mV. This waveform appears

DAC

on the T

pin when the thermistor is terminated at the

BAT

negative terminal of the battery. The thermistor slope is

typically –30mV/°C, so the switching noise can cause

premature fail-safes when the battery temperature is within

10°C of the LTF or HTF trip points. An RC filter (with time

constant much greater than the clock period of 10µ s) can

be inserted between the T

pin and the output of the

BAT

battery thermistor circuit to prevent false fail-safes.

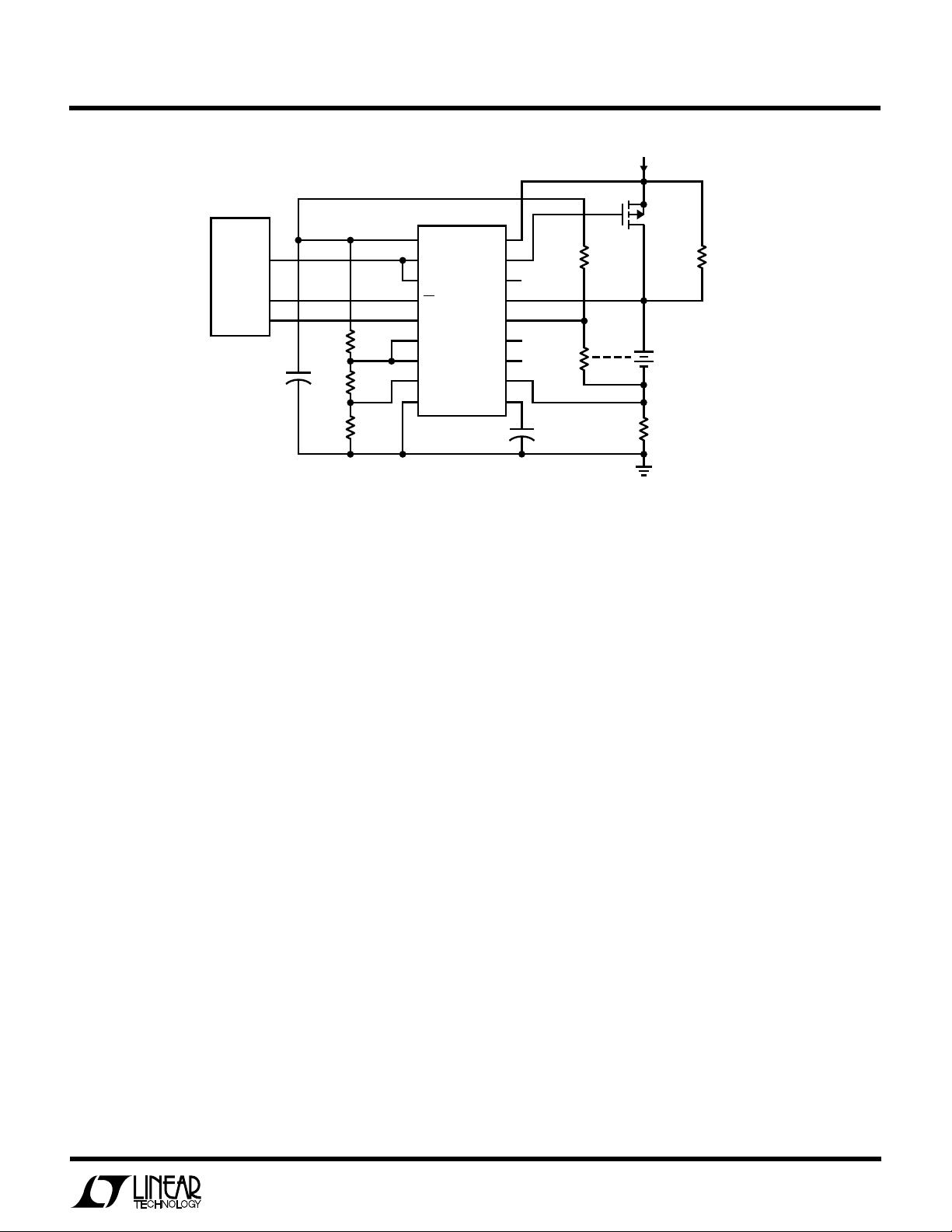

Disabling Fail-Safes

The LTC1325’s built-in battery voltage and temperature

fail-safes can be easily disabled as shown in Figure 8. To

disable temperature fail-safes, the T

pin is tied to the

BAT

top of resistor R3. The LTC1325 is made to think that the

battery temperature is constant and within the limits set by

the LTF and HTF pins. Similarly, V

may be tied to the

BAT

same point to disable all the battery voltage fail-safes

(MCV, EDV, BATR). The LTC1325 battery divider is programmed to divide-by-1. Battery temperature and cell

voltage can still be measured using the T

AMB

and V

IN

channels of the ADC. An external divider (R7, R8) replaces

the internal divider connected to the V

channel.

BAT

Gated P-Channel MOSFET Controller

When an external current-limited voltage source is available, and charging currents are low enough that efficiency

and heat dissipation are not major concerns, the LTC1325

can be used to turn on a P-channel MOSFET to gate the

current into the battery. This circuit makes an inexpensive

and effective combination. The battery’s current limit

during charging is set by the current limit of the charging

power supply VDC . The maximum available current should

therefore not exceed the permissible charge rate of the

battery. With the LTC1325 V

programmed to the

DAC

160mV setting, and the voltage at the Sense pin below this

value, the LTC1325 will hold MOSFET P1 on until charge

MPU

(e.g. 8051)

p1.4

p1.3

p1.2

p1.5

LTC1325

VDD

PGATE

DIS

V

BAT

T

BAT

T

AMB

V

SENSE

FILTER

IN

+ +

C

1µF

F

REG

D

OUT

D

IN

CS

R1

10k

REG

1%

R2

4.99k

1%

R3

4.99k

1%

R4

10k

1%

+

C

4.7µF

25V

NOTE 1: PANASONIC ERT-D2FHL103S NTC THERMISTOR OR EQUIVALENT.

NOTE 2: CHOOSE FOR C/20 TRICKLE CHARGE RATE.

CLK

LTF

MCV

HTF

GND

100Ω

500pF

R7

30.1k

1%

R8

10k

1%

Q1

VN2222LL

100µH

COILTRONICS

CTX100-1-52

R9

7.5k

1%

THERM 1

NOTE 1

V

DC

16V MAX

L1

R

1Ω

P1

IRF9531

D1

1N5818

V

BAT

500mA HR

SENSE

R

TRK

NOTE 2

AN64 F08

+

C

SPLY

10µF

AN64-10

Figure 8. Charger with T

BAT

and V

Fail-Safes Disabled

BAT

MPU

(e.g. 8051)

p1.4

p1.3

p1.2

LTC1325

VDD

PGATE

DIS

V

BAT

T

BAT

T

AMB

V

SENSE

FILTER

R4

7.5k

1%

IN

+

NTC

THERM 1

NOTE 1

C

F

1µF

REG

D

OUT

D

IN

CS

R1

10k

C

REG

4.7µF

1%

R2

10k

1%

R3

10k

1%

+

NOTE 1: PANASONIC ERT-D2FHL103S NTC THERMISTOR OR EQUIVALENT.

NOTE 2: CHOOSE FOR C/20 TRICKLE CHARGE.

CLK

LTF

MCV

HTF

GND

Application Note 64

V

DC

16V MAX

P1

IRF9531

R

TRK

NOTE 2

V

BAT

4 CELLS

500mA HR

R

SENSE

1Ω

AN64 F09

Figure 9. LTC1325 Charger Using an External Constant-Current Supply

is terminated by the microprocessor, or a fail-safe occurs.

As shown in Figure 9, the inductor and catch diode that are

normally connected to the positive terminal of the battery

are not required, as no PWM switching action occurs at the

drain of MOSFET P1.

With the wall adapter connected, the current into the

battery will always be (I

ADAPTER

– I

EQUIPMENT

). The use of

one additional operational amplifier, such as the LT1077,

allows monitoring this charging current by integrating the

voltage across R

during the charging interval. The

SENSE

result of this integration can then be measured using the

LTC1325’s auxiliary ADC input VIN. Combined with the

built-in gas gauge function during the discharge interval

(via the Sense input), the state of charge of the battery may

be reliably determined at any time.

If the battery pack is heavily depleted or is damaged, the

wall adapter can still be used to operate the equipment by

putting the LTC1325 into Idle mode. Under these conditions the battery will receive no charging current (except

through the trickle charging resistor, if one is provided). If

the gas gauge is not needed, R

can be removed and

SENSE

the Sense pin should be returned to ground.

Constant-Potential Charging (Lead-Acid and

Lithium-Ion)

Constant-current charging, which is the technique of

choice for NiCd and NiMH batteries, is not recommended

for most Lead-Acid or Lithium-Ion applications. Instead, a

constant-voltage charging regimen is required, usually

with a means of limiting the initial charging current. Such

a charging technique is generally referred to as a “Constant-Potential” (CP) regimen.

The LTC1325 is at first glance a constant-current part.

Such a view of its capabilities, however, is too limited. Its

power control section is more completely described as a

constant-average-current PWM with both hardware and

software feedback. The hardware loop used for current

sensing is the Sense input; the software loop, which can

be used to control the effective output voltage of an

LTC1325 charger circuit, is the microprocessor control

routine in conjunction with the ADC and the DAC. Given a

suitable output filter (the output inductor and the battery

itself), current from the PWM section can be made to

produce a current-limited constant voltage at the battery’s

terminals. A circuit intended for such CP operation is

shown in Figure 10.

AN64-11

Application Note 64

MPU

(e.g.,80C51)

+

C

4.7µF

NOTE 1: PANASONIC TYPE ERT-D2FHL103S NTC THERMISTOR OR EQUIVALENT

REG

R

R

P1.4

P1.3

P1.2

P1.5

MCV1

MCV2

4

DATA

3

CHIP SELECT

2

CLOCK

5

AUX SHDN

1

REG

2

D

OUT

3

LTC1325

D

R

TF1

R

TF2

R

TF3

IN

4

CS

5

CLK

6

LTF

7

MCV

8

HTF

9

GND

VDD

PGATE

DIS

V

BAT

T

BAT

T

AMB

V

SENSE

FILTER

IN

1µF

18

17

16

15

14

13

12

11

10

CF

Figure 10. Constant Potential Battery Management System

+

R1

7.5k

1%

THERM 2

NOTE 1

+ +

C

S

500pF

R5

470k

R3

R4

Q1

2N7002

RIN

2k

R

100Ω

CIN

47µF

VDC IN

P1

IRF9Z30

R

R2

7.5k

1%

THERM 1

NOTE 1

S

R

SENSE

62µH

L1

Y

TRK

D1

1N5818

R

DIS

IRF510

+

N1

AN64 F10

C

SPLY

10µF

Batteries that require a CP charging algorithm generally

need a rather accurate charging voltage, especially in fastcharge applications. For this reason the LTC1325’s internal battery divider often cannot be used to control the

charging voltage, due to its tolerance of ±2% at division

ratios other than 1:1. It does, however, remain useful for

MCV and/or FEDV detection. For measuring battery voltage an external resistive divider feeding VIN is recommended. The external divider resistors should be chosen

such that the voltage at the VIN pin will come as close as

possible to the ADC’c full-scale input voltage without

exceeding that value; 3.000V maximum is a good choice.

Using a near-full-scale input to the ADC improves measurement accuracy. To further improve charging voltage

accuracy, it’s a good idea to use ±0.1% or ±0.25%

tolerance resistors in the battery voltage divider. Under

such conditions, the voltage loop error is ideally only the

reference error (±0.8%), plus that of the ADC (4 bits out

of 1024, or ±0.4%) and of the battery divider (±0.1% or

±0.25%), for a total ±1.3% or ±1.5% error.

“Auxiliary Shutdown” is a static line from the microprocessor to a small-signal MOSFET, which prevents the

battery from discharging through the voltage divider string

when it is not charging. With the external divider in place,

the BATP flag will always be high except when Auxiliary

Shutdown is at a logic low and the battery is not installed

in the circuit (see “Charging ‘Tall’ Batteries” above). Battery voltage fail-safes will remain operational (assuming

that they use the V

input) although it may not be

BAT

possible to make simultaneous use of the MCV and EDV

fail-safes with all CP battery types. R

, if needed, main-

TRK

tains the battery in a fully charged condition.

A suitable software algorithm to implement a quasi-CP

charger is this:

1. Establish a regular repetition interval for the voltage

servo loop. t

values of 10ms to 20ms give good

LOOP

results.

2. Set V

to 160mV at the highest charge rates for best

DAC

resolution. Using a 95% maximum PWM duty cycle

[tON/(tON + t

I

), where I

MAX

)], R

OFF

is the nominal maximum current to

MAX

chosen as 160mV/(0.95 ×

SENSE

be allowed through the battery. A suitable minimum

duty cycle is 10%; beyond such a low duty cycle it is

AN64-12

Application Note 64

usually better to reduce the peak current through the

battery (by programming V

) than to reduce the duty

DAC

cycle further.

3. Perform each of the following tasks once each servo

loop interval (t

LOOP

):

a) Enter Idle mode of operation.

b) Read V

CELL

.

c) Adjust the value entered into a timer register (or

a software timer) up or down according to actual

V

vs target V

CELL

value is increased. If V

CELL

. If V

is too low, the timer

CELL

is too high, the timer

CELL

value is decreased.

d) The maximum Charge time of the LTC1325 has

been set at 95% of t

; the minimum at 10%.

LOOP

Within that range, the duty cycle at which the loop

will operate is set by the timer of 3(c). If the timer’s

interval is increased (V

each t

during which the LTC1325 is put into

LOOP

too low), the portion of

CELL

Charge mode is increased. If the timer’s interval is

decreased (V

is too high), the LTC1325 is com-

CELL

manded into Idle mode for a greater portion of each

t

.

LOOP

e) If tON < (0.1 × t

value (note that the V

), switch V

LOOP

to the next lower

DAC

value of 34mV is not used).

DAC

f) Repeat (a) through (e) until the average current into

the battery, or the net duty cycle, drops below a

chosen limit. A timer-based secondary cutoff is

often recommended for CP chargers.

g) Terminate the software loop with MOSFET P1 in the

“off” state, using R

(if required) to maintain the

TRK

battery’s charge.

A flow chart showing the principals of this voltage servo

loop is given in Appendix B, Figures B3a and B3b. Figure

B3a shows the “ramp-up” from the point where the

charger is first turned on to the maximum charging

current required and Figure B3b shows the “taper-down”

which simulates the necessary CP charging algorithm.

(This algorithm is undergoing refinement at press time.

For the latest information on its implementation and

optimization, please contact LTC.)

RIN and CIN have greater values in Figure 10 than in most

of the circuits in this Application Note. This is because

batteries requiring a CP charge tend to have a significant

positive ∆V during the interval in which charging current

is flowing through them. The time constant of (RIN × CIN)

filters the resulting 10ms to 20ms ripple before it is

presented to the V

and VIN pins. If only VIN input will be

BAT

used, RIN may be omitted, CIN may be placed from VIN to

ground, and its value can be decreased.

The circuit of Figure 10 has deliberately been generalized

to provide flexibility across all common battery types. For

applications requiring the support of only specific battery

types, or which do not need extensive thermal or other

protection mechanisms, various components can be

modified or removed to minimize cost and board space.

Overcurrent Protection

Three common scenarios in which battery current can

exceed acceptable levels are: accidental shorting of the

battery terminals, excessive loads and inserting the battery into the charger in reverse. Battery or charger damage

in all three cases can be prevented through the use of a

thermal or overcurrent device to limit fault currents.

Usually, it is desirable that this device reset itself when the

fault goes away. Possible choices are bimetallic (thermostatic) switches and polymer PTC thermistors. The high

series resistance of traditional ceramic PTC thermistors,

even in the unexcited state, make them unsuitable for this

application.

Bimetallic switches operate by sensing battery temperature. By the nature of their operation, these switches cycle

on and off as long as the fault remains, causing the battery

and all associated components (mechanical as well as

electrical) to heat up and cool down repeatedly. Polymer

based PTC thermistors such as the Raychem PolySwitch

®

also offer very low series resistance until “tripped,” and

have the advantages of a faster response and freedom

from thermal cycling.

Polymer PTCs should be chosen such that under normal

operation, the average charging current (V

DAC/RSENSE

) is

less than the Hold Current rating of the PTC to keep it in the

low resistance state. Under fault conditions, the Fuse

Current should exceed the Trip Current rating of the fuse.

This will cause the fuse’s resistance to increase dramatically and reduce the fault current to about V

PolySwitch is a registered trademark of Raychem Corporation.

BAT/RFUSE

(Trip).

AN64-13

Application Note 64

The PolySwitch should ideally be placed between cells in

the battery, in close physical contact with one of the cells.

In this way the trip point of the device will be reduced as

the battery’s temperature increases. Such a configuration

provides substantial protection for the battery against

shorts across its terminals and from excessive load currents. It will also protect the battery if it is accidentally

inserted into the charger in reverse.

Figure 11 shows the fault current path when a battery is

inserted into a charger in reverse. Potentially damaging

currents may flow through this path since the Sense

resistor is usually in the region of 1Ω or less. A PolySwitch

inside the battery pack (as described above), or in series

with the Schottky diode, limits fault currents to safe levels.

The following points should be noted in choosing the

diode and R

SENSE

.

• Normal charging currents should be equal to or less

than the holding current rating of the PolySwitch.

• Temperature affects PolySwitch performance. The

manufacturer’s data should be consulted for derating

factors.

• Initial fault currents will be approximately V

BAT/RSENSE

if the battery is inserted in reverse. This should exceed

the trip current rating of the PolySwitch.

• The surge current rating of D1 should exceed the initial

fault current of V

BAT/RSENSE

. It may be necessary to

confirm the selected diode’s applicability with the manufacturer of the part.

In addition to the above scenarios, the battery current may

exceed acceptable levels when a battery is inserted into a

charger which has the charging supply (VDC) turned off. If

the VDC supply exhibits a low impedance path to ground

when it is turned off, the diode that is intrinsic to the

P-channel MOSFET may turn on to form a battery discharge path which flows from the battery’s positive terminal through the inductor, the MOSFET internal diode, the

ground lead and the sense resistor before returning to the

negative terminal of the battery. This can be prevented by

connecting a Schottky diode between VDC (diode anode)

and the source of the P-channel. See the section on

“Current Sinking VDC Sources” for more details.

Current-Sinking VDC Sources

In some applications, it may be necessary to add a

Schottky rectifier between the VDC supply and the source

of MOSFET P1. This rectifier prevents the battery from

discharging backwards through MOSFET P1, which could

damage P1, L1, or R

. It is required if the following

SENSE

conditions are met:

• The wattage of R

should be high enough to

SENSE

withstand the initial fault currents of V

MPU

(e.g., 8051)

p1.4

p1.3

p1.2

C

REG

4.7µF

R1

R2

R3

+

REG

D

D

CS

CLK

LTF

MCV

HTF

GND

.

R4

+

CF

1µF

THERM 2

+

+

500pF

OUT

IN

LTC1325

BAT/RSENSE

VDD

PGATE

DIS

V

BAT

T

BAT

T

AMB

V

IN

SENSE

FILTER

Figure 11. Reversed Battery Protection

3.3µF

IRF9531

R5

100Ω

THERM 1

100Ω

V

DC

12V

P1

D1

R

TRK

L1

+

R

SENSE

FUSE

AN64 F11

C

SPLY

10µF

AN64-14

Application Note 64

• The voltage of the battery being charged can exceed

that of the supply.

• The VDC supply can sink current when it is at a lower

voltage than the battery being charged.

Most switching power supplies, such as those used for AC

adapter and battery charger supplies in portable computers, have a very small reverse leakage current––several

milliamperes at most. These would not generally need the

additional Schottky rectifier. Two examples of situations

where the rectifier is necessary are:

• Charging a 7.2V or greater battery from a 12V car

battery using the cigarette lighter socket. Under coldcranking conditions the 12V nominal battery drops to

6V to 7V and an automobile’s wiring will allow the

starter motor to pull current back out of the lighter

socket.

• Bench-top testing. Many power supplies have internal

protection circuitry which will sink current from the

load rather than allow a sourcing load, such as a

charged battery, to force current indiscriminately into

the supply’s output. Also, any supply with a crowbar

represents a possible current-sinking power supply.

Figure 12 depicts a basic charger circuit and shows the

proper placement of the Schottky rectifier DIN.

CONCLUSION

Through its ability to accept commands from almost any

microprocessor, the LTC1325 takes advantage of the

power and flexibility of software to avoid locking the user

into any given battery type. This almost endless

configurability enables the battery system designer to

choose the required charge regimen, charge rate and

charge termination technique(s) for virtually any task.

Possibilities range from a robust but basic battery charging technique to sophisticated multiple-stage charging

algorithms, or even several different algorithms entirely,

all executed with the same hardware. In this way a wide

range of battery types or end application needs can be

accommodated with the same circuit. The on-board fault

detection circuitry provides additional confidence in the

final design by acting as a “watchdog” on the microprocessor and the battery pack. The design of the overall

charging circuit is made as simple as possible by incorporating all the functional blocks needed and minimizing the

discrete component count. In addition to charging batteries, the LTC1325 has provisions to condition batteries and

to measure battery capacity. As with the LTC1325’s charging-related functions, these capabilities are afforded a

maximum of versatility and value by being placed almost

completely under software control.

MPU

(e.g., 8051)

p1.4

p1.3

p1.2

V

DC

D

(20V SCHOTTKY)

IN

P1

IRF9531

LTC1325

VDD

PGATE

DIS

V

BAT

T

BAT

T

AMB

V

SENSE

FILTER

IN

+ +

C

1µF

F

R5

THERM 2

500pF

R6

100Ω

+

THERM 1

3.3µF

100Ω

DC

REG

D

OUT

R1

C

REG

4.7µF

R2

R3

R4

+

D

IN

CS

CLK

LTF

MCV

HTF

GND

Figure 12. Protection Against Discharging Through V

L1

R

D1

SENSE

FUSE

R

TRK

AN64 F012

+

C

SPLY

10µF

AN64-15

Application Note 64

APPENDIX A

An Overview of Battery Types, Terminology, and

Techniques

The world is increasingly relying upon portable electronic

equipment, and the rechargeable battery systems (battery, battery charger and ancillary functional blocks)

which power that equipment. These battery systems are

among the defining elements of end product capability,

endurance and life. In spite of this, they are commonly

considered a necessary evil; their design and testing, a

black art. The truth is that commercially viable battery

management systems are comprised of well understood

electronic and electrochemical components, with well

defined performance characteristics. While this Appendix

is not intended as a comprehensive treatment of battery

technology, it will provide the equipment engineer with

practical information for the choice of battery types and

battery management techniques.

There are three rechargeable battery types commonly

used in portable devices. These are Nickel-Cadmium (NiCd),

Nickel-Metal Hydride (NiMH) and Sealed Lead-Acid (SLA).

Lithium-Ion (Li-Ion) is also beginning to receive significant attention, primarily due to its very high energy density

(as measured in terms of volume and of weight). Table A1

gives a quick overview of the characteristics of these

battery types:

Table A1. Battery Type Characteristics

BATTERY SEALED LITHIUMCHARACTERISTICS LEAD-ACID NiCd NiMH ION

Energy Density 30 40 60 90

W-h/kg

Energy Density 60 100 140 210

W-h/liter

Cell Voltage (V) 2.0 1.2 1.2 4.20 Max

3.60 Avg

2.50 Min

Charging Method Constant Constant Constant Constant

Potential Current Current Potential

Dicharge Profile Mildly Flat Flat Sloping

Sloping

#Charge/Discharge 300 >500 >500 500 to

Cycles* 1000

Self-Discharge 3%/MO 15%/MO 20%/MO 6%/MO

Internal Resistance Low Lowest Moderate Highest

Discharge Rate** > 4C > 10C 3C < 2C

* Until 80% of rated capacity is available upon discharge.

** C is the capacity rating of the battery in Ampere-Hours.

A useful first-approximation view of a rechargeable battery is that it is a container into which energy may be

poured as desired, to be subsequently consumed as

needed. This analogy generally conjures up an image of a

jar of water, which would impose few restrictions upon

rates of filling or emptying the vessel. In fact, a battery is

more akin to a bottle of thick syrup, with the bottle having

a narrow mouth and a wide base. With such a bottle, the

syrup must be delivered into the bottle at a controlled rate

and pressure (to prevent possible damage to the delivery

system or to the neck of the bottle), and may be drawn at

a maximum rate determined by the amount of syrup in the

bottle and the bottle’s shape. To carry this analogy just a

little further, it is true of batteries, as it is with the

hypothetical syrup bottle, that it is possible to get almost

all of the contents out of the container — but it may take

a long time to get the last few percent out. The flow rate will

vary with the amount remaining, meaning that in situations where a high rate of discharge is required of a

battery, not all the “contents of the bottle” — not all the

available energy — will be instantaneously available to the

discharging circuit.

Battery recharge times generally break down into several

groups. The most common of these are the “standardcharge,” suitable for overnight applications (typically requiring 16 hours) and the “fast-charge” (typically two

hours or less). Between the two is the “quick-charge,”

which is in many respects akin to a standard-charge but

requires a useably shorter interval (about five hours).

Examples of standard-charge applications are cordless

telephones and UPS systems for small computers. Quickcharge batteries are commonly found in devices which will

see brief but significant power drain several times daily,

such as cellular phones. Laptop computers and cordless

tools are excellent locations for fast-charge systems. In

these and other fast-charge uses there is a high average

drain on the battery, and the product’s value is determined

in large part by the availability of battery power upon

demand. The LTC1325 forms a comprehensive core for

battery management systems operating at any of these

charge rates; all that need be changed are a few external

components and the microprocessor algorithm used to

control the charge cycle. Only batteries designed and

rated for fast-charge should be subjected to a fast-

AN64-16

Application Note 64

charge regimen. Similarly, only batteries rated for quickcharge should be subjected to quick-charging conditions.

As might be expected, there are important differences

between the charging regimens used for the four different

battery types. There are also more similarities than might

be expected. Each of the following sections is intended to

stand alone, but it is suggested that the battery system

designer read all four sections in order to get a feel for

where the similarities and differences between battery

families lie. Terms which are specific to the battery user

community, or which have special meanings in this Appendix, are defined in the Glossary in Appendix C.

Using Nickel-Cadmium Batteries

Nickel-Cadmium batteries, in various forms, have been in

use for over 50 years. During that time they have evolved

from expensive, special purpose devices to the battery of

choice for most portable equipment. The availability of

inexpensive sealed cells, with ongoing improvements in

energy density and cycle life, have been the driving forces

for this acceptance. The LTC1325 adds to this the ability to

easily implement fast-charge routines, gas gauge algorithms and/or switch mode constant current sources, all

using very little system overhead and printed circuit board

space.

• Special purpose batteries are available with extended

operating temperature ranges.

The “cons”:

• Cadmium is commonly considered an environmentally

hazardous material. Nickel is also coming under environmental scrutiny.

• NiCd cells have a significant self-discharge rate (0.5%/

day at room temperature).

Nickel-Cadmium Standard-Charge

For applications which can allow a recharge period of

about 16 hours — an “overnight” charge — the standardcharge regimen is the method of choice. The reasons for

this include:

• Simplest charging algorithm.

• Least expensive charge termination techniques.

• Small power supply required to provide the charging

current.

• Small charging circuit power components.

• Low overall charging system power dissipation.

A standard-charge is relatively straightforward to implement. In “cookbook” form, such a charge requires:

A quick run-down of the pros and cons of Nickel-Cadmium

batteries:

The “pros”:

• Good energy density, both by weight and by volume,

relative to competing technologies.

• Acceptable charging rates range from 0.1C to 2C and

beyond.

• Most NiCd cells can accept a continuous overcharge

current of 0.1C.

• A very flat discharge profile.

• The lowest cell impedance of the major battery technologies.

• Well understood and documented electrical behavior

and electrochemistry.

• Cells and batteries are available in a variety of sizes

from a number of vendors.

• Charging Current: 0.1C.

• Required Charging Voltage: 1.60V/cell or greater, plus

charger overhead.

• Charging Temperature Range: 0°C to 45°C.

• Charging Time: 16 hours.

• Charge Termination Method: None required.

• Secondary Charge Termination Methods: None required.

• Special issues which may require further consideration

are: wide temperature range charging, wide temperature range discharging and accurate gas gauging at

temperature extremes.

A charging current of 0.1C, fed to the battery for 16 hours,

will deliver (16 hours × 0.1C) = 160% of standard capacity

to the battery. At temperatures between 0°C and 25°C, the

resulting 60% overcharge is adequate to ensure that the

battery is returned to 100% of its standard capacity. Once

AN64-17

Application Note 64

the cells in the battery reach their actual capacity for the

operating temperature, mild gassing will occur, but not

enough to cause venting or other cell damage. Since most

NiCd batteries will accept a continuous 0.1C charge at any

case temperature between 0°C and 50°C, charge termination per se is usually not required. For specialized applications, extended temperature range batteries are available

which can be charged at 70°C. Charging at temperatures

below 0°C is also possible if the charge current is “throttled

back” as the battery temperature decreases. The charging

current under such conditions should linearly decrease

from 0.1C at 0°C to zero current at –15°C to –25°C. In

wide temperature range applications, the use of a battery

(or ambient) temperature sensor in conjunction with the

LTC1325 is an excellent way to provide positive control of

battery charging current versus temperature, thereby extending battery life.

The charge acceptance of NiCd batteries is reduced significantly at temperatures above 40°C. This effect is only

marginally mitigated by longer charge times, and should

be taken into account if gas gauging is to be done over

extended temperature ranges. By way of example, a battery that can be fully recharged at 25°C in 16 hours will

reach only about 75% of standard capacity at 45°C after 48

hours. Again, no damage will be done to the battery, but its

available capacity during subsequent discharge will be

less than one would otherwise expect. If correction parameters for the gas gauging function of the LTC1325

will be employed, it is recommended that the manufacturer of the specific battery in question be consulted.

In the same way that charge acceptance is reduced for

temperatures above 25°C, actual capacity is reduced

when discharging a cell at temperatures much removed

from 25°C. The battery temperatures at which actual

capacity is 85% of standard capacity are approximately

0°C and 50°C. Again, for more specific data, the manufacturer of the battery to be used should be contacted.

the charger’s output current to a 0.05C trickle-charge after

the five-hour recharge interval. Checking the cell

manufacturer’s data will provide further information on

this, as well as the specified charge rate, permissible

continuous overcharge rate, and information on the allowable temperature range.

Under some conditions, it may be desirable to use a lower

charging rate than 0.1C (for instance, to reduce charger

power requirements). This is feasible only within a narrow

range: NiCd cells have a reduced charge acceptance at

lower charge rates, lengthening the required charge time.

This, and their self-discharge characteristic (approximately

0.5%/day at 23°C), combine to make anything under

0.05C a very slow and potentially unreliable charge rate for

most cell types.

Nickel-Cadmium Fast-Charge

In recent years a class of applications has arisen for which

5 hours to 16 hours may constitute an excessive recharge

time. Portable computer equipment is an excellent example of this — even if the battery pack in a laptop can be

“swapped out” for external recharge, it is often needed

again within several hours, fully charged and ready for

use. In this case, the fast-charge techniques which the

LTC1325 makes practical are the way to go. A fast-charge

regimen implies:

• 90% recharge within one hour; 100% recharge within

two to three hours.

• A method for determining the optimum charge termination point(s).

• Backup charge termination method(s) to ensure best

battery life.

• Highly efficient use of available charging energy.

• Increased product value through better battery utilization and greater customer satisfaction.

Specially rated NiCd cells can support a higher rate of

relatively uncontrolled overcharge than the ubiquitous

0.1C. This allows the quick-charge regimen, which is

typically 0.33C for 5 hours. Charging current and interval

aside, most other details for performing a quick-charge

are the same as for a standard-charge. It is often desirable

in quick-charge regimens to use a timed charge, reducing

AN64-18

Unlike the standard-charge and quick-charge regimens,

there is no one best way to fast-charge a Nickel-Cadmium

battery. Variables introduced by the allowable cost and

size of the end application, the continuing evolution of

Ni-Cd cells to accomodate faster charge rates, and the

specific battery vendor(s) chosen will all influence the final

choice of charging technique. There are several areas of

Application Note 64

industry consensus, however, regarding the suitable fastcharging of NiCd batteries:

• Charging Current: 1.0C to 2.0C.

• Required Charging Voltage: 1.80V/cell or greater, plus

charger overhead.

• Charging Temperature Range: 10°C to 40°C.

• Charging Time: Three hours (90% of charge is typically

returned within the first hour).

• Suitable Charge Termination Methods: See Table A2.

• Suitable Secondary Charge Termination Methods: See

Table A2.

• Special issues which may require further consideration

are: accurate gas gauging at temperatures over 25° C,

and appropriate mechanical integration of the battery

pack into the end equipment.

The objective of fast-charging a NiCd battery is, crudely

stated, to cram as much energy as it takes to bring the

battery back to a fully charged state into that battery in as

short a time as possible. Since current is proportional to

energy divided by time, the charging current should be as

high as the battery system will reasonably allow. Generally, NiCd batteries rated for fast-charge use are designed

around a 1C to 2C maximum charging rate. At the 1C rate,

more than 90% of the usable discharge capacity of the

battery is typically returned within the first hour. Higher

rate cells (up to 5C) do exist, but they are more oriented to

special applications and will not be discussed here, except

to note that the LTC1325 is capable of handling the

charging routines required for such cells, should that be

required.

Fast-charging has compelling benefits, but places certain

demands upon the battery system. A properly performed

fast-charge can yield a cell life of as many as 500 charge/

discharge cycles. The high charging rates involved, however, do engender correspondingly more rapid electrochemical reactions within the cell. Once the cell goes into

overcharge, these reactions cause a rapid increase in

internal cell pressure, and in the cell’s temperature. Figure

A1 shows the Voltage, Pressure and Temperature characteristics of a Nickel-Cadmium cell being charged at the 1C

rate. It can be seen that, as the cell approaches 100% of

Table A2. Fast-Charge Termination Techniques for Nickel-Cadmium Batteries

Voltage Cutoff (VCO) Uses absolute cell voltage to determine the cell’s state of charge. Not generally recommended for use

in NiCd charging regimens.

Negative ∆V (–∆V) Looks for the relatively pronounced downward slope in cell voltage which a NiCd exhibits (≈30mV to

50mV) upon entering overcharge. Very common in NiCd applications due to its simplicity and reliability.

Zero ∆V Waits for the time when the voltage of cell under charge stops rising, and is “at the top of the curve”

prior to the downslope seen in overcharge. Sometimes preferred over –∆V, as it causes less

overcharging.

Voltage Slope (dV/dt) Looks for an increasing slope in cell voltage (positive dV/dt) which occurs somewhat before the cell

reaches 100% returned charge (prior to the Zero ∆V point). No longer widely used.

Inflection Point Cutoff (d2V/dt2, IPCO) As a NiCd cell approaches full charge, the rate of its voltage rise begins to level off. This method looks

for a zero or, more commonly, slightly negative value of the second derivative of cell voltage with

respect to time.

Absolute Temperature Cutoff (TCO) Uses the cell’s case temperature (which will undergo a rapid rise as the cell enters high-rate overcharge)

to determine when to terminate high-rate charging. A good backup method, but too susceptible to

variations in ambient temperature conditions to make a good primary cutoff technique.

Incremental Temperature Cutoff (∆TCO) Uses a specified increase of a NiCd cell’s case temperature, relative to the ambient temperature, to

determine when to terminate high-rate charging. A popular, relatively inexpensive and reliable cutoff

method.

Delta Temperature/Delta Time (∆T/∆t) Uses the rate of increase of a NiCd cell’s case temperature to determine the point at which to terminate

the high-rate charge. This technique is inexpensive and relatively reliable as long as the cell and its

housing have been properly characterized.

AN64-19

Application Note 64

1.75

1.50

1.25

1.00

0.75

CELL VOLTAGE (V)

0.50

0.25

0

Reproduced with permission by Butterworth-Heinemann,

Batteries Applications Handbook

Figure A1. NiCd Voltage, Pressure, and Temperature

Characteristics During Charge at 1C (23°C Ambient)

120

100

80

60

40

20

INTERNAL PRESSURE (PSIG)

0

–20

90

80

70

60

50

40

CELL TEMPERATURE (°C)

30

20

0

, copyright 1992

CHARGE INPUT (% OF CAPACITY)

CELL VOLTAGE

PRESSURE

50 100

TEMPERATURE

Rechargeable

150

AN64 FA01

capacity, the charging current must be reduced or terminated. Left unchecked, overcharge at the C rate will ultimately cause the cell’s safety vent to open. This results in

a loss of gaseous electrolyte to the ambient, and a permanent diminution of cell capacity. Similarly, allowing the

temperature of the cell to rise excessively will cause a

degradation of the internal materials, again reducing cell

life. The science of fast-charging is largely that of determining when the battery has achieved between 90% and

100% of its dischargeable capacity. At that point the

charging circuit must switch from the fast-charge current

level to a level appropriate to finish the charging of, and/

or maintain the charge on, the battery. Some of the

common methods for doing this are outlined in Table A2.

As Table A2 shows, there are a number of techniques

which have been been successfully employed for the

purpose of determining when to terminate the high-rate

interval of a fast-charge regimen. Individual application

requirements, and manufacturer’s recommendations, must

of course be considered carefully before making a final

design decision. Nonetheless, two techniques for detecting the point at which to make the transition from high-rate

charging to top-charging have become especially popular

over the years, and are used here as examples. These are

the –∆V and the ∆TCO methods. The –∆V approach looks

for a point at which the cell or battery voltage reaches its

peak during charging, and holds this maximum value. The

high-rate charge is then terminated when the voltage per

cell has declined by a value of 15mV to 30mV. ∆TCO

sensing uses two thermistors to measure the case temperature of the cell, or of one of the cells in a battery, while

also measuring the ambient temperature. A 10°C differential between cell and ambient is the typical high-rate

termination criterion. (A single-thermistor variant on the

“classic” ∆TCO approach is made possible through the

combined power of the LTC1325 and a microprocessor:

cell temperature is measured just before commencing

charge, and assumed to be the ambient temperature. This

baseline value then becomes the reference against which

all further temperature measurements are compared.)

For illustration of the fast-charging of NiCd batteries, this

document will use a 1C charge rate, in a three-stage

algorithm. The three stages are:

• Fast-Charge at the 1C rate, until it is determined by the

charging system that the high-rate portion of the charge

regimen must be terminated. At this point, a 1C charge

will typically have returned between 90% and 95% of

the battery’s actual capacity.

• Top-Charge at 0.1C for two hours, to add an additional

0.2C to the battery. This will bring the battery back to

100% of usable capacity.

• Trickle-Charge at between 0.02C and 0.1C to counter

the NiCd’s self-discharge value of about 0.5%/day.

Unless the battery is being used in an unusual application,

there is little advantage in using a trickle-charge rate

different from the 0.1C top-charge rate, which most NiCd

cells can tolerate indefinitely. If the trickle-charge is the

same as the top-charge rate, the charge regimen illustrated effectively has only two stages. This is not uncommon for NiCd batteries.

It cannot be overstated that the high-rate portion of a fastcharge regimen must be terminated once the battery being

charged has reached the appropriate cutoff point. Murphy

has taught us to prepare for the unexpected. So for each

method consider: “How can this method fail?” To give just

one example of each case: contact resistance in the

charging path could mask the downslope of the battery’s

terminal voltage, causing the microprocessor to miss the

–∆V termination point. For ∆TCO termination, the ambient

temperature might not be indicative of the battery’s temperature at the start of charge (e.g., recharging of a battery

just removed from a cooler environment to a warmer one),

AN64-20

Application Note 64

which would keep a significant battery-to-ambient temperature differential from appearing. Failure of the charger

system to recognize the cutoff point, for whatever reason,

can quickly and irretrievably damage the battery. To avoid

such damage, inexpensive redundancy is the solution.

With the capabilities of the LTC1325 already at hand, the

best plan is to simply employ both methods. It is then

reasonable to expect that one of the two techniques will

result in a successful high-rate charge termination. In this

example regimen a good choice for the primary high-rate

charge termination for NiCd batteries would be –∆V sensing, with ∆TCO serving as a backup. To give Murphy’s

gremlins a harder time of it, there are maximum and

minimum operating temperatures and cell voltages which

the LTC1325 can be set to recognize. The LTC1325 also

has a timer feature which will turn off the charge current

to the battery unless the timer is reset within a certain

interval. These preset limits serve to protect the battery

from severe overcharge even if the system’s microprocessor should fail altogether.

As mentioned above, fast-charge current levels can cause

rapid gas evolution within a NiCd cell. Since gas recombination inside the cell is slower at reduced temperatures,

the pressure inside the cell will rise as the cell temperature

decreases. This places a lower limit on the permissible

fast-charge temperature range. Similarly, the cell’s charge

acceptance decreases at elevated temperatures. Hence,

although gas recombination occurs much more rapidly,