Datasheet LTC1272-8CCN, LTC1272-8ACS, LTC1272-3CCS, LTC1272-3CCN, LTC1272-3ACS Datasheet (Linear Technology)

...

LTC1272

FREQUENCY (kHz)

0

–140

AMPLITUDE (dB)

20 40 60 80

LTC1272 • TA02

–120

–100

–80

–60

–40

–20

0

100 120

S

(N+D)

= 72.1

12-Bit, 3µs, 250kHz

Sampling A/D Converter

EATU

F

■

AD7572 Pinout

■

12-Bit Resolution

■

3µs and 8µs Conversion Times

■

On-Chip Sample-and-Hold

■

Up to 250kHz Sample Rates

■

5V Single Supply Operation

■

No Negative Supply Required

■

On-Chip 25ppm/°C Reference

■

75mW (Typ) Power Consumption

■

24-Pin Narrow DIP and SOL Packages

■

ESD Protected on All Pins

PPLICATI

A

■

High Speed Data Acquisition

■

Digital Signal Processing (DSP)

■

Multiplexed Data Acquisition Systems

■

Single Supply Systems

RE

S

O

U

S

DUESCRIPTIO

The LTC1272 is a 3µs, 12-bit, successive approximation

sampling A/D converter. It has the same pinout as the

industry standard AD7572 and offers faster conversion

time, on-chip sample-and-hold, and single supply operation. It uses LTBiCMOSTM switched-capacitor technology to

combine a high speed 12-bit ADC with a fast, accurate

sample-and-hold and a precision reference.

The LTC1272 operates with a single 5V supply but can also

accept the 5V/–15V supplies required by the AD7572 (Pin

23, the negative supply pin of the AD7572, is not connected

on the LTC1272). The LTC1272 has the same 0V to 5V input

range as the AD7572 but, to achieve single supply operation, it provides a 2.42V reference output instead of the

–5.25V of the AD7572. It plugs in for the AD7572 if the

reference capacitor polarity is reversed and a 1µ s sampleand-hold acquisition time is allowed between conversions.

The output data can be read as a 12-bit word or as two

8-bit bytes. This allows easy interface to both 8-bit and

higher processors. The LTC1272 can be used with a

crystal or an external clock and comes in speed grades of

3µs and 8µs.

LTBiCMOS is a trademark of Linear Technology Corporation

A

PPLICATITYPICAL

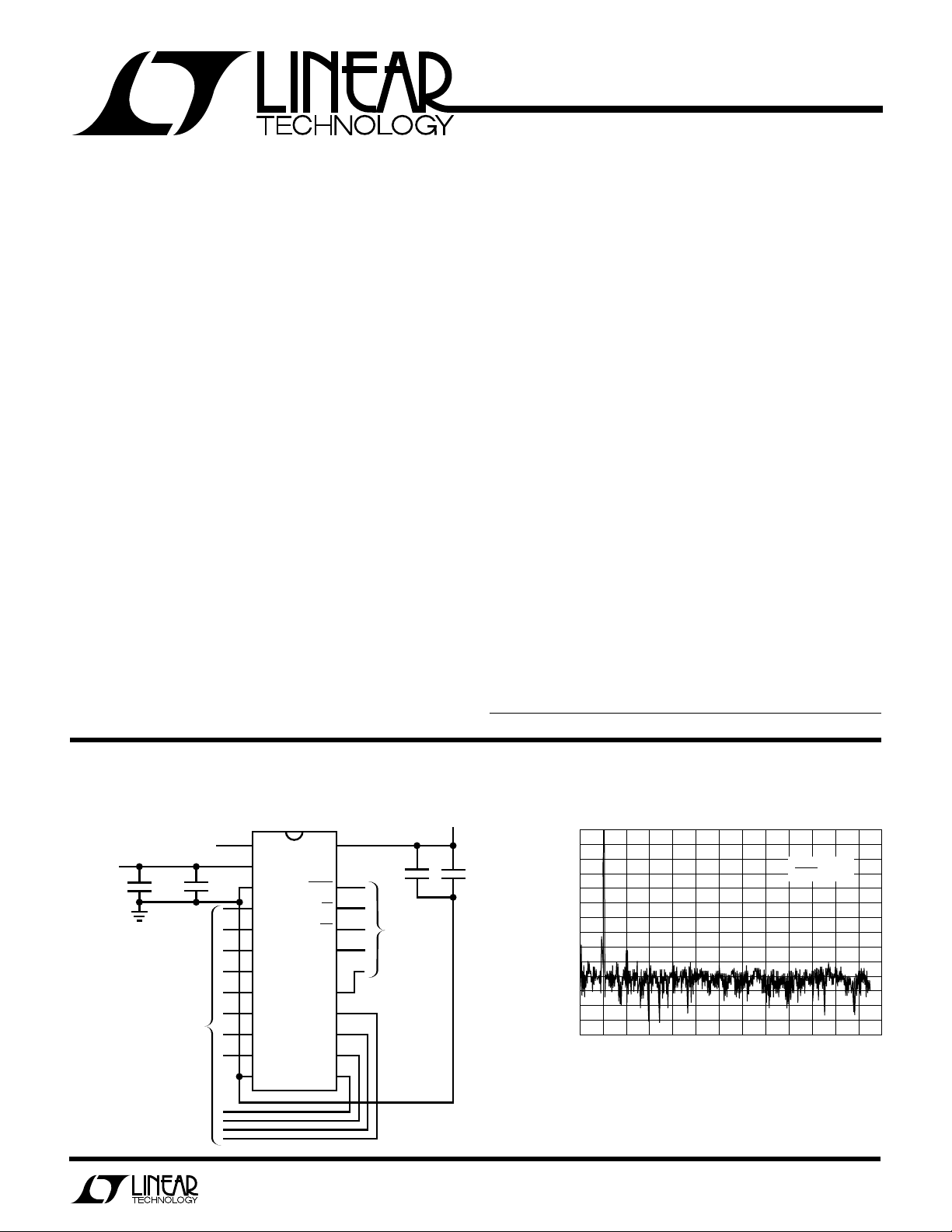

Single 5V Supply, 3µs, 12-Bit Sampling ADC

ANALOG INPUT

2.42V

V

REF

OUTPUT

(0V TO 5V)

+

0.1µF

8 OR 12-BIT

PARALLEL

BUS

10µF

LTC1272

A

IN

V

REF

AGND

D11 (MSB)

D10

D9

D8

D7

D6

D5

D4

DGND

O

V

NC

BUSY

RD

HBEN

CLK OUT

CLK IN

D0/8

D1/9

D2/10

D3/11

U

DD

CS

µ

10 F

P

µ

CONTROL

LINES

+

LTC1272 • TA01

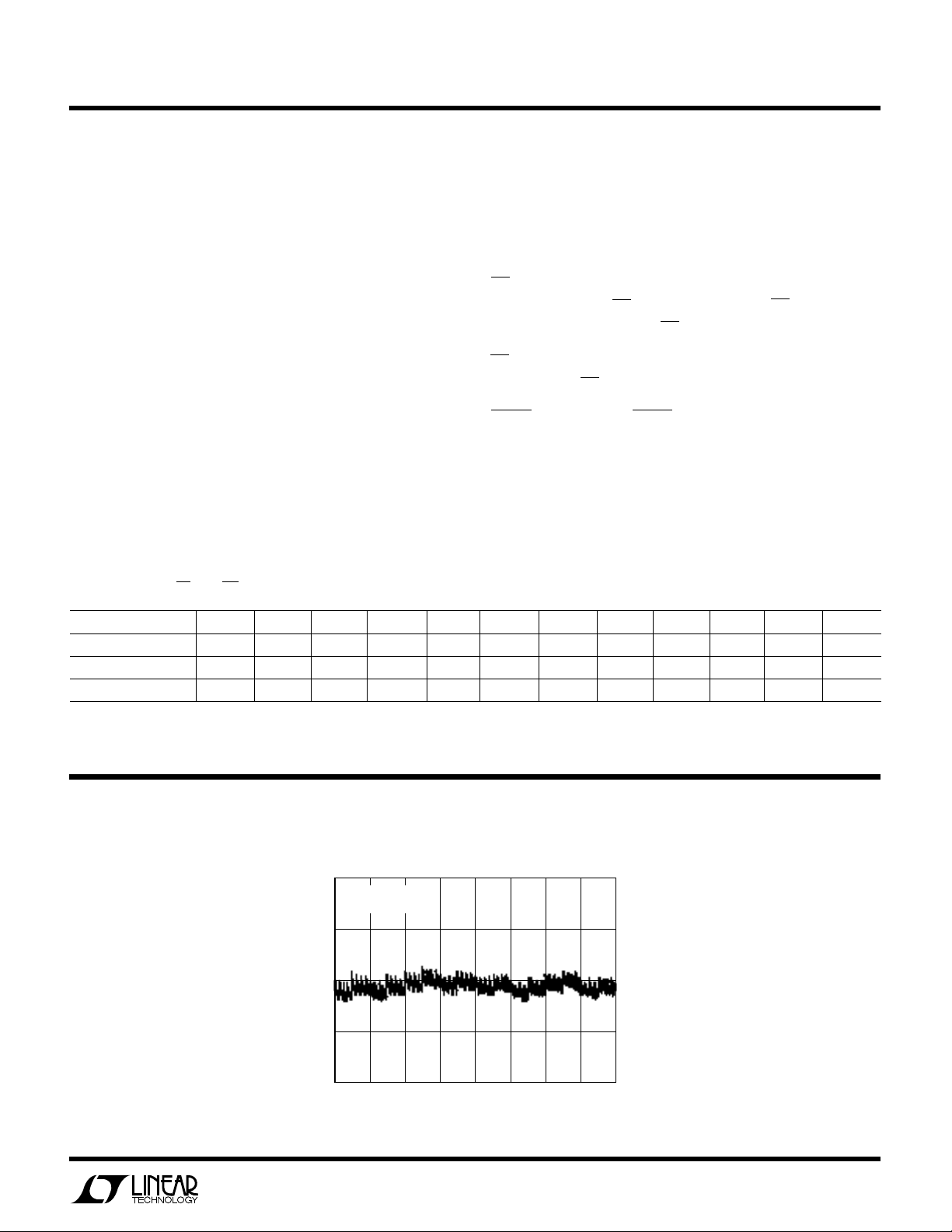

1024 Point FFT, fS = 250kHz, fIN = 10kHz

5V

µ

0.1 F

1

LTC1272

A

W

O

LUTEXI T

S

A

WUW

ARB

U

G

I

S

(Notes 1 and 2)

Supply Voltage (VDD)................................................. 6V

Analog Input Voltage (Note 3) ...................–0.3V to 15V

Digital Input Voltage ..................................–0.3V to 12V

Digital Output Voltage.................... –0.3V to VDD + 0.3V

Power Dissipation.............................................. 500mW

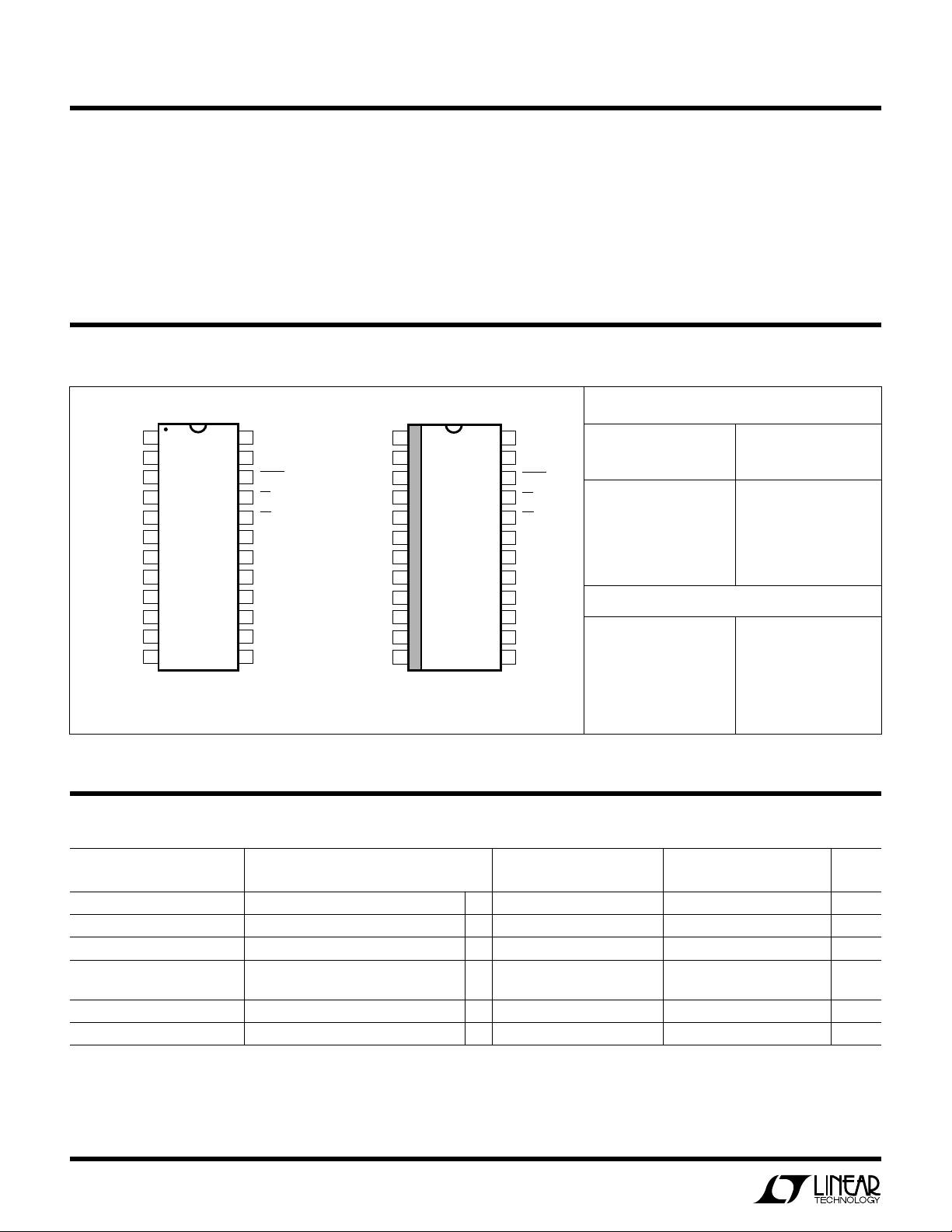

PACKAGE

1

A

IN

2

V

REF

AGND

3

(MSB) D11

4

D10

5

6

D9

7

D8

D7

D6

9

10

D5

11

D4

DGND

24-LEAD PLASTIC DIP

T

JMAX

= 110°C, θJA = 100°C/W

/

O

RDER I FOR ATIO

TOP VIEW

24

V

DD

23

NC

22

BUSY

21

N PACKAGE

20

19

18

178

16

15

14

1312

CS

RD

HBEN

CLK OUT

CLK IN

D0/8

D1/9

D2/10

D3/11

(MSB) D11

WU

1

A

IN

2

V

REF

AGND

3

4

D10

5

6

D9

7

D8

D7

D6

9

10

D5

11

D4

DGND

T

JMAX

U

TOP VIEW

S PACKAGE

24-LEAD PLASTIC SOL

= 110°C, θJA = 130°C/W

Operating Temperature Range

LTC1272-XAC, CC ................................. 0°C to 70°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ORDER PART NUMBER

24

V

23

22

21

20

19

18

178

16

15

14

1312

DD

NC

BUSY

CS

RD

HBEN

CLK OUT

CLK IN

D0/8

D1/9

D2/10

D3/11

CONVERSION CONVERSION

TIME = 3µs TIME = 8µs

LTC1272-3ACN LTC1272-8ACN

LTC1272-3CCN LTC1272-8CCN

S PACKAGE ONLY

LTC1272-3ACS LTC1272-8ACS

LTC1272-3CCS LTC1272-8CCS

Consult factory for Industrial and Military grade parts.

U

CO

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

Resolution (No Missing Codes) ● 12 12 Bits

Integral Linearity Error (Note 5) ● ±1/2 ±1 LSB

Differential Linearity Error ● ±1 ±1 LSB

Offset Error ±3 ±4 LSB

Gain Error ±10 ±15 LSB

Full-Scale Tempco I

VERTER

CCHARA TERIST

(Reference) = 0 ● ±5 ±25 ±10 ±45 ppm/°C

OUT

ICS

With Internal Reference (Note 4)

LTC1272-XA LTC1272-XC

● ±4 ±6 LSB

2

LTC1272

UUU

I TER AL REFERE CE CHARACTERISTICS

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

Output Voltage (Note 6) I

REF

V

Output Tempco I

REF

V

Line Regulation 4.75V ≤ VDD ≤ 5.25V, I

REF

V

Load Regulation (Sourcing Current) 0 ≤ I

REF

= 0 2.400 2.420 2.440 2.400 2.420 2.440 V

OUT

= 0 ● 5 25 10 45 ppm/°C

OUT

= 0 0.01 0.01 LSB/V

OUT

≤ 1mA 2 2 LSB/mA

OUT

(Note 4)

LTC1272-XA LTC1272-XC

U

DIGITAL AND DC ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IH

V

IL

I

IN

V

OH

V

OL

I

OZ

C

OZ

I

SOURCE

I

SINK

I

DD

P

D

High Level Input Voltage CS, RD, HBEN, CLK IN VDD = 5.25V ● 2.4 V

Low Level Input Voltage CS, RD, HBEN, CLK IN VDD = 4.75V ● 0.8 V

Input Current CS, RD, HBEN VIN = 0V to V

Input Current CLK IN VIN = 0V to V

High Level Output Voltage All Logic Outputs VDD = 4.75V I

I

Low Level Output Voltage All Logic Outputs VDD = 4.75V, I

High-Z Output Leakage D11-D0/8 V

High-Z Output Capacitance (Note 7) ● 15 pF

Output Source Current V

Output Sink Current V

Positive Supply Current CS = RD = VDD, AIN = 5V ● 15 30 mA

Power Dissipation 75 mW

OUT

OUT

OUT

DD

DD

= –10µA 4.7 V

OUT

= –200µA ● 4.0 V

OUT

= 1.6mA ● 0.4 V

OUT

= 0V to V

= 0V –10 mA

= V

DD

DD

(Note 4)

LTC1272-XA/C

● ±10 µA

● ±20 µA

● ±10 µA

10 mA

W

U

IC

DY

A

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

S/(N + D) Signal-to-Noise Plus Distortion Ratio 10kHz Input Signal 72 dB

THD Total Harmonic Distortion (Up to 5th Harmonic) 10kHz Input Signal –82 dB

U

A

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IINInput Current ● 3.5 mA

C

t

LOG

IN

IN

ACQ

ACCURACY

Peak Harmonic or Spurious Noise 10kHz Input Signal – 82 dB

U

PUT

IA

Input Voltage Range 4.75V ≤ VDD ≤ 5.25V ● 05V

Input Capacitance 50 pF

Sample-and-Hold Acquisition Time ● 0.45 1 µs

(Note 4)

(Note 4) f

= 250kHz (LTC1272-3), 111kHz (LTC1272-8)

SAMPLE

LTC1272-XA/C

LTC1272-XA/B/C

3

LTC1272

UW

CCHARA TERIST

GTI

I

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

t

12

t

13

t

CONV

CS to RD Setup Time ● 0ns

RD to BUSY Delay CL = 50pF 80 190 ns

Data Access Time After RD↓ CL = 20pF 50 90 ns

RD Pulse Width t

CS to RD Hold Time ● 0ns

Data Setup Time After BUSY 40 70 ns

Bus Relinquish Time 20 30 75 ns

HBEN to RD Setup Time ● 0ns

HBEN to RD Hold Time ● 0ns

Delay Between RD Operations ● 200 ns

Delay Between Conversions 1 µs

Aperture Delay of Sample and Hold Jitter <50ps 25 ns

CLK to BUSY Delay 80 170 ns

Conversion Time ● 12 13 CLK

ICS

(Note 8)

LTC1272-XA/C

COM Grade ● 230 ns

COM Grade ● 110 ns

CL = 100pF 70 125 ns

COM Grade ● 150 ns

COM Grade ● t

COM Grade ● 90 ns

COM Grade ● 20 85 ns

COM Grade ● 220 ns

3

3

ns

ns

CYCLES

The ● indicates specifications which apply over the full operating

temperature range; all other limits and typicals TA = 25°C.

Note 1: Absolute maximum ratings are those values beyond which the life

of a device may be impaired.

Note 2: All voltage values are with respect to ground with DGND and

AGND wired together, unless otherwise noted.

Note 3: When the analog input voltage is taken below ground it will be

clamped by an internal diode. This product can handle, with no external

diode, input currents of greater than 60mA below ground without latch-up.

VDD = 5V, f

Note 4:

LTC1272-8, t

performance, the LTC1272 clock should be synchronized to the RD and

CS control inputs with at least 40ns separating convert start from the

nearest clock edge.

r

= 4MHz for LTC1272-3, and 1.6MHz for

CLK

= tf = 5ns unless otherwise specified. For best analog

Note 5: Linearity error is specified between the actual end points of the

A/D transfer curve.

Note 6: The LTC1272 has the same 0V to 5V input range as the AD7572

but, to achieve single supply operation, it provides a 2.42V reference

output instead of the –5.25V of the AD7572. This requires that the polarity

of the reference bypass capacitor be reversed when plugging an LTC1272

into an AD7572 socket.

Note 7: Guaranteed by design, not subject to test.

Note 8: V

ensure compliance. All input control signals are specified with t

(10% to 90% of 5V) and timed from a voltage level of 1.6V. See Figures 13

through 17.

= 5V. Timing specifications are sample tested at 25°C to

DD

= tf = 5ns

r

4

LTC1272

U

PI

AIN (Pin 1): Analog Input, 0V to 5V Unipolar Input.

V

an AD7572 socket, reverse the reference bypass capacitor

polarity and short the 10Ω series resistor.

AGND (Pin 3): Analog Ground.

D11 to D4 (Pins 4-11): Three-State Data Outputs.

DGND (Pin 12): Digital Ground.

D3/11 to D0/8 (Pins 13-16): Three-State Data Outputs.

CLK IN (Pin 17): Clock Input. An external TTL/CMOS

compatible clock may be applied to this pin or a crystal can

be connected between CLK IN and CLK OUT.

CLK OUT (Pin 18): Clock Output. An inverted CLK IN signal

appears at this pin.

FUUC

(Pin 2): 2.42V Reference Output. When plugging into

REF

TI

O

U

S

HBEN (Pin 19): High Byte Enable Input. This pin is used to

multiplex the internal 12-bit conversion result into the

lower bit outputs (D7 to D0/8). See table below. HBEN also

disables conversion starts when HIGH.

RD (Pin 20): Read Input. This active low signal starts a

conversion when CS and HBEN are low. RD also enables

the output drivers when CS is low.

CS (Pin 21): The Chip Select Input must be low for the ADC

to recognize RD and HBEN inputs.

BUSY (Pin 22): The BUSY Output is low when a conversion is in progress.

NC (Pin 23): Not Connected Internally. The LTC1272 does

not require negative supply. This pin can accommodate

the –15V required by the AD7572 without problems.

VDD (Pin 24): Positive Supply, 5V.

Data Bus Output, CS and RD = LOW

Pin 4 Pin 5 Pin 6 Pin 7 Pin 8 Pin 9 Pin 10 Pin 11 Pin 13 Pin 14 Pin 15 Pin 16

MNEMONIC* D11 D10 D9 D8 D7 D6 D5 D4 D3/11 D2/10 D1/9 D0/8

HBEN = LOW DB11 DB10 DB9 DB8 DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

HBEN = HIGH DB11 DB10 DB9 DB8 LOW LOW LOW LOW DB11 DB10 DB9 DB8

*D11...D0/8 are the ADC data output pins.

DB11...DB0 are the 12-bit conversion results, DB11 is the MSB.

UW

LPER

F

O

R

ATYPICA

INL ERROR (LSBs)

CCHARA TERIST

E

C

Integral Nonlinearity

1.0

VDD = 5V

= 4MHz

f

CLK

0.5

0

–0.5

ICS

–1.0

0

512 1024 4096

0

1536 2048 2560 3072 3584

CODE

LTC1272 • TPC01

5

LTC1272

TEMPERATURE (°C)

–55

2

CLOCK FREQUENCY (MHz)

3

4

5

6

7

8

–25 25 50 125

LT1272 • TPC05

0 75 100

UW

LPER

F

O

R

ATYPICA

VDD Supply Current vs Minimum Clock Frequency vs Maximum Clock Frequency vs

Temperature Temperature Temperature

30

VDD = 5V

= 4MHz

f

CLK

25

(mA)

DD

20

CCHARA TERIST

E

C

Differential Nonlinearity

1.0

VDD = 5V

= 4MHz

f

CLK

0.5

0

INL ERROR (LSBs)

–0.5

–1.0

0

512 1024 4096

0

600

VDD = 5V

500

400

ICS

1536 2048 2560 3072 3584

CODE

LTC1272 • TPC02

15

10

SUPPLY CURRENT, I

DD

5

V

0

–55

0 75 100

–25 25 50 125

TEMPERATURE (°C)

V

REF

2.435

2.430

2.425

(V)

2.420

REF

V

2.415

2.410

2.405

–5

vs I

–4 –2 –1 2

LT1272 • TPC03

(mA) LTC1272 ENOBs* vs Frequency

LOAD

–3 0 1

IL (mA)

300

200

CLOCK FREQUENCY (kHz)

100

0

–25 25 50 125

–55

LT1272 • TPC06

0 75 100

TEMPERATURE (°C)

LT1272 • TPC04

*EFFECTIVE NUMBER OF BITS, ENOBs =

12

11

10

ENOBs*

9

8

7

6

5

4

3

2

fS = 250kHz

1

= 5V

V

DD

0

0

40 100

20 60 80 120

fIN (kHz)

LT1272 • TPC07

S/(N + D) – 1.76dB

6.02

6

LTC1272

V

DAC

LTC1272 • TA07

+

–

C

DAC

DAC

300Ω

SAMPLE

HOLD

C

SAMPLE

2.7k

A

IN

S

A

R

12-BIT

LATCH

COMPARATOR

SAMPLE

SI

FREQUENCY (kHz)

0

–110

AMPLITUDE (dB)

–90

–70

–50

–30

–10

0

20 40 80 120

LTC1272 • TA23

–20

–40

–60

–80

–100

60 100

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

Conversion Details

Conversion start is controlled by the CS, RD and HBEN

inputs. At the start of conversion the successive approximation register (SAR) is reset and the three-state data

outputs are enabled. Once a conversion cycle has begun

it cannot be restarted.

During conversion, the internal 12-bit capacitive DAC

output is sequenced by the SAR from the most significant

bit (MSB) to the least significant bit (LSB). Referring to

Figure 1, the AIN input connects to the sample-and-hold

capacitor through a 300Ω/2.7kΩ divider. The voltage

divider allows the LTC1272 to convert 0V to 5V input

signals while operating from a 4.5V supply. The conversion has two phases: the sample phase and the convert

phase. During the sample phase, the comparator offset is

nulled by the feedback switch and the analog input is

stored as a charge on the sample-and-hold capacitor,

C

SAMPLE

. This phase lasts from the end of the previous

conversion until the next conversion is started. A minimum delay between conversions (t10) of 1µs allows

enough time for the analog input to be acquired. During the

convert phase, the comparator feedback switch opens,

putting the comparator into the compare mode. The

sample-and-hold capacitor is switched to ground injecting the analog input charge onto the comparator summing

junction. This input charge is successively compared to

binary weighted charges supplied by the capacitive DAC.

Bit decisions are made by the comparator (zero crossing

detector) which checks the addition of each successive

weighted bit from the DAC output. The MSB decision is

made 50ns (typically) after the second falling edge of CLK

IN following a conversion start. Similarly, the succeeding

bit decisions are made approximately 50ns after a CLK IN

edge until the conversion is finished. At the end of a

conversion, the DAC output balances the AIN output charge.

The SAR contents (12-bit data word) which represent the

AIN input signal are loaded into a 12-bit latch.

Sample-and-Hold and Dynamic Performance

Traditionally A/D converters have been characterized by

such specs as offset and full-scale errors, integral

Figure 1. AIN Input

nonlinearity and differential nonlinearity. These specs are

useful for characterizing an ADC’s DC or low frequency

signal performance.

These specs alone are not adequate to fully specify the

LTC1272 because of its high speed sampling ability. FFT

(Fast Fourrier Transform) test techniques are used to

characterize the LTC1272’s frequency response, distortion and noise at the rated throughput.

By applying a low distortion sine wave and analyzing the

digital output using a FFT algorithm, the LTC1272’s spectral content can be examined for frequencies outside the

fundamental. Figure 2 shows a typical LTC1272 FFT plot.

Figure 2. LTC1272 Non-Averaged, 1024 Point FFT Plot.

fS = 250kHz, fIN = 10kHz

7

LTC1272

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

Signal-to-Noise Ratio

The Signal-to-Noise Ratio (SNR) is the ratio between the

RMS amplitude of the fundamental input frequency to the

RMS amplitude of all other frequency components at the

A/D output. This includes distortion as well as noise

products and for this reason it is sometimes referred to as

Signal-to-Noise + Distortion [S/(N + D)]. The output is

band limited to frequencies from DC to one half the

sampling frequency. Figure 2 shows spectral content from

DC to 125kHz which is 1/2 the 250kHz sampling rate.

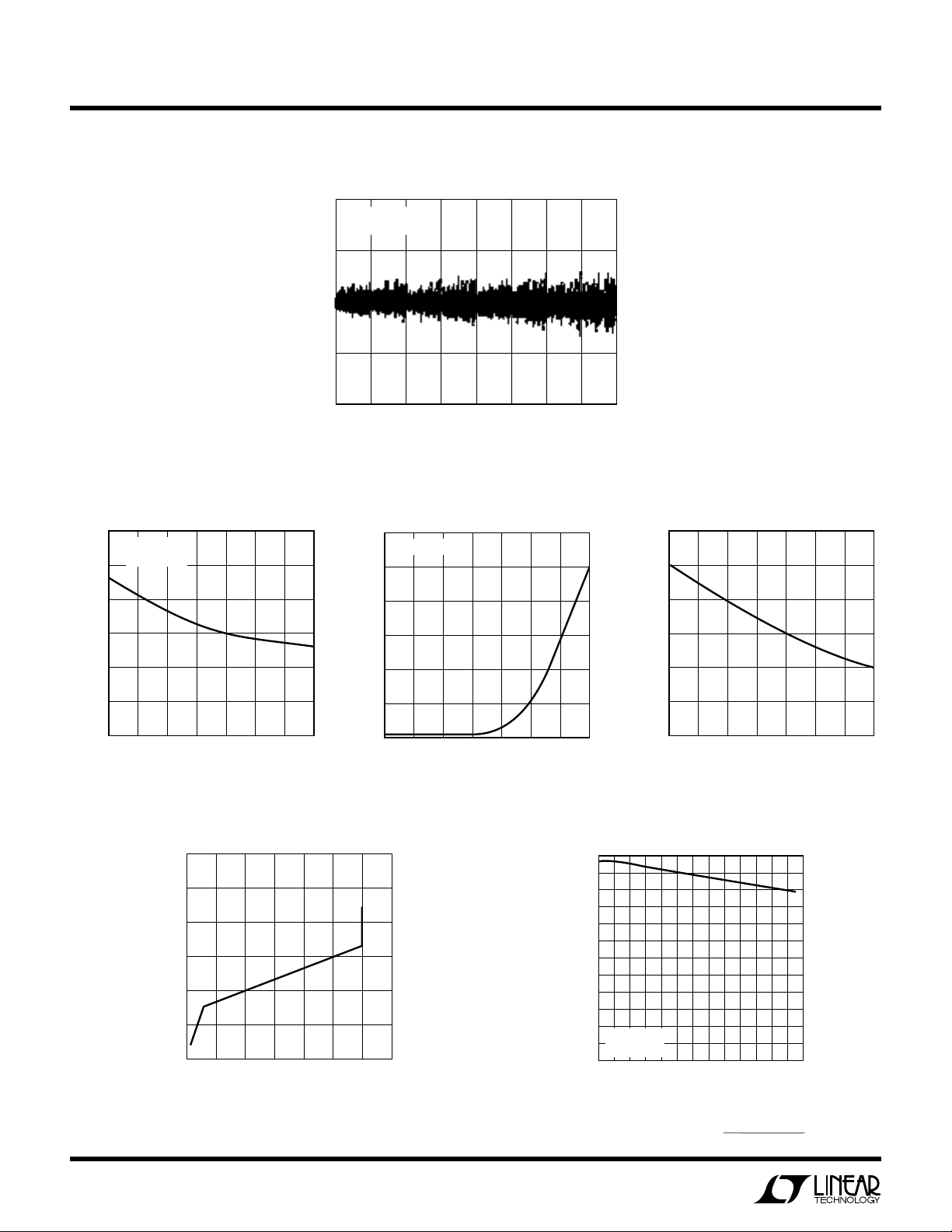

Effective Number of Bits

The effective number of bits (ENOBs) is a measurement of

the resolution of an A/D and is directly related to the

S/(N + D) by the equation:

N = [S/(N + D) –1.76]/6.02,

where N is the effective number of bits of resolution and

S/(N + D) is expressed in dB. At the maximum sampling

rate of 250kHz the LTC1272 maintains 11.5 ENOBs or

better to 20kHz. Above 20kHz the ENOBs gradually decline, as shown in Figure 3, due to increasing second

harmonic distortion. The noise floor remains approximately 90dB. The dynamic differential nonlinearity remains good out to 120kHz as shown in Figure 4.

1.0

0.5

0

ERROR (LSB)

–0.5

–1.0

0

0

Figure 4. LTC1272 Dynamic DNL. f

fS = 250kHz, fIN = 122.25342kHz, VCC = 5V

14

23

CODE (THOUSANDS)

LTC1272 • TA24

= 4MHz,

CLK

Total Harmonic Distortion

Total Harmonic Distortion (THD) is the ratio of the RMS

sum of all harmonics of the input signal to the fundamental

itself. The harmonics are limited to the frequency band

between DC and one half the sampling frequency. THD is

expressed as: 20 LOG [√V

2

+ V

2

+ ... + V

3

2

/V1] where

N

2

V1 is the RMS amplitude of the fundamental frequency and

V2 through VN are the amplitudes of the second through

Nth harmonics.

Clock and Control Synchronization

12

11

10

9

8

7

6

ENOBs*

5

4

3

2

fS = 250kHz

1

= 5V

V

DD

0

0

Figure 3. LTC1272 Effective Number of Bits (ENOBs) vs Input

Frequency. fS = 250kHz

40 100

20 60 80 120

fIN (kHz)

LT1272 • TPC07

8

For best analog performance, the LTC1272 clock should

be synchronized to the CS and RD control inputs as shown

in Figure 5, with at least 40ns separating convert start from

the nearest CLK IN edge. This ensures that transitions at

CLK IN and CLK OUT do not couple to the analog input and

get sampled by the sample-and-hold. The magnitude of

this feedthrough is only a few millivolts, but if CLK and

convert start (CS and RD) are asynchronous, frequency

components caused by mixing the clock and convert

signals may increase the apparent input noise.

When the clock and convert signals are synchronized,

small endpoint errors (offset and full-scale) are the most

that can be generated by clock feedthrough. Even these

errors (which can be trimmed out) can be eliminated by

ensuring that the start of a conversion (CS and RD’s falling

edge) does not occur within 40ns of a clock edge, as in

LTC1272

PPLICATI

A

U

O

S

I FOR ATIO

CS & RD

BUSY

CLK IN

UNCERTAIN CONVERSION TIME FOR 30ns < t

*

THE LTC1272 IS ALSO COMPATIBLE WITH THE AD7572 SYNCHRONIZATION MODES.

WU

t

2

≥ 40ns*

t

14

Figure 5. RD and CLK IN for Synchronous Operation

U

(MSB)

Figure 5. Nevertheless, even without observing this guideline, the LTC1272 is still compatible with AD7572 synchronization modes, with no increase in linearity error. This

means that either the falling or rising edge of CLK IN may

be near RD’s falling edge.

Driving the Analog Input

The analog input of the LTC1272 is much easier to drive

than that of the AD7572. The input current is not modulated by the DAC as in the AD7572. It has only one small

current spike from charging the sample-and-hold capacitor at the end of the conversion. During the conversion the

analog input draws only DC current. The only requirement

is that the amplifier driving the analog input must settle

after the small current spike before the next conversion is

started. Any op amp that settles in 1µs to small current

transients will allow maximum speed operation. If slower

op amps are used, more settling time can be provided by

increasing the time between conversions. Suitable devices capable of driving the LTC1272 AIN input include the

LT1006 and LT1007 op amps.

Internal Clock Oscillator

t

CONV

t

13

DB1DB10DB11

< 180ns

14

C1

C2

NOTES:

LTC1272-3 – 4MHz CRYSTAL/CERAMIC RESONATOR

LTC1272-8 – 1.6MHz CRYSTAL/CERAMIC RESONATOR

CLK OUT

CLK IN

Figure 6. LTC1272 Internal Clock Circuit

DB0

(LSB)

LTC1272 • TA06

18

17

LTC1272

CLOCK

1M

LTC1272 • TA09

connected to CLK IN. For an external clock the duty cycle

is not critical. An inverted CLK IN signal will appear at the

CLK OUT pin as shown in the operating waveforms of

Figure 7. Capacitance on the CLK OUT pin should be

minimized for best analog performance.

Internal Reference

The LTC1272 has an on-chip, temperature compensated,

curvature corrected, bandgap reference, which is factory

trimmed to 2.42V ±1%. It is internally connected to the

DAC and is also available at pin 2 to provide up to 1mA

current to an external load.

Figure 6 shows the LTC1272 internal clock circuit. A

crystal or ceramic resonator may be connected between

CLK IN (Pin 17) and CLK OUT (Pin 18) to provide a clock

oscillator for ADC timing. Alternatively the crystal/resonator may be omitted and an external clock source may be

For minimum code transition noise the reference output

should be decoupled with a capacitor to filter wideband

noise from the reference (10µF tantalum in parallel with a

0.1µF ceramic). A simplified schematic of the reference

with its recommended decoupling is shown in Figure 8.

9

LTC1272

PPLICATI

A

CURVATURE

CORRECTED

REFERENCE

Figure 8. LTC1272 Internal 2.42V Reference

5V

BANDGAP

U

O

S

I FOR ATIO

CS & RD

BUSY

CLK IN

CLK OUT

Figure 7. Operating Waveforms Using an External Clock Source for CLK IN

+

–

AGND

WU

LTC1272

23

0.1µF

10µF

+

V

REF

LTC1272 • TA10

U

(MSB)

TO DAC

50ns TYP

DB1DB10DB11

11...111

11...110

11...101

OUTPUT CODE

00...011

00...010

00...001

00...000

DB0

(LSB)

LTC1272 • TA08

FULL-SCALE

TRANSITION

FS = 5V

FS

1LSB =

––––

4096

0

1FS

23

LSB

LSBs

LSBs

AIN, INPUT VOLTAGE (IN TERMS OF LSBs)

FS – 1LSB

LT1272 • TA11

Figure 9. LTC1272 Ideal Input/Output Transfer Characteristic

Unipolar Operation

Figure 9 shows the ideal input/output characteristic for the

0V to 5V input range of the LTC1272. The code transitions

occur midway between successive integer LSB values

(i.e., 1/2LSB, 3/2LSBs, 5/2LSBs . . . FS – 3/2LSBs). The

output code is natural binary with 1 LSB = FS/4096 =

(5/4096)V = 1.22mV.

Unipolar Offset and Full-Scale Error Adjustment

In applications where absolute accuracy is important, then

offset and full-scale error can be adjusted to zero. Offset

10

error must be adjusted before full-scale error. Figure 10

shows the extra components required for full-scale error

adjustment. Zero offset is achieved by adjusting the offset

of the op amp driving AIN (i.e., A1 in Figure 10). For zero

offset error apply 0.61mV (i.e., 1/2LBS) at VIN and adjust

the op amp offset voltage until the ADC output code

flickers between 0000 0000 0000 and 0000 0000 0001.

For zero full-scale error apply an analog input of 4.99817V

(i.e., FS – 3/2LSBs or last code transition) at VIN and adjust

R1 until the ADC output code flickers between 1111 1111

1110 and 1111 1111 1111.

LTC1272

U

O

PPLICATI

A

0V TO 5V

ANALOG

Figure 10. Unipolar 0V to 5V Operation with Gain Error Adjust

V

IN

INPUT

+

A1

LT1007

–

*ADDITIONAL PINS OMITTED FOR CLARITY

S

I FOR ATIO

R3

15Ω

R1

200Ω

R2

20k

WU

1

3

A

IN

LTC1272

AGND

LTC1272 • TA12

U

Application Hints

Wire wrap boards are not recommended for high resolution or high speed A/D converters. To obtain the best

performance from the LTC1272 a printed circuit board is

required. Layout for the printed circuit board should

ensure that digital and analog signal lines are separated as

much as possible. In particular, care should be taken not

to run any digital track alongside an analog signal track or

underneath the LTC1272. The analog input should be

screened by AGND.

A single point analog ground separate from the logic

system ground should be established with an analog

ground plane at pin 3 (AGND) or as close as possible to the

LTC1272, as shown in Figure 11. Pin 12 (LTC1272 DGND)

and all other analog grounds should be connected to this

single analog ground point. No other digital grounds

should be connected to this analog ground point. Low

impedance analog and digital power supply common

returns are essential to low noise operation of the ADC and

the foil width for these tracks should be as wide as

possible.

Noise: Input signal leads to AIN and signal return leads

from AGND (pin 3) should be kept as short as possible to

minimize input noise coupling. In applications where this

is not possible, a shielded cable between source and ADC

is recommended. Also, since any potential difference in

grounds between the signal source and ADC appears as an

error voltage in series with the input signal, attention

should be paid to reducing the ground circuit impedances

as much as possible.

In applications where the LTC1272 data outputs and

control signals are connected to a continuously active

microprocessor bus, it is possible to get LSB errors in

conversion results. These errors are due to feedthrough

from the microprocessor to the successive approximation

comparator. The problem can be eliminated by forcing the

microprocessor into a Wait state during conversion (see

Slow Memory Mode interfacing), or by using three-state

buffers to isolate the LTC1272 data bus.

Timing and Control

Conversion start and data read operations are controlled

by three LTC1272 digital inputs; HBEN, CS and RD. Figure

12 shows the logic structure associated with these inputs.

The three signals are internally gated so that a logic “0” is

required on all three inputs to initiate a conversion. Once

initiated it cannot be restarted until conversion is complete. Converter status is indicated by the BUSY output,

and this is low while conversion is in progress.

ANALOG

INPUT

CIRCUITRY

1

A

IN

+

–

AGND

3 2 24 12

Figure 11. Power Supply Grounding Practice

LTC1272

V

REF

C2

C1

ANALOG GROUND PLANE

V

DD

C3 C4

DGND

DIGITAL

SYSTEM

GROUND CONNECTION

TO DIGITAL CIRCUITRY

LTC1272 • TA13

11

LTC1272

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

There are two modes of operation as outlined by the timing

diagrams of Figures 13 to 17. Slow Memory Mode is

designed for microprocessors which can be driven into a

Wait state, a Read operation brings CS and RD low which

initiates a conversion and data is read when conversion is

complete.

LTC1272

19

HBEN

21

CS

20

RD

D11....D0/8 ARE THE ADC DATA OUTPUT PINS

DB11....DB0 ARE THE 12-BIT CONVERSION RESULTS

5V

ACTIVE HIGH

ACTIVE HIGH

The second is the ROM Mode which does not require

microprocessor Wait states. A Read operation brings CS

and RD low which initiates a conversion and reads the

previous conversion result.

QD

CONVERSION START

(RISING EDGE TRIGGER)

FLIP

FLOP

CLEAR

BUSY

ENABLE THREE-STATE OUTPUTS

D11....D0/8 = DB11....DB0

ENABLE THREE-STATE OUTPUTS

D11....D8 = DB11....DB8

D7....D4 = LOW

D3/11....D0/8 = DB11....DB8

LTC1272 • TA14

Figure 12. Internal Logic for Control Inputs CS, RD and HBEN

CS & RD

t

2

BUSY

≥ 40ns*

CLK IN

t

14

(MSB)

UNCERTAIN CONVERSION TIME FOR 30ns < t

*

THE LTC1272 IS ALSO COMPATIBLE WITH THE AD7572 SYNCHRONIZATION MODES.

SEE “DIGITAL INTERFACE” TEXT.

< 180ns

14

t

CONV

t

13

DB1DB10DB11

DB0

(LSB)

LTC1272 • TA15

Figure 13. RD and CLK IN for Synchronous Operation

Table 1. Data Bus Output, CS and RD = Low

PIN 4 PIN 5 PIN 6 PIN 7 PIN 8 PIN 9 PIN 10 PIN 11 PIN 13 PIN 14 PIN 15 PIN 16

Data Outputs* D11 D10 D9 D8 D7 D6 D5 D4 D3/11 D2/10 D1/9 D0/8

HBEN = Low DB11 DB10 DB9 DB8 DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

HBEN = High DB11 DB10 DB9 DB8 Low Low Low Low DB11 DB10 DB9 DB8

Note: *D11 . . . D0/8 are the ADC data output pins

DB11 . . . DB0 are the 12-bit conversion results, DB11 is the MSB

12

LTC1272

U

O

PPLICATI

A

Table 2. Slow Memory Mode, Parallel Read Data Bus Status

Data Outputs D11 D10 D9 D8 D7 D6 D5 D4 D3/11 D2/10 D1/9 D0/8

Read DB11 DB10 DB9 DB8 DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

S

I FOR ATIO

RDCSRD

BUSY

DATA

HOLD

TRACK

Figure 14. Slow Memory Mode, Parallel Read Timing Diagram

WU

t

1

t

2

t

3

t

12

t

OLD DATA

DB11-DB0

CONV

U

t

6

NEW DATA

DB11-DB0

t

5

t

10

t

11

t

7

t

1

LTC1272 • TA16

Data Format

The output data format can be either a complete parallel

load for 16-bit microprocessors or a two byte load for

8-bit microprocessors. Data is always right justified (i.e.,

LSB is the most right-hand bit in a 16-bit word). For a two

byte read, only data outputs D7. . . D0/8 are used. Byte

selection is governed by the HBEN input which controls an

internal digital multiplexer. This multiplexes the 12 bits of

conversion data onto the lower D7. . . D0/8 outputs

(4MSBs or 8LSBs) where it can be read in two read cycles.

The 4MSBs always appear on D11 . . . D8 whenever the

three-state output drives are turned on.

Slow Memory Mode, Parallel Read (HBEN = Low)

Figure 14 and Table 2 show the timing diagram and data

bus status for Slow Memory Mode, Parallel Read. CS and

RD going low triggers a conversion and the LTC1272

acknowledges by taking BUSY low. Data from the previous

conversion appears on the three-state data outputs. BUSY

returns high at the end of conversion when the output

latches have been updated and the conversion result is

placed on data outputs D11 . . . D0/8.

Slow Memory Mode, Two Byte Read

For a two byte read, only 8 data outputs D7 . . . D0/8 are

used. Conversion start procedure and data output status

for the first read operation is identical to Slow Memory

Mode, Parallel Read. See Figure 15 timing diagram and

Table 3 data bus status. At the end of conversion the low

data byte (DB7 . . . DB0) is read from the ADC. A second

Read operation with HBEN high, places the high byte on

data outputs D3/11 . . . D0/8 and disables conversion start.

Note the 4MSBs appear on data outputs D11 . . . D8 during

the two Read operations above.

ROM Mode, Parallel Read (HBEN = Low)

The ROM Mode avoids placing a microprocessor into a

Wait state. A conversion is started with a Read operation

and the 12 bits of data from the previous conversion is

available on data outputs D11 . . . D0/8 (see Figure 16 and

Table 4). This data may be disregarded if not required. A

second Read operation reads the new data (DB11 . . . DB0)

and starts another conversion. A delay at least as long as

the LTC1272 conversion time plus the 1µs minimum delay

between conversions must be allowed between Read

operations.

13

LTC1272

PPLICATI

A

HBEN

CS

RD

RD

BUSY

DATA

HOLD

TRACK

U

O

S

I FOR ATIO

t

8

t

1

t

2

t

3

t

12

Figure 15. Slow Memory Mode, Two Byte Read Timing Diagram

WU

t

CONV

OLD DATA

DB7-DB0

U

t

6

NEW DATA

DB7-DB0

t

9

t

5

t

t

7

t

8

t

10

t

11

t

1

t

3

4

NEW DATA

DB11-DB8

t

9

t

5

t

10

t

7

t

12

LTC1272 • TA17

Table 3. Slow Memory Mode, Two Byte Read Data Bus Status

Data Outputs D7 D6 D5 D4 D3/11 D2/10 D1/9 D0/8

First Read DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

Second Read Low Low Low Low DB11 DB10 DB9 DB8

CS

t

RD

BUSY

DATA

HOLD

TRACK

t

1

t

2

t

3

OLD DATA

DB11-DB0

t

4

5

t

t

CONV

t

7

t

12

11

t

t

1

t

2

t

3

NEW DATA

DB11-DB0

t

4

5

t

CONV

t

7

t

12

LTC1272 • TA18

Figure 16. ROM Mode, Parallel Read Timing Diagram

Table 4. ROM Mode, Parallel Read Data Bus Status

Data Outputs D11 D10 D9 D8 D7 D6 D5 D4 D3/11 D2/10 D1/9 D0/8

First Read (Old Data) DB11 DB10 DB9 DB8 DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

Second Read DB11 DB10 DB9 DB8 DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

14

LTC1272

PPLICATI

A

HBEN

RD

RD

BUSY

DATA

HOLD

TRACK

U

O

S

I FOR ATIO

t

8

CS

t

t

1

t

2

t

3

OLD DATA

WU

t

9

t

4

DB7-DB0

t

12

5

t

CONV

t

7

U

t

8

t

1

t

3

t

4

NEW DATA

DB11-DB8

t

9

t

5

t

11

t

7

t

8

t

t

10

t

1

t

2

t

3

4

NEW DATA

DB7-DB0

t

12

t

9

t

5

t

7

LTC1272 • TA19

Figure 17. ROM Mode, Two Byte Read Timing Diagram

Table 5. ROM Mode, Two Byte Read Data Bus Status

Data Outputs D7 D6 D5 D4 D3/11 D2/10 D1/9 D0/8

First Read DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

Second Read Low Low Low Low DB11 DB10 DB9 DB8

Third Read DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

ROM Mode, Two Byte READ

As previously mentioned for a two byte read, only data

outputs D7 . . . D0/8 are used. Conversion is started in the

normal way with a Read operation and the data output

status is the same as the ROM Mode, Parallel Read. See

Figure 17 timing diagram and Table 5 data bus status. Two

more Read operations are required to access the new

Microprocessor Interfacing

The LTC1272 is designed to interface with microprocessors as a memory mapped device. The CS and RD control

inputs are common to all peripheral memory interfacing.

The HBEN input serves as a data byte select for 8-bit

processors and is normally connected to the micropro-

cessor address bus.

conversion result. A delay equal to the LTC1272 conversion time must be allowed between conversion start and

the second data Read operation. The second Read operation, with HBEN high, disables conversion start and places

the high byte (4 MSBs) on data outputs D3/11 . . . DO18.

A third read operation accesses the low data byte (DB7

. . . DB0) and starts another conversion. The 4 MSB’s

MC68000 Microprocessor

Figure 18 shows a typical interface for the MC68000. The

LTC1272 is operating in the Slow Memory Mode. Assum-

ing the LTC1272 is located at address C000, then the

following single 16-bit Move instruction both starts a

conversion and reads the conversion result:

appear on data outputs D11 . . . D8 during all three read

operations above.

Move.W $C000,D0

15

LTC1272

DATA BUS

LTC1272 • TA22

PORT ADDRESS BUS

D0

D11

DEN

PA0

PA2

TMS32010

ADDRESS

DECODE

EN

D0/8

D11

RD

CS

HBEN

LTC1272

LINEAR CIRCUITRY OMITTED FOR CLARITY

O

PPLICATI

A

A23

A1

AS

MC68000

DTACK

R/W

D11

D0

ADDITIONAL PINS OMITTED FOR CLARITY

U

S

I FOR ATIO

ADDRESS BUS

ADDRESS

EN

DECODE

DATA BUS

WU

CS

BUSY

RD

D11

D0/8

U

LTC1272

HBEN

LTC1272 • TA20

Figure 18. LTC1272 MC68000 Interface

At the beginning of the instruction cycle when the ADC

address is selected, BUSY and CS assert DTACK, so that

the MC68000 is forced into a Wait state. At the end of

conversion BUSY returns high and the conversion result

is placed in the D0 register of the microprocessor.

is accomplished with the single 16-bit Load instruction

below.

For the 8085A LHLD (B000)

For the Z80 LDHL, (B000)

This is a two byte read instruction which loads the ADC

data (address B000) into the HL register pair. During the

first read operation, BUSY forces the microprocessor to

Wait for the LTC1272 conversion. No Wait states are

inserted during the second read operation when the mi-

croprocessor is reading the high data byte.

TMS32010 Microcomputer

Figure 20 shows an LTC1272 TMS32010 interface. The

LTC1272 is operating in the ROM Mode. The interface is

designed for a maximum TMS32010 clock frequency of

18MHz but will typically work over the full TMS32010

clock frequency range.

8085A, Z80 Microprocessor

Figure 19 shows a LTC1272 interface for the Z80 and

8085A. The LTC1272 is operating in the Slow Memory

Mode and a two byte read is required. Not shown in the

figure is the 8-bit latch required to demultiplex the 8085A

common address/data bus. A0 is used to assert HBEN, so

that an even address (HBEN = LOW) to the LTC1272 will

start a conversion and read the low data byte. An odd

address (HBEN = HIGH) will read the high data byte. This

A15

A0

MREQ

Z80

8085A

WAIT

RD

LINEAR CIRCUITRY OMITTED FOR CLARITY

D7

D0

Figure 19. LTC1272 8085A/Z80 Interface

ADDRESS BUS

ADDRESS

EN

DECODE

DATA BUS

CS

BUSY

RD

D7

D0/8

A0

HBEN

LTC1272

LTC1272 • TA21

The LTC1272 is mapped at a port address. The following

I/O instruction starts a conversion and reads the previous

conversion result into data memory.

IN A,PA (PA = PORT ADDRESS)

When conversion is complete, a second I/O instruction

reads the up-to-date data into memory and starts another

conversion. A delay at least as long as the ADC conversion

time must be allowed between I/O instructions.

Figure 20. LTC1272 TMS32010 Interface

16

LTC1272

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

Compatibility with the AD7572

Figure 21 shows the simple, single 5V configuration

recommended for new designs with the LTC1272. If an

AD7572 replacement or upgrade is desired, the LTC1272

can be plugged into an AD7572 socket with minor modifications. It can be used as a replacement or to upgrade

with sample-and-hold, single supply operation and reduced power consumption.

The LTC1272, while consuming less power overall than

the AD7572, draws more current from the 5V supply (it

draws no power from the –15V supply). Also, a 1µs

LTC1272

2.42V

V

REF

OUTPUT

ANALOG INPUT

(0V TO 5V)

+

0.1µF

8 OR 12-BIT

PARALLEL

BUS

10µF

A

IN

V

REF

AGND

D11 (MSB)

D10

D9

D8

D7

D6

D5

D4

*

DGND

V

NC

BUSY

RD

HBEN

CLK OUT

CLK IN

D0/8

D1/9

D2/10

D3/11

DD

CS

minimum time between conversions must be provided to

allow the sample-and-hold to reacquire the analog input.

Figure 22 shows that if the clock is synchronous with CS

and RD, it is only necessary to short out the 10Ω series

resistor and reverse the polarity of the 10µF bypass

capacitor on the V

pin. The –15V supply is not required

REF

and can be removed, or, because there is no internal

connection to pin 23, it can remain unmodified. The clock

can be considered synchronous with CS and RD in cases

where the LTC1272 CLK IN signal is derived from the same

clock as the microprocessor reading the LTC1272.

5V

+

µ

10 F

µP

CONTROL

LINES

µ

0.1 F*

FOR GROUNDING AND BYPASSING HINTS

*

SEE FIGURE 11 AND APPLICATION HINTS

SECTION

Figure 21. Single 5V Supply, 3µs, 12-Bit Sampling ADC

LTC1272 • TA03

17

LTC1272

PPLICATI

A

2.42V

V

REF

OUTPUT

*

U

O

S

ANALOG INPUT

(0V TO 5V)

+

10µF

WU

I FOR ATIO

LTC1272

A

IN

V

REF

AGND

D11 (MSB)

D10

D9

D8

D7

D6

D5

D4

DGND

0.1µF

µ

DATA

BUS

Ω

10

*

P

V

NC

BUSY

RD

HBEN

CLK OUT

CLK IN**

D0/8

D1/9

D2/10

D3/11

DD

✝

CS

U

P

µ

CONTROL

LINES

**

5V

+

µ

–15V

µ

+

10 F

†

µ

µ

0.1 F

THE LTC1272 HAS THE SAME 0V TO 5V INPUT RANGE BUT PROVIDES A 2.42V

*

REFERENCE OUTPUT AS OPPOSED TO THE –5.25V OF THE AD7572. FOR PROPER

OPERATION, REVERSE THE REFERENCE CAPACITOR POLARITY AND SHORT OUT THE

10 RESISTOR.Ω

THE ADC CLOCK SHOULD BE SYNCHRONIZED TO THE CONVERSION START

SIGNALS (CS, RD) OR 1-2 LSBs OF OUTPUT CODE NOISE MAY OCCUR. DERIVING

THE ADC CLOCK FROM THE P CLOCK IS ADEQUATE.

✝

THE LTC1272 CAN ACCOMMODATE THE –15V SUPPLY OF THE AD7572 BUT DOES

NOT REQUIRE IT. PIN 23 OF THE LTC1272 IS NOT INTERNALLY CONNECTED.

0.1 F

10 F

µ

LTC1272 • TA04

Figure 22. Plugging the LTC1272 into an AD7572 Socket

Case 1: Clock Synchronous with CS and RD

If the clock signal for the AD7572 is derived from a

separate crystal or other signal which is not synchronous

with the microprocessor clock, then the signals need to be

synchronized for the LTC1272 to achieve best analog

performance (see Clock and Control Synchronization).

The best way to synchronize these signals is to drive the

CLK IN pin of the LTC1272 with a derivative of the

processor clock, as mentioned above and shown in Figure

22. Another way, shown in Figure 23, is to use a flip-flop

to synchronize the RD to the LTC1272 with the CLK IN

signal. This method will work but has two disavantages

over the first: because the RD is delayed by the flip-flop,

the actual conversion start and the enabling of the

LTC1272’s BUSY and data outputs can take up to one CLK

IN cycle to respond to a RD↓ convert command from the

processor. The sampling of the analog input no longer

occurs at the processor’s falling RD edge but may be

delayed as much as one CLK IN cycle. Although the

LTC1272 will still exhibit excellent DC performance, the

flip-flop will introduce jitter into the sampling which may

reduce the usefulness of this method for AC systems.

18

LTC1272

PPLICATI

A

2.42V

V

REF

OUTPUT

*

U

O

S

I FOR ATIO

ANALOG INPUT

(0V TO 5V)

+

10µF

0.1µF

P

µ

DATA

BUS

THE LTC1272 HAS THE SAME 0V TO 5V INPUT RANGE BUT PROVIDES A 2.42V

*

REFERENCE OUTPUT AS OPPOSED TO THE –5.25V OF THE AD7572. FOR PROPER

OPERATION, REVERSE THE REFERENCE CAPACITOR POLARITY AND SHORT OUT THE

10 RESISTOR.Ω

THE D FLIP-FLOP SYNCHRONIZES THE CONVERSION START SIGNAL (RD ) TO THE

**

ADC CLK SIGNAL TO PREVENT OUTPUT CODE NOISE WHICH OCCURS WITH

OUT

AN ASYNCHRONOUS CLOCK.

✝

THE LTC1272 CAN ACCOMMODATE THE –15V SUPPLY OF THE AD7572 BUT DOES

NOT REQUIRE IT. PIN 23 OF THE LTC1272 IS NOT INTERNALLY CONNECTED.

WU

A

Ω

10

*

IN

V

REF

AGND

D11 (MSB)

D10

D9

D8

D7

D6

D5

D4

DGND

U

LTC1272

CLK OUT

CLK IN

V

NC

BUSY

HBEN

D0/8

D1/9

D2/10

D3/11

DD

✝

CS

RD

ASYNCHRONOUS

0.1 F

Q

EXTERNAL

CLOCK

➞

µ

S

1/2

74HC74

CLK

D**

OR

–15V

10 F

+

5V

+

µ

10 F

µ

0.1 F

µ

†

P

RD

LTC1272 • TA05

µ

CONTROL

LINES

74HC04

➞

Figure 23. Plugging the LTC1272 into an AD7572 Socket

Case 2: Clock Not Synchronous with CS and RD

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

19

LTC1272

PACKAGEDESCRIPTI

O

U

Dimensions in inches (millimeters) unless otherwise noted.

N Package

24-Lead Plastic DIP

1.265*

(32.131)

24

0.260 ± 0.010*

(6.604 ± 0.254)

123456

0.300 – 0.325

(7.620 – 8.255)

0.009 – 0.015

(0.229 – 0.381)

+0.025

0.325

–0.015

+0.635

8.255

()

–0.381

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTURSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm).

0.015

(0.381)

MIN

(3.175)

0.125

MIN

0.130 ± 0.005

(3.302 ± 0.127)

0.050 – 0.085

(1.27 – 2.159)

(2.540 ± 0.254)

24-Lead Plastic SOL

2223

0.100 ± 0.010

SO Package

21

20

0.045 – 0.065

(1.143 – 1.651)

2324

7

89101911 12

0.598 – 0.614

(15.190 – 15.600)

22 21 20 19 18

(NOTE 2)

151718

0.018 ± 0.003

(0.457 ± 0.076)

16 15

17

131416

0.065

(1.651)

TYP

N24 0594

1314

20

0.291 – 0.299

(7.391 – 7.595)

0.005

(0.127)

RAD MIN

0.009 – 0.013

(0.229 – 0.330)

(NOTE 2)

0.010 – 0.029

(0.254 – 0.737)

NOTE 1

NOTE:

1. PIN 1 IDENT, NOTCH ON TOP AND CAVITIES ON THE BOTTOM OF PACKAGES ARE THE MANUFACTURING OPTIONS.

THE PART MAY BE SUPPLIED WITH OR WITHOUT ANY OF THE OPTIONS.

2. THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006 INCH (0.15mm).

× 45°

0.016 – 0.050

(0.406 – 1.270)

0° – 8° TYP

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7487

(408) 432-1900

●

FAX

: (408) 434-0507

●

TELEX

: 499-3977

NOTE 1

0.093 – 0.104

(2.362 – 2.642)

0.050

(1.270)

2345678

1

TYP

0.014 – 0.019

(0.356 – 0.482)

0.394 – 0.419

(10.007 – 10.643)

910

11 12

0.037 – 0.045

(0.940 – 1.143)

0.004 – 0.012

(0.102 – 0.305)

SOL24 0392

LT/GP 0694 5K REV A • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1994

Loading...

Loading...