DESIGN IDEAS L

SW CAP

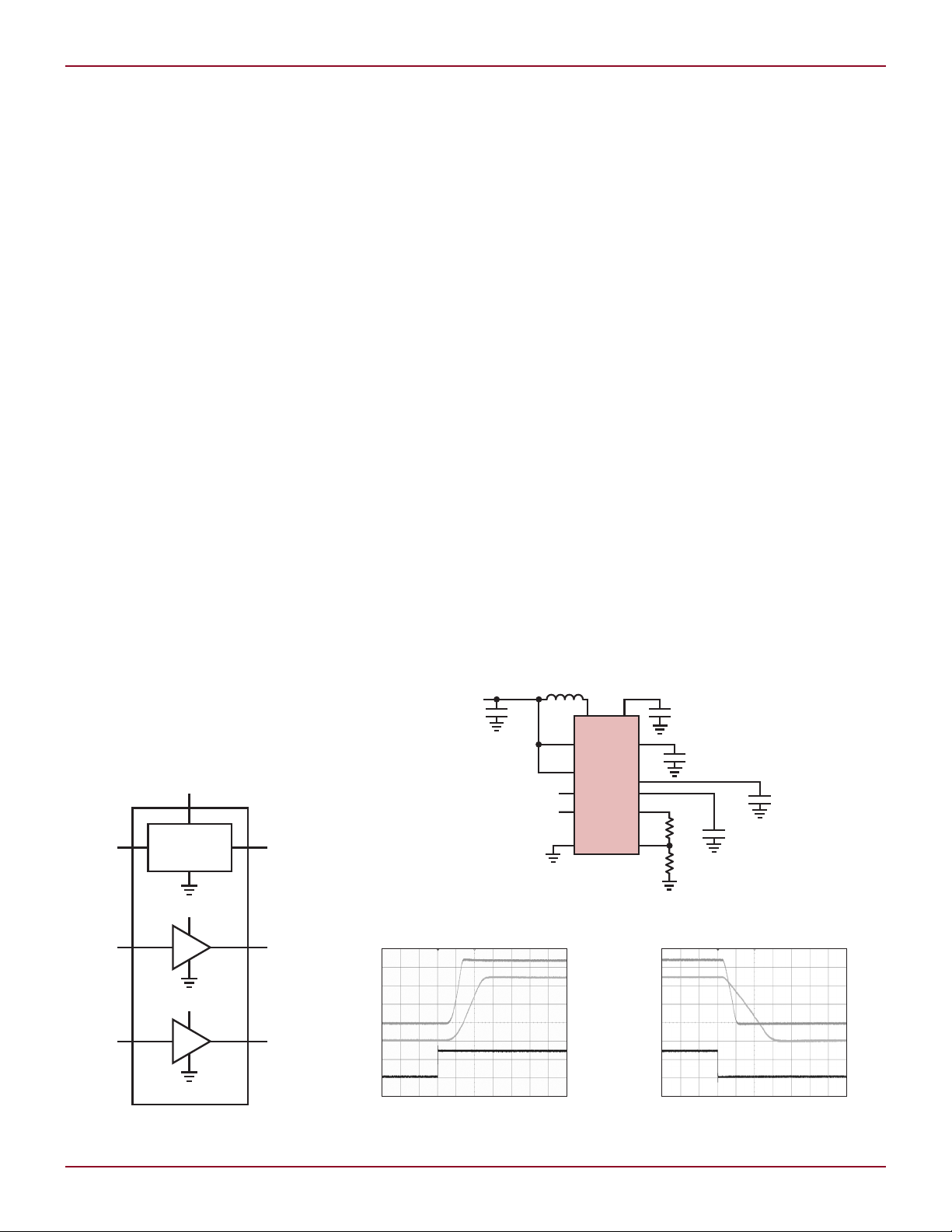

GND

FBP

OUT 2

OUT 1

IN 2

IN 1

LT8415

C1

2.2µF

LOGIC

LEVEL

L1

100µH

22nF

0.1µF

1nF

200pF

V

IN

2.6V to 5V

VCCV

OUT

V

REF

SHDN

137K

887K

34V/0V

34V/0V

L1: COILCRAFT DO2010-104ML

IN1/IN2

1V/DIV

OUT1

10V/DIV

OUT2

10V/DIV

5µs/DIV

IN1/IN2

1V/DIV

OUT1

10V/DIV

OUT2

10V/DIV

5µs/DIV

V

OUT

IN2 OUT2

V

OUT

V

IN

IN1 OUT1

ENABLE

V

OUT

40V MAX

BOOST

CONVERTER

LT8415

Low Power Boost Regulator with

Dual Half-Bridge in 3mm × 2mm DFN

Drives MEMS and Piezo Actuators

by Jesus Rosales

Introduction

Advances in manufacturing technology have made it possible for actuators,

sensors, RF relays, and other moveable

parts to be manufactured at a very

small scale. These devices, referred

to as MEMS (micro-electro-mechanical systems) or micro-machines, are

finding their way into daily life in

applications unheard of just a few

years ago. MEMS are used in automotive, military, medical and consumer

product applications.

Many types of MEMS devices consume very little power to operate and

generally require the use of two support circuits, a step-up converter and a

dual half-bridge driver. These support

circuits must be very small and highly

efficient to keep pace with ever-shrinking MEMS applications. To this end,

the LT8415 integrates the step-up

converter power switch and diode and

the dual half-bridge driver in a 12-pin,

3mm × 2mm DFN package. Its novel

switching architecture consumes very

little power throughout the load range,

making it an ideal match for driving

low current MEMS.

The LT8415 generates output voltages up to 40V from sources ranging

from 2.5V to 16V. The output is then

available for the integrated complementary half-bridge drivers and is

available via OUT1 and OUT2 (see Figure 1). Each half-bridge is made up of

an N-channel MOSFET and a P-channel MOSFET, which are synchronously

controlled by a single pin and never

turn on at the same time. OUT1 and

OUT2 are of the same polarity as IN1

and IN2, respectively. When the part is

turned off, all MOSFETs are turned off,

and the OUT1 and OUT2 nodes revert

to a high impedance state with 20MΩ

pull-down resistors to ground.

2.6V–5V Input to 34V Output

MEMS Driver

Figure 2 shows a MEMS driver that

takes a 2.6V–5V input and produces

a 34V output. This circuit draws very

little source current when the dual

half-bridge is disabled. The input

current is only 320µA at 2.6VIN and

128µA at 5VIN. A logic level signal at

IN1 and IN2 activates the dual halfbridge switches. Figure 3 shows the

turn-on delay and rise time for OUT1

and OUT2 with both half-bridges activated. Figure 4 shows the turn-off

delay and fall time with the 200pF

and 1nF capacitive loads shown in

Figure 2. See the data sheet details

for measuring delay time.

Figure 1. Simplified block diagram of the

LT8415

Linear Technology Magazine • September 2009

Figure 2. 2.6V–5V input to 34V dual half-bridge boost converter

Figure 3. Turn-on delay and rise time for OUT1

and OUT2

Figure 4. Turn-off delay and fall time for OUT1

and OUT2

3131

L DESIGN FEATURES

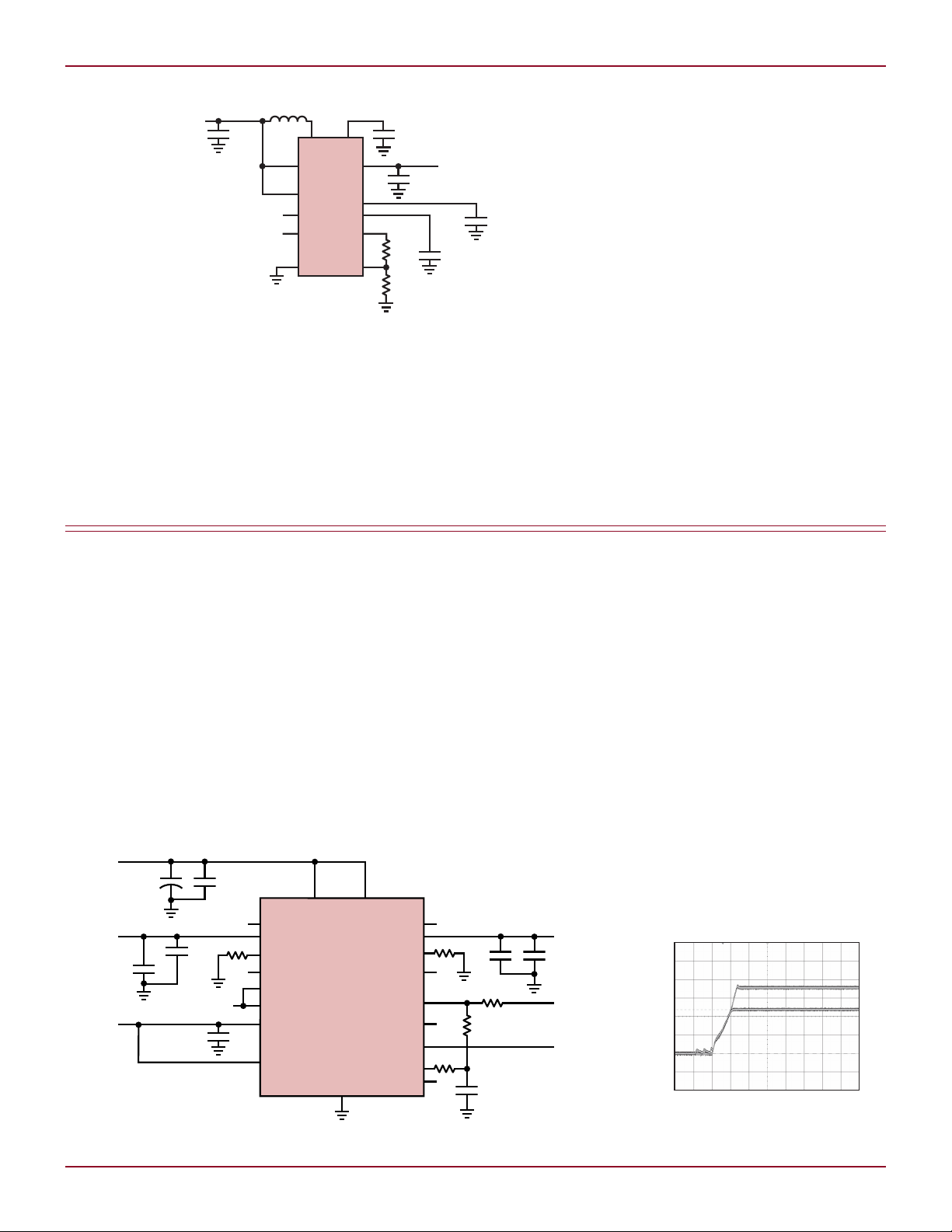

SW CAP

GND

FBP

OUT 2

OUT 1

IN 2

IN 1

LT8415

2.2µF

LOGIC

LEVEL

L1

100µH

0.1µF

1µF

16V

1.6mA AT 3V

IN

10mA AT 10V

IN

1nF

200pF

V

IN

3V to 10V

VCCV

OUT

V

REF

SHDN

604K

412K

16V/0V

16V/0V

L1: COILCRAFT DO2010-104ML

V

OUT1

(1.8V)

500mV/DIV

V

OUT2

(1.2V)

500mV/DIV

200µs/DIV

V

IN1

V

IN1

V

OUT1

1.8V

4A

V

OUT2

1.2V

4A

V

OUT1

V

OUT3

1V

1.5A

V

IN

5V

V

IN

V

OUT2

22µF

10µF

100µF

4.02k

10k

LTM4615

4.7µF

3.32k

V

IN2

P

GOOD1

P

GOOD2

V

OUT2

FB2

COMP2

V

OUT1

FB1

COMP1

TRACK1

RUN/SS1

LDO_IN

EN3

TRACK2

RUN/SS2

LDO_OUT

FB3

P

GOOD3

100µF

22µF

GND

10k

4.99k

10µF

=2

82µF

+

Figure 5. 3V–10V input to 16V dual half-bridge plus 16V output boost converter

3V–10V Input to 16V Output

MEMS Driver and Bias Supply

Figure 5 shows a 3V–10V input to

16V output converter, where the output drives the dual half-bridge and

also provides bias current for other

circuitry. The converter in Figure 2

can be used in a similar fashion, but

the current available at the output is

reduced as the output voltage is increased. See the data sheet for details

about maximum output current.

Integrated Resistor Divider

The LT8415 contains an integrated

resistor divider such that if the FBP

pin is at 1.235V or higher, the output

is clamped at 40V. For lower output

voltage levels use R1 and R2, calculating their values as instructed by the

data sheet. This method of setting the

output voltage ensures the voltage divider draws minimal current from the

input when the part is turned off.

Conclusion

The LT8415 is an ideal match for

driving low power MEMS. It integrates

a step-up converter power switch

and diode, a complementary dual

half-bridge, and a novel switching

architecture that minimizes power

dissipation.

L

LTM4614/15, continued from page 26

to promote good thermal conductivity.

Figure 10 shows that thermal dissipa

tion is well-balanced between the two

switching regulators.

Output Voltage Tracking

Tracking can be programmed using

the TRACK1 and TRACK2 pins. To

implement coincident tracking, at the

slave’s TRACK pin, divide the master

regulator’s output with a resistor

divider that is the same as the slave

regulator’s feedback divider. Figure 11

32

shows a tracking design and Figure 12

-

shows the output. V

in master-slave design with both

outputs ramping up coincidently. The

smooth start-up time is attributed to

the soft-start capacitor.

Conclusion

The cumbersome designs typical of

multivoltage regulation are a thing of

the past. The LTM4614 and LTM4615

µModule multiple-output regulators

can be easily fit into space-constrained

Figure 11. Output voltage tracking design example

OUT2

tracks V

OUT1

system boards with far fewer components than discrete solutions. The

dual-output LTM4614 µModule regulator and triple-output LTM4615 are

small in size, have excellent thermal

dissipation and have high efficiency.

Independent input and output voltage

rails give these µModule regulators

unmatched flexibility. They can be

used in a variety of input-output combinations, including input and output

current sharing, output voltage tracking, and low noise output.

Figure 12. Start-up waveforms for the circuit

in Figure 11

Linear Technology Magazine • September 2009

L

Loading...

Loading...