Monitor and Protect Automotive Systems with Integrated

Current Sensing –

Design Note 374

John Munson

Introduction

An automobile is an unforgiving environment for integrated circuits, where under-the-hood operating temperatures run from –40°C to 125°C and large transient

excursions on the battery voltage bus are expected. In the

past, electronics were part of the well-protected and

centralized Engine Control Unit (ECU), but the trend is

toward more distributed electronics. Electrically driven

accessories and fault-protection monitoring functions are

leaving the protective umbrella of the ECU and migrating

directly into vehicle subsystems.

For example, many functions formerly driven by the

engine—via belt and pulley or hydraulics—are now electrically driven (motorized), such as water pumps, steering

mechanisms, brake actuators and various body controls.

These functions can become a safety risk if they are not

continually monitored for operational readiness and/or

have a back-up mode of operation. In either case, realtime monitoring becomes necessary and generally

involves accurately measuring the current draw of each

subsystem.

Simple Current Monitoring Solutions

The LT®6100 and LTC6101 are high side current-sense

amplifiers that have been developed specifically to address

the automotive designers’ needs. These parts require a

minimum number of support components to operate in

the harsh automotive battery-bus environment.

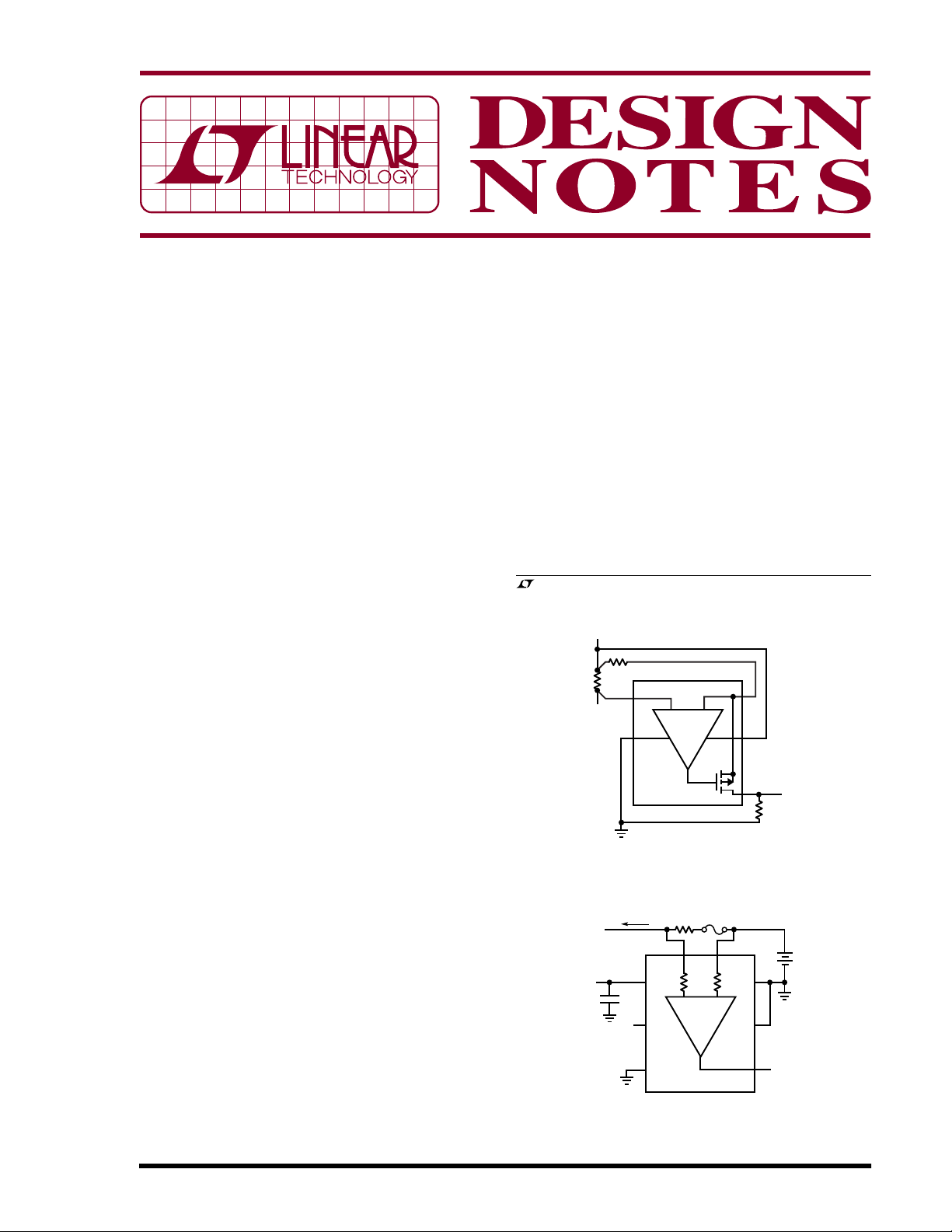

Figure 1 shows a basic high side current monitor using the

LTC6101. The selection of R

desired gain of this circuit, powered directly from the

battery bus. The current output of the LTC6101 allows it

to be located remotely to R

placed directly at the shunt, while R

monitoring electronics without ground drop errors.

This circuit has a fast 1µs response time that makes it ideal

for providing MOSFET load switch protection. The switch

element may be the high side type connected between the

sense resistor and the load, a low side type between the

and R

IN

. Thus, the amplifier can be

OUT

establishes the

OUT

is placed near the

OUT

load and ground or an H-bridge. The circuit is programmable to produce up to 1mA of full-scale output current

into R

, yet draws a mere 250µA supply current when

OUT

the load is off.

Figure 2 shows the LT6100 used as a combination

current sensor and fuse monitor. This part includes onchip output buffering and was designed to operate with

the low supply voltage (≥2.7V), typical of vehicle data

acquisition systems, while the sense inputs monitor

signals at the higher battery bus potential. The LT6100

, LTC and LT are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

BATTERY BUS

R

R

0.01Ω

POWER

Figure 2. Simple LT6100 High Side Current Sense

Amplifier and Fuse Monitor

IN

SENSE

LOAD

100Ω

4

+

2

LT6101

= I

V

OUT

LOAD(RSENSE

3

–

5

1

R

OUT

4.99k

• R

)

OUT/RIN

DN374 F01

Figure 1. Simple LTC6101 High Side

Current Sense Amplifier

R

SENSE

FUSE

2mΩ

A4

A2

OUT

DN374 F02

7

6

5

+

OUTPUT

2.5V = 25A

81

–

+

V

V

S

–

LT6100

S

+

2

V

CC

3

FIL

4

V

EE

ADC

≥2.7V

TO LOAD

C2

0.1µF

V

OUT

4.99V = 10A

BATTERY

BUS

10/05/374

inputs are tolerant of large input differentials, thus allowing the blown-fuse operating condition (this would be

detected by an output full-scale indication). The LT6100

can also be powered down while maintaining high impedance sense inputs, drawing less than 1µA max from the

battery bus.

Solving the H-Bridge Problem

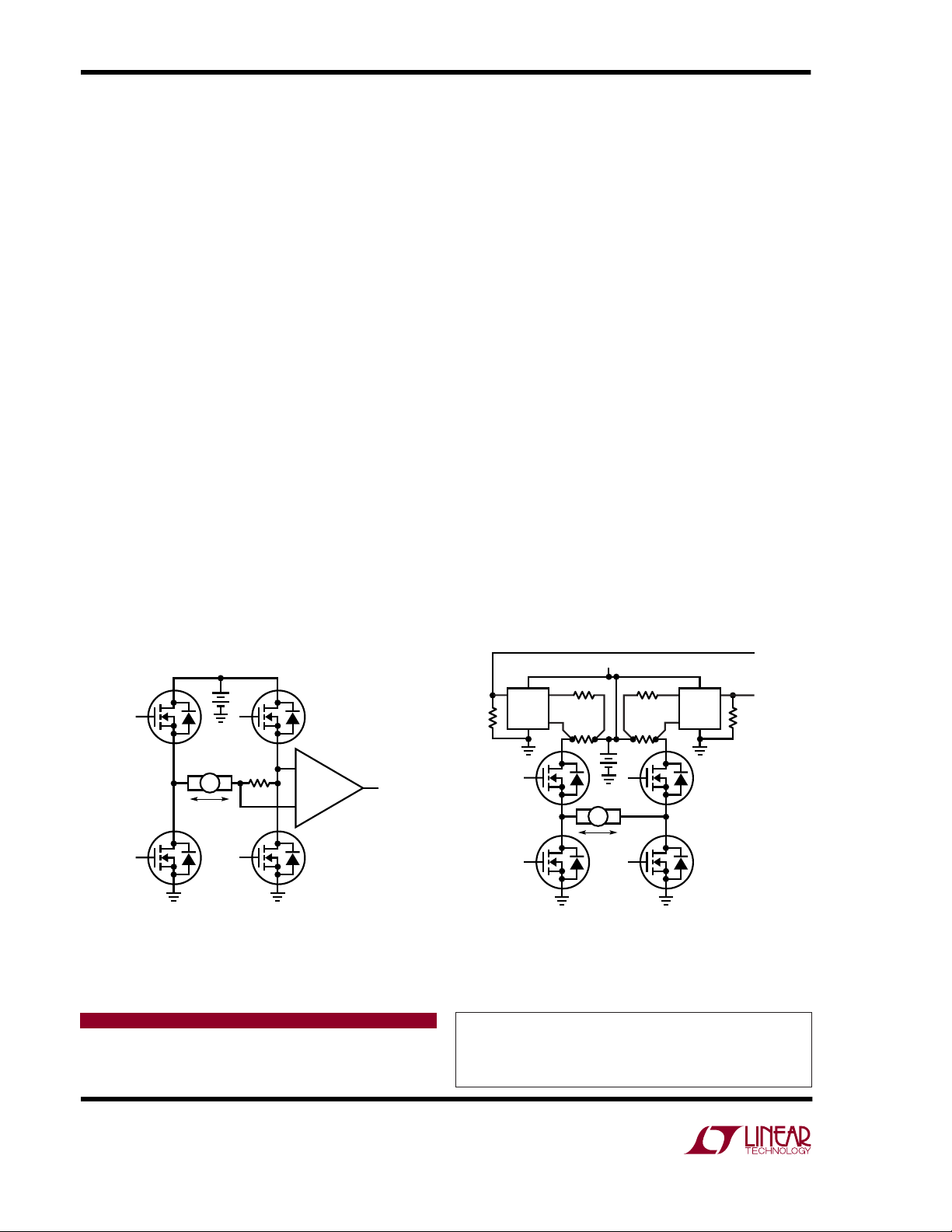

Many of the newer electric drive functions, such as

steering assist, are bidirectional in nature. These functions are generally driven by H-bridge MOSFET arrays

using pulse-width-modulation (PWM) methods to vary

the commanded torque. In these systems, there are two

main purposes for current monitoring. One is to monitor

the current in the load, to track its performance against the

desired command (i.e., closed-loop servo law), and

another is for fault detection and protection features.

A common monitoring approach in these systems is to

amplify the voltage on a “flying” sense resistor, as shown

in Figure 3. Unfortunately, several potentially hazardous

fault scenarios go undetected, such as a simple short to

ground at a motor terminal. Another complication is the

noise introduced by the PWM activity. While the PWM

noise may be filtered for purposes of the servo law,

information useful for protection becomes obscured. The

best solution is to simply provide two circuits that individually protect each half-bridge and report the bidirectional load current. In some cases, a smart MOSFET

bridge driver may already include sense resistors and

offer the protection features needed. In these situations,

the best solution is the one that derives the load information with the least additional circuitry.

Figure 4 shows a differential load measurement for an

ADC using twin unidirectional sense measurements. Each

LTC6101 performs high side sensing that rapidly responds

to fault conditions, including load shorts and MOSFET

failures. Hardware local to the switch module (not shown

in the diagram) can provide the protection logic and furnish a status flag to the control system. The two LTC6101

outputs taken differentially produce a bidirectional load

measurement for the control servo. The ground-referenced signals are compatible with most ∆Σ ADCs. The ∆Σ

ADC circuit also provides a “free” integration function that

removes PWM content from the measurement. This

scheme also eliminates the need for analog-to-digital

conversions at the rate needed to support switch protection, thus reducing cost and complexity.

Conclusion

The LT6100 and LTC6101 high side current-sense amplifiers simplify designs in the automotive environment.

High transient voltage tolerance (105V for the LTC6101HV)

and ground-referenced outputs make it possible to

improve robustness and substantially reduce the partscount over traditional solutions.

R

–

DIFF

OUTPUT

TO ADC

+

OUT

BATTERY BUS

+

BATTERY BUS

R

LTC6101

R

OUT

IN

R

S

R

IN

LTC6101

R

S

+

RANGE = ±100A,

+

R

S

I

M

DN374 F03

DIFF

AMP

–

I

M

FOR I

DIFF OUT = ±2.5V

R

R

R

DN374 F04

= 1mΩ

S

= 200Ω

IN

OUT

M

= 4.99k

Figure 3. Limited Performance H-Bridge Current Monitor Figure 4. Practical H-Bridge Current Monitor Offers

Fault Detection and Bidirectional Load Information

Data Sheet Download

http://www.linear.com

For applications help,

call (408) 432-1900, Ext. 2020

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

dn374f LT/TP 1005 409K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2005

Loading...

Loading...