FEATURES

■

Allows Safe Board Insertion and Removal

from a Live –48V Backplane

■

Circuit Breaker Immunity to Voltage Steps and

Current Spikes

■

Programmable Inrush and

Short-Circuit Current Limits

■

Pin Compatible with LT1640L/LT1640H

■

Operates from –20V to –80V

■

Programmable Overvoltage Protection

■

Programmable Undervoltage Lockout

■

Power Good Control Output

■

Bell-Core Compatible ON/OFF Threshold

U

APPLICATIO S

LT4250L/LT4250H

Negative 48V

Hot Swap Controller

U

DESCRIPTIO

The LT®4250L/LT4250H are 8-pin, negative 48V Hot Swap

controllers that allow a board to be safely inserted and

removed from a live backplane. Inrush current is limited to

a programmable value by controlling the gate voltage of an

external N-channel pass transistor. The pass transistor is

turned off if the input voltage is less than the programmable undervoltage threshold or greater than the overvoltage threshold. A programmable current limit protects

the system against shorts. After a 500µs timeout the

current limit activates the electronic circuit breaker. The

PWRGD (LT4250L) or PWRGD (LT4250H) signal can be

used to directly enable a power module. The LT4250L is

designed for modules with a low enable input and the

LT4250H for modules with a high enable input.

TM

■

Central Office Switching

■

–48V Distributed Power Systems

■

Negative Power Supply Control

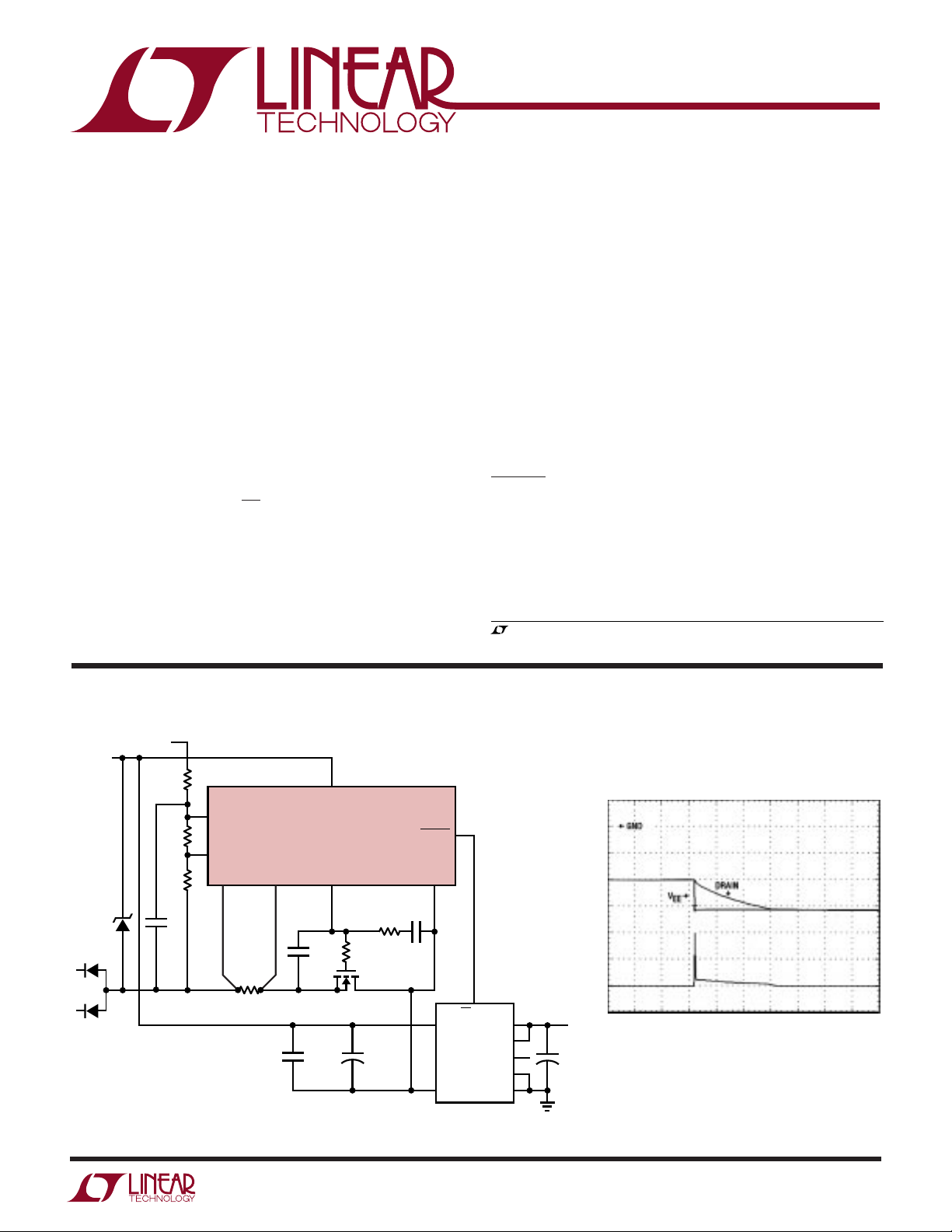

TYPICAL APPLICATIO

–48V RTN

(SHORT PIN)

–48V RTN

UV =

38.5V

UV

RELEASE

AT 43V

OV =

71V

*

–48V

INPUT 1

–48V

INPUT 2

* DIODES INC. SMAT70A

†

THESE COMPONENTS ARE APPLICATION

SPECIFIC AND MUST BE SELECTED BASED

UPON OPERATING CONDITIONS AND DESIRED

PERFORMANCE. SEE APPLICATIONS

INFORMATION.

R4

549k

1%

R5

6.49k

1%

R6

10k

1%

0.1µF

10V

†

3

UV

†

2

OV

†

V

SENSE

EE

4

56

†

R1

0.02Ω

5%

U

8

V

DD

LT4250L

GATE DRAIN

†

R3

1k, 5%

†

R2

C1

10Ω

470nF

5%

25V

Q1

IRF530

C3

0.1µF

100V

C4

+

100µF

100V

C2

15nF

100V

PWRGD

†

1

4

7

+

V

IN

–

V

IN

LUCENT

JW050A1-E

The LT4250L/LT4250H are available in 8-pin PDIP and SO

packages.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Hot Swap is a trademark of Linear Technology Corporation.

Voltage Step On Input Supply

1

VEE AND

DRAIN

20V/DIV

(Q1)

I

D

5A/DIV

2

ON/OFF

V

OUT

SENSE

TRIM

SENSE

V

OUT

9

+

8

+

7

6

–

5

–

5V

C5

+

100µF

16V

4250 TA01

500µs/DIV

4250lhf

1

LT4250L/LT4250H

WW

W

ABSOLUTE MAXIMUM RATINGS

U

(Note 1), All Voltages Referred to V

Supply Voltage (VDD – VEE) .................... –0.3V to 100V

PWRGD, PWRGD Pins ........................... –0.3V to 100V

SENSE, GATE Pins.................................... –0.3V to 20V

UV, OV Pins .............................................. –0.3V to 60V

DRAIN Pin .................................................. –2V to 100V

Maximum Junction Temperature ......................... 125°C

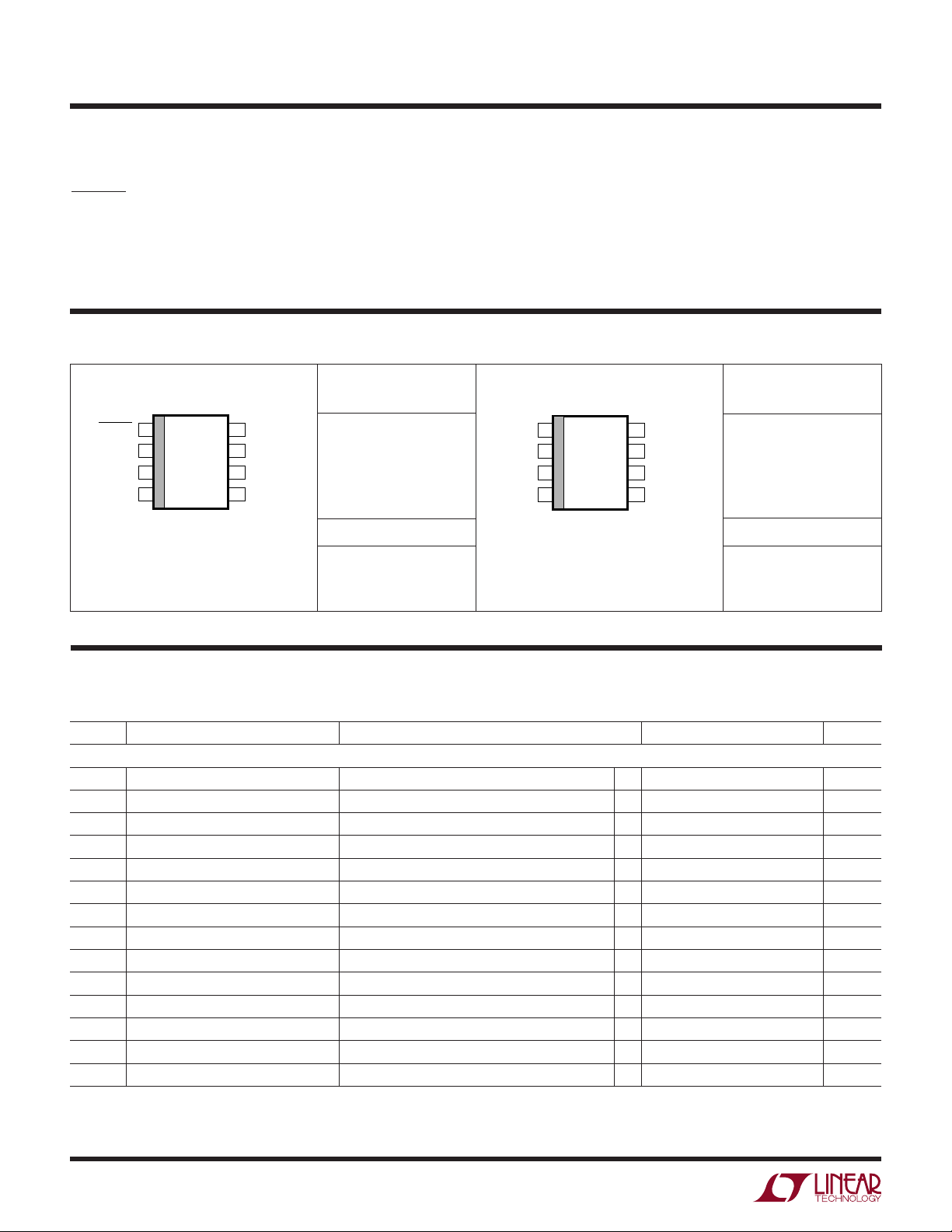

WU

/

PACKAGE

PWRGD

1

OV

2

UV

3

V

4

EE

N8 PACKAGE

8-LEAD PDIP

T

= 125°C, θJA = 120°C/W (N8)

JMAX

T

= 125°C, θJA = 150°C/W (S8)

JMAX

O

RDER I FOR ATIO

TOP VIEW

V

8

DD

DRAIN

7

GATE

6

SENSE

5

S8 PACKAGE

8-LEAD PLASTIC SO

S8 PART MARKING

ORDER PART

NUMBER

LT4250LCN8

LT4250LCS8

LT4250LIN8

LT4250LIS8

4250L

4250LI

EE

Operating Temperature Range

LT4250LC/LT4250HC ............................. 0°C to 70°C

LT4250LI/LT4250HI .......................... – 40°C to 85°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

U

ORDER PART

NUMBER

LT4250HCN8

LT4250HCS8

LT4250HIN8

LT4250HIS8

S8 PART MARKING

4250H

4250HI

PWRGD

OV

UV

V

EE

N8 PACKAGE

8-LEAD PDIP

T

JMAX

T

JMAX

TOP VIEW

1

2

3

4

8-LEAD PLASTIC SO

= 125°C, θJA = 120°C/W (N8)

= 125°C, θJA = 150°C/W (S8)

V

8

DRAIN

7

GATE

6

SENSE

5

S8 PACKAGE

DD

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. (Note 2), VDD = 48V, VEE = 0V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

DC

V

DD

I

DD

V

UVL

V

CL

I

PU

I

PD

I

SENSE

∆V

V

UVH

V

UVL

V

UVHY

I

INUV

V

OVH

V

OVL

GATE

Supply Voltage Operating Range ● 20 80 V

Supply Current UV = 3V, OV = VEE, SENSE = V

Undervoltage Lockout ● 15.4 V

Current Limit Trip Voltage VCL = (V

GATE Pin Pull-Up Current Gate Drive On, V

GATE Pin Pull-Down Current Gate Drive OFF 24 50 70 mA

SENSE Pin Current V

External Gate Drive (V

UV Pin High Threshold Voltage UV Increasing ● 1.240 1.255 1.270 V

UV Pin Low Threshold Voltage UV Decreasing ● 1.105 1.125 1.145 V

UV Pin Hysteresis 130 mV

UV Pin Input Current VUV = V

OV Pin High Threshold Voltage OV Increasing ● 1.235 1.255 1.275 V

OV Pin Low Threshold Voltage OV Decreasing ● 1.210 1.235 1.255 V

SENSE

GATE

– VEE) ● 40 50 60 mV

SENSE

= V

GATE

= 50mV –20 µA

– VEE), 20V ≤ VDD ≤ 80V ● 10 13.5 18 V

EE

EE

EE

● 1.6 5 mA

● –30 –45 –60 µA

● –0.02 –0.5 µA

2

4250lhf

LT4250L/LT4250H

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. (Note 2), VDD = 48V, VEE = 0V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

OVHY

I

INOV

V

DL

V

GH

I

DRAIN

V

OL

I

OH

AC

t

PHLOV

t

PHLUV

t

PLHOV

t

PLHUV

t

PHLSENSE

t

PHLCB

t

PHLDL

t

PHLGH

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

OV Pin Hysteresis 20 mV

OV Pin Input Current VOV = V

DRAIN Low Threshold V

GATE High Threshold ∆V

Drain Input Bias Current V

EE

– VEE, DRAIN Decreasing 1.1 1.6 2.3 V

DRAIN

– V

GATE

DRAIN

Decreasing 1.3 V

GATE

= 48V ● 10 80 500 µA

PWRGD Output Low Voltage PWRGD (LT4250L), (V

I

= 1mA ● 0.48 0.8 V

OUT

= 5mA ● 1.2 3.0 V

I

OUT

PWRGD Output Low Voltage PWRGD (LT4250H), V

(PWRGD – DRAIN) I

= 1mA ● 0.75 1.0 V

OUT

Output Leakage PWRGD (LT4250L), V

PWRGD (LT4250H), V

DRAIN

DRAIN

DRAIN

DRAIN

– VEE) < V

= 5V

= 48V, V

= 0V, V

DL

= 80V ● 0.05 10 µA

PWRGD

= 80V ● 0.05 10 µA

PWRGD

● – 0.03 –0.5 µA

OV High to GATE Low Figures 1a, 2 1.7 µs

UV Low to GATE Low Figures 1a, 3 1.5 µs

OV Low to GATE High Figures 1a, 2 5.5 µs

UV High to GATE High Figures 1a, 3 6.5 µs

SENSE High to Gate Low Figures 1a, 4a 1 3 µs

Current Limit to GATE Low Figures 1b, 4b 500 µs

DRAIN Low to PWRGD Low (LT4250L) Figures 1a, 5a 1 µs

DRAIN Low to (PWRGD – DRAIN) High (LT4250H) Figures 1a, 5a 1 µs

GATE High to PWRGD Low (LT4250L) Figures 1a, 5b 1.5 µs

GATE High to (PWRGD – DRAIN) High (LT4250H) Figures 1a, 5b 1.5 µs

Note 2: All currents into device pins are positive; all currents out of device

pins are negative. All voltages are referenced to V

unless otherwise

EE

specified.

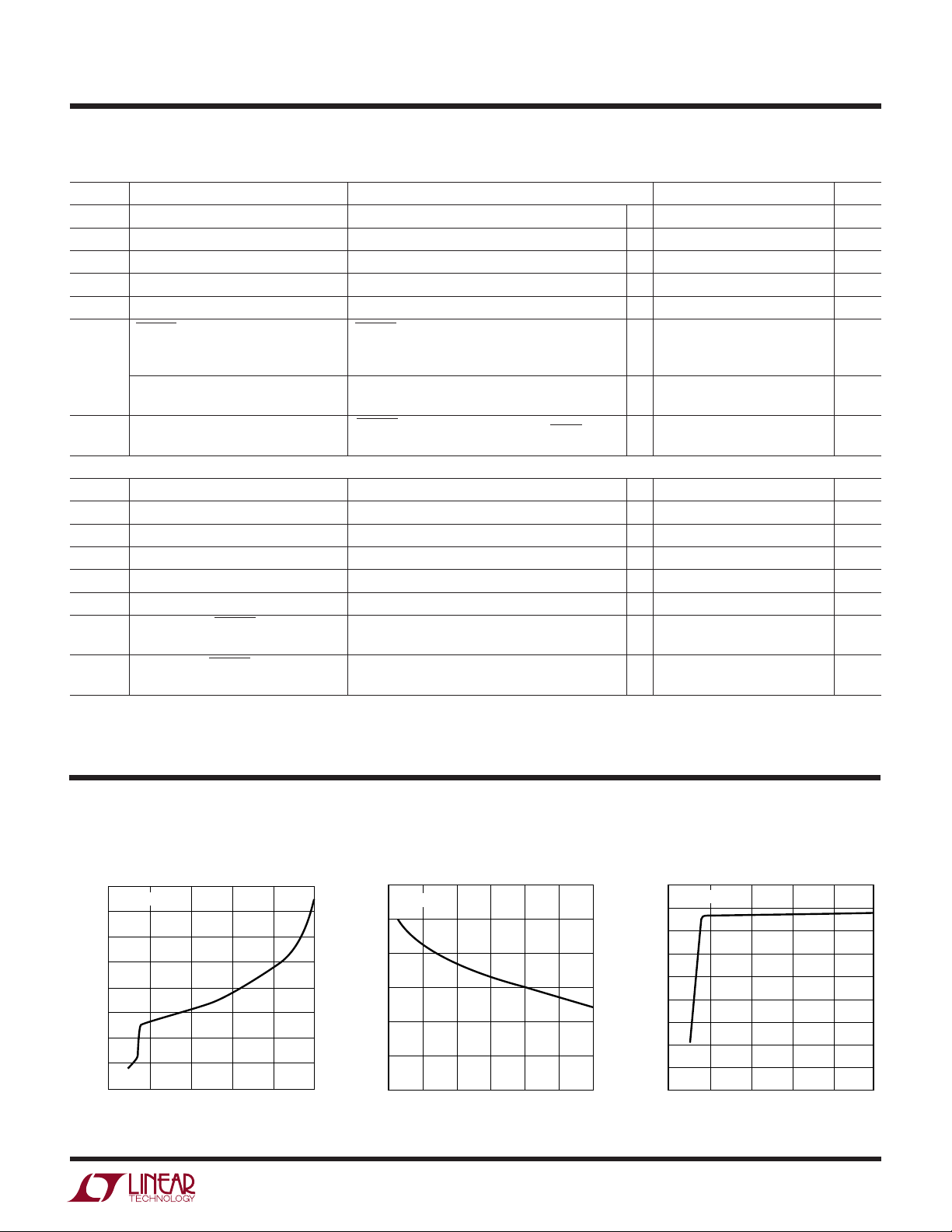

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Supply Current vs Supply Voltage

1.8

TA = 25°C

1.7

1.6

1.5

1.4

1.3

SUPPLY CURRENT (mA)

1.2

1.1

0

20 40 80

0

SUPPLY VOLTAGE (V)

60

100

1640 G01

Supply Current vs Temperature

1.6

VDD = 48V

1.5

1.4

1.3

1.2

SUPPLY CURRENT (mA)

1.1

1.0

–50 –25

0255075

TEMPERATURE (°C)

1640 G02

100

Gate Voltage vs Supply Voltage

15

TA = 25°C

14

13

12

11

10

9

GATE VOLTAGE (V)

8

7

6

0

20 60

40

SUPPLY VOLTAGE (V)

100

80

1640 G03

4250lhf

3

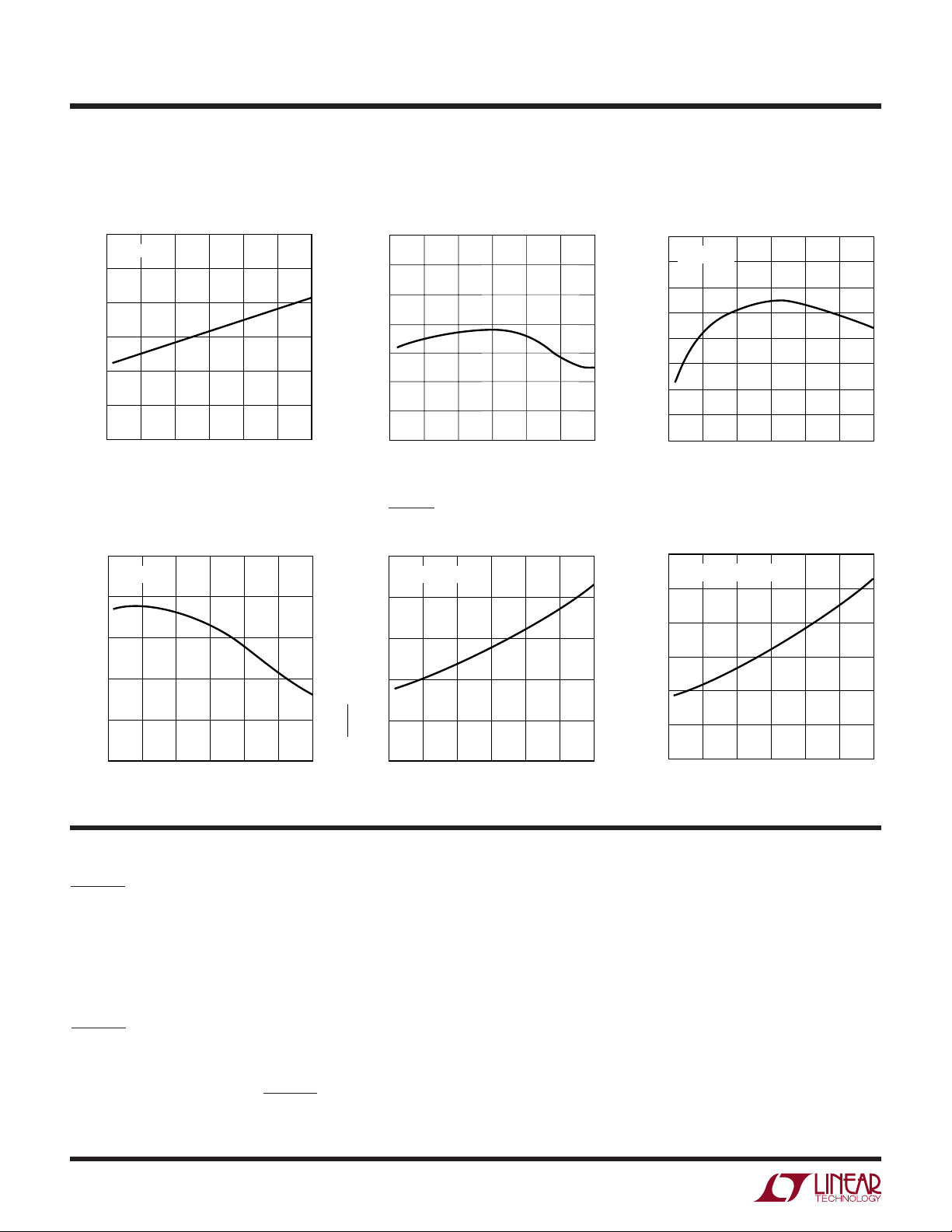

LT4250L/LT4250H

TEMPERATURE (°C)

–50

2

OUTPUT IMPEDANCE (kΩ)

3

4

5

6

7

8

–25 2505075

1640 G09

100

V

DRAIN

– VEE > 2.4V

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Gate Voltage vs Temperature

15.0

VDD = 48V

14.5

14.0

13.5

13.0

GATE VOLTAGE (V)

12.5

12.0

–25 0 75

TEMPERATURE (°C)

Gate Pull-Down Current

vs Temperature

55

V

= 2V

GATE

52

49

1640 G04

Current Limit Trip Voltage

vs Temperature

55

54

53

52

51

TRIP VOLTAGE (mV)

50

49

100–50 25 50

48

–50

–25

TEMPERATURE (°C)

50

250

100

75

1640 G05

PWRGD Output Low Voltage

vs Temperature (LT4250L)

0.5

I

= 1mA

OUT

0.4

0.3

Gate Pull-Up Current

vs Temperature

48

V

= 0V

GATE

47

46

45

44

43

42

GATE PULL-UP CURRENT (µA)

41

40

–25 10050250

–50

TEMPERATURE (°C)

PWRGD Output Impedance

vs Temperature (LT4250H)

75

1640 G06

46

43

GATE PULL-DOWN CURRENT (mA)

40

–25 0

–50

25

TEMPERATURE (°C)

50

75

100

1640 G07

0.2

0.1

PWRGD OUTPUT LOW VOLTAGE (V)

0

–25 25050

–50

TEMPERATURE (°C)

75

100

1640 G08

UUU

PIN FUNCTIONS

PWRGD/PWRGD (Pin 1): Power Good Output Pin. This pin

will latch a power good indication when V

of V

and V

EE

connected directly to the enable pin of a power module.

When the DRAIN pin of the LT4250L is above VEE by more

than V

DL

PWRGD pin will be high impedance, allowing the pull-up

is within VGH of ∆V

GATE

or V

is more than VGH from ∆V

GATE

GATE

is within V

DRAIN

. This pin can be

, the

GATE

current of the module’s enable pin to pull the pin high and

turn the module off. When V

V

rises above VGH, the PWRGD pin sinks current to

GATE

VEE, pulling the enable pin low and turning on the module.

drops below V

DRAIN

DL

and

This condition is latched until the GATE pin is turned off via

the UV, OV, UVLO or the electronic circuit breaker.

DL

When the DRAIN pin of the LT4250H is above VEE by more

than VDL or V

is more than VGH from ∆V

GATE

PWRGD pin will sink current to the DRAIN pin which pulls

the module’s enable pin low, forcing it off. When V

drops below VDL and V

rises above VGH, the PWRGD

GATE

sink current is turned off, allowing the module’s pull-up

current to pull the enable pin high and turn on the module.

This condition is latched until the GATE pin is turned off via

the UV, OV, UVLO or the electronic circuit breaker.

GATE

, the

DRAIN

4250lhf

4

UUU

PIN FUNCTIONS

LT4250L/LT4250H

OV (Pin 2): Analog Overvoltage Input. When OV is pulled

above the 1.255V threshold, an overvoltage condition is

detected and the GATE pin will be immediately pulled low.

The GATE pin will remain low until OV drops below the

1.235V threshold.

UV (Pin 3): Analog Undervoltage Input. When UV is

pulled below the 1.125V threshold, an undervoltage

condition is detected and the GATE pin will be immediately pulled low. The GATE pin will remain low until UV

rises above the 1.255 threshold.

The UV pin is also used to reset the electronic circuit

breaker. If the UV pin is cycled low and high following the

trip of the circuit breaker, the circuit breaker is reset and

a normal power-up sequence will occur. The response

time for this pin is 1.5µs. Add an external capacitor to this

pin for additional filtering.

VEE (Pin 4): Negative Supply Voltage Input. Connect to

the lower potential of the power supply.

SENSE (Pin 5): Circuit Breaker Sense Pin. With a sense

resistor placed in the supply path between VEE and

SENSE, the overcurrent condition will pull down the

GATE pin and regulate the voltage across the resistor to

be 50mV. If the overcurrent condition exists for more

than 500µs the electronic circuit breaker will trip and turn

off the external MOSFET.

If the current limit value is set to twice the normal

operating current, only 25mV is dropped across the

sense resistor during normal operation. To disable the

current limit feature, VEE and SENSE can be shorted

together.

GATE (Pin 6): Gate Drive Output for the External

N-Channel MOSFET. The GATE pin will go high when the

following start-up conditions are met: the UV pin is high,

the OV pin is low, (V

is greater than V

UVLOH

– VEE) < 50mV and the VDD pin

SENSE

. The GATE pin is pulled high by a

45µA current source and pulled low with a 50mA current

source. During current limit the GATE pin is pulled low

using a 100mA current source.

DRAIN (Pin 7): Analog Drain Sense Input. Connect this

pin to the drain of the external N-channel MOSFET and the

V– pin of the power module. When the DRAIN pin is

below VDL, the PWRGD/PWRGD pin will latch to indicate

the switch is on.

VDD (Pin 8): Positive Supply Voltage Input. Connect this

pin to the higher potential of the power supply inputs and

the V+ pin of the power module. An undervoltage lockout

circuit disables the chip until the VDD pin is greater than

the 16V V

UVLOH

threshold.

BLOCK DIAGRA

UV

OV

–

+

REF

–

+

W

V

DD

V

GATE

GATE

REF

CC

OUTPUT

DRIVE

+

+

V

DL

–

V

EE

DRAIN

+

–

∆V

–

–

+

GATE

V

4250 BD

GH

PWRGD/PWRGD

4250lhf

UVLO

50mV

–

+

–

+

SENSEV

EE

VCC AND

REFERENCE

GENERATOR

LOGIC

500µs

DELAY

DRIVER

5

LT4250L/LT4250H

2V

1V

4250 F03

t

PHLUV

1.125V

0V

UV

GATE

1V

1.255V

t

PLHUV

PWRGD/PWRGD V

DD

OV

48V

20V

DRAIN

LT4250L/LT4250H

UV GATE

V

EE

SENSE

4250 F01b

V

UV

0.1µF

+

–

+

–

10k

10Ω

10Ω

IRF530

R

5k

+

V

5V

V

OV

V

UV

PWRGD/PWRGD V

OV

LT4250L/LT4250H

UV GATE

V

EE

DRAIN

SENSE

DD

V

DRAIN

V

SENSE

1640 F01a

+

48V

–

Figure 1a. Test Circuit 1

WUW

TIMING DIAGRAMS

OV

GATE

100mV

SENSE

GATE

2V

0V

V

EE

DRAIN

1.255V

t

PHLOV

1V

Figure 2. OV to GATE Timing

60mV

t

PHLSENSE

1V

Figure 4a. SENSE to GATE Timing

1.4V

t

PHLDL

1.235V

Figure 1b. Test Circuit 2

t

PLHOV

1V

4250 F02

Figure 3. UV to GATE Timing

UV

t

PHLCB

GATE

4250 F04a

1V

1V

4250 F04b

Figure 4b. Active Current Limit Timeout

1.4V

∆V

– V

GATE

= 0

t

PHLGH

GATE

GATE

V

EE

PWRGD

DRAIN

PWRGD

V

PWRGD

– V

DRAIN

= 0V

Figure 5a. DRAIN to PWRGD/PWRGD Timing

6

1.4V

t

PHLDL

1V

1V

4250 F05a

V

EE

V

EE

PWRGD

∆V

GATE

PWRGD

V

PWRGD

– V

– V

GATE

DRAIN

1.4V

= 0

GATE

= 0

1V

t

PHLGH

1V

4250 F05b

Figure 5b. GATE to PWRGD/PWRGD Timing

V

EE

4250lhf

LT4250L/LT4250H

U

WUU

APPLICATIONS INFORMATION

Hot Circuit Insertion

When circuit boards are inserted into a live – 48V backplane,

the bypass capacitors at the input of the board’s power

module or switching power supply can draw huge transient currents as they charge up. The transient currents

can cause permanent damage to the board’s components

and cause glitches on the system power supply.

The LT4250 is designed to turn on a board’s supply

voltage in a controlled manner, allowing the board to be

safely inserted or removed from a live backplane. The chip

also provides undervoltage, overvoltage and overcurrent

protection while keeping the power module off until its

input voltage is stable and within tolerance.

Power Supply Ramping

The input to the power module on a board is controlled by

placing an external N-channel pass transistor (Q1) in the

power path (Figure 6a, all waveforms are with respect to

the VEE pin of the LT4250). R1 provides current fault

detection and R2 prevents high frequency oscillations.

Resistors R4, R5 and R6 provide undervoltage and overvoltage sensing. By ramping the gate of Q1 up at a slow

rate, the inrush current charging load capacitors C3 and

C4 can be limited to a safe value when the board makes

connection.

Resistor R3 and capacitor C2 act as a feedback network to

accurately control the inrush current. The C2 capacitor can

be calculated with the following equation:

C2 = (45µA • CL)/I

–48V RTN

(SHORT PIN)

–48V RTN

R4

549k

1%

6.49k

1%

10k

1%

3

R5

2

R6

UV = 38.5V

OV = 71V

*

–48V

* DIODES INC. SMAT70A

INRUSH

C3

8

V

DD

UV

OV

V

EE

4

R1

0.02Ω

5%

LT4250H PWRGD

SENSE

GATE DRAIN

56

C1

470nF

25V

43

21

Q1

IRF530

1k, 5%

R2

10Ω

5%

R3

C2

15nF

100V

0.1µF

100V

C4

+

100µF

100V

1

7

4250 F06a

VICOR

VI-J30-CY

+

V

IN

GATE IN

–

V

IN

+

V

OUT

–

V

OUT

where CL is the total load capacitance = C3 + C4 + module

input capacitance.

Capacitor C1 and resistor R3 prevent Q1 from momentarily turning on when the power pins first make contact.

Without C1 and R3, capacitor C2 would pull the gate of Q1

up to a voltage roughly equal to VEE • C2/C

GS(Q1)

before the

LT4250 could power up and actively pull the gate low. By

placing capacitor C1 in parallel with the gate capacitance

of Q1 and isolating them from C2 using resistor R3 the

problem is solved. The value of C1 is given by:

VV

12=

INMAX TH

C

C1≅ 35 • C2 for V

V

TH

−

CC

•+

()

INMAX

GD

= 72V

where VTH is the MOSFET’s minimum gate threshold and

V

is the maximum operating input voltage.

INMAX

R3 should not exceed a value that produces an

R3 • C2 time-constant of 150µs. A 1k value for R3 will

ensure this for C2 values up to 150nF.

The waveforms are shown in Figure 6b. When the power

pins make contact, they bounce several times. While the

contacts are bouncing, the LT4250 senses an undervoltage

condition and the GATE is immediately pulled low when

the power pins are disconnected.

Once the power pins stop bouncing, the GATE pin starts to

ramp up. When Q1 turns on, the GATE voltage is held

constant by the feedback network of R3 and C2. When the

DRAIN voltage has finished ramping, the GATE pin then

ramps to its final value.

INRUSH

CURRENT

500mA/DIV

5V

GATE –V

+

C5

100µF

16V

10V/DIV

DRAIN

50V/DIV

V

50V/DIV

EE

EE

CONTACT

CONTACT

BOUNCE

BOUNCE

25ms/DIV

MODULE

TURN-ON

MODULE

TURN-ON

4250 F06b

Figure 6a. Inrush Control Circuitry

Figure 6b. Inrush Control Waveforms

4250lhf

7

LT4250L/LT4250H

U

WUU

APPLICATIONS INFORMATION

Current Limit/Electronic Circuit Breaker

The LT4250 features a current limit function that protects

against short circuits or excessive supply currents. If the

current limit is active for more than 500µs the electronic

circuit breaker will trip. By placing a sense resistor

between the VEE and SENSE pin, the current limit will be

activated whenever the voltage across the sense resistor

is greater than 50mV.

Note that the current limit threshold should be set sufficiently high to account for the sum of the load current and

the inrush current. The maximum value of the inrush

current is given by:

I

INRUSH

≤

0840.• –

R

where the 0.8 factor is used as a worst case margin

combined with the minimum trip voltage (40mV).

mV

SENSE

I

LOAD

,

The LT4250 guards against voltage steps on the input

supply. A positive voltage step (increasing in magnitude)

on the input supply causes an inrush current that is

proportional to the voltage slew rate I = CL • ∆V/∆T. If the

inrush exceeds 50mV/R

, the current limit will acti-

SENSE

vate as shown in Figure 8. The GATE pin pulls low, limiting

the current to 50mV/R

. At this level the MOSFET

SENSE

drain will not follow the source as the input voltage rapidly

changes, but instead remains at the voltage stored on the

load capacitance. The load capacitance begins to charge

at a current of 50mV/R

, but not for long. As the load

SENSE

capacitance charges, C2 pushes back on the gate and

limits the MOSFET current in a manner identical to the

initial start-up condition which is less than the short circuit

limiting value of 50mV/R

. Thus the circuit breaker

SENSE

does not trip. To ensure correct operation under input

voltage step conditions, R

must be chosen to pro-

SENSE

vide a current limit value greater than the sum of the load

current and the dynamic current in the load capacitance.

In the case of a short circuit, the current limit circuitry

activates and immediately pulls the GATE low, servos the

SENSE voltage to 50mV, and starts a 500µs timer. The

MOSFET current is limited to 50mV/R

(see Figure 7).

SENSE

If the short circuit persists for more than 500µs, the circuit

breaker trips and pulls the GATE pin low, shutting off the

MOSFET. The circuit breaker is reset by pulling UV low, or

by cycling power to the part. If the short circuit clears

before the 500µs timing interval the current limit will

deactivate and release the GATE.

DRAIN

50V/DIV

GATE

10V/DIV

I

(Q1)

D

5A/DIV

For C2 values less than 10nF a positive voltage step on the

input supply can result in the Q1 turning off momentarily

which can shut down the output. By adding an additional

resistor and diode, Q1 remains on during the voltage step.

This is shown as D1 and R7 in Figure 9. The purpose of D1

is to shunt current around R7 when the power pins first

make contact and allow C1 to hold the GATE low. The value

of R7 should be sized to generate an R7 • C1 time constant

of 33µs.

Under some conditions, a short circuit at the output can

cause the input supply to dip below the UV threshold. The

LT4250 turns off once and then turns on until the electronic circuit breaker is tripped. This can be minimized by

adding a deglitching delay to the UV pin with a capacitor

from UV to VEE. This capacitor forms an RC time constant

with the resistors at UV, allowing the input supply to

recover before the UV pin resets the circuit breaker.

8

1ms/DIV

Figure 7. Short-Circuit Protection Waveforms

4250lhf

LT4250L/LT4250H

V

EE

V

DD

LT4250H

PWRGD

SENSE

C1

150nF

25V

C3

0.1µF

100V

C4

22µF

100V

Q1

IRF530

R2

10Ω

5%

R3

1k

5%

C2

3.3nF

100V

R4

549k

1%

R5

6.49k

1%

R6

10k

1%

R1

0.02Ω

5%

4

3

2

–48V RTN

–48V

OV

UV

56

8

1

GATE DRAIN

4250 F09

+

7

–48V RTN

(SHORT PIN)

*

* DIODES INC. SMAT70A

R7

220Ω

5%

43

21

D1

BAT85

U

WUU

APPLICATIONS INFORMATION

A circuit that automatically resets the circuit breaker after

a current fault is shown in Figure 10. Transistors Q2 and

Q3 along with R7, R8, C4 and D1 form a programmable

one-shot circuit. Before a short occurs, the GATE pin is

pulled high and Q3 is turned on, pulling node 2 to VEE.

Resistor R8 turns off Q2. When a short occurs, the GATE

pin is pulled low and Q3 turns off. Node 2 starts to charge

VEE AND

DRAIN

20V/DIV

(Q1)

I

D

5A/DIV

500µs/DIV

C4 and Q2 turns on, pulling the UV pin low and resetting

the circuit breaker. As soon as C4 is fully charged, R8 turns

off Q2, UV goes high and the GATE starts to ramp up. Q3

turns back on and quickly pulls node 2 back to VEE. Diode

D1 clamps node 3 one diode drop below VEE. The duty

cycle is set to 10% to prevent Q1 from overheating.

Figure 8. Voltage Step on

Input Supply Waveforms

–48V RTN

–48V RTN

Q2

2N2222

*

D1

1N4148

–48V

* DIODES INC. SMAT70A

(SHORT PIN)

549k

R4

R6

549k

1%

1%

R9

10k

1%

16.5k

3

UV

2

OV

R5

1%

1µF

100V

R7

1M

5%

C4

3

ZVN3310

R8

510k

5%

NODE 2

50V/DIV

GATE

2V/DIV

2

Q3

Figure 10. Automatic Restart After Current Fault

Figure 9. Circuit for Input Steps with Small C2 (<10nF)

8

V

DD

C2

15nF

100V

1

C3

+

100µF

100V

7

4250 F10a

V

EE

1s/DIV

4

SENSE

56

R1

0.02Ω

43

5%

21

LT4250L PWRGD

GATE DRAIN

R3

1k, 5%

R2

C1

10Ω

470nF

5%

25V

Q1

IRF530

4250lhf

9

LT4250L/LT4250H

U

WUU

APPLICATIONS INFORMATION

Undervoltage and Overvoltage Detection

The UV (Pin 3) and OV (Pin 2) pins can be used to detect

undervoltage and overvoltage conditions at the power

supply input. The UV and OV pins are internally connected

to analog comparators with 130mV and 20mV of hysteresis respectively. When the UV pin falls below its threshold

or the OV pin rises above its threshold, the GATE pin is

immediately pulled low. The GATE pin will be held low until

UV is high and OV is low.

The undervoltage and overvoltage trip voltages can be

programmed using a three resistor divider as shown in

Figure 11. With R4 = 549k, R5 = 6.49k and R6 = 10K, the

undervoltage threshold is set to 38.5V (with a 43V release

from undervoltage) and the overvoltage threshold is set to

71V. The resistor divider will also gain up the hysteresis

at the UV pin and OV pin to 4.5V and 1.2V at the input

respectively.

PWRGD/PWRGD Output

The PWRGD/PWRGD output can be used to directly enable a power module when the input voltage to the module

is within tolerance. The LT4250L has a PWRGD output for

modules with an active low enable input, and the LT4250H

has a PWRGD output for modules with an active high

enable input.

When the DRAIN voltage of the LT4250H is high with

respect to VEE (Figure 12) or the GATE voltage is low, the

internal transistor Q3 is turned off and I1 and Q2 clamp the

PWRGD pin one SAT drop (≈0.3V) above the DRAIN pin.

Transistor Q2 sinks the module’s pull-up current and the

module turns off.

When the DRAIN voltage drops below VDL and the GATE

voltage is high, Q3 will turn on, shorting the bottom of I

1

to DRAIN and turning Q2 off. The pull-up current in the

module pulls the PWRGD pin high and enables the

module.

When the DRAIN voltage of the LT4250L is high with

respect to VEE or the GATE voltage is low, the internal pulldown transistor Q2 is off and the PWRGD pin is in a high

impedance state (Figure␣ 13). The PWRGD pin will be

pulled high by the module’s internal pull-up current source,

turning the module off. When the DRAIN voltage drops

below VDL and the GATE voltage is high, Q2 will turn on and

the PWRGD pin will pull low, enabling the module.

The PWRGD signal can also be used to turn on an LED or

optoisolator to indicate that the power is good as shown

in Figure 14.

Gate Pin Voltage Regulation

When the supply voltage to the chip is more than 20V, the

GATE pin voltage is regulated at 13.5V above VEE. The gate

voltage will be no greater than 18V for supply voltages up

to 80V.

–48V RTN

4250 F11

VUV = 1.255

VOV = 1.255

–48V RTN

(SHORT PIN)

–48V RTN

R4

R4 + R5+ R6

()

R5 + R6

R4 + R5+ R6

()

R6

–48V

3

R5

2

R6

8

V

DD

UV

LT4250L/LT4250H

OV

V

EE

4

Figure 11. Undervoltage and Overvoltage Sensing

10

–48V RTN

(SHORT PIN)

R4

R5

R6

*

–48V

* DIODES INC. SMAT70A

3

2

V

GATE

C1

DD

I

1

LT4250H

UV

–

+

OV

∆V

GATE

+

GATE

V

GH

–

+

V

DL

+

–

–

V

SENSE

EE

4

56

43

R1

21

Figure 12. Active High Enable Module

ACTIVE HIGH

ENABLE MODULE

+

IN

ON/OFF

–

IN

+

V

OUT

–

V

OUT

4250lhf

8

PWRGD

1

V

+

C3

Q2

Q3

V

EE

R2

Q1

DRAIN

R3

7

C2

V

4250 F12

WUUU

APPLICATIO S I FOR ATIO

LT4250L/LT4250H

–48V RTN

(SHORT PIN)

–48V RTN

LT4250L

R4

3

R5

2

R6

*

–48V

* DIODES INC. SMAT70A

UV

–

+

OV

∆V

GATE

+

GATE

–

V

GH

+

V

DL

+

–

–

V

SENSE

EE

4

R1

21

GATE

56

C1

43

Figure 13. Active Low Enable Module

PACKAGE DESCRIPTIO

ACTIVE LOW

ENABLE MODULE

8

V

DD

PWRGD

1

+

C3

Q2

V

EE

7

DRAIN

R3

C2

R2

Q1

4250 F13

+

V

IN

ON/OFF

–

V

IN

+

V

OUT

–

V

OUT

–48V RTN

(SHORT PIN)

–48V RTN

*

–48V

* DIODES INC. SMAT70A

549k

6.49k

10k

PWRGD

R4

1%

3

UV

R5

2

1%

OV

R6

1%

SENSE

V

EE

4

R1

0.02Ω

5%

21

V

DD

LT4250L PWRGD

GATE DRAIN

Q1

IRF530

R2

10Ω

5%

R3

1k, 5%

C2

15nF

100V

5687

C1

470nF

25V

43

R7

51k

5%

1

MOC207

+

C3

100µF

100V

4250 F14

Figure 14. Using PWRGD to Drive an Optoisolator

U

N8 Package

8-Lead PDIP (Narrow .300 Inch)

(Reference LTC DWG # 05-08-1510)

0.300 – 0.325

(7.620 – 8.255)

0.065

(1.651)

0.009 – 0.015

(0.229 – 0.381)

+0.035

0.325

–0.015

+0.889

8.255

()

–0.381

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm)

TYP

0.045 – 0.065

(1.143 – 1.651)

0.100

(2.54)

BSC

8-Lead Plastic Small Outline (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1610)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

×

°

45

0.016 – 0.050

(0.406 – 1.270)

0°– 8° TYP

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

(3.302 ± 0.127)

0.018 ± 0.003

(0.457 ± 0.076)

S8 Package

(1.270)

0.130 ± 0.005

0.125

(3.175)

MIN

0.004 – 0.010

(0.101 – 0.254)

0.050

BSC

0.020

(0.508)

MIN

0.255 ± 0.015*

(6.477 ± 0.381)

0.228 – 0.244

(5.791 – 6.197)

0.189 – 0.197*

(4.801 – 5.004)

7

8

1

2

0.400*

(10.160)

MAX

876

1234

5

6

0.150 – 0.157**

(3.810 – 3.988)

3

4

5

N8 1098

SO8 1298

4250lhf

11

LT4250L/LT4250H

TYPICAL APPLICATION

U

Using an EMI Filter Module

Many applications place an EMI filter module in the power

path to prevent switching noise of the module from being

injected back onto the power supply. A typical application

–48V RTN

(SHORT PIN)

–48V RTN

8

V

R4

549k

1%

R5

6.49k

1%

R6

10k

1%

*

–48V

* DIODES INC. SMAT70A

DD

3

UV

LT4250L

2

OV

V

EE

4

R1

0.02Ω

5%

PWRGD

DRAIN

GATE

SENSE

21

1

7

C2

15nF

100V

6

5

43

C1

470nF

25V

Q1

IRF530

R3

1k

5%

R2

10Ω

5%

1N4003

C3

0.1µF

100V

V

V

Figure 15. Typical Application Using a Filter Module

using the Lucent FLTR100V10 filter module is shown in

Figure 15. When using a filter, an optoisolator is required

to prevent common mode transients from destroying the

PWRGD and ON/OFF pins.

R7

51k

5%

LUCENT

C6

0.1µF

100V

1

2

4

JW050A1-E

+

V

IN

ON/OFF

–

V

IN

CASE

V

OUT

SENSE

TRIM

SENSE

V

OUT

3

+

+

–

–

9

8

7

6

5

4250 F15

+

MOC207

+

V

OUT

IN

LUCENT

FLTR100V10

–

V

OUT

IN

CASE

+

C4

0.1µF

100V

–

C5

+

100µF

100V

C7

100µF

16V

5V

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC®1421 Dual Hot Swap Controller with Additional –12V Control Operates from 3V to 12V

LTC1422 Hot Swap Controller in SO-8 System Reset Output with Programmable Delay

LT1640AH/LT1640AL –48V Hot Swap Controller in SO-8 LT4250 is a Pin-Compatible Upgrade to LT1640

LT1641-1/LT1641-2 +48V Hot Swap Controller in SO-8 Foldback Current Limit, 9V to 80V, Auto-Retry/Latch-Off

LTC1642 Fault Protected Hot Swap Controller Operates Up to 16.5V, Protected to 33V

LTC1643 PCI Hot Swap Controller 3.3V, 5V, 12V, –12V Supplies for PCI Bus

LTC1645 Dual Hot Swap Controller Operates from 1.2V to 12V, Power Sequencing

LTC1646 Dual CompactPCI Hot Swap Controller 3.3V, 5V Supplies with Precharge and Local PCI Reset Logic

LTC1647 Dual Hot Swap Controller Dual ON Pins for Supplies from 3V to 15V

LTC4211 Hot Swap Controller with Multifunction Current Control 2.5V to 16.5V Supplies, Active Inrush Current Limiting

LTC4251 –48 Hot Swap Controller in SOT-23 Active Current Limiting, Fast Comparator

for Catastrophic Faults

LTC4252 –48 Hot Swap Controller in MSOP Active Current Limiting, Fast Comparator for Catastrophic

Faults, Separate UV/0V Pins, Power-Good Output

4250lhf

LT/TP 0402 2K • PRINTED IN USA

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

LINEAR TECHNOLOGY CORPORATION 2001

Loading...

Loading...