Page 1

FEATURES

■

Hot SwapTM Controller for Positive

and Negative Supplies

■

Supply Tracking Mode

■

±2.7V to ±16.5V Operation

■

Analog Current Limit with Foldback

■

Allows Safe Board Insertion and Removal

from a Live Backplane

■

Open-Collector Power Good Comparators

■

Automatic Retry or Latchoff After a Current Fault

■

Dual Undervoltage Lockout Comparator Inputs

■

Current Fault Indication

U

APPLICATIO S

■

Live Board Insertion

■

RAID Systems

■

–5.2V ECL Supplies

■

Industrial Controls

■

Split Supply Systems

LT4220

Dual Supply

Hot Swap Controller

U

DESCRIPTIO

The LT®4220 16-pin dual voltage Hot Swap controller

allows a board to be safely inserted and removed from a

live backplane. The device operates with any combination

of 2.7V to 16.5V and –2.7V to –16.5V supplies. Using two

external N-channel pass transistors, the board supply

voltages can be ramped up at an adjustable rate. A selectable tracking mode allows dual supply tracking control for

ramping the positive and negative supplies together.

The LT4220 features foldback current limit and latches off

both gates if either supply remains in current limit longer

than an adjustable time period. The IC can be configured

for automatic restart after a delay set by the same timer.

A power good signal indicates when the output voltages

monitored by the two FB comparators are within tolerance,

and the gate drive signals are at their full on voltage.

The LT4220 is available in a 16-lead narrow SSOP

package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Hot Swap is a trademark of Linear Technology Corporation.

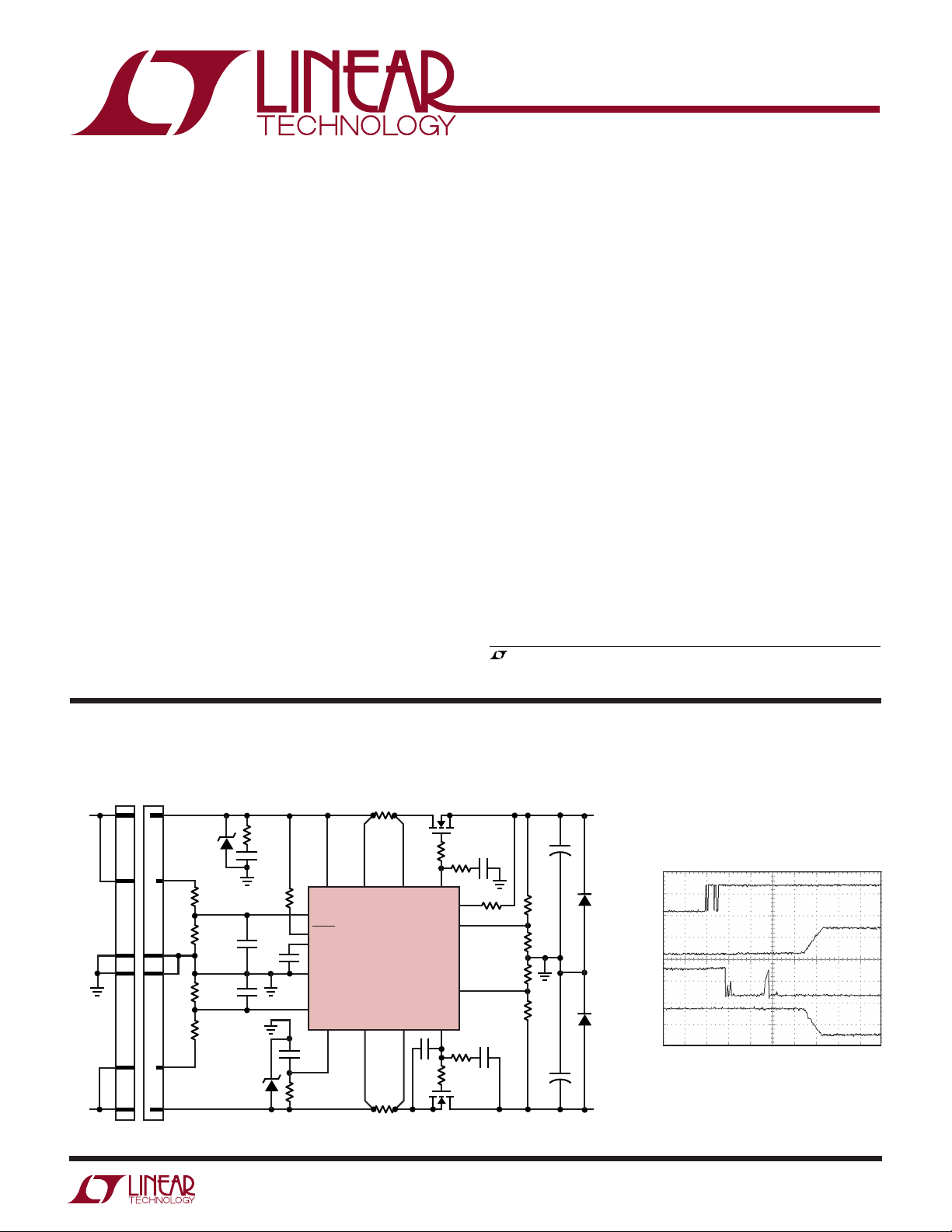

TYPICAL APPLICATIO

±12V 10A Hot Swap Controller

+

12V

V

–12V

V

CC

EE

V

36.5k

4.99k

CONNECTOR 1

CONNECTOR 2

4.99k

36.5k

V

IN

R13

Z1*

R1

R2

R4

R3

–

IN

10Ω

C4

100nF

R15

20k

C7

10nF

10nF

C6

1µF

C8

Z2*

* 1SMA13AT3 TRANSIENT

VOLTAGE SUPPRESSOR

12

11

R14

10Ω

8

9

6

C5

1µF

U

TRACK

+

ON

FAULT

TIMER

GND

–

ON

V

R

S

0.005Ω

716

V

CC

LT4220

EE

SENSEK

12

R

S

0.005Ω

+

SUB85N03-04

R5

10Ω

15 14

+

SENSE

PWRGD

–

SENSE

GATE

34

C3

100nF

–

SUB85N03-04

Q1

GATE

Q2

12V

+

V

OUT

R10

R12

CL1

R9

36.5k

R11

36.5k

CL2

+

–12V

V

OUT

4220 TA01

12V

V

+

IN

12V

+

V

OUT

–12V

–

V

IN

–12V

V

–

OUT

TIME (10ms/DIV)

–

4220f

D1

IN4001

D2

IN4001

+

C1

R6

10nF

1k

+

10

R16, 20k

13

+

FB

4.99k

4.99k

5

–

FB

–

C2

R8

10nF

1k

R7

10Ω

1

Page 2

LT4220

WW

W

U

ABSOLUTE MAXIMUM RATINGS

(Notes 1, 2)

VCC to GND ............................................................. 22V

VEE to GND ........................................................... –22V

TRACK, TIMER .............................. – 0.3V to VCC + 0.3V

ON+, FB+................................. V

ON–, FB–.................................. V

GATE+................................................ –0.3V to VCC + 8V

GATE–..............................–16.5V with VEE = –22V to 0V

SENSE+............................................. –0.3V to VCC + 5V

SENSE–, SENSEK ....................... VEE – 0.3V to V

PWRGD, FAULT ................................. –0.3V to VCC + 5V

Operating Temperature Range

LT4220C...........................................0°C ≤ TA ≤ 70°C

LT4220I ....................................... –40°C ≤ TA ≤ 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

– 0.3V to VCC + 0.3V

EE

– 0.3V to V

EE

CC

EE

+ 0.3V

+ 3V

U

W

U

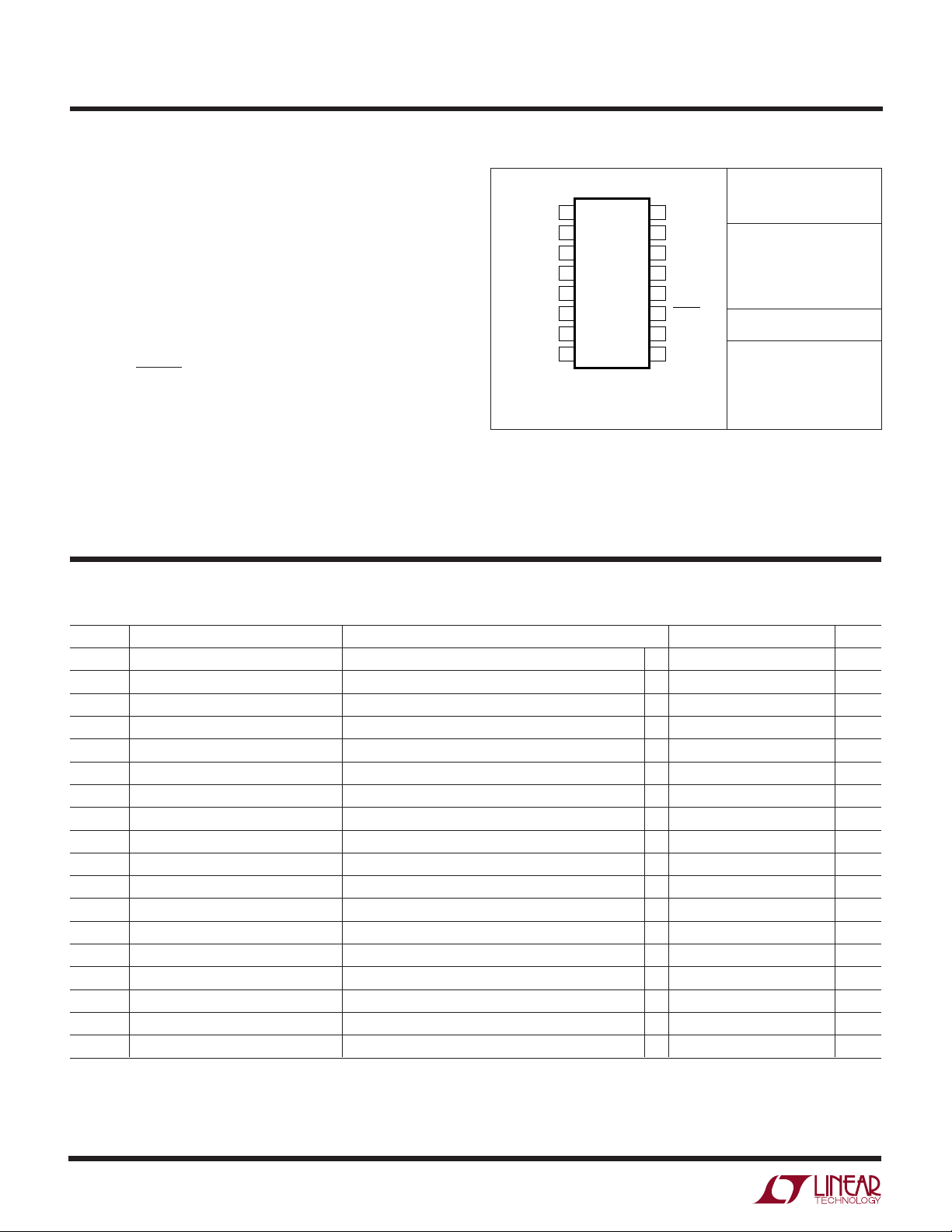

PACKAGE/ORDER INFORMATION

TOP VIEW

1

V

EE

SENSEK

SENSE

Consult LTC Marketing for parts specified with wider operating temperature ranges.

2

–

3

–

4

GATE

–

5

FB

–

6

ON

7

TRACK

8

TIMER

16-LEAD PLASTIC SSOP

T

= 125°C, θJA = 130°C/W

JMAX

GN PACKAGE

16

15

14

13

12

11

10

9

V

CC

SENSE

GATE

+

FB

+

ON

FAULT

PWRGD

GND

+

+

ORDER PART

NUMBER

LT4220CGN

LT4220IGN

GN PART MARKING

4220

4220I

DC ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V, VEE = –5V, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

I

CC

V

EE

I

EE

V

PLKO

V

MLKO

V

ON+H

V

ON+HYS

∆V

ON+H

∆V

ON–H

V

ON–HYS

V

ON–H

+

I

ON

–

I

ON

V

FB+H

V

FB+HYS

V

FB–H

V

FB–HYS

VCC Operating Range ● 2.7 16.5 V

VCC Supply Current ● 2.7 4 mA

VEE Operating Range ● –2.7 –16.5 V

VEE Supply Current –1.6 –2.4 mA

VCC Undervoltage Lockout ● 2.35 2.45 2.55 V

VEE Undervoltage Lockout ● –2.4 –2.45 –2.5 V

ON+ ON Threshold ON+ Rising ● 1.22 1.24 1.26 V

ON+ Hysteresis ● 25 50 70 mV

ON+ ON Threshold Line Regulation V

ON– ON Threshold Line Regulation V

ON– Hysteresis ● 25 50 70 mV

ON– ON Voltage Threshold ON– Falling ● –1.22 –1.24 –1.26 V

ON+ Input Current V

ON– Input Current V

FB+ PWRGD Voltage Threshold FB+ Rising ● 1.22 1.24 1.26 V

FB+ Hysteresis Gate = 5V ● 25 50 70 mV

FB– PWRGD Voltage Threshold FB– Falling ● –1.22 –1.24 –1.26 V

FB– Hysteresis Gate = 3V ● 25 50 70 mV

= 2.7V, V

CC

= 2.7V, V

CC

+

= 2V ● 0.01 ±1 µA

ON

–

= GND ● 0.01 ±1 µA

ON

= –2.7V to VCC = 16.5V, VEE = –16.5V ● 0.02 0.15 mV/V

EE

= –2.7V to VCC = 16.5V, VEE = –16.5V ● 0.05 1 mV/V

EE

2

4220f

Page 3

LT4220

DC ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V, VEE = –5V, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

+

I

INFB

I

INFB

∆V

∆

VFB–H

V

SENSE

V

SENSE

I

GATEUP

I

GATEUP

I

GATEDN

I

GATEDN

∆V

∆V

V

TIMERH

V

TIMERL

I

TIMERUP

I

TIMERDN

I

TIMER(R)

V

OL

I

OH

V

FOL

I

FPH

V

TRKTHR

I

TRK

V

TRKFB

V

TRKFB

FB+ Input Current FB+ = 3V ● 0.09 ±1 µA

–

FB– Input Current FB– = –3V ● 0.08 ±1 µA

FB+ PWRGD Threshold Line Regulation V

FB+H

FB– PWRGD Threshold Line Regulation V

+

SENSE+ Trip Voltage (VCC – V

–

SENSE– Trip Voltage (V

+

GATE+ Pull-Up Current Charge Pump On, V

–

GATE– Pull-Up Current V

+

GATE+ Pull-Down Current Any Fault Condition, V

–

GATE– Pull-Down Current Any Fault Condition, V

+

External N-Channel GATE+ Drive V

GATE

–

External N-Channel GATE– Drive V

GATE

SENSEK

+

)V

SENSE

– V

SENSE

= 2.7V, V

CC

= 2.7V, V

CC

+

= 0V, GATE+ – 0.5V ● 61522 mV

FB

+

V

= 1V, GATE+ – 0.5V 36 48 60 mV

FB

–

–

)V

= 0V, GATE– – 0.5V ● –10 –15 –22 mV

FB

–

= –1V, GATE– – 0.5V –43 –52 –61 mV

V

FB

– = –3V ● –6 –10 –14 µA

GATE

+

– VCC, VCC = 2.7V, VEE = –2.7V ● 3.5 4 6 V

GATE

= 5V to 16.5V, VEE = –5V to –16.5V 5 6.5 8 V

V

CC

–

– VEE, VCC = 2.7V, VEE = –2.7V ● 3.5 5.2 6 V

GATE

= 5V to 16.5V, VEE = –5V to –16.5V 7.5 8.5 9 V

V

CC

= –2.7V to VCC = 16.5V, VEE = –16.5V ● 0.015 0.15 mV/V

EE

= –2.7V to VCC = 16.5V, VEE = –16.5V ● 0.05 0.5 mV/V

EE

+

= 7V ● –9 –13 –17 µA

GATE

+

= 1V ● 20 40 60 mA

GATE

–

= VEE + 4V ● 30 70 130 mA

GATE

TIMER High Threshold, Sets FAULT ● 1.22 1.24 1.26 V

TIMER Low Threshold, Allows Restart ● 0.4 0.5 0.6 V

TIMER Pull-Up Current TIMER = 0V ● –40 –65 –85 µA

TIMER Pull-Down Current TIMER = 1V ● 2 3.3 4.5 µA

TIMER Current Ratio I

TIMERDN/ITIMERUP

57 %

PWRGD Output Low Voltage IO = 2mA ● 0.3 V

= 5mA 0.5 V

I

O

PWRGD Leakage Current V

= 16.5V ● 0.1 2 µA

PWRGD

FAULT Output Low Voltage IO = 2mA ● 0.3 V

= 5mA 0.5 V

I

O

FAULT Leakage Current V

= 16.5V ● 0.06 2 µA

FAULT

TRACK Input Threshold ● 0.3 0.8 1.1 V

TRACK Input Current TRACK = 16.5V ● 0.05 2 µA

+

TRACK Mode FB+ Threshold I

–

TRACK Mode FB– Threshold I

+

= 0µA, TRACK = V

GATE

–

= 0µA, TRACK = V

GATE

(Note 3) ● 40 70 mV

CC

(Note 3) ● 40 80 mV

CC

4220f

3

Page 4

LT4220

AC ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V, VEE = –5V, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

+

t

PHLON

t

PLHON

t

PHLFB

t

PLHFB

t

PHLON

t

PLHON

t

PHLFB

t

PLHFB

t

SENSE

t

SENSE

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: All currents into device pins are positive; all currents out of device

ON+ Low to GATE+ Low 5k Pull-Up to GATE+, 1nF Load Capacitor ● 0.6 0.8 1.2 µs

+

ON+ High to GATE+ High 5k Pull-Up to GATE+, 1nF Load Capacitor ● 0.6 1.5 3 µs

+

FB+ Low to PWRGD Low 5k Pull-Up to PWRGD ● 0.5 0.8 1.2 µs

+

FB+ High to PWRGD High 5k Pull-Up to PWRGD ● 0.6 1.25 3 µs

–

ON– Low to GATE– Low 5k Pull-Up to GATE–, 1nF Load Capacitor ● 0.6 1 1.5 µs

–

ON– High to GATE– High 5k Pull-Up to GATE–, 1nF Load Capacitor ● 1 2.1 3.5 µs

–

FB– Low to PWRGD Low 5k Pull-Up to PWRGD ● 0.6 1 1.5 µs

–

FB– High to PWRGD High 5k Pull-Up to PWRGD ● 0.8 1.25 2 µs

+

SENSE+ to GATE+ Low 1nF On GATE+, 100mV Step, 5k Pull-Up ● 146 µs

–

SENSE– to GATE– Low 1nF On GATE–, 100mV Step, 5k Pull-Up ● 146 µs

pins are negative. All voltages referenced to ground (GND) unless

specified.

+

Note 3: The absolute voltage difference between FB

force either the GATE

+

or GATE– current to 0µA.

and FB– required to

UW

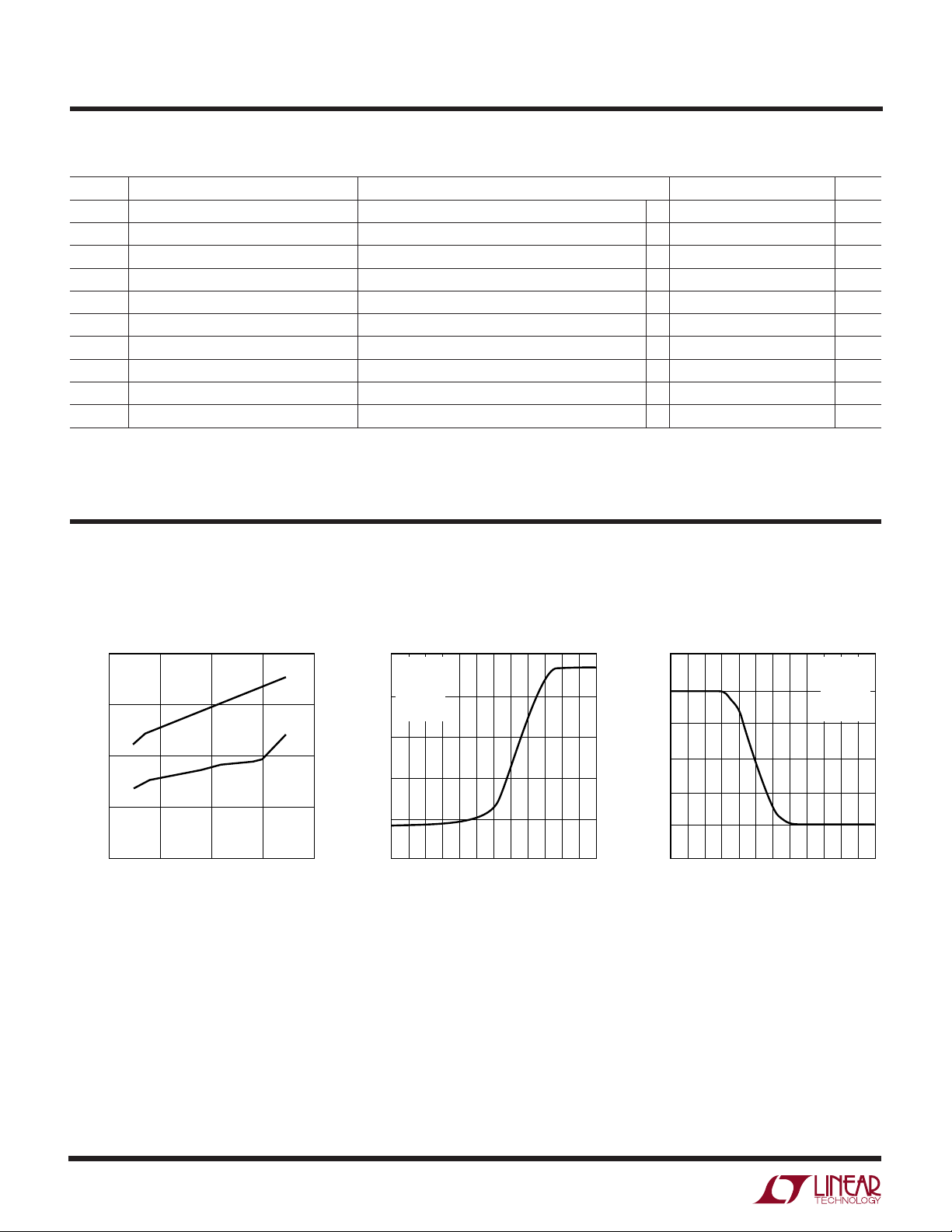

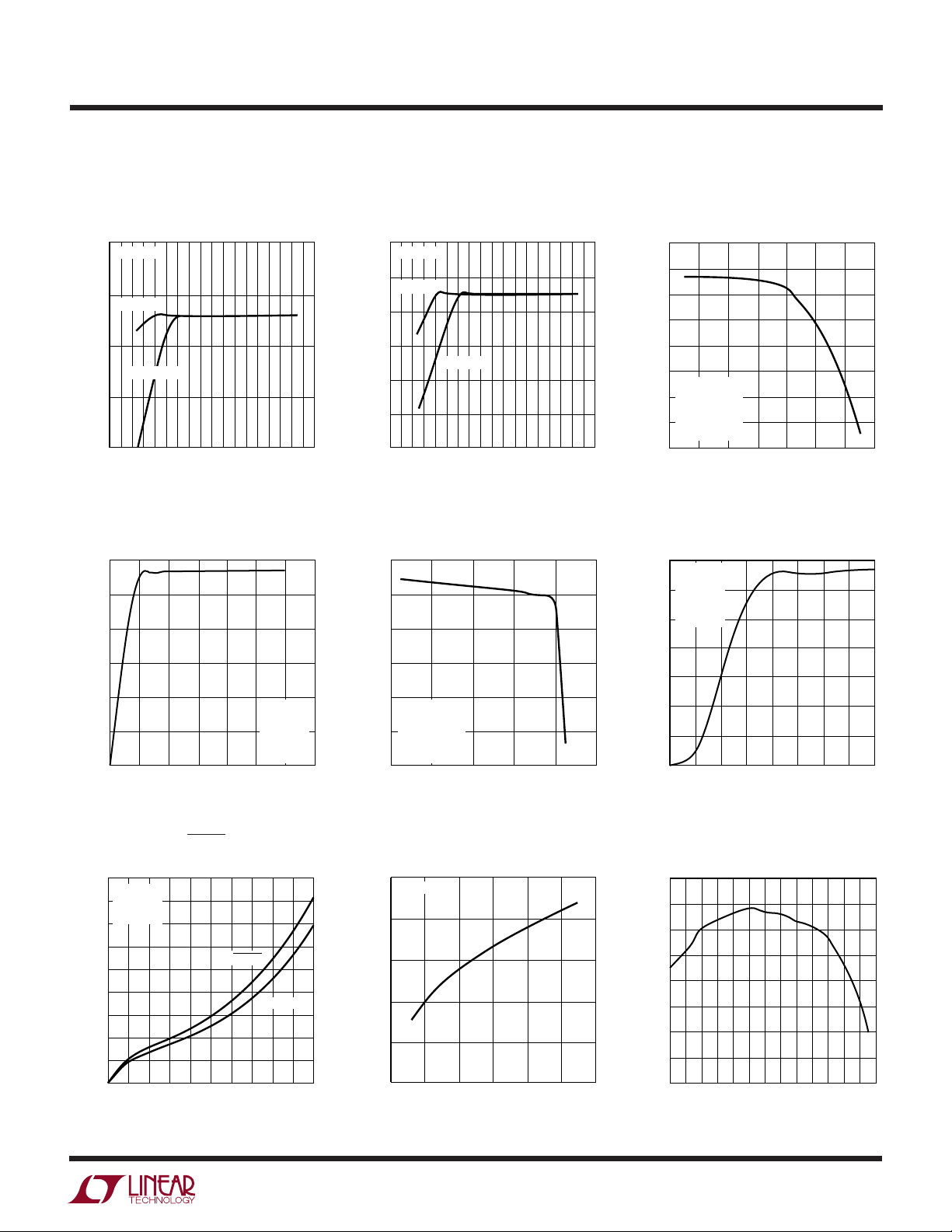

TYPICAL PERFOR A CE CHARACTERISTICS

Supply Current vs Supply Voltage

4

TA = 25°C

I

CC

3

2

I

EE

SUPPLY CURRENT (mA)

1

0

0

5

10

SUPPLY VOLTAGE (V)

Positive Circuit Breaker Sense

Voltage vs FB+ Voltage

50

VCC = 5V

= –5V

V

EE

+

= 2V

ON

40

–

= –2V

ON

= 25°C

T

A

30

VOLTAGE (mV)

+

20

-SENSE

CC

V

10

0

15

20

4220 G01

–1.5

–0.5 0 0.5

–1.0

FB+ VOLTAGE (V)

1.0 1.5 –1.5

4220 G02

Negative Circuit Breaker Sense

Voltage vs FB– Voltage

60

50

40

VOLTAGE (mV)

–

30

20

SENSEK-SENSE

10

0

–0.5 0 0.5 1.0 1.5

–1.0

–

VOLTAGE (V)

FB

VCC = 5V

= –5V

V

EE

+

= 2V

ON

–

= –2V

ON

= 25°C

T

A

4220 G03

4

4220f

Page 5

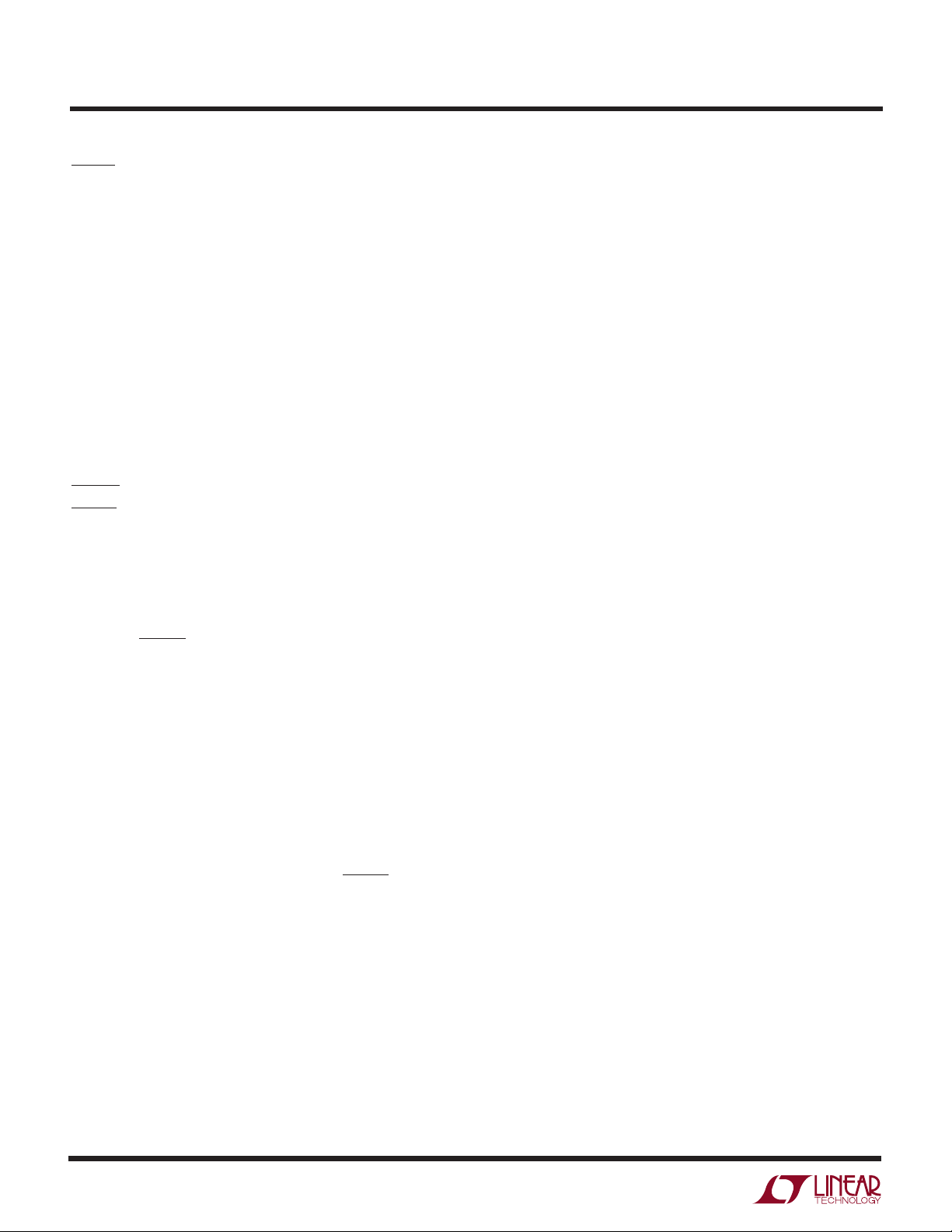

UW

TYPICAL PERFOR A CE CHARACTERISTICS

GATE+ Drive vs V

8

TA = 25°C

) (V)

7

CC

VEE = –5V

– V

+

GATE

6

DRIVE (V

+

GATE

VEE = –2.7V

5

4

CC

3069121518

VCC (V)

4220 G04

GATE– Drive vs V

10

TA = 25°C

9

VCC = 5V

) (V)

EE

8

– V

–

GATE

7

6

DRIVE (V

–

GATE

5

4

EE

VCC = 2.7V

3069121518

VEE (V)

4220 G05

GATE+ Pull-Up Current vs

GATE+ Voltage

16

14

12

10

8

6

PULL-UP CURRENT (µA)

VCC = 5V

+

GATE

= –5V

V

4

EE

+

= V

V

2

0

0

SENSE

V

SENSE

TA = 25°C

CC

–

= V

EE

24

1357

GATE+ VOLTAGE (V

LT4220

6

+

– VCC) (V)

GATE

4220 G06

GATE+ Pull-Down Current vs

GATE+ Voltage

60

50

40

30

20

PULL-DOWN CURRENT (mA)

+

10

GATE

0

0

48

2 6 10 14

GATE

+

VOLTAGE (V)

PWRGD and FAULT VOL vs

Sink Current

900

VCC = 5V

800

= –5V

V

EE

= 25°C

T

A

700

600

500

(mV)

OL

400

V

300

200

100

0

02

4

SINK CURRENT (mA)

VCC = 5V

= –5V

V

EE

+

ON

= 0V

+

= 2V

FB

= 25°C

T

A

12

4220 G07

FAULT

PWRGD

6810

4220 G10

GATE– Pull-Up Current vs

GATE– Voltage

12

10

8

6

4

PULL-UP CURRENT (µA)

–

VCC = 5V

= –5V

V

EE

SENSE

SENSE– = V

TA = 25°C

0

GATE

+

= V

CC

EE

48

2106

–

VOLTAGE (V

GATE

2

0

TIMER Pull-Up Current vs V

75

TA = 25°C

70

65

60

55

TIMER PULL-UP CURRENT (µA)

50

3069121518

VCC (V)

GATE

–

– VEE) (V)

CC

4220 G08

4220 G11

GATE– Pull-Down Current vs

GATE– Voltage

70

VCC = 5V

= –5V

V

EE

–

60

= 0V

ON

–

= –2V

FB

50

T

= 25°C

A

40

30

20

PULL-DOWN CURRENT (mA)

–

10

GATE

0

0

1

GATE

3658

24

–

VOLTAGE (V

ON+, ON– and FB+, FB

Hysteresis vs Temperature

45.0

44.5

44.0

43.5

43.0

42.5

42.0

HYSTERESIS VOLTAGE (mV)

41.5

41.0

–40

–20 0

20 60

TEMPERATURE (°C)

–

– VEE) (V)

GATE

–

40 80

7

4220 G09

4220 G12

4220f

5

Page 6

LT4220

UW

TYPICAL PERFOR A CE CHARACTERISTICS

FB+ and ON+ Threshold Voltage vs

Temperature

1.241

1.240

1.239

1.238

1.237

THRESHOLD VOLTAGE (V)

1.236

1.235

–40

–20 0

TEMPERATURE (°C)

40 80

20 60

4220 G13

FB– and ON– Threshold Voltage vs

Temperature

–1.241

–1.240

–1.239

–1.238

–1.237

THRESHOLD VOLTAGE (V)

–1.236

–1.235

–40 20 60

–20 0

TEMPERATURE (°C)

GATE+, GATE– Pull-Up Current vs

Temperature

15

+

GATE

14

13

40 80

4220 G14

TIMER Pull-Up Current vs

Temperature

70

69

68

67

66

TIMER PULL-UP CURRENT (µA)

65

64

–40 20 60

–20 0

TEMPERATURE (°C)

40 80

4220 G15

12

PULL-UP CURRENT (µA)

–

, GATE

+

11

GATE

10

–40 20 60

–20 0

TEMPERATURE (°C)

–

GATE

40 80

4220 G16

6

4220f

Page 7

LT4220

U

UU

PI FU CTIO S

VEE (Pin 1): Negative Supply. The negative supply input

ranges from –2.7V to –16.5V for normal operation. IEE is

typically –1.6mA. An internal undervoltage lockout circuit

disables the device for inputs greater than –2.45V. A 10Ω,

1µF RC bypass network from V

transients from the device.

SENSEK (Pin 2): Negative Supply Current Limit Kelvin

Sense Pin. Connect to V

IN

SENSE– (Pin 3): Negative Supply Current Limit Sense Pin.

A sense resistor is placed in the supply path between

SENSEK and SENSE–. The current limit circuit will regulate

the voltage across the sense resistor to

–50mV (SENSEK – SENSE–) when the FB– voltage is less

than –0.7V. If V

–

goes above –0.7V, the voltage across

FB

the sense resistor decreases linearly and stops at –15mV

when V

–

is 0V. If current limit is not used, connect to

FB

SENSEK.

GATE– (Pin 4): Gate Drive for the External Negative Supply

N-Channel FET. An internal 10µA current source drives the

pin. An external capacitor connected from the GATE– pin

to V

– will control the rising slope of the V

OUT

The voltage is clamped to 9V above VEE.

When the current limit is reached, the GATE– pin voltage

will be adjusted to maintain a constant voltage across the

–

R

resistor while the timer capacitor starts to charge. If

S

the TIMER pin voltage exceeds 1.24V, the fault latch will be

set and both GATE– and GATE+ pins will be pulled low.

The GATE– pin is pulled to VEE whenever the ON+ pin is

below 1.24V, the ON– pin is above –1.24V, or either supply

is in the undervoltage lockout voltage range, or the fault

latch is set by the TIMER pin rising above 1.24V.

FB– (Pin 5): Negative Power Good Comparator Input. This

pin monitors the negative output voltage (V

external resistive divider. When the voltage on FB– is

below –1.24V and the initial GATE– drive voltage has

reached a maximum (indicated by setting the internal

GATE– good latch) and the FB+ release conditions are met,

the PWRGD pin is released. PWRGD is pulled low when the

FB– pin is above –1.185V. Note the PWRGD pin is wireORed with the FB+ pin conditions.

–.

– to the V

IN

pin decouples

EE

– signal.

OUT

–) with an

OUT

FB– also controls the negative supply current limit sense

amplifier input offset to provide foldback current limit. The

FB– pin linearly reduces the negative supply sense amplifier offset from –52mV to –15mV for FB– in the range

–0.75V < FB– < 0V. To disable VEE PWRGD and foldback

current limit, the FB– pin should be set to a voltage in the

range: –1.3V > FB– > VEE + 0.5V but should never be more

negative then –5.8V for normal operation.

ON– (Pin 6): The Negative Supply Good Comparator Input.

This pin monitors the negative input voltage (VEE) with an

external resistive divider for undervoltage lockout. When

the voltage at the ON– pin is below the V

high-to-low

ON–H

threshold (–1.24V), the negative supply is considered

good. If the ON– pin rises above –1.185V, both GATE– and

GATE+ are pulled low. If ON– is not used, the ON– pin

should be set to –1.3V > ON– > VEE + 0.5V.

TRACK (Pin 7): Supply Tracking Mode Control. If the TRACK

pin is pulled high, the internal supply tracking circuit will

be enabled during start-up. The TRACK circuit monitors

the FB+ and the FB– pins to keep their magnitude within a

small voltage range by controlling the GATE+ and GATE

–

charge currents. The tracking is disabled when either FB

comparator indicates the output is good. Tracking is reenabled if ON+ is pulled below 1.185V, ON– is pulled above

–1.185V or either supply is below the internal undervoltage

lockout. Typically, the TRACK pin is tied to GND or to VCC.

If left floating, tracking is enabled.

TIMER (Pin 8): Fault Time Out Control. An external timing

capacitor at this pin programs the maximum time the part

is allowed to remain in current limit before issuing a fault

and turning off the external FETs. Additionally, for

autorestart, this pin controls the time before an autorestart

is initiated.

When the part goes into current limit, a 65µA pull-up

current source starts to charge the timing capacitor. When

the voltage reaches V

TIMERH

(1.24V), the internal fault

latch is set, FAULT pulls low and both GATE pins are pulled

low; the pull-up current will be turned off and the capacitor

is discharged by a 3.3µA pull-down current. When the

TIMER pin falls below 0.5V, the part is allowed to restart

if the ON+ pin is pulsed below 1.185V, thereby resetting

internal fault latch—typically done by connecting the

4220f

7

Page 8

LT4220

U

UU

PI FU CTIO S

FAULT pin to the ON+ pin, otherwise the part remains

latched off.

To disable the timeout circuit breaker, connect the TIMER

pin to GND.

GND (Pin 9): Supply Ground Pin.

PWRGD (Pin 10): Open-Collector Output to GND. PWRGD

goes to high impedance after the initial GATE– and final

GATE+ pins have reached their maximum voltage and after

the FB+ pin goes above 1.24V low-to-high threshold and

after the FB– pin falls below –1.24V high-to-low threshold.

An external pull-up resistor can pull the pin to a voltage

higher or lower than VCC. If not used, PWRGD can be left

floating or tied to GND.

FAULT (Pin 11): Open-Collector Output to GND. The

FAULT pin is pulled low whenever the TIMER pin rises

above V

TIMERH

internal fault latch. It goes to high impedance whenever the

internal fault latch is reset. The fault latch is reset with

either internal undervoltage lockout conditions, or by the

ON comparators if the TIMER pin is also below 0.5V. If not

used, the FAULT pin can be left floating or tied to GND.

ON+ (Pin 12): Positive Supply Good Comparator Input. It

monitors the positive input voltage (VCC) with an external

resistive divider for undervoltage lockout. When the voltage on ON+ is above the V

(1.24V) the positive supply is considered good. If ON

drops below 1.185V, both GATE– and GATE+ are pulled

low.

If ON+ is pulled low after a current limit fault and when the

TIMER pin is below 0.5V, the fault latch is reset allowing

the part to turn back on. Typically the FAULT pin is tied

back to the ON+ pin for autorestart. If not used, the ON+ pin

should be set to a voltage in the range of 1.3V < ON+ < V

+ 0.3V. The ON+ pin requires a bypass capacitor connected

to ground.

FB+ (Pin 13): Positive Power Good Comparator Input. This

pin monitors the positive output voltage (V

external resistor divider. When the voltage on FB+ is above

the V

FB+H

drive voltage has reached a maximum, the PWRGD is

(1.24V) threshold, thereby setting the

high-to-low threshold

ON+H

+) with an

OUT

low-to-high threshold (1.24V) and the GATE

+

CC

+

released. PWRGD is pulled low when the FB+ pin is below

1.185V. The PWRGD pin is wire-ORed with the FB– pin

conditions.

FB+ also controls the positive current limit sense amplifier

input offset to provide foldback current limit. The FB+ pin

linearly reduces the positive sense amplifier offset from

48mV to 15mV for FB+ in the range 0.85V > FB+ > 0V. If

PWRGD and foldback current limit are not used, the FB

+

pin should be set to a voltage in the range of 1.3V < FB+ <

VCC + 0.3V.

GATE+ (Pin 14): High Side Gate Drive for the External

Positive Supply N-Channel FET. An internal charge pump

guarantees at least 3.5V above VCC, for supply voltages at

±2.7V increasing to a minimum of 5V above VCC for supply

voltages greater than ±5V. A 10µA pull-up current source

drives the pin. An external capacitor connected from the

GATE+ pin to GND will control the rising slope of the GATE

+

signal. The voltage is clamped to 7V above VCC.

When the current limit is reached, the GATE+ pin voltage

will be adjusted to maintain a constant voltage across the

+

R

resistor while the timer capacitor starts to charge. If

S

the TIMER pin voltage exceeds 1.24V, the GATE+ pin will

be pulled low.

The GATE+ pin is pulled to GND whenever the ON+ pin is

below 1.24V, the ON– pin is above –1.24V, either supply is

in the undervoltage lockout voltage range, or the TIMER

pin rises above 1.24V.

SENSE+ (Pin 15): Positive Supply Current Limit Sense Pin.

A sense resistor must be placed in the supply path between V

and SENSE+. The current limit circuit will

CC

regulate the voltage across the sense resistor to 50mV

(V

– SENSE+) when the FB+ voltage is greater than

CC

0.85V. If V

+

goes below 0.85V, the voltage across the

FB

sense resistor decreases linearly and stops at 15mV when

+

V

is 0V.

FB

VCC (Pin 16): Positive Supply. The positive supply input

ranges from 2.7V to 16.5V for normal operation. ICC is

typically 2.7mA. An internal undervoltage lockout circuit

disables the chip for inputs less than 2.45V. Place a 0.1µF

bypass capacitor next to the VCC pin.

8

4220f

Page 9

BLOCK DIAGRA

1.24V

W

+

–

+

TIMER AND LOGIC

S

Q

R

R

Q

FAULT

LATCH

FAULT

CURRENT LIMIT

FROM SENSE AMPS

I

LIM

FAULT

11

LT4220

V

CC

60µA

TIMER

8

3µA

ON

12

ON

6

FB

13

FB

5

TRACK

7

0.5V

1.24V

+

+

–

–

+

–1.24V

1.24V

+

–

+

–

P GATE

GOOD

–

+

–1.24V

–

–

ON

PUMP

V

V

CC

EE

UVLO

AND

GOOD

GATE ON

10µA

+

V

CC

–

+

FB

+

–

53mV

+

GATE

14

+

SENSE

15

+

TRACK

–

EN

V

CC

ON

10µA

–

GATE

+

4

SRQ

Q

GATE GOOD

LATCHES

10

PWRGD

–

N GATE

GOOD

SRQ

Q

SRQ

Q

TRACK OFF

LATCH

TOFF

4220 BD

SUBSTRATE

+

52mV

WEAK DIODES

V

1

EE

–

GND

9 16

V

2

3

CC

SENSEK

SENSE

V

CC

–

4220f

9

Page 10

LT4220

WUW

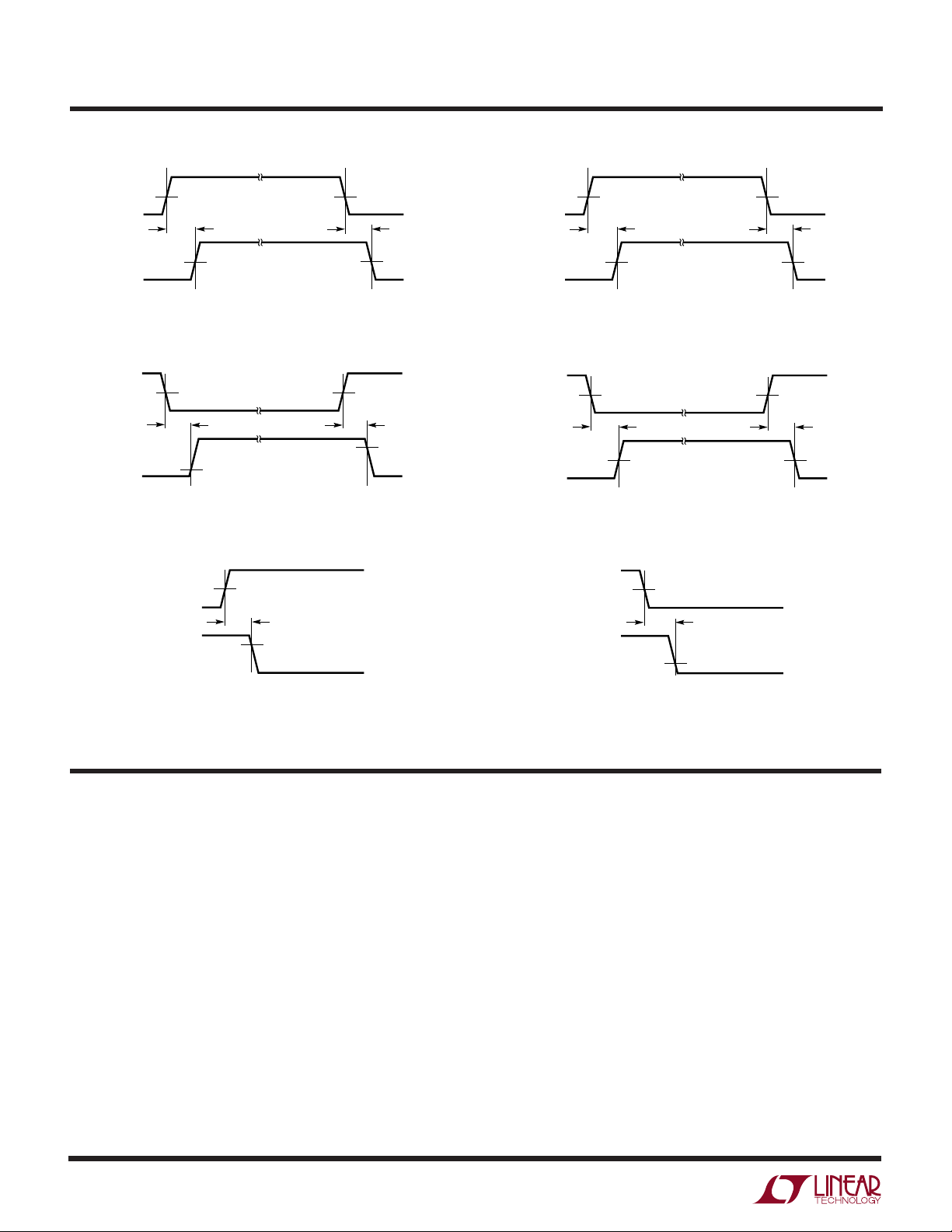

TI I G DIAGRA S

ON

GATE

ON

GATE

V

+

0V

+

0V

1V 1V

+

t

PLHON

0.5V

10V

100mV

t

4220 F01

PHLON

+

FB

PWRGD

+

0V

0V

1V 1V

+

t

PLHFB

2.5V

Figure 1. ON+-to-GATE+ Timing Figure 2. FB+-to-PWRGD Timing

0V

–

–

EE

–1V

t

PLHON

VEE + 1.2V

–1V

–

VEE + 3.5V

t

PHLON

4220 F03

–

FB

PWRGD

0V

–

0V

–1V

t

2.5V

PLHFB

–

Figure 3. ON–-to-GATE– Timing Figure 4. FB–-to-PWRGD Timing

VCC – SENSE

GATE

100mV

+

0V

+

50mV

t

SENSE

10V

VEE – SENSE

+

0V

4220 F05

GATE

0V

–

–

–50mV

t

–2V

SENSE

100mV

+

t

PHLFB

2.5V

4220 F02

–1V

–

t

PHLFB

2.5V

4220 F04

4220 F06

–100mV

V

EE

–

Figure 5. SENSE+-to-GATE+ Timing

WUUU

APPLICATIO S I FOR ATIO

Hot Circuit Insertion

When circuit boards are inserted into a live backplane, the

circuit board bypass capacitors can draw large peak

currents from the backplane power bus as they charge up.

The LT4220 is designed to turn on a board’s ±V dual

supplies in a controlled manner, allowing the circuit board

to be safely inserted or removed from a live backplane. The

part provides supply tracking as well as undervoltage and

overcurrent protection. Power good and fault output signals indicate, respectively, if both power output voltages

are ready or if an overcurrent time-out fault has occurred.

Figure 6. SENSE–-to-GATE– Timing

The dual power supply on the circuit board is controlled

with two external N-channel pass transistors Q1 and Q2 in

the ±V dual power supply path. The sense resistors R

and R

C2 control the V

– provide current detection while capacitor C1 and

S

OUT

+ and V

– slew rate. Optionally, the

OUT

+

S

TRACK pin can be tied to VCC enabling the dual output

voltages to ramp up together by tracking the voltages at

the FB+ and FB– pins. Resistors R6 and R8 provide current

control loop compensation while R5 and R7 prevent high

frequency oscillations in Q1 and Q2. C3 and R8 on Q2

prevent fast dV/dt transients from turning Q2 on during

4220f

10

Page 11

WUUU

APPLICATIO S I FOR ATIO

LT4220

live insertion. Resistive dividers R1, R2 and R3, R4 provide undervoltage sensing. Resistor dividers R9, R10 and

R11, R12 provide a power good signal and control output

voltage tracking when TRACK is enabled.

Internal Supply Diodes

The LT4220 contains two internal diodes which clamp V

EE

and VCC with respect to GND in the event either supply pin

is floating. VEE is clamped one diode above GND and V

CC

is clamped one diode below GND. The current through

these diodes are designed to handle 10mA internal device

current and should not be used for high load current

conditions.

BACKPLANE

CONNECTOR

V

CC

ESD

CONTROL

V

EE

GND MUST CONNECT FIRST

STAGGERED

PCB EDGE

CONNECTOR

GND

+

V

IN

R13

1µF

10Ω

C4

100nF

12

11

C5

1µF

R14

10Ω

8

9

6

C6

Z1*

R1

R2

R4

R3

–

V

IN

*TRANSIENT VOLTAGE SUPPRESSOR

C7

C8

CONNECT FOR

AUTO RESTART

Z2*

TRACK

FAULT

TIMER

GND

ON

Initial Power-Up Sequence

After the power pins first make contact, transistors Q1 and

Q2 remain off. If the voltage at the ON+ and ON– pins

exceed the turn-on threshold voltage, the internal voltage

on the VCC and VEE power pins exceed the undervoltage

lockout threshold, and the timer pin voltage is less than

1.24V, the gate drive to transistors Q1 and Q2 will be

turned on. The voltage on the GATE+ and GATE– pins will

be regulated to control the inrush current if the voltage

across R

+

S

or R

–

exceeds the sense amplifier current

S

limit threshold. If supply tracking is enabled, each gate will

also be regulated to keep the magnitudes at the FB+ and

FB– pins within 50mV of each other.

+

R

ON

7

16 15 14

V

CC

+

–

V

EE

SENSEK

S

LT4220

R

S

SENSE

SENSE

–

R5

10Ω

+

PWRGD

–

C3

100nF

Q1

GATE

GATE

Q2

FB

FB

4321

R7

10Ω

+

V

OUT

C1

R6

10nF

1k

+

10

R16, 20k

13

+

R10

R12

5

–

C2

10nF

R11

–

R8

1k

+

CL1

D1

IN4001

R9

D2

IN4001

+

CL2

V

–

OUT

4220 F07

Figure 7. Hot Swap Controller on Daughter Board with Tracking Disabled

4220f

11

Page 12

LT4220

WUUU

APPLICATIO S I FOR ATIO

Whenever the output voltages reach their final value as

sensed by R9, R10 and R11, R12 and both gate signals are

fully on, the PWRGD pin will go high impedance.

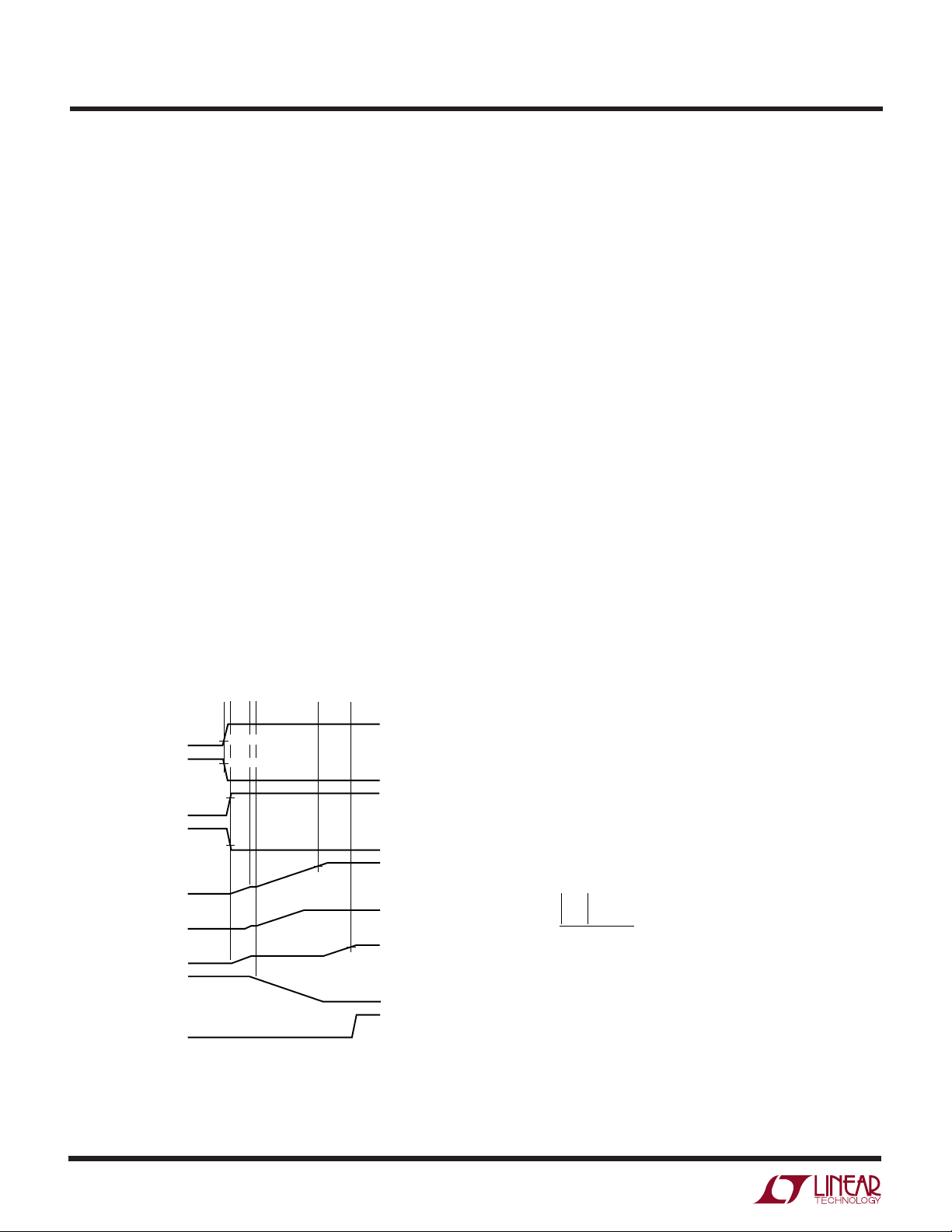

A typical timing sequence is shown in Figure 8 with

tracking enabled. The sequence is as follows:

1) The power pins make contact and the undervoltage

lockout thresholds are exceeded.

2) The ON comparator thresholds are exceeded and the

GATE pins start ramping up. V

+ follows GATE+ by

OUT

the N-channel FET threshold voltage.

3) GATE+ is limited by the tracking circuit because V

lags behind V

+. When V

OUT

– starts ramping, GATE

OUT

OUT

–

–

holds at approximately the threshold voltage of the

N-channel FET due to C2 slew rate control.

4) When the magnitude of V

GATE+ resumes ramping. The slowest V

the faster V

slew rate.

OUT

– catches up with V

OUT

will limit

OUT

OUT

+,

5) GATE+ internal gate good signal threshold is reached.

6) GATE– internal gate good signal threshold is reached,

enabling the FB output comparators. If both FB com-

12 3 4 5 6

V

GATE

CC

V

EE

+

ON

–

ON

+

+UVLO

–UVLO

parators indicate the output is good, the PWRGD pin

output goes high impedance and is pulled up by an

external pullup resistor.

Power Supply Ramping

For large capacitive loads, the inrush current will be limited

by the V

OUT

+ and V

– slew rate or by the fold-back

OUT

current limit. For a desired inrush current that is less than

the fold-back current limit, the feedback networks R6, C1

and R8, C2 can be used to control the V

slew rate. For

OUT

the desired inrush current and typical gate pull-up current,

the feedback network capacitors C1 and C2 can be calculated as:

C1 = (10µA • CL1)/I

C2 = (10µA • CL2)/I

+ and (1)

INRUSH

– (2)

INRUSH

where CL1 and CL2 are the positive and negative output

load capacitance. If the supply-tracking mode is enabled

(TRACK = High), during startup, the output with the

slowest slew rate will also limit the slew rate of the

opposite output (Note: Supply-tracking is also controlled

by the resistive dividers on the FB pins. See Supply

Tracking). Additionally, C1 and C2 should be greater than

5nF to prevent large overshoot in the output voltage for

transient loads with small capacitive loads.

Capacitor C3 and resistor R8 prevent Q2 from momentarily turning on when the power pins first make contact.

Without C3, capacitor C2 and C

would hold the gate

GD(Q2)

of Q2 near ground before the LT4220 could power up and

pull the gate low. The minimum required value of C3 can

be calculated by:

12

V

+

OUT

–

GATE

V

–

OUT

PWRGD

Figure 8. Typical Timing Sequence

4220 F08

VV

−

EE TH

C

3212

=

V

TH

CC

()•.

()

GD Q

2

+

(3)

where VTH is the MOSFET’s minimum gate threshold and

V

is the maximum negative supply input voltage. If

EEMAX

C2 is not used, the minimum value for C3 should be 10nF

to ensure stability. C2 and C3 must be the same type to

ensure tracking over temperature.

4220f

Page 13

WUUU

APPLICATIO S I FOR ATIO

LT4220

Current Limit/Electronic Circuit Breaker

The LT4220 features foldback current limit with an electronic circuit breaker that protects against short-circuits

or excessive supply currents. The current limit is set by

placing sense resistors between VCC (Pin 16) and SENSE

+

(Pin 15) and between SENSEK (Pin 2) and SENSE– (Pin 3).

An adjustable timer will trip an electronic circuit breaker if

the part remains in current limit for too long.

To prevent excessive power dissipation in the pass transistors and to prevent voltage spikes on the input supply

during overcurrent conditions at the output, the current

folds back as a function of the output voltage, which is

sensed at the feedback pins FB+ and FB– . When the voltage

at the FB+ (or FB–) pin is 0V, the sense amplifier offset is

15mV (–15mV), and limits the current to I

+

R

(–15mV/R

S

–

). As the output voltage increases, the

S

LIMIT

= 15mV/

sense amplifier offset increases until the FB+ (or FB–)

voltage reaches 0.85V (–0.75V), At which point the current limit reaches a maximum of I

(–52mV/R

–

).

S

LIMIT

= 48mV/R

+

S

Timer Function and Autorestart

The TIMER pin (Pin 8) provides a method for setting the

maximum time the LT4220 is allowed to operate in current

limit. When the current limit circuitry is not active, the

TIMER pin is pulled to GND by a 3.3µA current sink.

Whenever the current limit circuit becomes active, by

either a positive or negative sense amplifier operating in

current limit, a 65µA pull-up current source is connected

to the TIMER pin and the voltage rises with a slope equal

to dV/dt = 65µA/C

. The desired current limit time (t)

TIMER

can be set with a capacitor value of:

C

= t • 65µA/1.24V (4)

TIMER

If the current limit circuit turns off, the TIMER pin will be

discharged to GND at a rate of:

dV/dt = 3.3µA/C

TIMER

(5)

Whenever the TIMER pin ramps up and reaches the 1.24V

threshold, the internal fault latch is set and the FAULT pin

(Pin 11) is pulled low. GATE+ is pulled down to ground,

GATE– is pulled down to VEE, and the TIMER pin starts

ramping back to GND by the 3.3µA current sink. After the

fault latch is set, the LT4220 can be restarted by pulling the

ON+ pin low after the TIMER pin falls below 0.5V. The

LT4220 can also be restarted by cycling either supply

beyond its UVLO. Otherwise the part remains latched off.

For autorestart, the FAULT pin can be tied to the ON+ pin.

The autorestart will occur after the TIMER pin falls below

0.5V.

Undervoltage Detection

The ON+ and ON– pins can be used to detect an undervoltage

condition at the power supply inputs. The ON+ and ON

–

pins are connected to analog comparators with 50mV of

hysteresis. If the ON+ pin falls below its threshold voltage

or the ON– pin rises above its threshold voltage, the GATE

pins are pulled low and held low until the ON+ and ON– pins

exceed their turn-on thresholds (1.24V and –1.24V). External capacitance at the ON pins may be required to filter

supply ringing from crossing the ON comparator threshold.

Additionally there is an internal undervoltage lockout on

both supplies of approximately VCC < 2.45V and VEE >

–2.45V. If either supply is in UVLO, both GATE pins will be

pulled low and all internal latches will be reset.

ON– Protection

If the ON– pin is driven directly and not connected to the

negative supply through a resistor divider, a 10k resistor

must be connected between the driver and the ON– pin.

Power Good Detection

The LT4220 includes two comparators for monitoring the

output voltages. The FB+ and the FB– pins are compared

against 1.24V and –1.24V internal references respectively.

The comparators exhibit 50mV of hysteresis. The comparator outputs are wire-ORed to the open collector PWRGD

pin that is enabled once both GATE+ and GATE– pins have

reached their maximum gate drive voltage as indicated by

the internal gate good latches. The PWRGD pin goes high

impedance when both FB+ and FB– inputs exceed V

and V

thresholds, GATE+ is fully on and Gate– initially

FB–H

FB+H

has been fully on.

4220f

13

Page 14

LT4220

WUUU

APPLICATIO S I FOR ATIO

Supply Tracking

If the TRACK pin (Pin 7) is high the supply power-up

tracking mode is enabled. This feature forces both supplies to reach their final value at the same time, during

power-up and for faults that drive the output supplies to

zero. During this mode the GATE pins are controlled to

keep the differential magnitude of the FB pins to within

50mV. The FB pins are scaled versions of the output

voltages. Therefore, control of the FB pins, via the GATE

pins, will control the output voltages at the same scale.

|∆V

FB(TRK)

| = |V

FB

+

–

– V

| (6)

FB

Supply tracking will continue until: either FB pin reaches

the associated PWRGD threshold. If any fault condition

occurs that turns the GATE pins off, supply tracking will be

reenabled. The GATE off conditions include: (1) either ON

pin detects undervoltage, (2) internal undervoltage lockout, (3) the fault latch is set by a current limit time-out.

VEE Bypassing

The VEE supply pin should be filtered with an RC network

to reduce high dV/dt slew rates from disturbing internal

circuits. Typical RC bypassing sufficient to prevent circuit

misbehavior is R14 = 10Ω and C5 = 1µF. The GATE–,

SENSEK and SENSE– pins have been designed such that

they can be pulled below or above VEE for short periods of

time while the VEE pin is reaching its steady state voltage.

If desired, a higher R14 • C5 time constant may be used to

prevent short circuit transients from tripping the V

EE

undervoltage lockout circuit at –2.45V. R14 should be

sufficient to decouple C5 from causing transients on V

IN–

during live insertion.

Under the condition of a short circuit on V

inductance and resistance in the V

– path will cause VIN–

IN

–, parasitic

OUT

to collapse toward 0V causing the VEE pin voltage to also

discharge toward 0V before the external FET can be turned

off (typically 7µs to 10µs). To prevent a UVLO condition

from occurring, the R14 • C5 time constant should be

sufficient to hold the VEE pin voltage out of the VEE UVLO

voltage range. If the VEE pin reaches its UVLO voltage,

GATE+ will also be pulled low. For the case where C3 is

large, causing an even slower N-channel FET turnoff,

higher RC bypassing may be necessary to prevent tripping

the VEE UVLO.

ON+, ON– Bypass Capacitors

Bypass capacitors are required from ON+ to ground and

ON– to ground. A typical time constant is:

TC (ON+) = (R1||R2)C7 = 44µs

TC (ON–) = (R3||R4)C8 = 44µs

Supply Ringing

Normal circuit design practice calls for capacitive bypassing of the input supply to active devices. The opposite is

true for Hot Swap circuits that are connected into a

backplane, where capacitive loading would cause transients during an abrupt connection to the backplane. With

little or no capacitive decoupling on the powered side of

the N-channel FETs, connection transients or load transients will typically cause ringing on the supply leads due

to parasitic inductance. It is recommended to use a

snubber circuit comprising of a series 10Ω and 0.1µF

capacitor to dampen transient ringing. The supply

decoupling circuit on the VEE pin also provides a snubber

for V

–.

IN

Additionally, if the supply voltage overshoot can exceed

the ±22V maximum rating on the part, a transient voltage

suppressor is recommended. Voltage transients can occur during load short-circuit conditions, where parasitic

inductance in the supply leads can build up energy before

the external N-channel FET can be turned off. This is

especially true for the negative side FET where a large C3

value slows the turn off of the N-channel FET. Subsequent

overshoot when the FET is finally turned off can be as

much as 2× the supply voltage even with the snubber

circuit. Additional protection using a transient suppressor

may be needed to prevent exceeding the maximum supply

voltage rating.

Supply Reversal Protection

A variety of conditions on V

supply reversal. To protect devices connected to V

and V

– protection diodes should be used. 1N4001

OUT

OUT

+ and V

– may result in

OUT

OUT

+

diodes can be used for most aplications. Connection of

these diodes (D1, D2) are shown in the front page Typical

Application.

4220f

14

Page 15

PACKAGE DESCRIPTIO

LT4220

U

GN Package

16-Lead Plastic SSOP (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1641)

.045 ±.005

.254 MIN

RECOMMENDED SOLDER PAD LAYOUT

.007 – .0098

(0.178 – 0.249)

.016 – .050

NOTE:

1. CONTROLLING DIMENSION: INCHES

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

*DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

(0.406 – 1.270)

INCHES

(MILLIMETERS)

.150 – .165

.0250 TYP.0165 ±.0015

.015

(0.38 ± 0.10)

0° – 8° TYP

± .004

× 45°

.229 – .244

(5.817 – 6.198)

.053 – .068

(1.351 – 1.727)

.008 – .012

(0.203 – 0.305)

16

15

12

.189 – .196*

(4.801 – 4.978)

12 11 10

14

13

5

4

3

678

.0250

(0.635)

BSC

.009

(0.229)

9

(0.102 – 0.249)

REF

.150 – .157**

(3.810 – 3.988)

.004 – .0098

GN16 (SSOP) 0502

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

4220f

15

Page 16

LT4220

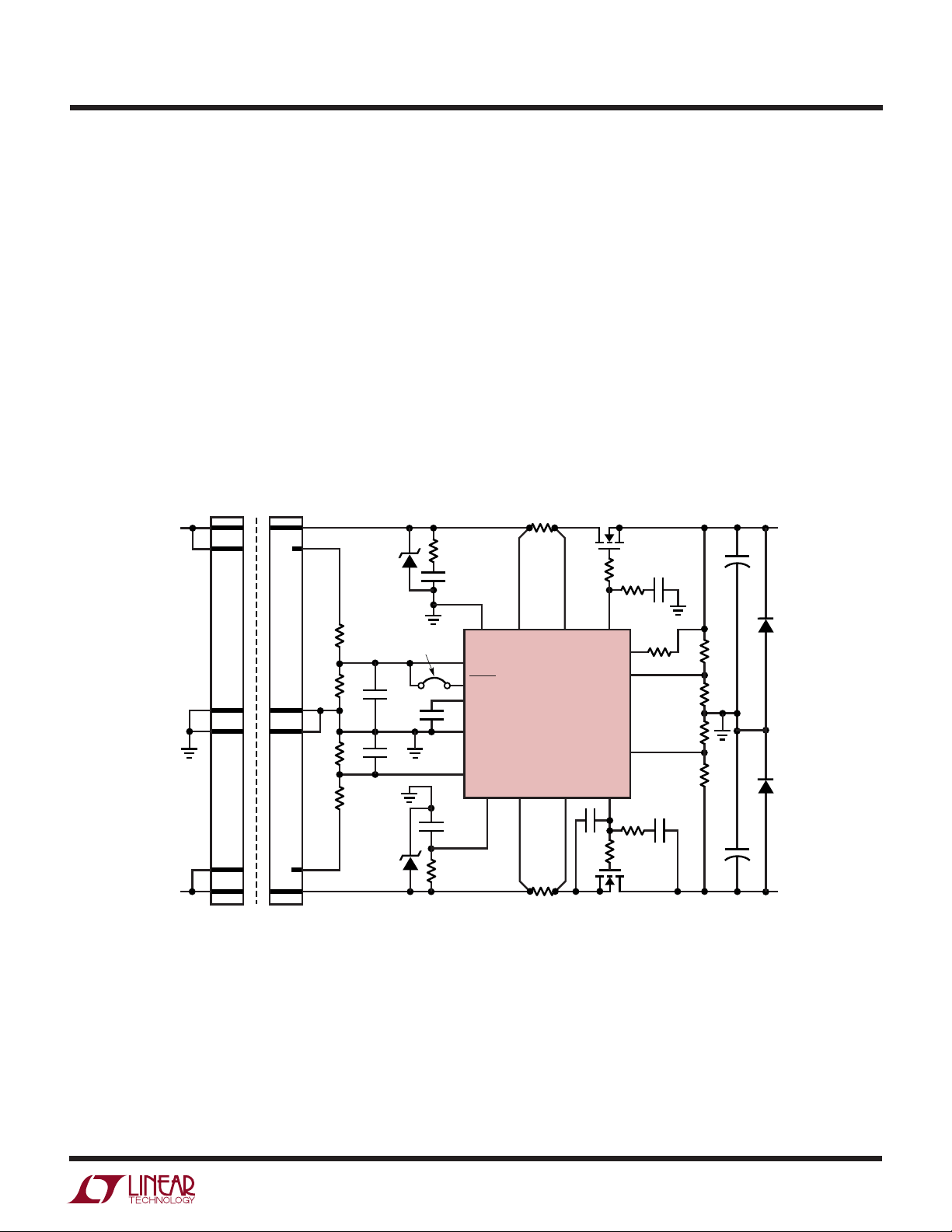

TYPICAL APPLICATIO

U

GND

STAGGERED

PCB EDGE

CONNECTOR

RPG

5.1k

CL1

ESD

CONTROL

CL2

+

+

4220 F09

V

V

OUT+

OUT

–

R9

R10

R12

R11

BACKPLANE

CONNECTOR

+

R

V

SENSEK

R14

10Ω

CC

S

SENSE

LT4220

SENSE

–

R

S

V

CC

CONNECT FOR

R1

AUTO RESTART

C7

C8

R2

C6

1µF

R4

R3

C5

1µF

V

EE

Z1*

R13

10Ω

C4

100nF

716 15 14

TRACK

12

+

ON

11

FAULT

8

TIMER

9

GND

6

–

ON

V

EE

Z2*

Q1

SUB85N03-04

R5

R6

10Ω

1k

+

+

GATE

PWRGD

+

FB

–

FB

–

–

GATE

4321

C3

R7

100nF

10Ω

Q2

SUB85N03-04

POWER GOOD

C1

10nF

10

13

5

C2

R8

10nF

1k

GND MUST CONNECT FIRST

*TRANSIENT VOLTAGE SUPPRESSOR

Figure 9. Hot Swap Controller on Mainboard with Tracking

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC®1421 Dual Hot Swap Controller Two Circuit Breakers for Supplies from 3V to 12V and Supports –12V

LTC1422 Single Hot Swap Controller in SO-8 Operates from 3V to 12V

LTC1645 Dual Hot Swap Controller Operates from 1.2V to 12V, Allows Supply Sequencing

LTC1647 Dual Hot Swap Controller Operates from 2.7V to 16.5V, Separate ON Pins

LTC4211 Single Hot Swap Controller with Multifunction 2.5V to 16.5V, Active Inrush Limiting, Fast Comparator

Current Control

LTC4230 Triple Hot Swap Controller with Multifunction 1.7V to 16.5V, Active Inrush Limiting, Fast Comparator

Current Control

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

4220f

LT/TP 0403 2K • PRINTED IN USA

LINEAR TECHNOLOGY CORP ORATION 2003

Loading...

Loading...