A Positive-to-Negative Voltage Converter Can Be Used for

Stable Outputs Even with a Widely Varying Input – Design Note 433

Victor Khasiev

+

V

An obvious application o f a positive-to-negative conver ter

is generating a negative voltage output from a positive

input. However, a not-so-obvious use is to produce a s table

output voltage in an application that has a widely varying input. For example, a converter in a battery-powered

device, which has an inherently variable input voltage, can

produce a stable output voltage even if input voltage falls

below the absolute value of t he output voltage. However, an

obvious drawback is reverse polarity, which can be easily

o v e r c o m e i n t h i s a p p l i c a t i o n . T h e s u p p l i e d c i r c u i t r y c a n u s e

the negative output as the system ground and the negative

battery terminal as the “positive” voltage source.

This topology is particularly useful when the input varies

above or below the output. In such cases, a traditional

step-down regulator would not be able to regulate once

the battery voltage drops below the output, thus shortening the useful battery run time. Buck-boost solutions

and other topologies such as a SEPIC solve this problem,

but they tend to be more complicated and expensive. The

positive-to-negative converter topology presented here

combines the simplicity of a step-down converter and

the regulation range of a buck-boost topology.

A new generation of Linear Technology high voltage syn-

®

chronous step-down converters, such as the LT

3845,

make it possible to implement positive-to-negative

conversions for a variety of applications.

Basic Operation

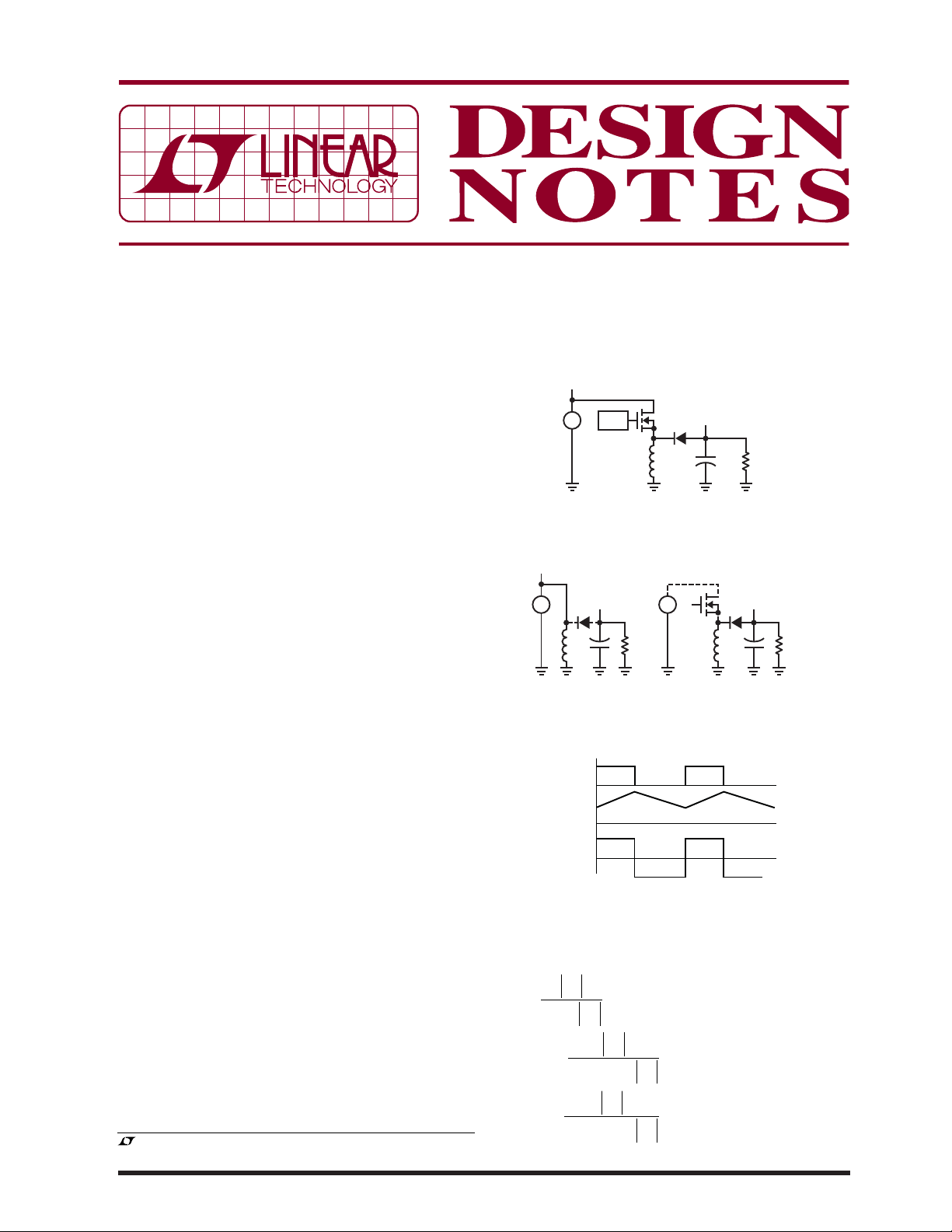

Figure 1 shows a simplifi ed block diagram of a positive -tonegative converter. Figure 2 shows an equivalent circuit,

which helps in understanding the basic operation of the

circuit in Figure 1. When transistor Q is on (Figure 2a),

diode D is reverse biased and the current in inductor L

increases. When Q is off (Figure 2b), inductor L changes

polarity, diode D becomes forward biased, and current

fl ows from inductor L to the load and capacitor C. The

voltage across c apacitor C and the load is negative, rel ative

to system ground. Figure 3 shows a timing diagram.

, LTC and LT are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

The duty cycle range can be found from following

expression:

D

D

D

IN

–

+

V1

PWM

–

V

D

O

+

CR

LOAD

DN433 F01

Q

L

Figure 1. Simplifed Block Diagram of

Positive-to-Negative Converter

+

V

IN

–

+

–

(2a) Transistor Q is On (2b) Transistor Q is Off

V

O

V1

D

+

C

L

+

+

V1

–

R

LOAD

+

–

V

O

Q

D

C

L

R

LOAD

+

DN433 F02

Figure 2. Equivalent Circuits Show the Operation

of the Positive-to-Negative Converter

Q GATE

I

L

V

L

ON ONOFF

V

IN

V

OUT

OFF

DN433 F03

Figure 3. Converter Timing Diagram

V

O

=

VV

+

IN O

V

MAX

MIN

=

=

V

O

VV

IN MIN O

IN MAX

+

()

V

O

++ V

()

O

01/08/433

Component Stress in a Positive-to-Negative

Topology

V

is the maximum voltage across transistor Q and

MAX

diode D (Figure 2), where:

V

The max imum current, I

MAX

= V

IN(MAX)

+ |VO|

MAX

, through transistor Q, inductor L and diode D can be derived based on the following

equations, assuming continuous conduction mode:

I

I

L

O

== =+

1–

D

MAX

VtD

,

dI

••

IN MIN MAX

()

L

,

II

MAX L

II

d

2

where t is a switching period.

Circuit Description

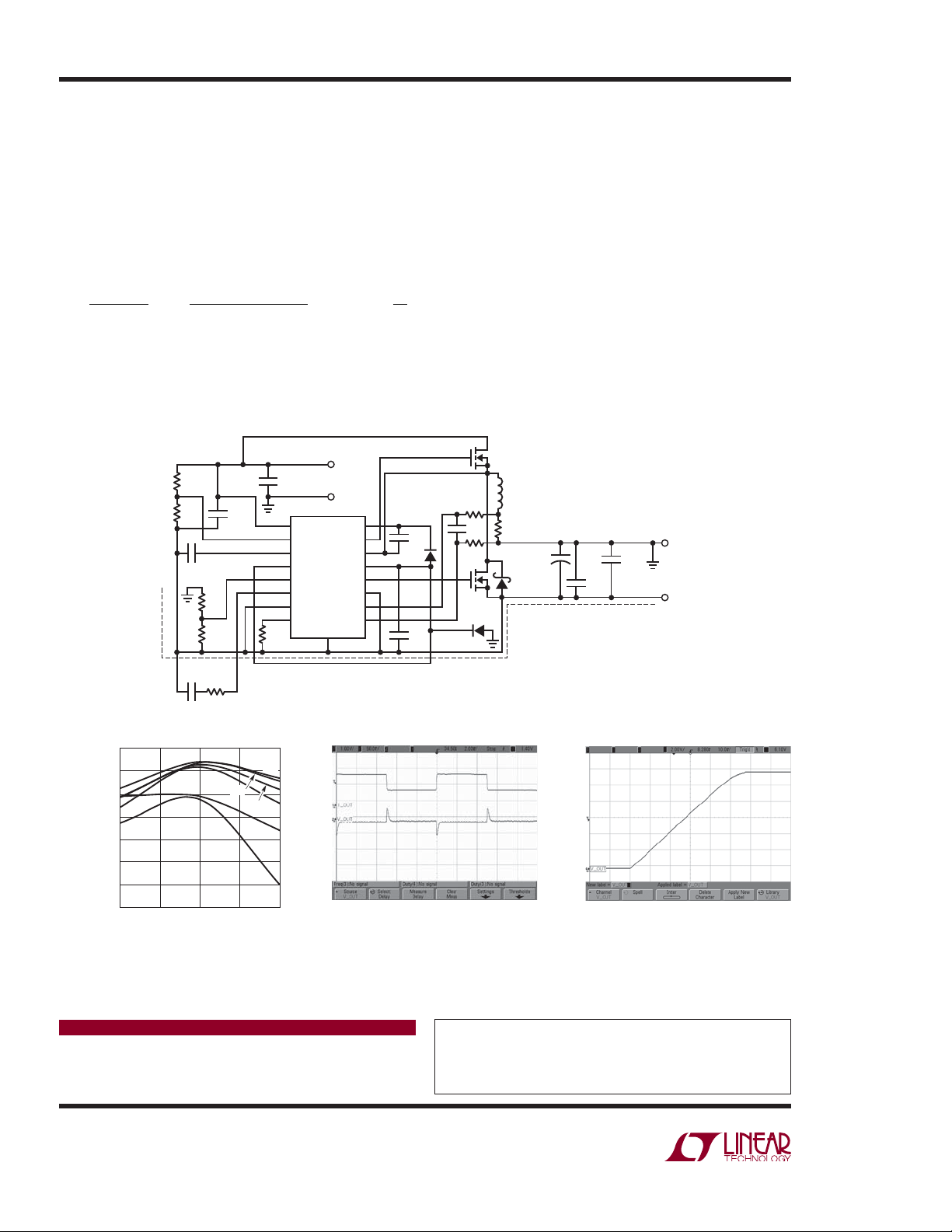

Figure 4 shows a 9V to 15V input to –12V at 3A output

converter. The high voltage LT3845 is used for several

V

IN

R1

249k

R2

51.1k

C1

0.1μF

R3

143k

R4

16.2k

–12V (IC GND)

C4

2.2μF

61.9k

9V TO 15V

C

IN1

22μF

25V

C5

0.47μF

R5

R6

49.9k

1

2

3

4

5

6

7

8

V

IN

SHDN

SS

BURST

FB

V

C

SYNC

f

SET

LT3845

SGND

V

GND

17

IN

BOOST

PGND

16

C3

15

TG

SW

V

CC

BG

+

I

S

–

I

S

0.1μF

14

D2

BAS521

13

12

11

10

9

C2

1μF

reasons, including the ability of its SW pin to withstand

65V, its integrated high side driver and differential current sense. The LT3845 can also provide synchronous

rectifi cation, which allows the use of effi cient MOSFETs

over less effi cient switching diodes.

The entire conver ter power path contains t he LT3 845 high

voltage PWM controller, MOSFETs Q1 and Q2, inductor

L1, diode D1 and output fi lter capacitors C

OUT1–COUT3

Diode D2 is a bootstrap diode and diode D3 provides bias

voltage for internal MOSFET drivers.

Conclusion

Very often electrical engineers have to design a negative

voltage source supplied from a positive voltage rail. The

positive-to -negative converter discus sed in the article can

be a good alternative to a fl yback or a SEPIC approach.

Q1

PH3075L

L1

13μH

R8

PB2020.153

10Ω

C6

R

S1

OPT

R7

10Ω

PH1875L

D3 BAS521

–12V (IC GND)

Q2

6mΩ

C

OUT1

16ME470WF

D1

B160

DN433 F04

+

C

10μF

25V

OUT3

C

10μF

25V

OUT2

GND

V

–12V

3A

OUT

.

Figure 4. Conversion of 9V-15V into –12V at 3A Based on the LT3845 High Voltage PWM Controller

91.5

15V

14V

13V

12V

10V9V

2.5

DN433 F05

91.0

90.5

90.0

89.5

EFFICIENCY (%)

89.0

88.5

88.0

1.0

1.5 2.0 3.0

LOAD CURRENT (A)

Figure 5. Effi ciency for the Figure 4

Circuit with Varying Input Voltage to

a Fixed –12V Output

Data Sheet Download

www.linear.com

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX: (408) 434-0507 ● www.linear.com

Figure 6. Transient Response to

an Output Load Step of 1A to 2A

call (408) 432-1900, Ext. 3161

Figure 7. Start-Up Waveform

for the Circuit in Figure 4 with

VIN = 14V, V

= –12V, I

OUT

For applications help,

dn433f LT/TP 0108 387K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2008

OUT

= 2A

Loading...

Loading...