LT3825

Isolated No-Opto

Synchronous Flyback Controller

FEATURES

■

Senses Output Voltage Directly from Primary Side

Winding—No Optoisolator Required

■

Synchronous Driver for High Efficiency

■

Input Voltage Limited Only by External

Power Components

■

Accurate Output Regulation Without User Trims

■

Switching Frequency from 50kHz to 250kHz

■

Synchronizable

■

Load Compensation

■

Programmable Undervoltage Lockout

■

Available in a Thermally Enhanced 16-Lead

TSSOP Package

U

APPLICATIO S

■

Isolated Medium Power (10W to 60W) Supplies

■

Isolated Telecom, Medical Converters

■

Instrumentation Power Supplies

■

Isolated Power over Ethernet Supplies

with Wide Input Supply Range

U

DESCRIPTIO

The LT®3825 is an isolated switching regulator controller

designed for medium power flyback topologies. A typical

application is 10W to 60W with input voltage limited only

by external power path components. A third transformer

winding provides output voltage feedback.

The LT3825 is a current mode controller that regulates

output voltage based on sensing secondary voltage via a

transformer winding during flyback. This allows for tight

output regulation without the use of an optoisolator,

improving dynamic response and reliability. Synchronous

rectification increases converter efficiency and improves

output cross regulation in multiple output converters.

The LT3825 operates in forced continuous conduction

mode which improves cross regulation in multiple winding

applications. Switching frequency is user programmable

and can be externally synchronized. The part also has load

compensation, undervoltage lockout and soft-start circuity.

, LTC and LT are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

Protected by U.S. Patents, including 6948466, 5841643.

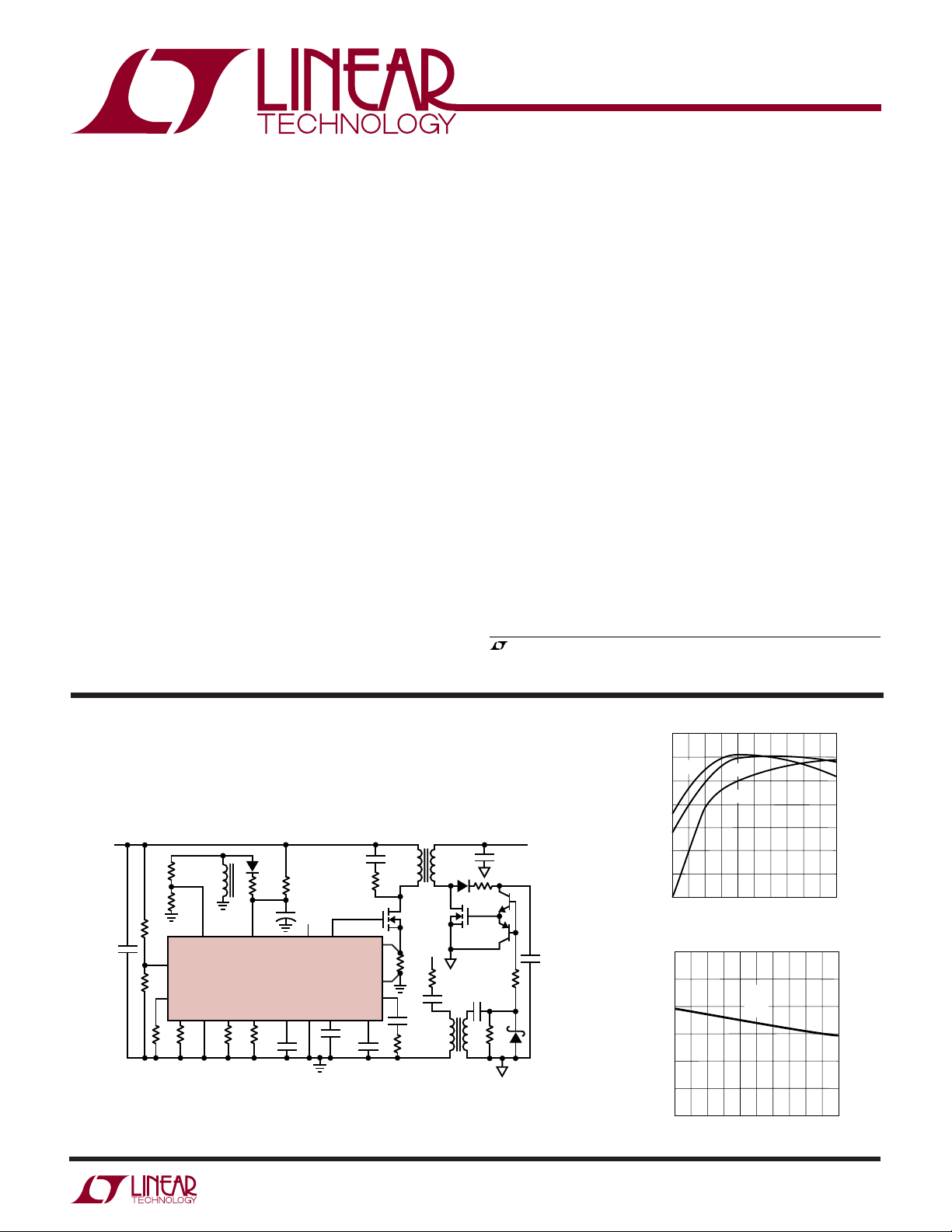

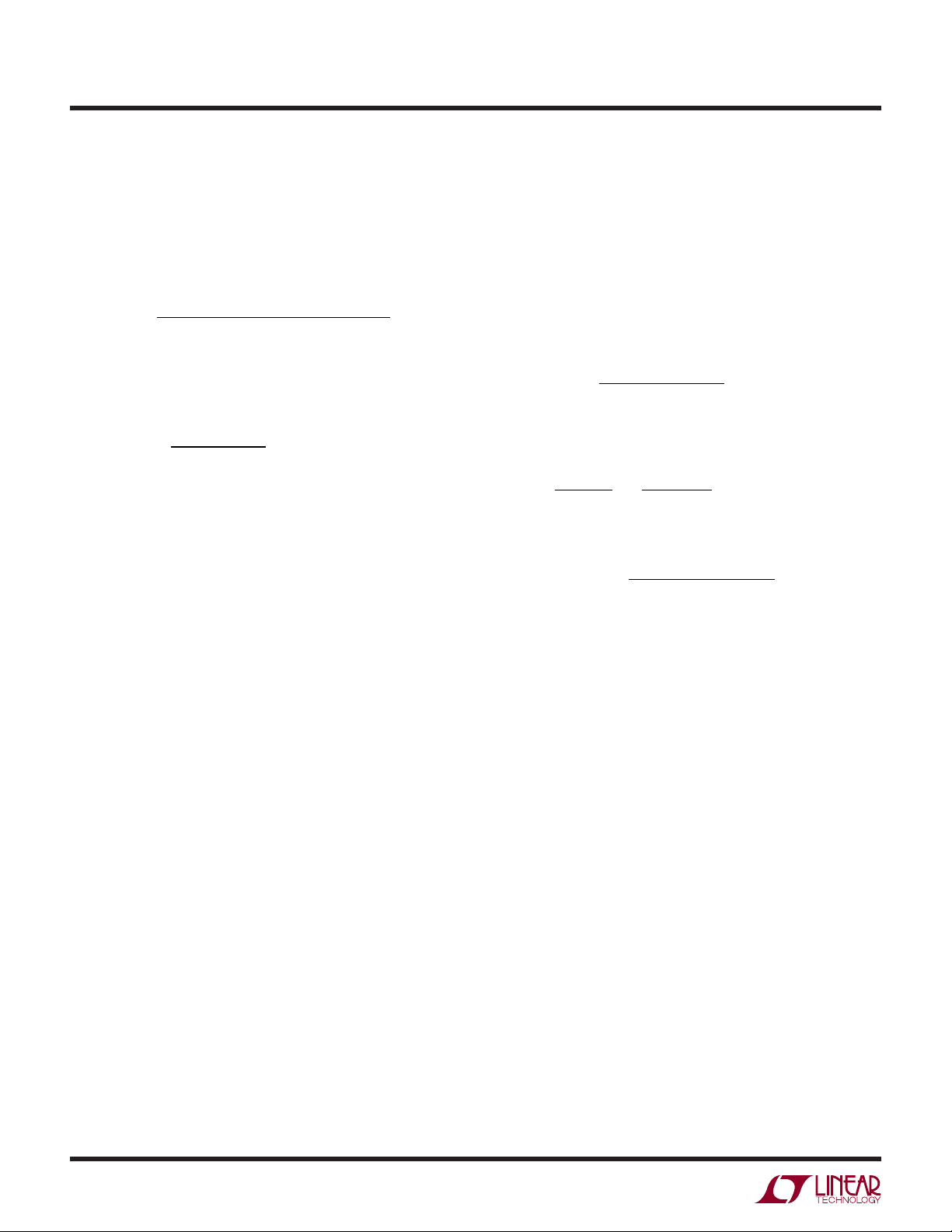

TYPICAL APPLICATIO

48V to 3.3V at 12A Isolated Supply

+

V

IN

36V TO 72V

28.7k

T1

20Ω

•

2.2µF

402k

15k

3.01k

UVLO

PGDLY

tONSYNC

100k12k

FB

R

CMP

47µF

V

CC

LT3825

ENDLY OSC

2.1k 150k

47pF

+

47k

SGSGPG

GND SFST

U

0.22µF

0.1µF

SENSE

SENSE

C

CMP

92

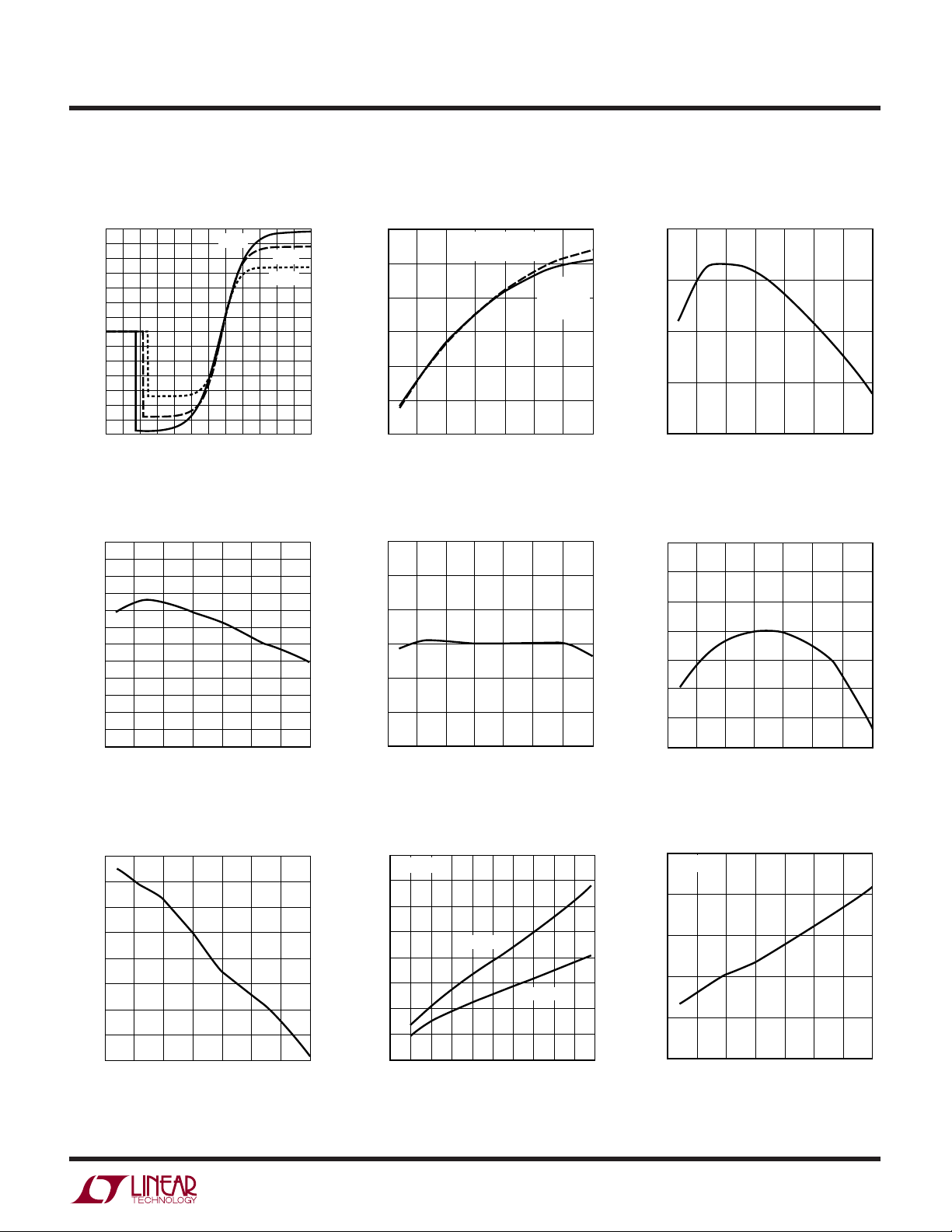

Efficiency

90

36V

IN

48V

88

86

+

V

OUT

3.3V

•

100pF

20Ω

+

–

V

C

0.02Ω

100k

10nF

T1

•

SG

330Ω

0.1µF

•

470µF

12A

×4

47Ω

×2

1µF

15Ω

2.2nF

•

10k

3825 TA01a

84

EFFICIENCY (%)

82

80

78

2

3

3.43

3.38

3.33

3.28

OUTPUT (V)

3.23

3.18

3.13

2

3

IN

72V

IN

5

6

4

LOAD CURRENT (A)

Regulation

5

6

4

LOAD CURRENT (A)

810

7

36V

IN

48V

IN

72V

IN

7

810

12

9

11

3825 TA01b

12

9

11

3825 TA01c

3825f

1

LT3825

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

VCC to GND

Low Impedance Source ........................ –0.3V to 18V

Current Fed

(VCC has Internal 19.5V Clamp) .......... 30mA into V

UVLO, SYNC Pin Voltage .......................... – 0.3V to V

SENSE–, SENSE+ Pin Voltage ................... – 0.5V, +0.5V

FB Pin Current ...................................................... ±2mA

V

Pin Current ..................................................... ±1mA

C

Operating Junction Temperature Range

(Notes 2, 3) .......................................... – 40°C to 125°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

CC

CC

UU

W

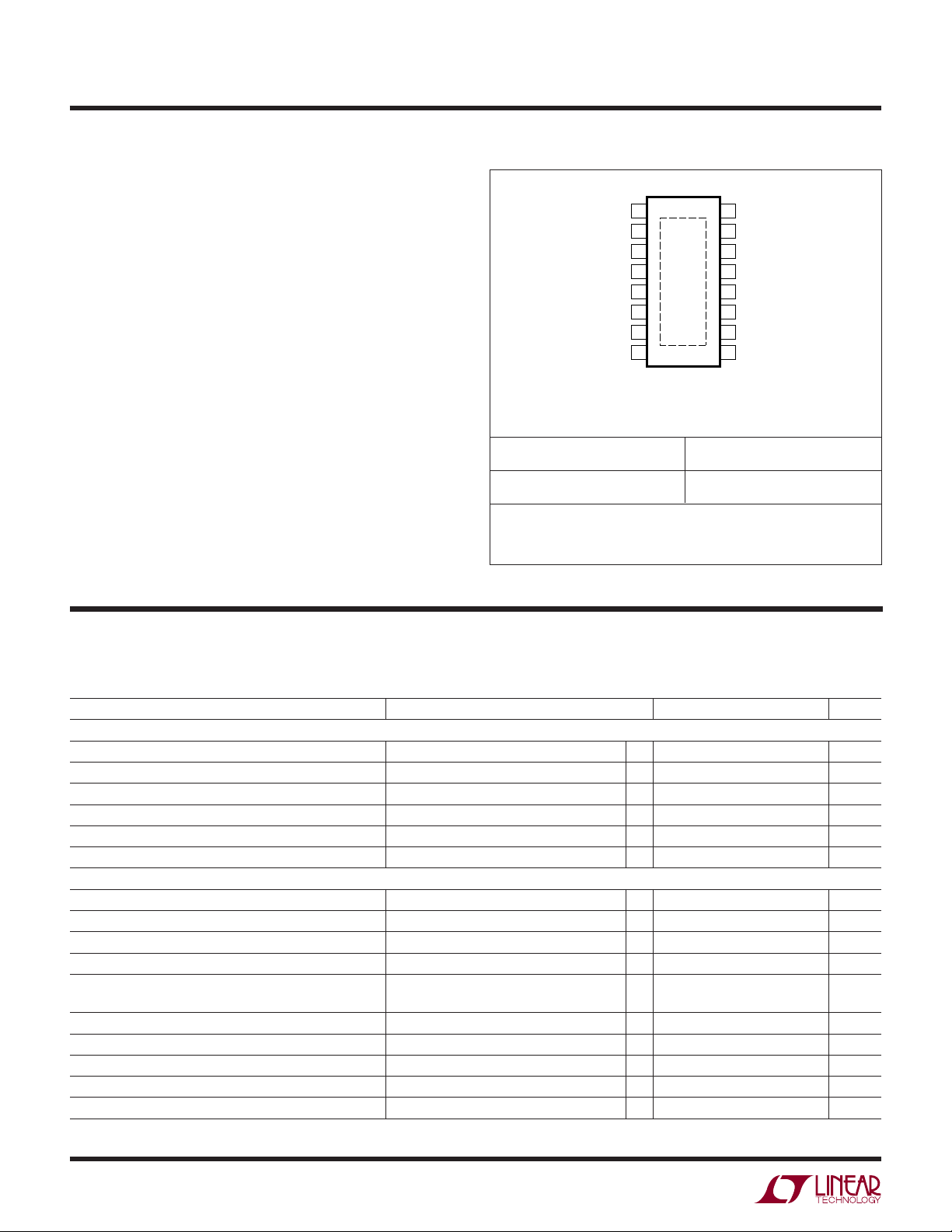

PACKAGE/ORDER I FOR ATIO

TOP VIEW

1

SG

2

V

CC

3

t

ON

4

ENDLY

SYNC

SFST

OSC

FB

16-LEAD PLASTIC TSSOP

T

= 125°C, θJA = 40°C/ W, θJC = 10°C/ W

JMAX

EXPOSED PAD (PIN 17) IS GND,MUST BE SOLDERED TO PCB

5

6

7

8

FE PACKAGE

17

ORDER PART NUMBER FE PART MARKING

LT3825EFE

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specified with wider operating temperature ranges.

PG

16

PGDLY

15

R

14

C

13

SENSE

12

SENSE

11

UVLO

10

V

9

CMP

CMP

+

–

C

3825EFE

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

= 14V; PG, SG Open; VC = 1.5V, V

V

CC

PARAMETER CONDITIONS MIN TYP MAX UNITS

Power Supply

VCC Turn-On Voltage

VCC Turn-Off Voltage

VCC Hysteresis V

VCC Shunt Clamp V

VCC Supply Current (Note 5) (ICC)V

VCC Start-Up Current VCC = 10V

Feedback Amplifier

Feedback Regulation Voltage (VFB)

Feedback Pin Input Bias Current R

Feedback Amplifier Transconductance ∆IC = ±10µA

Feedback Amplifier Source or Sink Current

Feedback Amplifier Clamp Voltage VFB = 0.9V 2.56 V

Reference Voltage Line Regulation 12V ≤ VCC ≤ 18V

Feedback Amplifier Voltage Gain VC = 1.2V to 1.7V 1400 V/V

Soft-Start Charging Current V

Soft-Start Discharge Current V

Control Pin Threshold (VC) Duty Cycle = Min 1.0 V

SENSE

–

= 0V; R

= 1k, R

CMP

CC(ON)

UVLO

= Open

C

Open 200 nA

CMP

= 1.4V 0.84 V

V

FB

= 0V 16 20 25 µA

SFST

= 1.5V, V

SFST

tON

– V

= 0V, I

= 90k, R

CC(OFF)

= 15mA

VCC

= 0V 0.8 1.3 mA

UVLO

PGDLY

= 27.4k, R

= 90k, unless otherwise specified.

ENDLY

●

14.0 15.3 16.0 V

●

●

●

●

●

●

●

●

●

8 9.7 11 V

4.0 5.6 6.5 V

19.5 20.5 V

4 6.4 10 mA

180 400 µA

1.220 1.237 1.251 V

700 1000 1400 µmho

25 55 90 µA

0.005 0.02 %/V

2

3825f

LT3825

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

= 14V; PG, SG Open; VC = 1.5V, V

V

CC

PARAMETER CONDITIONS MIN TYP MAX UNITS

Gate Outputs

PG, SG Output High Level

PG, SG Output Low Level

PG, SG Output Shutdown Strength V

PG Rise Time CPG = 1nF 11 ns

SG Rise Time CSG = 1nF 15 ns

PG, SG Fall Time CPG, CSG = 1nF 10 ns

Current Amplifier

Switch Current Limit at Maximum V

∆V

/∆V

SENSE

C

Sense Voltage Overcurrent Fault Voltage V

Timing

Switching Frequency (f

)C

OSC

Oscillator Capacitor Value (C

Minimum Switch On Time (t

Flyback Enable Delay Time (tED) 265 ns

PG Turn-On Delay Time (t

PGDLY

Maximum Switch Duty Cycle

SYNC Pin Threshold

SYNC Pin Input Resistance 40 kΩ

Load Compensation

Load Comp to V

Offset Voltage V

SENSE

Feedback Pin Load Compensation Current V

UVLO Function

UVLO Pin Threshold (V

UVLO

UVLO Pin Bias Current V

Note 1: Absolute Maximum ratings are those values beyond which the life

of a device may be impaired.

Note 2: This IC includes overtemperature protection that is intended to

protect the device during momentary overload conditions. Junction

temperature will exceed 125°C when overtemperature protection is active.

Continuous operation above the specified maximum operating junction

temperature may impair device reliability.

Note 3: The LT3825E is guaranteed to meet performance specifications

from 0°C to 125°C. Specifications over the –40°C to 125°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

C

) (Note 6) 33 200 pF

OSC

) 200 ns

ON(MIN)

) 200 ns

)

SENSE

–

= 0V; R

CMP

V

= 1k, R

UVLO

SENSE

= 90k, R

tON

PGDLY

= 0V; IPG, ISG = 20mA

+

= 27.4k, R

= 90k, unless otherwise specified.

ENDLY

●

6.6 7.4 8.0 V

●

●

●

88 98 110 mV

0.01 0.05 V

1.4 1.8 V

0.07 V/V

+

, V

SENSE

OSC

RCMP

SENSE

UVLO

V

UVLO

= 100pF

< 1V

SFST

with V

+

= 20mV, VFB = 1.230V 20 µA

+

= 0V 1 mV

SENSE

= 1.2V –0.25 0 ±0.25 µA

= 1.3V –4.50 –3.4 –2.50 µA

Note 4: T

dissipation P

is calculated from the ambient temperature TA and power

J

according to the following formula:

D

= TA + (PD • 40°C/W)

T

J

●

●

84 100 110 kHz

●

85 88 %

●

●

1.215 1.240 1.265 V

206 230 mV

1.53 2.1 V

Note 5: Supply current does not include gate charge current to the

MOSFETs. See Applications Information.

Note 6: Component value range guaranteed by design.

3825f

3

LT3825

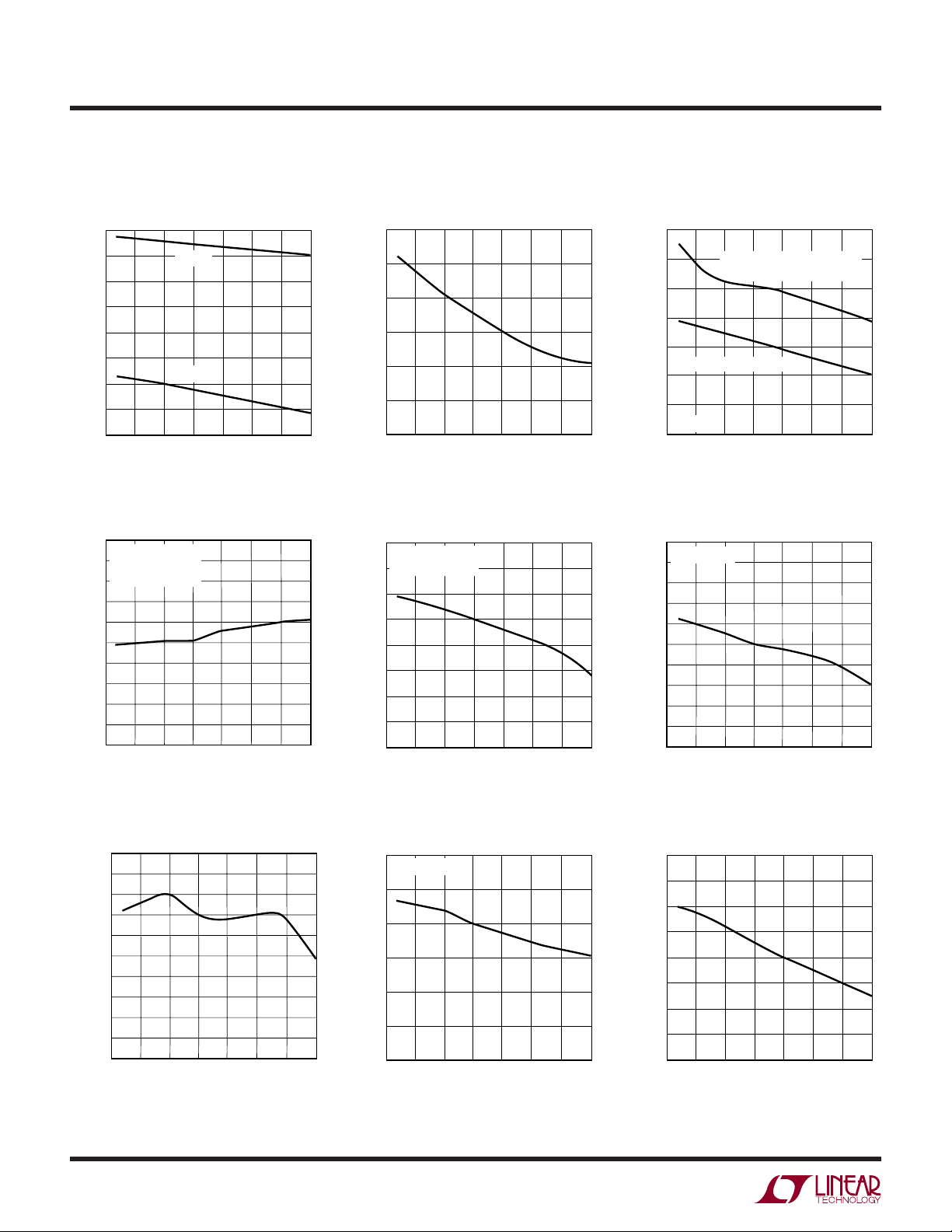

TEMPERATURE (°C)

–50

8

9

25 75

3825 G03

7

6

–25 0

50 100 125

5

4

3

10

I

VCC

(mA)

DYNAMIC CURRENT CPG = 1nF,

C

SG

= 1nF, f

OSC

= 100kHz

STATIC PART CURRENT

VCC = 14V

TEMPERATURE (°C)

–50

90

f

OSC

(kHz)

92

96

98

100

110

104

0

50

75

3825 G06

94

106

108

102

–25

25

100

125

C

OSC

= 100pF

TEMPERATURE (°C)

–50

V

FB

RESET (V)

1.03

25

3825 G09

1.00

0.98

–25 0 50

0.97

0.96

1.04

1.02

1.01

0.99

75 100 125

UW

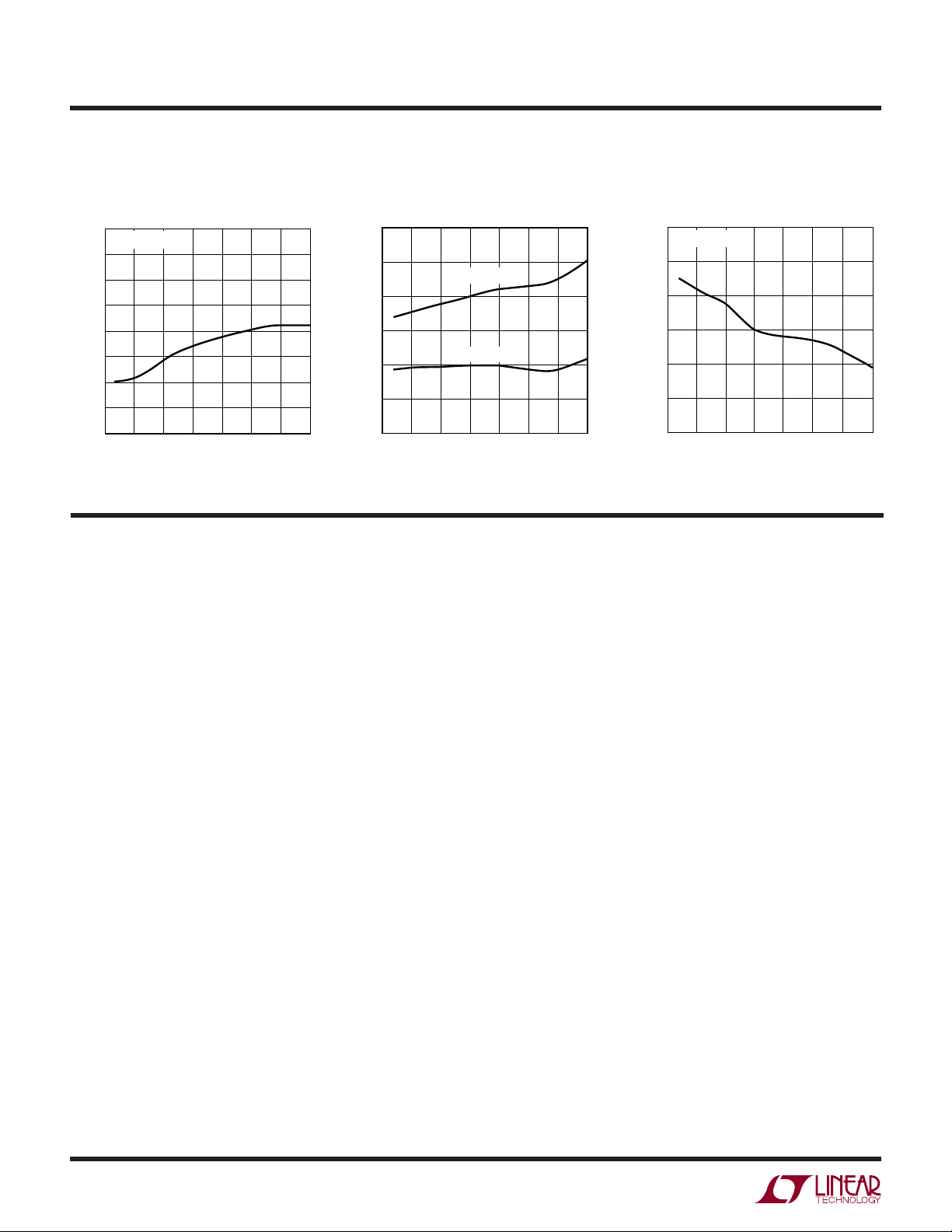

TYPICAL PERFOR A CE CHARACTERISTICS

V

CC(ON)

vs Temperature

16

15

14

13

(V)

12

CC

V

11

10

9

8

–25 0 50

–50

and V

CC(OFF)

V

CC(ON)

V

CC(OFF)

25

TEMPERATURE (°C)

75 100 125

3825 G01

(µA)

VCC

I

Start-Up Current

V

CC

vs Temperature

300

250

200

150

100

50

0

–50

–25 0

50 100 125

25 75

TEMPERATURE (°C)

3825 G02

V

Current vs Temperature

CC

110

108

106

104

102

100

98

96

SENSE VOLTAGE (mV)

94

92

90

–50

1.240

1.239

1.238

1.237

1.236

(V)

1.235

FB

V

1.234

1.233

1.232

1.231

1.230

4

SENSE Voltage vs Temperature

FB = 1.1V

SENSE = V

WITH V

–25

vs Temperature

V

FB

–50

–25

+

SENSE

–

= 0V

SENSE

50

25

0

TEMPERATURE (°C)

50

25

0

TEMPERATURE (°C)

75

100

3825 G04

75

100

125

3825 G07

125

SENSE Fault Voltage

vs Temperature

220

SENSE = V

WITH V

215

210

205

200

195

SENSE VOLTAGE (mV)

190

185

180

–25 0 50

–50

+

SENSE

–

= 0V

SENSE

25

TEMPERATURE (°C)

Feedback Pin Input Bias

vs Temperature

300

R

OPEN

CMP

250

200

150

100

FEEDBACK PIN INPUT BIAS (nA)

50

0

–50

–25 0

25 75

TEMPERATURE (°C)

Oscillator Frequency

vs Temperature

75 100 125

3825 G05

VFB Reset vs Temperature

50 100 125

3825 G08

3825f

UW

TEMPERATURE (°C)

–50

3.4

3.5

3.7

25 75

3825 G15

3.3

3.2

–25 0

50 100 125

3.1

3.0

3.6

I

UVLO

(µA)

TEMPERATURE (°C)

–50 –25

19.0

V

CC

(V)

20.0

21.5

0

50

75

3825 G18

19.5

21.0

20.5

25

100

125

ICC = 10mA

TYPICAL PERFOR A CE CHARACTERISTICS

LT3825

Feedback Amplifier Output

Current vs V

70

50

30

10

(µA)

VC

I

–10

–30

–50

–70

0.9

FB

125°C

1

1.1

1.2

VFB (V)

1.3

Feedback Amplifier Voltage Gain

vs Temperature

1700

1650

1600

1550

1500

1450

1400

(V/V)

V

A

1350

1300

1250

1200

1150

1100

–25 0 50

–50

25

TEMPERATURE (°C)

25°C

–40°C

1.5

1.4

3825 G10

75 100 125

3825 G13

Feedback Amplifier Source and

Sink Current vs Temperature

70

65

60

(µA)

55

VC

I

50

45

40

–50

–25 0

SOURCE CURRENT

25 75

TEMPERATURE (°C)

= 1.1V

V

FB

50 100 125

SINK

CURRENT

= 1.4V

V

FB

3825 G11

UVLO vs Temperature I

1.250

1.245

1.240

1.235

UVLO (V)

1.230

1.225

1.220

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

3825 G14

Feedback Amplifier g

vs Temperature

1100

1050

1000

(µmho)

m

g

950

900

–50

–25 0 25 50

TEMPERATURE (°C)

Hysteresis vs Temperature

UVLO

m

75 100 125

3825 G12

Soft-Start Charge Current

vs Temperature

23

22

21

20

19

18

17

SFST CHARGE CURRENT (µA)

16

15

–25 0 50

–50

TEMPERATURE (°C)

PG, SG Rise and Fall Times

vs Load Capacitance

80

TA = 25°C

70

60

50

40

TIME (ns)

30

20

10

0

0

75 100 125

3825 G16

25

FALL TIME

RISE TIME

246 107135 9

CAPACITANCE (nF)

8

3825 G17

VCC Clamp Voltage

vs Temperature

3825f

5

LT3825

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Minimum PG On Time

vs Temperature

340

R

tON(MIN)

330

320

310

(ns)

300

ON(MIN)

t

290

280

270

260

–25 0 50

–50

U

= 158k

25

TEMPERATURE (°C)

75 100 125

3825 G19

UU

PG Delay Time vs Temperature

300

250

200

(ns)

150

PGDLY

t

100

50

0

–50

–25 25

R

R

0

TEMPERATURE (°C)

PI FU CTIO S

SG (Pin 1): Synchronous Gate Drive Output. This pin

provides an output signal for a secondary-side synchronous switch. Large dynamic currents may flow during

voltage transitions. See the Applications Information for

details.

V

(Pin 2): Supply Voltage Pin. Bypass this pin to ground

CC

with a 4.7µF capacitor or more. This pin has a 19.5V clamp

to ground. V

turns the part on when V

at 9.7V. In a conventional “trickle-charge” bootstrapped

configuration, the V

cantly during turn-on causing a benign relaxation oscillation action on the VCC pin if the part does not start

normally.

(Pin 3): Pin for external programming resistor to set

t

ON

the minimum time that the primary switch is on for each

cycle. Minimum turn-on facilitates the isolated feedback

method. See Applications Information for details.

has an undervoltage lockout function that

CC

is approximately 15.3V and off

CC

supply current increases signifi-

CC

Enable Delay Time vs Temperature

260

R

= 90k

ENDLY

PGDLY

PGDLY

= 27.4k

= 16.9k

50

75

100 125

3825 G20

240

(ns)

ED

t

180

140

220

200

160

–50

–25 0

50 100 125

25 75

TEMPERATURE (°C)

SYNC (Pin 5): Pin for synchronizing the internal oscillator

with an external clock. The positive edge on a pulse causes

the oscillator to discharge causing PG to go low (off) and

SG high (on). The sync threshold is typically 1.6V. See

Applications Information for details. Tie to ground if

unused.

SFST (Pin 6): This pin, in conjunction with a capacitor to

ground, controls the ramp-up of peak primary current as

sensed through the sense resistor. This is used to control

converter inrush current at start-up. The VC pin voltage

cannot exceed the SFST pin voltage, so as SFST increases,

the maximum voltage on VC increases commensurately,

allowing higher peak currents. Total V

ramp time is

C

approximately 70ms per µF of capacitance. Leave pin open

if not using the soft-start function.

OSC (Pin 7): This pin in conjunction with an external

capacitor defines the controller oscillator frequency. The

frequency is approximately 100kHz • 100/C

OSC

(pF).

3825 G21

ENDLY (Pin 4): Pin for external programming resistor to

set enable delay time. The enable delay time disables the

feedback amplifier for a fixed time after the turn-off of the

primary-side MOSFET. This allows the leakage inductance

voltage spike to be ignored for flyback voltage sensing.

See Applications Information for details.

6

FB (Pin 8): Pin for the feedback node for the power supply

feedback amplifier. Feedback is usually sensed via a third

winding and enabled during the flyback period. This pin

also sinks additional current to compensate for load

current variation as set by the R

pin. Keep the Thevenin

CMP

equivalent resistance of the feedback divider at roughly 3k.

3825f

LT3825

U

UU

PI FU CTIO S

VC (Pin 9): Pin used for frequency compensation for the

switcher control loop. It is the output of the feedback

amplifier and the input to the current comparator. Switcher

frequency compensation components are normally placed

on this pin to ground. The voltage on this pin is proportional to the peak primary switch current. The feedback

amplifier output is enabled during the synchronous switch

on time.

UVLO (Pin 10): A resistive divider from V

an undervoltage lockout based upon V

When the UVLO pin is below its threshold, the gate drives

are disabled, but the part draws its normal quiescent

current from VCC. The VCC undervoltage lockout supersedes this function so V

the part.

The bias current on this pin has hysteresis such that the

bias current is sourced when the UVLO threshold is

exceeded. This introduces a hysteresis at the pin equivalent to the bias current change times the impedance of the

upper divider resistor. The user can control the amount of

hysteresis by adjusting the impedance of the divider. See

the Applications Information for details. Tie the UVLO pin

to V

SENSE– (Pin 11), SENSE+ (Pin 12): These pins are used

to measure primary side switch current through an external sense resistor. Peak primary side current is used in the

converter control loop. Make Kelvin connections to the

if you are not using this function.

CC

must be great enough to start

CC

to this pin sets

IN

level (not VCC).

IN

sense resistor to reduce noise problems. SENSE– connects to the ground side. At maximum current (V

maximum voltage) it has a 98mV threshold. The signal is

blanked (ignored) during the minimum turn-on time.

C

(Pin 13): Pin for external filter capacitor for the op-

CMP

tional load compensation function. Load compensation

reduces the effects of parasitic resistances in the feedback

sensing path. A 0.1µF ceramic capacitor suffices for most

applications. Short this pin to GND in less demanding

applications that don’t require load compensation.

R

(Pin 14): Pin for optional external load compensa-

CMP

tion resistor. Use of this pin allows for nominal compensation of parasitic resistances in the feedback sensing

path. In less demanding applications, this resistor is not

needed and this pin can be left open. See Applications

Information for details.

PGDLY (Pin 15): Pin for external programming resistor to

set delay from synchronous gate turn-off to primary gate

turn-on. See Applications Information for details.

PG (Pin 16): Gate Drive Pin for the Primary Side MOSFET

Switch. Large dynamic currents flow during voltage transitions. See the Applications Information for details.

GND (Exposed Pad, Pin 17): This is the ground connection for both signal ground and gate driver grounds. This

GND should be connected to the PCB ground plane.

Careful attention must be paid to ground layout. See

Applications Information for details.

at its

C

3825f

7

LT3825

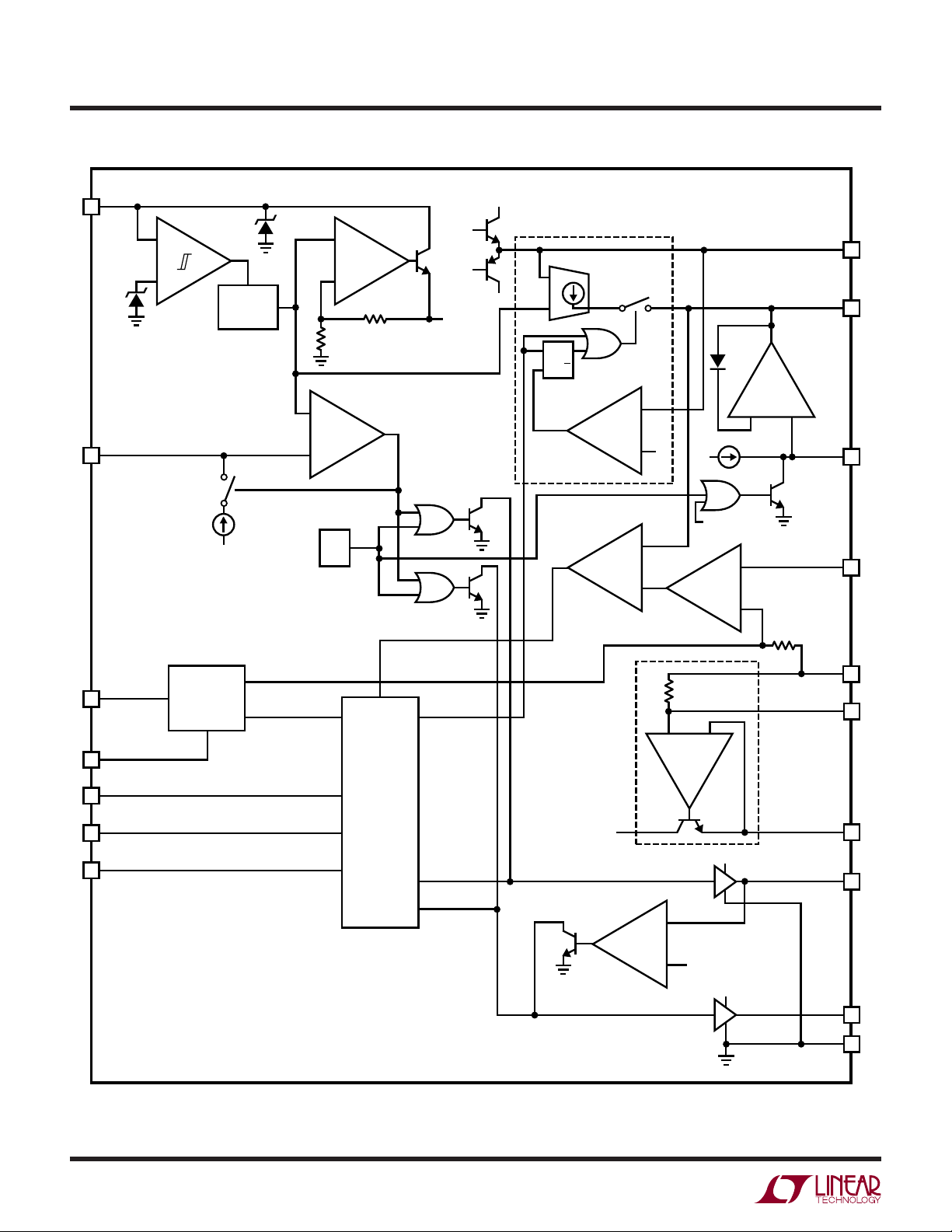

BLOCK DIAGRA

W

2

10

V

15.3V

UVLO

CC

V

UVLO

CC

+

–

REFERENCE

1.235V

(V

FB

19.5V

+

–

)

INTERNAL

REGULATOR

+

UVLO

–

I

UVLO

TSD

CURRENT TRIP

CLAMPS

0.7

1.3

3V

–

+

SRQ

CURRENT

COMPARATOR

ERROR AMP

Q

COLLAPSE DETECT

–

+

1V

OVERCURRENT

–

FAULT

–

–

+

CURRENT

SENSE AMP

+

+

SFST

SENSE

FB

8

V

C

9

6

–

11

+

SLOPE COMPENSATION

OSC

7

SYNC

5

t

ON

3

PGDLY

15

ENDLY

4

OSCILLATOR

SET

ENABLE

LOGIC

BLOCK

TO FB

PGATE

SGATE

R

CMPF

50k

+

GATE DRIVE

–

V

CC

SENSE

C

CMP

LOAD

COMPENSATION

R

CMP

PG

12

13

14

16

+

3V

–

V

CC

GATE DRIVE

SG

GND

1

17

8

3825f

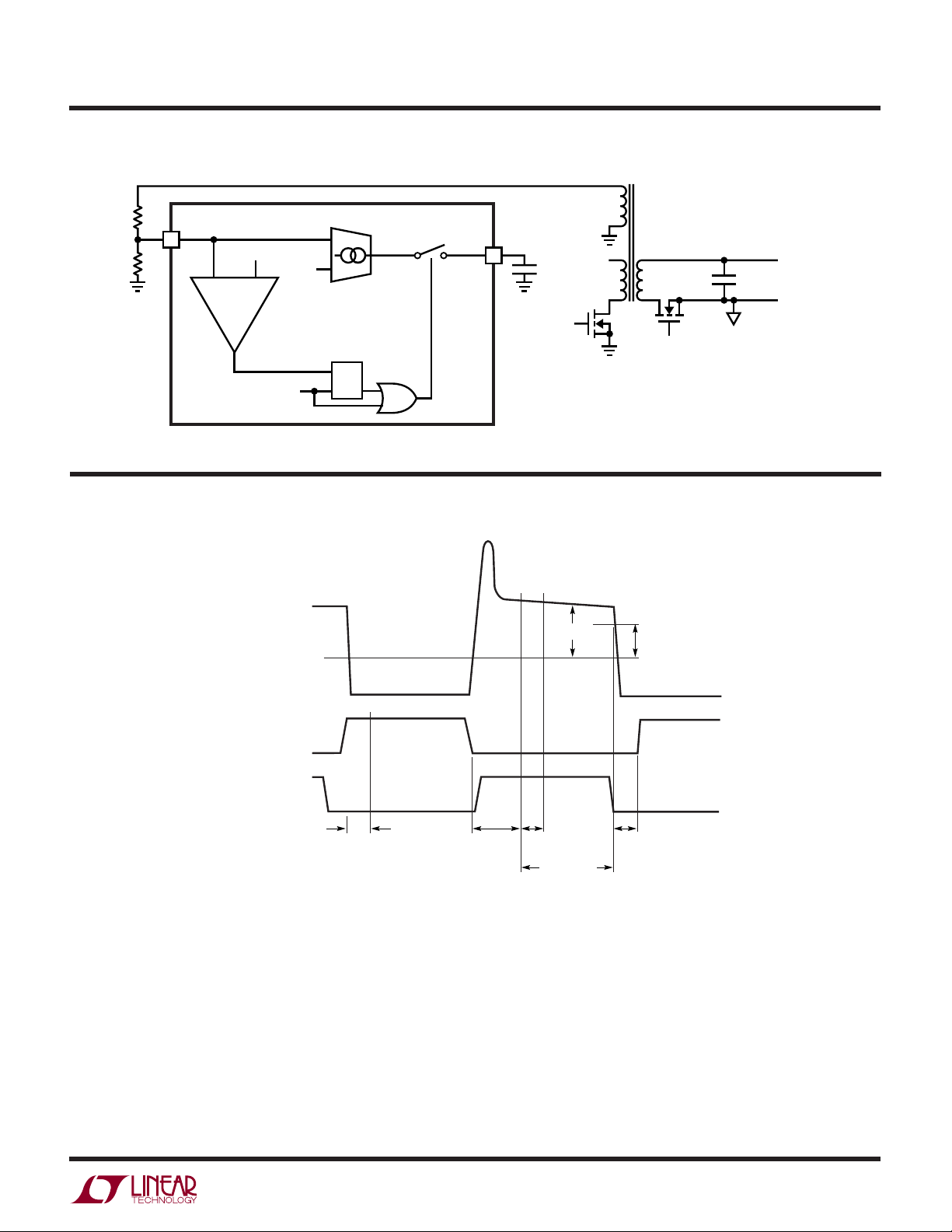

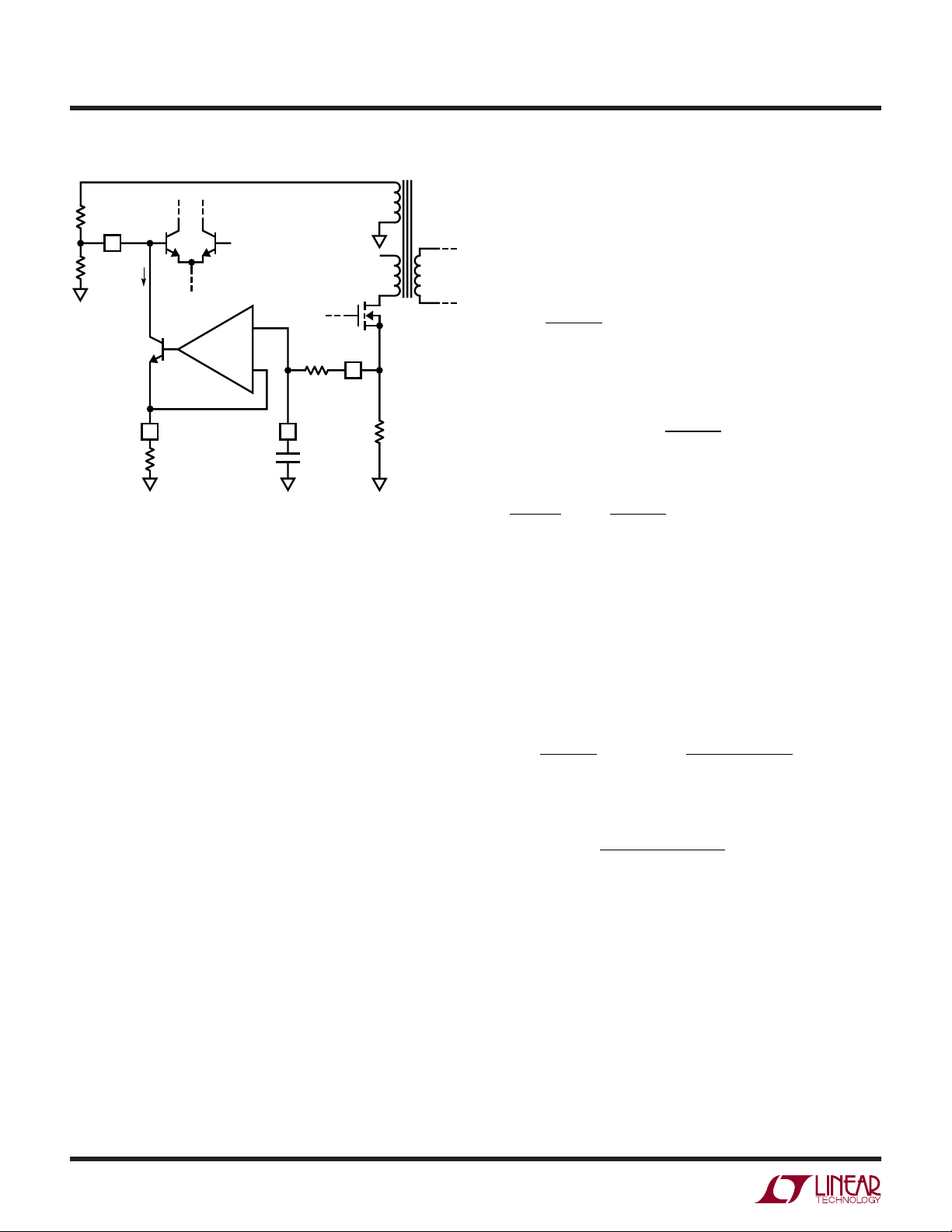

W

FLYBACK FEEDBACK A PLIFIER

LT3825

R1

FB

8

R2

–

UWW

TI I G DIAGRA

LT3825 FEEDBACK AMP

1V

V

FB

1.25V

+

COLLAPSE

DETECT

ENABLE

–

+

SRQ

V

FLBK

V

T1

FLYBACK

•

C

9

3825 FFA

V

IN

C

VC

V

PRIMARY

MP

IN

•

SECONDARY

•

MS

ISOLATED

C

OUT

OUTPUT

PRIMARY SIDE

MOSFET DRAIN

VOLTAGE

PG VOLTAGE

SG VOLTAGE

V

IN

t

ON(MIN)

ENABLE

DELAY

V

FLBK

MIN ENABLE

FEEDBACK

AMPLIFIER

ENABLED

0.8 • V

FLBK

PG DELAY

3825 TD

3825f

9

LT3825

OPERATIO

U

The LT3825 is a current mode switcher controller IC

designed specifically for use in an isolated flyback topology employing synchronous rectification. The LT3825

operation is similar to traditional current mode switchers.

The major difference is that output voltage feedback is

derived via sensing the output voltage through the transformer. This precludes the need of an optoisolator in

isolated designs greatly improving dynamic response and

reliability. The LT3825 has a unique feedback amplifier

that samples a transformer winding voltage during the

flyback period and uses that voltage to control output

voltage.

The internal blocks are similar to many current mode

controllers. The differences lie in the flyback feedback

amplifier and load compensation circuitry. The logic block

also contains circuitry to control the special dynamic

requirements of flyback control.

For more information on the basics of current mode

switcher/controllers and isolated flyback converters see

Application Note 19.

Feedback Amplifier—Pseudo DC Theory

For the following discussion refer to the simplified Flyback

Feedback Amplifier diagram. When the primary side MOSFET switch MP turns off, its drain voltage rises above the

V

rail. Flyback occurs when the primary MOSFET is off

IN

and the synchronous secondary MOSFET is on. During

flyback the voltage on nondriven transformer pins is

determined by the secondary voltage. The amplitude of

this flyback pulse as seen on the third winding is given as:

VI ESRR

++

•

V

FLBK

R

DS(ON)

I

= transformer secondary current

SEC

ESR = impedance of secondary circuit capacitor, winding

and traces

= transformer effective secondary-to-feedback wind-

N

SF

ing turns ratio (i.e., N

The flyback voltage is scaled by an external resistive

divider R1/R2 and presented at the FB pin. The feedback

OUT SEC DS ON

=

= on resistance of the synchronous MOSFET M

()

N

SF

S/NFLBK

)

()

S

amplifier compares the voltage to the internal bandgap

reference. The feedback amp is actually a transconductance

amplifier whose output is connected to V

period in the flyback time. An external capacitor on the V

pin integrates the net feedback amp current to provide the

control voltage to set the current mode trip point.

The regulation voltage at the FB pin is nearly equal to the

bandgap reference VFB because of the high gain in the

overall loop. The relationship between V

expressed as:

RR

V

FLBK FB

Combining this with the previous V

an expression for V

programming resistors and secondary resistances:

V

=

OUT FB SF SEC DS ON

The effect of nonzero secondary output impedance is

discussed in further detail; see Load Compensation Theory.

The practical aspects of applying this equation for V

found in the Applications Information.

Feedback Amplifier Dynamic Theory

So far, this has been a pseudo-DC treatment of flyback

feedback amplifier operation. But the flyback signal is a

pulse, not a DC level. Provision must be made to enable the

flyback amplifier only when the flyback pulse is present.

This is accomplished by the “Enable” line in the diagram.

Timing signals are then required to enable and disable the

flyback amplifier. There are several timing signals which

are required for proper LT3825 operation. Please refer to

the Timing Diagram.

Minimum Output Switch On Time (t

The LT3825 affects output voltage regulation via flyback

pulse action. If the output switch is not turned on, there

is no flyback pulse and output voltage information is not

available. This causes irregular loop response and startup/latch-up problems. The solution is to require the

primary switch to be on for an absolute minimum time per

each oscillator cycle. If the output load is less than that

=

R

RR

+

12

⎛

⎜

⎝

R

2

+12

V

•

2

FLBK

in terms of the internal reference,

OUT

VN I ESRR

•• – •

⎞

⎟

⎠

only during a

C

C

and VFB is

FLBK

expression yields

+

(()

ON(MIN)

)

()

OUT

are

3825f

10

R

ESR R

DC

S OUT

DS ON

()

()

–

=

+

1

OPERATIO

LT3825

U

developed under these conditions, forced continuous

operation normally occurs. See Applications Information

for further details.

Enable Delay (ENDLY)

The flyback pulse appears when the primary side switch

shuts off. However, it takes a finite time until the transformer primary side voltage waveform represents the

output voltage. This is partly due to rise time on the

primary side MOSFET drain node but, more importantly, is

due to transformer leakage inductance. The latter causes

a voltage spike on the primary side, not directly related to

output voltage. Some time is also required for internal

settling of the feedback amplifier circuitry. In order to

maintain immunity to these phenomena, a fixed delay is

introduced between the switch turn-off command and the

enabling of the feedback amplifier. This is termed “enable

delay.” In certain cases where the leakage spike is not

sufficiently settled by the end of the enable delay period,

regulation error may result. See Applications Information

for further details.

enable time described to a maximum of roughly the “off”

switch time minus the enable delay time. Certain parameters of feedback amp behavior are directly affected by

the variable enable period. These include effective

transconductance and V

node slew rate.

C

Load Compensation Theory

The LT3825 uses the flyback pulse to obtain information

about the isolated output voltage. An error source is

caused by transformer secondary current flow through the

synchronous MOSFET R

and real life nonzero im-

DS(ON)

pedances of the transformer secondary and output capacitor. This was represented previously by the expression

“I

• (ESR + R

SEC

).” However, it is generally more

DS(ON)

useful to convert this expression to effective output impedance. Because the secondary current only flows during

the off portion of the duty cycle (DC), the effective output

impedance equals the lumped secondary impedance divided by OFF time DC.

Since the OFF time duty cycle is equal to 1 – DC then:

Collapse Detect

Once the feedback amplifier is enabled, some mechanism

is then required to disable it. This is accomplished by a

collapse detect comparator, which compares the flyback

voltage (FB referred) to a fixed reference, nominally 80%

of V

. When the flyback waveform drops below this level,

FB

the feedback amplifier is disabled.

Minimum Enable Time

The feedback amplifier, once enabled, stays enabled for a

fixed minimum time period termed “minimum enable

time.” This prevents lockup, especially when the output

voltage is abnormally low; e.g., during start-up. The minimum enable time period ensures that the V

node is able

C

to “pump up” and increase the current mode trip point to

the level where the collapse detect system exhibits proper

operation. This time is set internally.

Effects of Variable Enable Period

The feedback amplifier is enabled during only a portion of

the cycle time. This can vary from the fixed minimum

where:

R

= effective supply output impedance

S(OUT)

DC = duty cycle

R

and ESR are as defined previously

DS(ON)

This impedance error may be judged acceptable in less

critical applications, or if the output load current remains

relatively constant. In these cases the external FB resistive

divider is adjusted to compensate for nominal expected

error. In more demanding applications, output impedance

error is minimized by the use of the load compensation

function.

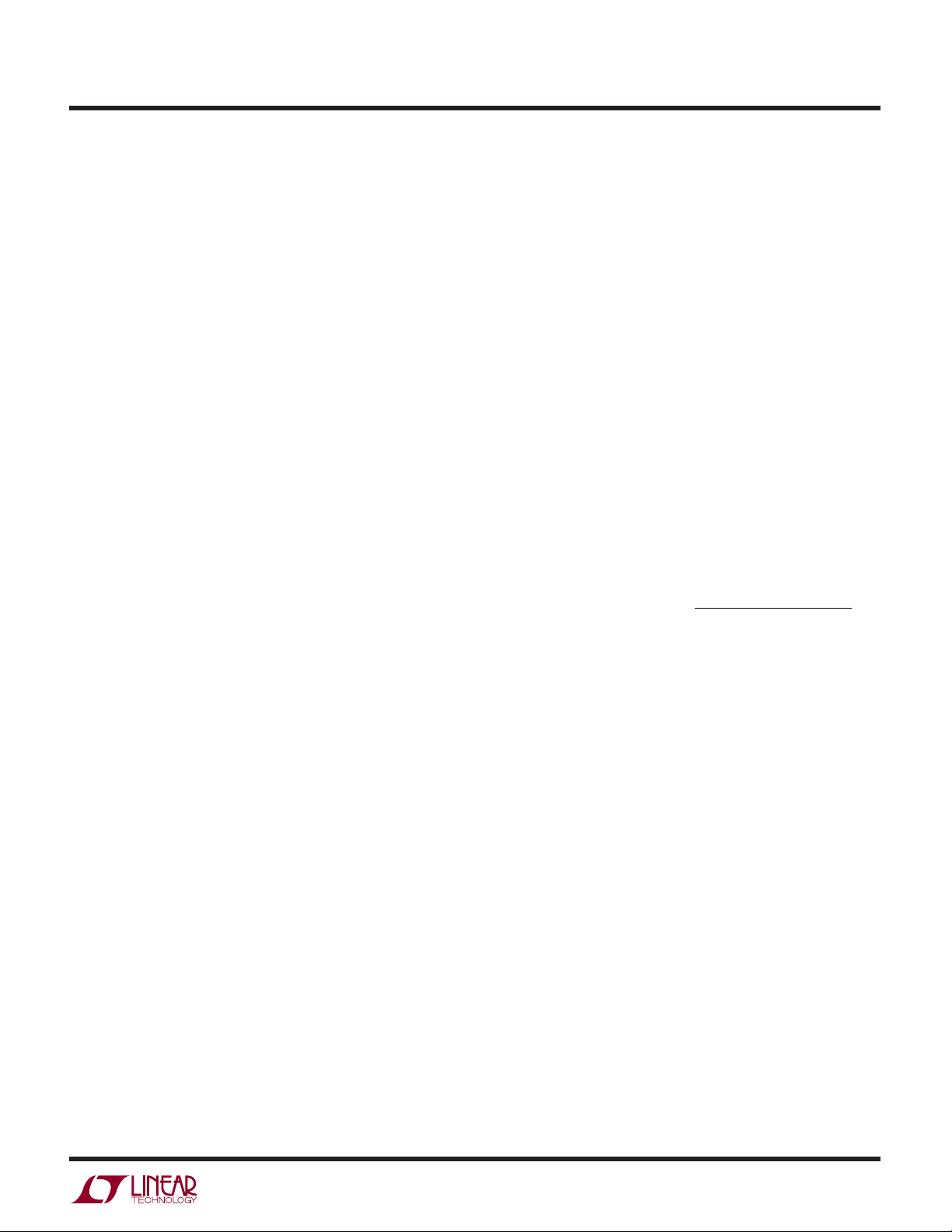

Figure 1 shows the Block Diagram of the load compensation function. Switch current is converted to a voltage by

the external sense resistor, averaged and lowpass filtered

by the internal 50k resistor R

capacitor on C

external R

CMP

. This voltage is impressed across the

CMP

resistor by op amp A1 and transistor Q3

and the external

CMPF

producing a current at the collector of Q3 that is

3825f

11

LT3825

OPERATIO

R1

FB

Q1 Q2

Q3

R

14 13

CMP

Figure 1. Load Compensation Diagram

R2

8

LOAD

COMP I

U

V

FLBK

T1

Average primary side current is expressed in terms of

output current as follows:

•

IKI

==11•

V

FB

+

R

C

CMPF

50k

CMP

A1

–

SENSE

12

V

IN

•

•

MP

+

R

SENSE

3825 F01

IN OUT

where

:

V

K

OUT

V Eff

•

IN

So the effective change in V

R

∆ = ∆

VKI

OUT OUT

thus

:

V

∆

OUT

∆

II

OUT

11•• ••

= 11•••

K

R

SENSE

R

CMP

SENSE

R

RN

target is:

OUT

CMP

RN

SF

SF

subtracted from the FB node. This effectively increases

the voltage required at the top of the R1/R2 feedback

divider to achieve equilibrium.

The average primary side switch current increases to

maintain output voltage regulation as output loading increases. The increase in average current increases the

R

resistor current which affects a corresponding in-

CMP

crease in sensed output voltage, compensating for the IR

drops.

Assuming a relatively fixed power supply efficiency, Eff,

power balance gives:

= Eff • P

P

V

OUT

OUT

• I

IN

= Eff • VIN • I

OUT

IN

where:

K1 = dimensionless variable related to V

IN

, V

OUT

and

efficiency as explained above

R

= external sense resistor

SENSE

Nominal output impedance cancellation is obtained by

equating this expression with R

R

SENSE

K

11

•••

R

CMP

Solving for R

RK

=

CMP

RN

gives:

CMP

RDC

SENSE

1

ESR R

ESR R

=

SF

11••–

()

+

()

DS ON

S(OUT)

+

1

–

DC

••

RN

:

()

DS ON

SF

The practical aspects of applying this equation to determine an appropriate value for the R

resistor are found

CMP

in the Applications Information.

12

3825f

WUUU

APPLICATIO S I FOR ATIO

LT3825

Transformer Design

Transformer design/specification is the most critical part

of a successful application of the LT3825. The following

sections provide basic information about designing the

transformer and potential tradeoffs.

If you need help, the LTC Applications group is available to

assist in the choice and/or design of the transformer.

Turns Ratios

The design of the transformer starts with determining duty

cycle (DC). DC impacts the current and voltage stress on

the power switches, input and output capacitor RMS

currents and transformer utilization (size vs power).

The ideal turns ratio is:

N

IDEAL

V

OUT

= •

V

IN

–1

DC

DC

Avoid extreme duty cycles as they, in general, increase

current stresses. A reasonable target for duty cycle is 50%

at nominal input voltage.

For instance, if we wanted a 48V to 5V converter at 50% DC

then:

548105051

N

IDEAL

==

–.

•

..

96

In general, better performance is obtained with a lower

turns ratio. A DC of 45.5% yields a 1:8 ratio.

Note the use of the external feedback resistive divider ratio

to set output voltage provides the user additional freedom

in selecting a suitable transformer turns ratio. Turns ratios

that are the simple ratios of small integers; e.g., 1:1, 2:1,

3:2 help facilitate transformer construction and improve

performance.

When building a supply with multiple outputs derived

through a multiple winding transformer, lower duty cycle

can improve cross regulation by keeping the synchronous

rectifier on longer, and thus, keep secondary windings

coupled longer.

For a multiple output transformer, the turns ratio between

output windings is critical and affects the accuracy of the

voltages. The ratio between two output voltages is set with

the formula V

OUT2

= V

• N21 where N21 is the turns

OUT1

ratio between the two windings. Also keep the secondary

MOSFET R

small to improve cross regulation.

DS(ON)

The feedback winding usually provides both the feedback

voltage and power for the LT3825. So set the turns ratio

between the output and feedback winding to provide a

rectified voltage that under worst-case conditions is greater

than the 11V maximum V

V

N

SF

For our example:

We will choose

OUT

>

+

V

11

F

N

SF

1

turn-off voltage.

CC

5

>

11 0 71.

=

+

2234.

3

Leakage Inductance

Transformer leakage inductance (on either the primary or

secondary) causes a spike after the primary side switch

turn-off. This is increasingly prominent at higher load

currents, where more stored energy is dissipated. Higher

flyback voltage may break down the MOSFET switch if it

has too low a BV

DSS

rating.

One solution to reducing this spike is to use a snubber

circuit to suppress the voltage excursion. However, suppressing the voltage extends the flyback pulse width. If the

flyback pulse extends beyond the enable delay time,

output voltage regulation is affected. The feedback system

has a deliberately limited input range, roughly ±50mV

referred to the FB node. This rejects higher voltage leakage

spikes because once a leakage spike is several volts in

amplitude, a further increase in amplitude has little effect

on the feedback system.

Therefore, it is advisable to arrange the snubber circuit to

clamp at as high a voltage as possible, observing MOSFET

breakdown, such that leakage spike duration is as short as

possible. Application Note 19 provides a good reference

on snubber design.

3825f

13

LT3825

WUUU

APPLICATIO S I FOR ATIO

As a rough guide, leakage inductance of several percent (of

mutual inductance) or less may require a snubber, but

exhibit little to no regulation error due to leakage spike

behavior. Inductances from several percent up to perhaps

ten percent cause increasing regulation error.

Avoid double digit percentage leakage inductances as there

is a potential for abrupt loss of control at high load current.

This curious condition potentially occurs when the leakage

spike becomes such a large portion of the flyback waveform

that the processing circuitry is fooled into thinking that the

leakage spike itself is the real flyback signal!

It then reverts to a potentially stable state whereby the top

of the leakage spike is the control point, and the trailing edge

of the leakage spike triggers the collapse detect circuitry.

This typically reduces the output voltage abruptly to a fraction, roughly one-third to two-thirds of its correct value.

Once load current is reduced sufficiently, the system

snaps back to normal operation. When using transformers with considerable leakage inductance, exercise this

worst-case check for potential bistability:

1. Operate the prototype supply at maximum expected

load current.

2. Temporarily short circuit the output.

3. Observe that normal operation is restored.

If the output voltage is found to hang up at an abnormally

low value, the system has a problem. This is usually

evident by simultaneously viewing the primary side

MOSFET drain voltage to observe firsthand the leakage

spike behavior.

A final note—the susceptibility of the system to bistable

behavior is somewhat a function of the load current/

voltage characteristics. A load with resistive—i.e., I = V/R

behavior—is the most apt to be bistable. Capacitive loads

that exhibit I = V

2

/R behavior are less susceptible.

Secondary Leakage Inductance

Leakage inductance on the secondary forms an inductive

divider on the transformer secondary, reducing the size of

the feedback flyback pulse. This increases the output

voltage target by a similar percentage.

Note that unlike leakage spike behavior, this phenomenon

is independent of load. Since the secondary leakage inductance is a constant percentage of mutual inductance

(within manufacturing variations), the solution is to adjust

the feedback resistive divider ratio to compensate.

Winding Resistance Effects

Primary or secondary winding resistance acts to reduce

overall efficiency (P

increases effective output impedance degrading load regulation. Load compensation can mitigate this to some extent but a good design keeps parasitic resistances low.

Bifilar Winding

A bifilar or similar winding is a good way to minimize

troublesome leakage inductances. Bifilar windings also

improve coupling coefficients and thus improve cross

regulation in multiple winding transformers. However,

tight coupling usually increases primary-to-secondary

capacitance and limits the primary-to-secondary breakdown voltage, so it isn’t always practical.

Primary Inductance

The transformer primary inductance, L

on the peak-to-peak ripple current ratio (X) in the transformer relative to its maximum value. As a general rule,

keep X in the range of 20% to 40% ripple current (i.e., X

= 0.2 to 0.4). Higher values of ripple will increase conduction losses, while lower values will require larger cores.

OUT/PIN

). Secondary winding resistance

, is selected based

P

14

3825f

WUUU

APPLICATIO S I FOR ATIO

LT3825

Ripple current and percentage ripple is largest at minimum duty cycle; in other words, at the highest input

voltage. L

L

=

P

is calculated from:

P

VDC

()

IN MAX MIN

fX P

OSC MAX IN

•

() ()

••

V

()

IN MAX

=

fX P

OSC MAX OUT

•2DDC Eff

••

MIN

2

•

where:

is the oscillator frequency

f

OSC

DC

is the DC at maximum input voltage

MIN

is ripple current ratio at maximum input voltage

X

MAX

For a 48V (V

efficiency, P

and f

OSC

DC

MIN

L

=

P

= 36V to 72V) to 5V/8A converter with 90%

IN

= 40W and PIN = 44.44W. Using X = 0.4

OUT

= 200kHz:

=

1

()

200 0 4 44 44

kHz W

1

•

NV

+

7

IN MAX

V

OUT

22 0 357

V

•.

•.• .

=

()

2

1

1872

•

+

1

5

=µ

186

H

=

35 7

.%

The main design goals for core selection are reducing

copper losses and preventing saturation. Ferrite core

material saturates hard, rapidly reducing inductance when

the peak design current is exceeded. This results in an

abrupt increase in inductor ripple current and, consequently, output voltage ripple. Do not allow the core to

saturate! The maximum peak primary current occurs at

minimum V

I

PK

now

DC

X

Using the example numbers leads to:

:

IN

P

=+

VDC

IN MIN MAX

XX

MA

=

MIN

=

IN

•

()

=

1

V

()

.

0 202

1

•

NV

()

IN MIN

+

V

OUT

DC

I

•

NNMIN MAX

()

fLP k

••

OSC P IN

⎛

•:1

⎜

⎝

=

X

⎞

MIN

⎟

⎠

2

1

=

52 6

1836

+

1

•

5

2

=

()

200

.%

36 52 6

•.%

HHz H••.

186 44 44

2

µ

Optimization might show that a more efficient solution is

obtained at higher peak current but lower inductance and

the associated winding series resistance. A simple spreadsheet program is useful for looking at tradeoffs.

Transformer Core Selection

Once L

is known, the type of transformer is selected. High

P

efficiency converters use ferrite cores to minimize core

loss. Actual core loss is independent of core size for a fixed

inductance, but decreases as inductance increases. Since

increased inductance is accomplished through more turns

of wire, copper losses increase. Thus transformer design

balances core and copper losses. Remember that increased winding resistance will degrade cross regulation

and increase the amount of load compensation required.

44 44

W

I

PK

.

=+

36 0 526

•.

0 202

.

⎛

1

•

⎜

⎝

⎞

=

⎟

⎠

2

258

.

A

Multiple Outputs

One advantage that the flyback topology offers is that

additional output voltages can be obtained simply by

adding windings. Designing a transformer for such a

situation is beyond the scope of this document. For

multiple windings, realize that the flyback winding signal

is a combination of activity on all the secondary windings.

Thus load regulation is affected by each windings load.

Take care to minimize cross regulation effects.

3825f

15

LT3825

RK

RDC

ESR R

RN R

CMP

SENSE

DS ON

SF

=

()

+

=1

11••–

••

()

SS OUT()

WUUU

APPLICATIO S I FOR ATIO

Setting Feedback Resistive Divider

The expression for V

developed in the Operation sec-

OUT

tion is rearranged to yield the following expression for the

feedback resistors:

⎛

12 1=

⎜⎜

⎜

⎝

RR

⎡

VI ESRR

OUT SEC DS ON

⎣

•

++

()

•

VN

FB SF

Continuing the example, if ESR + R

()

= 8mΩ, R2 =

DS(ON)

⎞

⎤

⎦

⎟

–

⎟

⎠

3.32k, then:

Rk k134

⎛

⎜

⎝

•.

1 232 1 3

.•/

⎞

1376=

=.

–.

⎟

⎠

5 8 0 008

+

choose 37.4k.

It is recommended that the Thevenin impedance of the

resistive divider (R1||R2) is roughly 3k for bias current

cancellation and other reasons.

Current Sense Resistor Considerations

above nominal so I

on R

and minimum V

SENSE

110% = 80mV/3.64A and nominal R

= 3.64A . If there is a 10% tolerance

PK

= 80mV, then R

SENSE

= 20mΩ. Round

SENSE

to the nearest available lower value.

Selecting the Load Compensation Resistor

The expression for R

was derived in the Operation

CMP

section as:

Continuing the example:

⎛

K

1

⎜

⎝

If ESR R

R

+

CMP

V

VEff

IN

DSS(ON)

=

⎞

OUT

⎟

••%

⎠

= Ω

0 116

.•

5

==

.

0 116=

48 90

m

8

m

20 1 0 455

•–.

Ω

()

m

8

37 4

•.ΩkkkΩ

= 196.

SENSE

•

The external current sense resistor is used to control peak

primary switch current, which controls a number of key

converter characteristics including maximum power and

external component ratings. Use a noninductive current

sense resistor (no wire-wound resistors). Mounting the

resistor directly above an unbroken ground plane connected with wide and short traces keeps stray resistance

and inductance low.

The dual sense pins allow for a fully Kelvined connection.

Make sure that SENSE

+

and SENSE– are isolated and

connect close to the sense resistor to preserve this.

Peak current occurs at 98mV of sense voltage V

the nominal sense resistor is V

SENSE/IPK.

For example, a

SENSE

. So

peak switch current of 10A requires a nominal sense resistor of 0.010Ω. Note that the instantaneous peak power in

the sense resistor is 1W, and that it is rated accordingly.

The use of parallel resistors can help achieve low resistance,

low parasitic inductance and increased power capability.

Size R

V

SENSE

using worst-case conditions, minimum LP,

SENSE

and maximum VIN. Continuing the example, let us

assume that our worst-case conditions yield an IPK 40%

This value for R

is a good starting point, but empirical

CMP

methods are required for producing the best results. This

is because several of the required input variables are

difficult to estimate precisely. For instance, the ESR term

above includes that of the transformer secondary, but its

effective ESR value depends on high frequency behavior,

not simply DC winding resistance. Similarly, K1 appears

as a simple ratio of V

to V

IN

times (differential) effi-

OUT

ciency, but theoretically estimating efficiency is not a

simple calculation.

The suggested empirical method is as follows:

1. Build a prototype of the desired supply including the

actual secondary components.

2. Temporarily ground the C

pin to disable the load

CMP

compensation function. Measure output voltage while

sweeping output current over the expected range.

Approximate the voltage variation as a straight line,

∆V

/∆I

OUT

= R

OUT

3. Calculate a value for the K1 constant based on VIN, V

S(OUT)

.

OUT

and the measured efficiency.

16

3825f

WUUU

APPLICATIO S I FOR ATIO

LT3825

4. Compute:

R

RK

= 11•••

CMP

SENSE

R

S OUT

()

RN

SF

5. Verify this result by connecting a resistor of this value

from the R

6. Disconnect the ground short to C

pin to ground.

CMP

and connect a

CMP

0.1µF filter capacitor to ground. Measure the output

impedance R

pensation in place. R

S(OUT)

= ∆V

S(OUT)

/∆I

OUT

with the new com-

OUT

should have decreased

significantly. Fine tuning is accomplished experimentally by slightly altering R

is:

R

CMP

⎛

R

1

⎜

S OUT CMP

=+

RR

′

CMP CMP

•

⎝

where R′

resistor, R

R

CMP

is the new value for the load compensation

CMP

S(OUT)CMP

in place and R

is the output impedance with

S(OUT)

. A revised estimate for

CMP

()

R

()

S OUT

⎞

⎟

⎠

is the output impedance with

no load compensation (from step 2).

Setting Frequency

The switching frequency of the LT3825 is set by an

external capacitor connected between the OSC pin and

ground. Recommended values are between 200pF and

33pF, yielding switching frequencies between 50kHz and

250kHz. Figure 2 shows the nominal relationship between

external capacitance and switching frequency. Place the

capacitor as close as possible to the IC and minimize OSC

trace length and area to minimize stray capacitance and

potential noise pickup.

Y

ou can synchronize the oscillator frequency to an external frequency. This is done with a signal on the SYNC pin.

Set the LT3825 frequency 10% slower than the desired

external frequency using the OSC pin capacitor, then use

a pulse on the SYNC pin of amplitude greater than 2V and

with the desired frequency. The rising edge of the SYNC

signal initiates an OSC capacitor discharge forcing primary MOSFET off (PG voltage goes low). If the oscillator

frequency is much different from the sync frequency,

300

200

(kHz)

OSC

f

100

50

30

Figure 2. f

vs OSC Capacitor Values

OSC

C

(pF)

OSC

100 200

3825 F02

problems may occur with slope compensation and system stability. Keep the sync pulse width greater than

500ns.

Selecting Timing Resistors

There are three internal “one-shot” times that are programmed by external application resistors: minimum on

time, enable delay time and primary MOSFET turn-on

delay. These are all part of the isolated flyback control

technique, and their functions are previously outlined in

the Theory of Operation section.

The following information should help in selecting and/or

optimizing these timing values.

Minimum On Time (t

ON(MIN)

)

Minimum on time is the programmable period during

which current limit is blanked (ignored) after the turn on

of the primary side switch. This improves regulator performance by eliminating false tripping on the leading edge

spike in the switch, especially at light loads. This spike is

due to both the gate/source charging current and the

discharge of drain capacitance. The isolated flyback sensing requires a pulse to sense the output. Minimum on time

ensures that there is always a signal to close the loop.

The LT3825 does not employ cycle skipping at light loads.

Therefore, minimum on time along with synchronous rectification sets the switch over to forced continuous mode

operation.

3825f

17

LT3825

WUUU

APPLICATIO S I FOR ATIO

The t

ON(MIN)

Rk

tON MIN

Keep R

resistor is set with the following equation:

()

()

tON(MIN)

tns

ON MIN

Ω =

greater than 70k. A good starting value is

()–

()

.

1 063

104

160k.

Enable Delay Time (ENDLY)

Enable delay time provides a programmable delay between

turn-off of the primary gate drive node and the subsequent

enabling of the feedback amplifier. As discussed earlier,

this delay allows the feedback amplifier to ignore the leakage inductance voltage spike on the primary side.

The worst-case leakage spike pulse width is at maximum

load conditions. So set the enable delay time at these

conditions.

While the typical applications for this part use forced

continuous operation, it is conceivable that a secondaryside controller might cause discontinuous operation at

light loads. Under such conditions the amount of energy

stored in the transformer is small. The flyback waveform

becomes “lazy” and some time elapses before it indicates

the actual secondary output voltage. The enable delay time

should be made long enough to ignore the “irrelevant”

portion of the flyback waveform at light load.

Even though the LT3825 has a robust gate drive, the gate

transition time slows with very large MOSFETs. Increase

delay time as required when using such MOSFETs.

The enable delay resistor is set with the following

equation:

Rk

Keep R

ENDLY

ENDLY

()

tns

Ω =

greater than 40k. A good starting point is

ENDLY

2 616

()–

.

30

56k.

Primary Gate Delay Time (PGDLY)

Primary gate delay is the programmable time from the

turn-off of the synchronous MOSFET to the turn-on of the

primary side MOSFET. Correct setting eliminates overlap

between the primary side switch and secondary side

synchronous switch(es) and the subsequent current spike

in the transformer. This spike will cause additional component stress and a loss in regulator efficiency.

The primary gate delay resistor is set with the following

equation:

Rk

PGDLY

()

Ω =

tns

PGDLY

()

.

901

+ 47

A good starting point is 27k.

Soft-Start Functions

The LT3825 contains an optional soft-start function that is

enabled by connecting an external capacitor between the

SFST pin and ground. Internal circuitry prevents the

control voltage at the V

pin from exceeding that on the

C

SFST pin. There is an initial pull-up circuit to quickly bring

the SFST voltage to approximately 0.8V. From there it

charges to approximately 2.8V with a 20µA current source.

The SFST node is discharged to 0.8V when a fault occurs.

A fault is V

too low (undervoltage lockout), current

CC

sense voltage greater than 200mV or the IC’s thermal

(over temperature) shutdown is tripped. When SFST discharges, the VC node voltage is also pulled low to below

the minimum current voltage. Once discharged and the

fault removed, the SFST recharges up again.

In this manner, switch currents are reduced and the stresses

in the converter are reduced during fault conditions.

The time it takes to fully charge soft-start is:

CV

•.

14

t

SS

SFST

=

20

A

µ

ms C F

=µ

•()

70

SFST

UVLO Pin Function

The UVLO pin provides a user programming undervoltage

lockout. This is typically used to provide undervoltage

lockout based on VIN. The gate drivers are disabled when

UVLO is below the 1.24V UVLO threshold. An external

resistive divider between the input supply and ground is

used to set the turn-on voltage.

18

3825f

WUUU

APPLICATIO S I FOR ATIO

LT3825

The bias current on this pin depends on the pin voltage

and UVLO state. The change provides the user with

adjustable UVLO hysteresis. When the pin rises above the

UVLO threshold a small current is sourced out of the pin,

increasing the voltage on the pin. As the pin voltage drops

below this threshold, the current is stopped, further

dropping the voltage on UVLO. In this manner, hysteresis

is produced.

Referring to Figure 3, the voltage hysteresis at V

to the change in bias current times R

procedure is to select the desired V

hysteresis, V

V

R

UVHYS

=

A

I

UVLO

UVHYS

. Then:

A

referred voltage

IN

is equal

IN

. The design

where:

I

= I

UVLO

R

is then selected with the desired turn-on voltage:

B

R

=

B

V

⎛

⎜

V

⎝

UVLOL

R

A

()

IN ON

UVLO

– I

–1

is approximately 3.4µA

UVLOH

⎞

⎟

⎠

If we wanted a VIN-referred trip point of 36V, with 1.8V

(5%) of hysteresis (on at 36V, off at 34.2V):

Even with good board layout, board noise may cause

problems with UVLO. You can filter the divider but keep

large capacitance off the UVLO node because it will slow

the hysteresis produced from the change in bias current.

Figure 3c shows an alternate method of filtering by splitting the R

resistor with the capacitor. The split should put

A

more of the resistance on the UVLO side.

Converter Start-Up

The standard topology for the LT3825 utilizes a third

transformer winding on the primary side that provides

both feedback information and local V

power for the

CC

LT3825 (see Figure 4). This power “bootstrapping”

improves converter efficiency but is not inherently

self-starting. Start-up is affected with an external “tricklecharge” resistor and the LT3825’s internal V

undervoltage

CC

lockout circuit. The VCC undervoltage lockout has wide

hysteresis to facilitate start-up.

In operation, the “trickle charge” resistor RTR is connected

to VIN and supplies a small current, typically on the order

of 1mA to charge C

only its start-up current. When C

. Initially the LT3825 is off and draws

TR

reaches the V

TR

CC

turnon threshold voltage the LT3825 turns on abruptly and

draws its normal supply current.

V

18

R

R

V

IN

R

A

R

B

(3a) UV Turning ON

.

=

A

=

B

UVLO

34

.

⎛

36

⎝⎝

.

123

LT3825

µ

523

I

UVLO

A

V

kuse k

=

529 523

,

k

= 18 5 18 7., .kuse k

⎞

–

1

⎠

V

I

UVLO

V

IN

R

A

UVLO

B

Figure 3

LT3825

R

(3b) UV Turning OFF (3c) UV Filtering

C

UVLO

V

IN

R

TR

+

C

TR

V

IN

R

A1

R

A2

R

B

3825 F03

UVLO

V

THRESHOLD

ON

Figure 4. Typical Power Bootstrapping

I

VCC

V

CC

LT3825 PG

GND

V

VCC

I

VCC

0

V

PG

•

V

IN

•

•

3825 F04

3825f

19

LT3825

WUUU

APPLICATIO S I FOR ATIO

Switching action commences and the converter begins to

deliver power to the output. Initially the output voltage is

low and the flyback voltage is also low, so C

supplies

TR

most of the LT3825 current (only a fraction comes from

R

.) VCC voltage continues to drop until after some time,

TR

typically tens of milliseconds, the output voltage approaches its desired value. The flyback winding then

provides the LT3825 supply current and the VCC voltage

stabilizes.

is undersized, VCC reaches the VCC turn-off thresh-

If C

TR

old before stabilization and the LT3825 turns off. The V

CC

node then begins to charge back up via RTR to the turn-on

threshold, where the part again turns on. Depending upon

the circuit, this may result in either several on-off cycles

before proper operation is reached, or permanent relaxation oscillation at the V

R

is selected to yield a worst-case minimum charging

TR

node.

CC

current greater than the maximum rated LT3825 start-up

current, and a worst-case maximum charging current less

than the minimum rated LT3825 supply current.

R

TR MAX

<

()

VV

IN MIN CC ON MAX

–

() (_ )

I

CC ST MAX

(_ )

and

R

TR MIN

>

()

VV

IN MAX CC ON MIN

–

() (_)

I

CC MIN

()

Make CTR large enough to avoid the relaxation oscillatory

behavior described above. This is complicated to determine theoretically as it depends on the particulars of the

secondary circuit and load behavior. Empirical testing is

recommended. Note that the use of the optional soft-start

function lengthens the power-up timing and requires a

correspondingly larger value for CTR.

If you have an available input voltage within the V

range,

CC

the internal wide hysteresis range UVLO function becomes counterproductive. In such cases it is better to

operate the LT3825 directly from the available supply. In

this case, use the LT3837 which is identical to the LT3825

except that it lacks the internal V

undervoltage lockout

CC

function. It is designed to operate directly from supplies in

the range of 4.5V to 19V. See the LT3837 data sheet for

further information.

The LT3825 has an internal clamp on V

of approximately

CC

19.5V. This provides some protection for the part in the

event that the switcher is off (UVLO low) and the V

is pulled high. If R

is sized correctly the part should

TR

CC

node

never attain this clamp voltage.

Control Loop Compensation

Loop frequency compensation is performed by connecting a capacitor network from the output of the feedback

amplifier (V

pin) to ground as shown in Figure 5. Because

C

of the sampling behavior of the feedback amplifier, compensation is different from traditional current mode switcher

controllers. Normally only CVC is required. RVC can be

used to add a “zero” but the phase margin improvement

traditionally offered by this extra resistor is usually already

accomplished by the nonzero secondary circuit impedance. C

pole and is usually sized at 0.1 times C

can be used to add an additional high frequency

VC2

.

VC

V

C

9

R

C

VC

VC2

C

VC

3825 F05

Figure 5. VC Compensation Network

In further contrast to traditional current mode switchers,

V

pin ripple is generally not an issue with the LT3825. The

C

dynamic nature of the clamped feedback amplifier forms

an effective track/hold type response, whereby the V

C

voltage changes during the flyback pulse, but is then

“held” during the subsequent “switch on” portion of the

20

3825f

WUUU

APPLICATIO S I FOR ATIO

LT3825

next cycle. This action naturally holds the VC voltage stable

during the current comparator sense action (current mode

switching).

AN19 provides a method for empirically tweaking frequency compensation. Basically it involves introducing a

load current step and monitoring the response.

Slope Compensation

This part incorporates current slope compensation. Slope

compensation is required to ensure current loop stability

when the DC is greater than 50%. In some switcher

controllers, slope compensation reduces the maximum

peak current at higher duty cycles. The LT3825 eliminates

this problem by having circuitry that compensates for the

slope compensation so that maximum current sense

voltage is constant across all duty cycles.

Minimum Load Considerations

At light loads, the LT3825 derived regulator goes into

forced continuous conduction mode. The primary side

switch always turns on for a short time as set by the

t

ON(MIN)

resistor. If this produces more power than the

load requires, power will flow back into the primary during

the “off” period when the synchronization switch is on.

This does not produce any inherently adverse problems,

though light load efficiency is reduced.

It is possible for the peak primary switch currents as

referred across R

to exceed the max 98mV rating

SENSE

because of the minimum switch on time blanking. If the

voltage on V

exceeds 206mV after the minimum

SENSE

turn-on time, the SFST capacitor is discharged, causing

the discharge of the V

capacitor. This then reduces the

C

peak current on the next cycle and will reduce overall

stress in the primary switch.

Short-Circuit Conditions

Loss of current limit is possible under certain conditions

such as an output short circuit. If the duty cycle exhibited

by the minimum on time is greater than the ratio of

secondary winding voltage (referred-to-primary) divided

by input voltage, then peak current is not controlled at the

nominal value. It ratchets up cycle-by-cycle to some

higher level. Expressed mathematically, the requirement

to maintain short-circuit control is:

DC t f

=<

MIN ON MIN OSC

•

()

IR R

•

SC SEC DS ON

+

()

VN

•

IN

()

SSP

where:

t

ON(MIN)

I

SC

N

= primary side switch minimum on time

= short-circuit output current

= secondary-to-primary turns ratio (N

SP

SEC/NPRI

)

Maximum Load Considerations

The current mode control uses the VC node voltage and

amplified sense resistor voltage as inputs to the current

comparator. When the amplified sense voltage exceeds

node voltage, the primary side switch is turned off.

the V

C

In normal use, the peak switch current increases while FB

is below the internal reference. This continues until V

C

reaches its 2.56V clamp. At clamp, the primary side

MOSFET will turn off at the rated 98mV V

SENSE

level. This

repeats on the next cycle.

Other variables as previously defined

Trouble is typically encountered only in applications with

a relatively high product of input voltage times secondaryto-primary turns ratio and/or a relatively long minimum

switch on time. Additionally, several real world effects

such as transformer leakage inductance, AC winding

losses, and output switch voltage drop combine to make

this simple theoretical calculation a conservative estimate.

Prudent design evaluates the switcher for short-circuit

protection and adds any additional circuitry to prevent

destruction.

3825f

21

LT3825

WUUU

APPLICATIO S I FOR ATIO

Output Voltage Error Sources

The LT3825’s feedback sensing introduces additional

sources of errors. The following is a summary list.

The internal bandgap voltage reference sets the reference

voltage for the feedback amplifier. The specifications

detail its variation.

The external feedback resistive divider ratio proportional

directly affects regulated voltage. Use 1% components.

Leakage inductance on the transformer secondary reduces

the effective secondary-to-feedback winding turns ratio

(N

) from its ideal value. This increases the output volt-

S/NF

age target by a similar percentage. Since secondary leakage inductance is constant from part to part (with a

tolerance) adjust the feedback resistor ratio to compensate.

The transformer secondary current flows through the

impedances of the winding resistance, synchronous MOSFET R

and output capacitor ESR. The DC equivalent

DS(ON)

current for these errors is higher than the load current

because conduction occurs only during the converter’s

“off” time. So divide the load current by (1 – DC).

If the output load current is relatively constant, the feedback resistive divider is used to compensate for these

losses. Otherwise, use the LT3825 load compensation

circuitry (see Load Compensation).

For the primary-side power MOSFET, the peak current is:

I

PK PRI

()

where X

P

IN

VDC

IN MIN MAX

is peak-to-peak current ratio as defined earlier.

MIN

•

()

X

MIN

2

⎞

⎟

⎠

⎛

1

•=+

⎜

⎝

For each secondary-side power MOSFET, the peak current

is:

I

I

PK SEC

()

OUT

1

–

DC

MAX

Select a primary-side power MOSFET with a BV

X

MIN

2

⎞

⎟

⎠

⎛

1

•=+

⎜

⎝

DSS

greater

than:

BV I

≥ ++

DSS PK

L

LKG

C

P

V

IN MAX

()

V

OUT MAX

()

N

SP

where NSP reflects the turns ratio of that secondary-toprimary winding. L

tance and C

the C

OSS

is the primary-side capacitance (mostly from

P

of the primary-side power MOSFET). A snubber

is the primary-side leakage induc-

LKG

may be added to reduce the leakage inductance as discussed earlier.

For each secondary-side power MOSFET, the BV

DSS

should

be greater than:

If multiple output windings are used, the flyback winding

will have a signal that represents an amalgamation of all

these windings impedances. Take care that you examine

worst-case loading conditions when tweaking the voltages.

Power MOSFET Selection

The power MOSFETs are selected primarily on the criteria

of “on” resistance R

source breakdown voltage (BV

age (VGS) and maximum drain current (I

, input capacitance, drain-to-

DS(ON)

), maximum gate volt-

DSS

D(MAX)

).

22

BV

≥ V

DSS

Choose the primary side MOSFET R

OUT

+ V

IN(MAX)

• N

SP

DS(ON)

at the nominal

gate drive voltage (7.5V). The secondary side MOSFET

gate drive voltage depends on the gate drive method.

Primary side power MOSFET RMS current is given by:

P

I

()

RMS PRI

=

VDC

IN MIN MAX

IN

()

3825f

WUUU

APPLICATIO S I FOR ATIO

LT3825

For each secondary-side power MOSFET RMS current is

given by:

I

–=1

OUT

DC

MAX

I

()

RMS SEC

Calculate MOSFET power dissipation next. Because the

primary-side power MOSFET operates at high V

transition power loss term is included for accuracy. C

, a

DS

MILLER

is the most critical parameter in determining the transition

loss, but is not directly specified on the data sheets.

C

is calculated from the gate charge curve included

MILLER

on most MOSFET data sheets (Figure 6).

V

GS

Figure 6. Gate Charge Curve

MILLER EFFECT

ab

Q

A

GATE CHARGE (Q

3825 F06

Q

B

)

G

The flat portion of the curve is the result of the Miller (gateto-drain) capacitance as the drain voltage drops. The

Miller capacitance is computed as:

where:

RDR is the gate driver resistance (≈10Ω)

is the MOSFET gate threshold voltage

V

TH

f

is the operating frequency

OSC

V

GATE(MAX)

= 7.5V for this part

(1 + δ) is generally given for a MOSFET in the form of a

normalized R

vs temperature curve. If you don’t

DS(ON)

have a curve, use δ = 0.005/°C • ∆T for low voltage

MOSFETs.

The secondary-side power MOSFETs typically operate at

substantially lower V

, so you can neglect transition

DS