High Efficiency 2-Phase Boost Converter Minimizes Input and

Output Current Ripple –

Design Note 371

Goran Perica

Introduction

Many automotive and industrial applications require higher

voltages than is available on the input power supply rail.

A simple DC/DC boost converter suffices when the power

levels are in the 10W to 50W range, but if higher power

levels are required, the limitations of a straightforward

boost converter become quickly apparent. Boost converters convert a low input voltage to a higher output

voltage by processing the input current with a boost

inductor, power switch, output diode and output capacitor. As the output power level increases, the currents in

these components increase as well. Switching currents

INPUT

10V TO 23V

13.3k

4.7nF

80.6k

12.4k

75k

12k

1

RUN

2

I

TH

4

FREQ

5

MODE/SYNC

3

V

FB

LTC1871-7

229k

GATE

SENSE

INTV

GND

V

IN

CC

Figure 1a. Single-Phase Boost Converter: Can be Used

to Convert 12V Input to 24V, 10A Output

22μF

L1

×2

4.7μH

HAT2165

×2

0.002Ω

MBRB2545

22μF

×6

9

7

10

8

4.7μF

6

L1: COOPER HC3-4R7

ALL CERAMIC CAPACITORS ARE X7R, TDK

also increase proportional to the output-to-input voltage

conversion ratio, so if the input voltage is low, the

switching currents can overwhelm a simple boost converter and generate unacceptable EMI.

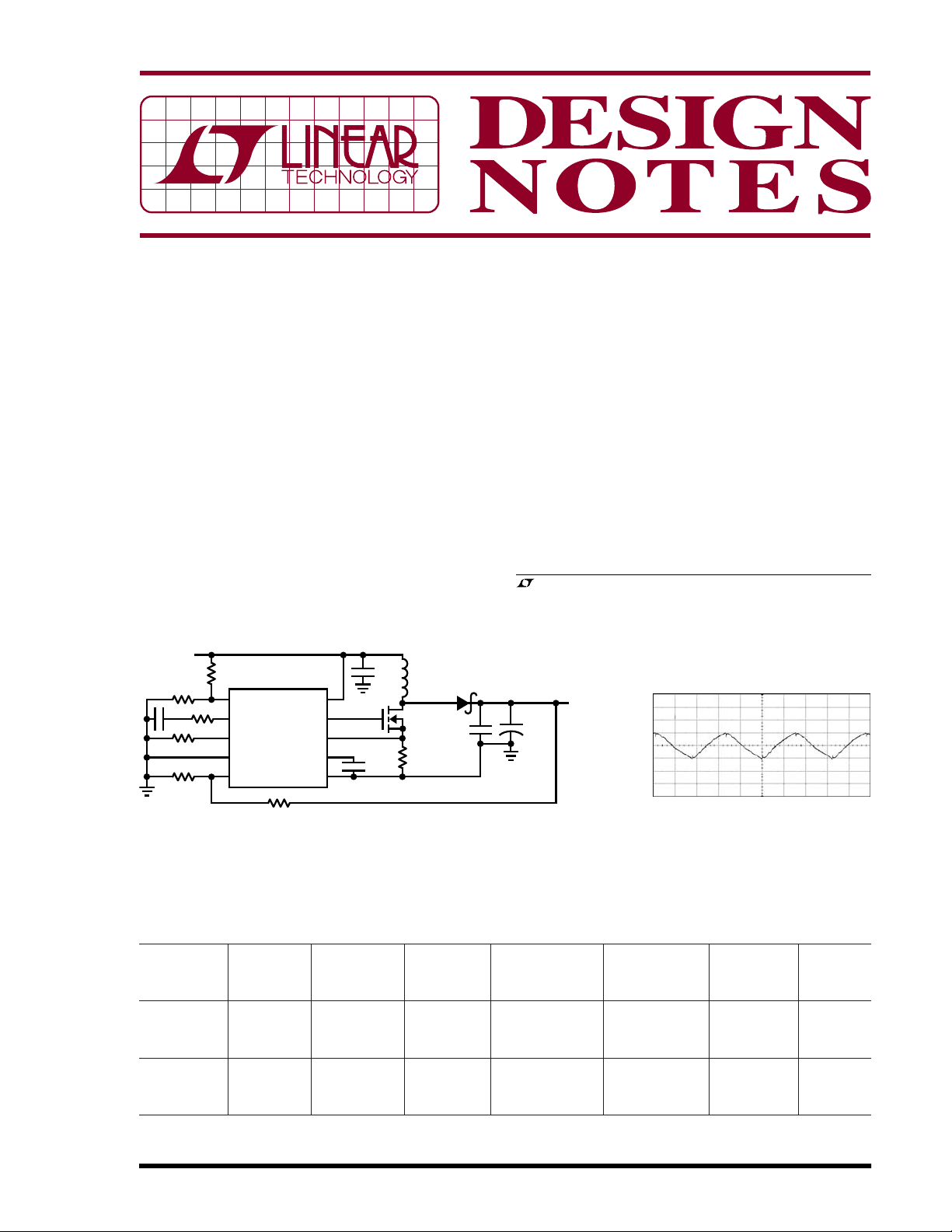

For example, consider Figure 1, a 12V input to 24V, 10A

output switching converter operating at 300kHz. The

currents processed by the converter in Figure 1 are shown

in the first row of Table 1. The relatively high current levels

in the switcher are reflected in high input and output ripple

currents, which results in increased EMI.

, LTC, LT and Burst Mode are registered trademarks of Linear Technology

Corporation. All other trademarks are the property of their respective owners.

OUTPUT

24V

+

220μF

10A

DN371 F01

V

OUT

100mV/DIV

1μs/DIV

DN371 F01b

Figure 1b. Single-Phase Boost

Converter Output Voltage Ripple

Table 1. Dual-Phase Boost Converter Has Lower Input and Output Ripple Currents and Voltages Than Single-Phase Boost

Converter

MOSFET OUTPUT OUTPUT OUTPUT OUTPUT

INPUT RMS INPUT RIPPLE RMS DRAIN DIODE CAPACITOR CAPACITOR VOLTAGE

CURRENT CURRENT CURRENT RMS CURRENT RMS CURRENT FREQUENCY RIPPLE

SINGLE-PHASE

BOOST 21.1A 4.2A

CONVERTER

DUAL-PHASE

BOOST 20.7A 0.17A

CONVERTER

09/05/371

P-P

P-P

15.4A 14.4A 10.5A 300kHz 212mV

2 × 7.4A 2 × 7.2A 1.9A 600kHz 65mV

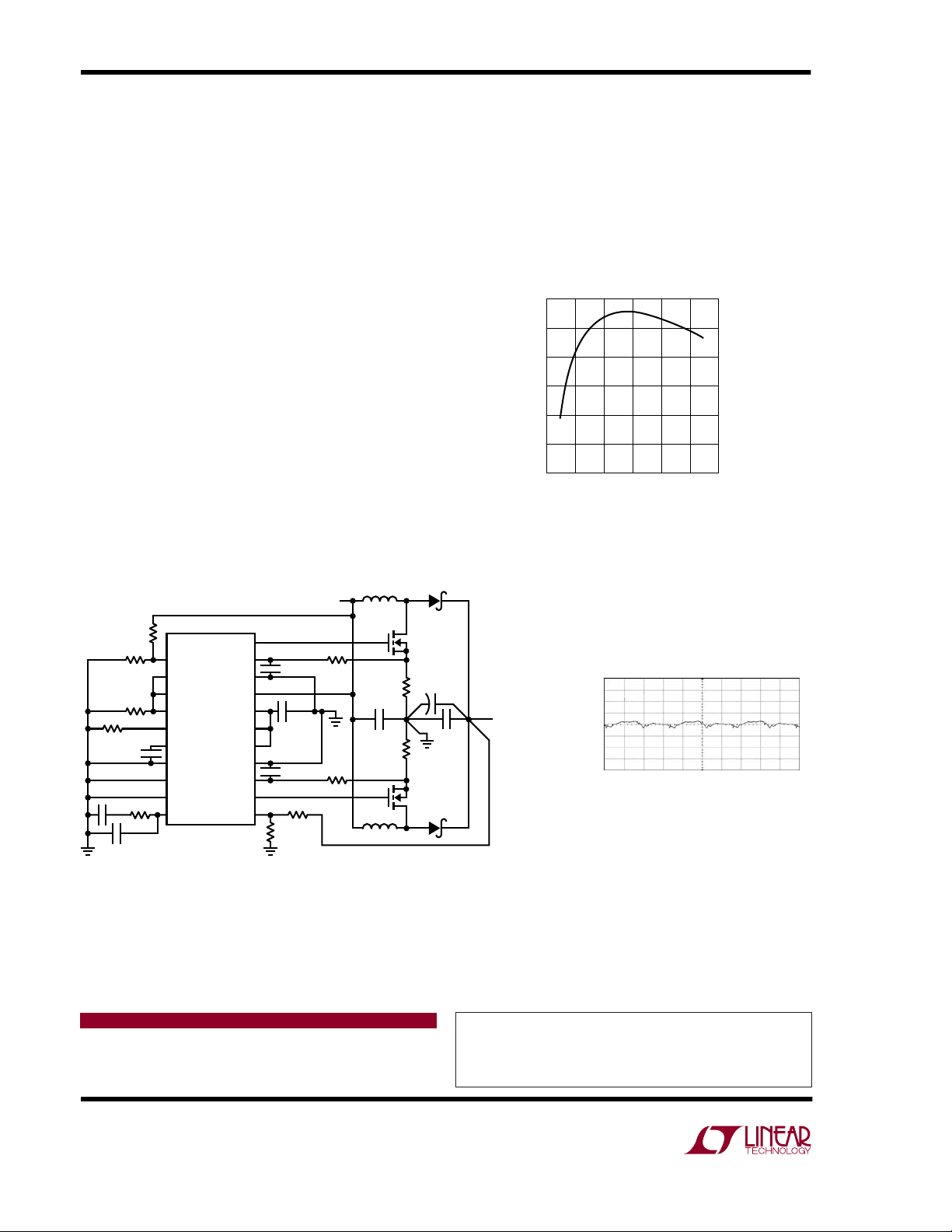

The circuit shown in Figure 2 performs the same DC/DC

conversion, but with greatly reduced input and output

ripple, significantly reducing EMI, and at a higher effective switching frequency, which allows the use of two

22μF output capacitors versus six 22μF output capacitors

required in Figure 1.

The trick is the 2-phase boost topology, which interleaves

two 180° out-of-phase output channels to mutually cancel out input and output ripple current—the results are

shown in the second row of Table 1. Each phase operates

at 50% duty cycle and the rectified output currents from

each phase flow directly to the load—namely the low

inductor ripple current—so only a small amount of output

current (shown in Table 1) is handled by the output

capacitors.

The centerpiece of the design in Figure 2 is the LT

®

3782

2-phase current mode PWM controller. Current mode

operation ensures balanced current sharing between the

two power converters resulting in even power dissipation

between the power stages.

The efficiency of the dual-phase converter, shown in

Figure 3, is high enough that it can be built entirely with

surface mount components—no need for heat sinks. In a

240W boost supply application, the power dissipation of

12.9W is relatively easy to manage in a well laid out, large

multilayer PCB with some forced airflow.

Conclusion

The simple LT3782 dual-phase switching boost converter

improves on single-phase alternatives by allowing high

power output with lower ripple currents, reduced heat

dissipation and a more compact design.

96

95

94

93

EFECIENCY (%)

92

91

90

0

468

2

OUTPUT CURRENT (A)

Figure 3. 12V Input to 24V Output Dual-Phase

Boost Converter Efficiency

10 12

DN371 F03

UPS840

HAT2165

220μF

HAT2165

UPS840

22μF

×2

+

59k

4.7nF

4.7nF

100pF

825k

274k

62k

15k

RUN

R

SET

DELAY

DCL

SLOPE

SS

GND

V

EE1

V

EE2

V

C

LT3782

BGATE1

SEN1P

SEN1N

V

GBIAS

GBIAS1

GBIAS2

SEN2N

SEN2P

BGATE2

INPUT

10V TO 23V

10nF

CC

FB

2.2μF

10nF

220k

24.9k

L1, L2: PULSE PB2020-153

ALL CERAMIC CAPACITORS ARE X7R TDK

L1

10Ω

0.004Ω

22μF

0.004Ω

10Ω

L2

Figure 2a. Dual-Phase Boost Converter Reduces EMI and Ripple

Currents with a Minimum Input and Output Filtering

Data Sheet Download

http://www.linear.com

OUTPUT

24V

10A

V

OUT

100mV/DIV

Figure 2b. Dual-Phase Boost

Converter Output Voltage Ripple

DN371 F02

For applications help,

call (408) 432-1900, Ext. 2593

1μs/DIV

DN371 F02b

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

dn371f LT/TP 0905 305K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2005

Loading...

Loading...