Transistor Synchronous Forward Controller

FEATURES

■

High Voltage Operation up to 72V

■

Synchronizable Operating Frequency and Output

Switch Phase for Multiple Controller Systems

■

Synchronous Switch Output

■

Undervoltage Lockout Protection with 6V Hysteresis

for Self-Biased Power

■

Fixed Frequency Operation to 350kHz

■

Local ±1% Voltage Reference

■

Input Overvoltage Protection

■

Low Start-Up Current

■

Programmable Start Inhibit for Power Supply

Sequencing and Protection

■

Optocoupler Support

■

Soft-Start Control

U

APPLICATIO S

■

Isolated Telecommunication Systems

■

Personal Computers and Peripherals

■

Distributed Power Step-Down Converters

■

Lead Acid Battery Backup Systems

■

Automotive and Heavy Equipment

U

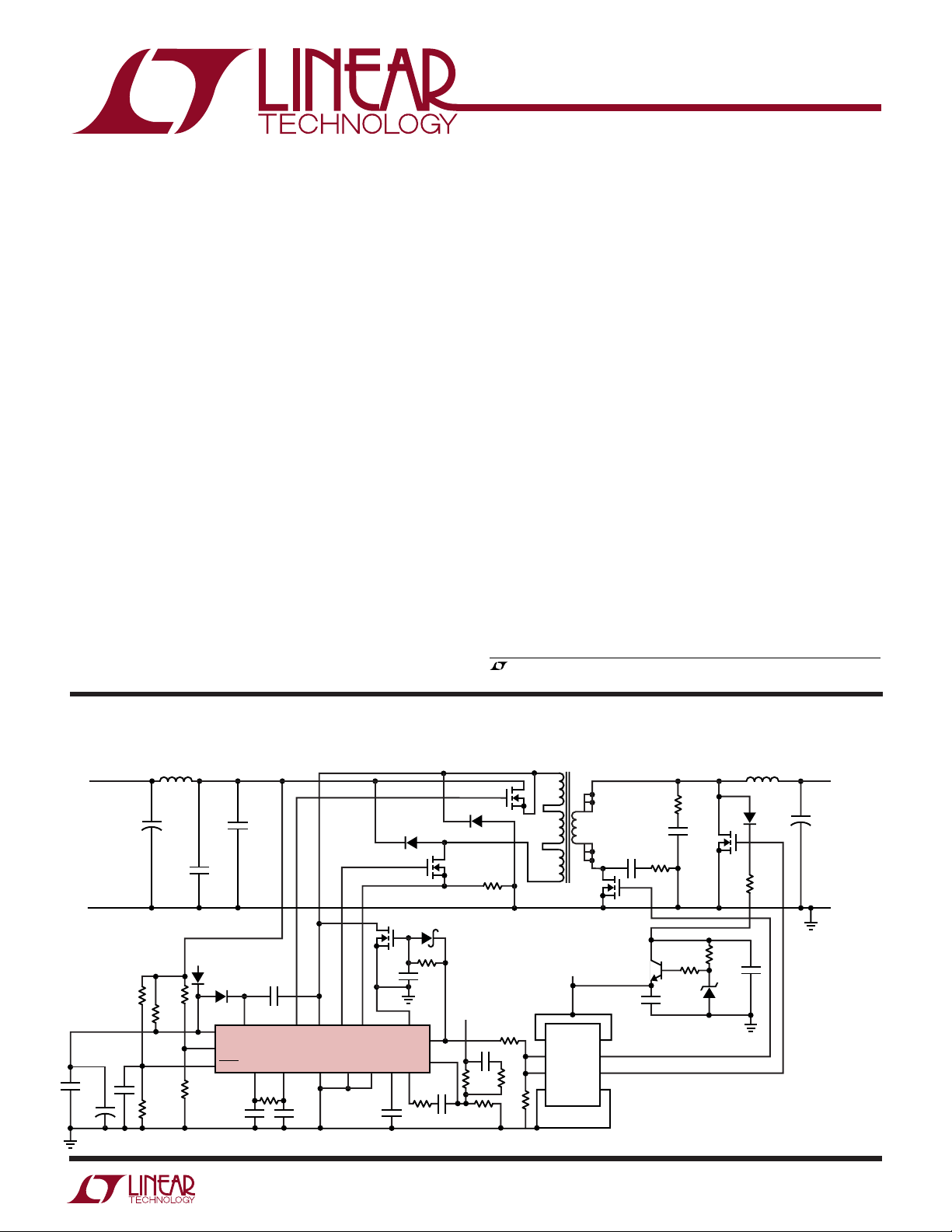

TYPICAL APPLICATIO

L1

+

V

IN

–

V

IN

4.7µH

C2

+

22µF

100V

C3

1.5µF

100V

C4

1.5µF

100V

Synchronous Forward Converter (Quarter-Brick Footprint)

36V-72V to 5V/7A DC/DC

MURS120T3

Q3

ZVN3310F

BAT54

LT3781

“Bootstrap” Start Dual

U

DESCRIPTIO

The LT®3781 controller simplifies the design of high

power synchronous dual transistor forward DC/DC converters. The part employs fixed frequency current mode

control and supports both isolated and nonisolated topologies. The IC drives external N-channel power MOSFETs

and operates with input voltages up to 72V.

The LT3781 is ideal for output derived power schemes,

through the use of a large undervoltage lockout hysteresis

range. The part is also equipped with an 18V VCC shunt

regulator, which prevents exceeding absolute maximum

ratings while in trickle start applications.

The LT3781’s operating frequency is programmable and

can be synchronized up to 350kHz. Switch phase is also

controlled during synchronized operation to accommodate multiple-converter systems. Internal logic guarantees 50% maximum duty cycle operation to prevent transformer saturation.

The LT3781 is available in a 20-lead SSOP package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

L2

4.7µH

MBR0540T1

4.7Ω

+

C5

330µF

10V

MURS120T3

0.025Ω

1/2W

T1

•

Q1

R9

6

1

7

2

3

•

•

5

8

10

11

•

4

12

9

Q5

1nF

100V

0.25W

1nF

100V

10Ω

0.25W

10Ω

Q6

V

= 5V

OUT

= 7A

I

OUT

+

V

OUT

–

V

OUT

68µF

20V

0.1µF

1OV

BIAS

MMBD914LT1

73.2k

270k

0.25W

+

1nF

10k

20k

1%

BAS21

13

2

1

1.24k

1%

0.1µF

100V

20

V

V

CC

BST

OVLO

SHDN

FSET

5V

REF

5

52.3k

1µF 150pF

19

BSTREF

TG

LT3781

THERM

6

11

15

18

SENSE

BG

SYNC SGND

374

4.7nF

PGND

V

8SS10

14

V

C

100Ω

10k

330pF

SG

FB

12

9

0.01µF

OUT

5V

0.047µF

3.01k

1%

1k

1%

3.3k

51Ω

6.8k

8

V

3

IN2

1

IN1

4

GND2

1OV

BIAS

LTC1693-2

CC1

FZT690

4.7µF

16V

6

V

CC2

5

OUT2

7

OUT1

2

GND1

C2:SANYO 100MV22AX

C3, C4: VITRAMON VJ1825Y155MXB

C5: 4X KEMET T510X337KO10AS

L1: COILCRAFT DO1608C-472

100Ω

CMPZ5242B

12V

2k

0.22µF

50V

L2: PANASONIC ETQP6F4R1LF4

Q1,Q3:100V SILICONIX SUD40N10-25

Q5,Q6: SILICONIX Si4450

T1:COILTRONICS VP5-1200

3781f

1

LT3781

WW

W

U

ABSOLUTE AXI U RATI GS

(Note 1)

Power Supply (VCC)

Low Impedance Source Voltage ............. –0.3V to 20V

Shutdown Mode:

(Supply Self-Regulates to 18V)

Maximum Input Current ............................... 20mA

Topside Supply (V

V

BSTREF

– 0.3V to V

Topside Reference Pin (V

SHDN Pin Voltage........................... –0.3V to V

All Other Input Voltages.............. –0.3V to 5V

5V

Pin Sink Current ......................................... 10mA

REF

FSET Pin Current ...................................... –2mA to 5mA

All Other Input Pin Currents...................... –2mA to 2mA

Operating Ambient

Temperature Range (Note 4) ...............–40°C to 85°C

Operating Junction

Temperature Range ...............................–40°C to 125°C

Storage Temperature Range ..................–65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

) ....................................................

BST

BSTREF

BSTREF

+20V (V

BST(MAX)

) ...............–0.6V to 75V

= 90V)

CC

+ 0.3V

REF

+ 0.3V

UUW

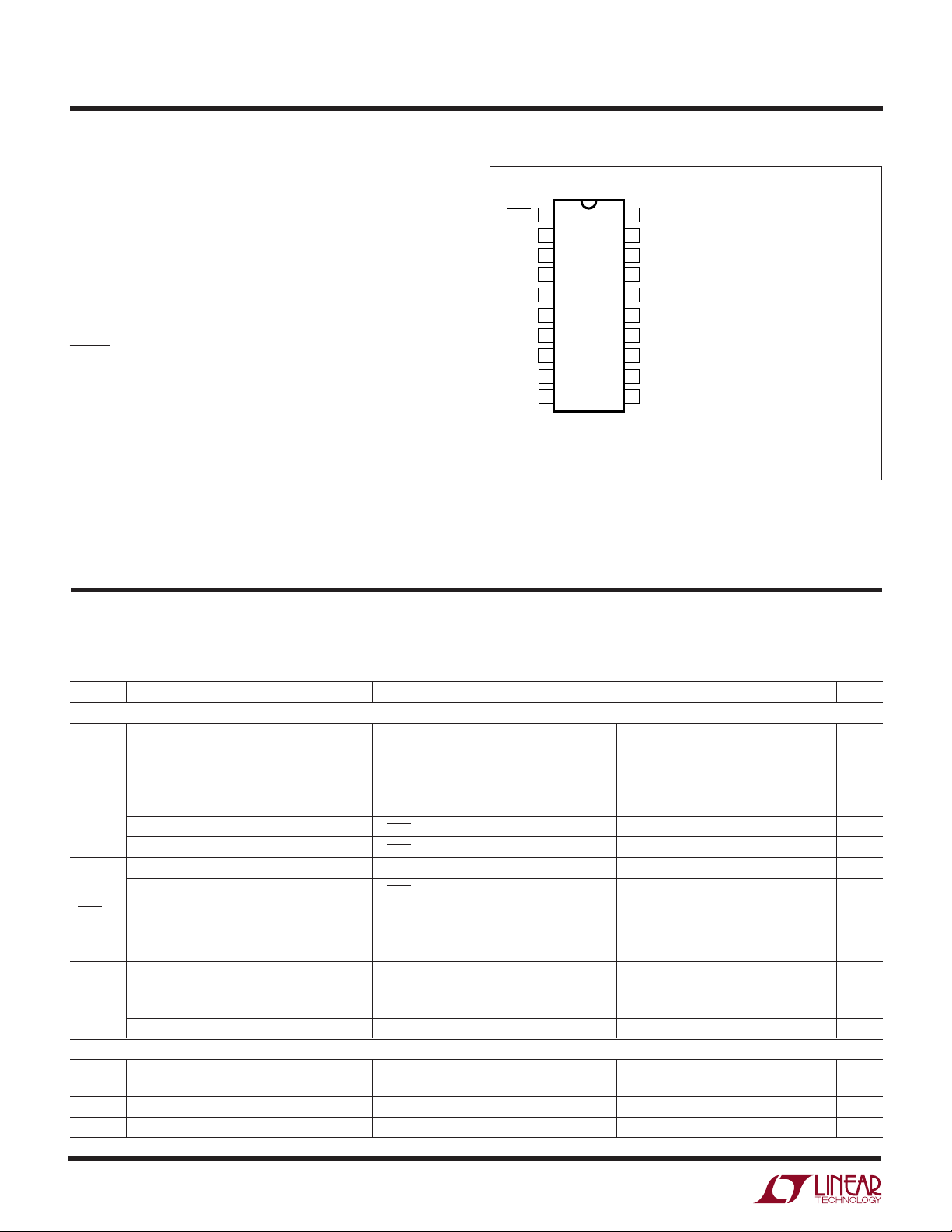

PACKAGE/ORDER I FOR ATIO

TOP VIEW

1

SHDN

2

OVLO

3

THERM

4

SGND

5

5V

REF

6

FSET

7

SYNC

8

SS

9

V

FB

10

V

C

G PACKAGE

20-LEAD PLASTIC SSOP

T

= 125°C, θJA = 90°C/W

JMAX

Consult LTC Marketing for parts specified with wider operating temperature ranges.

20

19

18

17

16

15

14

13

12

11

V

BST

TG

BSTREF

NC

NC

BG

PWRGND

V

CC

SG

SENSE

ORDER PART

NUMBER

LT3781EG

LT3781IG

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VCC = V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Supply and Protection

V

CCUVLO

V

CCSHDN

I

CC

V

BST

V

SHDN

I

SS

V

SS

V

BSTUVLO

5V External Reference

V

5VREF

I

5VREFSC

R

5VREF

= 12V, V

BST

Undervoltage Lockout Threshold Falling Edge ● 8.0 8.4 8.6 V

Shutdown Mode Shunt Regulator 100µA < I

DC Active Supply Current (Note 2) 17 22 mA

DC Active UVLO Supply Current V

DC Standby Supply Current V

DC Active Supply Current TG Logic High (Note 2) ● 5.0 8.5 mA

DC Standby Supply Current V

Shutdown Rising Threshold ● 1.15 1.25 1.35 V

Shutdown Threshold Hysteresis 100 150 200 mV

Soft-Start Charge Current VSS = 2V ● –14 –10 –6 µA

Soft-Start Reset Threshold 225 mV

Boost Undervoltage Lockout Falling Edge ● 5.7 6.4 7.1 V

(V

-BSTREF) Rising Edge ● 6.5 7.0 7.5 V

BST

Boost UVLO Hysteresis ● 0.3 0.6 V

5V Reference Voltage 0 ≤ (I

Short-Circuit Current Source, IVC = 0 ● 20 45 mA

Output Impedance 0 ≤ (I

= 0V, VVC = 2V, VFB = V

BSTREF

= 1.25V, CTG = CBG = CSG = 1000pF.

REF

Rising Edge

≤ 10mA ● 16.5 18 19.9 V

VCC

= 1.35V, VCC = 8V ● 800 1200 µA

SHDN

< 0.3V ● 16 30 µA

SHDN

< 0.3V 0.1 µA

SHDN

– IVC) < 20mA 4.85 5.0 5.10 V

5VREF

– IVC) < 20mA 1 Ω

5VREF

● 13 14.5 16 V

● 25 mA

● 4.80 5.15 V

3781f

2

LT3781

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VCC = V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Error Amp

V

FB

I

FB

A

V

I

VC

V

VC

GBW Gain Bandwidth Product (Note 3) 1 MHz

Current Sense

A

V

I

SENSE

V

SENSE

t

D

t

MIN

THERM and OVLO Fault Detectors

V

THERM

V

OVLO

t

D

Oscillator and Synchronization Decoder

f

OSC

I

FSET

V

SYNC

f

SYNC

t

H, L

Output Drivers

V

TG

t

TGr/f

V

BG

t

BGr/f

V

SG

t

SGr/f

t

SG-BG

t

TG-BG

= 12V, V

BST

= 0V, VVC = 2V, VTS = 0V, VFB = V

BSTREF

= 1.25V, CTG = CBG = CSG = 1000pF.

REF

Error Amplifier Reference Voltage Measured at Feedback Pin 1.242 1.250 1.258 V

● 1.225 1.265 V

Feedback Input Current VFB = V

REF

–50 nA

Error Amplifier Voltage Gain 72 dB

Error Amplifier Current Limit Source ● 10 25 mA

Sink

● 0.5 1 mA

Zero Current Output Voltage 1.4 V

Maximum Output Voltage 3.2 V

Amplifier DC Gain 12 V/V

Input Bias Current –275 µA

Current Limit Threshold Measured at SENSE Pin 135 150 165 mV

● 130 170 mV

Current Sense to Switch Delay 175 ns

Switch Minimum On Time Measured at BG Output 250 ns

/ Threshold (Rising Edge) ● 1.2 1.25 1.3 V

Threshold Hysteresis ● 20 40 60 mV

Fault Delay to Output Disable >50mV Overdrive 650 ns

Oscillator Frequency, Free Run Measured at F

Frequency Programming Error f

FSET Input Bias Current F

≤ 500kHz (Note 3) ● –10 5 %

OSC

Charging, V

SET

Pin 700 kHz

SET

= 2V 50 nA

FSET

SYNC Logic High Input Threshold Positive-Going Edge ● 1.4 2 V

SYNC Logic Low Input Threshold Negative-Going Edge ● 0.8 1.4 V

SYNC Frequency ● f

Maximum SYNC Pulse Width f

= Oscillator Free-Run Frequency 1/f

OSC

/2 350 kHz

OSC

OSC

(Logic High or Logic Low)

TG On Voltage ● 11 11.5 V

TG Off Voltage

● 0.1 0.5 V

TG Rise/Fall Time 10% to 90%/90% to 10% 35 ns

BG On Voltage ● 11 11.5 12 V

BG Off Voltage

● 0.1 0.5 V

BG Rise/Fall Time 10% to 90%/ 90% to 10% 35 ns

SG On Voltage ● 11 11.5 12 V

SG Off Voltage

● 0.1 0.5 V

SG Rise/Fall Time 10% to 90%/ 90% to 10% 35 ns

SG to BG Enable Lag Time 4V On/Off Thresholds ● 80 150 300 ns

TG to BG Enable Lag Time 4V On/Off Thresholds 100 ns

s

3781f

3

LT3781

ELECTRICAL CHARACTERISTICS

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Supply current specification does not include external FET gate

charge currents. Actual supply currents will be higher and vary with

operating frequency, operating voltages, and the type of external switch

elements used. See Applications Information.

Note 4: The LT3781E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

ambient temperature range are assured by design, characterization and

correlation with statistical process controls. For guaranteed performance

to specifications over the –40°C to 85°C operating ambient temperature

range, the LT3781I is available.

Note 3: Guaranteed but not tested.

UW

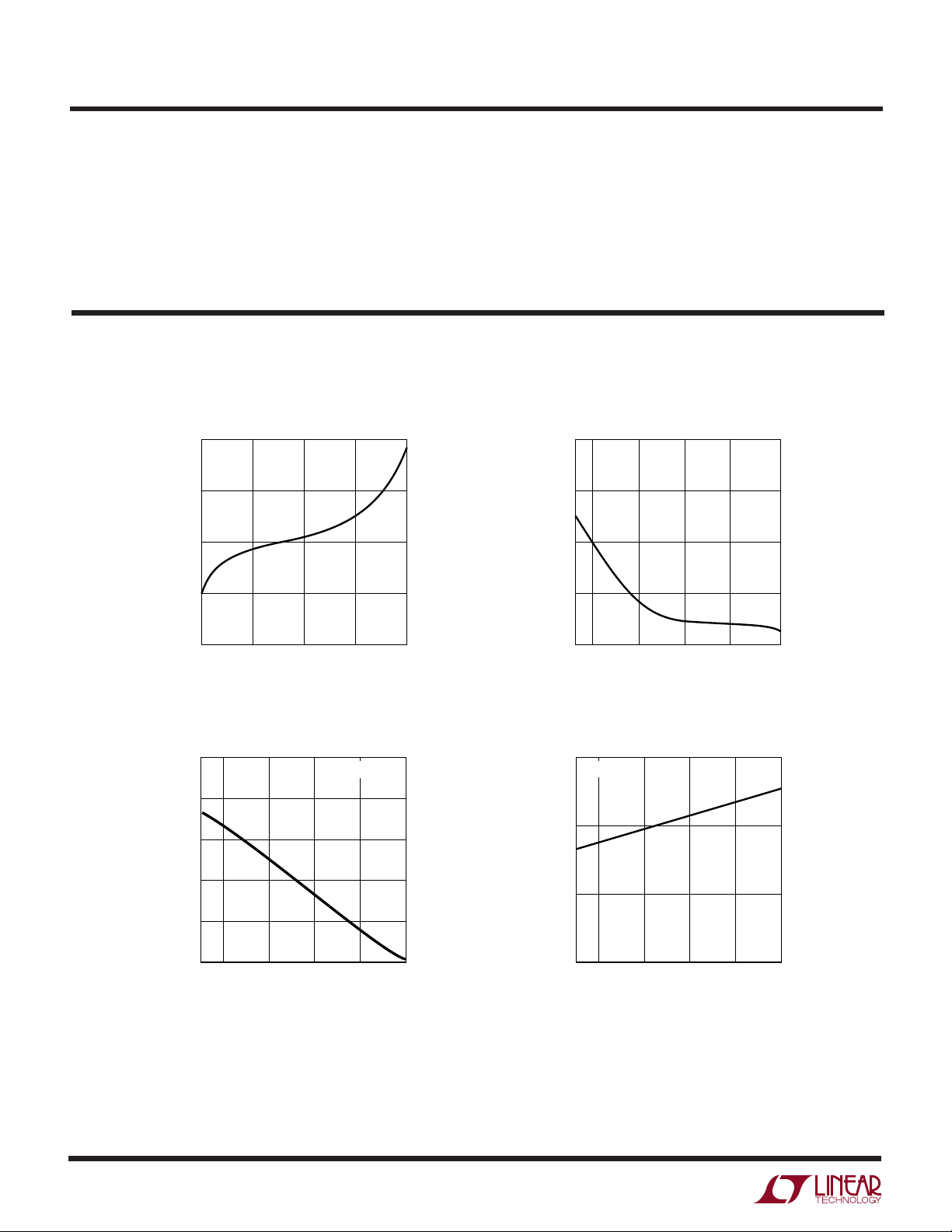

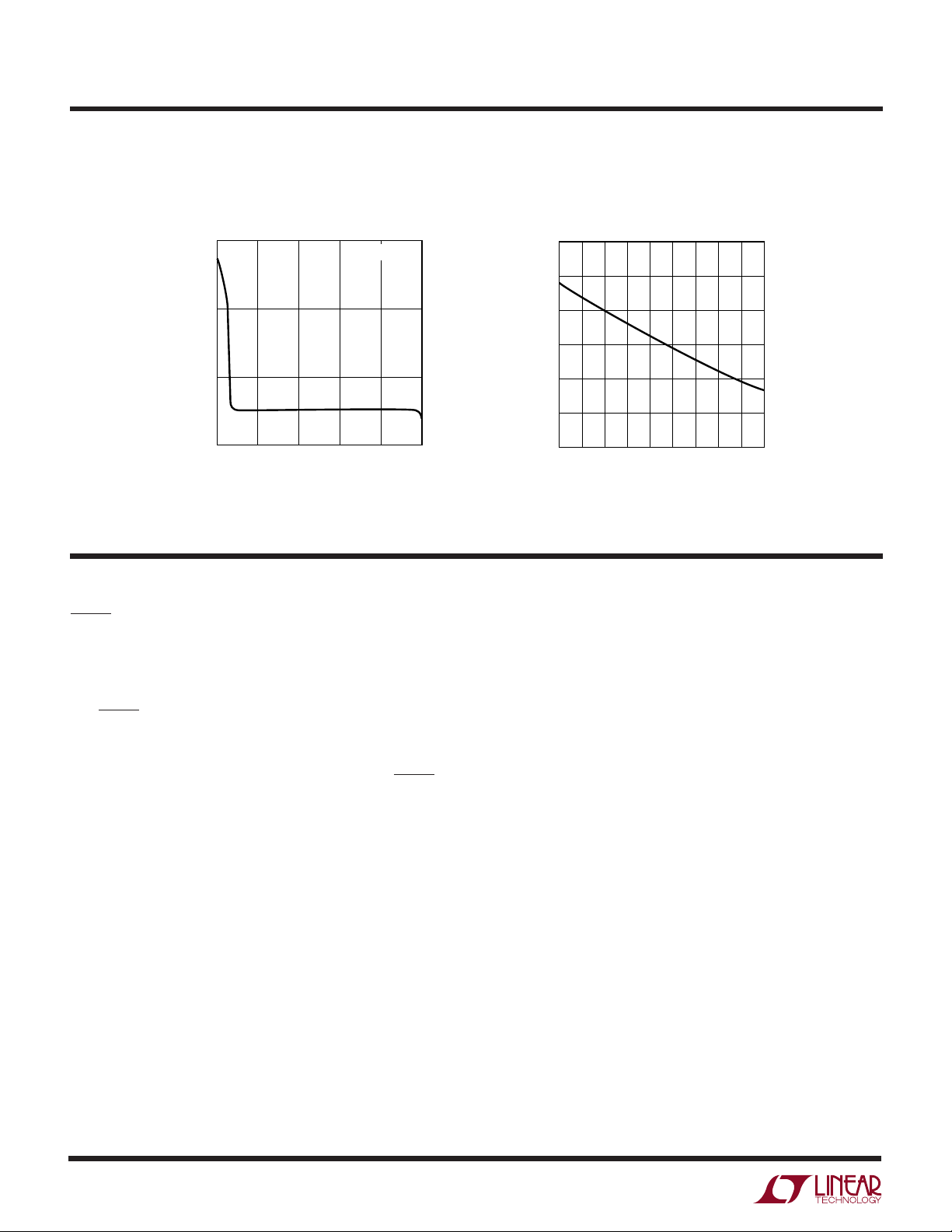

TYPICAL PERFOR A CE CHARACTERISTICS

Shutdown Mode: VCC vs I

18.4

TA = 25°C

18.2

(V)

18.0

CC

V

17.8

CC

18.20

18.15

(V)

18.10

CC

V

18.05

Shutdown Mode: VCC vs

Temperature (ICC = 1mA)

17.6

100µ

300µ

ICC Supply Current

vs Temperature

20

19

18

17

SUPPLY CURRENT (mA)

CC

I

16

15

–55

–40

0

TEMPERATURE (°C)

1m

ICC (A)

3m

3781 • G01a

10m

18.00

–55

–40

40

0

TEMPERATURE (°C)

80 125

3781 • G01b

ICC Supply Current

vs VCC Supply Voltage

18

VCC = 12V

40

12580

3781 G01

TA = 25°C

17

16

SUPPLY CURRENT (mA)

CC

I

15

9

12

10

SUPPLY VOLTAGE (V)

14

1816

3781 G03

4

3781f

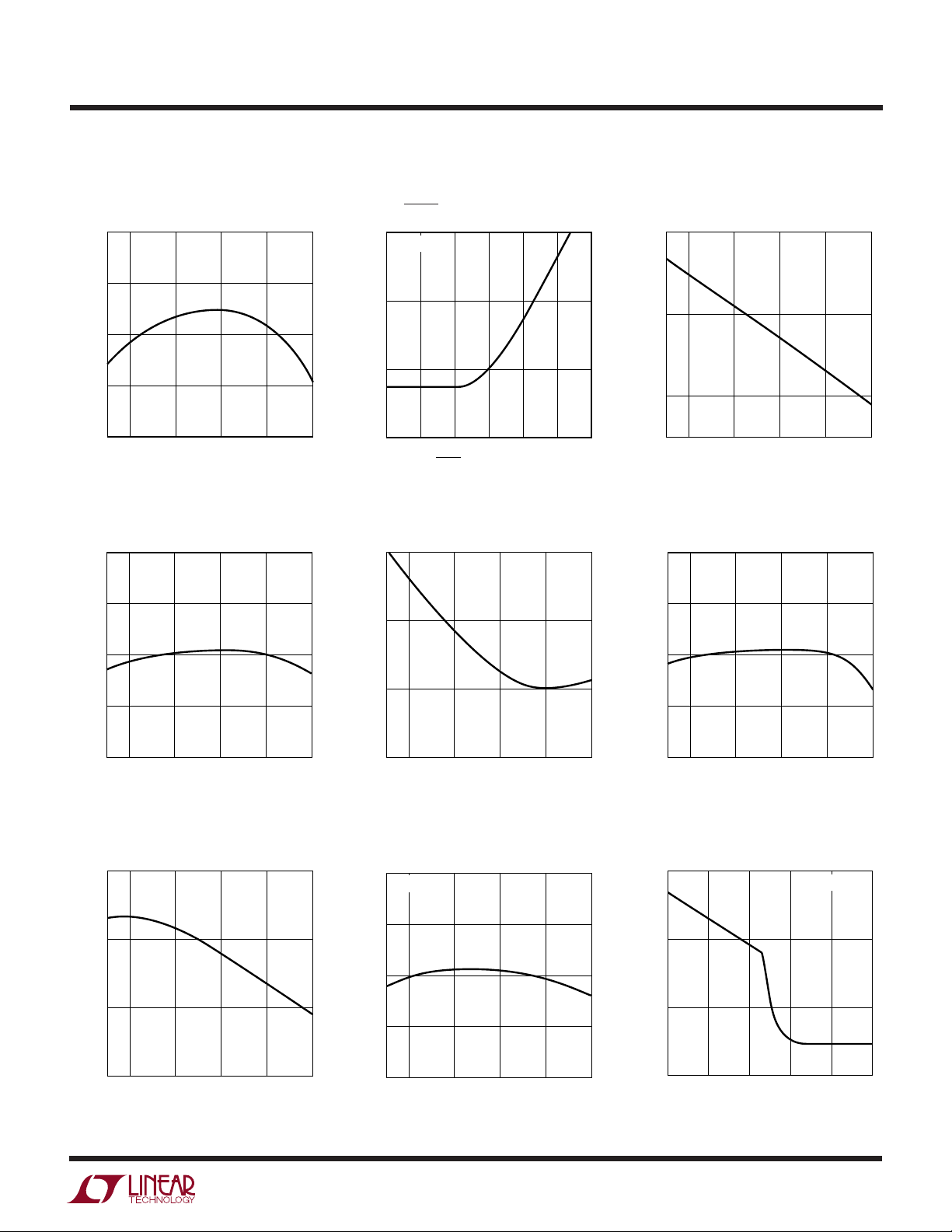

UW

SOFT-START PIN VOLTAGE (mV)

0

SOFT-START OUTPUT CURRENT (µA)

20

40

60

1000 200 300 400

3781 G12

500

TA = 25°C

TYPICAL PERFOR A CE CHARACTERISTICS

I

Boost Supply Current

BST

vs Temperature

5.2

5.1

5.0

ICC Supply Current

vs SHDN Pin Voltage

60

TA = 25°C

40

LT3781

UVLO ICC Supply Current

vs Temperature

1

0.8

4.9

BOOST SUPPLY CURRENT (mA)

BST

I

4.8

–55

–40

5V

REF

5.10

5.05

5.00

VOLTAGE (V)

REF

5V

4.95

4.90

–55

–40

0

TEMPERATURE (°C)

Voltage vs Temperature

0

TEMPERATURE (°C)

20

SUPPLY CURRENT (µA)

CC

I

40

12580

3781 G04

0

0.2 0.4 0.6 0.8

0

5V

SHDN PIN VOLTAGE (V)

Short-Circuit Current Limit

REF

1.0

1.2

3781 G05

vs Temperature

60

50

40

SHORT-CIRCUIT CURRENT LIMIT (mA)

REF

5V

40

12580

3781 G07

30

–55

–40

0

40

TEMPERATURE (°C)

12580

3781 G08

SUPPLY CURRENT (mA)

CC

0.6

UVLO I

0.5

–55

–40

0

TEMPERATURE (°C)

Error Amp Reference

vs Temperature

1.260

1.255

1.250

1.245

ERROR AMP REFERENCE (V)

1.240

–55

–40

0

TEMPERATURE (°C)

40

40

12580

3781 G06

12580

3781 G09

VC Pin Short-Circuit Current Limit

vs Temperature

25

20

15

PIN SHORT-CIRCUIT CURRENT LIMIT (mA)

C

V

10

–55

–40

0

40

TEMPERATURE (°C)

12580

3781 G10

Soft-Start Output Current

vs Temperature

12

VSS = 2V

11

10

9

SOFT-START OUTPUT CURRENT (µA)

8

–55

–40

0

TEMPERATURE (°C)

40

12580

3781 G11

Soft-Start Output Current

vs Soft-Start Pin Voltage

3781f

5

LT3781

TEMPERATURE (°C)

–55

2

CURRENT SENSE AMP BANDWIDTH (MHz)

3

5

6

7

–15

25

45 125

3781 G14

4

–35 5

65

85

105

8

UW

TYPICAL PERFOR A CE CHARACTERISTICS

U

PI FU CTIO S

SHDN (Pin 1): Shutdown Pin. Pin voltages exceeding

positive going threshold of 1.25V enables the LT3781.

150mV of input hysteresis resists mode switching instability.

The SHDN pin can be controlled by either a logic level input

or with an analog signal. This shutdown feature is typically

used for input supply undervoltage protection. A resistor

divider from the converter input supply to the SHDN pin

monitors that supply for control of system power-up

sequencing, etc.

An 18V clamp on the VCC pin is enabled during shutdown

mode, preventing a trickle start circuit from pulling that pin

above maximum operational levels. All other internal

functions are disabled during shutdown.

OVLO (Pin 2): Overvoltage Shutdown Sense. Typically

connected to input supply through a resistor divider. If pin

voltage exceeds 1.25V, LT3781 switching function is

disabled to protect boosted circuitry from exceeding absolute maximum voltage. 40mV of input hysteresis resists

mode switching instability. Exceeding the OVLO threshold

also triggers soft-start reset, resulting in a graceful recovery from an input transient event.

6

Soft-Start Output Current

vs Soft-Start Pin Voltage

60

40

20

SOFT-START OUTPUT CURRENT (µA)

0

10234

SOFT-START PIN VOLTAGE (V)

UU

TA = 25°C

3781 G13

Current Sense Amplifier

Bandwidth vs Temperature

5

THERM (Pin 3): System Thermal Shutdown. Auxiliary

shutdown pin that is typically used for system thermal

protection. If pin voltage exceeds 1.25V, LT3781

switching function is disabled. 40mV of input hysteresis

resists mode switching instability. Exceeding the THERM

threshold also triggers soft-start reset, resulting in a

graceful recovery.

SGND (Pin 4): Signal Ground Reference. Careful board

layout techniques must be used to prevent corruption of

signal ground reference. High-current switching paths

must be oriented on the converter ground plane such that

currents to/from the switches do not affect the integrity of

the LT3781 signal ground reference.

5V

(Pin 5): 5V Local Reference. Allows connection of

REF

external loads up to 20mA DC. Typically bypassed with

1µF ceramic capacitor to SGND. Reference output is

current limit protected to a typical value of 45mA. If the

load on the 5V reference exceeds the current limit value,

LT3781 switching function is disabled and the soft-start

function is reset.

FSET (Pin 6): Oscillator Timing Pin. Connect a resistor

(R

) from the 5V

FSET

(C

) from this pin to ground.

FSET

pin to this pin and a capacitor

REF

3781f

LT3781

U

UU

PI FU CTIO S

The LT3781 oscillator operates by monitoring the voltage

on C

FSET pin reaches 2.5V, the oscillator rapidly discharges

the capacitor with an average current of about 0.8mA.

Once the voltage on the pin is reduced to 1.5V, the pin

becomes high-impedance and the charging cycle repeats.

The oscillator operates at twice the switching frequency of

the controller.

Oscillator frequency f

relation:

fC

OSC FSET

SYNC (Pin 7): Oscillator Synchronization Input Pin with

TTL-Level Compatible Input. The SYNC input signal (at the

desired synchronized operating frequency) controls both

the internal oscillator (running at twice the SYNC frequency) and the output switch phase. If synchronization

function is not desired, this pin may be floated or shorted

to ground.

The LT3781 internal oscillator drives a toggle flip-flop that

assures a ≤50% duty-cycle condition during oscillator

free-run. The oscillator, therefore, runs at twice the operating frequency of the controller. The SYNC input decoder

incorporates a frequency doubling circuit for oscillator

synchronization, resetting the internal oscillator on both

the rising and falling edges of the input signal.

The SYNC input decoder also differentiates transition

phase and forces the toggle flip-flop to phase-lock with the

SYNC input. A transition to logic high on the SYNC input

signal corresponds to the initiation of a new switching

cycle (primary switches turning on pending current control) and a transition to logic low forces a primary switch

off state. As such, the maximum operating duty cycle is

equal to the duty cycle of the SYNC signal. The SYNC input

can therefore be used to reduce the maximum duty cycle

of the controller by reducing the duty cycle of the SYNC

input.

as it is charged via R

FSET

OSC

≅+ ++

05 10

64

––

.• •

R

. When the voltage on the

FSET

can be approximated by the

FSET

3

810

R

2

FSET

–

1

–

1

SS (Pin 8): Soft-Start. Connect a capacitor (CSS) from this

pin to ground.

The output voltage of the LT3781 error amplifier corresponds to the peak current sense amplifier output detected before resetting the switch outputs. The soft-start

circuit forces the error amplifier output to a zero sense

current for start-up. A 10µA current is forced from this pin

onto an external capacitor. As the SS pin voltage ramps up,

so does the LT3781 internally sensed current limit. This

effectively forces the internal current limit to ramp from

zero, allowing overall converter current to slowly increase

until normal output regulation is achieved. This function

reduces output overshoot on converter start-up. The softstart functions incorporate a 1VBE “dead zone” such that

a zero-current condition is maintained on the VC pin until

the SS pin rises to 1VBE above ground.

The SS pin voltage is reset to start-up condition during

shutdown, undervoltage lockout, and overvoltage or

overcurrent events, yielding a graceful converter output

recovery from these events.

VFB (Pin 9): Error Amplifier Inverting Input. Typically

connected to a resistor divider from the output and compensation components to the VC pin.

The VFB pin is the converter output voltage feedback node.

Input bias current of ~50nA forces pin high in the event of

an open feedback path condition. The error amplifier is

internally referenced to 1.25V.

Values for the V

to VFB feedback resistor (RFB1) and

OUT

the VFB to ground resistor (RFB2) can be calculated to

program converter output voltage (V

) via the following

OUT

relation:

V

= 1.25 • (RFB1 + RFB2)/RFB2

OUT

VC (Pin 10): Error Amplifier Output. The LT3781 error

amplifier is a low impedance output inverting gain stage.

The amplifier has ample current source capability to allow

easy integration of isolation optocouplers that require bias

currents up to 10mA. External DC loading of the VC pin

reduces the external current sourcing capacity of the

5V

pin by the same amount as the load on the VC pin.

REF

3781f

7

LT3781

U

UU

PI FU CTIO S

The error amplifier is typically configured using a feedback

RC network to realize an integrator circuit. This circuit

creates the dominant pole for the converter regulation

feedback loop. Integrator characteristics are dominated

by the value of the capacitor connected from the VC pin to

the VFB pin and the feedback resistor connected to the V

pin. Specific integrator characteristics can be configured

to optimize transient response.

The error amplifier can also be configured as a

transimpedance amplifier for use in secondary-side controller applications. (See the Applications Information

section for configuration and compensation details)

SENSE (Pin 11): Current Sense Amplifier (CSA)

Noninverting Input. Current is monitored via a ground

referenced current sense resistor, typically in series with

the source of the bottom side switch FET. Internal current

limit circuitry provides for a maximum peak value of

150mV across the sense resistor during normal operation.

SG (Pin 12): Synchronous Switch Output Driver. This pin

can be connected directly to gate of synchronous switch

if small FETs are used (C

of a gate drive buffer is recommended for peak efficiencies.

< 5000pF), however, the use

GATE

FB

BG (Pin 15): Bottom Side Primary Switch/Forward Switch

Output Driver. This pin can be connected directly to

gate(s) of primary bottom side and forward switches if

small FETs are used (C

use of a gate drive buffer is recommended for peak

efficiencies.

The BG output is enabled at the start of each oscillator

cycle in phase with the TG pin but is timed to “lag” the TG

output during turn-on and “lead” the TG output during

turn-off. These delays force the concentration of transitional losses onto the bottom side primary switch.

An adaptive blanking circuit disables the current sense

function (via the SENSE pin) while the BG pin is below 5V.

BSTREF (Pin 18): V

nects to source of topside external power FET switch.

TG (Pin 19): Topside (Boosted) Primary Output Driver.

This pin can be connected directly to gate of primary

topside switch if small FETs are used (C

however, the use of a gate drive buffer is recommended for

peak efficiencies.

V

(Pin 20): Topside Primary Driver Bootstrapped Sup-

BST

ply. This “boosted” supply rail is referenced to the BSTREF

pin.

BST

total < 5000pF), however, the

GATE

Supply Reference. Typically con-

< 5000pF),

GATE

The SG pin output is synchronized and out-of-phase with

the BG output. The control timing of the SG output cause

it to “lead” the primary switch path during turn-on by

150nS.

VCC (Pin 13): IC Local Power Supply Input. Bypass with at

a capacitor at least 10 times greater than C5V

incorporates undervoltage lockout that disables switching

functions if VCC is below 8.4V. The LT3781 supports

operational VCC power supply voltages from 9V to 18V

(20V absolute maximum). An 18V clamp on the VCC pin is

enabled during shutdown mode, preventing a trickle start

circuit from pulling that pin above maximum operational

levels during IC shutdown.

PWRGND (Pin 14): Output Driver Ground Reference.

Connect through low impedance trace to VIN decoupling

capacitor.

. LT3781

REF

Supply voltage is maintained by a bootstrap capacitor tied

from the V

pin. The charge on the capacitor is refreshed each switch

cycle through a Schottky diode connected from the V

supply (cathode) to the V

capacitor (C

the total load capacitance on the TG pin. A capacitor in the

range of 0.1µF to 1.0µF is generally adequate for most

applications. The bootstrap diode must have a reverse

breakdown voltage greater than the converter VIN. The

LT3781 supports operational V

90V (absolute maximum) referenced to ground.

Undervoltage Lockout disables the topside switch until

V

– BSTREF > 7.0V for start-up protection of the

BST

topside switch.

pin to the boosted supply reference (BSTREF)

BST

pin (anode). The bootstrap

BST

) must be at least 100 times greater than

BOOST

supply voltages up to

BST

CC

3781f

8

BLOCK DIAGRA

BST

TG

V

20

BSTREF

19

BG

18

15

W

SG

12

PWRGND

14

LT3781

SS

8

225mV

10µA

–

Q

R

S

1681 BD

+

NOL

LOGIC

f = ×2

T

S

PHASE

Q

DETECT

SQ

–

REF

5V

R

–

+

BLANKING

+

×12

LIM

I

–

ERROR AMP

+

1.25V

UVLO

(<8V)

×4

–

1.25V

REFERENCE

GENERATOR

+

+

1.25V

–

6

FSET

7

SYNC

18V

9

10

C

V

11

SENSE

13

FB

CC

V

V

+

1

SHDN

–

1.25V

2

OVLO

4

SGND

3781f

3

THERM

5

REF

5V

9

LT3781

WUUU

APPLICATIO S I FOR ATIO

Overview

The LT3781 is a high voltage, high current synchronous

regulator controller, optimized for use with dual transistor

forward topologies. The IC uses a constant frequency,

current mode architecture, with internal logic that prevents operation over 50% duty cycle. A unique synchronization scheme allows the system clock to be synchronized

up to an operational frequency of 350kHz, along with

phase control for easy integration of multicontroller systems. A local precision 5V supply rail is available for

external support circuitry and can be loaded up to 20mA.

Internal fault detection circuitry disables switching when

a variety of system faults are detected such as: input

supply overvoltage or undervoltage faults, excessive system temperature, and local supply overcurrent conditions.

The LT3781 has a current-limit soft-start feature, which

gradually increases the current drive capability of a converter system to yield a smooth start-up with minimal

overshoot. The soft-start circuitry is also used for smooth

recoveries from system fault conditions.

External FET switches are employed for the switch elements, and hearty switch drivers allow implementation of

high current designs. An adaptive blanking scheme built

into the LT3781 allows for correct current-sense blanking

regardless of switch size. The LT3781 employs a voltage

output error amplifier, providing superior integrator linearity and allowing easy high bandwidth integration of

optocoupler feedback for fully isolated solutions.

Theory of Operation (See Block Diagram)

The LT3781 senses the output voltage of its associated

converter via the VFB pin. The difference between the

voltage on this pin and an internal 1.25V reference is

amplified to generate an error voltage on the VC pin, which

is used as a threshold for the current sense comparator.

The current sense comparator gets its information from

the SENSE pin, which monitors the voltage drop across an

external current sense resistor. When the detected switch

current increases to the level corresponding to the error

voltage on the VC pin, the switches are disabled until the

next switch cycle.

During normal operation, the LT3781 internal oscillator

runs at twice the switching frequency. The oscillator

output toggles a T flip-flop, generating a 50% duty cycle

pulse that is used internally as the system clock for the IC.

When the output of this flip-flop transitions high, the

primary switches are enabled. The primary side switches

stay enabled until the transformer primary current, sensed

via the SENSE pin connected to a ground-referenced

resistor in series with the bottom side switch FET, is

sufficient to trip the current sense comparator and, in turn,

reset the RS latch. When the RS latch resets, the primary

switches are disabled and the synchronous switch is

enabled. The adaptive blanking circuit senses the bottom

side gate voltage and prevents current sensing until the

FET is fully enabled, preventing false triggering due to a

turn-on transition glitch. If the current comparator threshold is not obtained when the flip-flop output transitions

low, the RS latch is bypassed and the primary switches are

disabled until the next flip-flop output transition, forcing a

maximum switch duty cycle less than 50%.

System Fault Detection-The General Fault Condition

(GFC)

The LT3781 contains circuitry for detecting internal and

system faults. Detection of a fault triggers a “general fault

condition”, or GFC. When a GFC is detected, the LT3781

disables switching and discharges the soft-start capacitor. When the GFC subsides, the LT3781 initiates a startup cycle via the soft-start circuitry to assure a graceful

recovery. Recovery from a GFC is gated by the soft-start

capacitor discharge. The capacitor must be discharged to

a threshold of 225mV before the GFC can be concluded. As

the zero output current threshold of the SS pin is typically

a transistor VBE, or 0.7V, latching the GFC until a 225mV

threshold is achieved assures a zero output current state

in the event of a short-duration fault. A GFC is also

triggered during system state change event, such as

entering shutdown mode, to prevent any mode transition

abnormalities.

10

3781f

WUUU

APPLICATIO S I FOR ATIO

LT3781

Events that trigger a GFC are:

a) Exceeding the current limit of the 5V

b) Detecting an undervoltage condition on V

c) Detecting an undervoltage condition on 5V

REF

pin

CC

REF

d) Pulling the SHDN pin below the shutdown threshold

e) Exceeding the 1.25V fault detector threshold on

either the OVLO or THERM pins

OVLO and THERM pins is used to directly trigger a GFC. If

either of these pins are not used, they can be disabled by

connecting the pin to ground. The intention of the OVLO

pin is to allow the monitoring of the input supply to protect

from an overvoltage condition though the use of a resistor

divider from the input supply. Monitoring of system temperature (THERM) is possible through use of a resistor

divider using a thermistor as a divider component. The

5V

pin can provide the precision supply required for

REF

these applications. When these fault detection circuits are

disabled during shutdown or VCC pin UVLO conditions, a

reduction in OVLO and THERM pin input impedance to

ground will occur. To prevent excessive pin input currents,

low impedance pull-up devices must not be used on these

pins.

Undervoltage Lockout

The LT3781 maintains a low current operational mode

when an undervoltage condition is detected on the V

CC

supply pin, or when VCC is below the undervoltage lockout

(UVLO) threshold. During a UVLO condition on the V

CC

pin, the LT3781 disables all internal functions with the

exception of the shutdown and UVLO circuitry. The external 5V

supply is also disabled during this condition.

REF

Disabling of all switching control circuity reduces the

LT3781 supply current to <1mA, making for efficient

integration of trickle charging in systems that employ

output feedback supply generation.

The function of the high side switch output (TG) is also

gated by UVLO circuitry monitoring the bootstrap supply

(V

– BSTREF). Switching of the TG pin is disabled until

BST

the voltage across the bootstrap supply is greater than

7.4V. This helps prevent the possibility of forcing the high

side switch into a linear operational region, potentially

causing excessive power dissipation due to inadequate

gate drive during start-up.

Error Amplifer Configurations

The converter output voltage information is fed back to the

LT3781 onto the VFB pin where it is transformed into an

output current control voltage by the error amplifier. The

error amplifier is generally configured as an integrator and

is used to create the dominant pole for the main converter

feedback loop. The LT3781 error amplifier is a true high

gain voltage amplifier. The amplifier noninverting input is

internally referenced to 1.25V; the inverting input is the

VFB pin and the output is the VC pin. Because both low

frequency gain and integrator frequency characteristics

can be controlled with external components, this amplifier

allows far greater flexibility and precision compared with

use of a transconductance error amplifier.

In a nonisolated converter configuration where a resistor

divider is used to program the desired output voltage, the

error amplifier can be configured as a simple active

integrator, forming the system dominant pole ( Figure␣ 1).

Placing a capacitor C

set the single-pole crossover frequency at (2πRFBC

from the VFB pin to the VC pin will

ERR

ERR

)-1.

Additional poles and zeros can be added by increasing the

complexity of the RC network.

V

OUT

R

FB

Figure 1. Nonisolated Error Amp Configuration

V

FB

9

C

ERR

V

C

10

LT3781

–

+

1.25V

3781 F01

3781f

11

LT3781

WUUU

APPLICATIO S I FOR ATIO

Another common error amplifier configuration is for

optocoupler use in fully isolated converters with secondary side control (Figure 2). In such a system, the dominant

pole for the feedback loop is created at the secondary side

controller, so the error amplifier needs only to translate the

optocoupler information. The bandwidths of the

optocoupler and amplifier should be as high as possible to

simplify system compensation. This high bandwidth

operation is accomplished by using the error amplifier as

a transimpedance amplifier, with the optocoupler transistor emitter providing feedback information directly into

the VFB pin. A resistor from VFB to ground provides the DC

bias condition for the optocoupler. Connecting the

optocoupler transistor collector to the local 5V

reduces Miller capacitance effects and maximizes the

bandwidth of the optocoupler. Also, higher optocoupler

current means higher bandwidth, and the 5V

can provide collector currents up to 10mA.

V

OUT

SENSE

5

9

10

5V

REF

V

FB

V

C

LT3781

5V

–

+

1.25V

3781 F02

REF

REF

supply

supply

internally as the system clock for the IC. Free-run

frequency for the internal oscillator is programmed via an

RC timing network connected to the FSET pin. A pull-up

resistor R

provides current to charge a timing capacitor C

, connected from the 5V

FSET

pin to FSET,

REF

FSET

connected from the FSETpin to ground. The oscillator operates by allowing R

point R

is pulled back toward ground by a 2.5K resistor

FSET

internal to the LT3781. When the voltage across C

to charge C

FSET

up to 2.5V at which

FSET

FSET

is

pulled down to 1.5V, the FSET pin becomes high impedance, once again allowing R

Figure 3 is a plot of oscillator frequency vs C

to charge C

FSET

FSET

FSET

.

and R

FSET

is shown below. Typical values for 300kHz operation

(150kHz system frequency) are C

R

= 51kΩ.

FSET

600

550

500

450

400

350

300

250

200

OSCILLATOR FREQUENCY (kHz)

150

100

Figure 3. Oscillator Frequency vs. Timing Components

20

30 50

330pF

100pF

150pF

200pF

40

TIMING RESISTOR (kΩ)

60

= 150pF and

FSET

90

80

70

100

3781 F03

Figure 2. Optocoupler High-BW Configuration

Oscillator Frequency Programming and

Synchronization

The LT3781 internal oscillator runs at twice the system

switching frequency. The oscillator output toggles a T

flip-flop, generating a 50% duty cycle pulse that is used

12

Due the relatively fast fall time of the oscillator waveform,

the FSET pin is held at its 1.5V threshold by an internal low

impedance clamp to reduce undershoot error. As a result,

if this pin is externally forced low for any reason, external

current limiting is required to prevent damage to the

LT3781. Continuous source current from the FSET pin

should not exceed 1mA. Putting a 2k resistor in series with

any low impedance pull-down device will assure proper

function and protect the IC from damage.

3781f

WUUU

5V

REF

FSET

75k

51k 100pF

3781 F05

LT3781

5

6

APPLICATIO S I FOR ATIO

Oscillator Synchronization

Synchronization of the LT3781 system clock is accomplished by driving a TTL level logic pulse train at the

desired system switching frequency into the SYNC pin. In

order to assure proper synchronization, each phase of the

synchronization signal must be less than an oscillator

free-run cycle.

The SYNC input pulse controls the phasing as well as the

frequency of controller switching. The SYNC circuit functions by forcing the phase of the oscillator output flip-flop

to match the phase of the SYNC pulse and prematurely

ending the oscillator charge cycle on each transition edge.

At the SYNC logic low-to-high transition, the LT3781

starts a switch-on cycle and the minimum switch-off

period is forced during the SYNC logic low period. Because the SYNC logic low period corresponds directly to

the minimum off time, the converter maximum duty cycle

can be forced using the SYNC input. For example, a 30%

duty cycle SYNC pulse forces 30% maximum duty cycle

operation for the converter. Because the logic-low pulse

width exceeds the logic-high pulse width in < 50% duty

cycle operation, the oscillator free-run cycle time must be

programmed to exceed the logic-low duration.

LT3781

Figure 5. Oscillator Connection for SYNC-Only Mode Operation

Bootstrap Start

It is inefficient as well as impractical to power a controller

IC from a high-voltage input supply. Using a linear

preregulation scheme to provide the required VCC voltage

for the LT3781 would waste significant power, reducing

converter efficiencies and creating additional thermal concerns. Self-biased power schemes take advantage of

inherent converter efficiencies to significantly reduce losses

associated with powering the controller. Bootstrapped

power can be derived using auxiliary windings on the

power transformer or inductor, rectified taps on switching

nodes, or the converter output directly.

2.5V

FSET

1.5V

SYNC

SYSTEM

CLOCK

(INTERNAL)

Figure 4. Oscillator/SYNC Waveforms

3781 F04

It is also possible to run the LT3781 in a SYNC-only mode

by disabling the oscillator completely. Connecting a resistor divider from the 5V

pin to the FSET pin forcing a

REF

voltage within the charge range of 1.5V-2.5V will allow the

oscillator to follow the SYNC input exclusively with no

provision for free-run. Setting values to force a voltage as

close to 2V as possible is recommended.

Start-up circuitry built into the LT3781 allows VCC to

increase from 0V to 14.5V before the converter is enabled.

During this time, start-up current is less than 1mA. The

trickle current required for charging the VCC supply is

typically generated with a resistor from the converter high

voltage input. When combined with the VCC bypass capacitor, the current through the start-up resistor creates a

voltage ramp on VCC whose slope governs the turn-on

time of the converter. The low quiescent current of the

LT3781 allows the input voltage to be trickled up with

minimal power dissipation in the start-up resistor. At

VCC = 14.5V, the LT3781 internal circuitry is enabled and

switching begins. If enough bootstrap power is fed back

into VCC to keep that supply voltage above 8.4V, then

switching continues and a bootstrap start is accomplished. If the input voltage drops below 8.4V, the LT3781

is disabled and the switching regulator returns to the

start-up low current state.

3781f

13

LT3781

WUUU

APPLICATIO S I FOR ATIO

Shutdown

The LT3781 SHDN pin will support TTL and CMOS logic

signals and also analog inputs. The SHDN pin turn-on

(rising) threshold is 1.25V with 150mV of hysteresis. A

common use of the SHDN pin is for under voltage detection on the input supply. Driving the SHDN pin with a

resistor-divider connected from the input supply to ground

will prevent switching until the desired input supply voltage is achieved.

An 18V clamp on the VCC pin is enabled during shutdown

mode, preventing a trickle start circuit from pulling that pin

above maximum operational levels.

The LT3781 enters an ultralow current shutdown mode

when the SHDN pin is below 350mV. During this mode,

total supply current drops to a typical value of 16µA. When

SHDN rises above 350mV, the IC will draw increasing

amounts of supply current until just before the 1.25V

turn-on threshold is achieved, when the supply current

reaches 75µA.

The shutdown function can be disabled by connecting the

SHDN pin to VCC. This pin is internally clamped to 2.5V

through a 20k series input resistance and can therefore

draw almost 1mA when tied directly to the VCC supply. This

additional current can be minimized by making the connection through an external series resistor (100k is typically used).

Soft-Start

The SS pin sources a typical current of 10µA. Placing a

capacitor (CSS) from the SS pin to ground will cause the

voltage on the SS pin to ramp up at a controlled rate,

allowing a graceful increase of maximum converter output

current during a start-up condition. The start-up delay

time to full available current limit is:

tSS = 2.5 • 105 • CSS (sec)

The LT3781 internally pulls the SS pin below the zero

current threshold during any fault condition to assure

graceful recovery. The SS circuit also acts as a fault control

latch to assure a full-range recovery from a short duration

fault. Once a fault condition is detected, the LT3781 will

suspend switching until the SS pin has discharged to

approximately 225mV.

Layout Considerations-Grounding

The LT3781 is typically used in high current converter

designs that involve substantial switching transients. The

switch drivers on the IC are designed to drive large

capacitances and, as such, generate significant transient

currents. Careful consideration must be made regarding

input and local power supply bypassing to avoid corrupting the ground references used by the error amplifier and

current sense circuitry.

Effective grounding of the two-transistor synchronous

forward topology where the LT3781 is used is inherently

difficult. The situation is complicated further by the number of bypass elements that must be considered.

The LT3781 current control pin (VC) limits sensed current

to zero at voltage less than 1.4V through full current limit

at VC = 3.2V, yielding 1.8V over the full regulation range.

The voltage on the VC pin is internally forced to be less than

or equal to SS + 0.7V. As such, the SS pin has a “dead

zone” between 0V and 0.7V, where a zero sensed current

condition is maintained. At SS voltages above 0.7V, the

sensed current limit threshold on the VC pin may rise as

needed up to the SS maintained current limit value. Once

the SS pin rises to the VC pin maximum value less 0.7V, or

2.5V, the SS circuit has no effect.

14

Typically, high current paths and transients from the input

supply and any local drive supplies must be kept isolated

from SGND, to which sensitive circuits such as the error

amp reference and the current sense circuits, as well as the

local 5V

used in LT3781 applications, the large currents from the

primary switches, as well as the switch drive transients,

pass through the sense resistor to ground. This defines

the ground connection of the sense resistor as the reference point for both SGND and PGND. In nonisolated

applications where SGND is the output reference, we now

have a condition where every bypass capacitor in the

converter is referenced to the same point.

supply, are referred. By virtue of the topologies

REF

3781f

WUUU

APPLICATIO S I FOR ATIO

LT3781

Effective grounding can be achieved by considering the

return current paths from the sense resistor to each

respective bypass capacitor. Don’t be tempted to run

small traces to separate the grounds. A power ground

plane is important as always in high power converters, but

bypass elements must be oriented such that transient

LT3781

5V

REF

SGND

V

BST

BSTREF

V

CC

PGND

currents in the return paths of VIN and VCC do not mix. Care

must be taken to keep these transients away from the

SGND reference. An effective approach is to use a 2-layer

ground plane, reserving an entire layer for SGND. The

5V

and nonisolated converter output bypasses can

REF

then be directly connected to the SGND plane.

V

BST

V

CC

V

IN

Figure 6. High-Current Transient Return Paths

3781f

15

LT3781

V

CC

13

2

1

5

1µF 82pF

OVLO

SHDN

1.24k

1%

73.2k

1%

20k

10k

267k

0.25W

68µF

20V

5V

REF

6

F

SET

4700pF

8

SS

10

14

BAS21

BAT54

T2

S

S

BAS21

BAT54

BAT54

ZVN3310F

9

V

C

PGND

V

FB

374

THERM

LT3781

SYNC SGND

52.3k

10Ω

1k

3k

1k

3.3k

100Ω

0.25W

10k

2k

FZT690B

4.7µF

0.22µF

S

MMBZ5240BLT1

10V

1

3.3Ω

10k

5V

REF

ISO1

MOC207

7

143

3

1

4

6

5

14

15

6

5

82

3300pF

4700pF

0.1µF

5V

REF

12

SG

+

0.1µF

1nF

11

SENSE

15

BG

18

BSTREF

19

TG

20

BAS21

0.1µF

L3 1mH

V

BST

220pF

C4

1.5µF

100V

C3

1.5µF

100V

L1

4.7µH

0.022µF

1000pF

••

SYNC V

FB

OVPIN

MARGIN

I

COMP

V

DD

OPTODRV

V

AUX

0.1µF

12

I

SNS

11

I

SNSGND

16

FG

2

CG

PGND GND

LTC1698

PWRGD

6

8

9

7

13

1.24k

1%

976Ω

4.22k

1%

1043

V

COMP

3781 F07

3.01k

1k

0.1µF

MBR0530

0.030Ω

1/2W

1

2

5

4

Q3

NC

1000pF

100V

2.2nF

250V

1nF

100V

Q5, Q6

FDS6680A

×2

Q14, Q15

FDS6680A

×2

MURS120T3

MURS120T3

10Ω

6

11

10

879

12

•

•••

3

Q1

T1

10Ω

MMBT3906LT1

MMBT3906LT1

V

IN

+

V

IN

–

C2

1.5µF

100V

V

OUT

+

V

OUT

–

S

C5 TO C8

330µF

10V

×4

10Ω

0.25W

10Ω

0.25W

L2

4.8µH

330pF

+

C1: MURATA ERIE GHM3045X7R222K-GC

C2, C3, C4: VITRAMON VJ1825Y155MXB

C5 TO C8: 330µF 10V KEMET T510X337K010AS

OR 330µF 6.3V KEMET T520D337M006AS

ISO1: FAIRCHILD MOC207

L1: COILCRAFT DO1608C-472

L2: PANASONIC ETQPAF4R8HFA

L3: COILCRAFT DO1608C-105

Q1, Q3: SILICONIX Si4486EY

Q5, Q6, Q14,Q15: FAIRCHILD FDS6680A

T1: MIDCOM 31267R OR COILTRONICS CTX02-14675

(FUNCTIONAL INSULATION) OR

MIDCOM 31322R (BASIC INSULATION)

T2: MIDCOM 31264R

(FUNCTIONAL INSULATION) OR

MIDCOM 31323R (BASIC INSULATION)

4.7Ω

TYPICAL APPLICATIO S

U

Figure 7. 36V to 72V DC in to 5V/10A Isolated Synchronous Forward Converter

16

3781f

V

CC

13

2

1

5

1µF 82pF

OVLO

SHDN

1.24k

1%

73.2k

1%

20k

10k

267k

0.25W

C26

68µF

20V

5V

REF

6

F

SET

4700pF

8

SS

10

14

BAS21

BAT54

T2

S

S

BAS21

BAT54

BAT54

Q12

ZVN3310F

9

V

C

PGND

V

FB

374

THERM

LT3781

SYNC SGND

52.3k

1%

10Ω

1k

3k

1k

1k

100Ω

10k

2k

0.25W

Q13

FZT690B

4.7µF

16V

0.22µF

50V

S

MMBZ5240BLT1

10V

1

3.3Ω

10k

5V

REF

ISO1

MOC207

7

143

3

1

4

6

5

14

15

6

5

82

3300pF

4700pF

0.1µF

5V

REF

12

SG

+

0.1µF

1nF

11

SENSE

15

BG

18

BSTREF

19

TG

20

BAS21

0.1µF 100V

L3 1mH

V

BST

220pF

C4

1.5µF

100V

C3

1.5µF

100V

L1

3.3µH

0.022µF

1000pF

••

SYNC V

FB

OVPIN

MARGIN

I

COMP

V

DD

OPTODRV

V

AUX

0.1µF

12

I

SNS

11

I

SNSGND

16

FG

2

CG

PGND GND

LTC1698

PWRGD

6

8

9

7

TRIM

13

1.24k

1%

1.78k

1%

2.43k

1%

1043

V

COMP

1698 F11

3.01k

1k

0.33µF

MBR0530

0.025Ω

1/2W

3

4

Q3

1000pF

100V

C1

2200pF

250V

1000pF

100V

Q5, Q14

FDS6680A

×2

Q6, Q15, Q17

FDS6680A

×3

MURS120T3

MURS120T3

10Ω

2

7

V

SEC

5

•

••

1

Q1

T1

10Ω

MMBT3906LT1

MMBT3906LT1

V

IN

+

V

IN

–

C2

1.5µF

100V

V

OUT

+

V

OUT

–

S

C5 TO C8

330µF

10V

×4

10Ω

0.25W

10Ω

0.25W

4.7Ω

L2

2.35µH

330pF

+

C1: MURATA ERIE GHM3045X7R222K-GC

C2, C3, C4: VITRAMON VJ1825Y155MXB

C5 TO C8: 330µF 10V KEMET T510X337K010AS

OR 330µF 6.3V KEMET T520D337M006AS

C26: AVX TPSE686M020R0150

ISO1: FAIRCHILD MOC207

L1: COILCRAFT DO1608C-332

L2: PULSE P1977 PLANAR INDUCTOR

L3: COILCRAFT DO1608C-105

Q1, Q3: SILICONIX Si4486EY

Q5, Q6, Q14,Q15,Q17: FAIRCHILD FDS6680A

Q7: FAIRCHILD NDT410EL

Q12: ZETEX ZVN3310F

Q13: ZETEX FZT690

T1: PULSE P1976 PLANAR TRANSFORMER

(FUNCTIONAL INSULATION) OR

PULSE PA-0191 (BASIC INSULATION)

T2: MIDCOM 31264R (FUNCTIONAL INSULATION) OR

MIDCOM 31323R (BASIC INSULATION)

TYPICAL APPLICATIO S

LT3781

U

Figure 8. 36V to 72V DC in to 3.3V/20A Isolated Synchronous Forward Converter

3781f

17

LT3781

V

CC

13

2

1

5

1µF 82pF

OVLO

SHDN

1.24k

1%

73.2k

1%

20k

10k

267k

0.25W

C26

68µF

20V

5V

REF

6

F

SET

4700pF

8

SS

10

14

BAS21

BAT54

T2

S

S

BAS21

BAT54

BAT54

Q12

ZVN3310F

9

V

C

PGND

V

FB

374

THERM

LT3781

SYNC SGND

52.3k

1%

10Ω

1k

3k

1k

1k

100Ω

9V

10k

2k

0.25W

Q13

FZT690B

4.7µF

16V

0.22µF

50V

S

MMBZ5240BLT1

10V

1

3.3Ω

10k

5V

REF

ISO1

MOC207

7

143

3

1

4

6

5

14

15

6

5

82

3300pF

4700pF

0.1µF

5V

REF

12

SG

+

0.1µF

1nF

11

SENSE

15

BG

18

BSTREF

19

TG

20

BAS21

0.1µF 100V

L3 1mH

BLKSENS

V

BST

220pF

C4

1.5µF

100V

C3

1.5µF

100V

L1

3.3µH

0.022µF

1000pF

••

SYNC V

FB

OVPIN

MARGIN

I

COMP

V

DD

OPTODRV

V

AUX

0.1µF

12

I

SNS

11

I

SNSGND

16

FG

2

CG

PGND GND

LTC1698

PWRGD

6

8

9

7

13

1.24k

1%

1.78k

1%

3.01k

1%

SENSE

+

SENSE

–

TRIM

100Ω

0.25W

5

6

4

2

3

1

7

9V

V

OUT

+

2.43k

1%

1043

V

COMP

1698 F12

3.01k

1%

3.01k

1%

3.01k

1%

3.01k

1%

100Ω

0.25W

1k

0.33µF

MBR0530

0.025Ω

1/2W

3

4

Q3

1000pF

100V

C1

2200pF

250V

1000pF

100V

Q5, Q14

FDS6680A

×2

Q6, Q15, Q17

FDS6680A

×3

MURS120T3

MURS120T3

10Ω

2

7

V

SEC

5

•

••

1

Q1

T1

10Ω

MMBT3906LT1

MMBT3906LT1

V

IN

+

V

IN

–

C2

1.5µF

100V

V

OUT

+

V

OUT

–

S

C5 TO C8

330µF

10V

×4

10Ω

0.25W

10Ω

0.25W

4.7Ω

L2

2.35µH

330pF

+

62k

0.25W

MMBZ5248LT1

18V

MMBT3904LT1

47k

4.7µF

5V

REF

MMBD914LT1

Q7

NDT410EL

1.5k

0.25W

1.5k

0.25W

–

+

LT1006S8

C1: MURATA ERIE GHM3045X7R222K-GC

C2, C3, C4: VITRAMON VJ1825Y155MXB

C5 TO C8: 330µF 10V KEMET T510X337K010AS

OR 330µF 6.3V KEMET T520D337M006AS

C26: AVX TPSE686M020R0150

ISO1: FAIRCHILD MOC207

L1: COILCRAFT DO1608C-332

L2: PULSE P1977 PLANAR INDUCTOR

L3: COILCRAFT DO1608C-105

Q1, Q3: SILICONIX Si4486EY

Q5, Q6, Q14,Q15,Q17: FAIRCHILD FDS6680A

Q7: FAIRCHILD NDT410EL

Q12: ZETEX ZVN3310F

Q13: ZETEX FZT690

T1: PULSE P1976 PLANAR TRANSFORMER

(FUNCTIONAL INSULATION) OR

PULSE PA-0191 (BASIC INSULATION)

T2: MIDCOM 31264R (FUNCTIONAL INSULATION) OR

MIDCOM 31323R (BASIC INSULATION)

TYPICAL APPLICATIO S

U

Figure 9. 36V to 72V DC in to 3.3V/20A Isolated Synchronous Forward Converter with Fast Start and Differential Sense

18

3781f

PACKAGE DESCRIPTION

U

G Package

20-Lead Plastic SSOP (5.3mm)

(Reference LTC DWG # 05-08-1640)

1.25 ±0.12

LT3781

6.90 – 7.50*

(.272 – .295 )

1718 14 13 12 1115161920

7.8 – 8.2

0.42 ±0.03 0.65 BSC

RECOMMENDED SOLDER PAD LAYOUT

5.00 – 5.60**

(.197 – .221)

0.09 – 0.25

(.0035 – .010)

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

*

DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED .152mm (.006") PER SIDE

**

DIMENSIONS DO NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED .254mm (.010") PER SIDE

0.55 – 0.95

(.022 – .037)

MILLIMETERS

(INCHES)

5.3 – 5.7

0

° – 8°

12345678910

0.65

(.0256)

BSC

0.22 – 0.38

(.009 – .015)

7.40 – 8.20

(.291 – .323)

2.0

(.079)

0.05

(.002)

G20 SSOP 0802

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3781f

19

LT3781

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1158 Half-Bridge N-Channel MOSFET Driver Current Limit Protection, 100% of Duty Cycle

LT1160 Half-Bridge N-Channel MOSFET Driver Up to 60V Input Supply, No Shoot-Through

LT1162 Dual Half-Bridge N-Channel MOSFET Driver VIN to 60V, Good for Full-Bridge Applications

LT1336 Half-Bridge N-Channel MOSFET Driver Smooth Operation at High Duty Cycle (95% to 100%)

LT1339 High Power Synchronous DC/DC Controller 60V Dual N-Channel MOSFET Controller

LTC®1530 High Power Step-Down Switching Regulator Controller Excellent for 5V to 3.x Up to 50A

LTC1625 No R

LT1640 Negative Voltage Hot SwapTM Controller Allows Safe Board Insertion and Removal from a Live –48V Backplane,

LT1680 High Power DC/DC Current Mode Step-Up Controller High Side Current Sense, Up to 60V Input

LT1681 Dual Transistor Synchronous Foward Controller Operation up to 72V Maximum

LTC1696 Overvoltage Protection Controller in ThinSOTTM Package ±2% Overvoltage Threshold Protection Accuracy, Gate Drive for SCR

LTC1698 Secondary Synchronous Rectifier Controller Use with the LT1681, Isolated Power Supplies, Contains Voltage Merging,

LTC1735 Synchronous Step-Down Controller Current Mode, 3.5V ≤ VIN ≤ 36V, 0.5V ≤ V

LTC1922-1 Synchronous Phase Modulated Full-Bridge Controller 50W to 2kW Power Supply Design, Adaptive Direct Sense ZVS

LTC1929 2-Phase 42A Synchronous Controller Minimizes CIN and C

LT3710 Secondary Side Synchronous Post Regulator Generates Auxiliary Output in Isolated DC/DC Converters,

LTC3728 550kHz, Dual 2-Phase Synchronous Controller High Frequency Reduces Size of Inductors, Minimum CIN, 4V ≤ VIN ≤ 36V,

No R

, ThinSOT and Hot Swap are trademarks of Linear Technology Corporation.

SENSE

TM

Synchronous Controller 97% Efficient, 1.19V ≤ VIN ≤ 36V, 1.19V ≤ V

SENSE

Operates from –10V to –80V

Crowbar or External N-Channel MOSFET Disconnect,

Monitors Two Output Voltages

Optocoupler Driver, Synchronization Circuit with the Primary Side

, 4V ≤ VIN ≤ 36V, 300kHz

OUT

Programmable Current Limit Protection, 0.8V ±1.5% Reference

I

up to 20A

OUT1, 2

OUT

OUT

≤ 5V

≤ V

IN

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

3781f

LT/TP 0303 2K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2001

Loading...

Loading...