LINEAR TECHNOLOGY

LINEAR TECHNOLOGY

LINEAR TECHNOLOGY

JUNE 2009 VOLUME XIX NUMBER 2

SENSE

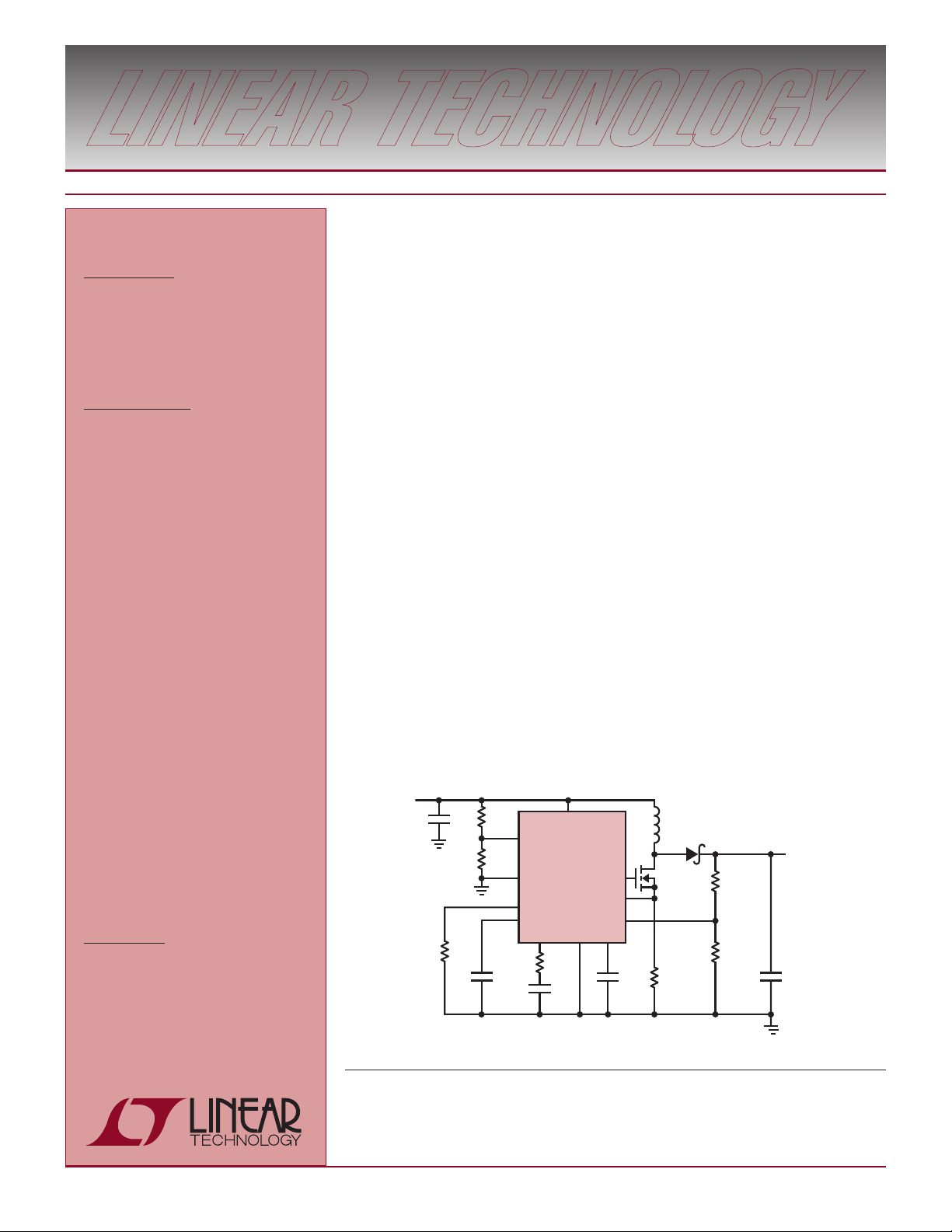

LT3757

V

IN

V

IN

10V TO 30V

4.7µF

50V

X5R

48V

1A

0.01Ω

42.2k

GATE

FBX

GND

INTV

CC

SHDN/UVLO

SYNC

RT

SS

V

C

200k

43.2k

0.1µF

8.45k

10nF

10µH

IHLP-5050EZ-01

MBRM360

590k

1%

M1

Si7850

20.0k

1%

4.7µF

10V

X5R

4.7µF

50V

X5R

s2

IN THIS ISSUE…

COVER ARTICLE

Two New Controllers for Boost,

Flyback, SEPIC and Inverting DC/DC

Converters Accept Inputs up to 100V

...........................................................1

Wei Gu

Linear in the News… ...........................2

DESIGN FEATURES

Charge Li-Ion Batteries Directly

from High Voltage Automotive

and Industrial Supplies Using

Standalone Charger in a

3mm × 3mm DFN .................................5

Jay Celani

Power Management IC Combines

USB On-The-Go and USB Charging

in Compact Easy-to-Use Solution .........8

George H. Barbehenn and Sauparna Das

Power Management IC with

Pushbutton Control Generates

Six Voltage Rails from USB or

2 AA Cells Via Low Loss

PowerPath™ Topology .......................12

John Canfield

Improve Hot Swap Performance and

Save Design Time with Hot Swap™

Controller that Integrates

2A MOSFET and Sense Resistor .........16

David Soo

Compact No R

Feature Fast Transient Response

and Regulate to Low V

Wide Ranging V

.........................................................18

Terry J. Groom

™ Controllers

SENSE

IN

OUT

from

Two New Controllers for Boost, Flyback, SEPIC and Inverting DC/DC Converters Accept Inputs up to 100V

Introduction

Two new versatile DC/DC controller

ICs, the LT®3757 and LT3758, are

optimized for boost, flyback, SEPIC

and inverting converter applications.

The LT3757 operates over an input

range of 2.9V to 40V, suitable for applications from single-cell lithium-ion

battery portable electronics up to high

voltage automotive and industrial

power supplies. The LT3758 extends

the input voltage to 100V, providing

flexible, high performance operation

in high voltage, high power telecommunications equipment. Both ICs

exhibit low shutdown quiescent cur -

rent of 1µA, making them an ideal fit

for battery-operated systems.

Both integrate a high voltage, low

dropout linear (LDO) regulator. Thanks

to a novel FBX pin architecture, the

LT3757 and LT3758 can be connected

directly to a divider from either the

positive output or the negative output to ground. They also pack many

popular features such as soft-start,

input undervoltage lockout, adjustable frequency and synchronization

in a small 10-lead MSOP package or

a 3mm × 3mm QFN package.

by Wei Gu

continued on page 3

Space-Saving, Dual Output

DC/DC Converter Yields

Plus/Minus Voltage Outputs

with (Optional) I2C Programming .......22

Mathew Wich

DESIGN IDEAS

....................................................26–36

(complete list on page 26)

New Device Cameos ...........................37

Design Tools ......................................39

Sales Offices .....................................40

L

, Li nea r E xpr ess , L ine ar Te chn olo gy, L T, LTC , L T M, Bo de CAD , B urs t M ode , F ilt erC AD, L T spi ce,

OPTI-LOOP, Over-The-Top, PolyPhase, SwitcherCAD, µModule and the Linear logo are registered trademarks of Linear

Technology Corporation. Adaptive Power, Bat-Track, C-Load, DirectSense, Easy Drive, FilterView, Hot Swap, LTBiCMOS,

LTCMOS, LinearView, Micropower SwitcherCAD, Multimode Dimming, No Latency ∆Σ, No Latency Delta-Sigma, No R

Operational Filter, PanelProtect, PowerPath, PowerSOT, SafeSlot, SmartStart, SNEAK-A-BIT, SoftSpan, Stage Shedding,

Super Burst, ThinSOT, TimerBlox, Triple Mode, True Color PWM, UltraFast and VLDO are trademarks of Linear Technology

Corporation. All other trademarks are the property of their respective owners.

Figure 1. A 10V–30V input, 48V at 1A output boost converter

SENSE

,

L LINEAR IN THE NEWS

Linear in the News…

EDN Innovation Award Winners

EDN magazine on March 30 announced the winners of their

annual Innovation Awards. Linear Technology’s LTM®4606

Ultralow EMI, 6A DC/DC µModule® Regulator was selected

as the winner in the Power ICs: Modules category. This

innovative device significantly reduces switching regulator noise by attenuating conducted and radiated energy

at the source. The µModule device is a complete DC/DC

system-in-a-package, including the inductor, controller IC,

MOSFETs, input and output capacitors and the compensation circuitry—all in a surface mount plastic package

in an IC form factor.

The other Innovation Award winner, in the category

Best Contributed Article, was Jim Williams for his article,

“High Voltage, Low-Noise DC/DC Converters,” which you

can read at www.edn.com/jimwilliams.

In addition to these winners, two other Linear Technology products were finalists for Innovation Awards:

q

LTC®6802 Battery Stack Monitor in the Battery ICs

Category

q

LTC3642 50mA Synchronous Step-Down Converter

in the Power ICs Category

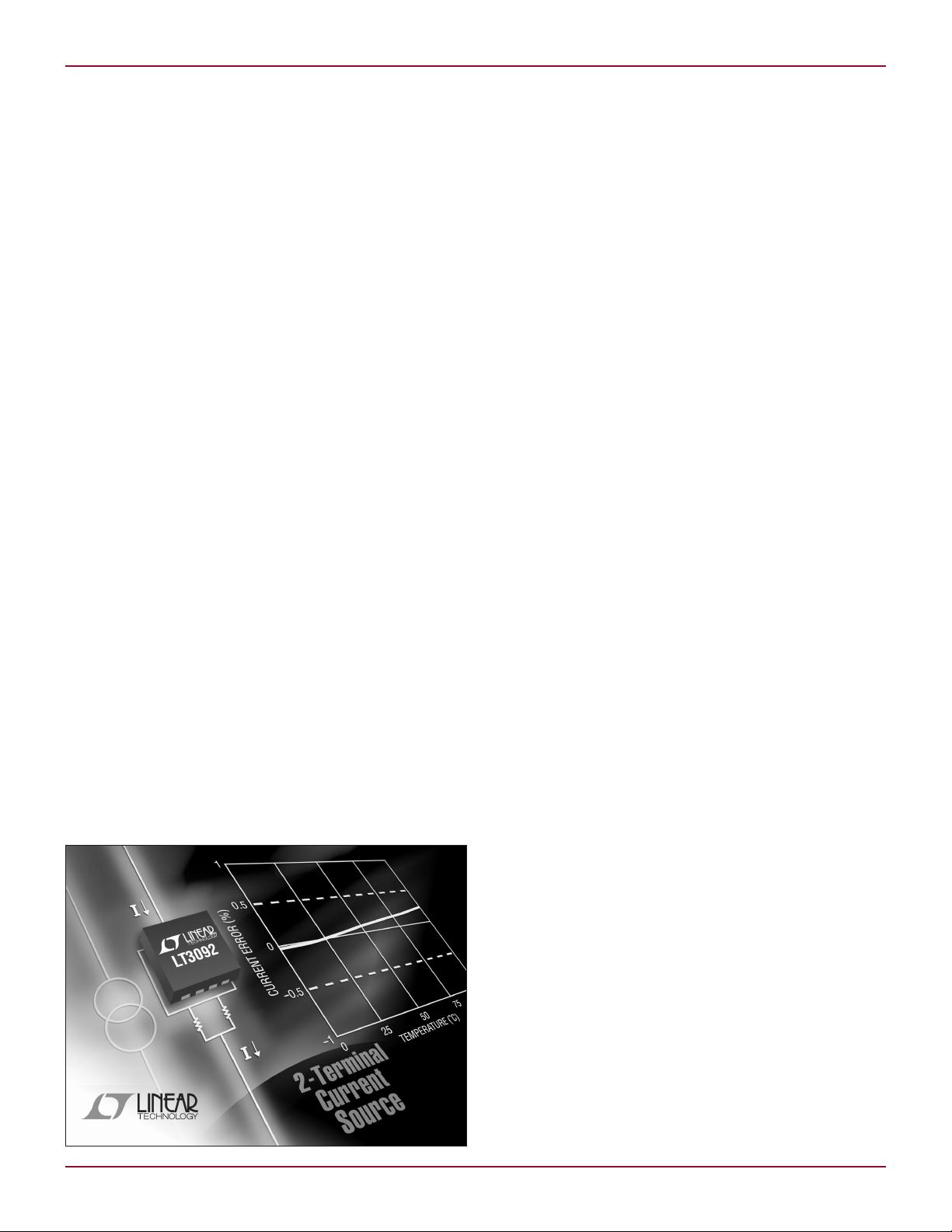

Current Source Makes Worldwide Debut

Linear Technology has just introduced an elegant building-block component that promises to simplify many

power designs—the LT3092 2-terminal current source.

The LT3092 has recently been announced worldwide in a

series of articles by Linear Technology CTO Bob Dobkin.

The LT3092 is a new solution to an old problem: how

to create an easy-to-use current source that maintains

regulation in a variety of conditions. In the past, a designer

would have to choose between an imprecise IC solution,

or build a current source from discrete components.

The LT3092 200mA 2-terminal current source solves

the problems of prior approaches, with its wide voltage

range, high AC and DC impedance, good regulation, low

temperature coefficient, and the fact that it requires no

capacitors. The device’s two floating terminals make it

eminently easy to use.

easy, but it is fraught with problems. Although high quality

voltage sources are readily available, the current source

as an IC has, until now, remained elusive.

set of issues, especially if high accuracy and stability over

temperature are required features. A current source must

operate over a wide voltage range, have high DC and AC

impedance when connected in series with unknown reactance, and exhibit good regulation and a low temperature

coefficient. For optimal 2-terminal solutions, no power

supply bypass capacitor should be used since it degrades

AC impedance.

than 1% initial accuracy and a very low temperature coefficient. Output currents can be set from 0.5mA to 200mA,

and current regulation is typically 10ppm per volt. The

LT3092 operates down to 1.5V or up to 40V. This gives an

impedance of 100MΩ at 1mA or 1 MΩ at 100mA. Unlike

almost any other analog integrated circuit, special design

techniques have been used for stable operation without a

supply bypass capacitor, allowing the LT3092 to provide

high AC impedance as well as high DC impedance. Transient and start-up times are about 20µs.

Linear Announces

New Quad PSE Controller for PoE+

Last month, Linear Technology held press meetings in the

US, Europe and Asia to introduce the LTC4266, a 4-port

Power over Ethernet (PoE) controller for Power Sourcing

Equipment (PSE), designed to meet the IEEE 802.3at requirements of 25.5W or proprietary higher power levels.

Next-generation PoE applications call for more power to

support demanding features, while increasing power efficiency in an effort to be more green and reduce costs.

cabling and is fully compliant with the new IEEE 802.3at

PoE+ standard and backward compatible with the prior

IEEE 802.3af PoE standard. To help conserve power, the

LTC4266 delivers the lowest-in-industry heat dissipation

by using low R

eliminating the need for expensive heat sinks and providing a more robust PSE solution.

plications, including next-generation switches, routers,

hubs and midspans. Users will appreciate the extremely

low power dissipation, which simplifies thermal design

when compared to designs that use PSEs with more fragile,

normally higher R

On the surface, current source design appears relatively

The desirable 2-terminal current source brings its own

The LT3092 meets these expectations. It has better

The LTC4266 provides up to 100W over 4-pair Ethernet

MOSFETs and 0.25Ω sense resistors,

DS(ON)

The LTC4266 is suitable for a wide variety of PSE ap-

, MOSFETs.

DS(ON)

L

2

2

Linear Technology Magazine • June 2009

DESIGN FEATURES L

EFFICIENCY (%)

I

LOAD

(mA)

200

98

93

300 400 500 600 700 800 900 1000

94

94

95

95

96

VIN = 12V

V

IN

= 24V

SENSE

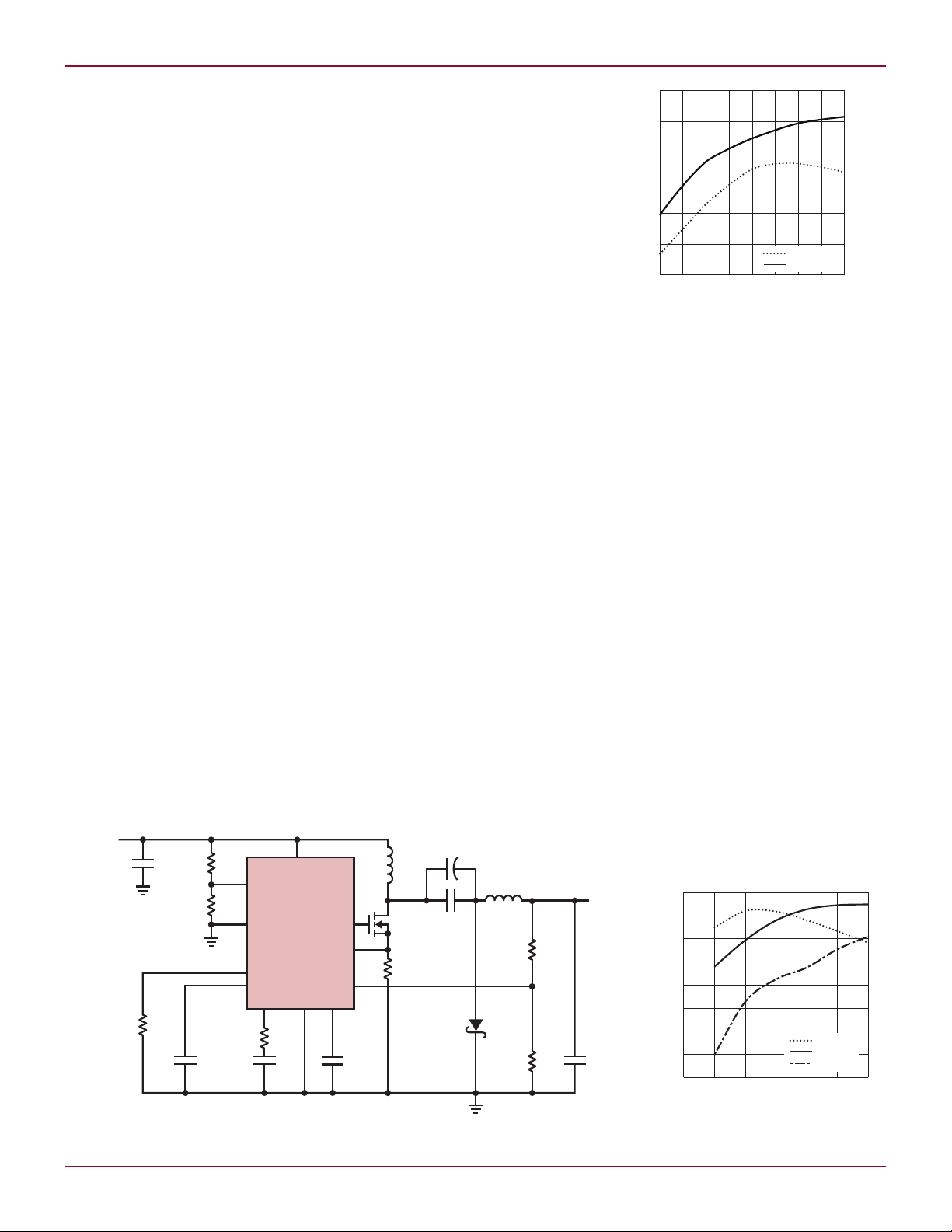

LT3757

V

IN

V

IN

4.5V TO 36V

4.7µF

50V

X5R

4.7µF

10V

X5R

10µF

50V

X5R

C1

22µF

50V

V

OUT

–5V

3A

0.01Ω

M1

Si7850

42.2k

GATE

FBX

GND

INTV

CC

SHDN/UVLO

SYNC

RT

SS

V

C

215k

100k

0.1µF

10nF

8.45k

L1

6.8µH

L2

6.8µH

D1

PDS1045

C1: SANYO 50CE22BS

L1, L2: VISHAY IHLP4040DZ-11

105k

1%

20k

1%

100µF

6.3V, X5R

s2

+

EFFICIENCY (%)

I

LOAD

(mA)

0

88

86

72

500 1000 1500 2000 2500 3000

74

76

82

78

80

84

VIN = 5V

V

IN

= 12V

V

IN

= 36V

LT3757/58, continued from page 1

Internal High Voltage LDO

In high voltage applications, the

LT3757 and LT3758 eliminate the

need for an external regulator or a

slow-charge hysteretic start scheme

through the integration of an onboard

linear regulator, allowing simple

start-up and biasing. This regulator

generates INTVCC, the local supply

that runs the IC from the converter

input VIN. The internal LDO can operate the IC continuously, provided

the input voltage and/or MOSFET

gate charge currents are low enough

to avoid excessive power dissipation

in the part.

When the INTVCC pin is driven

externally above its regulated voltage

during operation—from the input,

the output or a third winding—the

internal LDO is automatically turned

off, reducing the power dissipation in

the IC. The LDO also provides internal

current limit function to protect IC

from excessive on-chip power dissipation. The current limit decreases

as VIN increases. If the current limit

is exceeded, the INTVCC voltage falls

and triggers the soft-start.

Sensing Output Voltage

Made Easier

Unlike traditional controllers, which

can only sense positive outputs, the

LT3757 and LT3758 have a novel FBX

pin architecture that simplifies the

design of inverting and non-inverting

converters. The LT3757 and LT3758

each contain two internal error amplifiers; one senses positive outputs

and the other negative. When the

converter starts switching and the

output voltage starts ramping up or

down, depending on the topologies,

one of the error amplifiers seamlessly

takes over the feedback control, while

the other becomes inactive.

The FBX pin can be connected

directly to a divider from either a

positive output or a negative output.

This direct connection saves space and

expense by eliminating the traditional

glue circuitry normally required to

level-shift the feedback signal above

ground in negative converters. The

power supply designer simply decides

the output polarity he needs, the topology he wants to use and the LT3757

or LT3758 does the rest.

Precision UVLO Voltage

and Soft-Start

Input supply UVLO for sequencing

or start-up over-current protection is

easily achieved by driving the UVLO

with a resistor divider from the VIN

supply. The divider output produces

1.25V at the UVLO pin when VIN is at

the desired UVLO rising threshold voltage. The UVLO pin has an adjustable

input hysteresis, which allows the IC

to resist a settable input supply droop

before disabling the converter. During

a UVLO event, the IC is disabled and

VIN quiescent current drops to 1µA

or lower.

Figure 2. Efficiency of the

converter in Figure 1

The SS pin provides access to the

soft-start feature, which reduces the

peak input current and prevents output voltage overshoot during start-up

or recovery from a fault condition. The

SS pin reduces the inrush current by

not only lowering the current limit but

also reducing the switching frequency.

In this way soft-start allows the output

capacitor to charge gradually towards

its final value.

Adjustable/Synchronizable

Switching Frequency

The operating frequency of the LT3757

and LT3758 can be programmed from

100kHz to 1MHz range with a single

resistor from the RT pin to ground, or

synchronized to an external clock via

the SYNC pin.

The adjustable operating frequency

allows it to be set outside certain

frequency bands to fit applications

that are sensitive to spectral noise.

Linear Technology Magazine • June 2009

Figure 3. A 4.5V–36V to –5V at 3A inverting converter

Figure 4. Efficiency of the

converter in Figure 3

3

L DESIGN FEATURES

SENSE

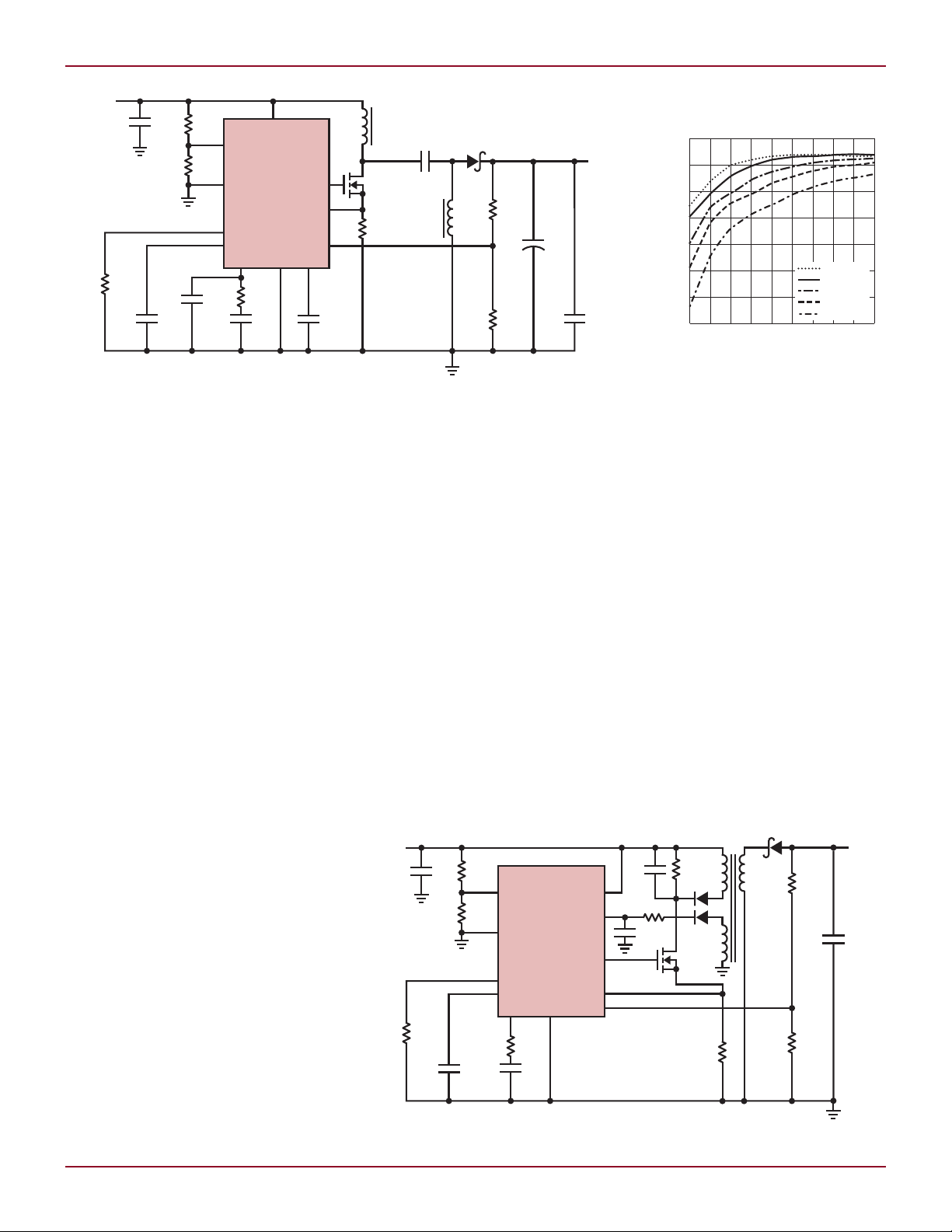

LT3758

V

IN

V

IN

18V TO 72V

C

IN

1µF

× 2

INTV

CC

C

OUT

100µF

× 2

V

OUT

–3.3V

2A

0.04Ω

M1

Si4848

36.5k

GATE

FBX

GND

SHDN/UVLO

SYNC

RT

SS

V

C

t

t

t

105k

8.66k

0.1µF

10k

2.2nF

T1

PA1277NL

BAS516

BAV21W

D1

UPS840

31.6k

10k

4.7nF

4.7µF

10k

51.1Ω

EFFICIENCY (%)

LOAD CURRENT (mA)

100

95

55

200 300 400 500 600 700 800 900 1000

60

70

85

75

80

90

VIN = 18V

V

IN

= 24V

V

IN

= 36V

V

IN

= 48V

V

IN

= 72V

SENSE

LT3758

V

IN

V

IN

18V TO 72V

4.7µF

100V

V

OUT

24V

1A

0.02Ω

M1

FDMS2572

42.2k

GATE

FBX

GND

INTV

CC

SHDN/UVLO

SYNC

RT

SS

V

C

•

•

232k

20k

0.1µF

100pF

2.2µF

100V

4.7nF 4.7nF

30.9k

L1B

L1A

WURTH 744 870 470

D1

PDS3100

280k

1%

20k

1%

C

OUT1

22µF

35V

x2

C

OUT2

3.3µF

25V, X5R

+

Figure 5. A 18V–72V input, 24V/1A output SEPIC converter

Figure 6. Efficiency of the

converter in Figure 5

In space constrained applications,

higher switching frequencies can be

used to reduce the overall solution

size and the output ripple. If power

loss is a concern, switching at a lower

frequency reduces switching losses,

improving efficiency.

Current Mode Control

The LT3757 and LT3758 use a current mode control architecture to

enable a higher supply bandwidth,

thus improving response to line and

load transients. Current mode control

also requires fewer compensation

components than voltage mode control architectures, making it much

easier to compensate over all operating

conditions.

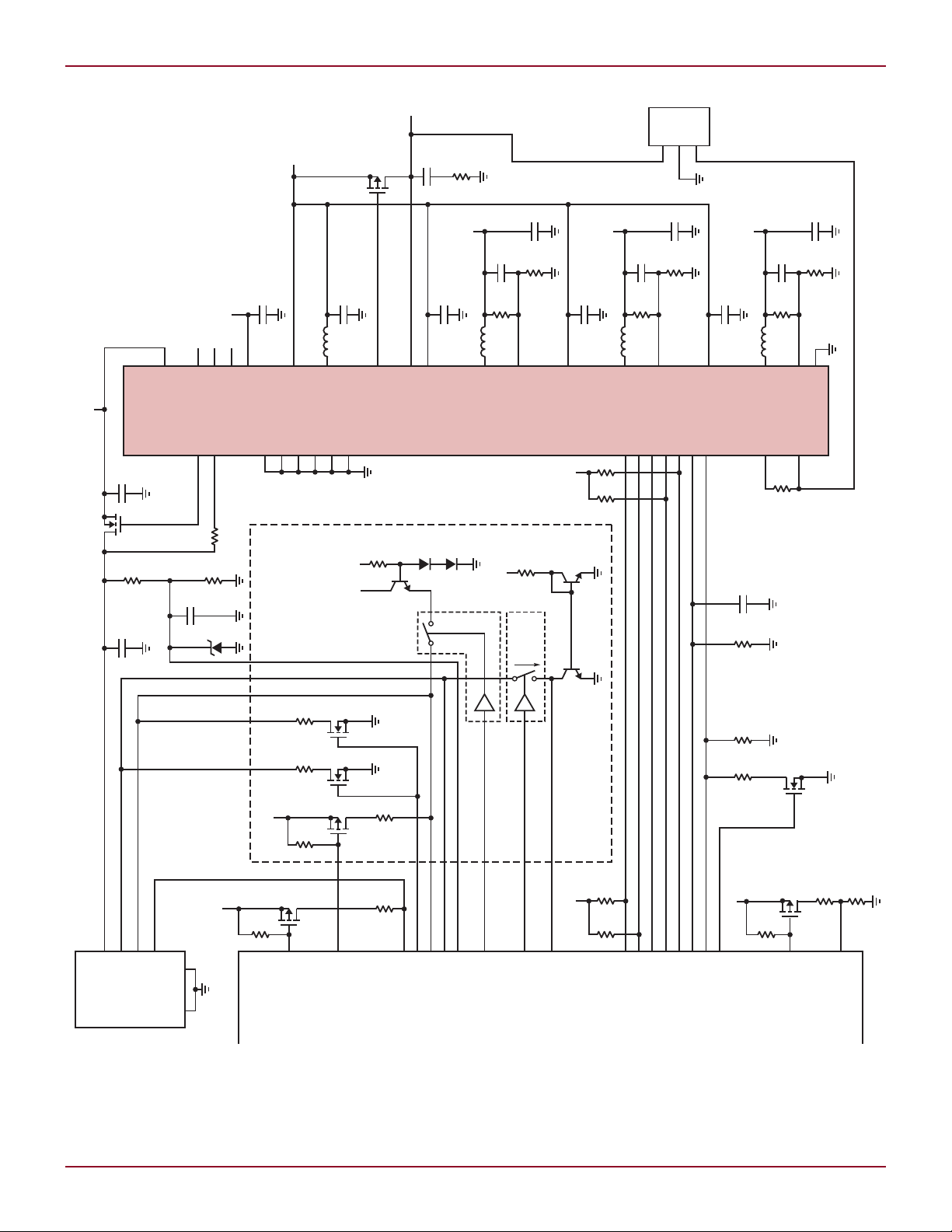

A 10V–30V Input, 48V/1A

Output Boost Converter

Figure 1 shows a 48V, 1A output

converter that takes an input of 10V

to 30V. The LT3757 is configured as

a boost converter for this applications

where the converter output voltage

is higher than the input voltage.

Figure 2 shows the efficiency for this

converter.

A 4.5V–36V Input, –5V/3A

Output Inverting Converter

Figure 3 shows the LT3757 in an inverting converter that operates from a

4.5V to 36V input and delivers 3A to

a –5V load. The negative output can

be either higher or lower in amplitude

than the input. It has output short-

4

circuit protection, which is further

enhanced by the frequency foldback

feature in the LT3757. The 300kHz

operating frequency allows the use of

small inductors. The ceramic capacitor

used for the DC coupling capacitor provides low ESR and high RMS

current capability. The output power

can easily scaled by the choice of the

components around the chip without

modifying the basic design. Figure 4

shows the efficiency for this converter

at different input voltages.

An 18V–72V Input, 24V/1A

Output SEPIC Converter

A SEPIC converter is similar to the

inverting converter in that it can step

up or step down the input, but with

a positive output. It also offers output

Figure 7. 18V–72V input, –3.3V/2A output flyback converter

disconnect and short-circuit protection. Figure 5 illustrates an 18V–72V

input, 24/1A output SEPIC power

supply using LT3758 as the controller.

Figure 6 shows the efficiency for this

converter at different input voltages.

An 18V–72V Input, –3.3V/2A

Output Flyback Converter

Figure 7 shows the LT3758 in a nonisolated flyback converter with an

18V to 72V input voltage range and a

–3.3V / 2A output. It provides robust

output short-circuit protection thanks

to the frequency foldback feature in the

LT3758. The circuit can also be used

for different negative voltages simply

by changing the value of the resistor

divider on the FBX pin.

continued on page 21

Linear Technology Magazine • June 2009

DESIGN FEATURES L

SW

V

IN

V

IN

7.5V TO 32V

(40 MAX)

CLP

RNG/SS

BOOST

SENSE

BAT

NTC

TIMER

CMPSH1-4

CMSH3-40MA

1µF

10µF

6.8µH

0.05Ω

10µF

LT3650-4.2

Li-Ion

CELL

+

SHDN

CHRG

FAULT

GND

Charge Li-Ion Batteries Directly from High Voltage Automotive and Industrial Supplies Using Standalone Charger in a 3mm × 3mm DFN

Introduction

Growth of the portable electronics

market is in no small part due to the

continued evolution of battery capacities. For many portable devices,

rechargeable Li-Ion batteries are the

power source of choice because of their

high energy density, light weight, low

internal resistance, and fast charge

times. Charging these batteries safely

and efficiently, however, requires

a relatively sophisticated charging

system.

One additional problem faced by

battery charger designers is how to deal

with relatively high voltage sources,

such as those found in industrial

and automotive applications. In these

environments, system supply voltages exceed the input ranges of most

charger ICs, so a DC/DC step-down

converter is required to provide a local

low voltage supply for the charger IC.

The LT3650 standalone monolithic

switching battery charger does not

need this additional DC/DC converter.

It directly accepts input voltages up to

40V and provides charge currents as

high as 2A. It also includes a wealth

of advanced features that assure safe

battery charging and expand its applicability.

The LT3650 includes features that

minimize the overall solution size,

requiring only a few external components to complete a charger circuit. A

fast 1MHz switching frequency allows

the use of small inductors, and the IC

is housed inside a tiny 3mm × 3mm

DFN12-pin package. The IC has builtin reverse current protection, which

blocks current flow from the battery

back to the input supply if that supply

is disabled or discharged to ground,

so a single-cell LT3650 charger does

not require an external blocking diode

on the input supply.

A Charger Designed for

Lithium-Ion Batteries

A Li-Ion battery requires constantcurrent/constant-voltage (CC/CV)

charging system. A Li-Ion battery

is initially charged with a constant

current, generally between 0.5C and

1C, where C is the battery capacity

in ampere-hours. As it is charged,

the battery voltage increases until

it approaches the full-charge float

voltage. The charger then transitions

into constant voltage operation as

the charge current is slowly reduced.

The LT3650-4.1 and LT3650-4.2 are

designed to charge single-cell Li-Ion

by Jay Celani

batteries to float voltages of 4.1V and

4.2V, respectively. The LT3650-8.2

and LT3650-8.4 are designed to charge

2-cell battery stacks to float voltages

of 8.2V and 8.4V.

Once the charge current falls below

one tenth of the maximum constant

charge current, or 0.1C, the battery

is considered charged and the charging cycle is terminated. The charger

must be completely disabled after

terminating charging, since indefinite

trickle charging of Li-Ion cells, even at

miniscule currents, can cause battery

damage and compromise battery stability. A charger can top-off a battery

by continuing to operate as the current falls lower than the 0.1C charge

current threshold to make full use of

battery capacity, but in such cases a

backup timer is used to disable the

charger after a controlled period of

time. Most Li-Ion batteries charge fully

in three hours.

The LT3650 addresses all of the

charging requirements for a Li-Ion

battery. The IC provides a CC/CV

charging characteristic, transitioning

automatically as the requirements of

the battery change during a charging

cycle. During constant-current operation, the maximum charge current

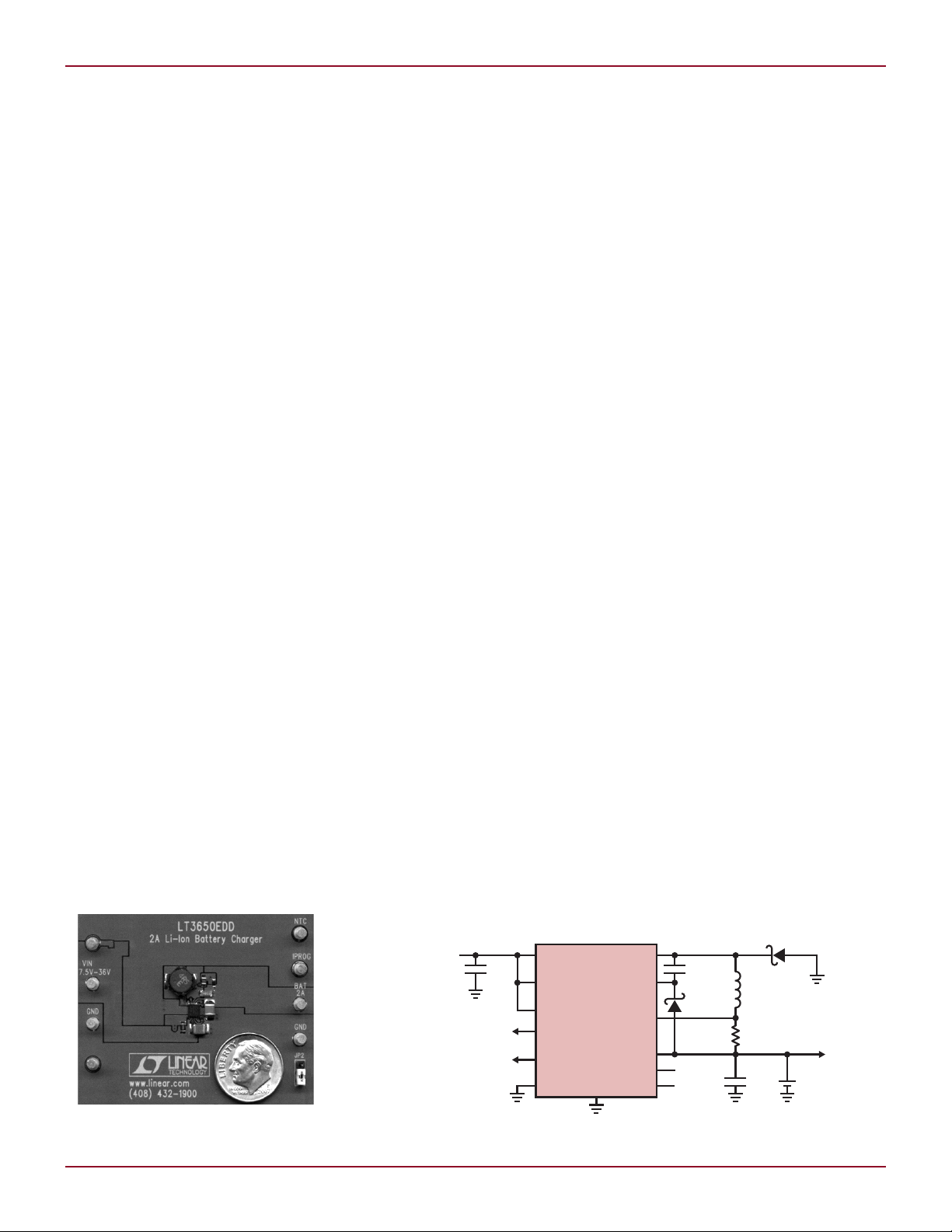

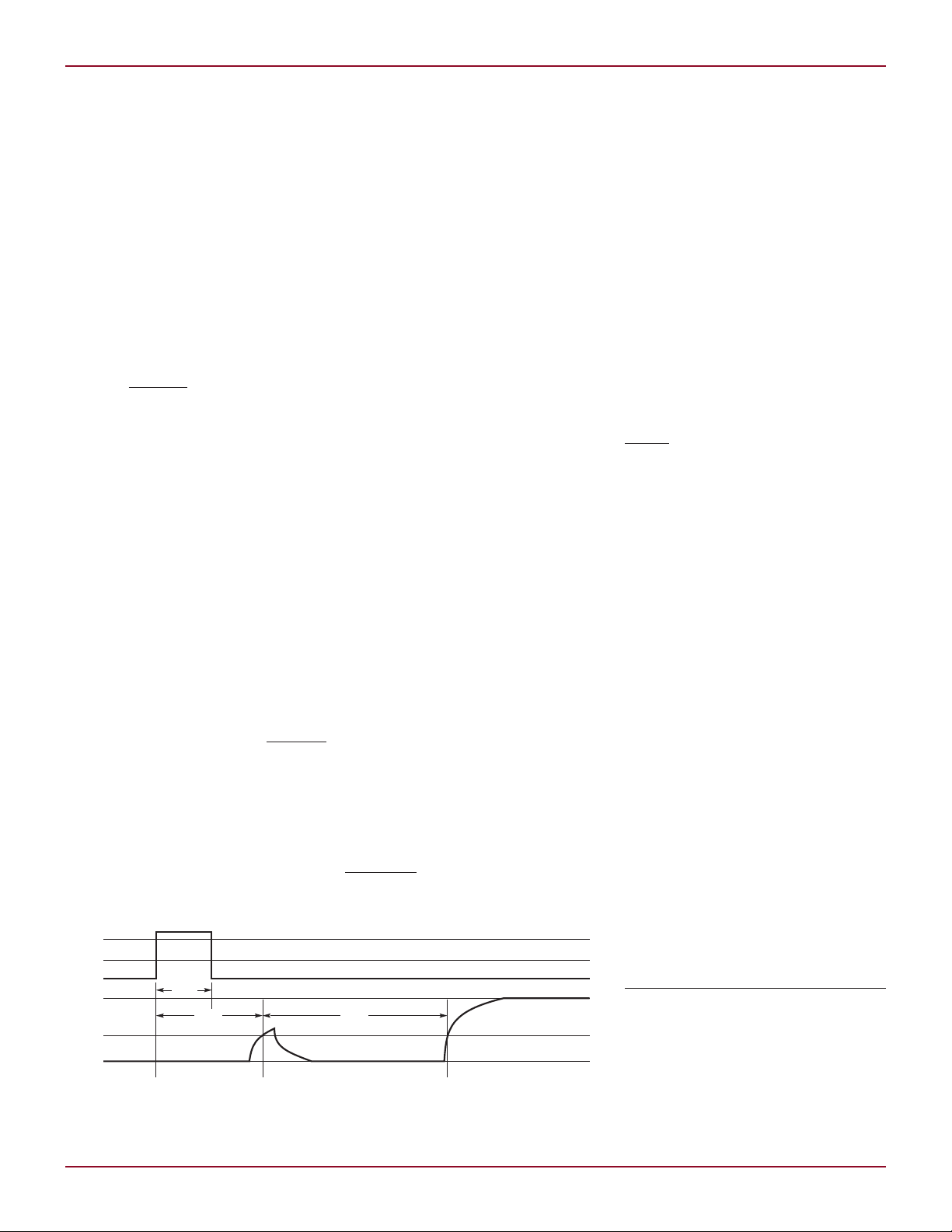

Figure 1. An LT3650 standalone battery

charger is small and efficient.

Linear Technology Magazine • June 2009

Figure 2. A single-cell 2A Li-Ion battery charger configured for C/10 charge termination

5

L DESIGN FEATURES

I

BAT

(A)

0

EFFICIENCY (%)

80

90

100

70

60

0.5

1

1.5

2

VIN = 12V

VIN = 20V

V

BAT

(V)

CHARGE CURRENT (A)

1.0

1.2

1.4

1.6

1.8

2.0

0.6

0.8

0

0.2

0.4

3.0 3.22.6 2.8

3.4

3.8 4.0 4.23.6

FAULT

CHG

V

IN

10k

10k

LT3650

Figure 3. Battery charge current vs BAT pin

voltage for the charger shown in Figure 2

provided to the battery is programmable via a sense resistor, up to a

maximum of 2A. Maximum charge

current can also be adjusted using the

RNG/SS pin. The charger transitions

to constant-voltage mode operation as

the battery approaches the full-charge

float voltage. Power is transferred

through an internal NPN switch element, driven by a boosted drive to

maximize efficiency. A precision SHDN

pin threshold allows incorporation

of accurate UVLO functions using a

simple resistor divider.

Charge Cycle Termination

and Automatic Restart

A LT3650 charger can be configured

to terminate a battery charge cycle

using one of two methods: it can use

low charge current (C/10) detection,

enabled by connecting the TIMER

pin to ground, or terminate based on

the onboard safety timer, enabled by

connecting a capacitor to the TIMER

pin. After termination, a new charge

cycle automatically restarts should

the battery voltage fall to 97.5% of the

float voltage.

is selected, the LT3650 terminates

a charging cycle when the output

current has dropped to 1/10 of the

6

When C/10 ter mination mode

Figure 5. Visual charger status is

easily implemented using LEDs

A Basic Charger

Figure 2 shows a basic 2A single-cell

Li-Ion battery charger that operates

from a 7.5V to 32V input. Charging is

suspended if the input supply voltage

exceeds 32V, but the IC can withstand

input voltages as high as 40V without

damage. The 2A maximum charge

current corresponds to 100mV across

the 0.05Ω external sense resistor. This

basic design does not take advantage

of the status pins, battery temperature

Figure 4. Power conversion efficiency vs

charger output current (I

charger shown in Figure 2

) for the battery

BAT

programmed maximum. In a 2A

charger, for example, the charge cycle

terminates when the battery charge

current falls to 200mA.

Timer termination, or top-of f

charging, is enabled when a capacitor is connected to the TIMER pin.

The value of the capacitor sets the

safety timer duration—0.68µF corresponds to a 3-hour cycle time. When

timer termination is implemented,

the charger continues to operate in

constant-voltage mode when charge

currents fall below C/10, allowing additional low current charging to occur

until the timer cycle has elapsed, thus

maximizing use of the battery capacity.

During top-off charging, the CHRG

and FAULT status pins communicate

“charge complete.” At the end of the

timer cycle, the LT3650 terminates

the charging cycle.

After charge cycle termination, the

LT3650 enters standby mode where

the IC draws 85µA from the input supply and less than 1µA from the battery.

Both the CHRG and FAULT pins are

high impedance during standby mode.

Should the battery voltage drop to

97.5% of the float voltage, the LT3650

automatically restarts and initializes

a new charging cycle.

Table 1. Status pin state and corresponding operating states

CHRG FAULT Charger Status

High Impedance High Impedance Standby/Shutdown/Top-off

Low High Impedance CV/CC Charging (>C/10)

High Impedance Low Bad Battery Detected

Low Low Temperature Fault

monitoring, or a safety timer features.

The battery charging cycle terminates

when the battery voltage approaches

4.2V and the charge current falls to

200mA. A new charge cycle is automatically initiated when the battery

voltage falls to 4.1V.

Safety Features:

Preconditioning,

Bad Battery Detection,

and Temperature Monitor

Li-Ion batteries can sustain irreversible damage when deeply discharged,

so care must be taken when charging

such a battery. A gentle preconditioning charge current is recommended to

activate any safety circuitry in a battery

pack and to re-energize deeply discharged cells, followed by a full charge

cycle. If a battery has sustained damage from excessive discharge, however,

the battery should not be recharged.

Deeply discharged cells can form

copper shunts that create resistive

shorts, and charging such a damaged

battery could cause an unsafe condition due to excessive heat generation.

Should a deeply discharged battery be

encountered, a battery charger must

be intelligent enough to determine

whether or not the battery has sustained deep-discharge damage, and

avoid initiating a full charge cycle on

such a damaged battery.

Linear Technology Magazine • June 2009

DESIGN FEATURES L

CLP

SYSTEM LOAD

INPUT SUPPLY

V

IN

R

CLP

LT3650

SW

V

IN

CLP

RUN/SS

BOOST

SENSE

BAT

NTC

TIMER

1N914

CMSH3-40MA

SYSTEM LOAD

1µF

6.8µH

0.057

LT3650-X

GND

10µF

Li-Ion

CELL

10k

INPUT SUPPLY

12V TO 32V

(40V MAX)

BZX384-C9V1

(9.1V)

10µF

10µF

0.05Ω

SHDN

CHRG

FAULT

10k

36k

3k

10k

0.68µF

+

0.1µF

The LT3650 employs an automatic

precondition mode, which gracefully

initiates a charging cycle into a deeply

discharged battery. If the battery voltage is below the precondition threshold

of 70% of the float voltage, the maximum charge current is reduced to 15%

of the programmed maximum (0.15C)

until the battery voltage rises past the

precondition threshold.

If the battery does not respond

to the precondition current and the

battery voltage does not rise past the

temperature, and suspends charging

should the temperature fall outside of

the safe charging range.

precondition threshold, a full-current

charge cycle does not initiate.

If the safety timer is used for termination, the LT3650 also enables

deep-discharge damage detection

and incorporates a “bad battery”

detection fault. Should the battery

voltage remain below the precondition threshold for 1/8 of the charge

cycle time (typically 22.5 minutes), the

charger suspends the charging cycle

and signals a “bad battery” fault on

the status pins. The LT3650 maintains this fault state indefinitely, but

automatically resets itself and starts

a new charging cycle if the damaged

battery is removed and another battery

is connected.

Li-Ion batteries have a relatively

narrow temperature range where they

can be safely charged. The LT3650

has a provision for monitoring battery

Figure 7. A single cell Li-Ion 2A battery charger with 3 hour safety timer termination, LED status

indicators, temperature sensing, low input voltage charge current foldback, and input supply

current limit

Linear Technology Magazine • June 2009

is enabled by connecting a 10k (B =

3380) NTC thermistor from the IC’s

NTC pin to ground. This thermistor

must be in close proximity to the battery, and is generally housed in the

battery case. This function suspends a

charging cycle if the temperature of the

thermistor is greater than 40°C or less

than 0°C. Hysteresis corresponding to

5°C on both thresholds prevents mode

glitching. Both the CHRG and FAULT

status output pins are pulled low during a temperature fault, signaling that

the charging cycle is suspended. If the

safety timer is used for termination,

the timer is paused for the duration

of a temperature fault, so a battery

receives a full-duration charging cycle,

even if that cycle is interrupted by

the battery being out of the allowed

temperature range.

Figure 6. R

supply current limit

Under/overtemperature protection

sets the input

CLP

Status Indicator Pins

The status of a LT3650 charger is communicated via the state of two pins:

CHRG and FAULT. These status pins

are open-collector pull-down, reporting the operational and fault status of

the battery charger. CC/CV charging

is indicated while charge currents are

greater than 1/10 the programmed

maximum charge current. The status

pins also communicate bad battery

and battery temperature fault states.

Table 1 shows a fault-state matrix for

these two pins.

The status outputs can be used as

digital status signals in processorcontrolled systems, and/or connected

to pull current through an LED for

visual status display. The status pins

can sink currents up to 10mA and can

handle voltages as high as 40V, so a

visual display can be implemented by

simply connecting an LED and series

resistor to VIN.

Maximum Charging Current

Programming and Adjustment

Maximum charge current is set using an external sense resistor placed

between the BAT and SENSE pins of

the LT3650. Maximum charge current

corresponds to 100mV across this resistor. The LT3650 supports maximum

charge currents up to 2A, corresponding to a 0.05Ω sense resistor.

The LT3650 includes two control

pins that allow reduction of the programmed maximum charge current.

The RNG/SS pin voltage directly affects the maximum charge current

such that the maximum voltage allowed across the sense resistor is 1/10

the voltage on RNG/SS for RNG/SS

< 1V. This pin sources a constant

50µA, so the voltage on the pin can

be programmed by simply connecting

a resistor from the pin to ground. A

capacitor tied to this pin generates a

voltage ramp at start-up, creating a

soft-start function. The pin voltage can

be forced externally for direct control

over charge current.

The IC includes a PowerPath™

control feature, activated via the CLP

pin, which acts to reduce battery

charge current should the load on a

continued on page 38

7

16

20

39

+

+

–

+

–

ENABLE

V

IN3

SW3

FB3

GND

37

I

LIM0

30

CHRG

1

CLPROG

3

NTCBIAS

4

NTC

6

OVSENS

V

C

5

OVGATE

38

I

LIM1

11

ENOTG

10

EN1

22

EN2

19

EN3

12

DV

CC

14

SDA

13

SCL

1A 2.25MHz

BUCK

REGULATOR

17

24

25

ENABLE

V

IN2

SW2

FB2

400mA 2.25MHz

BUCK

REGULATOR

23

8

7

ENABLE

V

IN1

29

PROG

32

BAT

15mV

0.3V

3.6V

IDEAL

1.18V

OR 1.15V

+

–

5.1V

SW1

FB1

21

RST3

400mA 2.25MHz

BUCK

REGULATOR

2.25MHz

BIDIRECTIONAL

PowerPath

SWITCHING

REGULATOR

9

D/A

D/A

D/A

4

4

4

I2C PORT

I

LIM

DECODE

LOGIC

CC/CV

CHARGER

3.3V LDO

CHARGE

STATUS

OVP

27

26

28

WALL

DETECT

V

C

CONTROL

31

IDGATE

33

V

OUT

SW

ACPR

WALL

+

–

+

–

+

–

BATTERY

TEMPERATURE

MONITOR

SUSPEND LDO

500µA/2.5mA

36

LDO3V3

2

35

V

BUS

34

V

BUS

L DESIGN FEATURES

Power Management IC Combines USB On-The-Go and USB Charging in Compact Easy-to-Use Solution

by George H. Barbehenn and Sauparna Das

Introduction

The USB interface was originally

designed so that the device providing

power (an “A” device) would act as the

host and the device receiving power (a

“B” device) was the peripheral. The A

plug of the USB cable would always

connect to the host device and the B

plug would connect to the peripheral.

The USB On-The-Go (OTG) standard,

however, removes that restriction, so

that the B device can now become a

host and the A device can act as a

peripheral.

In the USB specification, standard

hosts and hubs are limited to providing

500mA to each downstream device,

but if a device is designated as a USB

charger, it can supply up to 1.5A. USB

chargers come in two flavors. A “dedicated charger” is a charger that is not

capable of data communication with

the attached B device. A ”host/hub

charger” is a charger that is capable

of data communications with attached

B devices.

When USB OTG functionality is

combined with a USB battery charger

in an end-user product, power can

flow in both directions, with relatively

complicated logic and handshaking

steering the flow. To implement a

robust solution, an integrated USB

battery charger and power manager

is a necessity. This article shows how

to use the LTC3576 USB power management IC to easily combine USB

On-The-Go functionality and battery

charger capability into a single portable product.

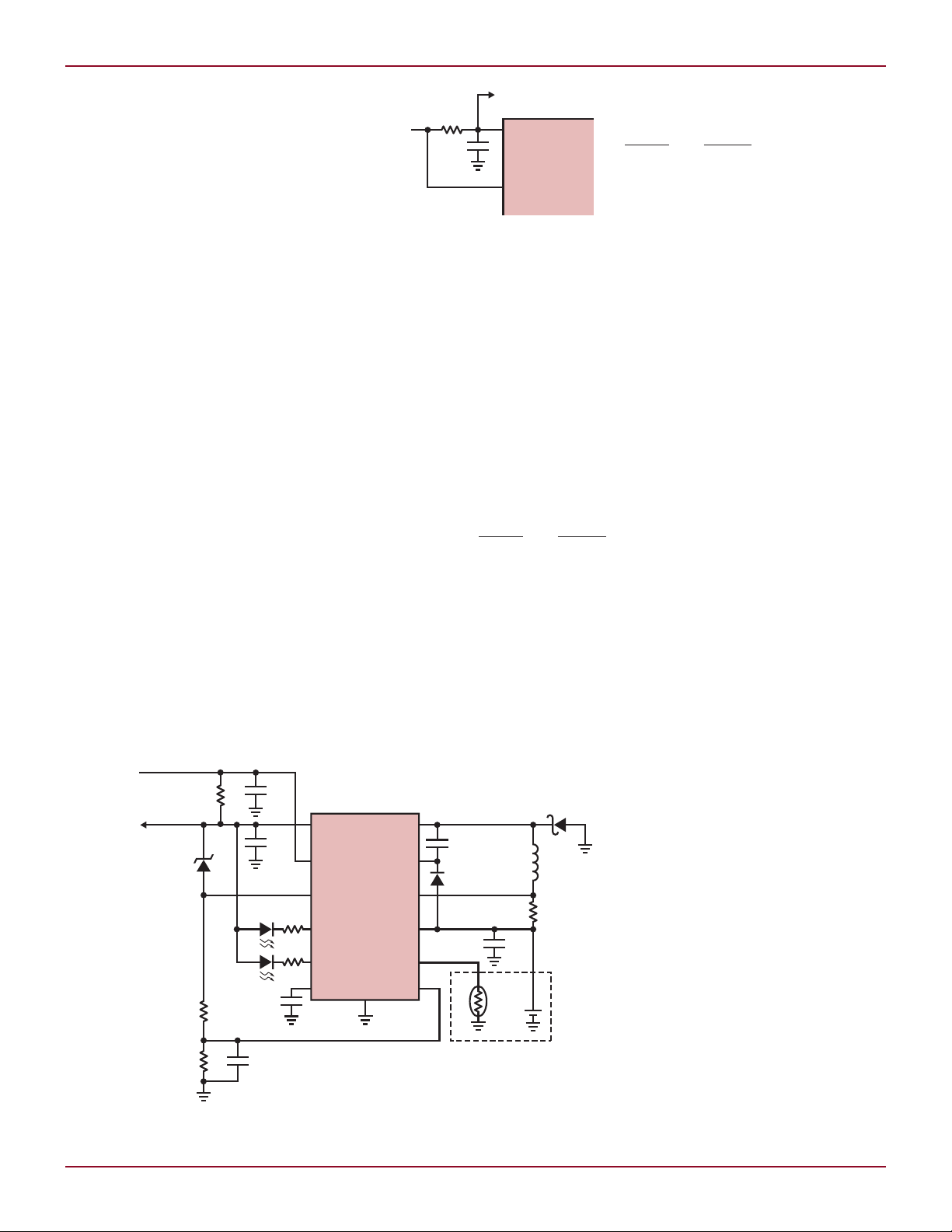

Overview of the LTC3576

The LTC3576 provides the power

resources needed to implement a portable device with USB OTG and USB

battery charger detection capabilities

(see block diagram in Figure 1). The

USB input block contains a bidirec-

8

Figure 1. The LTC3576 combines USB charging and USB On-The-Go by using bidirectional DC/DC

conversion from V

BUS

to V

OUT

Linear Technology Magazine • June 2009

DESIGN FEATURES L

< 6.5µF

ENOTG

MINI/MICRO A/B

MINI/MICRO A PLUG

OTG

COMPATIBLE

DEVICE SUCH

AS LTC3576

OTG

COMPATIBLE

BUSS

TRANSCEIVER

A DEVICE

B DEVICE

MINI/MICRO A/B

MINI/MICRO A PLUG

ENOTG

OTG

COMPATIBLE

DEVICE SUCH

AS LTC3576

OTG

COMPATIBLE

BUSS

TRANSCEIVER

VBUS

D+

D–

ID

GND

VBUS

D+

D–

ID

GND

3.3V

FOR LOW SPEED

ONLY

FOR FULL/HIGH SPEED

ONLY

3.3V

< 6.5µF

ATTACH PHASE

PHYSICAL CONNECTION

OF DEVICES

CONNECT PHASE

DETECT VOLTAGE LEVELS ON

D+/D– TO DETERMINE DATA

SPEED AND POWER LEVELS

ENUMERATION PHASE

SOFTWARE

HANDSHAKE

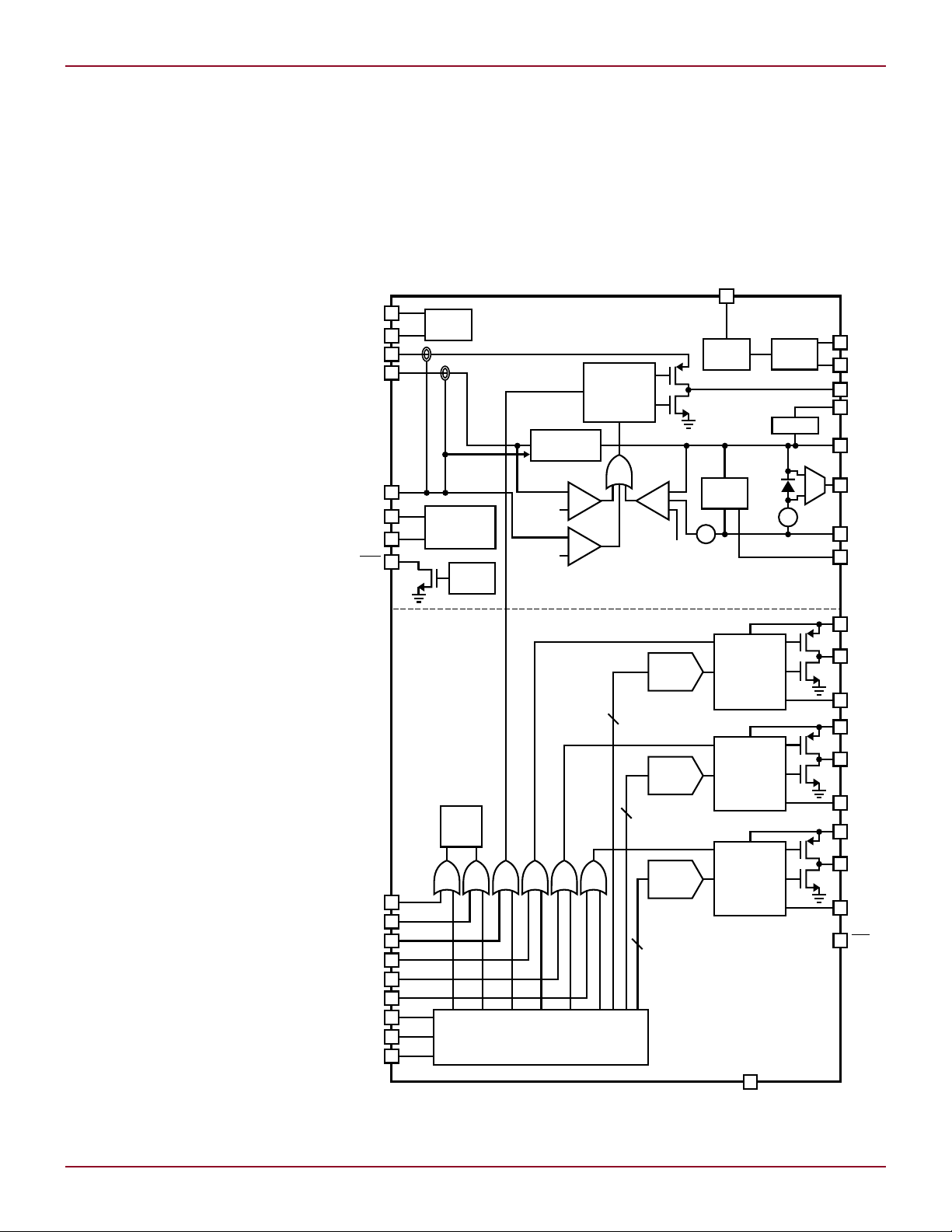

Figure 2. USB On-The-Go system diagram

Figure 3. USB sequence of events at start-up

tional switching regulator between

V

BUS

from the USB input, this regulator operates as a step-down converter. Using

the Bat-Track™ charging technique,

the switching regulator sets the voltage at V

very efficient charging solution. When

operating as an OTG A device, the

regulator acts as a step-up converter

by taking power from V

5V on V

The LTC3576 also has overvoltage

protection and can be used with an

external HV Buck regulator to provide

V

OUT

switching regulator can take power

from the HV buck regulator to supply

power to the USB connection.

In addition, the LTC3576 provides

two 400mA and one 1A step-down

1.5kΩ to 3.3V on D– during Connect for

1.5kΩ to 3.3V on D+ during Connect for

Full/High Speed, measure voltage on D–

Linear Technology Magazine • June 2009

and V

. When power is coming

OUT

OUT

BUS

to V

.

+ 0.3V, providing a

BAT

OUT

to produce

. In OTG mode, the bidirectional

Table 1. Load power signaling during Attach and Connect

Voltage on D–

with VDAT_SRC on D+ during Attach

Low Speed, measure voltage on D+

switching regulators for generating

three independent voltage rails for the

portable device. The LTC3576 allows

all three step-down switching regulator

output voltages to be enabled/disabled

and adjusted over a 2:1 range via I2C.

All three step-down regulators feature

pulse-skipping mode, Burst Mode

®

operation and LDO mode, which can

also be adjusted on-the-fly via I

2

C.

Mode Detection

The USB specification allows for a

number of different modes of operation

for products supporting both the USB

OTG specification1 and the battery

charger specification2. Figure 2 shows

a typical OTG system and Figure 3

shows the sequence of events that

occur when the USB cable is plugged

in. The product can be a B device

I

BUS

Host/Hub

< 500mA

0V 0.5V–0.7V 0.5V–0.7V

— > 2V < 0.8V

— > 2V < 0.8V

Dedicated Charger

I

BUS

< 1.5A

and can draw up to 100mA, 500mA,

900mA or 1.5A, depending on the type

of A device powering V

, as shown

BUS

in the Table 1.

When an OTG device has a micro/

mini-A plug connected to its micro/

mini-AB connector, the OTG device

becomes the A device and starts off as

the host. The OTG A device supplies

power to V

, as any other host A

BUS

device would, when requested by an

attached peripheral or OTG B Device.

As an A device, the LTC3576 can supply up to 500mA

The USB OTG specification provides

two means for a B device to signal to

the A device that it wants power. The

B device may drive the V

line above

BUS

2.1V, momentarily, or it may signal

by driving the D+ or D– signal lines.

The D+/D– signaling method could be

Host/Hub Charger

I

< (LS,FS < 1.5A/HS < 0.9A)

BUS

9

L DESIGN FEATURES

R5

7.68k

C

C1

1500pF

V

PROCESSOR

M3

UNLESS NOTED, RESISTORS: OHMS, 0402 1% 1/16 WATT

* THREE 1Ω, 5% RESISTORS IN PARALLEL

CAPACTORS: µF, 0402, 10% 25V

D2, D3: 1N4148

L1: 1098AS-2R0M

L2, L3: 1098AS-4R7M

L4: LPS4018-3R3MLC

M2, M3, M6: NDS0610

M4, M5, M7: 2N7002L

Q1, Q2, Q3: MMBT3904LT1

DV

CC

4.35V TO 5.5V

NON-OPERATING FAULT TOLERANCE

TO 30V CONTINUOUS

47k

10k

100k 100k

VBUS

D–

D+

IO

GNDSHGND

IDPUEN

FSPUEN

VBATVEN

VBATV

1ACHARGEEN

BAT

J2

DF3-3P-2DSA

GND

NTC-EXT

V

PROCESSOR

M2

V

PROCESSOR

V

PROCESSOR

V

PROCESSOR

V

PROCESSOR

3.6V AT

400mA

V

BUS

47k 15k 15k

V

BAT

M6

M7

47k

2.00k 2.00k

10k

10k

M4

BATTERY CHARGER HANDSHAKE

M5

U2B

LTC202

Q1

Q3

44.2k

D2

D3

100k

100k

100k

LEAKAGE

CURRENT

MUST BE

<400nA

6.2k

PROGV

CLPROGV

SCL

SDA

DV

CC

RST3

CHRG

VDAT_SRCEN

IDAT_SINKEN

D-V

VBUSV

D–

D+

HUBEN

IDV

DV

CC

I

DAT_SINK

V

DAT_SRC

4.7k

4.7k

100k

1.5k

3.01k

4.7µF

50V

22µF

6.3V

1µF

10V

22µF

6.3V

10µF

6.3V

0.1µF

16V

3.3V

U2A

LTC202

“V” SUF FIX

INDICATES

A/D INP UT

VC

WALL

ACPR

LD03V3

OVSENS

OVGATE

ILM0

ILM1

V

BUS

ENOTG

EN1

EN2

EN3

V

OUT

V

OUT

V

BAT

SW

IDGATE

BAT

V

IN1

SW1

FB1

CHRG

RST3

DVCC

SDA

SCL

CLPROG

PROG

NTCBIAS

NTC

M1

Si2306BDS

M8

Si2333DS

100µF

6.3V

0.337*

U1

LTC3576EUFE

L4

3.3µH

LEAKAGE CURRENT MUST BE < 50nA

0.1µF

16V

L3

4.7µH

2.2µF

6.3V

1.02M

324k

12pF

50V 5%

3.3V AT

400mA

10µF

6.3V

V

IN2

SW2

FB2

L2

4.7µH

2.2µF

6.3V

1.02M

R23

324k

18pF

50V 5%

1.8V

AT1A

22µF

6.3V

V

IN1

SW3

FB3

GND

L1

2.0µH

2.2µF

6.3V

402k

324k

27pF

50V 5%

Q2

J1

USBMICRO-AB

µC

10

Figure 4. Portable system with OTG and battery charger support

Linear Technology Magazine • June 2009

DESIGN FEATURES L

V

IH

V

(D+ or D–)

V

BUS

V

IL

5V

2.1V

0V

100ms

7.5ms

4.9s

B DEVICE SIGNALING

A DEVICE DELIVERING V

USB

detected by an OTG compatible USB

module on the system microcontroller

(µC ). The V

signaling method could

BUS

be detected via an A/D on the µC.

The LTC3576 bidirectional switching

regulator is then enabled as a step-up

converter (OTG mode) by setting the

appropriate bit in the control registers

via I2C.

Implementing a System

for USB OTG and

Battery Charging

Figure 4 shows an application for a portable device that supports both USB

battery charging and USB OTG.

When IDPUEN is low, the ID pin is

pulled up via R5, and if IDV is > 3V

then it is configured to be a B device.

If IDV is < 0.5V then it is configured

to be an A device. The components

enclosed in the box labeled “battery

charger handshake” enable communication of the power capabilities

depending on whether the portable

device is configured as an A device or

a B device. During the Attach phase,

if the portable device is a B device, it

can apply V

DAT_SRC

D+ line, load the D– line with I

(50µA~150µA), and measure the resultant voltage on D– via D–V. If the

voltage is 0, the A device is a Host/Hub,

if the voltage is V

device is a USB Charger.

During the Connect phase, FSPUEN

is pulled low to apply 3.3V to D+,

indicating a full/high speed device.

At the same time the voltage on the

D– line is read again via D–V. If it is

less than 0.8V, then the A device is a

Host/Hub Charger. If the voltage on

D–V is above 2V, then the A device is

a Dedicated Charger.

Linear Technology Magazine • June 2009

(0.5V~0.7V) to the

DAT_SRC

Figure 5. Session Request Protocol timing reference

then the A

DAT_SINK

For OTG functionality, if the portable device is configured as an A

device, then it must drive V

V

, which in this case is powered

OUT

BUS

from

from the battery. Since the LTC3576

is capable of supplying 500mA as an A

device, the µC asserts HUBEN to indi-

cate it is a Host/Hub. The bidirectional

switching regulator in the LTC3576

is enabled by setting the appropriate

bit in the control registers via the I2C

port. If the B device drawing current

from the V

line goes idle, then the

BUS

OTG A device may turn off the V

voltage to conserve the battery. When

the B device needs the V

voltage

BUS

to be present at some later time, it

can request that the A device again

drive V

by turning the bidirectional

BUS

switching regulator back on. It can do

this by signaling on the D+ or D– lines

or by driving the V

line to > 2.1V

BUS

(see Figure 5).

The Host A device only needs to

respond to one of two SRP signaling

methods. However, since not all USB

engines respond to the D+/D– signaling, the V

line is sensed to check if

BUS

it is higher than 2.1V via the VBUSV

A/D input.

When the portable device’s µC detects that the B device is requesting

power on V

, either by sensing the

BUS

D+/D– signaling or by sensing that

V

has been driven higher than 2.1V,

BUS

it should again turn on the OTG stepup converter in the LTC3576.

The PROG (PROGV) and BAT

(VBATV) pins allow a Coulomb counter

to be implemented in the µC. Reading the BAT voltage requires that the

sensing divider be enabled by setting

VBATVEN low. This ensures that the

sense divider network does not dis-

1

charge the battery when the battery

voltage isn’t being measured.

The default battery charge current has been set to 500mA, but can

be increased to 1A by asserting the

1AchargeEN signal. This turns on M7,

halving the PROG resistance and increasing the charge current. The input

current limit will need to be set to 10X

mode (1A) using the I2C port.

The optional network of C14 and

R27/R28/R29 suppresses ripple on

the BAT pin (and consequently on the

V

BUS

pin) if there is no battery present.

BUS

This ripple can be in the tens of mV.

While this will not damage anything,

it may be desirable to suppress this

signal.

The CLPROG (CLPROGV) and

CHRG signals are often useful for

housekeeping tasks in the µC.

The LTC3576 has an overvoltage

protection function that controls M1,

and protects the system from excessive

voltages on the USB (J1) connector.

Because the A/D is configured to monitor V

, it must also be protected by

BUS

D1 from excessive voltages.

The LDO3V3 regulator is configured

to power the µC in low power mode

(<20mA). When the µC needs to leave

low power mode it first enables Buck

Regulator 2, which will provide up to

400mA.

Conclusion

The LTC3576 is a versatile PMIC

consisting of a bidirectional power

manager, overvoltage protection, three

step-down switching regulators and

a controller for an external high voltage step-down switching regulator.

In conjunction with a few support

components, the LTC3576 allows the

implementation of a complete power

management system for portable devices that support both USB OTG and

USB battery charging.

Bibliography

1

”On-The-Go Supplement to the USB Specification”,

Revision 1.3

2

“Battery Charging Specification”, Revision 1.0

3

www.usb,org/developers/docs

L

11

L DESIGN FEATURES

LTC3101

BUCK-BOOST

LDO

ON/OFF

AC

ADAPTER

USB

or

HOT SWAP OUT

3.xV AT 300 to 800mA

1.xV AT 350mA

1.xV AT 350mA

1.8V AT 50mA

3.xV AT 100mA

x.xV AT 200mA

TRACKING OUT

LI-ION

USB

BAT

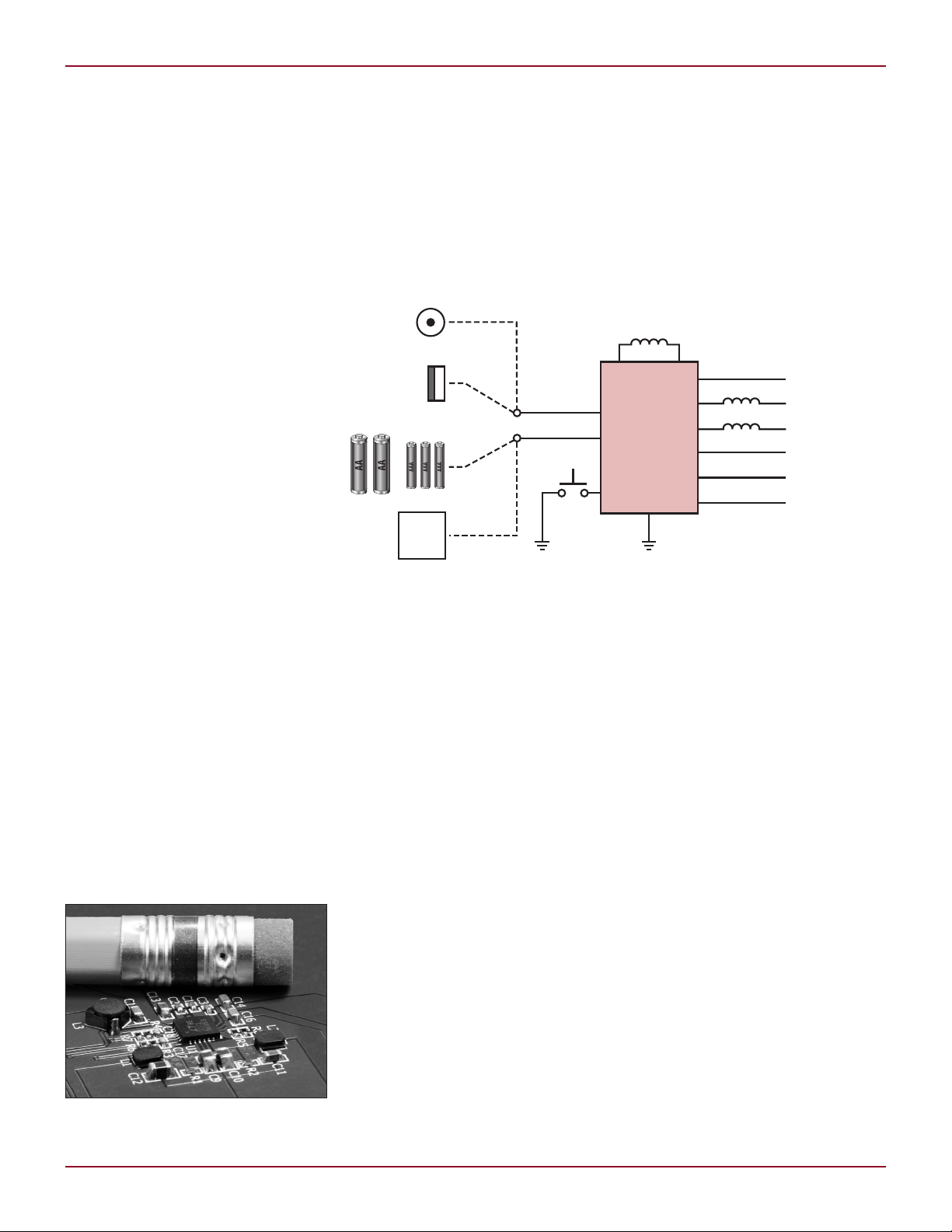

Power Management IC with Pushbutton Control Generates Six Voltage Rails from USB or 2 AA Cells Via Low Loss PowerPath Topology

Introduction

As the complexity of portable electronic

devices continues to increase, the demands placed on power supplies, and

their designers, expand dramatically.

Not only must typical power systems

accommodate multiple input sources,

with voltages as low as 1.8V for two

AA cells, but they must also provide

an increasing number of independent

output rails to support a wide range

of requirements—for memory, microprocessors, backlights, audio and RF

components. To further complicate

matters, expanding feature sets add up

to increased power dissipation, making

it important to optimize overall power

system efficiency. This is particularly

challenging given that the constant

drive to minimize the required board

area and profile height of the power

system is at direct odds with improving efficiency.

The LTC3101 addresses all of these

challenges with a single-IC power

management solution that allows a

designer to easily maximize overall

power system efficiency while minimizing space requirements. The LTC3101

can generate six power rails by integrating three synchronous switching

converters, two protected switched

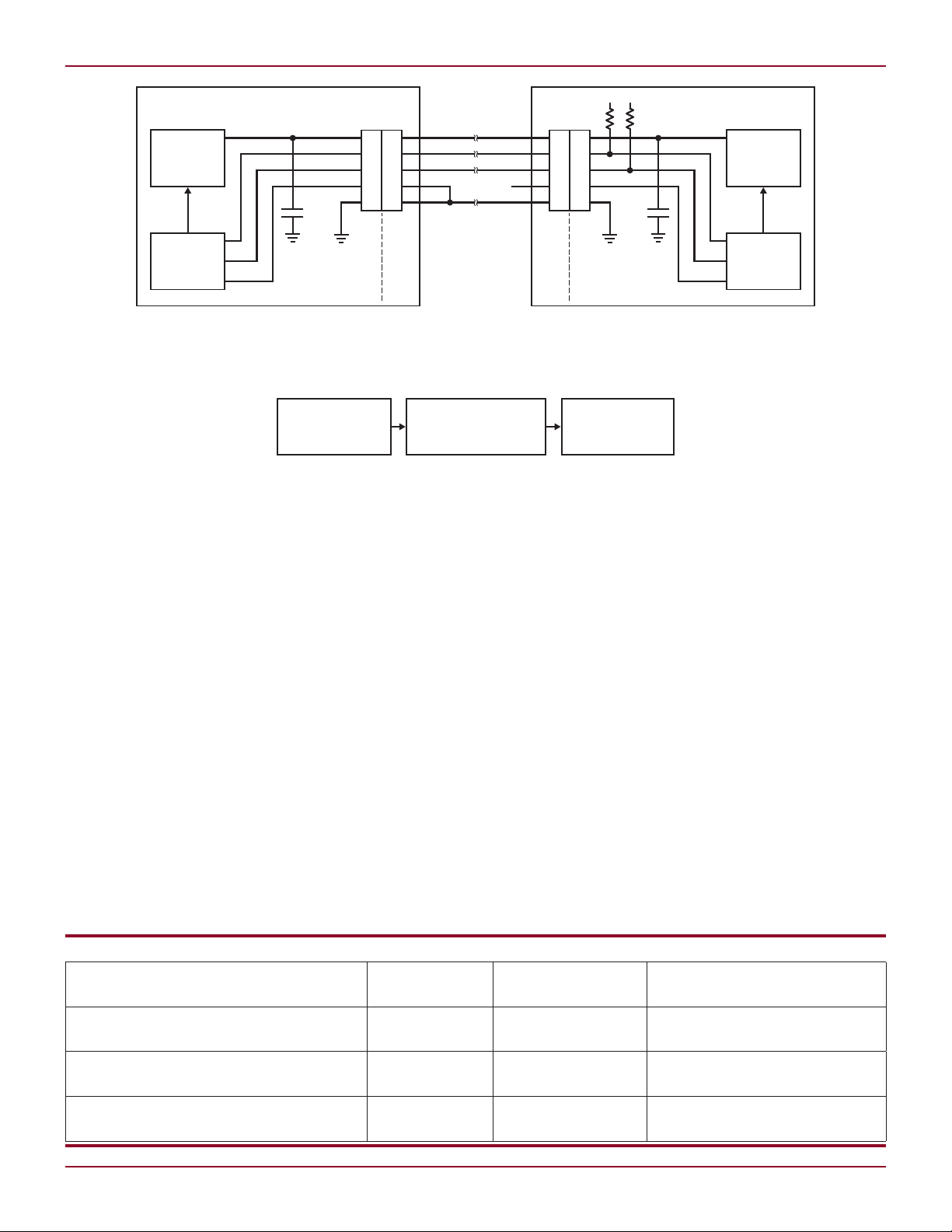

Figure 2. Complete portable power

solution with a 16mm × 19mm footprint

12

by John Canfield

Figure 1. Six output rails, a low loss PowerPath and integrated pushbutton control

power outputs, and an LDO. Its integrated low loss PowerPath™ topology

allows each switching converter to

run directly from either of two input

power sources.

Two 350mA, high efficiency low

voltage rails, typically used to power

processors and memory, are generated

by synchronous buck converters. Each

converter is able to operate down to an

input voltage of 1.8V thereby enabling

single stage conversion from any input

power source.

A single inductor buck-boost

converter generates a high efficiency

intermediate output rail, typically at

3V or 3.3V, and is able to operate from

either input power source and with

input voltages that are above, below,

or even equal to the output regulation

voltage. The buck-boost converter

can supply a 300mA load at 3.3V for

battery voltages down to 1.8V and an

800mA load for input voltages of 3.0V

and greater.

Two always-alive outputs—MAX,

which tracks the higher voltage input

power source and LDO, a fixed 1.8V

output—provide power to critical

functions that must remain powered

under all conditions. An integrated

pushbutton controller with programmable µP reset generator provides

complete ON/OFF control using only

a minimal number of external components while independent enables allow

total power-up sequencing flexibility.

This complete portable power solution

is packaged in a single low profile 24lead 4mm × 4mm QFN package and

the entire power supply, including

all external components, occupies a

PCB area of less than 3cm2 as shown

in Figure 2.

Zero Loss PowerPath

Topology Maximizes

Efficiency

Although rechargeable Li-Ion and

Li-Polymer batteries are the leading

chemistries for powering portable

devices due to their high energy density and long cycle life, many portable

devices continue to be powered by

alkaline and NiMH cells. This allows

indefinite periods of use away from a

Linear Technology Magazine • June 2009

BAT1

USB1

C

RS

ENA1

ENA2

ENA3

PWRKEY

PWRON

PWM

PBSTAT

RESET

USB2

FB3

LDO

SW2

FB2

HSO

MAX

10µF

10µF

2 AA

CELLS

USB/WALL

ADAPTER

1.8V TO 5.5V

10µF

1M

V

OUT3

= 3.3V

300mA FOR VIN ≥ 1.8V

800mA FOR VIN ≥ 3V

221k

Hot Swap OUTPUT: 3.3V AT 100mA

TRACKING OUTPUT: 200mA

4.7µH

4.7µF

1.8V AT 50mA

V

OUT2

1.8V

350mA

V

OUT1

1.5V

350mA

10µF

221k

110k

4.7µH

SW1

FB1

10µF

221k

147k

4.7µH

0.1µF

ON/OFF

BAT2 SW3A

LTC3101

GND

µP

SW3B OUT3

DIS ENA

+

USB

BAT

+

BUCK

V

OUT

USB

BAT

+

BUCK-BOOST

V

OUT

charging socket—which is particularly

important for devices intended for use

in remote locales such as handheld

personal navigation devices or portable

medical devices. Voice recorders, digital still cameras and ultra-small video

recorders are additional examples of

devices that benefit from the ability to

operate from a pair of commonly available batteries, rather than requiring

the lengthy recharging cycle needed

for an internal Li-Ion battery.

Even in portable devices where the

primary power source is restricted

to AA or AAA form factor cells, there

still exist a wide variety of compatible chemistries including alkaline,

rechargeable alkaline, NiMH and

single-use lithium. As a result, the

AA/AAA powered device must accommodate a wide range of input voltages,

from 1.8V for two series alkaline cells

near end of life, to approximately 3.7V

for a pair of fresh non-rechargeable

lithium cells. With its wide 1.8V to

5.5V input voltage range, the LTC3101

can easily support all of these battery chemistries. In addition, the

LTC3101 is able to operate from a

single standard Li-Ion/Polymer cell in

cases where recharging is performed

independently.

Although rechargeable cells are

usually charged outside these types

of devices, the power supply must

accommodate a secondary tethered

power source such as USB or a regulated wall adapter. Consequently, the

power supply must include a means to

generate every power rail from either of

two input sources, and the ubiquitous

3.3V rail must be generated from input

power sources that can be higher or

lower voltage.

In many devices, the capability to

handle dual power sources is provided

by using discrete power MOSFETs to

switch regulator inputs between the

two input power sources or by utilizing

two regulators for generation of each

rail (for example, a buck converter

that generates a 3.3V rail from the

USB input in conjunction with a boost

converter that generates the 3.3V rail

from the battery input).

Both of these approaches suffer

from significant drawbacks. The par-

Linear Technology Magazine • June 2009

allel converter approach increases

system cost and size given that only

one converter is ever active at any given

time and often suffers from glitches

and disruptions to the output rails

during the transition between the

two input power sources. Similarly,

the discrete power switch technique

reduces efficiency due to the addition

of extra series elements in the power

path, increases component count,

and can also lead to disruptions in

the output rails unless the supply

crossover is carefully controlled.

The LTC3101 avoids these problems by using a low loss PowerPath

topology as shown in Figure 4, where

each converter is able to operate directly from either input power source.

In this architecture, each switching

converter utilizes an additional power

switch, which is connected to the

alternate power input. As a result,

each converter is able to run with

maximum efficiency from either input

power source so no efficiency penalty

DESIGN FEATURES L

Figure 3. Typical application

is incurred in supporting dual input

power sources.

The total solution area is minimized

by the fact that the same inductor is

used in either case. In addition, the

automatic transition between the

two input power sources is seamless—there is no interruption to any

of the output rails. Figure 5 shows the

transient response of the buck-boost

converter as the input power source

transitions from battery power to USB

power in response to a live cable plug

into a USB port.

Integrated Buck-Boost

Provides High Efficiency

3V/3.3V Rail from

Any Power Source

In many portable devices an intermediate supply rail, typically regulated to

3.3V, is required to power an RF stage

or audio amplifiers. Often this rail is

generated from the two series AA cells

using a boost converter. However, the

higher cell voltage of single-use lithium

Figure 4. The low loss PowerPath architecture

13

L DESIGN FEATURES

OUTPUT

VOLTAGE

200mV/DIV

INDUCTOR

CURRENT

200mA/DIV

V

USB

2V/DIV

100µs/DIV

batteries such as the Energizer e2

brand can cause problems when the

battery voltage is significantly higher

than the output voltage. Depending

on the boost converter utilized, this

can result in low efficiency operation

or even loss of regulation on the 3.3V

rail.

To avoid this problem, the LTC3101

generates the 3.3V rail utilizing a

buck-boost converter, which accepts

any input voltage in the range 1.8V to

5.5V without sacrificing efficiency. In

fact, when operating with a fresh pair

of single-use lithium batteries at 3.7V,

the LTC3101 buck-boost efficiency is

greater than 94% at 150mA load current. In addition, the same buck-boost

converter is able to operate directly

from the USB input, so generation

of the 3.3V rail requires only a single

inductor.

Reverse Blocking LDO

Enables Data Retention

During Battery Swaps

Many portable electronic devices contain critical circuitry such as real time

clocks, which must remain powered

under all conditions. The MAX and

LDO outputs of the LTC3101 are alive

as long as either input power source

is present, regardless of the state of

the pushbutton interface or enable

inputs. It is also possible to connect

a large capacitor directly to the LDO

output to serve as a charge reservoir

for powering critical functions during

times, such as battery swaps, when

both input power sources are temporarily removed. In its reverse blocking

state, the maximum reverse current

through the LDO is limited to under

1µA in order to preserve charge in the

reservoir capacitor.

Figure 5. Buck-boost output voltage transient on USB hot plug

14

MAX and Hot Swap Outputs

Power Additional Regulators

and Flash Memory Cards

Portable electronic devices often require additional miscellaneous power

supplies, such as current regulated

drivers for LED backlighting and LDOs

for low power rails. Typically these

secondary supplies must be functional

whenever either input power source

is present, so they also require power

path control to switch between the two

input power sources.

External supplies can take advantage of the LTC3101’s PowerPath

control circuit via the MAX output,

which continuously tracks the higher

voltage input power source. Additional

regulators can be directly connected

to this output, thus freeing the designer from the need to implement

an additional switched power path.

The MAX output is able to support a

200mA load and is current limited to

protect against overload conditions

and short circuits.

Many portable electronic devices

provide flash memory card interfaces for use as bulk storage memory.

Typical flash memory cards such as

Compact Flash (CF) and Secure Digital (SD) formats require a regulated

3.3V supply that is typically capable

of providing tens of milliamps. However, many flash memory cards have

a significant amount of supply bypass

capacitance installed on the card and

when hot plugged into a live 3.3V rail,

the inrush current required to charge

these supply bypass capacitors on

the memory card can momentarily

drag down the host’s supply, causing disruption to other ICs powered

by that rail.

The LTC3101’s dedicated 100mA

hot swap output (powered from the

buck-boost converter rail) does not

have this problem. The independent

current limit of the hot swap switch

allows flash memory cards to be hot

plugged without disruption to the

primary 3.3V rail. In addition, the

hot swap output is fully short circuit

protected to safeguard against accidental shorts at the memory card

interface port.

Low Quiescent Current

Minimizes Battery Drain

Most portable electronic devices spend

significant, if not the majority, of their

time in sleep or standby modes. In fact,

even when an appliance is off, there is

often circuitry that must remain powered, including real time clocks and

volatile memory storing configuration

settings. The always-alive 1.8V LDO

and tracking MAX outputs remain

powered whenever either input power

source is present allowing them to be

utilized for supplying such critical

functions. In order to minimize battery

discharge during this time, the total

quiescent current draw of the LTC3101

with both the MAX and LDO outputs

active is reduced to 15µA.

Many portable electronic devices

also support a standby mode in which

several of the system’s voltage rails

must be kept in regulation. Typically,

in standby the microprocessor and

memory remain powered and the

processor is placed in a low current

sleep mode enabling the device to return to an active operating state with

minimal delay.

In order to minimize battery drain

in such modes of operation, all three

switching converters in the LTC3101

feature Burst Mode operation, which

can be enabled via a dedicated pin.

With Burst Mode operation enabled,

the buck converters automatically

transition from PWM to Burst Mode

operation at sufficiently light load

(typically 10mA) while the buck-boost

converter uses Burst Mode operation

at all load currents. In Burst Mode

operation with all six output rails

maintained in regulation the total

quiescent current draw of the LTC3101

Linear Technology Magazine • June 2009

is reduced to only 38µA. In addition,

HSO

(OPTIONAL)

ENA1

ENA2

R

FILT

C

FILT

500µs/DIV

V

OUT

BUCK 1

(1V/DIV)

V

OUT

BUCK 2

(1V/DIV)

V

OUT

BUCK-BOOST

(2V/DIV)

HOT SWAP

(2V/DIV)

500µs/DIV

V

OUT

BUCK 1

(1V/DIV)

V

OUT

BUCK 2

(1V/DIV)

V

OUT

BUCK-BOOST

(2V/DIV)

HOT SWAP

(2V/DIV)

to ensure low supply rail noise, the

Burst Mode operation output voltage

ripple is typically less than 1% of the

regulation voltage of each output rail.

All three switching converters can be

forced into fixed frequency PWM mode

operation to ensure low noise operation while critical system functions

are underway.

DESIGN FEATURES L

Figure 6. Default power-up sequencing

Flexible Power-Up

Sequencing Options

The LTC3101 provides a variety of

sequencing options. Most systems

that incorporate multiple power

supply rails require that they come

into regulation in a certain sequence

with specific timing. This is because

individual ICs and modules that are

powered from multiple rails need

particular sequencing to minimize

start-up current and ensure predictable power-up behavior.

Common examples include microprocessors and FPGAs, which often

require that the peripheral supply

powering the I/O buffers is made

available only after the lower voltage

core is in regulation. In addition, at

the board level, many systems bring

up the supplies for peripheral devices

only after the processor is powered up

to avoid erratic behavior from peripherals lacking processor oversight.

Each switching converter in the

LTC3101 has an internal power-good

comparator, which is used internally

to sense when that rail is in regulation. The default power-up sequence

enables the individual outputs in the

following order: buck converter 1, buck

converter 2, buck-boost converter,

and finally the hot swap output. Each

converter is enabled once the preceding converter in the sequence reaches

regulation (typically 94% of the target

output voltage). The default power-up

sequence using all converter channels

is shown in Figure 6.

If the dedicated enable pin for any

switching converter is held low during

the pushbutton triggered initiation,

that converter is simply skipped in

the default power-up sequence, but

that channel can still be enabled at a

later time. This functionality allows the

LTC3101 to implement any arbitrary

power-up sequence using few if any

external components.

can be accomplished by adding a

simple RC filter with the desired time

constant between the hot swap output

and the buck enables. Notice however,

that if the hot swap output is forced

to ground, the buck converters will

be disabled. If there is a potential for

the hot swap output to fall below the

enable threshold (typically 0.7V) during normal operation, then the buck

enables can instead be driven through

an RC delay from the buck-boost voltage directly rather than from the hot

swap output.

For example, in some systems the

3.3V buck-boost rail must come up

first, followed by both buck rails in

unison. This can be accomplished

by driving the buck enables from the

hot swap output, HSO, as shown in

Figure 7. The bucks do not power up

in the normal sequence since their

enables are low to start. Once the

buck-boost reaches regulation, the hot

swap output is enabled, which in turn

enables the two buck converters. Since

the hot swap output is not powered

until the buck-boost is in regulation,

this configuration ensures that the

buck converters do not become active

until after the buck-boost is in regulation, as shown by the waveforms in

Figure 8.

If an additional delay is required

Conclusion

The LTC3101 is perfectly suited for

the needs of the next generation of

extended functionality compact portable electronic devices.

The job of the power system designer

is simplified by its compact solution

footprint and ability to generate six

commonly required output voltage

rails automatically from two independent wide input voltage range power

sources. The LTC3101’s low quiescent

current and a high efficiency, low loss

PowerPath architecture maximize

battery life. A wide range of output

voltages, programmable duration

µP reset generator, and independent

enables offer flexibility and easy customization.

before the bucks are enabled, this

L

Figure 7. Sequencing the buck enables

using the hot swap output rail

Linear Technology Magazine • June 2009

Figure 8. Power-up sequencing, buck-boost followed by the buck outputs

15

L DESIGN FEATURES

ADC

0.1µF

12V

V

OUT

12V

1.5A

20k

10k

12V

330µF

V

DD

UV

OUT

PG

GND

I

MON

LTC4217DHC-12

INTV

CC

TIMER

FLT

AUTO

RETRY

+

TEMPERATURE (°C)

–50

0.9

0.8

0.7

0.6

0.5

0.4

0.3

–25 0 25 50 75 150125100

V

ISET

(V)

Improve Hot Swap Performance and Save Design Time with Hot Swap Controller that Integrates 2A MOSFET and Sense Resistor

Introduction

The LTC4217 Hot Swap controller

turns a board’s supply voltage on and

off in a controlled manner allowing

the board to be safely inserted and

removed from a live backplane. No surprise there, this is generally what Hot

Swap controllers do, but the LTC4217

has a feature that gives it an advantage over other Hot Swap controllers.

It simplifies the design of Hot Swap

systems by integrating the controller,

MOSFET and sense resistor in a single

IC. This saves significant design time

that would otherwise be spent choosing an optimum controller/MOSFET

combination, setting current limits,

and carefully designing a layout that

protects the MOSFET from excessive

power dissipation.

One significant advantage of an

integrated solution over discrete solutions is that the current limit accuracy

is well known. In discrete solutions, the

overall precision of the current limit

is a function of adding the tolerances

of contributing components, while in

the LTC4217, it appears as a single

2A specification.

The integrated solution also simplifies layout issues by optimizing

MOSFET and sense resistor connections. The inrush current, current

limit threshold and timeout can be

set to default values with no external

16

components or easily adjusted using

resistors and capacitors to better suit a

large range of applications. The part is

able to cover a wide 2.9V to 26.5V voltage range and includes a temperature

and current monitor. The MOSFET

is kept in the safe-operating–area

(SOA) by using a time-limited foldback

current limit and overtemperature

protection.

The LTC4217 can be easily applied

in its basic configuration, or, with a

few additional external components,

set up for applications with special

requirements.

Monitoring the MOSFET

The LTC4217 features MOSFET

current and temperature monitoring. The current monitor outputs a

current proportional to the MOSFET

current, while a voltage proportional

to the MOSFET temperature is available. This allows external circuits to

predict possible failure and shutdown

the system.

The current in the MOSFET passes

through a sense resistor, and the voltage on the sense resistor is converted

to a current that is sourced out the

I

pin. The gain is 50µA from I

MON

for 1A of MOSFET current. The output

current can be converted to a voltage

using an external resistor to drive a

Figure 2. 12V, 1.5A card resident application

by David Soo

Figure 1. V

comparator or ADC. The voltage compliance for the I

(INTVCC – 0.7V).

The MOSFET temperature corresponds linearly to the voltage on the

I

pin, with the temperature profile

SET

shown in Figure 1. The open circuit

voltage on this pin at room temperature

is 0.63V. In addition, the overtemperature shutdown circuit turns off

the MOSFET when the controller die

temperature exceeds 145°C, and turns

it on again when the temperature

drops to 125°C.

12V Application

Figure 2 shows the LTC4217-12 in a

MON

12V Hot Swap application with default

settings. The only external component

required is the capacitor on the INTVCC

pin. The current limit, inrush current

control, and protection timer are internally set at levels that protect the

integrated MOSFET. The input voltage

monitors are preset for a 12V supply

using internal resistive dividers from

the V

pins. The UV condition occurs when

VDD falls below 9.23V; OV when VDD

exceeds 15.05V.

ply voltage on and off in a controlled

supply to drive the UV and OV

DD

The LTC4217 turns a board’s sup-

Linear Technology Magazine • June 2009

vs temperature

ISET

pin is from 0V to

MON

DESIGN FEATURES L

150k

20k

ADC

224k

0.1µF

20k

12V

12V

10k

0.47µF

330µF

V

OUT

12V

0.8A

V

DD

UV

OUT

FB

PG

GND

I

MON

20k

20k

I

SET

0.1µF

1k

GATE

LTC4217FE

OV

INTV

CC

TIMER

FLT

+

140k

20k

FB VOLTAGE (V)

0

0

CURRENT LIMIT VALUE (A)

0.5

1.0

1.5

2.0

2.5