Page 1

FEATURES

■

Charges Any Size Capacitor

■

Easily Adjustable Output Voltage

■

Drives High Current NMOS FETs

■

Primary-Side Sense—No Output Voltage Divider

Necessary

■

Wide Input Range: 3V to 24V

■

Drives Gate to VCC – 2V

■

Available in 10-Lead MS Package

U

APPLICATIO S

■

Emergency Warning Beacons

■

Professional Photoflash Systems

■

Security/Inventory Control Systems

■

High Voltage Power Supply

■

Electric Fences

■

Detonators

LT3750

Capacitor Charger

Controller

U

DESCRIPTIO

The LT®3750 is a flyback converter designed to rapidly

charge large capacitors to a user-adjustable target voltage. A patented boundary mode control scheme* minimizes transition losses and reduces transformer size. The

transformer turns ratio and two external resistors easily

adjust the output voltage.* A low 78mV current sense

accurately limits peak switch current and also helps to

maximize efficiency. With a wide input voltage range, the

LT3750 can operate from a variety of power sources. A

typical application can charge a 100µF capacitor to 300V

in less than 300ms.

The CHARGE pin gives full control of the LT3750 to the

user. The DONE pin indicates when the capacitor has

reached its programmed value and the part has stopped

charging.

, LTC and LT are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

*Protected by U.S. Patents, including 6518733, 6636021.

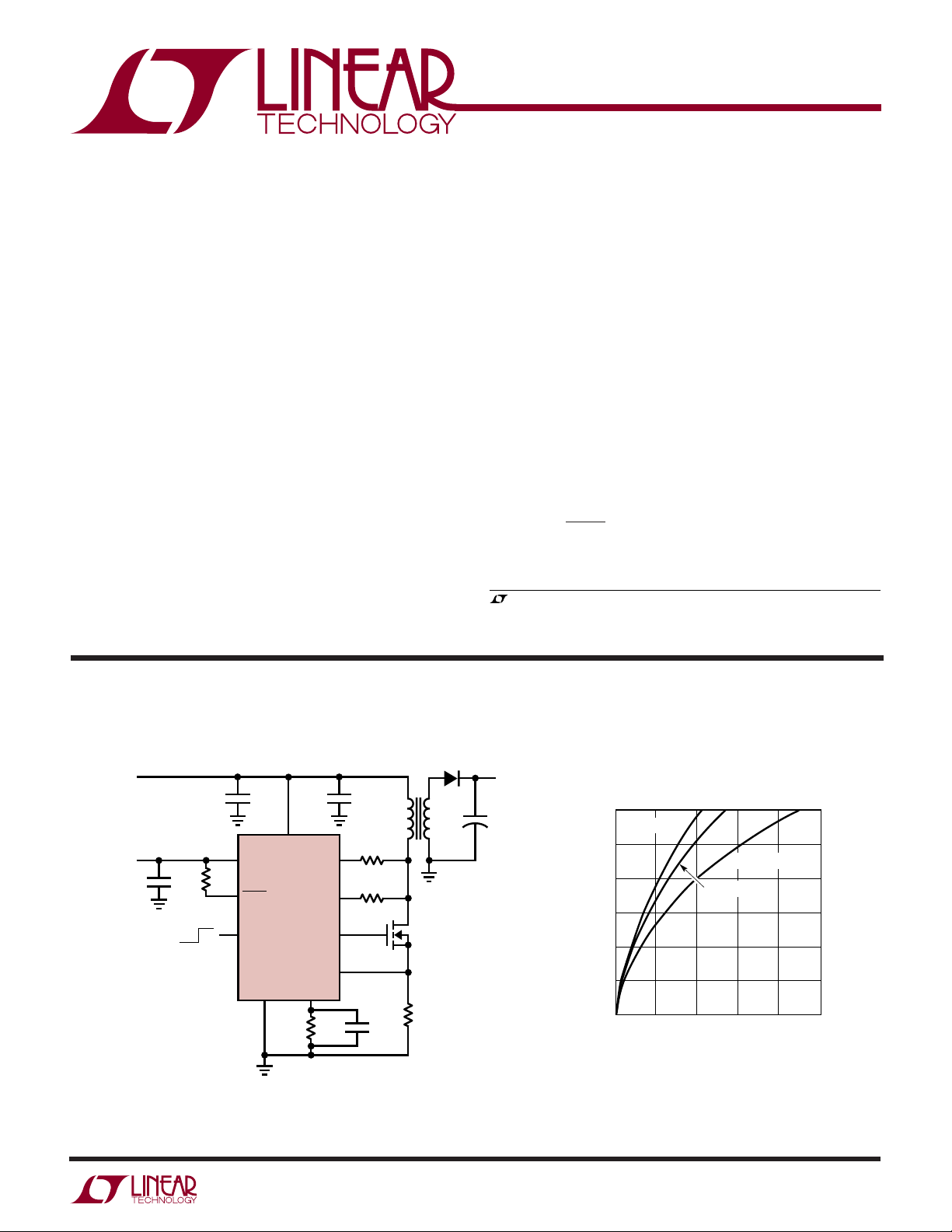

TYPICAL APPLICATIO

300V, 6A Capacitor Charger

V

TRANS

10µF

V

V

12V

CC

100k

10µF

OFF ON

TRANS

V

CC

DONE

LT3750

CHARGE

GND RBG

U

RV

OUT

RDCM

GATE

SOURCE

2.49k 100pF

56µF

×2

60.4k

43k

3750 TA01a

•

T1

1:10

M1

12mΩ

D1

•

V

OUT

300V

+

100µF

(V)

OUT

V

300

250

200

150

100

V

50

0

0

6A Charge Time

= 18V

TRANS

V

TRANS

0.1 0.2 0.3 0.4

TIME (SECONDS)

V

TRANS

= 12V

= 6V

0.5

3750 TA03c

3750fa

1

Page 2

LT3750

WWWU

ABSOLUTE AXI U RATI GS

PACKAGE/ORDER I FOR ATIO

UU

W

(Note 1)

VCC, V

RBG ....................................................................... 1.5V

SOURCE ................................................................... 1V

Current into RDCM Pin ........................................ ±1mA

Current into RV

, GATE, DONE, CHARGE ...................... 24V

TRANS

Pin ........................................ ±1mA

OUT

V

TRANS

DONE

CHARGE

V

GND

Current into DONE Pin ......................................... ±1mA

Operating Temperature Range (Note 2) .. – 40°C to 85°C

Storage Temperature Range ................ –65°C to 150°C

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are T

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum V

Minimum V

VCC Quiescent Current Not Switching, CHARGE = 5V 1.6 2.5 mA

V

TRANS

CHARGE Pin Current CHARGE = 24V 24 µA

CHARGE Pin Enable Voltage

CHARGE Pin Disable Voltage

Minimum CHARGE Pin Low Time High→Low→High 20 µs

V

OUT

V

OUT

RBG Pin Bias Current RBG = 1.2V 70 500 nA

DCM Comparator Trip Voltage Measured as V

Current Limit Comparator Trip Voltage

DONE Output Signal High 100kΩ to 5V 4.9 5 V

DONE Output Signal Low 100kΩ to 5V 0.1 0.2 V

DONE Pin Leakage Current DONE = 2.5V 0.2 µA

NMOS Minimum On Time 0.6 µs

GATE Rise Time 50 ns

GATE High Voltage C

GATE Turn Off Propagation Delay C

CC

TRANS

Quiescent Current Not Switching, CHARGE = 5V 140 250 µA

Comparator Trip Voltage Measured RBG Pin

Comparator Overdrive 1µs Pulse Width, Measured on RBG Pin 30 mV

A

Not Switching, CHARGE = 0V 1 µA

Not Switching, CHARGE = 0V 1 µA

CHARGE = 5V 19 µA

CHARGE = 0V 1 µA

= 1nF, VCC = 5V 3 3.8 4.5 V

GATE

= 1nF, VCC = 24V 22 22.6 23.5 V

C

GATE

= 1nF 100 ns

GATE

The ● denotes specifications which apply over the full operating

= 25°C. VCC = V

– V

DRAIN

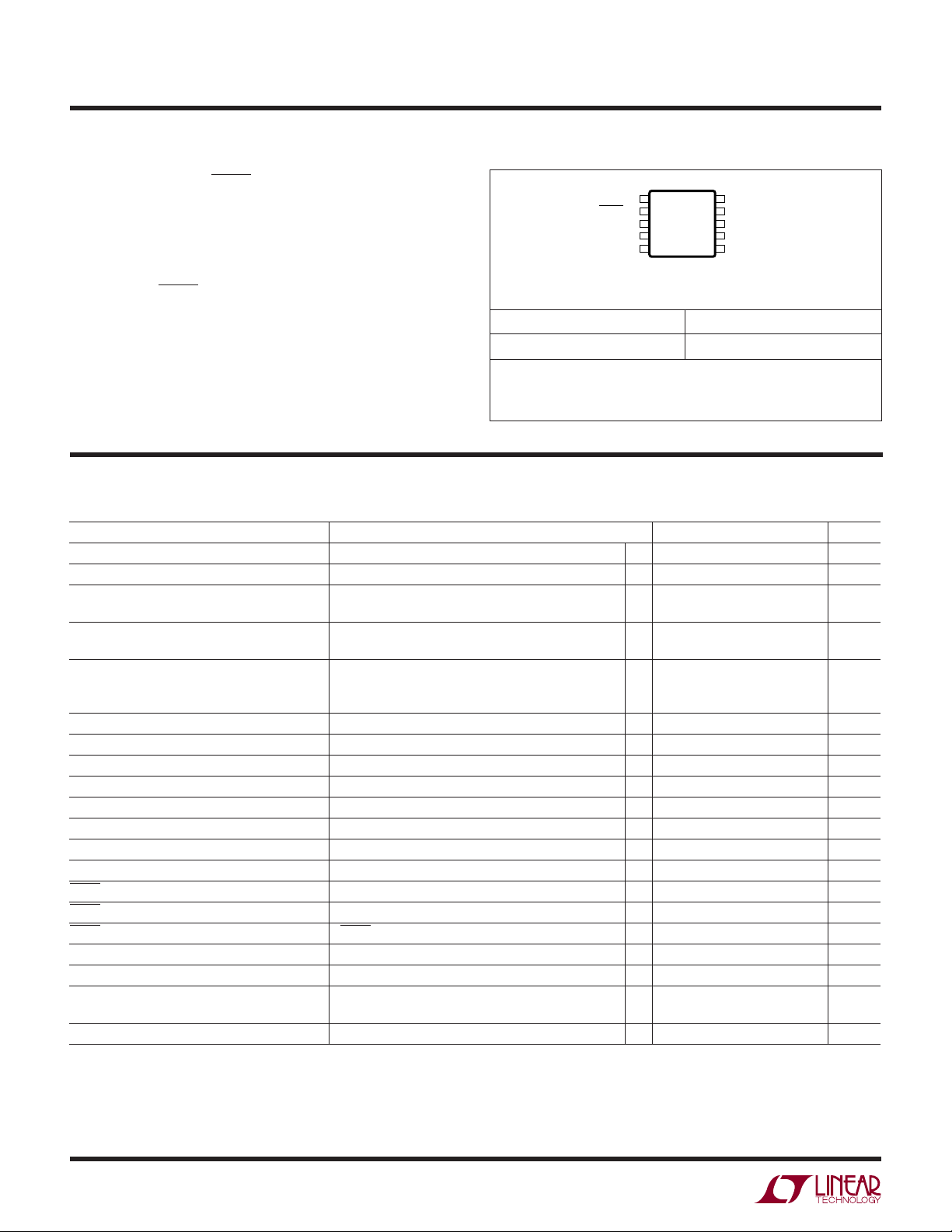

ORDER PART NUMBER MS PART MARKING

LT3750EMS

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specified with wider operating temperature ranges.

= 5V unless otherwise specified.

TRANS

, R

TRANS

= 43k (Note 3)

DCM

TOP VIEW

1

2

3

4

CC

5

MS PACKAGE

10-LEAD PLASTIC MSOP

T

= 125°C, θJA = 120°C/ W

JMAX

●

●

●

●

0.2 0.6 V

●

1.215 1.24 1.265 V

●

●

53680 mV

68 78 88 mV

10

RBG

9

RV

OUT

RDCM

8

GATE

7

SOURCE

6

LTBQD

2.8 3 V

2.5 3 V

0.87 1.1 V

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

2

Note 2: The LT3750E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: Refer to Block Diagram for V

DRAIN

definition.

3750fa

Page 3

UW

V

CHARGE

(V)

0

0

CHARGE PIN CURRENT (µA)

5

15

20

25

16

45

3750 G03

10

8

4

20

12 24

30

35

40

–50°C

25°C

125°C

TEMPERATURE (°C)

–50 –25

0

GATE PIN VOLTAGE (V)

10

25

0

50

75

3750 G06

5

20

15

25

100

125

VCC = 24V

VCC = 12V

VCC = 5V

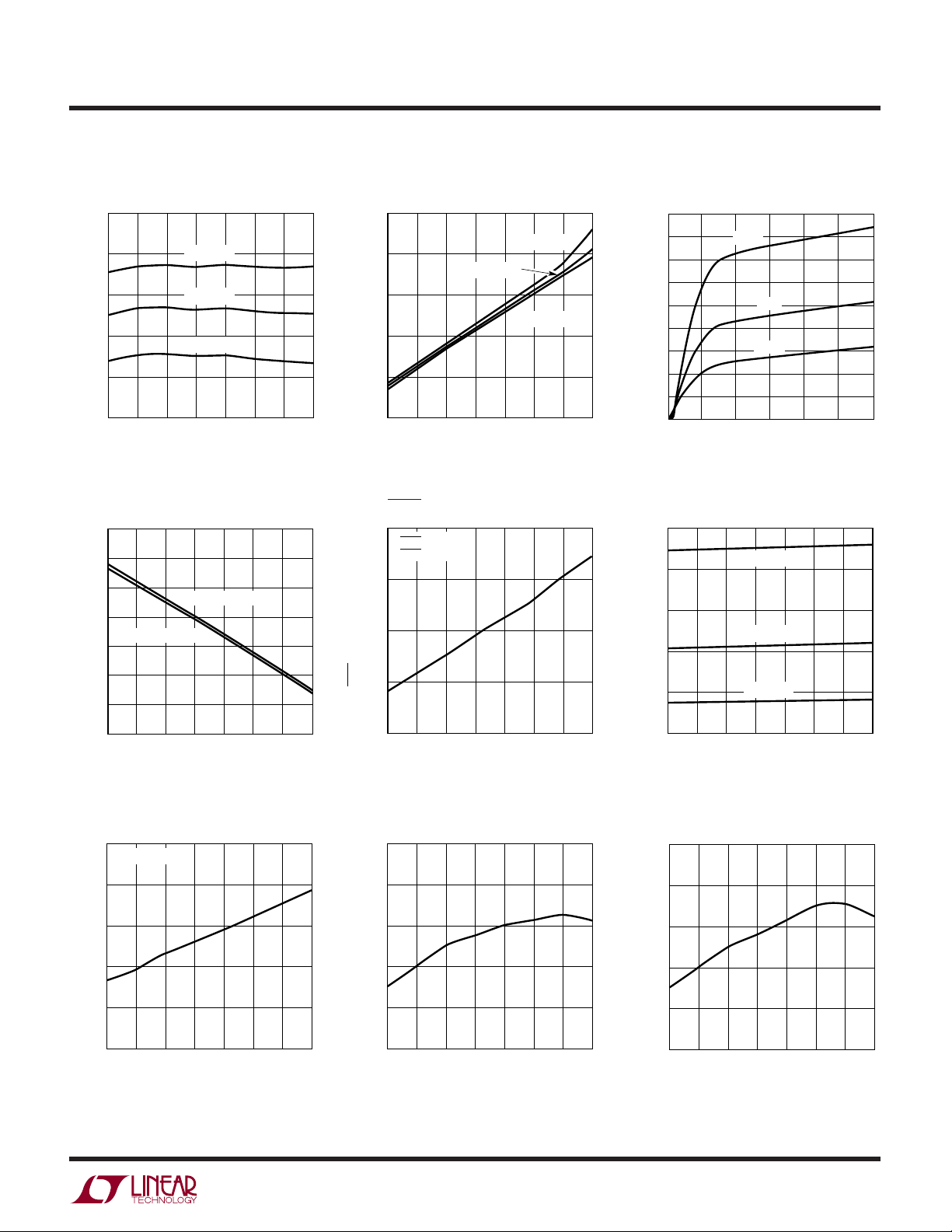

TYPICAL PERFOR A CE CHARACTERISTICS

LT3750

VCC Pin Current

1.8

1.7

1.6

1.5

PIN CURRENT (mA)

CC

V

1.4

1.3

–50 –25

VCC = 24V

VCC = 12V

VCC = 3V

25

0

TEMPERATURE (°C)

CHARGE Pin Enable/Disable

Voltage

0.9

0.8

0.7

0.6

CHARGE PIN DISABLE

0.5

CHARGE PIN ENABLE

V

Pin Current CHARGE Pin Current

TRANS

225

V

= 24V

200

V

TRANS

175

150

PIN CURRENT (µA)

TRANS

V

125

50

75

100

125

3750 G01

100

–50 –25

0

TEMPERATURE (°C)

DONE Output Signal Low

160

V

= 5V

DONE

= 100k

R

DONE

140

120

TRANS

= 12V

V

= 3V

TRANS

50

25

75

100

125

3750 G02

GATE High Voltage

0.4

CHARGE PIN VOLTAGE (V)

0.3

0.2

–50

60

50

40

30

20

DCM COMPARATOR TRIP VOLTAGE (mV)

10

–50 –25

50 100 125

–25 0

25 75

TEMPERATURE (°C)

DCM Comparator Trip Voltage

R

= 43k

DCM

50

25

0

TEMPERATURE (°C)

75

100

3750 G04

3750 G07

125

100

DONE PIN VOLTAGE (mV)

80

–50

–25 0 25 50

TEMPERATURE (°C)

V

Comparator Trip Voltage

OUT

1.240

1.236

1.232

1.228

COMPARATOR TRIP VOLTAGE (V)

1.224

OUT

V

1.220

–50 –25

25

0

TEMPERATURE (°C)

50

75 100 125

3750 G05

100

125

3750 G08

75

Current Limit Comparator Trip

Voltage

82

80

78

76

74

72

CURRENT LIMIT COMPARATOR TRIP VOLTAGE (mV)

–50 –25

0

TEMPERATURE (°C)

50

25

75

100

3750 G09

3750fa

3

125

Page 4

LT3750

U

UU

PI FU CTIO S

V

primary coil of the transformer as well as internal circuitry

that performs boundary mode detection. Bypass at the pin

with a 1µF to 10µF capacitor. Bypass the primary winding

of the transformer with a large capacitor.

DONE (Pin 2): Open Collector Indication Pin. When target

output voltage is reached, an NPN transistor turns on.

Requires a pull-up resistor or current source. Any fault

conditions such as thermal shutdown or undervoltage

lockout will also turn on the NPN.

CHARGE (Pin 3): Charge Pin. Initiates a new charge cycle

when brought high or discontinues charging and puts part

into shutdown when low. To properly enable the device, a

step input with a minimum ramp rate of 1V/µs is required.

Drive to 1.1V or higher to enable the device; drive below

0.2V to disable the device.

V

ceramic capacitor. A 1µF to 10µF ceramic capacitor should

be sufficient for most applications.

GND (Pin 5): Ground Pin. Connect directly to local ground

plane.

(Pin 1): Transformer Supply Pin. Powers the

TRANS

(Pin 4): Input Supply Pin. Bypass locally with a

CC

SOURCE (Pin 6): Source Pin. Senses NMOS drain current.

Connect NMOS source terminal and current sense resistor

to this pin. The current limit is 78mV/R

GATE (Pin 7): Gate Pin. Connect NMOS gate terminal to

this pin. Internal gate driver will drive voltage to within

VCC – 2V during each switching cycle.

RDCM (Pin 8): Discontinuous Mode Sense Pin. Senses

when current in transformer has decayed to zero and initiates a new charge cycle if output voltage target has not

been reached. Place a resistor between this pin and the drain

of the NMOS. A good choice is a 43k, 5% resistor.

RV

(Pin 9): Output Voltage VI Converter Pin. Develops

OUT

a current proportional to output capacitor voltage. Connect a resistor between this pin and the drain of the NMOS.

RBG (Pin 10): Output Voltage Sense Pin. Senses the

voltage across the RBG resistor, which is proportional to

the current flowing into the R

equals 1.24V, charging is disabled and DONE pin goes

low. Connect a resistor (2.5k or less is recommended)

from this pin to GND. A 2.49k, 1% resistor is a good

choice.

pin. When voltage

VOUT

SENSE

.

4

3750fa

Page 5

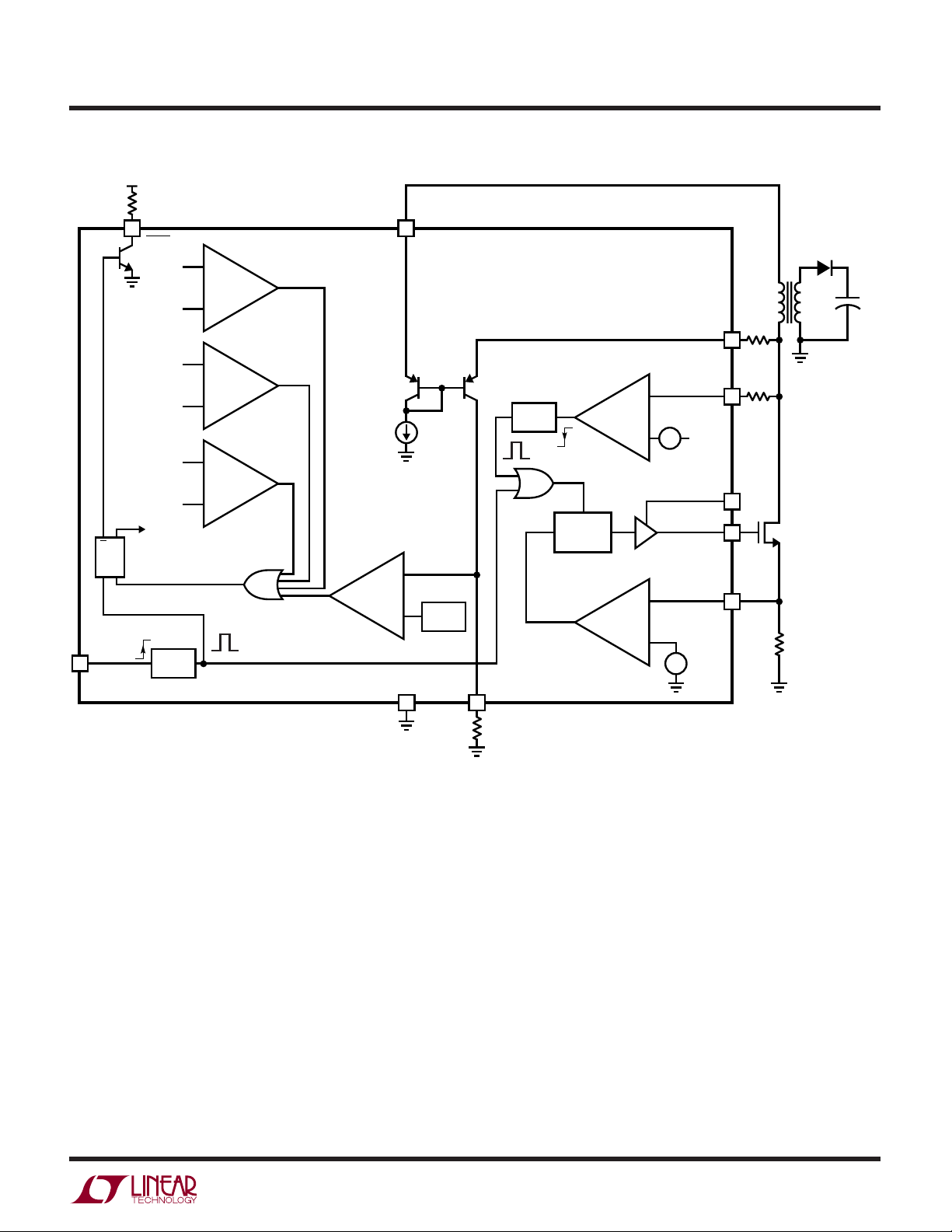

BLOCK DIAGRA

R

DONE

2

3

Q

RQS

CHARGE

DONE

2.8V

V

2.5V

V

TRANS

DIE

TEMP

160°C

M1

ENABLE

ONE

SHOT

CC

V

CC

UVLO

+

–

V

TRANS

UVLO

+

–

TSD

+

–

W

V

OUT

COMPARATOR

1

+

–

GND

5

V

TRANS

1.24V

LT3750

V

TRANS

D1

T1

1:N

•

R

RV

OUT

DCM

COMPARATOR

+

ONE

SHOT

–

S

QR

+

CURRENT LIMIT

COMPARATOR

RBG

10

R

BG

–

+

–

36mV

SOURCE

+

–

RDCM

V

TRANS

V

GATE

78mV

VOUT

9

R

DCM

8

V

CC

4

7

6

M1

R

3750 BD

DRAIN

SENSE

+

V

OUT

•

C

OUT

3750fa

5

Page 6

LT3750

OPERATIO

U

The LT3750 is designed to charge capacitors quickly and

efficiently. Operation can be best understood by referring

to Figures 1 and 2. Operation proceeds in four phases:

1. Start-up, 2. Primary-side charging, 3. Secondary energy transfer, 4. Discontinuous mode sensing.

1. Start-Up

Start-up occurs for approximately 20µs after the charge

pin is raised high. During this phase, a one-shot enables

the master latch and turns on the NMOS. The master latch

will remain in the set state until the target output voltage

is reached or a fault condition resets it.

I

LSEC

S2

+

•

V

SEC

–

3750 F01a

V

TRANS

I

LPRI

V

DRAIN

1:N

+

V

PRI

•

–

+

S1

–

2. Primary Side Charging

When the NMOS on latch is set, the gate driver rapidly

charges the gate pin to V

on forcing V

TRANS

– V

– 2V. The external NMOS turns

CC

across the primary winding.

DS(ON)

Consequently, current in the primary coil rises linearly at

I

LPRI

V

– V

TRANS

TRANS

DS(ON)

L

PRI

V

+ V

OUT

DIODE

L

SEC

– V

DS(ON)

I

I

LSEC

I

V

PK

PK

N

PRI

V

(1a) Equivalent Circuit During Primary-Side Charging

I

LSEC

S2

+

•

–

3750 F01b

V

TRANS

I

LPRI

V

DRAIN

+

+

V

•

–

1:N

PRIVSEC

S1

–

(1b) Equivalent Circuit During Secondary Energy

Transfer and Output Detection

I

LSEC

S2

+

•

V

SEC

–

3750 F01c

V

TRANS

I

V

LPRI

DRAIN

1:N

+

V

PRI

•

–

+

S1

–

(1c) Equivalent Circuit During Discontinuous Mode Detection

Figure 1. Equivalent Circuits

V

V

SEC

DRAIN

+

–(V

V

N

+ V

+

DIODE

DIODE

V

)

+ V

OUT

DIODE

N

DISCONTINUOUS

DETECTION

–N (V

TRANS

V

DS(ON)

1.

PRIMARY-SIDE

CHARGING

– V

)

DS(ON)

ENERGY TRANSFER

OUT

V

OUT

V

TRANS

2.

SECONDARY

AND OUTPUT

DETECTION

Figure 2. Idealized Charging Waveforms

3.

MODE

V

TRANS

V

DS(ON)

3750 F02

3750fa

6

Page 7

OPERATIO

LT3750

U

a rate (V

rored on the secondary winding –N • (V

TRANS

– V

DS(ON)

)/L

. The input voltage is mir-

PRI

TRANS

– V

DS(ON)

)

which reverse biases the diode and prevents current flow

in the secondary winding. Thus, energy is stored in the

core of the transformer.

3. Secondary Energy Transfer

When current limit is reached, the current limit comparator resets the NMOS on-latch and the device enters the

third phase of operation, secondary energy transfer. The

energy stored in the transformer core forward biases the

diode and current flows into the output capacitor. During

this time, the output voltage (neglecting the diode drop) is

reflected back to the primary coil. If the target output

voltage is reached, the V

comparator resets the master

OUT

latch and the DONE pin goes low. Otherwise, the device

enters the next phase of operation.

4. Discontinuous Mode Detection

Once all the current is transferred to the output capacitor,

(V

OUT

+ V

)/N will appear across the primary winding.

DIODE

A transformer with no energy cannot support a DC voltage,

so, the voltage across the primary will decay to zero. In

other words, the drain of the NMOS will ring down from

V

voltage falls to V

TRANS

+ (V

OUT

+ V

TRANS

DIODE

)/N to V

. When the drain

TRANS

+ 36mV, the DCM comparator sets

the NMOS on-latch and a new charge cycle begins. Steps

2-4 continue until the target output voltage is reached.

3750fa

7

Page 8

LT3750

WUUU

APPLICATIO S I FOR ATIO

Safety Warning

Large capacitors charged to high voltage can deliver a

lethal amount of energy if handled improperly. It is particularly important to observe appropriate safety measures when designing the LT3750 into applications. First,

create a discharge circuit that allows the designer to safely

discharge the output capacitor. Second, adequately space

high voltage nodes from adjacent traces to satisfy printed

circuit board voltage breakdown requirements. High voltage nodes are the drain of the NMOS, the secondary side

of the transformer, and the output.

Transformer Selection

The flyback transformer is critical to proper operation of

the LT3750. It must be designed carefully so that it does

not cause excessive current or voltage on any pin of the

part.

As with all circuits, the LT3750 has finite bandwidth. In

order to give the LT3750 sufficient time to detect the

output voltage, observe the following restrictions on the

primary inductance:

Switching Period

The LT3750 employs an open-loop control scheme causing the switching period to decrease with output voltage.

Typical switching frequency is between 100kHz to 300kHz.

Figure 3 shows typical switching period in an application

with a 3A peak current.

20

16

12

TIME (µs)

8

4

0

0

Figure 3. Typical Switching Period vs V

100 150 200

50

V

(V)

OUT

250 300

3750 F03

OUT

Output Diode Selection

When choosing the rectifying diode, ensure its peak

L

Vµs

OUT

≥

PRI

NI

••1

PK

repetitive forward current rating exceeds the peak cur-

otherwise, the LT3750 may overcharge the output.

Linear Technology has worked with several leading magnetic component manufacturers to produce flyback transformers for use with the LT3750. Table 1 summarizes the

particular transformer characteristics.

Table 1. Recommended Transformers

MANUFACTURER PART NUMBER SIZE L × W × H (mm) MAXIMUM I

TDK DCT15EFD-U44S003 22.5 × 16.5 × 8.5 5 10 1:10

(www.tdk.com) DCT20EFD-U32S003 30 × 22 × 12 10 10 1:10

Sumida C8118 Rev P1 21 × 14 × 8 3 10 1:10

(www.sumida.com) C8117 Rev P1 23 × 18.6 × 10.8 5 10 1:10

C8119 Rev P1 32.3 × 27 × 14 10 10 1:10

Midcom 32050 23.1 × 18 × 9.4 3 10 1:10

(www.midcom.com) 32051 28.7 × 22 × 11.4 5 10 1:10

32052 28.7 × 22 × 11.4 10 10 1:10

Coilcraft DA2032-AL 17.2 × 22 × 8.9 3 10 1:10

(www.coilcraft.com) DA2033-AL 17.4 × 24.1 × 10.2 5 10 1:10

DA2034-AL 20.6 × 30 × 11.3 10 10 1:10

rent (I

rating exceeds V

through the diode varies during the charge cycle because

the switching period decreases as V

average current through the diode is greatest when the

/N) and that the peak repetitive reverse voltage

PK

OUT

(A) L

PRI

+ (N)(V

(µH) TURNS RATIO (PRI:SEC)

PRI

). The average current

TRANS

increases. The

OUT

8

3750fa

Page 9

WUUU

APPLICATIO S I FOR ATIO

LT3750

output capacitor is almost completely charged and is

given by:

IV

•

I

AVG D

=

,

2

PK TRANS

VNV

()

OUT PK TRANS

()

•

+

The output diode’s continuous forward current rating

must exceed I

AVG,D

.

At a minimum, the diode must satisfy all the previously

mentioned specifications to guarantee proper operation.

However, to optimize charge time, reverse recovery time

and reverse bias leakage current should be considered.

Excessive diode reverse recovery times can cause appreciable discharging of the output capacitor thereby increasing charge time. Choose a diode with a reverse

recovery time of less than 100ns. Diode leakage current

under high reverse bias bleeds the output capacitor of

charge, also increasing charge time. Choose a diode that

has minimal reverse bias leakage current. Table 2 recommends several output diodes for various output voltages

with adequate reverse recovery time.

Table 2. Recommended Output Diodes

PEAK

REPETITIVE

REVERSE

PART I

MANUFACTURER NUMBER (A) (V) PACKAGE

Diodes Inc. MURS140 1 400 SMB

(www.diodes.com) MURS160 1 600 SMB

ES2G 2 400 SMB

US1M 1 1000 SMA

Philips BYD147 1 400 SOD87

(www.semiconductors. BYD167 1 500 SOD87

philips.com)

DC

VOLTAGE

Bypass Capacitor Selection

Use a high quality X5R or X7R dielectric ceramic capacitor

placed close to the LT3750 to locally bypass the VCC and

V

pins. For most applications, a 1µF to 10µF ceramic

TRANS

capacitor should suffice for VCC and a 1µF to 10µF for the

V

TRANS

pin.

can result in improper operation. This most often manifests itself in two ways. The first is when the primary winding current looks distorted instead of triangular. This

substantially reduces the efficiency and increases the

charge time. The second way is when the LT3750 fails to

detect discontinuous mode after the first switching cycle.

Both of these problems are solved by increasing the amount

of capacitive bypassing for the transformer. Choose capacitors that can handle the high RMS ripple currents

common in flyback regulators.

Output Capacitor Selection

For photoflash applications, the output capacitor will be

discharged into a Xenon flash bulb. Only a pulse capacitor

or photoflash capacitor is able to survive such a harsh

event. Igniting a typical Xenon bulb requires approximately 250V to 350V stored on a capacitor on the order of

hundreds of microfarads.

Table 3. Recommended Output Capacitor Vendors

VENDOR WEBSITE

Rubycon www.rubycon.com

Cornell Dubilier www.cornell-dubilier.com

NWL www.nwl.com

NMOS Selection

Choose an external NMOS with minimal gate charge and

on resistance that satisfies current limit and voltage breakdown requirements. The gate is nominally driven to VCC –

2V during each charge cycle. Ensure that this does not

exceed the maximum gate to source voltage rating of the

NMOS but enhaces the channel enough to minimize the on

resistance. Similarly, the maximum drain-source voltage

rating of the NMOS must exceed V

TRANS

+ V

/N or the

OUT

magnitude of the leakage inductance spike, whichever is

greater. The maximum instantaneous drain current must

exceed current limit. Because the switching period decreases with output voltage, the average current through

the NMOS is greatest when the output is nearly charged

and is given by:

The high peak currents flowing through the transformer

necessitate a larger (>>10µF) capacitor to bypass the pri-

mary winding of the transformer. Inadequate bypassing

I

AVG M

•

IV

=

,

PK OUT PK

2

VNV

()

()

OUT PK TRANS

+

()

•

3750fa

9

Page 10

LT3750

WUUU

APPLICATIO S I FOR ATIO

Table 4. Recommended NMOS Transisitors

MANUFACTURER PART NUMBER ID (A) V

Philips Semiconductor PHM21NQ15T 22.2 150 20 55 HVSON8

(www.semiconductors.philips.com) PHK12NQ10T 11.6 100 20 28 SO-8

PHT6NQ10Y 6.5 100 20 90 SOT223

PSMN038-100K 6.3 100 20 38 SO-8

International Rectifier IRF7488 6.3 80 20 29 SO-8

(www.irf.com) IRF7493 9.3 80 20 15 SO-8

IRF6644 10.3 100 20 10.7 DirectFET

DS(MAX)

(V) V

GS(MAX)

(V) R

(mΩ) PACKAGE

DS(ON)

The transistor’s continuous drain current rating must

exceed I

AVG,M

.

Table 4 lists recommended NMOS transistors.

Setting Current Limit

A sense resistor from the SOURCE pin to GND implements

current limit. The current limit is nominally 78mV/R

SENSE

.

The average power dissipation rating of the current sense

resistor must exceed:

P

RESISTOR

2

IR

•

PK SENSE

≥

3

⎛

⎜

⎝

V

OUT PK

()

+

VNV

OUT PK T

()

•

RRANS

⎞

⎟

⎠

Additionally, there is approximately a 100ns propagation

delay from the time that peak current limit is detected to

when the gate transitions to the low state. This delay

increases the peak current limit by (V

TRANS

)(t

DELAY

)/L

PRI

.

Setting The Target Output Voltage

The parameters that determine the target output voltage

are the resistors R

and RBG, the turns ratio of the

VOUT

transformer (N), and the voltage drop across the output

diode (V

). The target output voltage is set according

DIODE

to the following equation:

VV

⎛

=

OUT

124.• •–

⎜

⎝

R

VOUT

R

BG

⎞

NV

DIODE

⎟

⎠

Use at least 1% tolerance resistors for R

Choosing large value resistors for R

BG

and RBG.

VOUT

decreases the

amount of current that charges the parasitic internal

capacitances and degrades the response time of the V

OUT

comparator. This may result in overcharging of the output

capacitor. The maximum recommended value for R

BG

is

2.5k for typical applications.

When high primary currents are used, a voltage spike

can prematurely trip the output voltage comparator. A

33pF to 100pF capacitor in parallel with R

is sufficient to

BG

filter this spike for most applications. Always check that

the voltage waveform on RBG does not overshoot and that

it reaches a plateau at maximum V

OUT

.

Discontinuous Mode Detection

The R

resistor stands off voltage transients on the

DCM

drain node. A 43k, 5% resistor is recommended for 300V

applications. Higher output voltages will require a larger

resistor.

In order for the LT3750 to properly detect discontinuous

mode and start a new charge cycle, the reflected voltage to

the primary winding must exceed the discontinuous mode

comparator threshold which is nominally 36mV. The

worst-case condition occurs when V

is shorted to

OUT

ground. When this occurs, the reflected voltage is simply

the diode forward voltage drop divided by N.

10

3750fa

Page 11

WUUU

APPLICATIO S I FOR ATIO

LT3750

Board Layout

The high voltage operation of the the LT3750 demands

careful attention to board layout. Observe the following

points:

1. Minimize the area of the high voltage end of the secondary winding.

2. Provide sufficient spacing for all high voltage nodes

(NMOS drain, V

and the secondary winding of the

OUT

transformer) in order to meet breakdown voltage

requirements.

C

V

TRANS

R

DONE

CHARGE

V

TRANS

1

2

3

CC

4

5

C

IN

LT3750

R

R

SENSE

BG

10

9

8

7

6

3. Keep the electrical path formed by C1, the primary of T1

and drain of the NMOS as small as possible. Increasing

the size of this path effectively increases the leakage

inductance of T1 resulting in an overvoltage condition

on the drain of the NMOS.

D

C

PRI

R

DCMRVOUT

T1

1:N

PRIMARY

•

OUT

•

SECONDARY

+

C

OUT

M1

Figure 4. Recommended Board Layout

(Not to Scale)

3750 F04

3750fa

11

Page 12

LT3750

TYPICAL APPLICATIO S

V

TRANS

V

CC

12V

U

300V, 3A Capacitor Charger

C2

10µF

V

TRANS

V

C1

10µF

OFF ON

C1: 25V X5R OR X7R CERAMIC CAPACITOR

C2: 25V X5R OR X7R CERAMIC CAPACITOR

C3: 25V SANYO OS-CON 25SVP56M

C4: 330V RUBYCON PHOTOFLASH CAPACITOR

D1: DIODES INC. MURS160

M1: PHILIPS PHT6NQ10T

T1: TDK DCT15EFD-U44S003 FLYBACK TRANSFORMER

CC

100k

DONE

CHARGE

GND RBG

RV

RDCM

LT3750

SOURCE

C3

56µF

60.4k

OUT

43k

GATE

2.49k 33pF

1:10

4, 5

•

6, 7110

3750 TA02a

T1

M1

25mΩ

D1

•

V

OUT

300V

+

C4

100µF

100

90

80

70

EFFICIENCY (%)

60

50

0

3A Charging Efficiency 3A Charge Time

300

V

= 18V

(V)

OUT

V

250

200

150

100

TRANS

V

TRANS

V

= 12V

TRANS

50

0

0

0.2 0.4 0.6 0.8

TIME (SECONDS)

TRANS

100 150 200

50

V

TRANS

= 12V

V

OUT

(V)

= 18V

V

TRANS

= 6VV

250 300

3750 TA02b

= 6V

3750 TA02c

1.0

NMOS DRAIN

CURRENT

1A/DIV

NMOS DRAIN

VOLTAGE

20V/DIV

Typical Switching Waveforms

5µs/DIV

3750 TA02d

12

3750fa

Page 13

U

TYPICAL APPLICATIO S

V

TRANS

V

CC

12V

300V, 6A Capacitor Charger

C2

10µF

V

TRANS

V

C1

10µF

OFF ON

C1: 25V X5R OR X7R CERAMIC CAPACITOR

C2: 25V X5R OR X7R CERAMIC CAPACITOR

C3: 25V SANYO OS-CON 25SVP56M

C4: 330V RUBYCON PHOTOFLASH CAPACITOR

D1: DIODES INC. MURS160

M1: PHILIPS PHT6NQ10T

T1: TDK DCT20EFD-U32S003 FLYBACK TRANSFORMER

CC

100k

DONE

CHARGE

GND RBG

RV

RDCM

LT3750

SOURCE

C3

56µF

×2

60.4k

OUT

43k

GATE

2.49k 100pF

T1

1:10

3, 4, 5, 6

•

7, 8, 9, 10112

M1

12mΩ

3750 TA03a

LT3750

D1

•

V

OUT

300V

+

C4

100µF

100

90

80

70

EFFICIENCY (%)

60

50

0

6A Charging Efficiency 6A Charge Time

300

V

= 18V

TRANS

(V)

OUT

V

250

200

150

100

V

TRANS

V

= 12V

TRANS

50

0

0

0.1 0.2 0.3 0.4

TIME (SECONDS)

100 150 200

50

V

TRANS

V

TRANS

V

TRANS

V

OUT

= 18V

= 12V

= 6V

250 300

(V)

3750 TA03b

= 6V

3750 TA03c

0.5

NMOS DRAIN

CURRENT

2A/DIV

NMOS DRAIN

VOLTAGE

20V/DIV

Typical Switching Waveforms

5µs/DIV

3750 TA03d

3750fa

13

Page 14

LT3750

TYPICAL APPLICATIO S

V

TRANS

V

CC

12V

U

C1

10µF

OFF ON

300V, 9A Capacitor Charger

C2

10µF

V

TRANS

V

CC

100k

DONE

CHARGE

GND RBG

LT3750

RV

OUT

RDCM

GATE

SOURCE

2.49k 100pF

C3

56µF

×3

60.4k

43k

3, 4, 5, 6

7, 8, 9, 10

3750 TA04a

T1

D1

1:10

1

•

•

12

M1

8mΩ

V

OUT

300V

+

C4

100µF

100

90

80

EFFICIENCY (%)

70

60

0

C1: 25V X5R OR X7R CERAMIC CAPACITOR

C2: 25V X5R OR X7R CERAMIC CAPACITOR

C3: 25V SANYO OS-CON 25SVP56M

C4: 330V RUBYCON PHOTOFLASH CAPACITOR

D1: DIODES INC. MURS160

M1: PHILIPS PHM2INQ15T

T1: TDK DCT20EFD-U32S003 FLYBACK TRANSFORMER

9A Charging Efficiency 9A Charge Time

300

V

= 18V

TRANS

(V)

OUT

V

250

200

150

100

50

0

0

0.05 0.10 0.15 0.20

V

V

TRANS

TIME (SECONDS)

TRANS

100 150 200

50

V

TRANS

V

TRANS

V

TRANS

V

OUT

= 18V

= 12V

= 6V

250 300

(V)

3750 TA04b

= 12V

= 6V

3750 TA04c

0.300.25

NMOS DRAIN

CURRENT

4A/DIV

NMOS DRAIN

VOLTAGE

20V/DIV

Typical Switching Waveforms

5µs/DIV

3750 TA04d

14

3750fa

Page 15

PACKAGE DESCRIPTIO

U

MS Package

10-Lead Plastic MSOP

(Reference LTC DWG # 05-08-1661)

0.889 ± 0.127

(.035 ± .005)

LT3750

5.23

(.206)

MIN

0.305 ± 0.038

(.0120 ± .0015)

TYP

RECOMMENDED SOLDER PAD LAYOUT

0.254

(.010)

GAUGE PLANE

0.18

(.007)

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

3.20 – 3.45

(.126 – .136)

DETAIL “A”

DETAIL “A”

0.50

(.0197)

BSC

° – 6° TYP

0

0.53 ± 0.152

(.021 ± .006)

SEATING

PLANE

3.00 ± 0.102

(.118 ± .004)

(NOTE 3)

4.90 ± 0.152

(.193 ± .006)

0.17 – 0.27

(.007 – .011)

TYP

1.10

(.043)

MAX

12

0.50

(.0197)

BSC

8910

3

7

6

45

0.497 ± 0.076

(.0196 ± .003)

REF

3.00 ± 0.102

(.118 ± .004)

(NOTE 4)

0.86

(.034)

REF

0.127 ± 0.076

(.005 ± .003)

MSOP (MS) 0603

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3750fa

15

Page 16

LT3750

TYPICAL APPLICATIO

V

TRANS

V

12V

U

300V, 9A, 2.5mF Capacitor Charger

T1

D1

1:10

C3

60.4k

43k

56µF

×3

3750 TA05a

4, 5

•

6, 7110

M1

8mΩ

•

C2

10µF

V

CC

C1

100k

10µF

OFF ON

TRANS

V

CC

DONE

CHARGE

GND RBG

RV

RDCM

LT3750

GATE

SOURCE

OUT

2.49k 100pF

V

OUT

300V

+

C4

2.5mF

C1, C2: 25V X5R OR X7R CERAMIC CAPACITOR

C3: 25V SANYO OS-CON 25SVP56M

C4: CORNELL DUBILIER 7P252V360N082

D1: DIODES INC. MURS160

M1: PHILIPS PHM21NQ15T

T1: MIDCOM 32052 FLYBACK TRANSFORMER

Efficiency Charge Time

100

95

90

85

EFFICIENCY (%)

80

75

70

0

100 150 200

50

V

TRANS

V

TRANS

V

TRANS

V

OUT

= 18V

= 12V

= 6V

250 300

(V)

3750 TA05b

(V)

OUT

V

300

V

= 18V

TRANS

250

200

150

100

50

0

0

123456

TIME (SECONDS)

V

TRANS

= 6V

V

TRANS

= 12V

87

3750 TA05c

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT3420/LT3420-1 1.4A/1A, Photoflash Capacitor Charger with Charges 220µF to 320V in 3.7 Seconds from 5V, VIN: 2.2V to 16V,

Automatic Top-Off I

LT3468/LT3468-1 1.4A, 1A, 0.7A, Photoflash Capacitor Charger VIN: 2.5V to 16V, Charge Time: 4.6 Seconds for LT3468 (0V to 320V, 100µF,

LT3468-2 V

LT3484-0/LT3484-1 1.4A, 0.7A, 1A Photoflash Capacitor Charger VIN: 1.8V to 16V, Charge Time: 4.6 Seconds for LT3484-0

LT3484-2 (0V to 320V, 100µF, V

LT3485-0/LT3485-1 1.4A, 0.7A, 1A, 2A Photoflash Capacitor Charger VIN: 1.8V to 10V, Charge Time: 3.7 Seconds for LT3485-0

LT3485-2/LT3485-3 with Output Voltage Monitor and Integrated IGBT (0V to 320V, 100µF, V

< 1µA, 10-Lead MS Package

SD

= 3.6V), ISD < 1µA, ThinSOT Package

IN

= 3.6V), ISD < 1µA, 2mm × 3mm 6-Lead

IN

DFN Package

= 3.6V), ISD < 1µA, 3mm × 3mm 10-Lead DFN

IN

Driver

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

3750fa

LT 0106 REV A • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2005

Loading...

Loading...