L DESIGN FEATURES

CTRL_SEL

PWM

SW

INDUCTOR

CURRENT

PWMGH

PWMGL

LED CURRENT

I

CTRL_L

I

CTRL_L

I

CTRL_H

I

CTRL_H

LT3743

V

IN

V

IN

I

REG

V

OUT

FOR I

REG

DETERMINED

BY CTRL_H

V

OUT

FOR I

REG

DETERMINED

BY CTRL_L

HG

CBOOT

PWM

CTRL_SEL

CTRL_L

CTRL_H

LED LOAD

SW

V

CC_INT

LG

GND

SENSE

+

SENSE

_

PWMGH

PWMGL

L R

S

+ +

High Current/High Speed LED Driver

Revolutionizes PWM Dimming

Introduction

Power drivers that can produce regulated high current pulses are used

in a number of lighting applications,

ranging from high current LEDs in

DLP projectors to high power laser

diodes. For instance, in high end

video projectors, high power LEDs are

used to produce color illumination.

The RGB LEDs in these projectors

require precise dimming control for

accurate color mixing—in this case,

more control than simple PWM dimming can offer. Typically, to achieve

the wide dynamic range required in

color mixing, LED drivers must be

able to rapidly switch between the

two disparate regulated peak current

states, and overlay PWM dimming

without disruption. The LT3743 has

the ability to meet these demanding

accuracy and speed requirements.

The LT3743 is a synchronous

buck DC/DC controller that utilizes

fixed-frequency, average current mode

control to accurately regulate the

inductor current through a sense

resistor in series with the inductor.

The LT3743 regulates the current in

any load with an output voltage range

from 0V to 2V below the input rail with

±6% accuracy.

Precision, broad-range LED current

control is achieved by combining accurate analog dimming (high and low

states) with PWM dimming. Analog

dimming is controlled via the CTRL_L,

CTRL_H, and CTRL_T pins; PWM

dimming via the PWM and CTRL_SEL

pins. A rapid transition between the

high and low analog states is made

possible with the LT3743’s unique use

of externally switched load capacitors,

which allows the LT3743 to change

regulated LED current levels within

several microseconds. The switching

frequency may be programmed from

200kHz to 1MHz using an external resistor and synchronized to an external

clock from 300kHz to 1MHz.

16

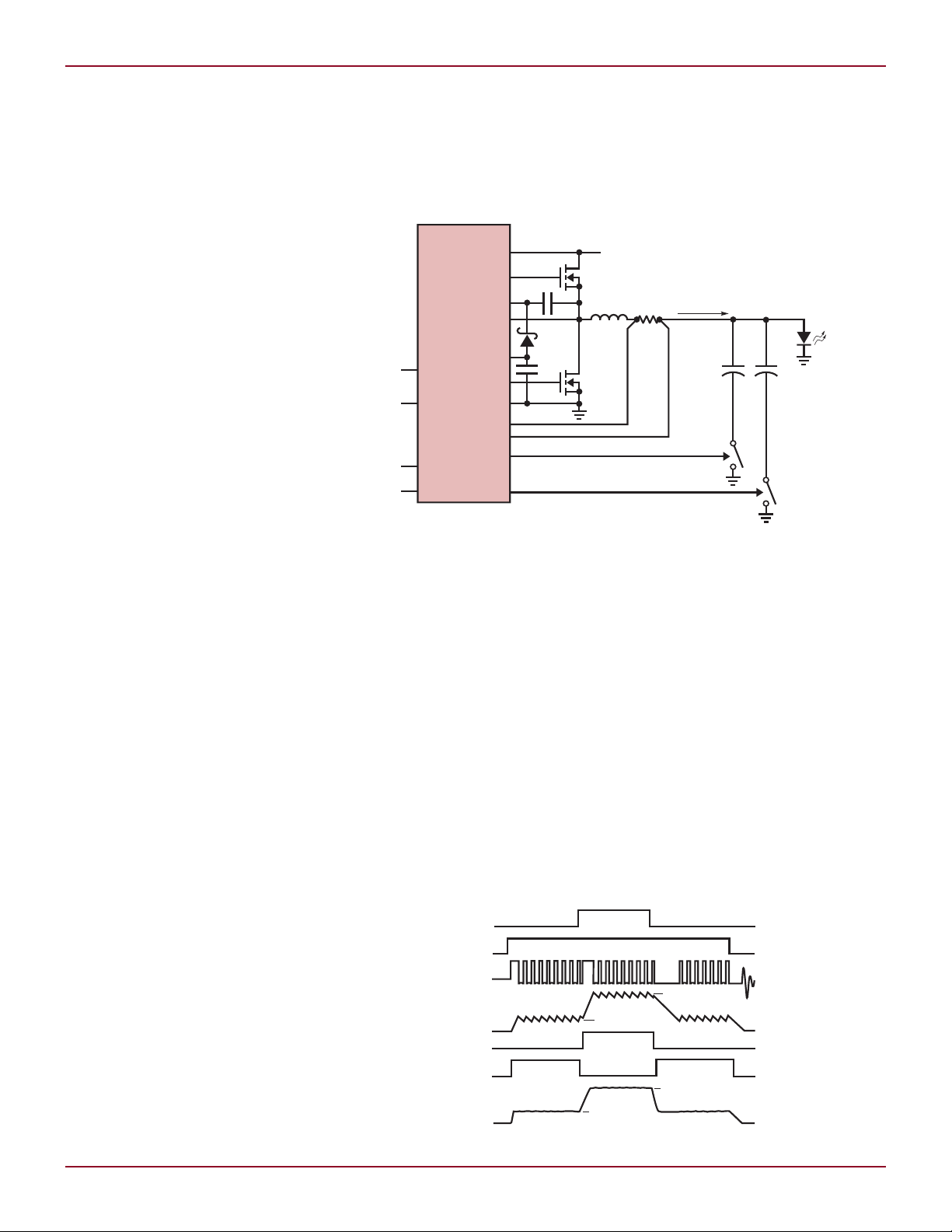

Figure 1. Basic switched-capacitor topology

Switched Output

Capacitor Topology

In traditional current regulators, the

voltage across the load is stored in the

output capacitor. If the load current

is suddenly changed, the voltage in

the output capacitor must charge or

discharge to match the new regulated

current. During the transition, current in the load is poorly controlled,

resulting in slow load current response

time.

The LT3743 solves this problem

with a unique switched output capacitor topology, which enables ultrafast

load current rise and fall times. The

basic idea behind the topology is that

Figure 2. LED current PWM and CTRL_SEL dimming

by Josh Caldwell

the LT3743 acts as a regulated current source driving into the load. The

voltage drop across the load for a given

current is stored in the first switched

output capacitor. When a different

regulated current state is desired, the

first output capacitor is switched off

and a second capacitor is switched in.

This allows each capacitor to store the

voltage drop for the load corresponding

to the desired regulated current.

Figure 1 shows the basic topology

with the various control pins. The PWM

and CTRL_SEL pins are digital control

pins that determine the state of the

regulated current. The CTRL_H and

CTRL_L pins are analog inputs with a

Linear Technology Magazine • December 2009

DESIGN FEATURES L

PWM DIMMING DUTY CYCLE (%)

0 20 40 60 80 100

EFFICIENCY (%)

0

10

20

30

40

50

60

70

80

90

100

EN/UVLO

PWM

CTRL_SEL

EN/UVLO

PWM

CTRL_SEL

HG

V

IN

CBOOT

V

REF

CTRL_L

CTRL_H

CTRL_T

LT3743

RT

SYNC

SW

LG

GND

VCH

VCL

SENSE

+

SENSE

–

PWMGH

PWMGL

V

CC_INT

100nF

L1

1.0µH

22µF

C1

330µF

×3

2.5mΩ

FB

10nF

34k

4.7nF

34k

D1: LUMINUS PT120

D2: PMEG4002EB

L1: IHLP4040DZER1R0M01

M1: RJK0365DPA

M2: RJK0346DPA

M3, M4: Si7236DP

C1, C2, C3: PTPR330M9L (THREE IN PARALLEL)

D2

4.7nF

82.5k

100k

100k

C3

330µF

×3

D1

40.2k

10k

1µF

2nF

R

NTC

10k

220µF

M1

M2

M3

M4

V

IN

12V

V

OUT

20A MAXIMUM

1µF

C2

330µF

×3

SS

R

HOT

499Ω

10Ω 10Ω

33nF

CTRL_SEL

5V/DIV

PWM

5V/DIV

SW

20V/DIV

I

LED

10A/DIV

20µs/DIVV

IN

= 24V

0A TO 2A TO 20A LED CURRENT STEP

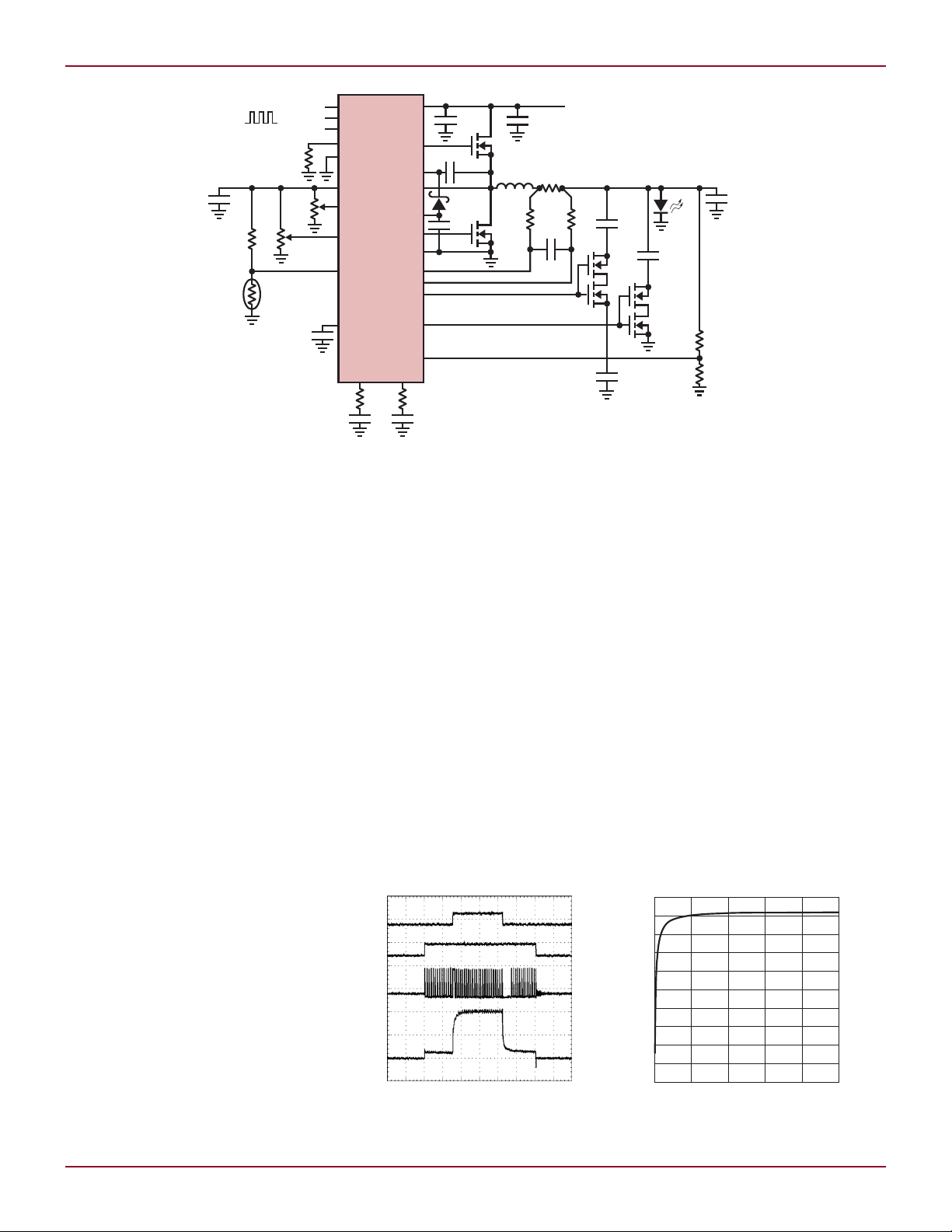

Figure 3. A 24V, 20A LED driver using switched output capacitors

full-scale range of 0 to 1.5V, producing

a regulated voltage of 0mV to 50mV

across the current sense resistor.

Figure 2 shows the timing waveforms in response to the various states

of the PWM and CTRL_SEL pins. When

PWM is low, all switching is terminated

and both output capacitors are disconnected from the load.

Although the LT3743 may be

configured with switched output

capacitors, it is easily adapted to any

traditional analog and/or PWM dimming scheme.

Switching Cycle

Synchronization

The LT3743 synchronizes all switching edges to the PWM and CTRL_SEL

rising edges. Synchronization gives

system designers the freedom to use

any periodic or non-periodic PWMdimming pulse width and duty cycle.

This is an essential feature for high

current LED drivers during recovery

from a zero or low current state to a

high current state. By restarting the

clock whenever the CTRL_SEL or PWM

signals go high, the inductor current

begins ramping up immediately without having to wait for a rising edge of

the clock. Without synchronization,

the phase relationship of the clock

edge and the PWM edge would be

uncontrolled, possibly resulting in

Linear Technology Magazine • December 2009

visible jitter in the LED light output.

When using an external clock with

the SYNC pin, the switching cycle

resynchronizes to the external clock

within eight switching cycles.

A 24V, 20A LED Driver Using

Switched Output Capacitors

for High End DLP Projectors

High end DLP projectors demand

the highest quality image and color

reproduction. To achieve high color

accuracy, variations in the color of

individual LEDs are corrected by mixing in the other two color LEDs. For

example, when the red LED is on at full

current, the blue and green LEDs are

turned on at low current levels so they

can be mixed in to produce accurate

red. This technique requires the ability

Figure 4. Zero to 2A to 20A LED current steps

to rapidly transition between relatively

low (~2A) and high (~20A) LED currents so that PWM dimming edges are

preserved. Figure 3 shows a 24V/20A

LED driver for use specifically with

high end DLP projectors.

The relatively low switching frequency of 450kHz allows for a very

small 1.0µH inductor. With 25% ripple

current, the transition times between

the high and low current states is

about two microseconds. The large

1mF output capacitors store the voltage drop across the LED for the two

different current states and provide

instantaneous current when the

MOSFET dimming switches are turned

on. Use of several low ESR capacitors

in parallel is critical to providing rapid

LED current transitions.

Figure 5. 12V, 20A PWM dimming efficiency

using a green LED

17

L DESIGN FEATURES

EN/UVLO

PWM

CTRL_SEL

EN/UVLO

INTV

CC

CTRL_SEL

HG

V

IN

CBOOT

V

REF

CTRL_H

CTRL_L

CTRL_T

LT3743

RT

SYNC

SW

LG

GND

VCH

VCL

SENSE

+

SENSE

–

PWMGH

PWMGL

V

CC_INT

100nF

L1

10µH

22µF

25mΩ

FB

10nF

34k

4.7nF

34k

4.7nF

82.5k

40.2k

D1

10k

2.2nF

8.2µF

M1

M2

M3

V

IN

6V TO 36V

V

OUT

2A MAXIMUM

2.2µF

1µF

SS

CONTROL

INPUT

D1: LUMINUS CBT-40

D2: PMEG4002EB

L1: IHLP4040DZE10R0M01

M1, M2: Si7848BDP

M3: Si2312BDS

D2

SW

10V/DIV

I

L

2A/DIV

CTRL_SEL

5V/DIV

I

LED

1A/DIV

20µs/DIV

EN/UVLO

PWM

CTRL_SEL

EN/UVLO

PWM

V

CC_INT

HG

V

IN

CBOOT

V

REF

CTRL_L

CTRL_H

CTRL_T

LT3743

RT

SYNC

SW

LG

GND

VCH

VCL

SENSE

+

SENSE

–

PWMGL

PWMGH

V

CC_INT

150nF

L1

1.65µH

22µF

2.5mΩ

FB

10nF

51k

4.7nF

82.5k

10Ω 10Ω

60.4k

10k

2.2nF

R

NTC

10k

82µF

M1

D2

M2

M3

D1: LUMINUS PT121

D2: PMEG4002EB

L1: MVR1271C-162ML

M1: RJK0365DPA

M2: RJK0328DPB

M3: SiR496DP

C1: PTPR330M9L (THREE IN PARALLEL)

V

IN

6V TO 30V

V

OUT

20A MAXIMUM

C1

330µF

×3

D1

1µF

SS

R

HOT

499Ω

CONTROL

INPUT

33nF

Figure 6. A 6V to 36V input, 2A LED driver with current limited shunted output

The regulated high and low currents

are set by voltage dividers from the

V

pin to the CTRL_L and CTRL_H

REF

pins. The ±2%, 2V reference at V

is also used to provide the reference

signal the temperature derating circuit

applied at CTRL_T (see “Thermally

Derating the LED Current” below).

To reduce potentially large start-up

currents, the LT3743 uses a unique

soft-start circuit that throttles back the

regulated currents, providing full drive

when the soft-start pin is charged to

Figure 8. A 6V to 30V input, 20A LED driver with switched cathode PWM dimming

18

1.5V. To minimize the transition time

between current levels, the LT3743

employs individual compensation for

each level so that the current control

REF

loop may return to steady-state operation as quickly as possible. Figure 4

shows the LED current step from 0A

to 2A to 20A.

High Efficiency Over a Wide

Range of PWM Duty Cycles

Power dissipation is a critical design

parameter in portable DLP projectors.

Figure 7. 0A to 2A current limited shunted

output PWM dimming

Unlike many shunt-type high current

LED drivers currently available, the

LT3743 has excellent efficiency over

a wide range of PWM duty cycles. By

delivering power only to the load instead of either shunting power away or

charging the output capacitor, most of

the energy lost in common traditional

PWM-dimmed drivers is conserved.

Figure 5 shows the efficiency with VIN

= 12V, driving a green LED between

0A and 20A over the entire duty cycle

range.

Linear Technology Magazine • December 2009

DESIGN FEATURES L

PWM

5V/DIV

I

LED

10A/DIV

SW

10V/DIV

10µs/DIV

Shutdown and

Precision Enable

When delivering high load currents,

the amount of supply undervoltage

lock-out (UVLO) hysteresis required

for proper operation is highly dependent on board layout. For maximum

flexibility, the LT3743 incorporates

a precision enable threshold with a

5.5µA current source flowing into the

pin when the EN/UVLO pin is lower

than 1.55V. Using a voltage divider

from the input supply to ground any

amount of hysteresis may be added

to the system. To conserve power in

portable applications, the LT3743

is completely disabled and supply

current drops below 1µA when the

EN/UVLO pin is lower than 0.5V.

Thermally Derating

the LED Current

Proper thermal management is vital

with any high current load to protect

expensive high current LEDs and

prevent system-wide damage. The

LT3743 uses the CTRL_T pin to reduce

the effective regulated current in the

load for both the high and low control

currents. Whenever CTRL_T is lower

than the control voltage on the CTRL_L

or CTRL_H pins, the regulated current

is reduced. The temperature derating

is programmed using a temperature

dependent resistor divider from the

V

pin to ground.

REF

Output Voltage Protection

Voltage protection is important to

prevent damaging expensive projector

LEDs. The LT3743 utilizes the FB pin

to provide a regulated voltage point for

the output. To simplify system design,

the LT3743 uses an internal 1V reference, softly reducing the regulated

current when the FB voltage reaches

900mV.

Powerful Gate Drivers

To provide adequate drive and reduce

switching losses in high current

power MOSFETs, the LT3743 uses very

strong switching MOSFET drivers. The

on-resistance of the LG and HG PMOS

pull-up drivers is typically 2.5Ω. The

LG and HG NMOS pull-down drivers

on-resistance is typically less than

1.3Ω. With on-resistance this low, two

high current MOSFETs may be used

in parallel for applications exceeding

20A. Most currently available LED

drivers do not provide adequate gate

drive for dimming MOSFETs and as a

result need an additional external gate

driver. The LT3743 integrates this into

the PWMGL and PWMGH drivers and

has a 2Ω typical NMOS pull-down and

a 3.7Ω typical PMOS pull-up to drive

any 5V dimming MOSFET.

Traditional PWM Dimming

The LT3743 adapts to any traditional

PWM dimming method. Shunted output dimming used by competing LED

drivers wastes energy and has poor

efficiency for LED duty cycles below

The LT3743 produces

ultrafast high current

LED rise times while

providing accurate current

regulation. Its ability to

support multiple current

states meets the demands of

high performance theater-

quality DLP projectors by

allowing LED colors to be

easily mixed. In addition to

speed, the LT3743’s switched

capacitor topology reduces

board size by allowing the

use of a compact, low value

inductor. Additional features

include switching cycle

synchronization, overvoltage

protection, high efficiency

and easy adaptability for

varied application needs.

approximately 50%. Since the LT3743

has two levels of current regulation,

the regulated current can to drop to

zero when the shunt is engaged. This

provides excellent efficiency even for

low LED duty cycles.

Figure 6 shows a 2A LED driver configured with a current-limited shunted

output. Note that the CTRL_L pin is

tied to ground, PWMGL is used to drive

Figure 9. 0A to 20A switched cathode PWM

dimming

the shunting MOSFET, and CTRL_SEL

is used for dimming. With CTRL_L tied

to ground, when the CTRL_SEL pin

is low, the shunt is engaged and the

current in the inductor is regulated

at 0A. When CTRL_SEL is high, the

shunting MOSFET is turned off, and

the regulated current is determined by

the voltage at the CTRL_H pin. Figure

7 shows the current-limited shunted

PWM dimming with a 12V input.

In addition to the shunt, the LT3743

is readily configured to driving the

dimming MOSFET in series with the

cathode of the LED. When multiple

current states are not required, this is

the preferred method of PWM dimming.

Figure 8 illustrates a 6V to 30V, 20A

LED driver with switched cathode PWM

dimming. Figure 9 shows switched

cathode, PWM dimming with a 0A to

20A current step and a dimming ratio

of 100:1.

Conclusion

The LT3743 produces ultrafast high

current LED rise times while providing accurate current regulation. Its

ability to support multiple current

states meets the demands of high

performance theater-quality DLP

projectors by allowing LED colors to

be easily mixed. In addition to speed,

the LT3743’s switched capacitor topology reduces board size by allowing the

use of a compact, low value inductor.

Additional features include switching

cycle synchronization, overvoltage

protection, high efficiency and easy

adaptability for varied application

needs.

L

Linear Technology Magazine • December 2009

19

Loading...

Loading...