Page 1

LT3742

Dual, 2-Phase Step-Down

Switching Controller

FEATURES

■

Wide Input Voltage Range: 4V to 30V

■

Wide Output Voltage Range: 0.8V to V

■

Low Shutdown IQ: 20μA

■

Out-of-Phase Controllers Reduce Required Input

IN

Capacitance and Power Supply Induced Noise

■

0.8V ±1.5% Voltage Reference

■

500kHz Current Mode Fixed Frequency Operation

■

Internal Boost Converter Provides Bias Rail for

N-Channel MOSFET Gate Drive

■

Power Good Voltage Monitor for Each Output

■

Programmable Soft-Start

■

24-Lead 4mm × 4mm × 0.75mm Package

APPLICATIONS

■

Satellite and Cable TV Set-Top Boxes

■

Distributed Power Regulation

■

Automotive Systems

■

Super Capacitor Charger

DESCRIPTION

The LT®3742 is a dual step-down DC/DC switching regulator

controller that drives high side N-channel power MOSFETs.

A 500kHz fi xed frequency current mode architecture provides fast transient response with simple loop compensation components and cycle-by-cycle current limiting. The

output stages of the two controllers operate 180° out of

phase to reduce the input ripple current, minimizing the

noise induced on the input supply, and allowing less input

capacitance.

An internal boost regulator generates a bias rail of V

to provide gate drive for the N-channel MOSFETs allowing

low dropout and 100% duty cycle operation. The LT3742

can be used for applications where both controllers need

to operate independently, or where both controllers are

used to provide a single higher current output.

The device is available in a thermally enhanced 4mm ×

4mm QFN package.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

IN

+ 7V

TYPICAL APPLICATION

8V and 5V Dual Step-Down Converter

V

IN

V

OUT1

RUN1

8V

4A

47μF

14V

V

IN

10μF

0.010Ω

1.8k

200Ω

1000pF

1nF

6.5μH

1μF

PG1

30k

45.3k

20.0k

V

UVLO

G1

SW1

SENSE1

SENSE1

FB1

PG1

RUN/SS1

V

10μH

SWB

IN

LT3742

+

SENSE2

–

SENSE2

C1

RUN/SS2

GND

BIAS

SW2

FB2

PG2

V

μF

4.7

Effi ciency vs Load Current

100

90

V

IN

1.05k

200Ω

1nF

10μF

47μF

3742 TA03a

V

OUT2

5V

4A

RUN2

G2

6.5μH

0.010Ω

+

–

PG2

C2

20k

1000pF

80

70

EFFICIENCY (%)

60

50

40

0.5 1.5

0

12

LOAD CURRENT (A)

8V

OUT

5V

OUT

3

2.5

3.5

3742 TA03b

4

3742f

1

Page 2

LT3742

ABSOLUTE MAXIMUM RATINGS

(Note 1)

VIN Voltage ................................................................30V

UVLO Voltage ............................................................30V

PG1, PG2 Voltage .....................................................30V

SWB, BIAS Voltage ...................................................40V

+

SENSE1

SENSE1

, SENSE2+ Voltage ......................................30V

–

, SENSE2– Voltage ......................................30V

RUN/SS1, RUN/SS2 Voltage .......................................6V

FB1, FB2 Voltage .........................................................6V

, VC2 Voltage ..........................................................6V

V

C1

Junction Temperature ........................................... 125°C

Operating Junction Temperature Range

(Note 2) .................................................. –40°C to 125°C

Storage Temperature Range ................... –65°C to 125°C

ORDER INFORMATION

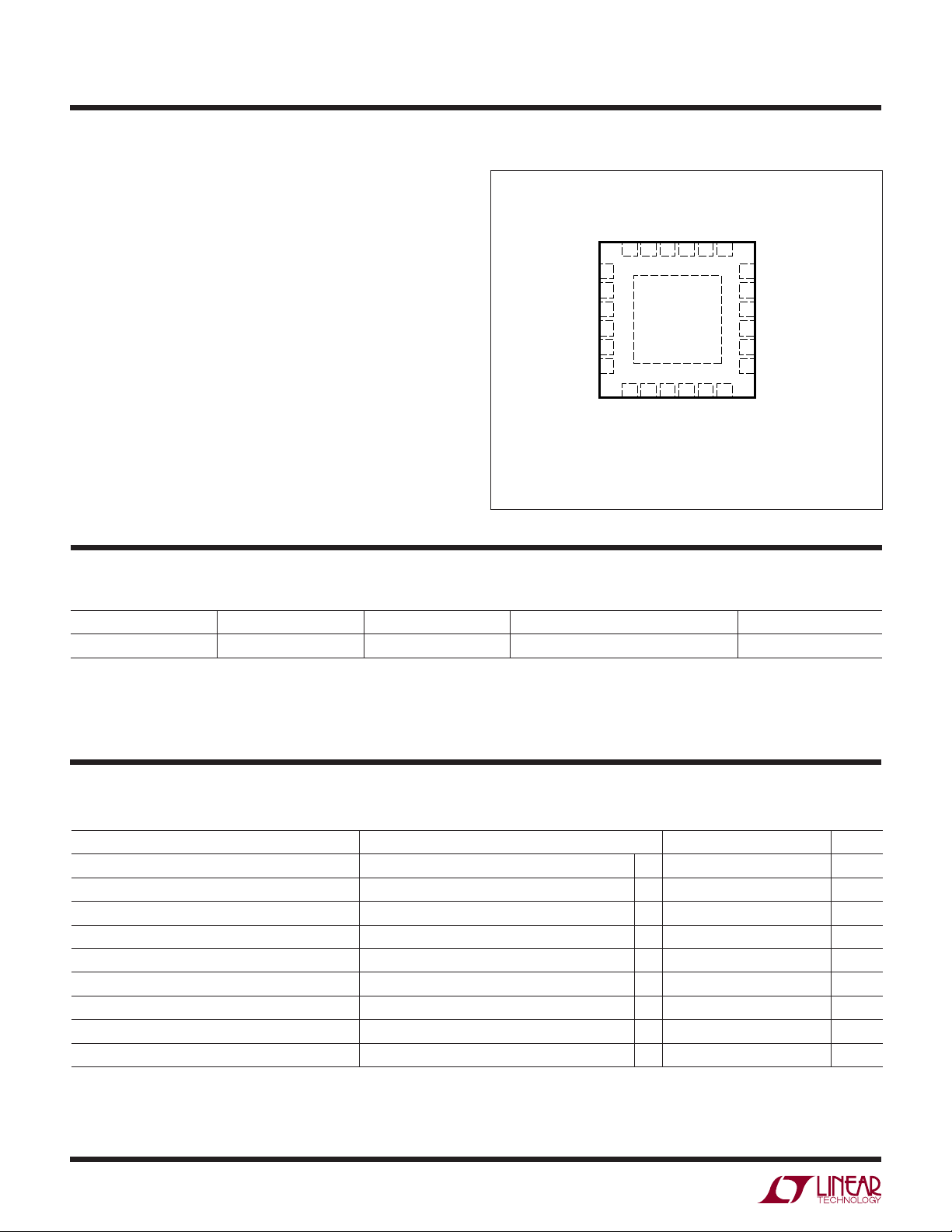

PIN CONFIGURATION

TOP VIEW

SW1NCNC

24 23 22 21 20 19

1

V

2

IN

UVLO

3

BIAS

4

SWB

5

6

G2

7 8 9

SW2

24-LEAD (4mm × 4mm) PLASTIC QFN

T

EXPOSED PAD (PIN 25) IS GND, MUST BE SOLDERED TO PCB

JMAX

SENSE1+SENSE1–FB1

25

10 11 12

+

NC

–

SENSE2

SENSE2

NC

UF PACKAGE

= 125°C, θJA = 36°C/W

FB2

18G1

17

16

15

14

13

V

C1

PG1

RUN/SS1

RUN/SS2

PG2

V

C2

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3742EUF#PBF LT3742EUF#TRPBF 3742 24-Lead (4mm × 4mm) Plastic QFN –40°C to 125°C (Note 2)

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

Consult LTC Marketing for information on non-standard lead based fi nish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifi cations, go to: http://www.linear.com/tapeandreel/

ELECTRICAL CHARACTERISTICS

The ● denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at TA = 25°C. VIN = 5V unless otherwise specifi ed.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Input Voltage V

Quiescent Current V

Shutdown Current V

= 1.5V

UVLO

RUN/SS1

RUN/SS1

= V

= V

= V

= V

RUN/SS2

RUN/SS2

FB1

= 0V 20 35 μA

= 1V 5.0 7.0 mA

FB2

UVLO Pin Threshold UVLO Pin Voltage Rising

UVLO Pin Hysteresis Current V

= 1V, Current Flows Into Pin 1.8 2.7 4 μA

UVLO

RUN/SS Pin Threshold 0.2 0.6 V

RUN/SS Pin Charge Current V

= 0V 0.5 0.9 1.5 μA

RUN/SS

FB Pin Voltage

FB Pin Voltage Line Regulation V

= 5V to 30V 0.01 %/V

IN

●

●

1.20 1.24 1.28 V

●

0.788 0.800 0.812 V

3.5 4.0 V

2

3742f

Page 3

LT3742

ELECTRICAL CHARACTERISTICS

The ● denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

FB Pin Bias Current V

FB Pin Voltage Matching –4 0 4 mV

Error Amplifi er Transconductance 250 μmho

Error Amplifi er Voltage Gain 500 V/V

Pin Source Current VFB = 0.6V 15 μA

V

C

Pin Sink Current VFB = 1V 15 μA

V

C

Controller Switching Frequency 440 500 560 kHz

Switching Phase 180 Deg

Maximum Current Sense Voltage V

Current Sense Matching Between Controllers ±5 %

Current SENSE Pins Total Current SENSE

Gate Rise Time C

Gate Fall Time C

Gate On Voltage (V

Gate Off Voltage (V

PG Pin Voltage Low I

Lower PG Trip Level (Relative to V

Lower PG Trip Level (Relative to V

Upper PG Trip Level (Relative to V

Upper PG Trip Level (Relative to V

PG Pin Leakage Current V

PG Pin Sink Current V

Bias Pin Voltage V

SWB Pin Current Limit 250 340 500 mA

SWB Pin Leakage Current V

Bias Supply Switching Frequency 0.88 1.0 1.12 MHz

– VSW)V

G

– VSW)V

G

)V

FB

)V

FB

)V

FB

)V

FB

= 25°C. VIN = 5V unless otherwise specifi ed.

A

= 0.8V, VC = 0.4V 50 200 nA

FB

–

= 3.3V

SENSE

–

, SENSE+ = 0V

–

SENSE

, SENSE+ = 3.3V

= 3300pF 40 ns

LOAD

= 3300pF 60 ns

LOAD

= 5V, V

IN

= 5V, V

IN

= 100μA 0.20 0.5 V

PG

Increasing –7 –10 –13 %

FB

Decreasing –10 –13 –16 %

FB

Increasing 7 10 13 %

FB

Decreasing 4 7 10 %

FB

= 2V, VFB = 1V 0.1 μA

PG

= 0.5V 200 500 μA

PG

= 12V 0.01 1 μA

SWB

= 12V 6.0 6.7 7.0 V

BIAS

= 12V 0.4 0.75 V

BIAS

●

50 60 70 mV

–1.0

40

+ 6.6 VIN + 7 VIN + 7.7 V

IN

mA

μA

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LT3742E is guaranteed to meet performance specifi cations

from 0°C to 125°C operating junction temperature range. Specifi cations

over the –40°C to 125°C operating junction temperature range are

assured by design, characterization and correlation with statistical process

controls.

3742f

3

Page 4

LT3742

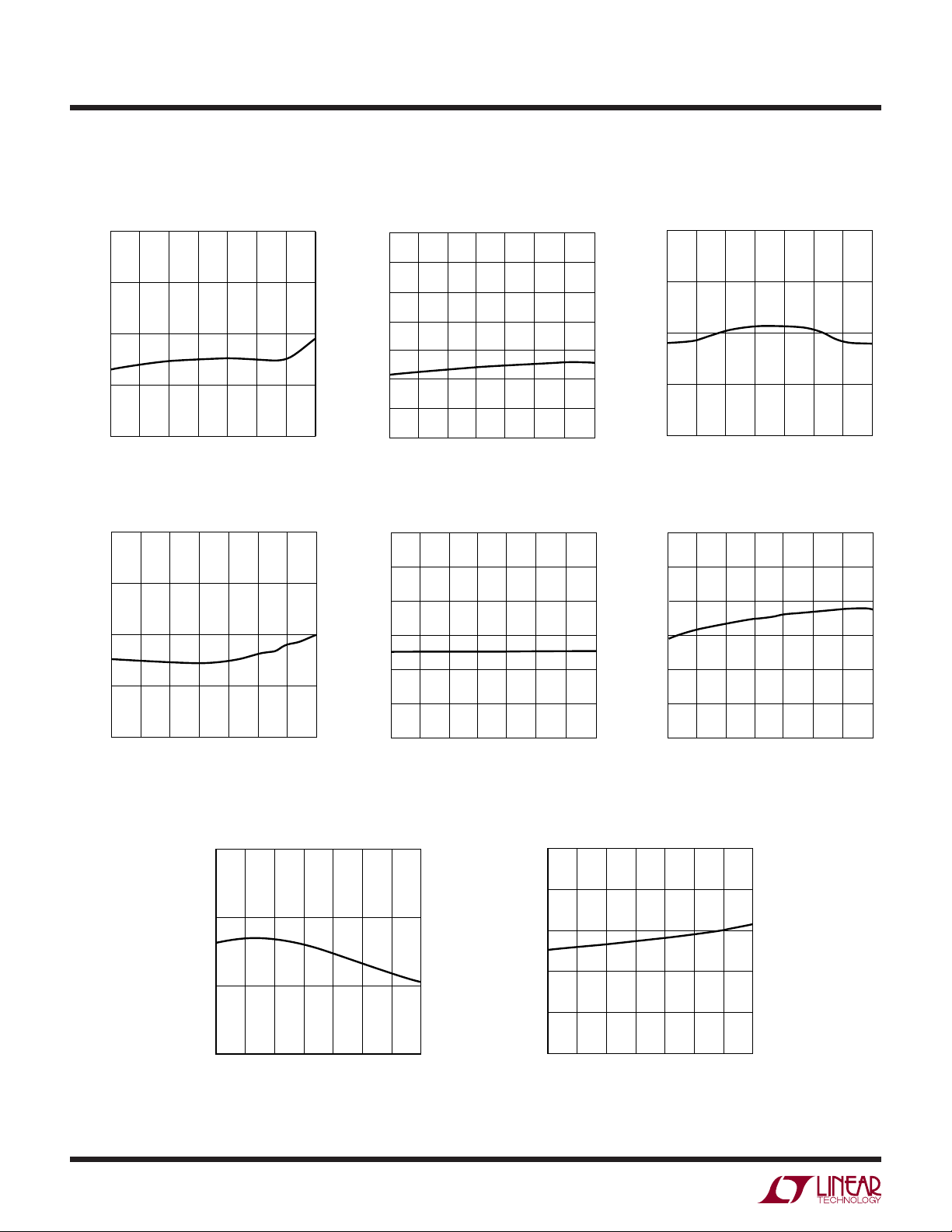

TYPICAL PERFORMANCE CHARACTERISTICS

IQ-SHDN vs Temperature IQ-Running vs Temperature

50

40

10

9

8

Controller Current Sense Voltage

vs Temperature

70

65

30

CURRENT (μA)

20

10

–50

–25 0 25 50

TEMPERATURE (°C)

75 100 125

3742 G01

7

6

CURRENT (mA)

5

4

3

–50

–25 0

50 100 125

25 75

TEMPERATURE (°C)

3742 G02

VIN Minimum vs Temperature UVLO Threshold vs Temperature V

3.0

2.5

2.0

1.5

UVLO (V)

1.0

0.5

0

–50

–25 0

50 100 125

25 75

TEMPERATURE (°C)

3742 G05

(V)

IN

V

5

4

3

2

1

–50

–25 0 25 50

TEMPERATURE (°C)

75 100 125

3742 G04

60

SENSE VOLTAGE (mV)

55

50

–50

–25 0 25 50

vs Temperature

FB

830

820

810

(mV)

800

FB

V

790

780

770

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

TEMPERATURE (°C)

75 100 125

3742 G03

3742 G06

4

RUN/SS Current vs Temperature UVLO I

1.8

1.2

(μA)

HYST

I

0.6

RUN/SS CURRENT (μA)

0

–25–50

0 255075

TEMPERATURE (°C)

100 125

3742 G07

3.0

2.8

2.6

2.4

2.2

2.0

–50 –25

vs Temperature

HYST

25

0

TEMPERATURE (°C)

50

75

100

125

3742 G08

3742f

Page 5

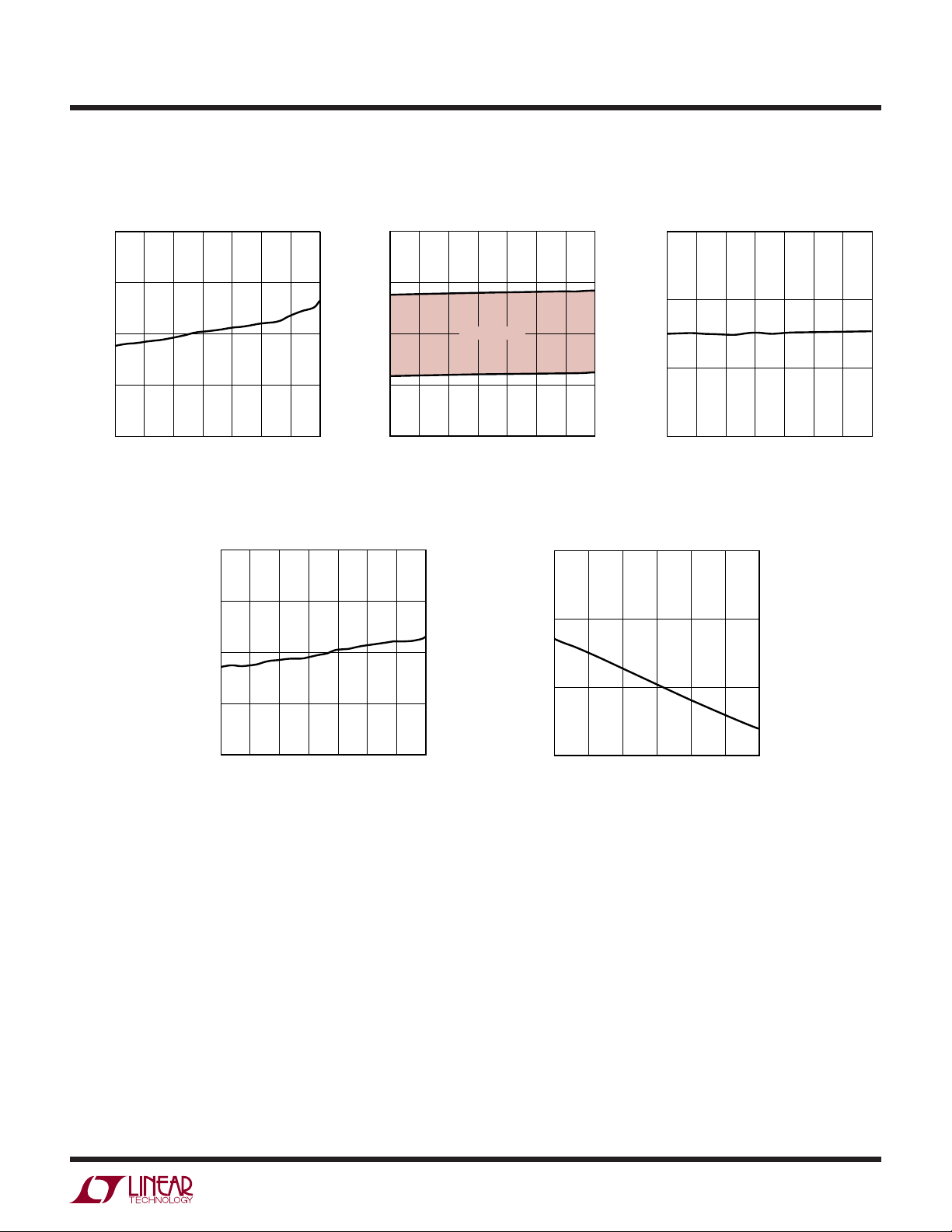

TYPICAL PERFORMANCE CHARACTERISTICS

Controller Frequency vs

Temperature

600

PG Threshold vs Temperature V

1.0

LT3742

– V

BIAS

10

vs Temperature

IN

550

500

FREQUENCY (kHz)

450

400

–50

–25 0 25 50

TEMPERATURE (°C)

75 100 125

SWB Current Limit vs

Temperature

380

360

340

320

SWB CURRENT LIMIT (mA)

3742 G09

0.9

0.8

0.7

FEEDBACK VOLTS RISING (V)

0.6

–50

–25 0 25 50

POWER GOOD

TEMPERATURE (°C)

75 100 125

3742 G10

RUN/SS Threshold vs

Temperature

1.0

0.7

0.4

RUN/SS VOLTS (V)

8

) (V)

IN

– V

BIAS

(V

6

4

–50 –25 0 25 50

TEMPERATURE (°C)

75 100 125

3742 G11

300

–50

–25 0 25 50

TEMPERATURE (°C)

75 100 125

3742 G12

0.1

–25

0255075

TEMPERATURE (°C)

100 125

3742 G13

3742f

5

Page 6

LT3742

PIN FUNCTIONS

G1, G2 (Pins 1, 6): Gate Drives. These pins provide high

current gate drive for the external N-channel MOSFETs.

These pins are the outputs of fl oating drivers whose voltage swings between the BIAS and SW pins.

(Pin 2): Input Voltage. This pin supplies current to the

V

IN

internal circuitry of the LT3742. This pin must be locally

bypassed with a capacitor.

UVLO (Pin 3): Undervoltage Lockout. Do not leave this

pin open ; connect it to V

connected to V

input voltage at which the LT3742 will operate. When this

pin is less than 1.25V, the controllers are disabled (the

RUN/SS pins are still used to turn on each switching

regulator). Once this pin drops below 1.25V, a 3μA current

sink draws current into the pin to provide programmable

hysteresis for UVLO.

BIAS (Pin 4): Bias for Gate Drive. This pin provides a bias

voltage higher than the input voltage to drive the external

N-channel MOSFETs. The voltage on this pin is regulated

+ 7V.

to V

IN

SWB (Pin 5): Bias Regulator Switch. This is the collector of an internal NPN switch used to generate the bias

voltage to provide gate drive for the external N-channel

MOSFETs.

is tied to this pin to program the minimum

IN

if not used. A resistor divider

IN

PG1, PG2 (Pins 17, 14): Power Good. These pins are

open-collector outputs of internal comparators. PG remains

low until the FB pin is within 90% of the fi nal regulation

voltage. As well as indicating output regulation, the PG

pins can be used to sequence the switching regulators.

The PG outputs are valid when V

and either of the RUN/SS pins is high. The power good

comparators are disabled in shutdown. If not used, these

pins should be left unconnected.

, VC2 (Pins 18, 13): Control Voltage and Compensation

V

C1

Pins for Internal Error Amplifi ers. Connect a series RC

from these pins to ground to compensate each switching

regulator loop.

FB1, FB2 (Pins 19, 12): Feedback Pins. The LT3742

regulates these pins to 800mV. Connect the feedback

resistors to this pin to set the output voltage for each

switching regulator.

–

SENSE1

Sense Inputs. These pins (along with the SENSE

are used to sense the inductor current for each switching

regulator.

SENSE1

Inputs. These pins (along with the SENSE

sense the inductor current for each switching regulator.

, SENSE2– (Pins 20, 11): Negative Current

+

, SENSE2+ (Pins 21, 10): Positive Current Sense

is greater than 3.5V

IN

+

pins)

–

pins) are used to

RUN/SS1, RUN/SS2 (Pins 16, 15): Run/Soft-Start Pins.

These pins are used to shut down each controller. They

also provide a soft-start function with the addition of an

external capacitor. To shut down any regulator, pull the

RUN/SS pin to ground with an open-drain or open-collector device. If neither feature is used, leave these pins

unconnected.

SW1, SW2 (Pins 24, 7): Switch Nodes. These pins connect

to the source of the external N-channel MOSFETs and to

the external inductors and diodes.

Exposed Pad (Pin 25): Ground. The Exposed Pad of the

package provides both electrical contact to ground and

good thermal contact to the printed circuit board. The

Exposed Pad must be soldered to the circuit board to

ensure proper operation.

3742f

6

Page 7

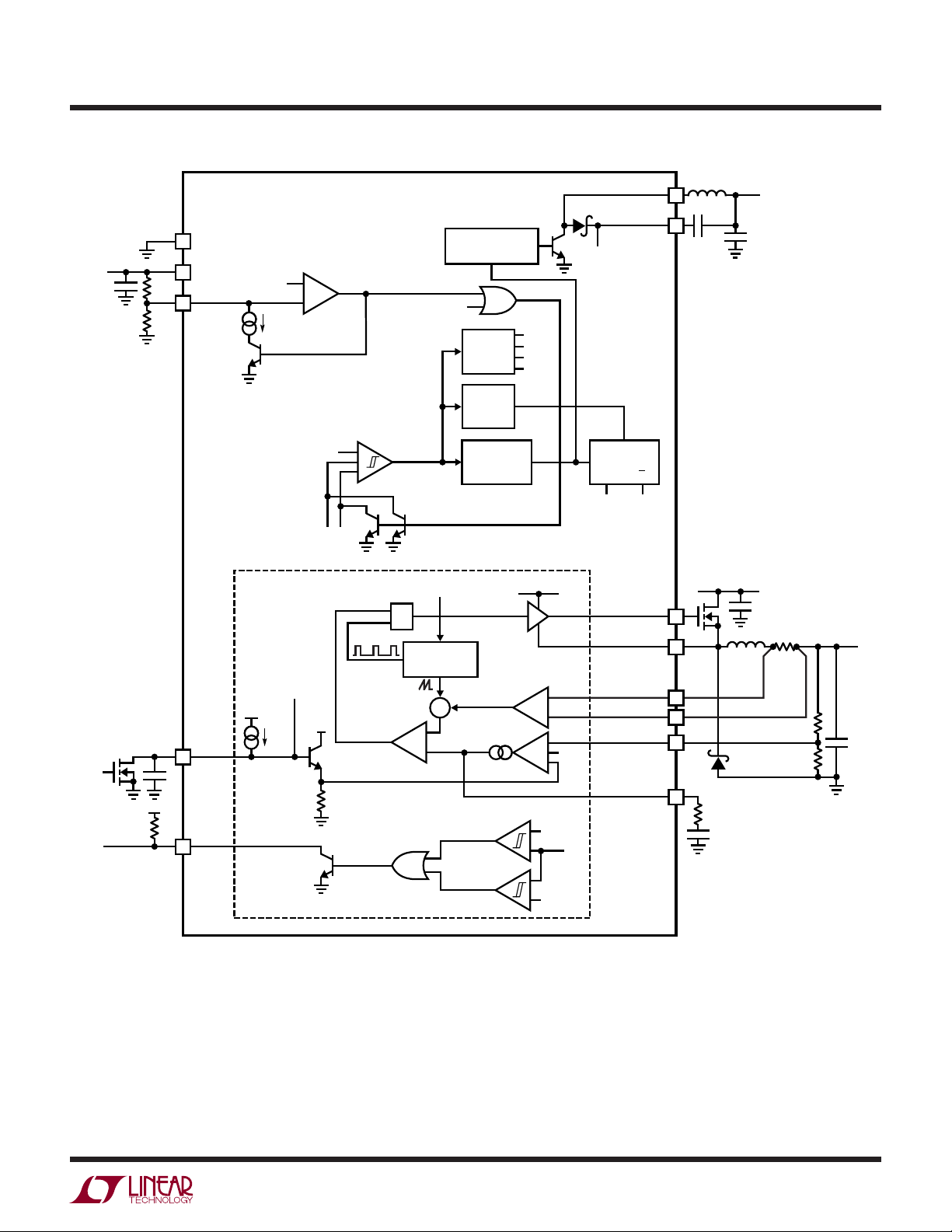

BLOCK DIAGRAM

LT3742

SHDN

SWB

5

BIAS

SENSE

SENSE

SW

4

G

+

–

FB

V

C

GND

25

V

IN

2

3

V

IN

UVLO

RUN/SS

1.25V

LT3742 CONTROLLER 1 AND 2

COMPARATOR

3μA

TO ENABLE

1μA

UNDERVOLTAGE

+

–

UVLO

≈0.5V

TO

RUN/SS1

RUN/SS2

LOCKOUT

ENABLE

COMPARATOR

–

+

+

PWM

COMPARATOR

SS

ENABLE

R

Q

S

GATE DRIVE BIAS

BOOST REGULATOR

THERMAL

SHUTDOWN

PHASE SYNC

500kHz SLAVE

OSCILLATOR

Σ

+

–

V

REF

INTERNAL

SUPPLY

1MHz MASTER

OSCILLATOR

CURRENT

SENSE

AMPLIFIER

ERROR

AMPLIFIER

1.25V

0.86V

0.80V

0.74V

DC/DC CONTROLLERS

BIAS

GATE

DRIVER

+

–

–

+

0.80V

+

BIAS

ENABLE

QDQ

PHASE SYNC FOR

V

IN

V

IN

V

OUT

PGOOD

–

PG

POWER GOOD

COMPARATORS

0.86V

+

FB

–

+

0.74V

3742 BD1

3742f

7

Page 8

LT3742

OPERATION

The LT3742 is a dual, constant frequency, current mode

DC/DC step-down controller. The two controllers in each

device share some common circuitry including protection circuitry, the internal bias supply, voltage reference,

master oscillator and the gate drive boost regulator. The

Block Diagram shows the shared common circuitry and

the independent circuitry for both DC/DC controllers.

Important protection features included in the LT3742 are

undervoltage lockout and thermal shutdown. When either

of these conditions exist, the gate drive bias regulator and

both DC/DC controllers are disabled and both RUN/SS pins

are discharged to ~0.7V to get ready for a new soft-start

cycle. Undervoltage lockout (UVLO) is programmed using

two external resistors. When the UVLO pin drops below

1.25V, a 3μA current sink is activated to provide programmable hysteresis for the UVLO function. A separate, less

accurate, internal undervoltage lockout will disable the

LT3742 when V

The gate drive boost regulator is enabled when all internal

fault conditions have been cleared. This regulator uses

both an internal NPN power switch and Schottky diode to

generate a voltage at the BIAS pin that is 7V higher than

the input voltage. Both DC/DC controllers are disabled until

the BIAS voltage has reached ~90% of its fi nal regulation

voltage. This ensures that suffi cient gate drive to fully

enhance the external MOSFETs is present before the driver

is allowed to turn on.

The master oscillator runs at 1MHz and clocks the gate

drive boost regulator at this frequency. The master oscillator also generates two 500kHz clocks, 180° out of phase,

for the DC/DC controllers.

is less than 3V.

IN

A power good comparator pulls the PG pin low whenever

the FB pin is not within ±7.5% of the 800mV internal

reference voltage. PG is the open-collector output of an

NPN that is off when the FB pin is in regulation, allowing

an external resistor to pull the PG pin high. This power

good indication is valid only when the device is enabled

(RUN/SS is high) and V

The LT3742 enables each controller independently when its

RUN/SS pin is above ~0.5V and each controller generates

its own soft-start ramp. During start-up, the error amplifi er

compares the FB pin to the soft-start ramp instead of the

precision 800mV reference, which slowly raises the output

voltage until it reaches its resistor programmed regulation

point. Control of the inductor current is strictly maintained

until the output voltage is reached. The LT3742 is ideal

for applications where both DC/DC controllers need to

operate separately.

A pulse from the 500kHz oscillator sets the RS fl ip-fl op

and turns on the external N-channel MOSFET. Current in

the switch and the external inductor begins to increase.

When this current reaches a level determined by the control

voltage (V

turning off the MOSFET. The current in the inductor then

fl ows through the external Schottky diode and begins to

decrease. This cycle begins again at the next set pulse from

the slave oscillator. In this way, the voltage at the V

controls the current through the inductor to the output.

The internal error amplifi er regulates the output voltage

by continually adjusting the V

of the peak inductor current on a cycle-by-cycle basis is

managed by the current sense amplifi er. Because the inductor current is constantly monitored, the devices inherently

provide excellent output short-circuit protection.

), the PWM comparator resets the fl ip-fl op,

C

is 4V or greater.

IN

pin voltage. Direct control

C

pin

C

8

3742f

Page 9

APPLICATIONS INFORMATION

LT3742

Soft-Start and Shutdown

The RUN/SS (Run/Soft-Start) pins are used to enable each

controller independently, and to provide a user-programmable soft-start function that reduces the peak input

current and prevents output voltage overshoot during

start-up. To disable either controller, pull its RUN/SS pin

to ground with an open-drain or open-collector device.

If both RUN/SS pins are pulled to ground, the LT3742 is

placed in shutdown mode, and quiescent current is reduced to ~20μA. Internal 1μA current sources pull up on

each RUN/SS pin, and when either pin reaches ~0.5V, that

controller is enabled, along with the internal bias supply,

gate drive boost regulator, voltage reference and master

oscillator. If both outputs are always enabled together,

one soft-start capacitor can be used with both RUN/SS

pins tied together.

The Benefi ts of Soft-Start

When a capacitor is tied from the RUN/SS pin to ground,

the internal 1μA pull-up current source generates a voltage ramp on this pin. During start-up, the error amplifi er

compares the FB pin to this ramp instead of to the 800mV

reference; this slowly and smoothly increases the output

voltage to its fi nal value, while maintaining control of the

inductor current. Always check the inductor current and

output voltage waveforms to ensure that the programmed

soft-start time is long enough. A new soft-start cycle will

be initiated whenever V

drops low enough to trigger

IN

undervoltage lockout (programmed using the UVLO pin),

or the LT3742 die temperature exceeds thermal shutdown.

A typical value for the soft-start capacitor is 1nF.

Soft-start is strongly recommended for all LT3742 applications, as it provides the least amount of stress on

the external power MOSFET and catch diode. Without

soft-start, both of these components will see the maximum current limit every start-up cycle. Figures 1a and 1b

show start-up waveforms with and without soft-start for

the circuit of Figure 1. Notice the large inductor current

spike and the output voltage overshoot when soft-start is

not used. While this may be acceptable for some systems,

the addition of a single capacitor dramatically improves

the start-up behavior of each DC/DC controller.

V

OUT

5V/DIV

I

L

2A/DIV

0.5ms/DIV

Figure 1a. Start-Up Waveforms Without Soft-Start Figure 1b. Start-Up Waveforms with 1nF Soft-Start Capacitor

3742 F01a

V

OUT

5V/DIV

2A/DIV

I

L

0.5ms/DIV

3742 F01b

3742f

9

Page 10

LT3742

APPLICATIONS INFORMATION

Power Good Indicators

The PG pin is the open-collector output of an internal

window comparator that is pulled low whenever the FB

pin is not within ±7.5% of the 800mV internal reference

voltage. Tie the PG pin to any supply less than 30V with

a pull-up resistor that will supply less than 200μA. This

pin will be open when the LT3742 is placed in shutdown

mode regardless of the voltage at the FB pin. The power

good indication is valid only when the LT3742 is enabled

(RUN/SS is high) and V

SHDN

Figure 2a. Supply Sequencing with Controller 2 Delayed Until After Controller 1 is in Regulation

is 3V or greater.

IN

4.7nF

4.7nF

LT3742

RUN/SS1

PG1

RUN/SS2

SHDN (REFERENCE)

Output Sequencing and Tracking

The RUN/SS and PG pins can be used together to sequence

the two outputs of the LT3742. Figure 3 shows three

circuits to do this. For the fi rst two cases, controller 1

starts fi rst.

In Figure 2a, controller 2 turns on only after controller

1 has reached within 10% of its fi nal regulation voltage.

A larger value for the soft-start capacitor on RUN/SS2

will provide additional delay between the outputs. One

V

OUT1

5V/DIV

V

OUT2

10V/DIV

5ms/DIV

3742 F02a

LT3742

SHDN

RUN/SS1

4.7nF

RUN/SS2

10nF

SHDN (REFERENCE)

V

OUT1

5V/DIV

V

OUT2

10V/DIV

5ms/DIV

Figure 2b. Supply Sequencing with Controller 2 Having a Fixed Delay Relative to Controller 1

LT3742

SHDN

RUN/SS1

10nF

RUN/SS2

SHDN (REFERENCE)

V

OUT1

5V/DIV

V

OUT2

10V/DIV

5ms/DIV

Figure 2c. Both Conditions Start Up Together with Ratiometic Tracking

3742 F02b

3742 F02c

3742f

10

Page 11

APPLICATIONS INFORMATION

LT3742

characteristic to notice about this method is that if the

output of controller 1 goes out of regulation enough

to trip the power good comparator, controller 2 will be

disabled.

In Figure 2b, a slightly larger capacitor on RUN/SS2 delays

the turn-on of controller 2 with respect to controller 1. The

start-up waveforms for this method look very similar to

the one shown in Figure 6a, but here controller 2 is not

disabled if controller 1 goes out of regulation.

In Figure 2c, both RUN/SS pins share a single capacitor

and start up at the same time. By sharing the same softstart signal, this method provides ratiometric tracking of

the two outputs.

Undervoltage Lockout (UVLO)

An external resistor divider can be used to accurately

set the minimum input voltage at which the LT3742 will

operate. Figure 3 shows the basic UVLO operation. Once

the UVLO pin drops below 1.25V, an undervoltage lockout event is signaled, turning on a 3μA current source to

provide hysteresis.

During a UVLO event, both controllers and the gate drive

boost regulator are disabled. For the LT3742, all RUN/SS

pins are discharged to get ready for a new soft-start cycle.

For each controller that is enabled, it’s RUNSS pin will be

held to ~700mV until the input voltage rises above the

upper UVLO trip voltage. The UVLO function is only active

when one or more of the controllers are enabled using the

RUN/SS pin. The UVLO pin can not be used to directly

start the part. Do not leave the UVLO pin unconnected;

tie it to V

undervoltage lockout will disable the LT3742 when V

if not used. A separate, less accurate, internal

IN

is

IN

less than 3.5V.

The UVLO resistor values are chosen to give the desired

minimum operating voltage (V

amount of hysteresis (V

). The LT3742 will turn on

HYST

when the input voltage is above (V

once on, will turn off when V

the value for R

V

=

R

UV

1

27

RR

UV UV

21

fi rst, then select the value for R

UV1

HYST

μ=.

A

•

V

()

IN MIN

drops below V

IN

125

.

V

125

–.

) and the desired

IN(MIN)

+ V

IN(MIN)

IN(MIN)

VV

HYST

), and

. Select

.

UV2

Input Voltage Range

The minimum input voltage is determined by either the

LT3742’s minimum operating voltage of 4V, UVLO or by

the output voltages of a given application. The LT3742 can

operate at 100% duty cycle, so if the input voltage drops

close to or equal to one of the output voltages, the controller will go into low dropout operation (100% duty cycle).

The duty cycle is the fraction of the time the N-channel

MOSFET is on every switch cycle, and is determined by

the input and output voltages:

⎛

VV

+

DC

=

OUT D

⎜

⎝

VV V

–

IN DS D

⎞

⎟

⎠

+

where VD is the forward drop of the catch diode (~0.4V)

and V

is the typical MOSFET voltage drop (~0.1V).

DS

V

V

IN

R

UV1

R

UV2

IN

2

1.25V

UVLO

3

Figure 3. Undervoltage Lockout

+

–

3μA

UVLO

3742 F03

3742f

11

Page 12

LT3742

APPLICATIONS INFORMATION

The maximum input voltage is determined by the absolute

maximum ratings of the V

spectively) and by the minimum duty cycle, DC

⎛

VV

OUT D

⎜

⎝

DC

V

IN MAX

and BIAS pins (30V and 40V, re-

IN

⎞

+

MIN

VV

+

⎟

SW D()

⎠

–=

MIN

= 15%.

The formula above calculates the maximum input voltage

that allows the part to regulate without pulse-skipping,

and is mainly a concern for applications with output voltages lower than 3.3V. For example, for a 2.5V output, the

maximum input voltage is:

V

IN MAX()

⎛

25 04

..

+

VV

⎜

015

⎝

.

⎞

+=

01 04 19

.–.=

⎟

⎠

VVV

If an input voltage higher than ~19V is used, the 2.5V output

will still regulate correctly, but the part must pulse-skip

to do so. Pulse skipping does not damage the LT3742,

but it will result in erratic inductor current waveforms

and higher peak currents. Note that this is a restriction

on the operating input voltage only for a specifi c output

voltage; the circuit will tolerate inputs up to the absolute

maximum rating.

The Benefi ts of 2-Phase Operation

Traditionally, dual controllers operate with a single phase.

This means that both power MOSFETs are turned on at

the same time, causing current pulses of up to twice the

amplitude of those from a single regulator to be drawn

from the input capacitor. These large amplitude pulses

increase the RMS current fl owing in the input capacitor,

require the use of larger and more expensive input capacitors, increase EMI, and causes increased power losses in

the input capacitor and input power supply.

The two controllers of the LT3742 are guaranteed by design

to operate 180° out of phase. This assures that the current

in each power MOSFET will never overlap, always presenting a signifi cantly low peak and RMS current demand to

the input capacitor. This allows the use of a smaller, less

expensive input capacitor, improving EMI performance

and real world operating effi ciency.

Figure 4 shows example waveforms for a single phase dual

controller versus a 2-phase LT3742 system. In this case,

5V and 3.3V outputs, each drawing a load current of 2A,

are derived from a 12V supply. In this example, 2-phase

Single Phase

Dual Controller

SW1 (V)

SW2 (V)

I

L1

I

L2

I

IN

Figure 4. Example Waveforms for a Single Phase Dual Controller vs the 2-Phase LT3742

2-Phase

Dual Controller

3742 F04

3742f

12

Page 13

APPLICATIONS INFORMATION

LT3742

operation would reduce the RMS input capacitor current

from ~1.8A

RMS

to ~0.8A

. While this is an impressive

RMS

reduction by itself, remember that power losses are pro-

2

portional to I

, meaning that the actual power wasted

RMS

due to the input capacitor is reduced by a factor of ~4.

Figure 5 shows the reduction in RMS ripple current for a

typical application.

The reduced input ripple current also means that less

power is lost in the input power path. Improvements in

both conducted and radiated EMI also directly accrue as

a result of the reduced RMS input current and voltage.

Signifi cant cost and board footprint savings are also realized by being able to use smaller, less expensive, lower

RMS current-rated input capacitors.

Of course, the improvement afforded by 2-phase operation is a function of the relative duty cycles of the two

controllers, which in turn, are dependent upon the input

voltage (DC ≈ V

OUT/VIN

).

It can be readily seen that the advantages of 2-phase operation are not limited to a narrow operating range, but in

fact extend over a wide region. A good rule of thumb for

most applications is that 2-phase operation will reduce the

input capacitor requirement to that for just one channel

operating at maximum current and 50% duty cycle.

Inductor Value Selection

The inductor value directly affects inductor ripple current,

I

RIPPLE

, and maximum output current, I

OUT(MAX)

. Lower

ripple current reduces core losses in the inductor, ESR

losses in the output capacitors and output voltage ripple.

Too large of a value, however, will result in a physically

large inductor. A good tradeoff is to choose the inductor

ripple current to be ~30% of the maximum output current.

This will provide a good tradeoff between the inductor

size, maximum output current, and the amount of ripple

current. Note that the largest ripple current occurs at the

highest the input voltage, so applications with a wide V

range should consider both V

IN(TYP)

and V

IN(MAX)

IN

when

calculating the inductor value:

VVIV

≥

03

IN OUT

.•

OUT MAX

()

L

OUT

••

V kHz

IN

–

1

500

This equation provides a good starting point for picking the inductor value. Most systems can easily tolerate

ripple currents in the range of 10% to 50%, so deviating

slightly from the calculated value is acceptable for most

applications. Pick a standard value inductor close to the

3.0

SINGLE PHASE

2.5

2.0

1.5

1.0

INPUT RMS CURRENT (A)

0.5

VO1 = 5V/3A

= 3.3V/3A

V

O2

0

0

Figure 5. RMS Input Current Comparison

DUAL CONTROLLER

2-PHASE

DUAL CONTROLLER

10 20 30 40

INPUT VOLTAGE (V)

3742 F05

3742f

13

Page 14

LT3742

APPLICATIONS INFORMATION

value calculated above, and then recheck the amount of

ripple current:

VVLV

I

RIPPLE

–

IN OUT OUT

=

••

V kHz

IN

1

500

The DC resistance (DCR) of the inductor can have a

signifi cant impact on total system effi ciency, as it causes

2

R

an I

power loss. Consider inductance value, DCR,

DCR

and current rating when choosing an inductor. Table 1

shows several recommended inductor vendors. Each offers numerous devices in a wide variety of values, current

ratings, and package sizes.

Table 1. Recommended Inductor Manufacturers

VENDOR WEBSITE

Sumida www.sumida.com

Toko www.toko.com

Würth www.we-online.com

NEC-Tokin www.nec-tokinamerica.com

TDK www.tdk.com

Maximum Output Current (R

Value Selection)

SENSE

Maximum output current is determined largely by the

values of the current sense resistor, RSENSE (which sets

the inductor peak current), and the inductor (which sets

the inductor ripple current). The LT3742 current comparator has a guaranteed minimum threshold of 50mV, which

does not vary with duty cycle. The maximum output current is calculated:

–=

I

RIPPLE

2

I

OUT MAX

()

50

R

SENSE

mV

Rearranging the equation above to solve for RSENSE

gives:

mV

R

SENSE

=

I

OUT MAX

50

+

()

I

⎛

RIPPLE

⎜

⎝

⎞

⎟

⎠

2

Inductor, Catch Diode and MOSFET Current Rating

Once the inductor and R

values have been chosen, the

SENSE

current ratings of the inductor, catch diode and MOSFET

can then be determined. The LT3742 current comparator

has a guaranteed maximum threshold of 70mV, and there

is a small amount of current overshoot resulting from

the response time of the current sense comparator. The

components should be rated to handle:

I

RATED

70

mV

≥+

R

SENSE

V

⎛

IN

⎜

⎝

L

⎞

100•

ns

⎟

⎠

Schottky Catch Diode Selection

During output short-circuits, the diode will conduct current

most of the time, so it is important to choose a device

with a suffi cient current rating. In addition, the diode must

have a reverse voltage rating greater than the maximum

input voltage. Many surface mount Schottky diodes are

available in very small packages. Read their data sheets

carefully as they typically must be temperature derated.

Basically, excessive heating prevents them from being

used effectively at their rated maximum current. A few

recommended diodes are listed in Table 2.

Table 2. Recommended Schottky Diodes

VENDOR DEVICE

Diodes, Inc.

www.diodes.com

Microsemi

www.microsemi.com

On Semiconductor

www.onsemi.com

PDS540 (5A, 40V)

SBM1040 (10A, 40V)

UPS340 (3A, 40V)

UPS840 (8A, 40V)

MBRD320 (3A, 20V)

MBRD340 (3A, 40V)

Power MOSFET Selection

There are several important parameters to consider when

choosing an N-channel power MOSFET: drain current

(maximum I

); threshold voltage (V

V

GS

reverse transfer capacitance (C

); breakdown voltage (maximum VDS and

D

); on-resistance (R

GS(TH)

); and total gate charge

RSS

DS(ON)

);

14

3742f

Page 15

APPLICATIONS INFORMATION

LT3742

(QG). A few simple guidelines will make the selection

process easier.

The maximum drain current must be higher than the

maximum rated current, I

page. Note that the I

dependent (lower I

specifi cation is largely temperature

D

at higher ambient temperatures), so

D

most data sheets provide a graph or table of I

, calculated on the previous

RATED

versus

D

temperature to show this.

Ensure that the V

the maximum input voltage and that the V

breakdown voltage is greater than

DS

breakdown

GS

voltage is 8V or greater. The peak-to-peak gate drive

for each MOSFET is ~7V, so also ensure that the device

chosen will be fully enhanced with a V

preclude the use of some MOSFETs with a 20V V

of 7V. This may

GS

rating,

GS

as some have too high of a threshold voltage. A good rule

of thumb is that the maximum threshold voltage should be

V

GS(TH)(MAX)

≤ 3V. 4.5V MOSFETs will work as well.

Power losses in the N-channel MOSFET come from two

main sources: the on-resistance, R

transfer capacitance, C

2

ohmic losses (I

R

DS(ON)

. The on-resistance causes

RSS

) which typically dominate at

, and the reverse

DS(ON)

input voltages below ~15V. The reverse transfer capacitance results in transition losses which typically dominate

for input voltages above ~15V. At higher input voltages,

transition losses rapidly increase to the point that the use

of a higher R

device with lower C

DS(ON)

will actually

RSS

provide higher effi ciency. The power loss in the MOSFET

can be approximated by:

P ohmic loss transition loss

=

LOSS

P

LOSS

()

⎛

V

OU

≈

TTD

⎜

VV

+

⎝

IN D

VI

••

2

()

IN O

V

+

2

+

()

2

IR

OUT DS ON T

Cf••

UUT RSS

()

⎞

ρ

⎟

⎠

+••

where f is the switching frequency (500kHz) and ρT is a

normalizing term to account for the on-resistance change

due to temperature. For a maximum ambient temperature

of 70°C, using ρ

The tradeoff in R

≈ 1.3 is a reasonable choice.

T

DS(ON)

and C

can easily be seen in an

RSS

example using real MOSFET values. To generate a 3.3V,

3A (10W) output, consider two typical N-channel power

MOSFETs, both rated at V

= 30V and both available in

DS

the same SO-8 package, but having ~5x differences in

on-resistance and reverse transfer capacitance:

= 11.5A, VGS = 12V, R

M1: I

D

= 6.5A, VGS = 20V, R

M2: I

D

DS(ON)

DS(ON)

= 10mΩ, C

= 50mΩ, C

RSS

RSS

= 230pF

= 45pF

Power loss is calculated for both devices over a wide input

voltage range (4V ≤ V

≤ 30V), and shown in Figure 6 (as

IN

a percentage of the 10W total power). Note that while the

low R

device power loss is 5× lower at low input

DS(ON)

0.7

0.6

0.5

0.4

0.3

0.2

MOSFET POWER LOSS (W)

0.1

0

0

Figure 6a. Power Loss Example for M1 (10mΩ, 230pF)

OHMIC + TRANSITION

510

INPUT VOLTAGE (V)

TOTAL =

TRANSITION

OHMIC

20 30

15 25

3742 F06a

0.7

0.6

0.5

0.4

0.3

0.2

MOSFET POWER LOSS (W)

0.1

0

0

510

Figure 6b. Power Loss Example for M2 (50mΩ, 45pF)

TOTAL =

OHMIC + TRANSITION

OHMIC

TRANSITION

INPUT VOLTAGE (V)

20 30

15 25

3742 F06b

15

3742f

Page 16

LT3742

APPLICATIONS INFORMATION

voltages, it is also 3× higher at high input voltages when

compared to the low C

Total gate charge, Q

gate charge corresponds to a small value of C

device.

RSS

, is closely related to C

G

RSS

RSS

. Low

. Many

manufacturers have MOSFETs advertised as “low gate

charge” devices (which means they are low C

devices)

RSS

that are specifi cally designed for low transition loss, and

are ideal for high input voltage applications.

Input Capacitor Selection

For most applications, 10μF to 22μF of input capacitance

per channel will be suffi cient. A small 1μF bypass capacitor

between the V

and ground pins of the LT3742, placed

IN

close to the device, is also suggested for optimal noise

immunity. Step-down regulators draw current from the

input supply in pulses with very fast rise and fall times.

The input capacitor is required to reduce the resulting

voltage ripple at the LT3742 and to force this very high

frequency switching current into a tight local loop, minimizing EMI. The input capacitor must have low impedance at

the switching frequency to do this effectively, and it must

have an adequate ripple current rating. With two controllers operating at the same frequency but with different

phases and duty cycles, calculating the input capacitor

RMS current is not simple. However, a conservative value

is the RMS input current for the channel that is delivering

• I

the most power (V

I

I

RMS CIN

I

RMS(CIN)

OUT

V

IN

is largest (I

OUT

••–=

OUT

):

OUT

VVV

()

OUT IN OUT()

/2) when VIN = 2V

(at DC =

OUT

50%). As the second, lower power channel draws input

current, the input capacitor’s RMS current actually decreases as the out-of-phase current cancels the current

drawn by the higher power channel, so choosing an input

capacitor with an RMS ripple current rating of I

OUT,MAX

/2

is suffi cient.

The combination of small size and low impedance (low

equivalent series resistance, or ESR) of ceramic capacitors

make them the preferred choice. The low ESR results in

very low input voltage ripple and the capacitors can handle

plenty of RMS current. They are also comparatively robust

and can be used at their rated voltage. Use only X5R or

X7R types because they retain their capacitance over wider

voltage and temperature ranges than other ceramics.

An alternative to a high value ceramic capacitor is a lower

value (1μF) along with a larger value (10μF to 22μF) electrolytic or tantalum capacitor. Because the input capacitor

is likely to see high surge currents when the input source

is applied, tantalum capacitors should always be surge

rated. The manufacturer may also recommend operation

below the rated voltage of the capacitor. Be sure to place

the 1μF ceramic as close as possible to the N-channel

power MOSFET.

Output Capacitor Selection

A good starting value for output capacitance is to provide

10μF of C

for every 1A of output current. For lower

OUT

output voltages (under 3.3V) and for applications needing

the best possible transient performance, the ratio should

be 20μF to 30μF of C

for every 1A of output current.

OUT

X5R and X7R ceramics are an excellent choice for the

output capacitance. Aluminum electrolytics can be used,

but typically the ESR is too large to deliver low output

voltage ripple. Tantalum and newer, lower ESR organic

electrolytic capacitors are also possible choices, and the

manufactures will specify the ESR. Because the volume of

the capacitor determines the ESR, both the size and value

will be larger than a ceramic capacitor that would give you

similar output ripple voltage performance.

The output capacitor fi lters the inductor ripple current to

generate an output with low ripple. It also stores energy

in order to satisfy transient loads and to stabilize the

16

3742f

Page 17

APPLICATIONS INFORMATION

LT3742

LT3742’s control loop. Output ripple can be estimated

with the following equation:

VI

RIPPLE L

⎛

=Δ +

⎜

⎝

1

fC

8• •

SW OUT

ESR

⎞

⎟

⎠

where ΔIL is the inductor ripple current and fSW is the

switching frequency (500kHz). The ESR is so low for ceramic capacitors that it can be left out of the above calculation. The output voltage ripple will be highest at maximum

input voltage (ΔI

increases with input voltage). Table 3

L

shows several low-ESR capacitor manufacturers.

Table 3. Low ESR Surface Mount Capacitors

VENDOR TYPE SERIES

Taiyo Yuden

www.t-yuden.com

Murata

www.murata.com

Kemet

www.kemet.com

Sanyo

www.sanyo.com

Panasonic

www.panasonic.com

TDK

www.tdk.com

Nippon Chemicon

www.chemi-con.co.jp

Ceramic X5R, X7R

Ceramic X5R, X7R

Tantalum

Ta Organic

Al Organic

Ta or Al Organic POSCAP

Al Organic SP CAP

Ceramic X5R, X7R

Ceramic X5R, X7R

T491, T494, T495

T520

A700

Setting Output Voltage

The output of a bipolar controller requires a minimum load

to prevent current sourced from the switch pin charging

the output capacitor above the desired output voltage.

This current, approximately 5mA, may be accounted for

in the feedback string or the user may choose to force a

minimum load in their application.

The output voltage for each controller is programmed

with a resistor divider between the output and the FB pin.

Always use 1% resistors (or better) for the best output

voltage accuracy. The value of R

should be 8k or less,

A

and the value of R1 should be chosen according to:

RR

BA

⎛

=

OUT

•

⎜

⎝

.–08

⎞

1

⎟

⎠

V

V

Output Short-Circuit Protection

Because the LT3742 constantly monitors the inductor

current, both devices inherently providing excellent output

short-circuit protection. The N-channel MOSFET is not allowed to turn on unless the inductor current is below the

threshold of the current sense comparator. This guarantees that the inductor current will not “run away” and the

controller will skip cycles until the inductor current has

dropped below the current sense threshold.

Loop Compensation

An external resistor and capacitor connected in series from

pin to ground provides loop compensation for each

the V

C

controller. Sometimes a second, smaller valued capacitor

is placed in parallel to fi lter switching frequency noise from

pin. Loop compensation determines the stability

the V

C

and transient performance of each controller.

A practical approach is to start with values of R

and C

= 330pF, then tune the compensation network to

C

= 10k

C

optimize the performance. When adjusting these values,

change only one value at a time (R

or CC), then see how

C

the transient response is affected. The simplest way to

check loop stability is to apply a load current step while

observing the transient response at the output. Stability

should then be checked across all operating conditions,

including load current, input voltage, and temperature to

ensure a robust design.

V

OUT1

LT3742

R1B

V

FB1

R1A

Figure 7. Setting Output Voltage with the FB Pin

V

FB2

3742 F07

V

OUT2

R2B

R2A

3742f

17

Page 18

LT3742

APPLICATIONS INFORMATION

Bias Supply Considerations

The LT3742 uses an internal boost regulator to provide a

bias rail for enhancement of the external MOSFETs. This

bias rail is regulated to V

+ 7V and must be in regula-

IN

tion before either controller is allowed to start switching.

As this is a high speed switching regulator, standard

procedures must be followed regarding placement of the

external components. The SWB node should be kept small

to reduce EMI effects and the bias decoupling capacitor

) should be kept close to the BIAS pin and VIN. A

(C

BIAS

slight surplus of power is available from this supply and

it can be tapped after stringent engineering evaluation.

PC Board Layout Considerations

As with all switching regulators, careful attention must be

paid to the PCB board layout and component placement.

■

Place the power components close together with short

and wide interconnecting traces. The power components consist of the top MOSFETs, catch diodes and

the inductors C

and C

IN

. One way to approach this

OUT

is to simply place them on the board fi rst.

■

Similar attention should be paid to the power compo-

nents that make up the boost converter. They should also

be placed close together with short and wide traces.

■

Always use a ground plane under the switching regulator

to minimize interplane coupling.

■

Minimize the parasitic inductance in the loop of CIN,

MOSFET and catch diode, which carry large switching

currents.

■

Use compact plane for switch node (SW) to improve

cooling of the MOSFETs and to keep EMI low.

■

Use planes for VIN and V

to maintain good voltage

OUT

fi ltering and to keep power losses low. Unused areas

can be fi lled with copper and connect to any DC node

, V

(V

IN

■

Place CB close to BIAS pin and input capacitor.

■

Keep the high dv/dt nodes (SW1, SW2, G1, G2, C

C

IN2

, GND).

OUT

IN1

, SWB) away from sensitive small-signal nodes.

,

Demo board gerber fi les are available to assist with a

reliable layout. It will be diffi cult to achieve data sheet

performance specifi cations with improper layout.

18

3742f

Page 19

APPLICATIONS INFORMATION

V

IN

V

IN

SYSTEM

GROUND

V

OUT1

LT3742

RUN1

SHDN

RUN2

SHDN

V

IN

VIAS TO LOCAL GROUND PLANE

OUTLINE OF LOCAL GROUND PLANE

Figure 8. A Good PCB Layout Ensures Proper, Low EMI Operation

V

OUT2

3742 F08

3742f

19

Page 20

LT3742

TYPICAL APPLICATIONS

Supercap Charger Plus a DC/DC Buck Converter

V

OUT1

PG1

5V

4A

V

5.5V TO 30V

V

RUN1

IN

IN

C2

150μF

C5

1μF

C1

6.8μF

R

S1

4.7μH

0.010Ω

R1

1.05k

R2

200Ω

M3

C7

1nF

C

C1

680pF

D1, D2: DIODES INC. PDS1040

M1, M2: SILICONIX Si7884DP

L1

357k

124k

D1

R7

R8

M1

R

51k

L3

μH

22

254

V

SWB

IN

3

UVLO

LT3742

1

G1

24

SW1

21

20

19

17

16

18

C1

SENSE1

SENSE1

FB1

PG1

RUN/SS1

V

C1

+

–

GND

25

BIAS

SW2

SENSE2

SENSE2

FB2

PG2

RUN/SS2

V

C6

μF

4.7

V

3742 TA02

IN

SUPERCAP

CHARGER

OUTPUT

150mF

RUN2

PG2

6

G2

+

–

C2

M2

L2

7

10

11

12

14

15

13

47μH

D2

C8

1nF

C

C2

1000pF

R

S2

0.030Ω

6.8μF

47μF

M4

C3

C4

V

OUT1

PG1

8V and 5V Dual Step-Down Converter

L3

μH

V

IN

14V

1μF

V

IN

C1

10μF

R

S1

8V

4A

C2

47μF

RUN1

0.01Ω

R1

1.8k

R2

200Ω

M3

C2, C4: MURATA GRM32ER71A476K

D1, D2: DIODES INC. PDS1040

L1, L2: WÜRTH ELEKTRONIK 744314650

M1, M2: FAIRCHILD FDS4470

C5

C7

1nF

1000pF

C

L1

6.5μH

C1

45.3k

20k

D1

R1

R1

M1

R

30k

24

21

20

19

17

16

18

C1

22

254

V

SWB

IN

3

UVLO

LT3742

1

G1

SW1

+

SENSE1

–

SENSE1

FB1

PG1

RUN/SS1

V

C1

GND

25

BIAS

SW2

SENSE2

SENSE2

FB2

PG2

RUN/SS2

V

C6

μF

2.2

V

6

G2

+

–

C2

M2

L2

R

20k

6.5μH

D2

C8

C2

1nF

C

C2

1000pF

7

10

11

12

14

15

13

R

S2

0.01Ω

10μF

1.05k

200Ω

M4

C3

IN

V

OUT2

5V

R3

C4

47μF

R4

RUN2

3742 TA05

4A

PG2

3742f

20

Page 21

TYPICAL APPLICATIONS

V

IN

14V

V

IN

10μF 10μF

V

OUT1

3.3V

220μF

4A

10mΩ 10mΩ

619Ω

200Ω

5V and 3.3V Dual Step-Down Converter

L3

μH

1μF

L1

3.3μH

348k

130k

V

IN

UVLO

G1

SW1

SENSE1

SENSE1

FB1

22

SWB

LT3742

+

–

BIAS

SW2

SENSE2

SENSE2

2.2

G2

+

–

FB2

LT3742

μF

V

IN

L2

4.7μH

D2

1.05k

200Ω

V

5V

4A

150μF

OUT2

PG1

PG1

RUN/SS1

1nF 1nF

680pF 68pF

51k

D1, D2: DIODES INC. PDS1040

L1: VISHAY IHLP2525CZER3R3

L2: VISHAY IHLP2525CZER4R7

L3: COILCRAFT: ME3220-223KL

M1, M2: VISHAY Si7848DP-T1-E3

V

C1

GND

PG2

RUN/SS2

V

PG2

C2

51k

680pF

Effi ciency vs Load Current

90

5V

OUT

3.3V

80

70

EFFICIENCY (%)

60

50

0

1

LOAD CURRENT (A)

OUT

2

3

4

3742 TA01b

3742 TA01

3742f

21

Page 22

LT3742

TYPICAL APPLICATIONS

High Current, Low Ripple 12V Step-Down Converter

V

IN

24V

V

IN

V

OUT1

12V

8A

C

OUTA-COUTD

D1, D2: DIODES INC. PDS1040

L1, L2: NEC/TOKIN PLC12458R2

M1, M2: ROHM RSS065N03

: KEMET T495E107K020E060

C1

10μF

R1

2.8k

R2

200Ω

R

S1

0.010Ω

C7

1nF

C

680pF

8.2μH

C1

L1

C5

1μF

D1

M1

R7

124k

R8

20.0k

R

C1

51k

C

OUTA

100μF

20V

PG1

L3 10μH

V

IN

UVLO

G1

SW1

SENSE1

SENSE1

PG1

FB1

RUN/SS1

V

C1

C

OUTB

100μF

20V

SWB

LT3742

+

–

GND

BIAS

SW2

SENSE2

SENSE2

FB2

PG2

RUN/SS2

V

C

OUTC

100μF

20V

C6

4.7

μF

V

IN

R

S2

0.010Ω

C3

10μF

3742 TA04a

PG2

C

100μF

20V

M2

L2

8.2μH

D2

OUTD

G2

+

–

C2

22

12V

OUT

100

90

85

EFFICIENCY (%)

70

60

0

1234

Effi ciency vs Load Currnt

5678

LOAD CURRENT (A)

3742 TA04b

3742f

Page 23

PACKAGE DESCRIPTION

LT3742

UF Package

24-Lead Plastic QFN (4mm × 4mm)

(Reference LTC DWG # 05-08-1697)

0.70 ±0.05

4.50 ± 0.05

3.10 ± 0.05

2.45 ± 0.05

(4 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

4.00 ± 0.10

(4 SIDES)

PIN 1

TOP MARK

(NOTE 6)

NOTE:

1. DRAWING PROPOSED TO BE MADE A JEDEC PACKAGE OUTLINE MO-220 VARIATION (WGGD-X)—TO BE APPROVED

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE, IF PRESENT

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON THE TOP AND BOTTOM OF PACKAGE

0.25 ±0.05

0.50 BSC

PACKAGE OUTLINE

0.75 ± 0.05

2.45 ± 0.10

(4-SIDES)

0.200 REF

0.00 – 0.05

BOTTOM VIEW—EXPOSED PAD

R = 0.115

TYP

2423

PIN 1 NOTCH

R = 0.20 TYP OR

0.35 × 45° CHAMFER

0.40 ± 0.10

1

2

(UF24) QFN 0105

0.25 ± 0.05

0.50 BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3742f

23

Page 24

LT3742

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

TM

LTC1625/LTC1775 No R

Current Mode Synchronous Step-Down

SENSE

Controllers

LTC1735 High Effi ciency Synchronous Step-Down Switching

Regulator

LTC1778 No R

Wide Input Range Synchronous Step-Down

SENSE

Contr oller

LT3430/LT3431 Monolithic 3A, 200kHz/500kHz Step-Down Regulators 5.5V = <V

LTC3703/LTC3703-5 100V Synchronous Switching Regulator Controllers No R

LT3724 High Voltage Current Mode Switching Regulator Controllers V

LT3800 High Voltage Synchronous Controller V

LT3844 High Voltage Current Mode Controller with Programmable

Operating Frequency

LTC3727A-1 Dual, 2-Phase Synchronous Controller Very Low Dropout; V

LTC3728 2-Phase 550kHz, Dual Synchronous Step-Down Controller QFN and SSOP Packages, High Frequency for Smaller L and C

LTC3729

20A to 200A PolyPhase

®

Synchronous Controllers

LTC3731 3-Phase, 600kHz Synchronous Step-Down Controller 0.6V ≤ V

LTC3773 Triple Output DC/DC Synchronous Controller 3-Phase Step-Down DC/DC Controller, 3.3V ≤ VIN ≤ 36V,

LTC3826/LTC3826-1 30μA IQ, Dual, 2-Phase Synchronous Step-Down Controllers 2-Phase Operation, 30μA One Channel No Load IQ (50μA Total),

LTC3827/LTC3827-1 Low I

LTC3834/LTC3834-1 Low I

LTC3835/LTC3835-1 Low I

Dual Synchronous Controllers 2-Phase Operation, 115μA Total No Load IQ, 4V ≤ VIN ≤ 36V, 80μA

Q

Synchronous Step-Down Controllers 30μA No Load IQ, 4V ≤ VIN ≤ 36V, 0.8V ≤ V

Q

Synchronous Step-Down Controllers 80μA No Load IQ, 4V ≤ VIN ≤ 36V, 0.8V ≤ V

Q

LTC3850 Dual, 2-Phase Synchronous Step-Down DC/DC Controller 2-Phase Operation, 4V ≤ V

LT3845 High Voltage Synchronous Step-Down Single Output

Controller

PolyPhase is a registered trademark of Linear Technology Corporation. No R

97% Effi ciency, No Sense Resistor, 16-Pin SSOP

Output Fault Protection, 16-Pin SSOP

Up to 97% Effi ciency, 4V ≤ VIN ≤ 36V, 0.8V ≤ V

I

up to 20A

OUT

= <60V, 0.1Ω Saturation Switch, 16-Lead SSOP Package

IN

, Voltage Mode Control, GN16 Package

SENSE

up to 60V, I

IN

Regulator, Burst Mode Operation, I

up to 60V, I

IN

Burst Mode Operation, I

up to 60V, I

V

IN

Operation, Sync Capability, I

≤ 5A, 16-Lead TSSOP Package, Onboard Bias

OUT

≤ 20A, Current Mode, Onboard Bias Regulator,

OUT

OUT

= 100μA, 16-Lead TSSOP Package

Q

≤ 5A, Onboard Bias Regulator, Burst Mode

≤ 14V

OUT

< 100μA, 200kHz Operation

Q

= 120μA, 16-Lead TSSOP Package

Q

Expandable from 2-Phase to 12-Phase, Uses All Surface Mount

Components, No Heat Sink

≤ 6V, 4.5V ≤ VIN ≤ 32V, I

OUT

OUT

≤ 60A,

Integrated MOSFET Drivers

Fixed Frequency 160kHz to 700kHz

4V ≤ V

≤ 36V, 0.8V ≤ V

IN

No Load I

Option, I

with One Channel On

Q

up to 20A, 4mm × 4mm QFN

OUT

Very Low Quiescent Current (120μA), V

≤ 10V

OUT

OUT

OUT

≤ 24V, 95% Effi ciency, No R

IN

up to 60V, Fixed Frequency

IN

100kHz to 500kHz, Synchronizable up to 600kHz

is a trademark of Linear Technology Corporation.

SENSE

≤ (0.9)(VIN),

OUT

≤ 10V

≤ 10V

SENSE

24

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

3742f

LT 1207 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2007

Loading...

Loading...