L DESIGN FEATURES

V

BUS

OV

SENS

D0–D2

CHRG

NTC

USB

WALL

ADAPTER

HIGH VOLTAGE INPUT

7.5V TO 30V

TRANSIENT

TO 60V

SYSTEM

LOAD

M1

(OPTIONAL)

L1 = TDK, VLCF5020T-4R7NIR7-1

L2 = COILCRAFT, LPS4018-332MLC

M1 = VISHAY, Si 2333DS

D1 = DIODES INC., DFLS240

SEE THE LTC4098 DATASHEET FOR MORE INFORMATION

ON CONFIGURING THE NTC BATTERY TEMPERATURE

QUALIFICATION OR REDUCED IDEAL DIODE IMPEDANCE.

SINGLE-CELL

Li-Ion

C5

0.1µF

L2

3.3µH

L1

4.7µH

LTC4098

GND

SW

V

OUT

BATSENS

PROGCLPROG

WALLV

C

LT3653

HVOKGNDV

C

I

LIM

R3

1k

R2

3.01k

R4

6.04k

R1

27.4k

C4

10µF

6.3V

D1

TO µC

TO µC

C1

4.7µF

50V

C2

22µF

6.3V

C3

0.1µF

10V

V

IN

V

OUT

I

SENSE

SW

BOOST

OV

GATE

BAT

IDGATE

1.2A Monolithic Buck Regulator

Shrinks Supply Size and Cost with

Programmable Output Current Limit

Introduction

Power supplies are often overqualified

for their job. This is because power

ICs often specify a current limit that

is more than twice the rated output

current of the device. The power supply

components are sized to handle the

maximum current that the IC can deliver, even if loads are unlikely to draw

that current during normal operation.

The components are bigger and more

expensive than they need to be.

set an accurate maximum output cur-

rent on the supply once the real world

load is known. Accurately setting the

maximum output current reduces the

required current rating of the regulator’s power path components, thus

replacing big, expensive components

with smaller, less expensive ones.

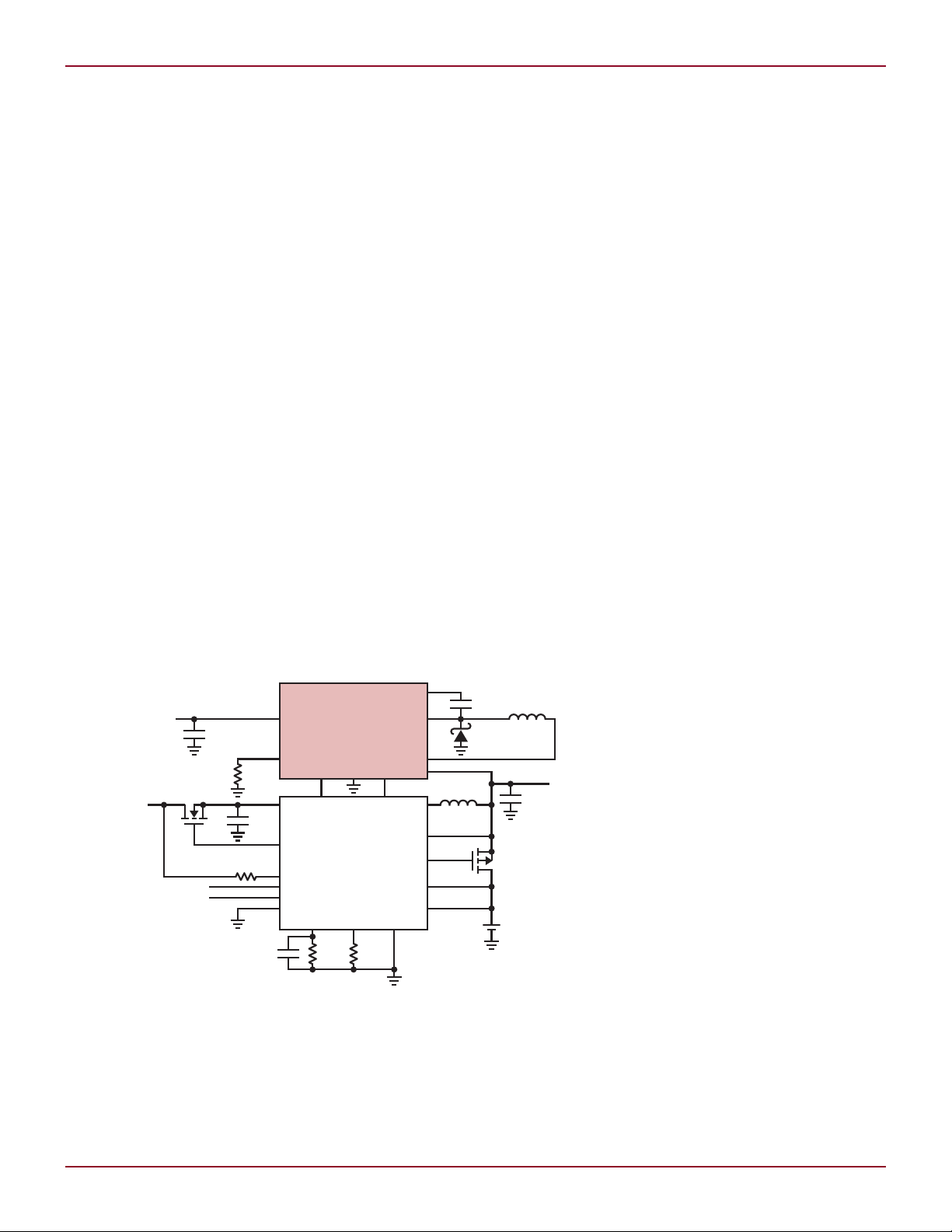

A limit on the regulator’s maximum

Figure 1. Charging a single cell Li-ion battery from either a USB input or high voltage input. This

solution offers a seamless, highly efficient, low part count approach to dual input charging and

PowerPath™ control of a Li-ion battery-powered application. If additional integration is required

for more system supplies, the LT3653 can be used in a similar fashion with the LTC3576 PMIC.

20

There is, however, an alternative:

output limits the maximum power

dissipation of both the supply and

the load, thus reducing the potential

for localized heating. Monitoring and

controlling the output current also

makes for a robust solution, which is

able to withstand harsh overload and

short circuit conditions.

The LT3653 and LT3663 are monolithic step-down switching regulators

that have an accurate output current

limit programmable from 400mA to

1.2A. The LT3663 is a general purpose high voltage step-down regulator

while the LT3653 is designed for use

with Linear Technology Bat-Track™

enabled battery chargers and power

management ICs (PMICs). The maximum input voltages of 30V (LT3653)

or 36V (LT3663) with 60V transient

ride through capability are well suited

by Tom Sheehan

to automotive, industrial, distributed

supply, and wall transformer applications.

Programmable

Output Current Limit

Monolithic switching regulators typically limit the peak switch current to

protect the internal switch from being

damaged during an overload or short

circuit event. The maximum switch

peak current limit is typically more

than two times the maximum output

current rating of the part. While the

peak switch current limit prevents

overstressing the IC, it does not keep

the entire application from overheating during an overload condition. For

example, a regulator with an output

current rating of 1A is typically capable

of providing over 2A at the output.

During an output overload condition,

the power dissipation of the regulator could more than double, making

thermal management more difficult.

The LT3653 and LT3663 reduce localized hot spots by controlling the total

power dissipation of the application

with a programmable, accurate current limit.

Conservative design principles call

for power path components that are

rated for worst-case currents. In the

above example, where a 1A part is

capable of delivering 2A, the power

path components must be sized for

greater than 2A, because during an

output short circuit or overload the

inductor and diode can conduct up

to 2A. In contrast, the PowerPath

components in LT3653 and LT3663

applications are sized based on the

programmed maximum output current limit. Therefore, an application

with a 750mA output current limit

requires only 750mA rated components. This allows for smaller, lower

Linear Technology Magazine • March 2009

DESIGN FEATURES L

LT3663

V

IN

V

IN

RUN

I

LIM

BOOST

SW

GND

0.1µF

2.2µF

22µF59k28.7k

11k

6.8µH

DIODES,

INC.

DFLS240

I

SENSE

V

OUT

V

OUT

FB

ON OFF

OUTPUT CURRENT (A)

OUTPUT VOLTAGE (V)

6

5

4

0

1

2

3

0 0.2 0.4 0.6 0.8 1 1.41.2

R

ILIM

= 28.7k

cost devices and a smaller overall

application footprint.

In early product development,

system designers usually don’t know

how much current their load will draw.

Once they choose a power supply, they

are committed. However, with the programmable current limit of the LT3653

and LT3663, once the load has been

fully characterized, they can change

the output current limit by changing

an inexpensive 1% resistor.

The output current limit is implemented by monitoring and controlling

the average inductor current. When an

overcurrent event occurs, the regulator

disables the power switch. This robust

solution withstands short circuit and

overload conditions throughout the

entire input voltage range.

The LT3653 Plays Well with

Bat-Track Battery Chargers

The LT3653 is a 1.5MHz constant

frequency, current mode control,

step-down regulator designed for use

with Linear Technology’s Bat-Track-

enabled battery charger PowerPath

power managers. The LT3653 steps

down a high voltage input to power the

system load and charge a single-cell

Li-ion battery charger.

Minimizing the voltage across

a linear battery charger increases

efficiency. To accomplish this, a BatTrack battery charger controls the

LT3653’s VC Pin, overriding the error

amplifier. In this way, the output voltage of the LT3653 is regulated by the

battery charger to a potential slightly

above the battery voltage, typically

300mV.

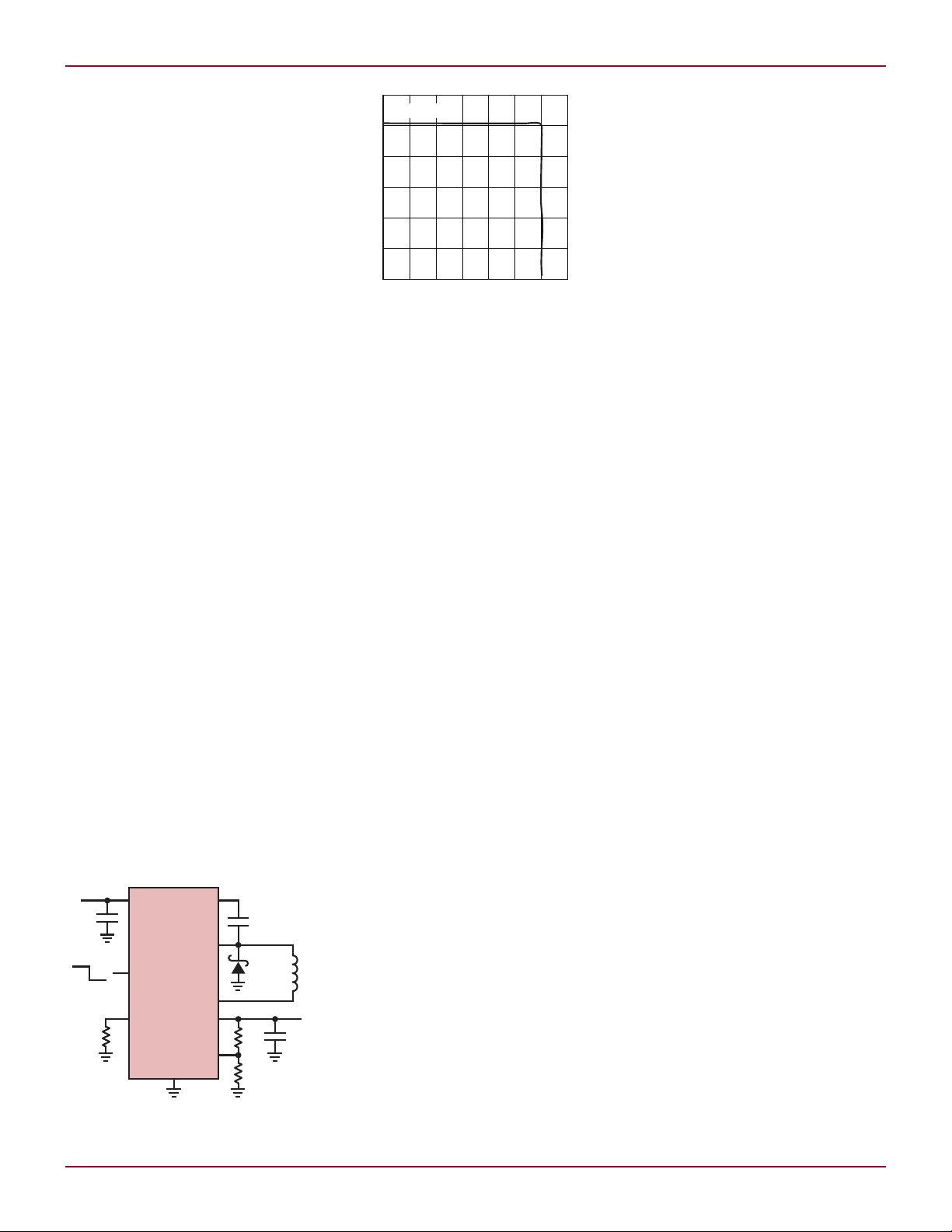

Figure 3. A LT3663 application producing

5V at 1.2A from an input of 7.5V to 36V. The

input is capable of handling 60V transients.

Linear Technology Magazine • March 2009

LT3653 programmed current limit, the

regulator’s output voltage decreases to

reduce charge current as the battery

charger enters dropout. If the system

load continues to increase, the battery

charge current first decreases to zero

and then reverses direction to deliver

power to the system load, supplementing the LT3653. The transitions

between these modes of operation are

seamless to the system load. The output current from the LT3653 regulator

Figure 2. The LT3663 output

current limit at 1.2A

Input overvoltage protection allows

the LT3653 to handle 60V input transients. The HVOK pin indicates that

the internal bias supplies are present

and no faults have occurred (i.e., overtemperature and input overvoltage

and undervoltage). The LT3653 includes internal compensation, and

an internal boost diode to minimize

the number of external components.

The LT3653 is available in an 8-lead

2mm × 3mm DFN package with an

exposed pad.

never exceeds the programmed output

current limit.

The LT3663 Directly

Accepts 36V Inputs

The LT3663 is a 1.5MHz constant

frequency, current mode control,

general purpose, monolithic switching regulator suited for automotive

batteries, industrial power supplies, distributed supplies, and wall

transformers. The LT3663 includes

a low current shutdown mode, input

overvoltage and undervoltage lockout,

and thermal shutdown. The LT3663 is

available in 8-lead (2mm × 3mm) DFN

package with exposed pad. An 8-lead

Charging a Single Cell Li-Ion

Battery from Either a USB

or High Voltage Input

Figure 1 shows a LT3653 and LTC4098

application charging a single cell Liion battery from either a USB input

or high voltage input. This solution

offers a seamless, highly efficient, low

part count approach to dual input

charging and power path control of a

Li-ion battery-powered application. If

additional integration is required for

more system supplies, the LT3653 can

be used in a similar fashion with the

LTC3576 PMIC.

When a high voltage input is applied, the LT3653 HVOK pin signals

the LTC4098 that it is capable of

delivering power. The LTC4098 takes

control of the LT3653’s VC pin and

MSOP package with exposed pad will

be available soon.

The LT3663 can also function as

a constant current, constant voltage

(CC/CV) source to charge a supercapacitor or other energy storage device.

The IC operates in constant current

mode at the programmed current

limit until the capacitor reaches the

programmed output voltage. It then

operates in a constant voltage mode

to maintain that voltage.

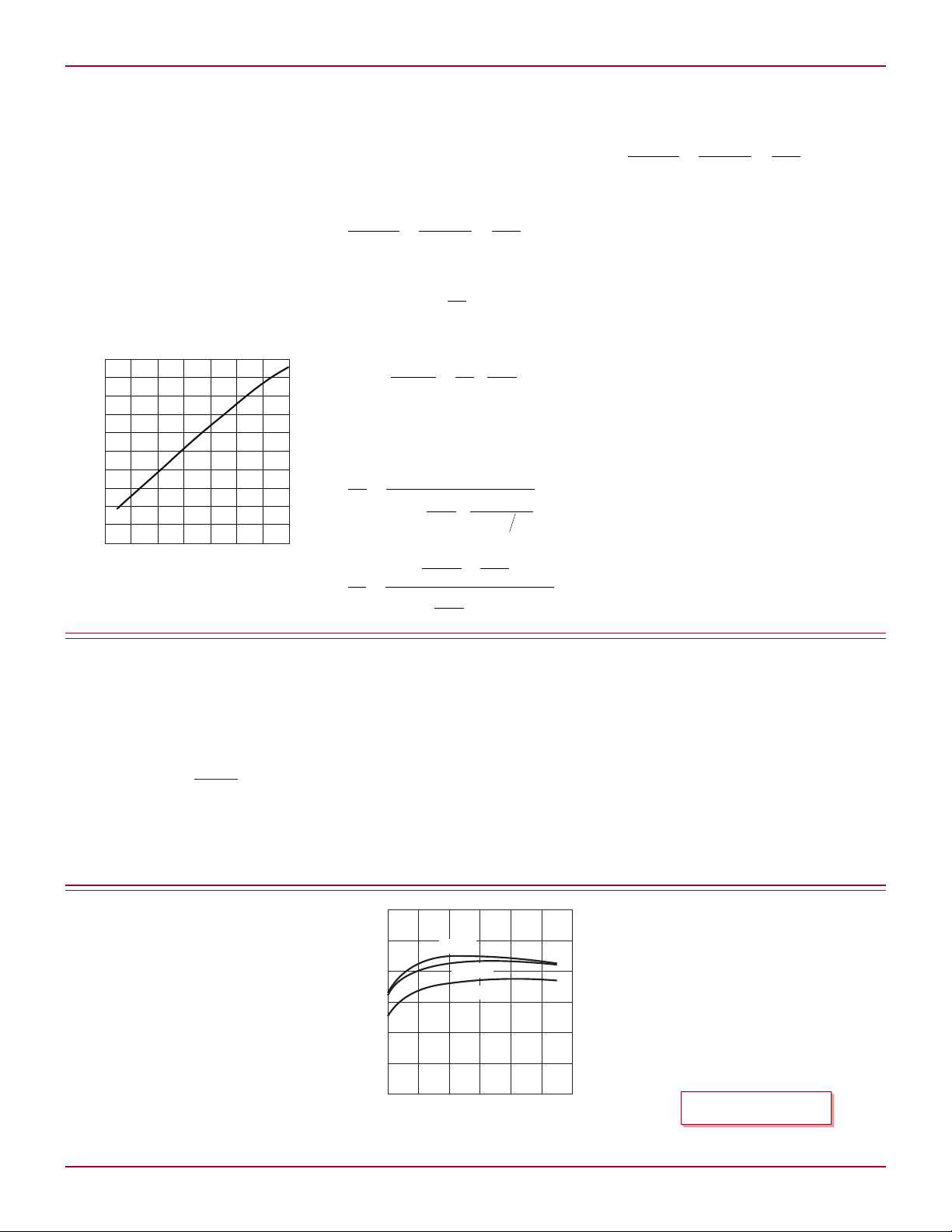

Figure 2 shows the LT3663 output current limit at 1.2A. For output

currents below 1.2A the regulator is

in constant voltage mode. When the

output current is increased to 1.2A it

goes into constant current mode. The

output current is maintained at 1.2A

from V

nominal down to 0V.

OUT

regulates the output voltage to just

above the battery voltage. This BatTrack function optimizes the battery

charger efficiency.

When present, the high voltage

input supplies the battery charge current and the system load current. If

the total current increases beyond the

7.5V–36V to 5V Buck

Regulator with 1.2A

Output Current Limit

Figure 3 shows a LT3663 application

producing 5V at 1.2A from an input

of 7.5V to 36V. The input is capable

continued on page 29

21

DESIGN FEATURES L

V V V

BE Q BE Q BE( ) ( )1 2

= =

dV

dT

dV

dT

mV

C

BE Q BE Q( ) ( )1 2

2

= =

°

V V

R

R

V

CTRL REF BE

= −

8

7

PTC

dV

dT

RRmV

C

CTRL

= = •

872

°

R

R

V

V

mV

CVdV dT

REF

BE

OUT

OUT

8

7

2

=

+ •

°

R

R

V

dV

dT

mV

C

V

mV

C

V

BE

OUT

OUT

REF

1

2

2

2

1=

• + •

•

°

°

−

dV

dT

dV

dT

mV

C

BE Q BE Q( ) ( )1 2

2

= =

°

TEMPERATURE (°C)

–50

V

APD

(V)

60

42

58

54

50

46

56

52

48

44

40

7525 125500 100–25

OUTPUT CURRENT (A)

0.1

EFFICIENCY (%)

100

90

80

70

60

50

40

0.5 0.90.3 0.7 1.1 1.3

VIN = 15V

VIN = 8V

VIN = 30V

Authors can be contacted

at (408) 432-1900

and expensive solution than typical

microprocessor-controlled methods.

The simplest scheme uses a resistor

divider from the V

pin to the CTRL

REF

pin, where the top resistor in the divider is an NTC (negative temperature

coefficient) resistor. While simple,

this method suffers from nonlinear

temperature coefficient of the NTC

resistor. A more precise method uses

a transistor network as shown in Figure 7. The PTC (Positive Temperature

Coefficient) of the CTRL pin voltage is

Figure 8. Temperature response

of the circuit shown in Figure 7

realized by an emitter follower of Q1

and a VBE multiplier of Q2.

Assuming:

and

then the CTRL pin voltage is

with

Given V

at room and dV

OUT

OUT

/DT,

the R1/R2 and R8/R7 can be calculated as follows

Resistors R5–R9 are selected to make

I(Q1) = I(Q2) ≈ 10µA, and

Simulation using LTspice always

gives a good starting point. The circuit

shown in Figure 7 is designed to have

V

= 50V (V

APD

dV

/dT = 100mV/°C (dV

APD

= 55V) at room and

OUT

OUT

/dT =

100mV/°C). The measured temperature response is shown in Figure 8,

which is very close to the design

target.

Conclusion

The LT3571 is a highly integrated,

compact solution to APD bias supply

design. It provides a useful feature set

and the flexibility to meet a variety of

challenging requirements, such as low

noise, fast transient response speed,

and temperature compensation. With

a high level of integration and superior performance, the LT3571 is the

natural choice for APD bias supply

design.

L

LT8410, continued from page 23

out of shutdown, the V

discharged for 70µs with a strong pull

down current, and then charged with

10µA to 1.235V. This achieves soft

start since the output is proportional

to V

. Full soft-start cycles occur

REF

even with short SHDN low pulses

since V

part is enabled.

In addition, the LT8410/-1 features

a 2.5V to 16V input voltage range, up

LT3653/63, continued from page 21

of handling 60V transients. Figure 4

shows the circuit efficiency at multiple

input voltages.

The current limit of the application

is set to 1.2A, therefore, the power path

components are sized to handle 1.2A

maximum. To reduce the application

footprint, the LT3663 includes internal

compensation and a boost diode. The

RUN pin, when low, puts the LT3663

into a low current shutdown mode.

Linear Technology Magazine • March 2009

pin is first

REF

is discharged when the

REF

to 40V output voltage and overvoltage

protection for CAP and V

OUT

.

Conclusion

The LT8410/-1 is a smart choice

for applications which require low

quiescent current and low input current. The ultralow quiescent current,

combined with high value integrated

feedback resistors, keeps the average

input current very low, significantly

Figure 4. Efficiency of the circuit in Figure 3

extending battery operating time.

Low current limit internal switches

(8mA for the LT8410-1, 25mA for the

LT8410) make the part ideal for high

impedance sources such as coin cell

batteries. The LT8410/-1 is packed

with features without compromising

performance or ease of use and is

available in a tiny 8-pin 2mm × 2mm

package.

L

Conclusion

The accurate programmable output

current limit of the LT3653 and

LT3663 eliminates localized heating

from an output overload, reduces the

maximum current requirements on the

power components, and makes for a

robust power supply solutions.

L

29

Loading...

Loading...