Page 1

DESIGN FEATURES L

SW

V

IN

V

IN

7.5V TO 32V

(40 MAX)

CLP

RNG/SS

BOOST

SENSE

BAT

NTC

TIMER

CMPSH1-4

CMSH3-40MA

1µF

10µF

6.8µH

0.05Ω

10µF

LT3650-4.2

Li-Ion

CELL

+

SHDN

CHRG

FAULT

GND

Charge Li-Ion Batteries Directly

from High Voltage Automotive and

Industrial Supplies Using Standalone

Charger in a 3mm × 3mm DFN

Introduction

Growth of the portable electronics

market is in no small part due to the

continued evolution of battery capacities. For many portable devices,

rechargeable Li-Ion batteries are the

power source of choice because of their

high energy density, light weight, low

internal resistance, and fast charge

times. Charging these batteries safely

and efficiently, however, requires

a relatively sophisticated charging

system.

One additional problem faced by

battery charger designers is how to deal

with relatively high voltage sources,

such as those found in industrial

and automotive applications. In these

environments, system supply voltages exceed the input ranges of most

charger ICs, so a DC/DC step-down

converter is required to provide a local

low voltage supply for the charger IC.

The LT3650 standalone monolithic

switching battery charger does not

need this additional DC/DC converter.

It directly accepts input voltages up to

40V and provides charge currents as

high as 2A. It also includes a wealth

of advanced features that assure safe

battery charging and expand its applicability.

The LT3650 includes features that

minimize the overall solution size,

requiring only a few external components to complete a charger circuit. A

fast 1MHz switching frequency allows

the use of small inductors, and the IC

is housed inside a tiny 3mm × 3mm

DFN12-pin package. The IC has builtin reverse current protection, which

blocks current flow from the battery

back to the input supply if that supply

is disabled or discharged to ground,

so a single-cell LT3650 charger does

not require an external blocking diode

on the input supply.

A Charger Designed for

Lithium-Ion Batteries

A Li-Ion battery requires constantcurrent/constant-voltage (CC/CV)

charging system. A Li-Ion battery

is initially charged with a constant

current, generally between 0.5C and

1C, where C is the battery capacity

in ampere-hours. As it is charged,

the battery voltage increases until

it approaches the full-charge float

voltage. The charger then transitions

into constant voltage operation as

the charge current is slowly reduced.

The LT3650-4.1 and LT3650-4.2 are

designed to charge single-cell Li-Ion

by Jay Celani

batteries to float voltages of 4.1V and

4.2V, respectively. The LT3650-8.2

and LT3650-8.4 are designed to charge

2-cell battery stacks to float voltages

of 8.2V and 8.4V.

Once the charge current falls below

one tenth of the maximum constant

charge current, or 0.1C, the battery

is considered charged and the charging cycle is terminated. The charger

must be completely disabled after

terminating charging, since indefinite

trickle charging of Li-Ion cells, even at

miniscule currents, can cause battery

damage and compromise battery stability. A charger can top-off a battery

by continuing to operate as the current falls lower than the 0.1C charge

current threshold to make full use of

battery capacity, but in such cases a

backup timer is used to disable the

charger after a controlled period of

time. Most Li-Ion batteries charge fully

in three hours.

The LT3650 addresses all of the

charging requirements for a Li-Ion

battery. The IC provides a CC/CV

charging characteristic, transitioning

automatically as the requirements of

the battery change during a charging

cycle. During constant-current operation, the maximum charge current

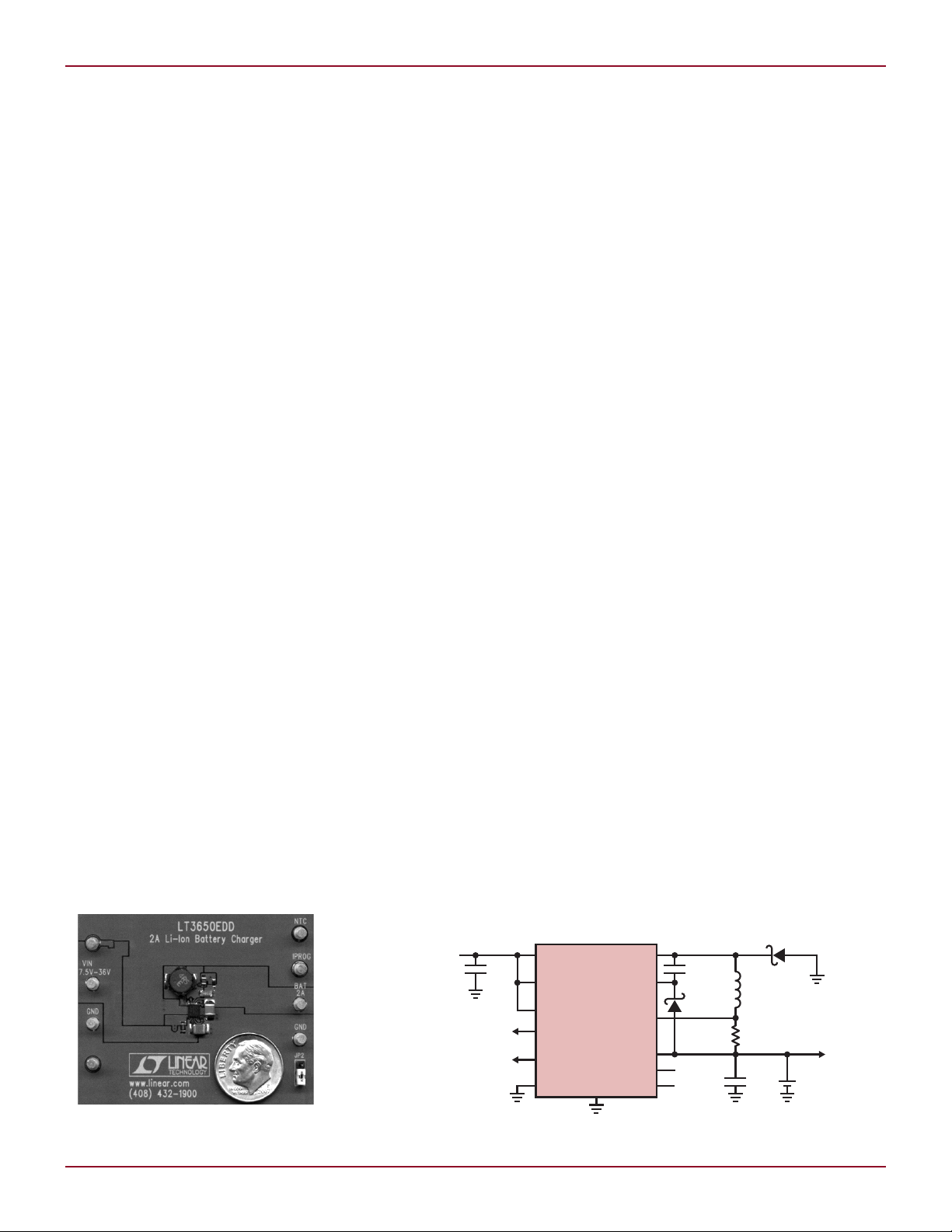

Figure 1. An LT3650 standalone battery

charger is small and efficient.

Linear Technology Magazine • June 2009

Figure 2. A single-cell 2A Li-Ion battery charger configured for C/10 charge termination

5

Page 2

L DESIGN FEATURES

I

BAT

(A)

0

EFFICIENCY (%)

80

90

100

70

60

0.5

1

1.5

2

VIN = 12V

VIN = 20V

V

BAT

(V)

CHARGE CURRENT (A)

1.0

1.2

1.4

1.6

1.8

2.0

0.6

0.8

0

0.2

0.4

3.0 3.22.6 2.8

3.4

3.8 4.0 4.23.6

FAULT

CHG

V

IN

10k

10k

LT3650

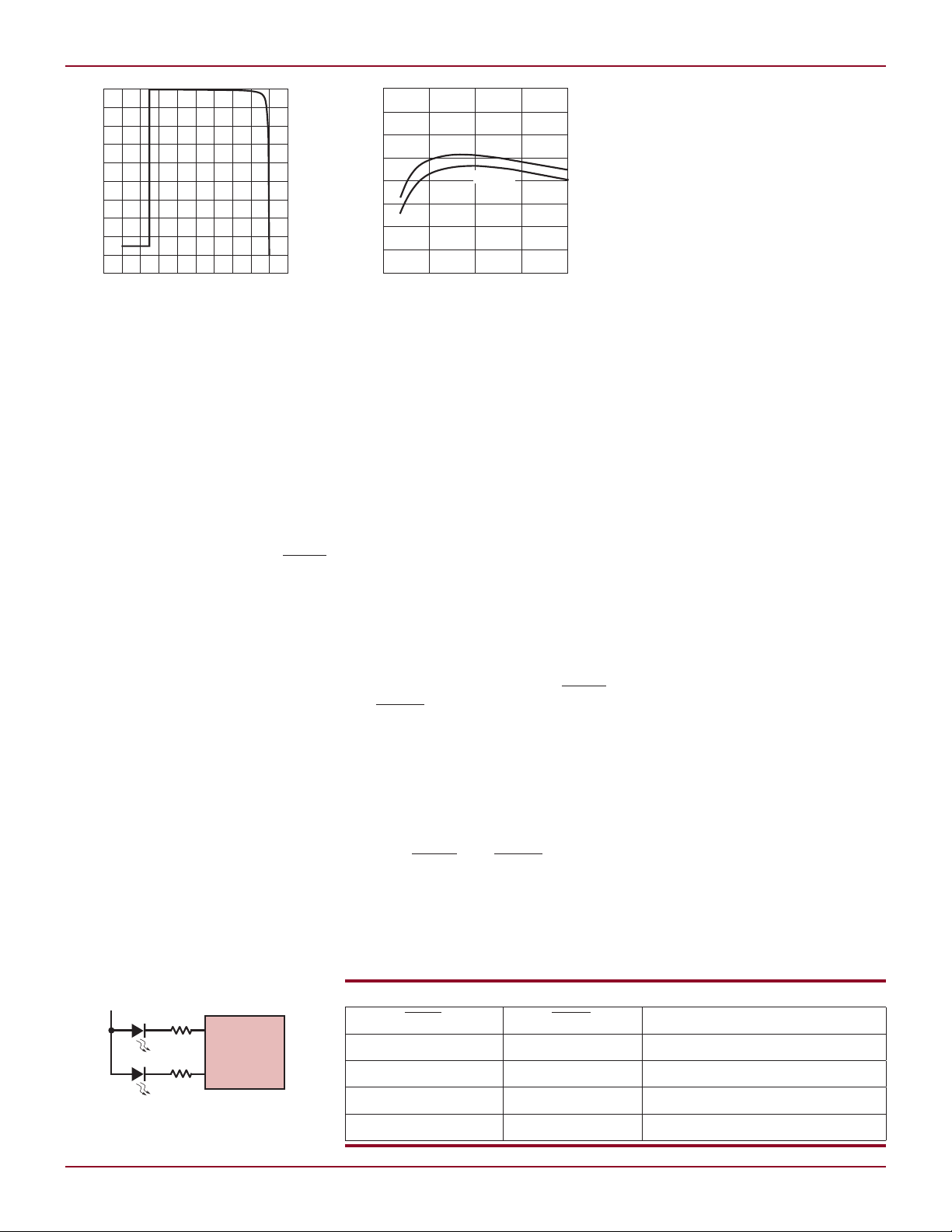

Figure 3. Battery charge current vs BAT pin

voltage for the charger shown in Figure 2

provided to the battery is programmable via a sense resistor, up to a

maximum of 2A. Maximum charge

current can also be adjusted using the

RNG/SS pin. The charger transitions

to constant-voltage mode operation as

the battery approaches the full-charge

float voltage. Power is transferred

through an internal NPN switch element, driven by a boosted drive to

maximize efficiency. A precision SHDN

pin threshold allows incorporation

of accurate UVLO functions using a

simple resistor divider.

Charge Cycle Termination

and Automatic Restart

A LT3650 charger can be configured

to terminate a battery charge cycle

using one of two methods: it can use

low charge current (C/10) detection,

enabled by connecting the TIMER

pin to ground, or terminate based on

the onboard safety timer, enabled by

connecting a capacitor to the TIMER

pin. After termination, a new charge

cycle automatically restarts should

the battery voltage fall to 97.5% of the

float voltage.

is selected, the LT3650 terminates

a charging cycle when the output

current has dropped to 1/10 of the

6

When C/10 termination mode

Figure 5. Visual charger status is

easily implemented using LEDs

A Basic Charger

Figure 2 shows a basic 2A single-cell

Li-Ion battery charger that operates

from a 7.5V to 32V input. Charging is

suspended if the input supply voltage

exceeds 32V, but the IC can withstand

input voltages as high as 40V without

damage. The 2A maximum charge

current corresponds to 100mV across

the 0.05

basic design does not take advantage

of the status pins, battery temperature

Figure 4. Power conversion efficiency vs

charger output current (I

charger shown in Figure 2

) for the battery

BAT

programmed maximum. In a 2A

charger, for example, the charge cycle

terminates when the battery charge

current falls to 200mA.

monitoring, or a safety timer features.

The battery charging cycle terminates

when the battery voltage approaches

4.2V and the charge current falls to

200mA. A new charge cycle is automatically initiated when the battery

voltage falls to 4.1V.

Timer termination, or top-off

charging, is enabled when a capacitor is connected to the TIMER pin.

The value of the capacitor sets the

safety timer duration—0.68µF corresponds to a 3-hour cycle time. When

timer termination is implemented,

the charger continues to operate in

constant-voltage mode when charge

currents fall below C/10, allowing additional low current charging to occur

until the timer cycle has elapsed, thus

maximizing use of the battery capacity.

During top-off charging, the CHRG

and FAULT status pins communicate

“charge complete.” At the end of the

timer cycle, the LT3650 terminates

the charging cycle.

After charge cycle termination, the

LT3650 enters standby mode where

the IC draws 85µA from the input sup

ply and less than 1µA from the battery.

Both the CHRG and FAULT pins are

high impedance during standby mode.

Should the battery voltage drop to

97.5% of the float voltage, the LT3650

automatically restarts and initializes

a new charging cycle.

Table 1. Status pin state and corresponding operating states

CHRG FAULT Charger Status

High Impedance High Impedance Standby/Shutdown/Top-off

Low High Impedance CV/CC Charging (>C/10)

High Impedance Low Bad Battery Detected

Low Low Temperature Fault

Safety Features:

Preconditioning,

Bad Battery Detection,

and Temperature Monitor

Li-Ion batteries can sustain irreversible damage when deeply discharged,

so care must be taken when charging

such a battery. A gentle preconditioning charge current is recommended to

activate any safety circuitry in a battery

pack and to re-energize deeply discharged cells, followed by a full charge

cycle. If a battery has sustained damage from excessive discharge, however,

the battery should not be recharged.

Deeply discharged cells can form

copper shunts that create resistive

shorts, and charging such a damaged

battery could cause an unsafe condi-

-

tion due to excessive heat generation.

Should a deeply discharged battery be

encountered, a battery charger must

be intelligent enough to determine

whether or not the battery has sustained deep-discharge damage, and

avoid initiating a full charge cycle on

such a damaged battery.

Ω external sense resistor. This

Linear Technology Magazine • June 2009

Page 3

DESIGN FEATURES L

CLP

SYSTEM LOAD

INPUT SUPPLY

V

IN

R

CLP

LT3650

SW

V

IN

CLP

RUN/SS

BOOST

SENSE

BAT

NTC

TIMER

1N914

CMSH3-40MA

SYSTEM LOAD

1µF

6.8µH

0.057

LT3650-X

GND

10µF

Li-Ion

CELL

10k

INPUT SUPPLY

12V TO 32V

(40V MAX)

BZX384-C9V1

(9.1V)

10µF

10µF

0.05Ω

SHDN

CHRG

FAULT

10k

36k

3k

10k

0.68µF

+

0.1µF

The LT3650 employs an automatic

precondition mode, which gracefully

initiates a charging cycle into a deeply

discharged battery. If the battery voltage is below the precondition threshold

of 70% of the float voltage, the maximum charge current is reduced to 15%

of the programmed maximum (0.15C)

until the battery voltage rises past the

precondition threshold.

If the battery does not respond

to the precondition current and the

battery voltage does not rise past the

temperature, and suspends charging

should the temperature fall outside of

the safe charging range.

precondition threshold, a full-current

charge cycle does not initiate.

If the safety timer is used for ter mination, the LT3650 also enables

deep-discharge damage detection

and incorporates a “bad battery”

detection fault. Should the battery

voltage remain below the precondition threshold for 1/8 of the charge

cycle time (typically 22.5 minutes), the

charger suspends the charging cycle

and signals a “bad battery” fault on

the status pins. The LT3650 main

tains this fault state indefinitely, but

automatically resets itself and starts

a new charging cycle if the damaged

battery is removed and another battery

is connected.

Li-Ion batteries have a relatively

narrow temperature range where they

can be safely charged. The LT3650

has a provision for monitoring battery

Figure 7. A single cell Li-Ion 2A battery charger with 3 hour safety timer termination, LED status

indicators, temperature sensing, low input voltage charge current foldback, and input supply

current limit

Linear Technology Magazine • June 2009

is enabled by connecting a 10k (B =

3380) NTC thermistor from the IC’s

NTC pin to ground. This thermistor

must be in close proximity to the battery, and is generally housed in the

battery case. This function suspends a

charging cycle if the temperature of the

thermistor is greater than 40°C or less

than 0°C. Hysteresis corresponding to

5°C on both thresholds prevents mode

glitching. Both the CHRG and FAULT

-

status output pins are pulled low during a temperature fault, signaling that

the charging cycle is suspended. If the

safety timer is used for termination,

the timer is paused for the duration

of a temperature fault, so a battery

receives a full-duration charging cycle,

even if that cycle is interrupted by

the battery being out of the allowed

temperature range.

Figure 6. R

supply current limit

Under/overtemperature protection

sets the input

CLP

Status Indicator Pins

The status of a LT3650 charger is communicated via the state of two pins:

CHRG and FAULT. These status pins

are open-collector pull-down, reporting the operational and fault status of

the battery charger. CC/CV charging

is indicated while charge currents are

greater than 1/10 the programmed

maximum charge current. The status

pins also communicate bad battery

and battery temperature fault states.

Table 1 shows a fault-state matrix for

these two pins.

The status outputs can be used as

digital status signals in processorcontrolled systems, and/or connected

to pull current through an LED for

visual status display. The status pins

can sink currents up to 10mA and can

handle voltages as high as 40V, so a

visual display can be implemented by

simply connecting an LED and series

resistor to VIN.

Maximum Charging Current

Programming and Adjustment

Maximum charge current is set using an external sense resistor placed

between the BAT and SENSE pins of

the LT3650. Maximum charge current

corresponds to 100mV across this resistor. The LT3650 supports maximum

charge currents up to 2A, corresponding to a 0.05

The LT3650 includes two control

pins that allow reduction of the programmed maximum charge current.

The RNG/SS pin voltage directly affects the maximum charge current

such that the maximum voltage allowed across the sense resistor is 1/10

the voltage on RNG/SS for RNG/SS

< 1V. This pin sources a constant

50µA, so the voltage on the pin can

be programmed by simply connecting

a resistor from the pin to ground. A

capacitor tied to this pin generates a

voltage ramp at start-up, creating a

soft-start function. The pin voltage can

be forced externally for direct control

over charge current.

The IC includes a PowerPath™

control feature, activated via the CLP

pin, which acts to reduce battery

charge current should the load on a

Ω sense resistor.

continued on page 38

7

Page 4

L NEW DEVICE CAMEOS

CURRENT (A)

0.5

0.6

0.7

0.8

0.9

1.0

0.3

0.4

0

0.1

0.2

0.5

0.6

0.7

0.8 0.9

1.0

0.3

0.4

0

0.1

0.2

INPUT

SUPPLY

CURRENT

VIN = 24V

CHARGER

INPUT

CURRENT

SYSTEM LOAD CURRENT (A)

VIN (V)

I

OUT(MAX)

(A)

I

IN

(A)

1.0

1.2

1.4

1.6

1.8

2.0

0.6

0.8

0

0.2

0.4

0.25

0.30

0.35

0.40

0.45

0.50

0.15

0.20

0

0.05

0.10

16 181210 32 4014

20

24 26 3022

I

OUT(MAX)

I

INPUT

The LT5581’s RMS measurement capability provides accurate RF power

readings to within ±0.2dB regardless

of waveforms that have high crest-factor modulated content, multicarrier

or multitone. Moreover, the LT5581

offers exceptional accuracy of ±1dB

over its operating temperature range

of –40°C to 85°C.

Operating over a wide supply voltage

range of 2.7V to 5.25V, the LT5581’s

low power consumption makes it ideal

for battery-powered communication

LT3650, continued from page 7

monitored input supply become excessive. The CLP pin can be configured

to implement an input current limit

function for systems having multiple

loads that share the LT3650 V

sup-

IN

ply. The LT3650 reduces maximum

battery charge current if the voltage

on the CLP pin exceeds the voltage on

VIN by 50mV. Total load current on the

input power supply can be monitored

by connecting a sense resistor from the

CLP pin to VIN, and connecting any external loads to the VIN pin. The LT3650

servos the charger maximum output

current such that 50mV is maintained

across the CLP sense resistor.

A Full Complement of

Battery Charger Features

Figure 7 shows a battery charger that

incorporates many of the LT3650’s

unique features. This charger incor-

and multimedia devices. Yet, it has

the accuracy performance to meet the

performance required by basestations,

picocells and femtocells, cable infrastructure and optical communication

systems. Additionally, the LT5581’s

wide frequency range extends to

applications including WiMAX and

wireless systems in the 5GHz ISM

bands. The LT5581’s single-ended RF

input does not require an external RF

transformer, thus simplifying the application design while reducing costs.

porates top off charging with a 3-hour

backup safety timer, and directly

accepts input voltages from 12V to

40V (32V operating maximum). This

charger uses a 9.1V Zener diode to

level-shift the input supply, incorporating an undervoltage lockout

function for VIN < 10V.

Battery pack temperature-sensing is enabled by connecting an NTC

thermistor to the NTC pin. Charging is

suspended if the battery temperature

does not remain within a 0°C to 40°C

range. The charger uses a resistor

divider to modulate the voltage on

RNG/SS, which reduces the maximum

battery charge current if VIN is below

20V, useful for current-limited input

sources such as wall adapters. A capacitor on the RNG/SS pin enables

a soft-start function. A secondary

system load is supported, with the

input supply protected by an input

The LT5581 has a fast response time

of 1µs rise time to a full power swing,

suitable for time-division duplexing

systems.

The LT5581 also incorporates a

shutdown feature. When the LT5581’s

Enable input pin is pulled low, the chip

draws a typical shutdown current of

0.2µA, and a maximum of 6µA. The

device is offered in a tiny 8-lead, 3mm

× 2mm DFN surface mount package.

L

current limit feature, incorporated

by connecting the input supply to the

CLP pin via a 0.05

Ω sense resistor. The

maximum charge current is automatically reduced to keep the total input

supply current from exceeding the 1A

limit set by the sense resistor.

Conclusion

The LT3650 provides a versatile and

easy-to-use platform for a wide variety

of efficient Li-Ion battery charger solutions. Low power dissipation makes

continuous charging up to 2A practical, deriving power directly from input

supplies up to 32V without the need

for an intermediate DC/DC converter.

The compact size of the IC coupled with

modest external component requirements allows construction of space

saving, cost-effective, and feature-rich

Li-Ion battery chargers.

L

Figure 8. Charger maximum input current (IIN) and maximum output

current (I

7. Charge current reduction for V

supply current below 0.5A

38

38

OUT(MAX)

) vs VIN for the battery charger shown in Figure

< 20V keeps the charger input

IN

Figure 9. Charger maximum input current, system load current, and total

input supply current for the battery charger shown in Figure 7 for V

24V. Battery charger output current is reduced to maintain a maximum

input supply current of 1A, which corresponds to 50mV across the 0.05Ω

resistor that is connected between the CLP and V

Linear Technology Magazine • June 2009

pins of the LT3650.

IN

IN

=

Loading...

Loading...