Page 1

LT3593

1MHz White LED Driver with

Output Disconnect and One

Pin Current Programming

FEATURES

n

Drives Up to Ten White LEDs from a 3V Supply

n

One Pin Shutdown and Current Programming

n

LEDs Disconnected in Shutdown

n

32:1 Linear Brightness Control Range

n

VIN Range: 2.7V to 5.5V

n

±5% Output Current Accuracy at Full Scale

n

Low Shutdown Current: 3µA

n

1MHz Switching Frequency

n

Requires Only 1µF Output Capacitor

n

Low Profi le 6-Lead DFN (2mm × 2mm × 0.75mm)

and 6-Lead SOT-23 Packages

APPLICATIONS

n

Cell Phones

n

Digital Cameras

n

PDAs, Handheld Computers

n

MP3 Players

n

GPS Receivers

DESCRIPTION

The LT®3593 is a step-up DC/DC converter designed to

drive up to ten white LEDs in series from a Li-Ion cell.

Series connection of the LEDs provides identical LED

currents and eliminates the need for ballast resistors. The

device features a unique high side LED current sense that

enables the part to function as a “one wire current source”

where the low side of the LED string can be returned to

ground anywhere.

Additional features include output disconnect in shutdown,

open LED protection and 1-pin shutdown/LED current

control. The CTRL pin is toggled to adjust the LED current

via an internal counter and a 5-bit DAC.

The LT3593 switches at 1MHz, allowing the use of tiny

external components. Constant frequency switching results in low input noise and a small output capacitor. The

LT3593 is available in the 6-lead DFN (2mm × 2mm) as

well as the 6-lead SOT-23 packages.

L, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

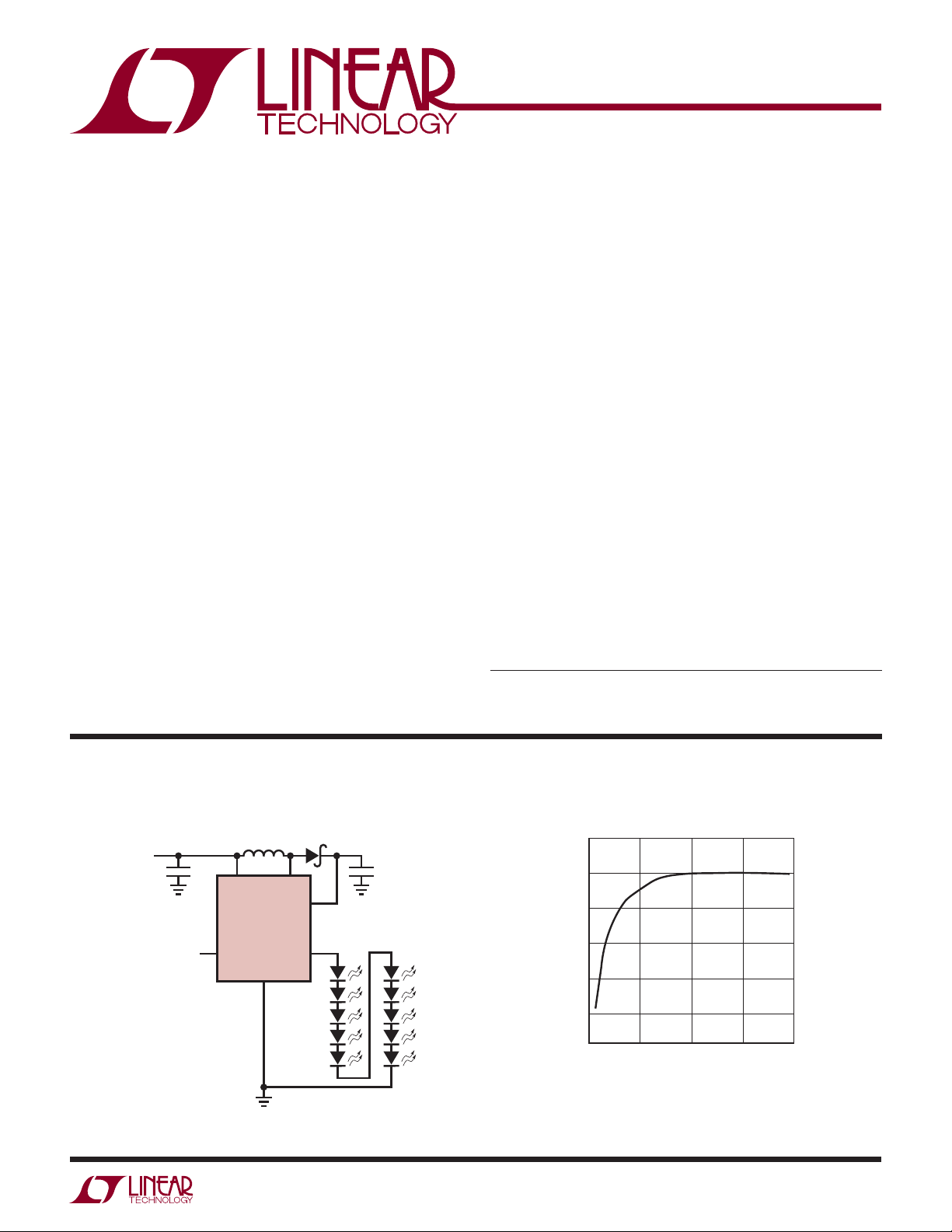

TYPICAL APPLICATION

Li-Ion Driver for Ten White LEDs

V

CTRL

IN

10µH

SW

CAP

LT3593

LED

GND

V

IN

3V TO 5V

SHUTDOWN AND

CURRENT CONTROL

1µF 1µF

3593 TA01a

Conversion Effi ciency

90

VIN = 3.6V

10 LEDs

80

70

60

EFFI CIENCY (%)

50

40

30

0

10

LED CURRENT (mA)

20155

3593 TA01b

3593f

1

Page 2

LT3593

ABSOLUTE MAXIMUM RATINGS

Input Voltage ...............................................................6V

CTRL Voltage ..............................................................6V

SW Voltage ...............................................................45V

CAP Voltage ..............................................................45V

LED Voltage ..............................................................45V

PIN CONFIGURATION

TOP VIEW

6

1

V

IN

GND

CTRL

6-LEAD (2mm × 2mm) PLASTIC DFN

T

EXPOSED PAD (PIN 7) IS GND, MUST BE SOLDERED TO PCB

7

2

3

DC PACKAGE

= 125°C, θJA = 106°C/W

JMAX

SW

5

CAP

LED

4

(Note 1)

Operating Junction Temperature Range

(Note 2) .................................................... –40°C to 85°C

Maximum Junction Temperature........................... 125°C

Storage Temperature Range ................... –65°C to 150°C

Lead Temperature (Soldering, 10 sec)

TSOT Package ................................................... 300°C

TOP VIEW

CTRL 1

GND 2

V

3

IN

S6 PACKAGE

6-LEAD PLASTIC TSOT-23

T

= 125°C, θJA = 192°C/W

JMAX

6 LED

5 CAP

4 SW

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3593EDC#PBF LT3593EDC#TRPBF LDBR

LT3593ES6#PBF LT3593ES6#TRPBF LTDBS 6-Lead Plastic TSOT-23 –40°C to 85°C

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

Consult LTC Marketing for information on non-standard lead based fi nish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifi cations, go to: http://www.linear.com/tapeandreel/

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at TA = 25°C. VIN = 3.6V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Operating Voltage Range 2.7 5.5 V

Supply Current Not Switching; During Current Programming 300 µA

CTRL = 0 3 10 µA

Switching Frequency 0.85 1 1.15 MHz

Maximum Duty Cycle 92 94 %

Switch Current Limit 550 700 mA

Switch V

CESAT

ISW = 250mA 250 mV

6-Lead (2mm × 2mm) Plastic DFN

= 3.6V, unless otherwise specifi ed.

CTRL

–40°C to 85°C

2

3593f

Page 3

LT3593

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

Switch Leakage Current V

– V

LED Pin Voltage Drop (V

LED Pin Leakage Current CTRL = 0, V

CTRL High Threshold 1.6 V

CTRL Low Threshold 0.4 V

CTRL t

PW

CTRL t

SD

CTRL t

EN

Full-Scale LED Current V

LED Current Programming Resolution Linear Increments 625 µA

LED Current Limit 45 mA

CTRL Pin Bias Current V

Overvoltage Protection

CAP

)I

LED

= 25°C. VIN = 3.6V, V

A

= 30V 1 µA

SW

= 20mA 250 mV

LED

= 35V 1 µA

CAP

Programming Pulse Width (Note 3) 250 ns

Time from CTRL = 0 to Shutdown 95 128 200 µs

Time from CTRL = 1 to Enable 95 128 200 µs

= 16V

CAP

V

= 16V

CAP

= 5.5V 1 µA

CTRL

= 3.6V, unless otherwise specifi ed.

CTRL

19

l

18.5

l

36 38 40 V

20

20

21

21.5

mA

mA

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LTC3593E is guaranteed to meet performance specifi cations

from 0°C to 85°C operating junction temperature range. Specifi cations

over the –40°C to 85°C operating junction temperature range are assured

by design, characterization and correlation with statistical process

controls.

Note 3: Guaranteed by design.

3593f

3

Page 4

LT3593

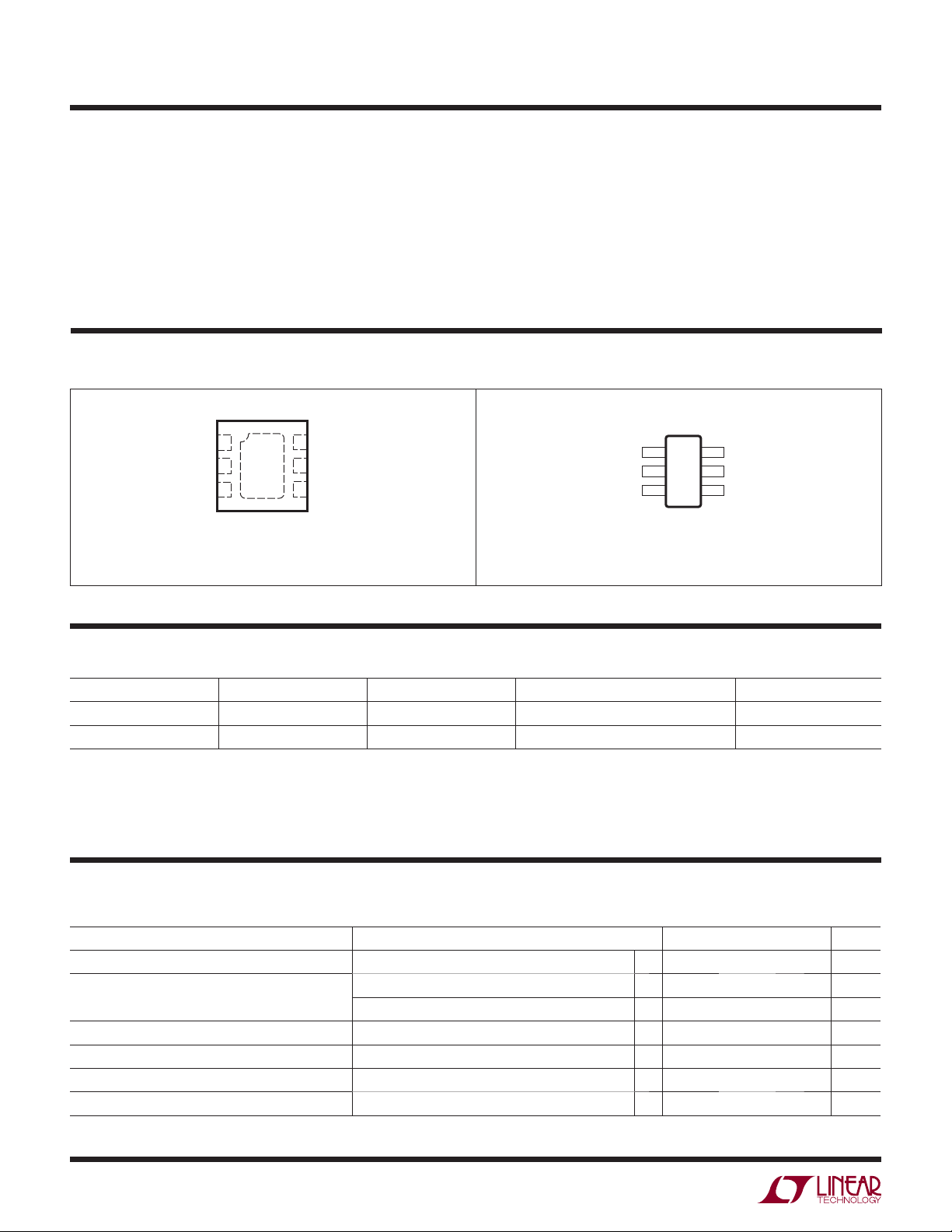

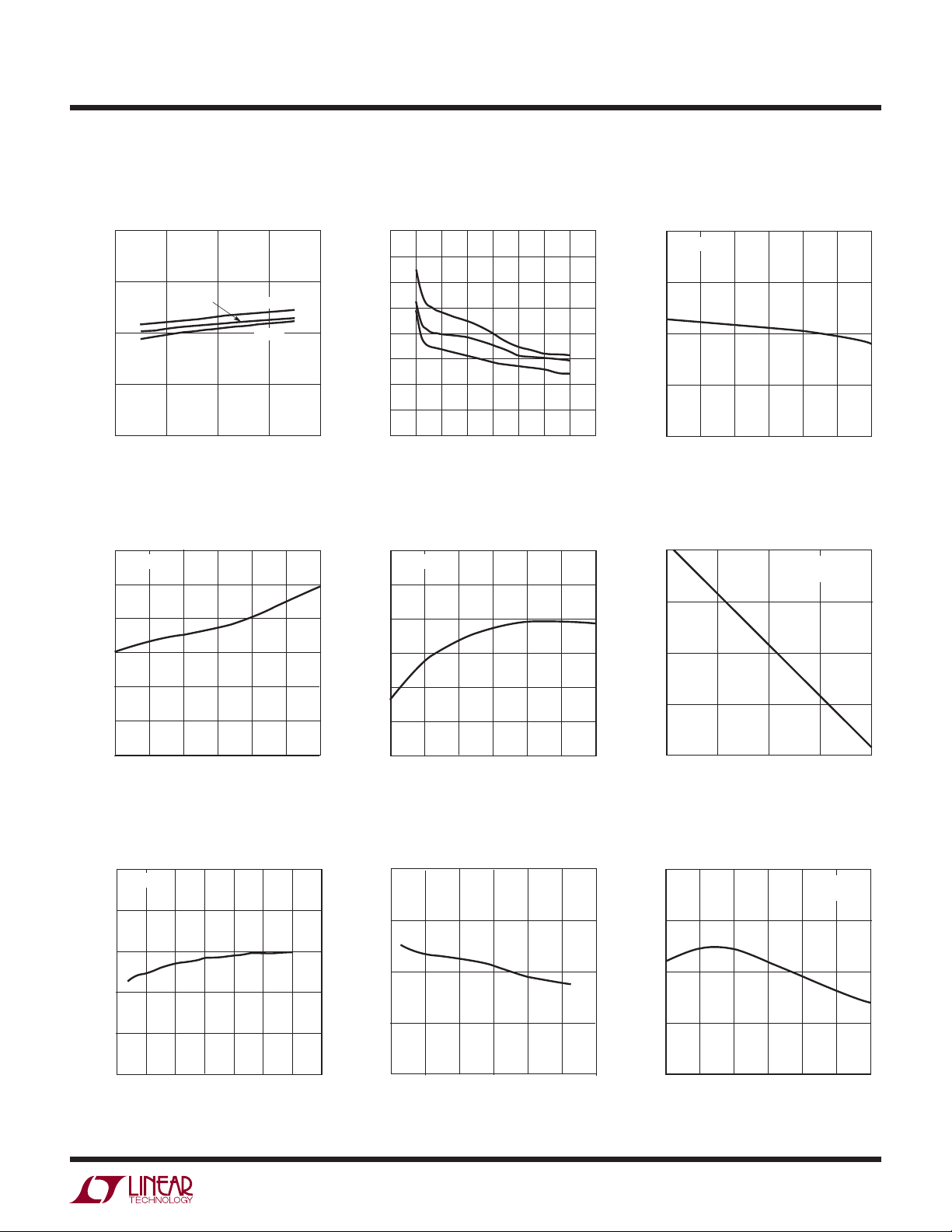

TYPICAL PERFORMANCE CHARACTERISTICS

Switch Saturation Voltage

)

(V

CESAT

600

500

400

300

200

100

SWITCH SATURATION VOLTAGE (mV)

0

0

100 500

SWITCH CURRENT (mA)

LED Pin Voltage Drop

– V

(V

CAP

LED

300

VIN = 3.6V

= 16V

V

CAP

250

200

(mV)

LED

150

– V

CAP

100

V

50

100°C

25°C

–50°C

400200

600300

3593 G01

)

100°C

25°C

–50°C

Shutdown Current (V

6

5

4

3

2

SHUTDOWN CURRENT (µA)

1

0

2

VIN (V)

LED Pin Current Limit

46

45

44

43

LED PIN CURRENT LIMIT (mA)

CTRL

100°C

25°C

= 0V)

53

VIN = 3.6V

V

CAP

= 25°C unless otherwise specifi ed.

T

A

Quiescent Current (V

3.50

3.25

3.00

–50°C

64

3593 G02

2.75

2.50

QUIESCENT CURRENT (mA)

2.25

2.00

2

Switching Current Limit vs

Temperature

750

VIN = 3.6V

= 16V

700

650

600

SWITCH CURRNET LIMIT (mA)

VIN (V)

CTRL

100°C

25°C

–50°C

= 3.6V)

53

3593 G03

64

4

0

0

LED CURRENT (mA)

155

2010

3593 G04

Switching Waveform

I

L

200mA/DIV

V

CAP

200mV/DIV

AC COUPLED

V

SW

20V/DIV

FRONT PAGE

APPLICATION CIRCUIT

1µs/DIVVIN = 3.6V

42

–50

TEMPERATURE (°C)

750–25 25

10050

3593 G05

550

–50

25 50 75–25

TEMPERATURE (°C)

1000

3593 G06

Transient Response

V

CTRL

5V/DIV

I

L

200mA/DIV

V

CAP

10V/DIV

3393 G08

3593f

3393 G07

= 3.6V

IN

FRONT PAGE

APPLICATION CIRCUIT

200µs/DIVV

Page 5

LT3593

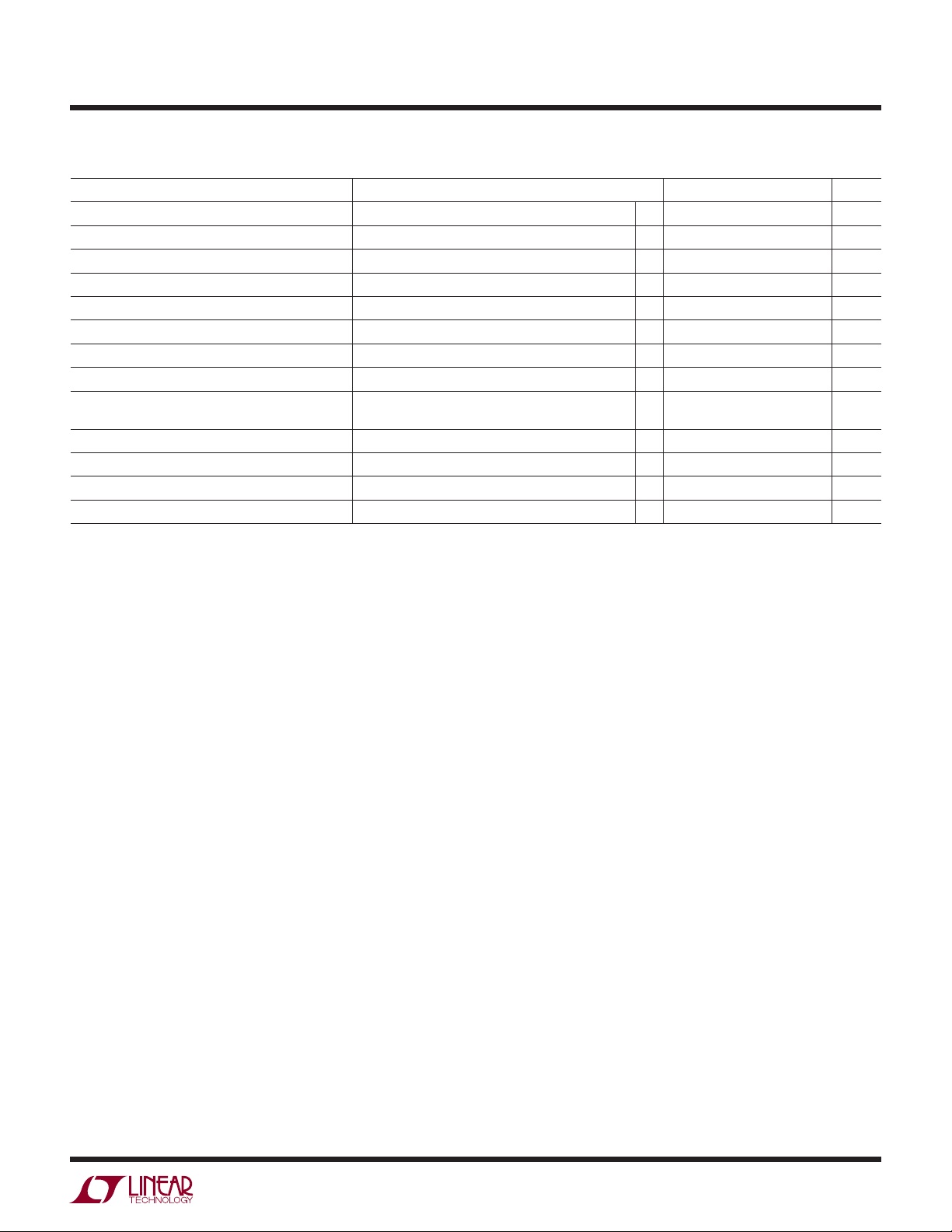

TYPICAL PERFORMANCE CHARACTERISTICS

Open-Circuit Output Clamp

Voltage

40

39

25°C

38

37

OPEN-CIRCUIT CLAMP VOLTAGE (V)

36

2

VIN (V)

Input Current in Output

Open-Circuit vs Temperatue

8

VIN = 3.6V

7

6

100°C

–50°C

543

6

3593 G09

Input Current in Output Open

Circuit

10

9

8

7

6

5

4

3

INPUT CURRENT OUTPUT OPEN-CIRCUIT (mA)

2

2.0 2.5

VIN (V)

5.0 5.53.0 3.5

Switching Frequency vs

Temperature

1150

VIN = 3.6V

1100

1050

TA = 25°C unless otherwise specifi ed.

Open-Circuit Output Clamp

Voltage vs Temperature

40

VIN = 3.6V

39

38

37

OPEN-CIRCUIT CLAMP VOLTAGE (V)

6.04.0 4.5

3593 G10

36

–50

TEMPERATURE (°C)

LED Current vs CTRL Strobe

Pulses

20

15

750–25 25

VIN = 3.6V

10LEDS

10050

3593 G11

5

4

3

INPUT CURRENT OUTPUT OPEN-CIRCUIT (mA)

2

–50

Full-Scale Current vs V

21.0

10 LEDs

20.5

20.0

LED CURRENT (mA)

19.5

19.0

2.5

TEMPERATURE (°C)

IN

5.03.53.0 4.0

VIN (V)

1000

950

SWITCHING FREQUENCY (kHz)

900

750–25 25

10050

3593 G12

850

–50

TEMPERATURE (°C)

10050

750–25 25

3593 G13

10

LED CURRENT (mA)

5

0

0

NUMBER OF CTRL STROBES

16824

32

3593 G14

Full-Scale Current vs

Temperature

21.0

20.5

20.0

19.5

FULL SCALE CURRENT (mA)

19.0

–50

0–25 50 7525

TEMPERATURE (°C)

VIN = 3.6V

10LEDS

100

3593 G17

6.05.54.5

3593 G15

Full-Scale Current vs V

21.0

20.5

20.0

LED CURRENT (mA)

19.5

19.0

5

CAP

35

3593 G16

CAP

25201510 30

(V)

V

3593f

5

Page 6

LT3593

PIN FUNCTIONS

(DFN/TSOT)

VIN (Pin 1/Pin 3): Input Supply Pin. Must be locally by-

passed with a 1F X5R or X7R type ceramic capacitor.

GND (Pin 2/Pin 2): Ground Pin. Connect directly to local

ground plane.

SW (Pin 6/Pin 4): Switch Pin. Connect inductor between

this pin and the V

pin. Minimize inductance at this pin

IN

to minimize EMI.

CAP (Pin 5/Pin 5): Output Pin. Connect to output capacitor. Minimize trace between this pin and output capacitor

to reduce EMI.

CTRL (Pin 3/Pin 1): Current Control and Shutdown Pin.

This pin is used to program the LED output current. This

pin is strobed up to 32 times to decrement the internal

5-bit DACs from full-scale to 1LSB. The counter will stop

at 1LSB if the strobing continues beyond 32 counts.

The pin must be held high after the fi nal desired positive

strobe edge. The data is transferred after a 128s (typ)

delay. The part can be reprogrammed to a different value

after it has been enabled, however the current will change

to the new value after 128µs. If CTRL is held low for longer

than 128s (typ), the part will go into shutdown.

LED (Pin 4/Pin 6): LED Pin. An internal switch connects

this pin to CAP. The top of the LED string is connected

to this pin. When the part is in shutdown, the LED pin is

switched off from CAP so no current runs through the

LEDs. The switch is also used to sense the LED current

when the part is on.

Exposed Pad (Pin 7/NA): Ground. The Exposed Pad must

be soldered to the PCB.

BLOCK DIAGRAM

SHDN

PIN NUMBERS REFER TO DFN PACKAGE. REFER TO PIN CONFIGURATION FOR TSOT PIN NUMBERS

V

1.24V

REF

61

IN

PWM

–

COMP

A2

+

R

S

DRIVER

Q

SWV

Q1

OVERVOLTAGE

PROTECTION

CAP

5

+

+

–

RAMP

GENERATOR

OSCILLATOR

A3

–

A1

R

C

C

C

+

–

R

M2 M1

5-BIT

LINEAR DAC

5-BIT

COUNTER

GND

27 3

CTRL

SHDN

SHDN

LED

4

3593 F01

6

Figure 1. Block Diagram

3593f

Page 7

OPERATION

LT3593

The LT3593 uses a constant frequency, current mode

control boost scheme to provide excellent line and load

regulation. Operation can be best understood by referring

to the Block Diagram in Figure 1.

Output Disconnect

An internal switch connects between the CAP pin and the

LED pin. The top of the LED string is connected to the

LED pin. The string can be terminated to ground or to

if a low number of LEDs are driven. When the part is

V

IN

in shutdown, the switch is off; allowing no current to run

through the LEDs.

Current Programming

The LED current can be set to 32 different values

(625µA – 20mA) by strobing the CTRL pin. A 5-bit

counter is decremented by 1 on a CTRL pin rising edge,

reducing the programmed current by 625µA each time.

The desired current can be calculated by:

I

= 20mA – (N – 1) • 625µA

LED

where N is the number of rising edges. When the desired

current setting is reached, the CTRL pin must stay high.

128µs after the last rising edge on the CTRL pin, the

regulator will enable the output and start to regulate the

LED current to the programmed value. Figure 2 shows

an example of how the part can be programmed.

If a different current is desired, the CTRL pin can be strobed

again. The fi rst falling edge will reset the internal register

to the 20mA setting. While the new current is being programmed, the device will continue to regulate the previously

programmed value until the CTRL pin has remained high

for at least 128µs, at which time the regulated current will

slew to the newly programmed value. Figure 3 shows how

to program a new LED current level.

If the CTRL pin is held low for longer than 128µs, the part

will go into the shutdown mode.

CTRL

CTRL 17.5mA

CTRL 15mA

CTRL 12.5mA

Figure 2. Current Programming

128µs

CTRL

20mA 20mA

LED

CURRENT

Figure 3. Current Programming and Shutdown Timing

128µs 128µs

17.5mA 17.5mA

FULL CURRENT

20mA

3593 F02

SHDN

3593 F03

3593f

7

Page 8

LT3593

APPLICATIONS INFORMATION

Inductor Selection

A 10µH inductor is recommended for most LT3593 applications. Although small size and high effi ciency are

major concerns, the inductor should have low core losses

at 1MHz and low DCR (copper wire resistance). Some

inductors in this category with small size are listed in

Table 1. The effi ciency comparison of different inductors

is shown in Figure 4.

Table 1. Recommended Inductors

()

CURRENT

RATING

(mA) VENDOR

650

450

500

490

580

400

Murata

TDK

TOKO

L

PART

LQH43CN100

LQH32CN100

NR3010T100M 10 0.45 500 Taiyo Yuden

VLF4012AT-100M

VLF3010AT-100M

DE2812-1098AS-100M

DB3015C-1068AS-100M1010

90.00

80.00

70.00

DCR

(μH)

10100.24

0.44

10100.20

0.58

0.29

0.38

Table 2 shows a list of several ceramic capacitor manufacturers. Consult the manufacturers for detailed information

on their entire selection of ceramic parts.

Table 2. Recommended Ceramic Capacitor Manufacturers

Taiyo Yuden (408) 573-4150

AVX (803) 448-9411

Murata (714) 852-2001

Kemet (408) 986-0424

www.t-yuden.com

www.avxcorp.com

www.murata.com

www.kemet.com

Diode Selection

Schottky diodes, with their low forward voltage drop and

fast reverse recovery, are the ideal choices for LT3593 applications. The forward voltage drop of a Schottky diode

represents the conduction losses in the diode, while the

diode capacitance (C

or CD) represents the switching

T

losses. For diode selection, both forward voltage drop and

diode capacitance need to be considered. Schottky diodes

with higher current ratings usually have lower forward

voltage drop and larger diode capacitance, which can

cause signifi cant switching losses at the 1.0MHz switching

frequency of the LT3593. A Schottky diode rated at 400mA

to 500mA is suffi cient for most LT3593 applications. Some

recommended Schottky diodes are listed in Table 3.

60.00

NR3010T100M

EFFI CIENCY (%)

50.00

40.00

30.00

0.00

VLF4012-AT-100MR50

LQH43CN100K03

VLF3010AT-100MR49

LQH32CN100K53

DB3015C-1068AS-100M

10.00

LED CURRENT (mA)

20.0015.005.00

3593 F04

Figure 4. Effi ciency Comparison of Different Inductors

Capacitor Selection

The small size of ceramic capacitors makes them ideal

for LT3593 applications. Use only X5R and X7R types

because they retain their capacitance over wider voltage

and temperature ranges than other types such as Y5V or

Z5U. A 1µF input capacitor and a 1µF output capacitor are

suffi cient for most applications.

8

Table 3. Recommended Schottky Diodes

PART

NUMBER

CMDSH05-4 500 0.47 at

CMMSH1-40 1000 0.55 at 1A80 at 4V

ZLL5400 520 0.50 at

PMEG4005AEA

FORWARD

CURRENT

(mA)

VOLTAGE

DROP

(V)

500mA

400mA

500 0.47 at

500mA

DIODE

CAPACITANCE

(pF) MANUFACTURER

50 at 1V Central

15 at 30V Zetex

50 at 1V Phillips

631-435-1110

www.centralsemi.com

631-543-7100

www.zetex.com

+3140 27 24825

www.semiconductors.

phillips.com

3593f

Page 9

APPLICATIONS INFORMATION

LT3593

Overvoltage Protection

The LT3593 has an internal open-circuit protection circuit.

In the case of an output open circuit, when the LEDs are

disconnected from the circuit or the LEDs fail open, V

CAP

is clamped at 38V. The LT3593 will then switch at a very

low frequency to minimize input current. V

and input

CAP

current during output open circuit are shown in the Typical

Performance Characteristics. Figure 5 shows the transient

response when the LEDs are disconnected.

I

L

200mA/DIV

V

CAP

20V/DIV

Low Input Voltage Applications

The LT3593 can be used in low input voltage applications.

The input supply voltage to the LT3593 must be 2.7V or

higher, but the inductor can be run off a lower battery

voltage. This technique allows the LEDs to be powered off

two alkaline cells. Most portable devices have a 3.3V logic

supply voltage which can be used to power the LT3593.

The LEDs can be driven straight from the battery, resulting

in higher effi ciency.

Figure 6 shows three LEDs powered by two AA cells.

The battery is connected to the inductors and the chip is

powered off a 3.3V logic supply voltage.

L1

µH

2 AA CELLS

2V TO 3.2V

3.3V

SHUTDOWN AND

CURRENT CONTROL

10

C1

µF

1

V

IN

C3

µF

1

CTRL

SW

LT3593

GND

CAP

LED

D1

C2

µF

1

V

SW

20V/DIV

FRONT PAGE

APPLICATION CIRCUIT

400µs/DIVVIN = 3.6V

LEDs DISCONNECTED

AT THIS INSTANT

Figure 5. Output Open-Circuit Waveform

3593 F05

3593 F06

C1: TAIYO YUDEN EMK107B5105MA

C2: MURATA GRM31MR71H105KA88

L1: MURATA LQH43CN100

D1: CENTRAL CMDSH05-4

Figure 6. Two AA Cells to Three White LEDs

3593f

9

Page 10

LT3593

APPLICATIONS INFORMATION

Board Layout Considerations

As with all switching regulators, careful attention must

be paid to the PCB layout and component placement. To

prevent electromagnetic interference (EMI) problems,

proper layout of high frequency switching paths is essential.

Minimize the length and area of all traces connected to the

L1 L1

V

IN

CTRL

GND

C1

1

2

3

DFN Package TSOT-23 Package

6

5

7

4

C2

D1

Switching node pin (SW). Keep the sense voltage pins (CAP

and LED) away from the switching node. Place C2 next to

the CAP pin. Always use a ground plane under the switching

regulator to minimize interplane coupling. Recommended

component placement is shown in Figure 7.

V

IN

D1

43

52

61

C2

C1

CTRL

GND

3593 F07

Figure 7. Recommended Component Placement

10

3593f

Page 11

TYPICAL APPLICATIONS

LT3593

Li-Ion Driver for One White LED

V

IN

CTRL

10

LT3593

GND

V

IN

3V TO 5V

SHUTDOWN AND

CURRENT CONTROL

C1: TAIYO YUDEN EMK107BJ105MA

C2: TAIYO YUDEN GMK316BJ105ML

L1: MURATA LQH43CN100

D1: CENTRAL CMDSH05-4

C1

µF

1

Li-Ion Driver for Two White LED

V

CTRL

10

IN

LT3593

V

IN

3V TO 5V

SHUTDOWN AND

CURRENT CONTROL

C1: TAIYO YUDEN EMK107BJ105MA

C2: TAIYO YUDEN GMK316BJ105ML

L1: MURATA LQH43CN100

D1: CENTRAL CMDSH05-4

C1

µF

1

L1

µH

L1

GND

Conversion Effi ciency

70

VIN = 3.6V

1 LED

60

50

40

EFFICIENCY (%)

30

20

10

0

10

LED CURRENT (mA)

20155

3593 TA02b

SW

C2

1

CAP

LED

µF

D1

3593 TA02a

Conversion Effi ciency

80

VIN = 3.6V

C2

µF

1

µH

D1

SW

CAP

LED

3593 TA03a

2 LEDs

70

60

50

EFFICIENCY (%)

40

30

20

0

10

LED CURRENT (mA)

20155

3593 TA03b

3593f

11

Page 12

LT3593

TYPICAL APPLICATIONS

Li-Ion Driver for Three White LEDs

L1

10

µH

V

IN

3V TO 5V

SHUTDOWN AND

CURRENT CONTROL

C1

µF

1

V

IN

LT3593

CTRL

GND

C1: TAIYO YUDEN EMK107BJ105MA

C2: TAIYO YUDEN GMK316BJ105ML

L1: MURATA LQH43CN100

D1: CENTRAL CMDSH05-4

D1

SW

CAP

LED

3593 TA04a

Li-Ion Driver for Four White LEDs

L1

D1

µH

V

IN

3V TO 5V

SHUTDOWN AND

CURRENT CONTROL

C1

1

10

µF

V

SW

IN

CAP

LT3593

CTRL

LED

GND

Effi ciency

90

VIN = 3.6V

C2

µF

1

3 LEDs

80

70

60

EFFICIENCY (%)

50

40

30

0

10

LED CURRENT (mA)

20155

3593 TA04b

Effi ciency

90

VIN = 3.6V

C2

µF

1

4 LEDs

80

70

60

EFFICIENCY (%)

50

C1: TAIYO YUDEN EMK107BJ105MA

C2: TAIYO YUDEN GMK316BJ105ML

L1: MURATA LQH43CN100

D1: CENTRAL CMDSH05-4

Li-Ion Driver for Six White LEDs

L1

µH

V

IN

3V TO 5V

SHUTDOWN AND

CURRENT CONTROL

C1

1

10

µF

V

SW

IN

CAP

LT3593

CTRL

C1: TAIYO YUDEN EMK107BJ105MA

C2: TAIYO YUDEN GMK316BJ105ML

L1: MURATA LQH43CN100

D1: CENTRAL CMDSH05-4

LED

GND

3593 TA05a

D1

3593 TA06a

40

30

0

10

LED CURRENT (mA)

20155

3593 TA05b

Effi ciency

90

VIN = 3.6V

6 LEDs

C2

µF

1

80

70

60

EFFICIENCY (%)

50

40

30

0

10

LED CURRENT (mA)

20155

3593 TA06b

12

3593f

Page 13

TYPICAL APPLICATIONS

LT3593

Li-Ion Driver For Ten White LEDs

V

IN

3V TO 5V

SHUTDOWN AND

CURRENT CONTROL

Li-Ion Driver For Ten White LEDs

V

IN

3V TO 5V

SHUTDOWN AND

CURRENT CONTROL

L1

10

C1

µF

1

V

IN

LT3593

CTRL

GND

C1: TAIYO YUDEN EMK107BJ105MA

C2: MURATA GRM31MR71H105KA88

L1: MURATA LQH43CN100

D1: CENTRAL CMDSH05-4

22

C1

µF

1

V

IN

LT3593

CTRL

GND

D1

µH

SW

CAP

LED

L1

D1

µH

SW

CAP

LED

3593 TA07a

Effi ciency

90

VIN = 3.6V

10 LEDs

C2

µF

1

80

70

60

EFFICIENCY (%)

50

40

30

0

10

LED CURRENT (mA)

20155

3593 TA07b

Effi ciency

90

VIN = 3.6V

10 LEDs

C2

2.2

µF

80

70

60

EFFICIENCY (%)

50

40

3593 TA08a

C1: TAIYO YUDEN EMK107BJ105MA

C2: MURATA GRM31CR71H225KA88

L1: MURATA LQH43CN220

D1: CENTRAL CMDSH05-4

30

0

10

LED CURRENT (mA)

20155

3593 TA08b

3593f

13

Page 14

LT3593

PACKAGE DESCRIPTION

DC Package

6-Lead Plastic DFN (2mm × 2mm)

(Reference LTC DWG # 05-08-1703)

0.675 ±0.05

2.50 ±0.05

1.15 ±0.05

0.61 ±0.05

(2 SIDES)

0.50 BSC

1.42 ±0.05

(2 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

PIN 1 BAR

TOP MARK

(SEE NOTE 6)

0.200 REF

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WCCD-2)

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE

TOP AND BOTTOM OF PACKAGE

PACKAGE

OUTLINE

0.25 ± 0.05

2.00 ±0.10

(4 SIDES)

0.75 ±0.05

0.00 – 0.05

R = 0.115

TYP

0.56 ± 0.05

(2 SIDES)

1.37 ±0.05

BOTTOM VIEW—EXPOSED PAD

3

(2 SIDES)

0.38 ± 0.05

64

1

0.50 BSC

PIN 1

CHAMFER OF

EXPOSED PAD

(DC6) DFN 1103

0.25 ± 0.05

14

3593f

Page 15

PACKAGE DESCRIPTION

LT3593

S6 Package

6-Lead Plastic TSOT-23

(Reference LTC DWG # 05-08-1636)

0.62

MAX

3.85 MAX

2.62 REF

RECOMMENDED SOLDER PAD LAYOUT

PER IPC CALCULATOR

0.20 BSC

DATUM ‘A’

NOTE:

1. DIMENSIONS ARE IN MILLIMETERS

2. DRAWING NOT TO SCALE

3. DIMENSIONS ARE INCLUSIVE OF PLATING

4. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

5. MOLD FLASH SHALL NOT EXCEED 0.254mm

6. JEDEC PACKAGE REFERENCE IS MO-193

0.95

REF

1.22 REF

1.4 MIN

0.30 – 0.50 REF

2.80 BSC

0.09 – 0.20

(NOTE 3)

1.50 – 1.75

(NOTE 4)

1.00 MAX

0.95 BSC

0.80 – 0.90

2.90 BSC

(NOTE 4)

PIN ONE ID

0.30 – 0.45

6 PLCS (NOTE 3)

0.01 – 0.10

1.90 BSC

S6 TSOT-23 0302 REV B

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3593f

15

Page 16

LT3593

TYPICAL APPLICATION

Li-Ion Driver for Six LEDs Effi ciency

L1

µH

V

CTRL

IN

10

SW

CAP

LT3593

LED

GND

V

IN

3V TO 5V

SHUTDOWN AND

CURRENT CONTROL

C1

µF

1

90

D1

C2

µF

1

VIN = 3.6V

6 LEDs

80

70

60

EFFICIENCY (%)

50

40

3593 TA06a

C1: TAIYO YUDEN EMK107BJ105MA

C2: TAIYO YUDEN GMK316BJ105ML

L1: MURATA LQH43CN100

D1: CENTRAL CMDSH05-4

30

0

10

LED CURRENT (mA)

3593 TA06b

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1932 Constant Current, 1.2MHz, High Effi ciency White LED

Boost Regulator

LT1937 Constant Current, 1.2MHz, High Effi ciency White LED

Boost Regulator

®

3200 Low Noise, 2MHz Regulated Charge Pump White

LT C

Up to 8 White LEDs, V

I

< 1µA, ThinSOTTM Package

SD

Up to 4 White LEDs, V

I

< 1µA, ThinSOT and SC70 Packages

SD

Up to 6 White LEDs, VIN: 2.7V to 4.5V, IQ = 8mA, ISD < 1µA, MS Package

: 1V to 10V, V

IN

: 2.5V to 10V, V

IN

LED Driver

LTC3200-5 Low Noise, 2MHz Regulated Charge Pump White

LED Driver

LTC3201 Low Noise, 1.7MHz Regulated Charge Pump White

Up to 6 White LEDs, V

Package

Up to 6 White LEDs, V

: 2.7V to 4.5V, IQ = 8mA, ISD < 1µA, ThinSOT

IN

: 2.7V to 4.5V, IQ = 6.5mA, ISD < 1µA, MS Package

IN

LED Driver

LTC3202 Low Noise, 1.5MHz Regulated Charge Pump White

Up to 8 White LEDs, V

: 2.7V to 4.5V, IQ = 5mA, ISD < 1µA, MS Package

IN

LED Driver

LTC3205 High Effi ciency, Multidisplay LED Controller Up to 4 (Main), 2 (Sub) and RGB, V

IN

24-Lead QFN Package

LTC3210 Low Noise Charge Pump LED Controller Up to 4 White LEDs and One High current CAM LED, V

I

= 4.5mA, ISD < 6µA, UD Package

Q

LT3465/LT3465A Constant Current, 1.2MHz/2.7MHz, High Effi ciency

White LED Boost Regulator with Integrated Schottky

Up to 6 White LEDs, V

I

< 1µA, ThinSOT Package

SD

: 2.7V to 16V, V

IN

Diode

LT3466/LT3466-1 Dual Full Function, 2MHz Diodes White LED Step-Up

Converter with Built-In Schottkys

LT3486 Dual 1.3A White LED Converter with 1000:1 True

Color PWM Dimming

Up to 20 White LEDs, V

DFN and TSSOP-16 Packages

Drives Up to 16 100mA White LEDs. V

DFN and TSSOP Packages

LT3491 White LED Driver with Integrated Schottky Up to 6 White LEDs, V

: 2.7V to 24V, V

IN

: 2.5V to 12V, IQ = 2.6mA, ISD < 10µA, SC70 and

IN

2mm × 2mm DFN Packages

LT3591 White LED Driver with Integrated Schottky Up to 10 White LEDs, V

: 2.5V to 12V, IQ = 4mA, ISD < 11µA,

IN

3mm × 2mm DFN Package

ThinSOT is a trademark of Linear Technology Corporation.

= 34V, IQ = 1.2mA,

OUT(MAX)

= 34V, IQ = 1.9mA,

OUT(MAX)

: 2.8V to 4.5V, IQ = 50µA, ISD < 1µA,

IN

= 34V, IQ = 1.9mA,

OUT(MAX)

= 39V,

OUT(MAX)

: 2.5V to 24V, V

IN

20155

: 2.9V to 4.5V,

= 36V,

OUT(MAX)

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

3593f

LT 0308 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2008

Loading...

Loading...