L DESIGN IDEAS

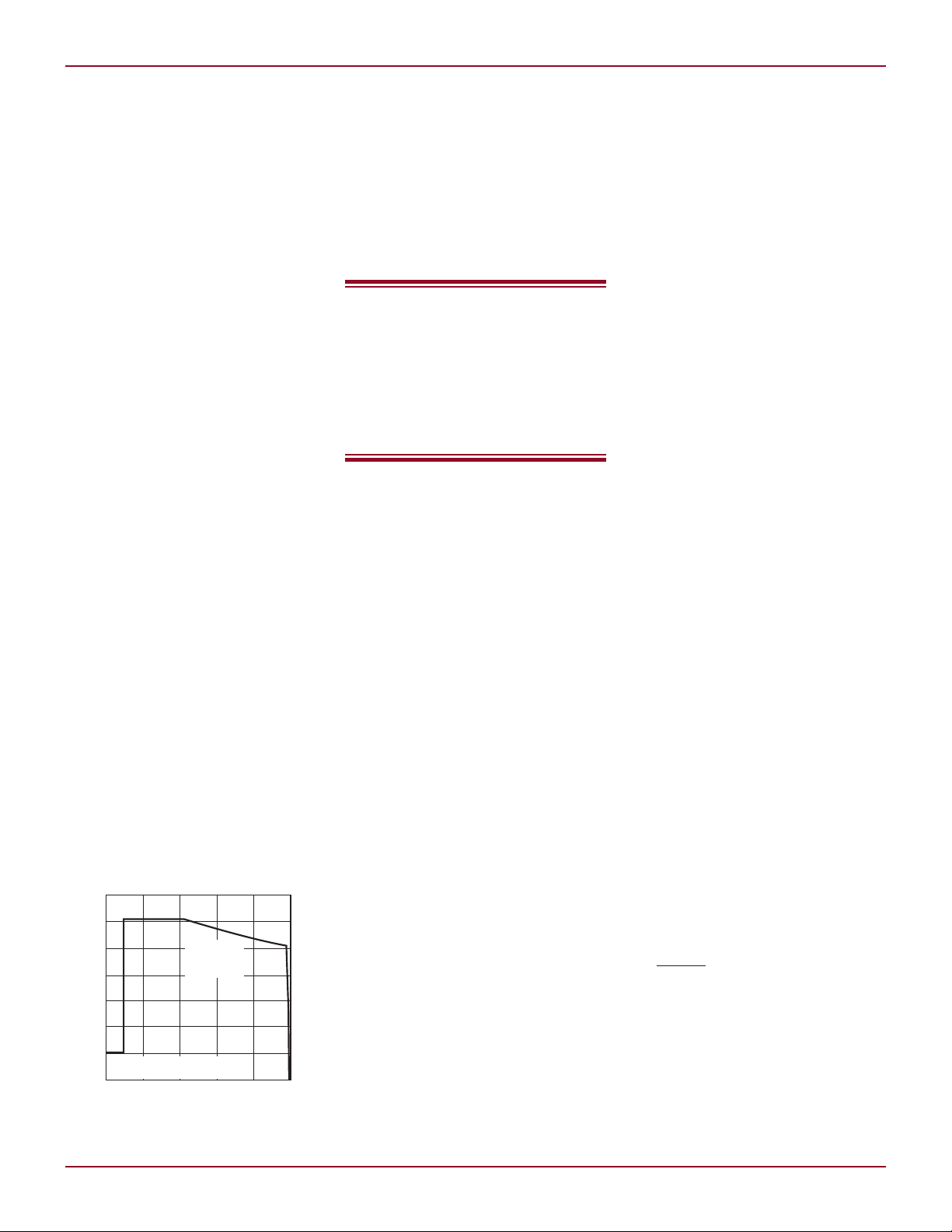

BATTERY VOLTAGE (V)

2.7

500

600

700

3.9

400

300

3.0 3.3 3.6 4.2

200

100

0

CHARGE CURRENT (mA)

V

BUS

= 5V

R

PROG

= 1k

R

CLPROG

= 3k

5x USB SETTING,

BATTERY CHARGER SET FOR 1A

Complete Power Solution for Digital

Cameras and Other Complex

Compact Portable Applications

Introduction

Digital cameras, portable GPS systems,

MP3 players and other feature-rich

mobile devices have complicated

power requirements. In these complex

devices, the flow of power must be

carefully managed between a number of specialized sources and loads,

including charging/discharging the

battery, current-limited USB power

and a set of multivoltage power supply rails, including negative rails for

CCDs or LCDs. The supply rails must

be sequenced and tracked and faults

must be handled cleanly and communicated to a microcontroller.

When these requirements are

added together, the task of squeezing

an efficient and robust power system

into a handheld device can seem near

impossible. Linear Technology solves

this problem with a family of devices

called PMICs (Power Management Integrated Circuits) that greatly simplify

the design of complex rechargeable

battery power systems.

Some Linear Technology PMICs

use a switching PowerPath controller

topology with the unique Bat-Track

feature, which allows charge currents

above the USB limit (see Figure 1) for

faster battery charging. The power

solution for digital cameras presented

34

34

Figure 1. Battery charge current

vs battery voltage

The LTC3586 implements

Linear Technology’s unique

Bat-Track™ technology,

which can use more power

from a USB source than

traditional linear chargers,

resulting in faster charging.

here takes advantage of this and other

powerful PMIC features.

Complete Digital Camera

Power System

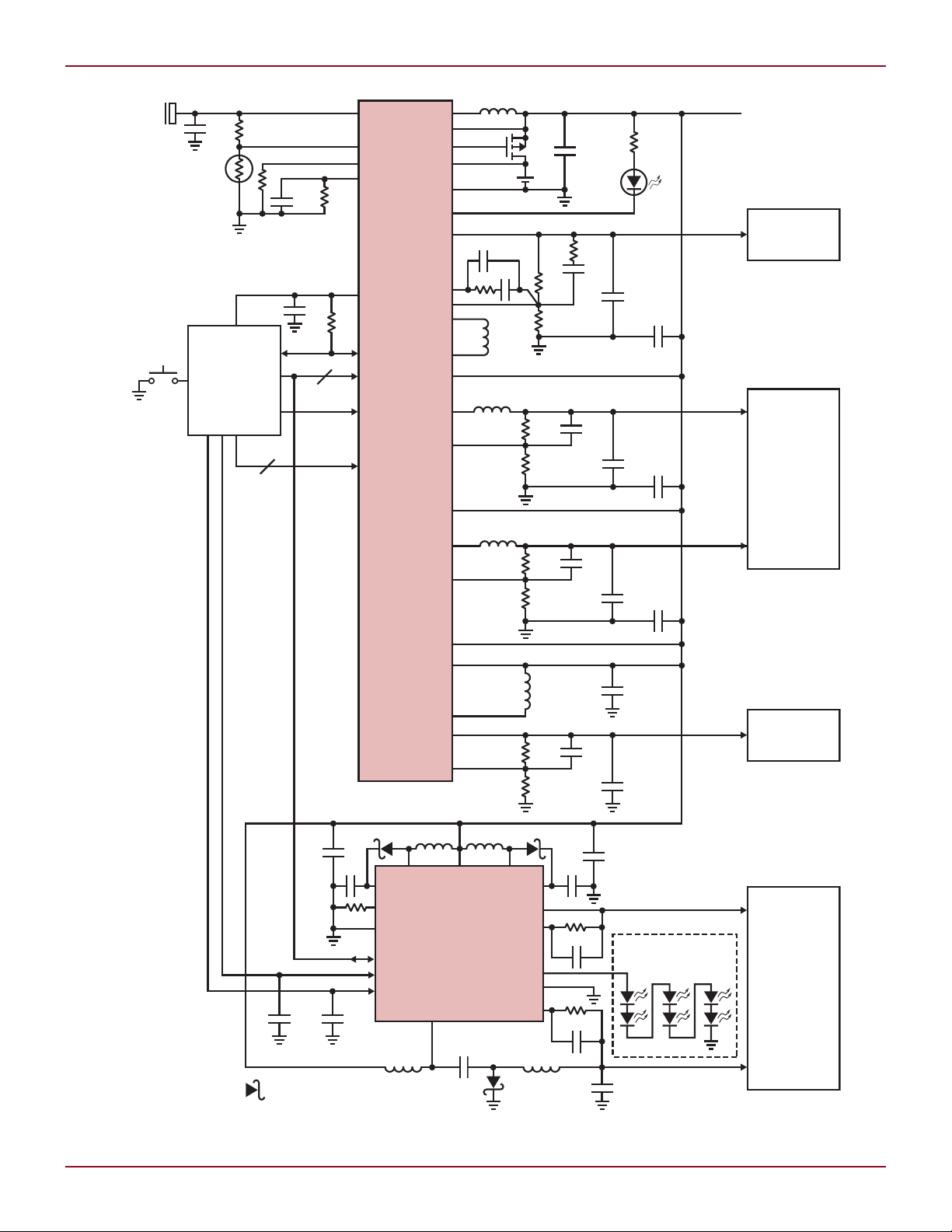

Figure 2 shows a complete digital

camera power solution using the

LTC3586 PMIC as the power traffic

control center. Its 4mm × 6mm QFN

package includes a USB PowerPath

manager, a battery charger, plus a

boost DC/DC converter, a buck-boost

and two buck converters. The LT3587

in a 3mm × 3mm package is used to

drive a CCD and an LED backlight

for an LCD screen with a high voltage

monolithic inverter and dual boost

converter.

Switching PowerPath

Controller Maximizes

Available Power

The LTC3586 implements Linear

Technology’s unique Bat-T rack™

technology, which maximizes the use

of available power from a USB source

for either providing current to the

load or charging the battery at rates

greater than achievable from linear

chargers.

The switching PowerPath controller maintains accurate control of the

average input current for USB applications. The average level of input

current is controlled by the state

of two digital inputs and can be set

by Brian Shaffer

to 100mA, 500mA, 1A or suspend

(500µA). The switching PowerPath

controller is highly efficient, which

results in battery charge currents of

well over 600mA from a 500mA USB

source (Figure 1).

The battery charging efficiency is

between 85% and 90% for the entire

battery voltage range. In contrast,

the efficiency of a traditional linear

charger falls as low as 57%, generating

the losses as heat. See Figure 3 for a

graph of the battery charger efficiency

as a function of battery voltage.

Instant-On Operation

The LTC3586 also features instant-on

operation, which allows the camera to

function immediately when external

power is applied even if the battery

voltage is below the system cutoff

voltage. This is achieved by generating

a separate voltage rail, V

is decoupled from the battery voltage when the battery is below 3.3V.

When external power is applied, the

PowerPath controller prioritizes load

current over battery charge current

and regulates V

to 3.6V, enabling

OUT

the system to operate immediately

upon the application of external power.

The instant-on feature is important in

camera applications because impor tant moments do not wait for batteries

to charge.

Fault Handling

The FAULT signals on both of these

devices are designed to work together

for seamless fault handling. By making

the fault signals both an input and

an output, the two chips can communicate fault events to each other.

If either of the devices has a fault then

all the outputs turn off, protecting

the system and battery from damage.

The enable lines and the fault signal

Linear Technology Magazine • September 2008

, which

OUT

+

MP1

C2

22µF

Li-Ion

510Ω

324k

121k

105k

RED

3.3V

1A

1.8V

400mA

MICROPROCESSOR

1.6V

400mA

5V

800mA

15V

50mA

BACKLIGHT LEDs

–8V

100mA

L1

3.3µH

L2

2.2µH

SW

V

BUS

T

NTC

PROG

CLPROG

100k

LTC3586

V

OUT3

V

C3

3.3V, 20mA

FB3

SWCD3

SWAB3

LDO3V3

I

LIM

MODE

FAULT

4

EN

V

OUT

BAT

GND

CHRG

GATE

2.2µF

330pF

33pF

10pF

15k

1µF

1µF

22µF

V

IN3

10pF1.02M

C1, C2: TDK C2012X5R0J226M

L1: COILCRAFT LPS4018-332LM

L2, L5: TOKO 1098AS-2R2M

L3, L4: TOKO 1098AS-4R7M

MP1: SILICONIX Si2333

806k

10k

L3

4.7µH

SW2

FB2

I/O/MEMORY

CORE

10µF

V

IN2

10pF

10pF

806k

806k

L4

4.7µH

L5

2.2µH

SW1

FB1

10µF

88.7k

16.9k

V

IN1

SW4

V

OUT4

FB4

V

IN4

SYSTEM RAIL/

I/O

AUDIO/

MOTOR DRIVE

CCD

2.94k

2k

0.1µF

C1

22µF

USB/WALL

4.5V TO 5.5V

1µF

PUSHBUTTON

MICROCONTROLLER

2

10µF

22µF

100nF100nF

15µH

10µH

VOUT3

CAP3

VFB3

IFB3

SW2

FB2

GND

CAP1

FB1

VOUT1

LT3587

EN/SS1

EN/SS3

SW3 SW1VIN

10µF

2.2µF

15µH 15µH

CCD POSITIVE

CCD NEGATIVE

8.06k

1µF

LED DRIVER

20mA, UP TO 6 LEDS

2.2µF

1M

1M

22µF

V

OUT

2.7pF

6.8pF

FLT

1µF

= IR05H40CSPTR

DESIGN IDEAS L

Linear Technology Magazine • September 2008

Figure 2. Complete power solution for portable cameras

3535

L DESIGN IDEAS

BATTERY VOLTAGE (V)

2.7

EFFICIENCY (%)

80

90

3.9

70

60

3

3.3

3.5

4.2

100

R

CLPROG

= 3.01K

R

PROG

= 1K

I

VOUT

= 0mA

5x CHARGING EFFICIENCY

1x CHARGING EFFICIENCY

10µH

VOUT3

CAP3

IFB3

LT3587

8.06k

R

IFB3

EN/SS3

SW3

VIN

1µF

V

VIN

2.5V TO 5V

V

DAC-OUT

DAC

LTC2630

PWM

FREQ

2.5V

0V

MN1

Si1304BDL

IR05H40CSPTR

Figure 3. Battery charging efficiency vs

battery voltage with no external load

(P

should be pulled-up to the same voltage. In Figure 2 the LDO3V3 regulator

is used as the pull-up voltage for the

FAULT signal and the power supply

for the low power microcontroller

used to process pushbutton events

and sequence the power supplies.

The FAULT pin also acts as an input

and hence, must be high before any

outputs are enabled.

Compact LED Driver

The LT3587 LED driver is designed

to drive up to six LEDs with average

LED currents between 20mA and 1µA.

When the LT3587’s V

a current regulated LED driver, the

V

FB3

protection function. By connecting a

resistor between V

device limits the maximum allowable

output voltage on V

is extremely important in LED applications because without it the client

device may be damaged if one of the

LEDs were to open; in such a case,

the output would continue to rise as

)

BAT/PBUS

is used as

OUT3

pin can be used as an overvoltage

and V

OUT

. This feature

OUT3

FB3

the

Figure 4. Six white LED driver with PWM and analog dimming

the current regulation loop increases

voltage in an attempt to regulate the

current.

The integrated LED driver in the

LT3587 is capable of accepting a direct

PWM dimming signal into its enable

input (EN/SS3) and/or accommodates

analog dimming via an external DAC.

See Figure 4 for a partial application

circuit showing the LED driver with

direct PWM and analog dimming.

LEDs can change color when the

current through them changes, but

PWM dimming maintains color consistency over the dimming range, as the

ON part of the PWM cycle is always the

same current. In PWM dimming, the

brightness of the LEDs is a function of

average current, adjusted by changing

the duty cycle of the PWM signal. In

analog dimming, the constant current

through the LEDs is adjusted, which

causes variations in color.

The LT3587 accepts PWM signals

with frequencies over 60Hz to assure

flicker-free operation. High PWM frequencies are achievable because of

the internal disconnect FET between

CAP3 and V

. This FET ensures

OUT3

that CAP3 maintains its steady-state

value while the PWM signal is low,

resulting in minimal startup delays.

For a 100Hz PWM dimming signal and

allowing for 10% deviation from linearity at the lowest duty cycle, the LT3587

allows for a dimming ratio of 30:1. If

the maximum amount of adjustment

range is desired, an external DAC,

such as the LTC2630, can be used to

feed an adjustment voltage onto the

IFB3 resistor, creating an LED current

range of 20,000:1.

Conclusion

Two highly integrated devices, the

LTC3586 and LT3587 can be combined

to create a complete USB compatible

power solution for portable cameras

and other feature-rich portable devices. The solution is robust, high

performance and compact, with efficient battery charging, instant-on

capability and LED protection.

L

LTC3851, continued from page 17

protects against insufficient turn-on

voltage for the top MOSFET.

3.3V/15A Regulator with

DCR Sensing

Figure 2 shows a 400kHz, 3.3V output

regulator using DCR current sensing.

The DC resistance of the inductor is

used as the current sense element,

eliminating the need for a discrete

sense resistor and thus maximizing

efficiency. Figure 3 shows a plot of the

36

36

efficiency vs load for all three modes

of operation with an input voltage of

12V.

1.5V/15A Regulator

Synchronized at 350kHz

Figure 4 illustrates a 1.5V output

regulator that is synchronized to

an external clock. The loop filter

components connected to the FREQ/

PLLFLTR pin are optimized to achieve

a jitter free oscillator frequency and

reduced lock time.

Conclusion

The LTC3851 combines high performance, ease of use and a comprehensive

feature set in a 3mm × 3mm 16-pin

package. DCR current sensing and

Burst Mode® operation keep efficiency

high. With a broad 4V to 38V input

range, strong MOSFET drivers, low

minimum on-time and tracking, the

LTC3851 is ideal for automotive electronics, server farms, datacom and

telecom power supply systems and

industrial equipment.

Linear Technology Magazine • September 2008

L

Loading...

Loading...