V

IN

5V

V

IN

6.04k

100k

130k

43.2k

4.7µF

1.5µH

1nF

3581 TA01

0.1µF

4.7µF

10.5k

4.7µF

V

OUT

12V

830mA

SW1 SW2

FB

CLKOUT

GATE

V

C

SS

V

IN

RT

GND

SYNC

FAULT

SHDN

LT3581

56pF

18.7k

10k

LOAD CURRENT (mA)

0

50

EFFICIENCY (%)

POWER LOSS (mW)

55

65

70

75

400

100

95

3581 TA01b

60

200 1000800600

80

85

90

0

200

600

2000

1200

1400

1600

1800

400

800

1000

查询LT3581供应商

LT3581

3.3A Boost/Inverting DC/DC

Converter with Fault Protection

FeaTures

n

3.3A, 42V Combined Power Switch

n

Master/Slave (1.9A/1.4A) Switch Design

n

Output Short Circuit Protection

n

Wide Input Range: 2.5V to 22V Operating,

40V Maximum Transient

n

Switching Frequency Up to 2.5MHz

n

Easily Configurable as a Boost, SEPIC, Inverting or

Flyback Converter

n

User Configurable Undervoltage Lockout

n

Low V

n

Can be Synchronized to External Clock

n

Can Be Synchronized to other Switching Regulators

n

High Gain SHDN Pin Accepts Slowly Varying Input

Switch: 250mV at 2.75A (Typical)

CESAT

Signals

n

14-Pin 4mm × 3mm DFN and 16-Lead MSE Packages

applicaTions

n

Local Power Supply

n

Vacuum Fluorescent Display (VFD) Bias Supplies

n

TFT-LCD Bias Supplies

n

Automotive Engine Control Unit (ECU) Power

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Linear

Technology Corporation. All other trademarks are the property of their respective owners.

Protected by U.S. Patents, including 7579816.

DescripTion

The LT®3581 is a PWM DC/DC converter with built-in fault

protection features to aid in protecting against output

shorts, input/output overvoltages, and overtemperature

conditions. The part consists of a 42V master switch, and

a 42V slave switch that can be tied together for a total

current limit of 3.3A.

The LT3581 is ideal for many local power supply designs. It

can be easily configured in Boost, SEPIC, Inverting or Flyback

configurations, and is capable of generating 12V at 830mA,

or –12V at 625mA from a 5V input. In addition, the LT3581’s

slave switch allows the part to be configured in high voltage,

high power charge pump topologies that are very efficient

and require fewer components than traditional circuits.

he LT3581’s switching frequency range can be set between

T

200kHz and 2.5MHz. The part may be clocked internally at

a frequency set by the resistor from the RT pin to ground,

or it may be synchronized to an external clock. A buffered

version of the clock signal is driven out of the CLKOUT

pin, and may be used to synchronize other compatible

switching regulator ICs to the LT3581.

The LT3581 also features innovative SHDN pin circuitry

that allows for slowly varying input signals and an adjustable undervoltage lockout function. Additional features

such as frequency foldback and soft-start are integrated.

The LT3581 is available in 14-Pin 4mm × 3mm DFN and

16-Lead MSE packages.

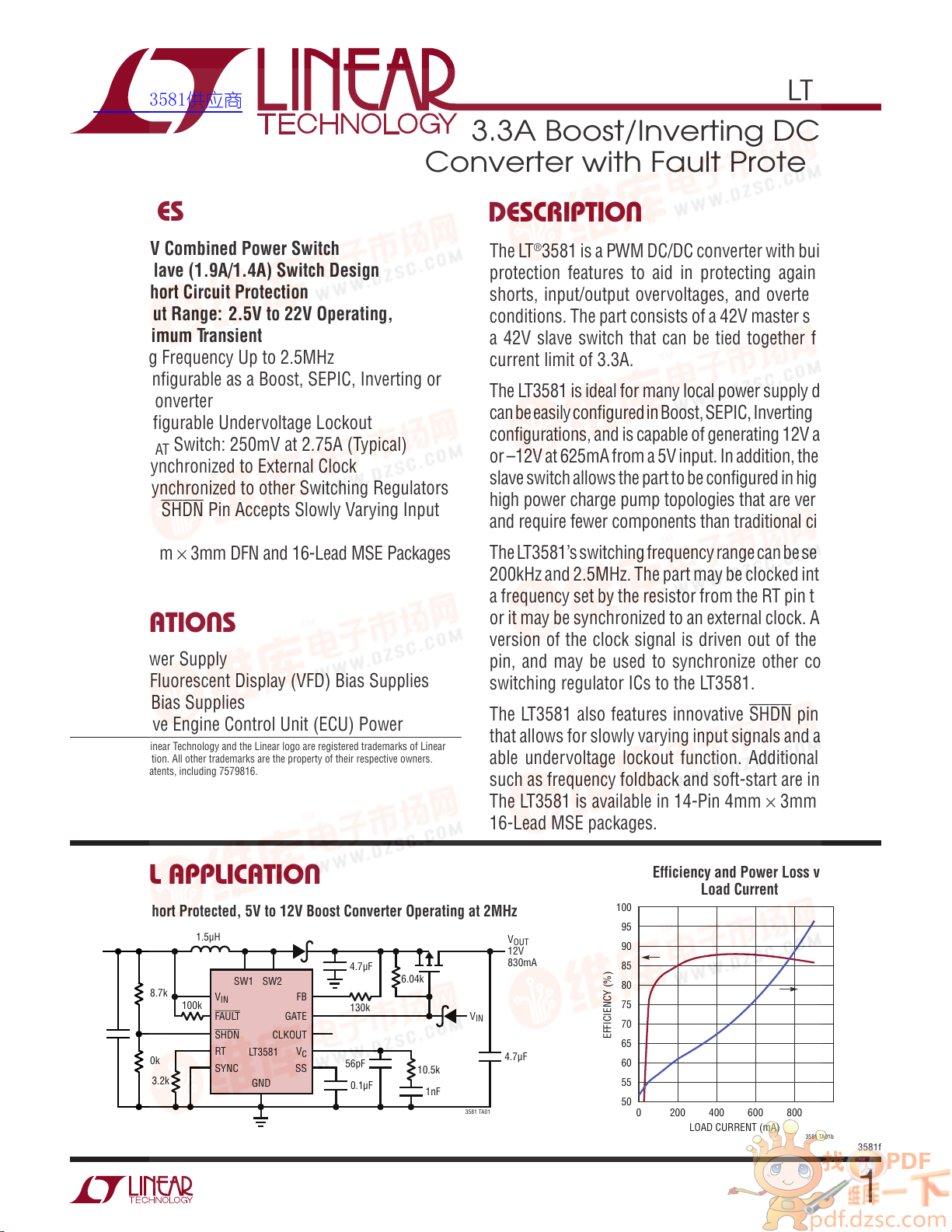

Typical applicaTion

Output Short Protected, 5V to 12V Boost Converter Operating at 2MHz

Efficiency and Power Loss vs

Load Current

3581f

1

LT3581

1

2

3

4

5

6

7

14

13

12

11

10

9

8

SYNC

SS

RT

SHDN

CLKOUT

SW2

SW2

FB

V

C

GATE

FAULT

V

IN

SW1

SW1

TOP VIEW

DE14 PACKAGE

14-PIN (4mm s 3mm) PLASTIC DFN

15

GND

1

2

3

4

5

6

7

8

FB

V

C

GATE

FAULT

V

IN

SW1

SW1

SW1

16

15

14

13

12

11

10

9

SYNC

SS

RT

SHDN

CLKOUT

SW2

SW2

SW2

TOP VIEW

MSE PACKAGE

16-LEAD PLASTIC MSOP

17

GND

查询LT3581供应商

absoluTe MaxiMuM raTings

(Note 1)

VIN Voltage .................................................–0.3V to 40V

SW1/SW2 Voltage ..................................... –0.4V to 42V

RT Voltage ...................................................–0.3V to 5V

SS, FB Voltage .......................................... –0.3V to 2.5V

Voltage .................................................... –0.3V to 2V

V

C

SHDN Voltage ............................................ –0.3V to 40V

SYNC Voltage ............................................ –0.3V to 5.5V

GATE Voltage ............................................. –0.3V to 80V

pin conFiguraTion

= 125°C, θJA = 43°C/W, θJC = 4.3°C/W

T

JMAX

EXPOSED PAD (PIN 15) IS GND, MUST BE SOLDERED TO PCB

FAULT Voltage ............................................ –0.3V to 40V

FAULT Current .....................................................±500µA

CLKOUT Voltage .......................................... –0.3V to 3V

CLKOUT Current ......................................................1mA

Operating Junction Temperature Range

LT3581E (Notes 2, 4) ......................... –40°C to 125°C

LT3581I (Notes 2, 4) ..........................– 40°C to 125°C

Storage Temperature Range .................. – 65°C to 150°C

T

= 125°C, θJA = 45°C/W, θJC = 10°C/W

JMAX

EXPOSED PAD (PIN 17) IS GND, MUST BE SOLDERED TO PCB

orDer inForMaTion

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3581EDE#PBF LT3581EDE#TRPBF 3581

LT3581IDE#PBF LT3581IDE#TRPBF 3581

LT3581EMSE#PBF LT3581EMSE#TRPBF 3581 16-Lead Plastic MSOP –40°C to 125°C

LT3581IMSE#PBF LT3581IMSE#TRPBF 3581 16-Lead Plastic MSOP –40°C to 125°C

Consult LTC Marketing for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

Consult LTC Marketing for information on non-standard lead based finish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifications, go to: http://www.linear.com/tapeandreel/

2

14-Lead (4mm × 3mm) Plastic DFN

14-Lead (4mm × 3mm) Plastic DFN

–40°C to 125°C

–40°C to 125°C

3581f

查询LT3581供应商

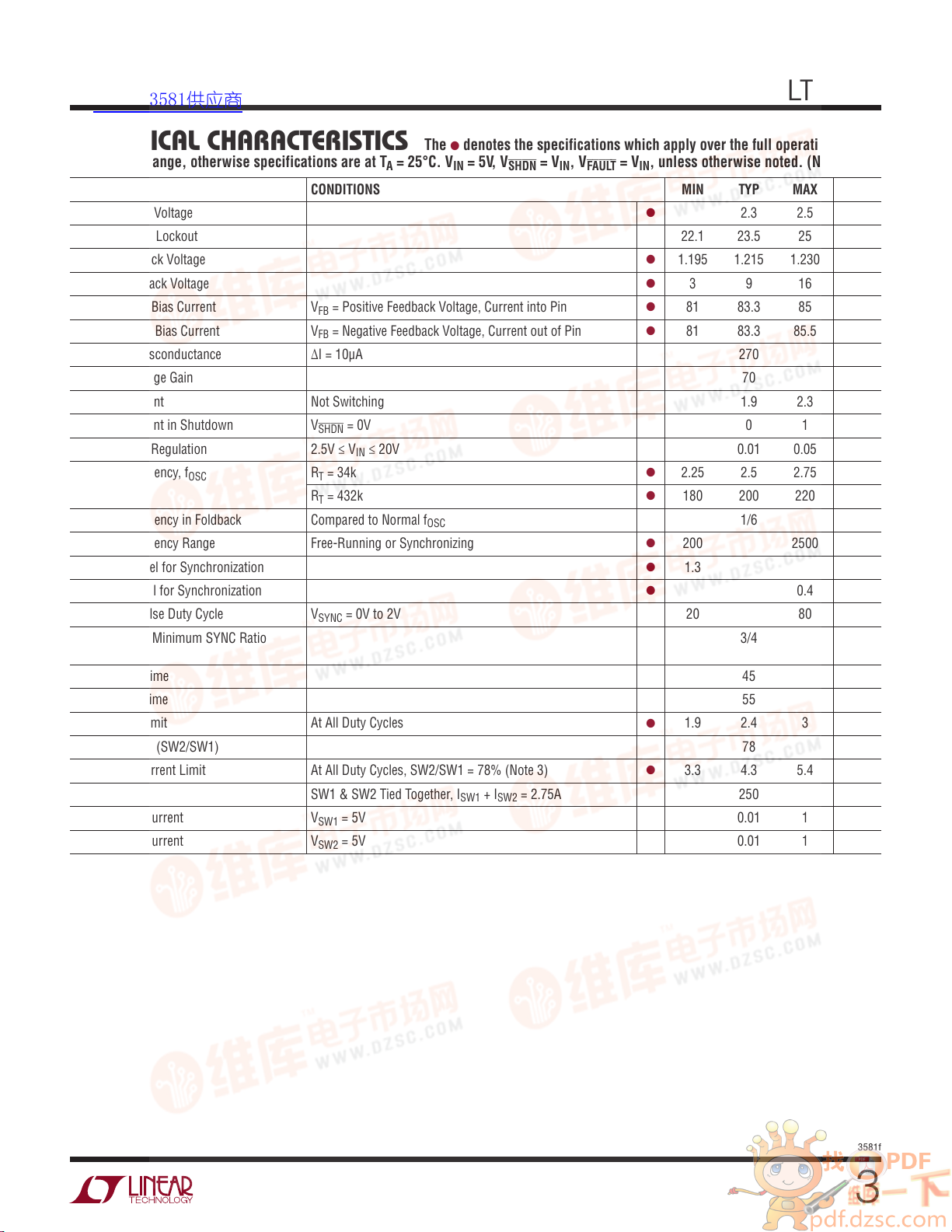

elecTrical characTerisTics

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VIN = 5V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Input Voltage

Overvoltage Lockout 22.1 23.5 25 V

V

IN

Positive Feedback Voltage

Negative Feedback Voltage

Positive FB Pin Bias Current V

Negative FB Pin Bias Current V

Error Amp Transconductance ΔI = 10μA 270 µmhos

Error Amp Voltage Gain 70 V/V

Quiescent Current Not Switching 1.9 2.3 mA

Quiescent Current in Shutdown V

Reference Line Regulation 2.5V ≤ V

Switching Frequency, f

Switching Frequency in Foldback Compared to Normal f

Switching Frequency Range Free-Running or Synchronizing

SYNC High Level for Synchronization

SYNC Low Level for Synchronization

SYNC Clock Pulse Duty Cycle V

Recommended Minimum SYNC Ratio

f

SYNC/fOSC

Minimum Off-Time 45 ns

Minimum On-Time 55 ns

SW1 Current Limit At All Duty Cycles

Current Sharing (SW2/SW1) 78 %

SW1 + SW2 Current Limit At All Duty Cycles, SW2/SW1 = 78% (Note 3)

Switch V

CESAT

SW1 Leakage Current V

SW2 Leakage Current V

OSC

= Positive Feedback Voltage, Current into Pin

FB

= Negative Feedback Voltage, Current out of Pin

FB

= 0V 0 1 µA

SHDN

≤ 20V 0.01 0.05 %/V

IN

RT = 34k

= 432k

R

T

OSC

= 0V to 2V 20 80 %

SYNC

SW1 & SW2 Tied Together, I

= 5V 0.01 1 µA

SW1

= 5V 0.01 1 µA

SW2

SW1

+ I

= VIN, V

SHDN

= 2.75A 250 mV

SW2

= VIN, unless otherwise noted. (Note 2).

FAULT

l

l

1.195 1.215 1.230 V

l

3 9 16 mV

l

81 83.3 85 µA

l

81 83.3 85.5 µA

l

2.25 2.5 2.75 MHz

l

180 200 220 kHz

l

200 2500 kHz

l

1.3 V

l

l

1.9 2.4 3 A

l

3.3 4.3 5.4 A

LT3581

2.3 2.5 V

1/6 ratio

0.4 V

3/4

3581f

3

LT3581

查询LT3581供应商

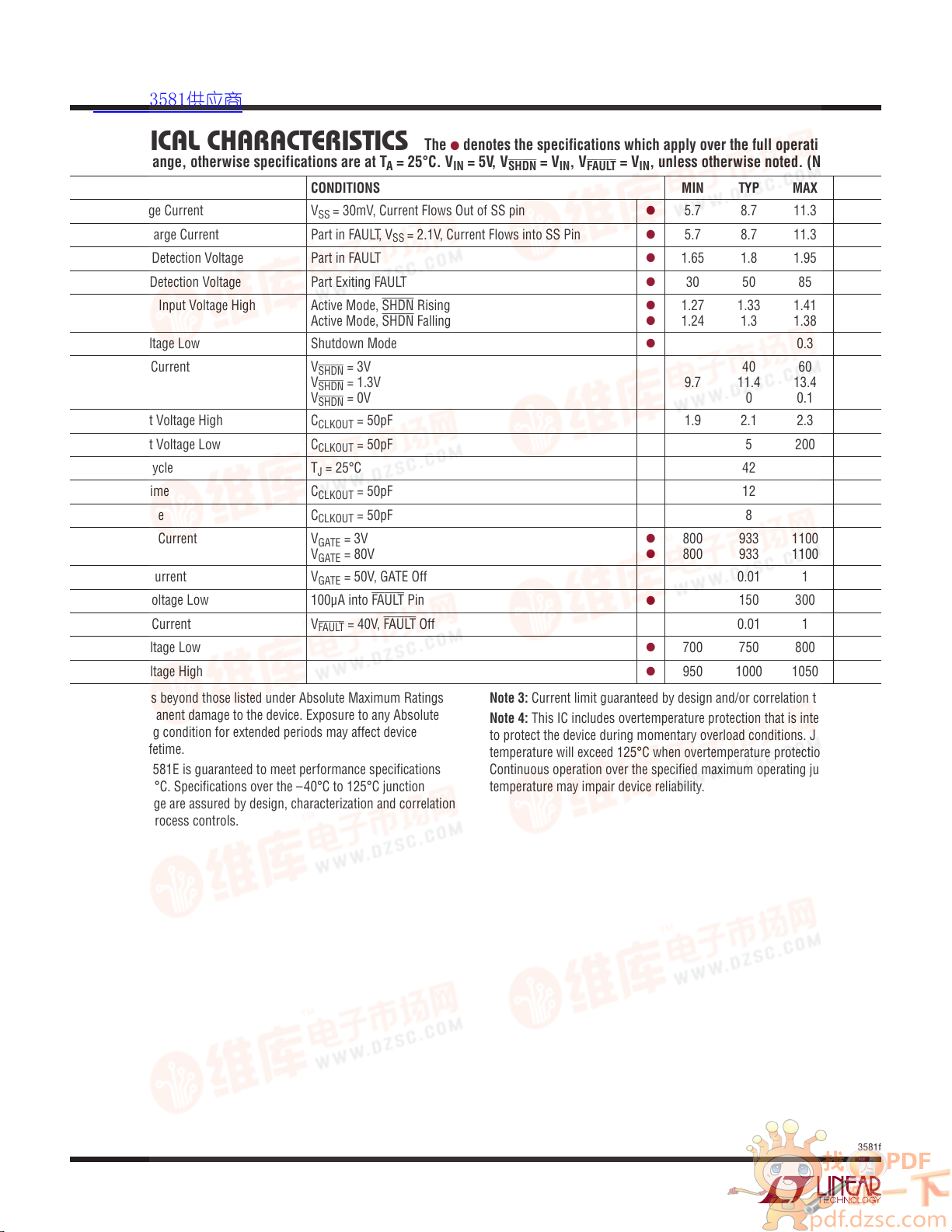

elecTrical characTerisTics

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VIN = 5V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Soft-Start Charge Current V

Soft-Start Discharge Current Part in FAULT, V

Soft-Start High Detection Voltage Part in FAULT

Soft-Start Low Detection Voltage Part Exiting FAULT

SHDN Minimum Input Voltage High Active Mode, SHDN Rising

SHDN Input Voltage Low Shutdown Mode

SHDN Pin Bias Current V

CLKOUT Output Voltage High C

CLKOUT Output Voltage Low C

CLKOUT Duty Cycle T

CLKOUT Rise Time C

CLKOUT Fall Time C

GATE Pull Down Current V

GATE Leakage Current V

FAULT Output Voltage Low 100μA into FAULT Pin

FAULT Leakage Current V

FAULT Input Voltage Low

FAULT Input Voltage High

= 30mV, Current Flows Out of SS pin

SS

= 2.1V, Current Flows into SS Pin

SS

Active Mode, SHDN Falling

= 3V

SHDN

V

= 1.3V

SHDN

V

= 0V

SHDN

= 50pF 1.9 2.1 2.3 V

CLKOUT

= 50pF 5 200 mV

CLKOUT

= 25°C 42 %

J

= 50pF 12 ns

CLKOUT

= 50pF 8 ns

CLKOUT

= 3V

GATE

V

= 80V

GATE

= 50V, GATE Off 0.01 1 µA

GATE

= 40V, FAULT Off 0.01 1 µA

FAULT

SHDN

= VIN, V

= VIN, unless otherwise noted. (Note 2).

FAULT

l

5.7 8.7 11.3 µA

l

5.7 8.7 11.3 µA

l

1.65 1.8 1.95 V

l

30 50 85 mV

l

1.27

l

1.24

l

9.7

l

800

l

800

l

l

700 750 800 mV

l

950 1000 1050 mV

1.33

1.3

40

11.4

0

933

933

150 300 mV

1.41

1.38

13.4

1100

1100

0.3 V

60

0.1

µA

µA

µA

µA

µA

V

V

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LT3581E is guaranteed to meet performance specifications

from 0°C to 125°C. Specifications over the –40°C to 125°C junction

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: Current limit guaranteed by design and/or correlation to static test.

Note 4: This IC includes overtemperature protection that is intended

to protect the device during momentary overload conditions. Junction

temperature will exceed 125°C when overtemperature protection is active.

Continuous operation over the specified maximum operating junction

temperature may impair device reliability.

3581f

4

DUTY CYCLE (%)

20

0

SW1 + SW2 FAULT CURRENT LIMIT (A)

1

2

3

4

30 50

70

80

3581 G01

5

6

40

60

SW1 + SW2 CURRENT (A)

0

SATURATION VOLTAGE (mV)

200

250

300

54

3581 G02

150

100

0

321

50

450

400

350

SW1 + SW2 CURRENT (A)

0

CURRENT SHARING = SW2/SW1 (%)

50

60

70

54

3581 G03

40

30

0

321

10

20

100

90

80

TEMPERATURE (°C)

–50 –25

0

SW1 + SW2 FAULT CURRENT LIMIT (A)

1

2

3

4

0 50 125 150

3581 G04

5

6

25 75 100

–50 –25 0 50 125 15025 75 100

TEMPERATURE (°C)

1.2100

POSITIVE FB VOLTAGE (V)

1.2125

1.2200

3581 G05

1.2175

1.2150

TEMPERATURE (°C)

–75 –50 –25

10

CLKOUT DC (%)

20

30

40

50

0 50 125 150

3581 G06

60

80

70

25 75 100

–50 –25 0 50 125 15025 75 100

TEMPERATURE (°C)

0

FREQUENCY (kHz)

3200

3581 G07

2800

2400

2000

1600

1200

800

400

RT = 34k

RT = 432k

FB VOLTAGE (V)

0

0

SWITCHING FREQUENCY RATIO (f

SW

/f

OSC

)

1/4

1/5

1/6

1/2

1/3

1

0.2 0.4 0.6 0.8

3581 G08

1.0 1.2

BOOSTING

CONFIGURATIONS

INVERTING

CONFIGURATIONS

0 60 8020 40

GATE VOLTAGE (V)

0

GATE CURRENT (µA)

1000

3581 G09

900

800

700

600

500

400

200

100

300

125°C

–40°C

25°C

查询LT3581供应商

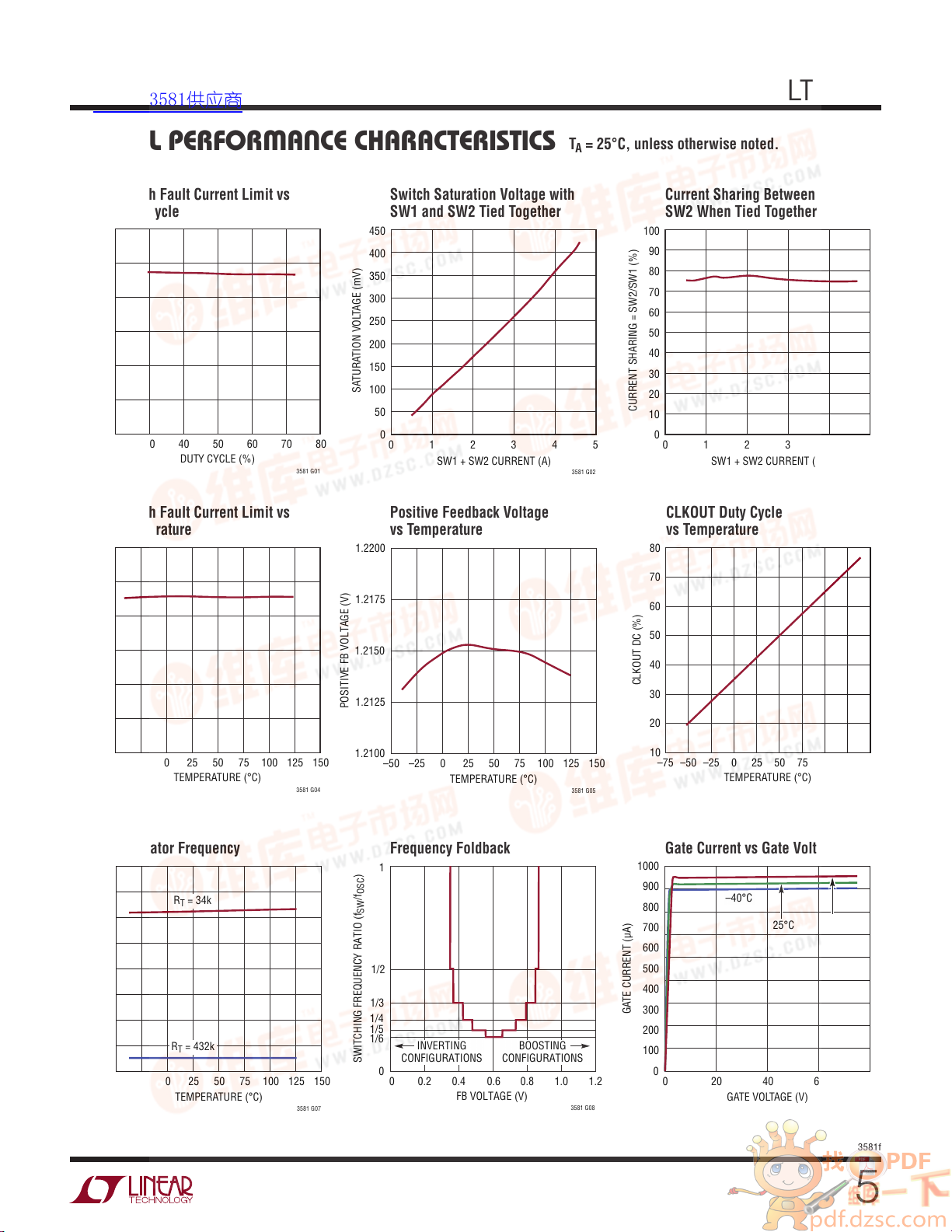

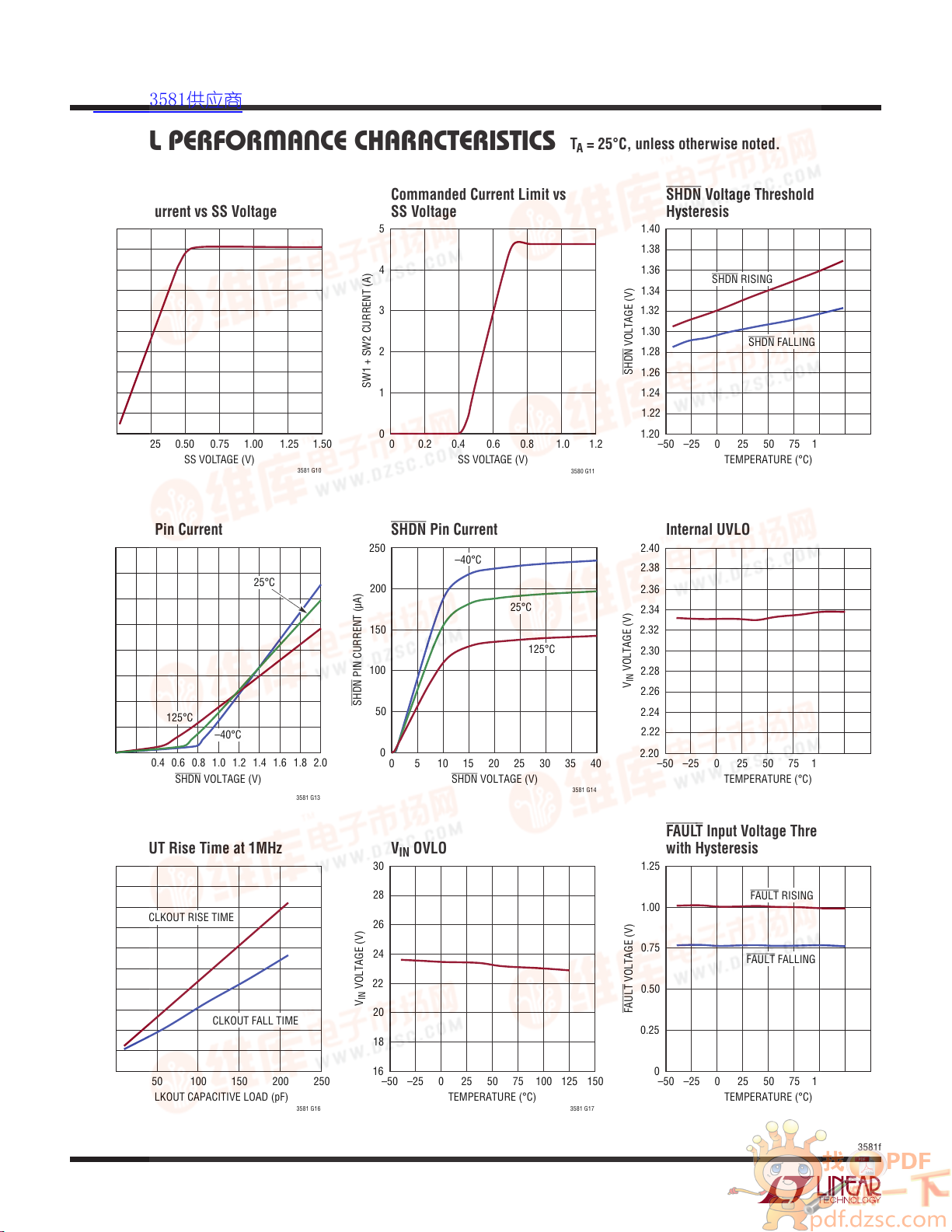

Typical perForMance characTerisTics

= 25°C, unless otherwise noted.

T

A

LT3581

Switch Fault Current Limit vs

Duty Cycle

Switch Fault Current Limit vs

Temperature

Switch Saturation Voltage with

SW1 and SW2 Tied Together

Positive Feedback Voltage

vs Temperature

Current Sharing Between SW1 and

SW2 When Tied Together

CLKOUT Duty Cycle

vs Temperature

Oscillator Frequency Frequency Foldback Gate Current vs Gate Voltage

3581f

5

LT3581

SS VOLTAGE (V)

0

0

GATE CURRENT (µA)

100

300

500

700

200

400

600

800

0.25 0.50 0.75 1.00

3581 G10

1.25 1.50

900

1000

SS VOLTAGE (V)

0

0

SW1 + SW2 CURRENT (A)

1

2

3

0.2 0.4 0.6 0.8

3580 G11

1.0 1.2

4

5

–50 –25 0 50 125 15025 75 100

TEMPERATURE (°C)

1.20

SHDN VOLTAGE (V)

1.22

1.26

1.28

1.30

1.40

1.34

3581 G12

1.24

1.36

1.38

1.32

SHDN RISING

SHDN FALLING

SHDN VOLTAGE (V)

0

0

SHDN PIN CURRENT (µA)

4

8

12

16

20

24

28

32

0.4 1.0 1.40.2 1.20.6 1.60.8 1.8 2.0

3581 G13

125°C

–40°C

25°C

SHDN VOLTAGE (V)

0

SHDN PIN CURRENT (µA)

200

250

15 25

3581 G14

150

100

5 10 20 403530

50

0

125°C

–40°C

25°C

–50 –25 0 50 125 15025 75 100

TEMPERATURE (°C)

2.20

V

IN

VOLTAGE (V)

2.22

2.26

2.28

2.30

2.40

2.34

3581 G15

2.24

2.36

2.38

2.32

–50 –25 0 50 125 15025 75 100

TEMPERATURE (°C)

16

V

IN

VOLTAGE (V)

18

20

30

24

3581 G17

26

28

22

–50 –25 0 50 125 15025 75 100

TEMPERATURE (°C)

0

FAULT VOLTAGE (V)

1.25

0.50

3581 G18

0.75

1.00

0.25

FAULT RISING

FAULT FALLING

0 50 250200150100

CLKOUT CAPACITIVE LOAD (pF)

0

CLKOUT RISE OR FALL TIME (ns)

5

15

20

25

50

35

3581 G16

10

40

45

30

CLKOUT FALL TIME

CLKOUT RISE TIME

查询LT3581供应商

Typical perForMance characTerisTics

TA = 25°C, unless otherwise noted.

Commanded Current Limit vs

Gate Current vs SS Voltage

SS Voltage

SHDN Pin Current SHDN Pin Current Internal UVLO

SHDN Voltage Threshold with

Hysteresis

CLKOUT Rise Time at 1MHz VIN OVLO

6

FAULT Input Voltage Threshold

with Hysteresis

3581f

R

V V

Boost or SEPIC

FB

OUT

=

•

– .

.

;

–

1 215

83 3 10

6

CConverter

R

V mV

Inv

FB

OUT

=

+

•

| |

.

;

–

9

83 3 10

6

eertingConverter

查询LT3581供应商

LT3581

pin FuncTions

(DFN/MSOP)

FB (Pin 1/Pin 1): Positive and Negative Feedback Pin. For

a Boost or Inverting Converter, tie a resistor from the FB

pin to V

according to the following equations:

OUT

VC (Pin 2/Pin 2): Error Amplifier Output Pin. Tie external

compensation network to this pin.

GATE (Pin 3/Pin 3): PMOS Gate Drive Pin. The GATE pin

is a pull-down current source, used to drive the gate of

an external PMOS for output short circuit protection or

output disconnect. The GATE pin current increases linearly

with the SS pin’s voltage, with a maximum pull-down

current of 933µA at SS voltages exceeding 500mV. Note

that if the SS voltage is greater than 500mV and the GATE

pin voltage is less than 2V, then the GATE pin looks like

a 2kΩ impedance to ground. See the Appendix for more

information.

FAULT (Pin 4/Pin 4): Fault Indication Pin. This active low,

bidirectional pin can either be pulled low (below 750mV)

by an external source, or internally by the chip to indicate a

fault. When pulled low, this pin causes the power switches

to turn off, the GATE pin to become high impedance, the

CLKOUT pin to become disabled, and the SS pin to go

through a charge/discharge sequence. The end/absence

of a fault is indicated when the voltage on this pin exceeds

1V. A pull-up resistor or current source is needed on this

pin to pull it above 1V in the absence of a fault.

(Pin 5/Pin 5): Input Supply Pin. Must be locally by-

V

IN

passed.

SW1 (Pins 6, 7/Pins 6,7, 8): Master Switch Pin. This is the

collector of the internal master NPN power switch.

Minimize the metal trace area connected to this pin to

minimize EMI.

CLKOUT (Pin 10/Pin 12): Clock Output Pin. Use this pin

to synchronize one or more other compatible switching

regulator ICs to the LT3581. The clock that this pin outputs

runs at the same frequency as the internal oscillator of the

part or as the SYNC pin. CLKOUT may also be used as a

temperature monitor since the CLKOUT pin’s duty cycle

varies linearly with the part’s junction temperature. Note

that the CLKOUT pin is only meant to drive capacitive

loads up to 50pF.

SHDN (Pin 11/Pin 13): Shutdown Pin. In conjunction

with the UVLO (undervoltage lockout) circuit, this pin is

used to enable/disable the chip and restart the soft-start

sequence. Drive below 300mV to disable the chip. Drive

above 1.33V (typical) to activate the chip and restart the

soft-start sequence. Do not float this pin.

RT (Pin 12/Pin 14): Timing Resistor Pin. Adjusts the

LT3581’s switching frequency. Place a resistor from this

pin to ground to set the frequency to a fixed free running

level. Do not float this pin.

SS (Pin 13/Pin 15): Soft-Start Pin. Place a soft-start

capacitor here. Upon start-up, the SS pin will be charged

by a (nominally) 250k resistor to about 2.1V. During a

fault, the SS pin will be slowly charged up and eventually

discharged as part of a timeout sequence (see the State

Diagram for more information on the SS pin’s role during

a fault event).

SYNC (Pin 14/Pin 16): To synchronize the switching

frequency to an outside clock, simply drive this pin with

a clock. The high voltage level of the clock must exceed

1.3V, and the low level must be less than 0.4V. Drive this

pin to less than 0.4V to revert to the internal free running

clock. See the Applications Information section for more

information.

GND (Exposed Pad Pin 15/Exposed Pad Pin 17): Ground.

Exposed pad must be soldered directly to local ground

plane.

SW2 (Pins 8, 9/Pins 9, 10, 11): Slave Switch Pin. This

is the collector of the internal slave NPN power switch.

Minimize the metal trace area connected to this pin to

minimize EMI.

3581f

7

LT3581

FREQUENCY

FOLDBACK

RAMP

GENERATOR

COMPARATOR

DRIVER

DISABLE

SS

LDO

V

C

R

GATE

14.6k

14.6k

SR1

A3

SYNC CLKOUT

÷N

SS

SHDN

C

OUT1

SW1

SW2

FB

27mΩ

R

S

20mΩ

GND

R

T

RT

R

C

C

C

V

C

R

FB

DRIVER

D1

V

IN

SYNC

BLOCK

UVLO

R

S

Q

3581 BD

–

+

A4

Q2

+

–

TD ~ 30ns

VBE • 0.9

1.17V

45mV

L1

FB

∑

ADJUSTABLE

OSCILLATOR

–

+

–

+

A1

A3

C

SS

C

IN

1.33V

+

–

–

+

+

–

250k

2.1V

1.8V

50mV

SOFT-

START

STARTUP

AND FAULT

LOGIC

C

OUT2

V

OUT

V

IN

M1

GATE

OPTIONAL

SAMPLE MODE BLOCK

R

FAULT

FAULT

933µA

–

+

+

–

+

–

+

–

+

–

+

–

+

–

+

–

DIE TEMP

22V

MIN

165°C

V

IN

750mV

SW1

**

**SW OVERVOLTAGE PROTECTION IS NOT GUARANTEED TO PROTECT THE LT3581 DURING SW OVERVOLTAGE EVENTS

**

I

SW1

42V

MIN

42V

MIN

1.9A

MIN

SW2

SAMPLE

–

+

A2

1.215V

REFERENCE

Q1

查询LT3581供应商

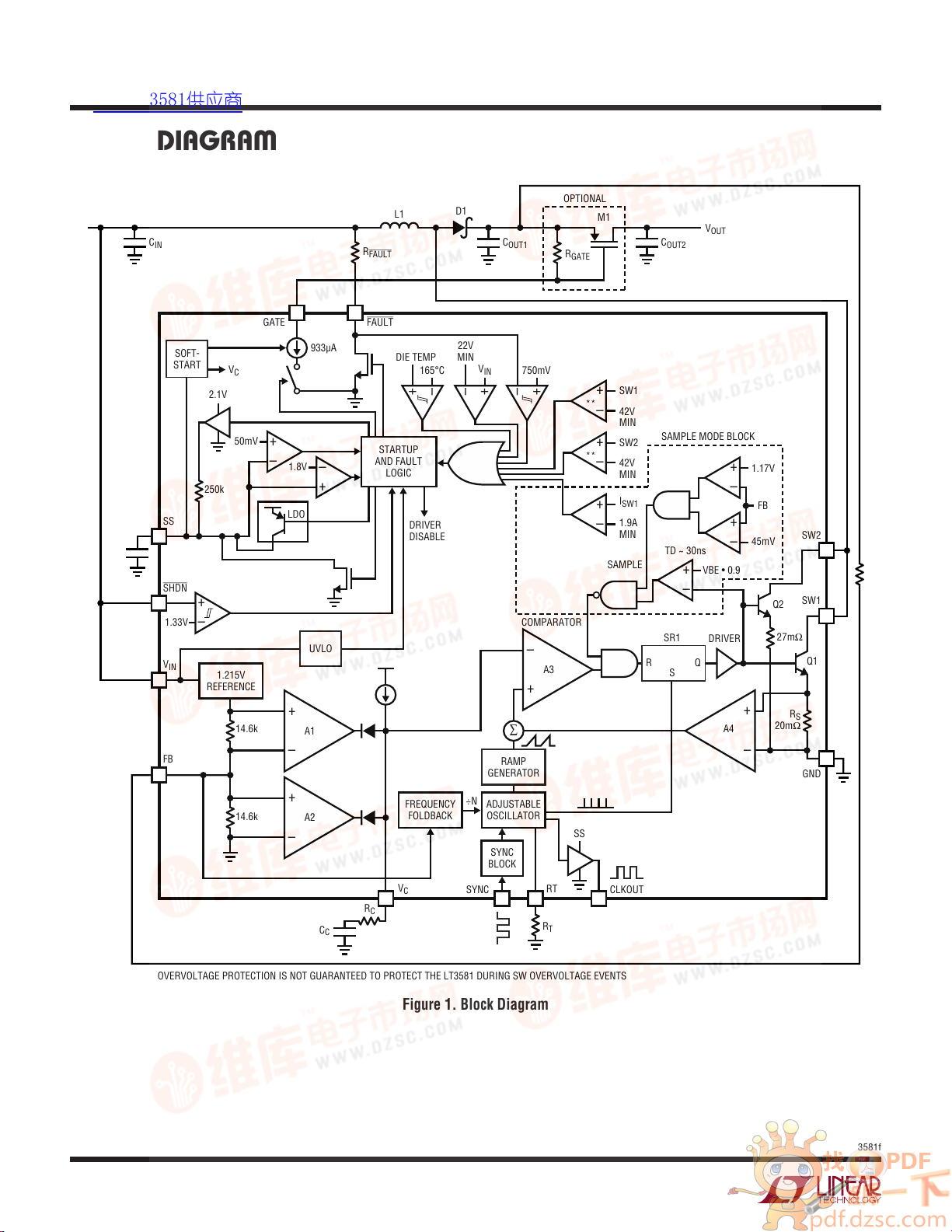

block DiagraM

3581f

Figure 1. Block Diagram

8

SHDN < 1.33V (TYPICAL)

or

V

IN

< 2.3V (TYPICAL)

SHDN > 1.33V (TYPICAL)

AND

V

IN

> 2.3V (TYPICAL)

FAULT DETECTED

• SS CHARGES UP

• IGATE OFF

• FAULT PIN PULLED LOW

INTERNALLY BY LT3581

• SWITCHER DISABLED

• CLKOUT DISABLED

SS < 50mV

IF |V

OUT

| DROPS CAUSING:

FB < 1.17V (BOOST)

OR

FB > 45mV (INVERTING)

FAULT1

FAULT1

SS > 1.8V AND

NO FAULT1 CONDITIONS

STILL DETECTED

SS < 50mV

FAULT1

FAULT1

FAULT1

FAULT1

FAULT2

FAULT PIN > 1.0V

FAULT1 = OVER VOLTAGE PROTECTION ON V

IN

(VIN > 22V MIN)

OVER TEMPERATURE (T

JUNCTION

> 165°C)

OVER CURRENT ON SW1 (I

SW1

> 1.9A MIN)

OVER VOLTAGE PROTECTION ON SW1 (V

SW1

> 42V MIN)

OVER VOLTAGE PROTECTION ON SW2 (V

SW2

> 42V MIN)

FAULT2 = FAULT PULLED LOW EXTERNALLY (FAULT < 0.75V)

CHIP OFF

• ALL SWITCHES DISABLED

• I

GATE

OFF

• FAULTS CLEARED

INITIALIZE

• SS PULLED LOW

NORMAL MODE

• NORMAL OPERATION

• CLKOUT ENABLED WHEN

SS > 1.8V

SAMPLE MODE

• Q1 & Q2 SWITCHES

FORCED ON EVERY CYCLE

FOR AT LEAST MINIMUM

ON TIME

• I

GATE

FULLY ACTIVATED

WHEN SS > 500mV

SOFT START

• I

GATE

ENABLED

• SS CHARGES UP

• SWITCHER ENABLED

POST FAULT DELAY

• SS SLOWLY DISCHARGES

LOCAL FAULT OVER

• INTERNAL FAULT PIN PULLDOWN

RELEASED BY LT3581

• SS CONTINUES DISCHARGING

TO GND

3581 SD

查询LT3581供应商

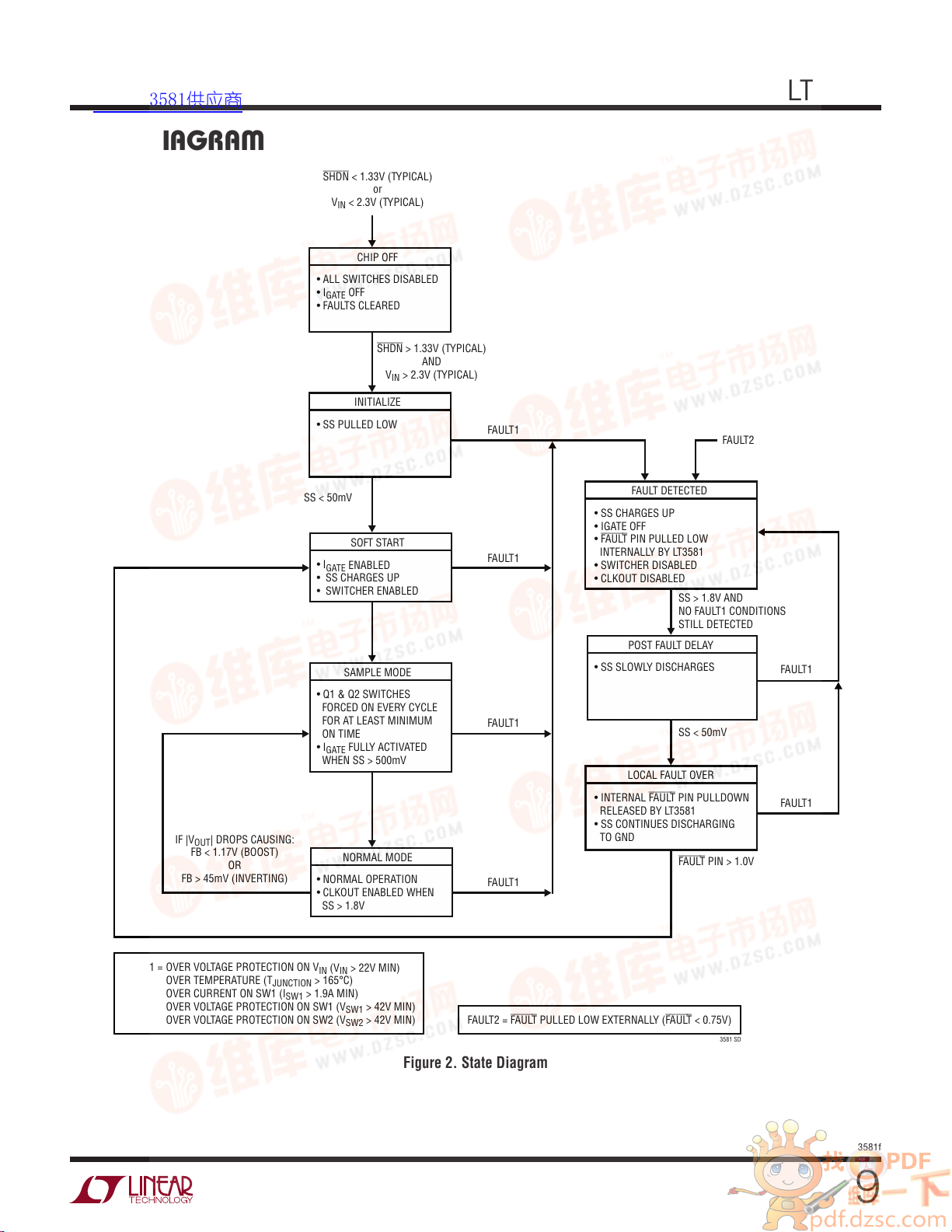

sTaTe DiagraM

LT3581

Figure 2. State Diagram

3581f

9

LT3581

R

V V

V

R

µ

UVLO

INUVLO

UVLO12

1 33

1 33

11 6

=

+

– .

.

.

AA

R

UVLO2

(OPTIONAL)

1.33V

R

UVLO1

3581 F03

V

IN

V

IN

ACTIVE/

LOCKOUT

GND

11.6µA

AT 1.33V

–

+

SHDN

查询LT3581供应商

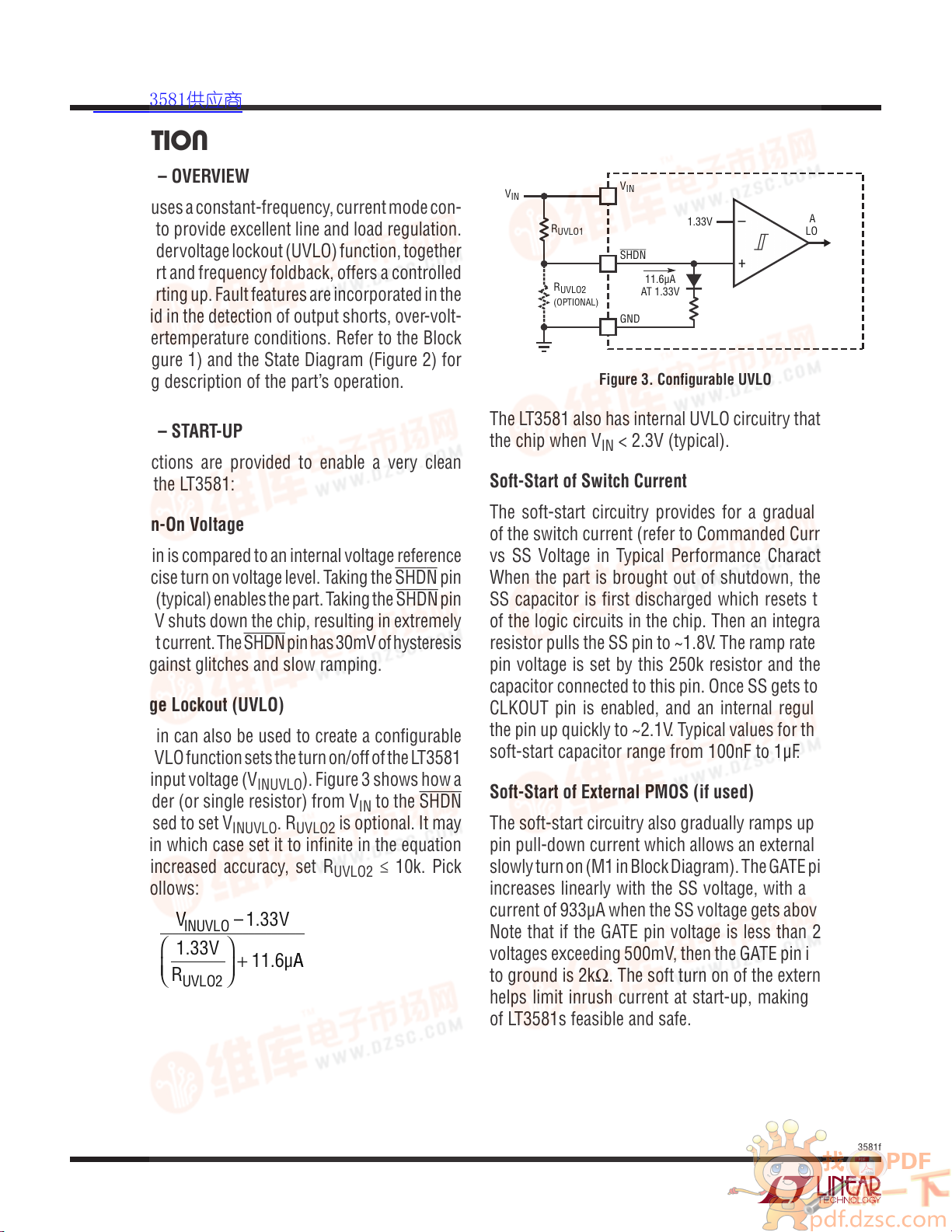

operaTion

OPERATION – OVERVIEW

The LT3581 uses a constant-frequency, current mode con-

trol scheme to provide excellent line and load regulation.

The part’s undervoltage lockout (UVLO) function, together

with soft-start and frequency foldback, offers a controlled

means of starting up. Fault features are incorporated in the

LT3581 to aid in the detection of output shorts, over-volt-

age, and overtemperature conditions. Refer to the Block

Diagram (Figure 1) and the State Diagram (Figure 2) for

the following description of the part’s operation.

Figure 3. Configurable UVLO

PERATION – START-UP

O

Several functions are provided to enable a very clean

start-up for the LT3581:

Precise Turn-On Voltage

The SHDN pin is compared to an internal voltage reference

to give a precise turn on voltage level. Taking the SHDN pin

above 1.33V (typical) enables the part. Taking the SHDN pin

below 300mV shuts down the chip, resulting in extremely

low quiescent current. The SHDN pin has 30mV of hysteresis

to protect against glitches and slow ramping.

Undervoltage Lockout (UVLO)

The SHDN pin can also be used to create a configurable

UVLO. The UVLO function sets the turn on/off of the LT3581

at a desired input voltage (V

resistor divider (or single resistor) from V

pin can be used to set V

INUVLO

). Figure 3 shows how a

INUVLO

IN

. R

is optional. It may

UVLO2

to the SHDN

be left out, in which case set it to infinite in the equation

below. For increased accuracy, set R

UVLO1

as follows:

R

≤ 10k. Pick

UVLO2

The LT3581 also has internal UVLO circuitry that disables

the chip when V

< 2.3V (typical).

IN

Soft-Start of Switch Current

The soft-start circuitry provides for a gradual ramp-up

of the switch current (refer to Commanded Current Limit

vs SS Voltage in Typical Performance Characteristics).

When the part is brought out of shutdown, the external

SS capacitor is first discharged which resets the states

of the logic circuits in the chip. Then an integrated 250k

resistor pulls the SS pin to ~1.8V. The ramp rate of the SS

pin voltage is set by this 250k resistor and the external

capacitor connected to this pin. Once SS gets to 1.8V, the

CLKOUT pin is enabled, and an internal regulator pulls

the pin up quickly to ~2.1V. Typical values for the external

soft-start capacitor range from 100nF to 1μF.

Soft-Start of External PMOS (if used)

The soft-start circuitry also gradually ramps up the GATE

pin pull-down current which allows an external PMOS to

slowly turn on (M1 in Block Diagram). The GATE pin current

increases linearly with the SS voltage, with a maximum

current of 933µA when the SS voltage gets above 500mV.

Note that if the GATE pin voltage is less than 2V for SS

voltages exceeding 500mV, then the GATE pin impedance

to ground is 2kΩ. The soft turn on of the external PMOS

helps limit inrush current at start-up, making hot-plugs

of LT3581s feasible and safe.

10

3581f

查询LT3581供应商

operaTion

LT3581

Sample Mode

Sample Mode is the mechanism used by the LT3581 to

aid in the detection of output shorts. It refers to a state of

the LT3581 where the master and slave power switches

(Q1 and Q2) are turned on for a minimum period of time

every clock cycle (or every few clock cycles in frequency

foldback) in order to “sample” the inductor current. If the

sampled current through Q1 exceeds the master switch cur-

rent limit of 1.9A (min), the LT3581 triggers an overcurrent

fault internally (see Operation-Fault section for details).

Sample Mode is active when FB is out of regulation by

more than approximately 3.7% (45mV < FB < 1.17V).

Frequency Foldback

The frequency foldback circuit reduces the switching fre-

quency when 350mV < FB < 900mV (typical). This feature

lowers the minimum duty cycle that the part can achieve,

thus allowing better control of the inductor current dur-

ing start-up. When the FB voltage is pulled outside of this

range, the switching frequency returns to normal.

Note that the peak inductor current at start-up is a function

of many variables including load profile, output capacitance,

target V

every application’s performance at start-up to ensure that

the peak inductor current does not exceed the minimum

fault current limit.

, VIN, switching frequency, etc. Test each and

OUT

Q1’s emitter current flows through a current sense resistor

) generating a voltage proportional to the total switch

(R

S

current. This voltage (amplified by A4) is added to a stabilizing ramp and the resulting sum is fed into the positive

terminal of the PWM comparator A3. When the voltage on

the positive input of A3 exceeds the voltage on the negative

input, the SR latch is reset, turning off the master and slave

power switches. The voltage on the negative input of A3

pin) is set by A1 (or A2), which is simply an amplified

(V

C

difference between the FB pin voltage and the reference

voltage (1.215V if the LT3581 is configured as a boost

converter, or 9mV if configured as an inverting converter).

In this manner, the error amplifier sets the correct peak

current level to maintain output regulation.

As long as the part is not in fault (see Operation – Fault

section) and the SS pin exceeds 1.8V, the LT3581 drives its

CLKOUT pin at the frequency set by the RT pin or the SYNC

pin. The CLKOUT pin can be used to synchronize other

compatible switching regulator ICs (including additional

LT3581s) with the LT3581. Additionally, CLKOUT’s duty

cycle varies linearly with the part’s junction temperature,

and may be used as a temperature monitor.

TION – FAULT

PERA

O

The LT3581’s FAULT pin is an active low, bidirectional pin

that is pulled low to indicate a fault. Each of the following

events can trigger a fault in the LT3581:

PERATION – REGULATION

O

The following description of the LT3581’s operation as-

sumes that the FB voltage is close enough to its regulation

target so that the part is not in sample mode. Use the

Block Diagram as a reference when stepping through the

following description of the LT3581 operating in regulation.

At the start of each oscillator cycle, the SR latch (SR1) is

set, which turns on the power switches Q1 and Q2. The

collector current through the master switch, Q1, is ~1.3

times the collector current through the slave switch, Q2,

when the collectors of the two switches are tied together.

AULT1 events:

A. F

1. SW Over

a.

b. (I

2. V

3. SW1 Voltage and/or SW2 Voltage > 42V

(minimum)

4. Die T

B. FAULT2 events:

1. Pulling the F

I

IN

current:

> 1.9A (minimum)

SW1

+ I

SW1

Voltage > 22V (minimum)

emperature > 165°C

) > 3.3A (minimum)

SW2

AULT pin low externally

3581f

11

LT3581

V

OUT

10V/DIV

V

CLKOUT

2V/DIV

I

L

2A/DIV

V

FAULT

5V/DIV

3581 F04

5µs/DIV

查询LT3581供应商

operaTion

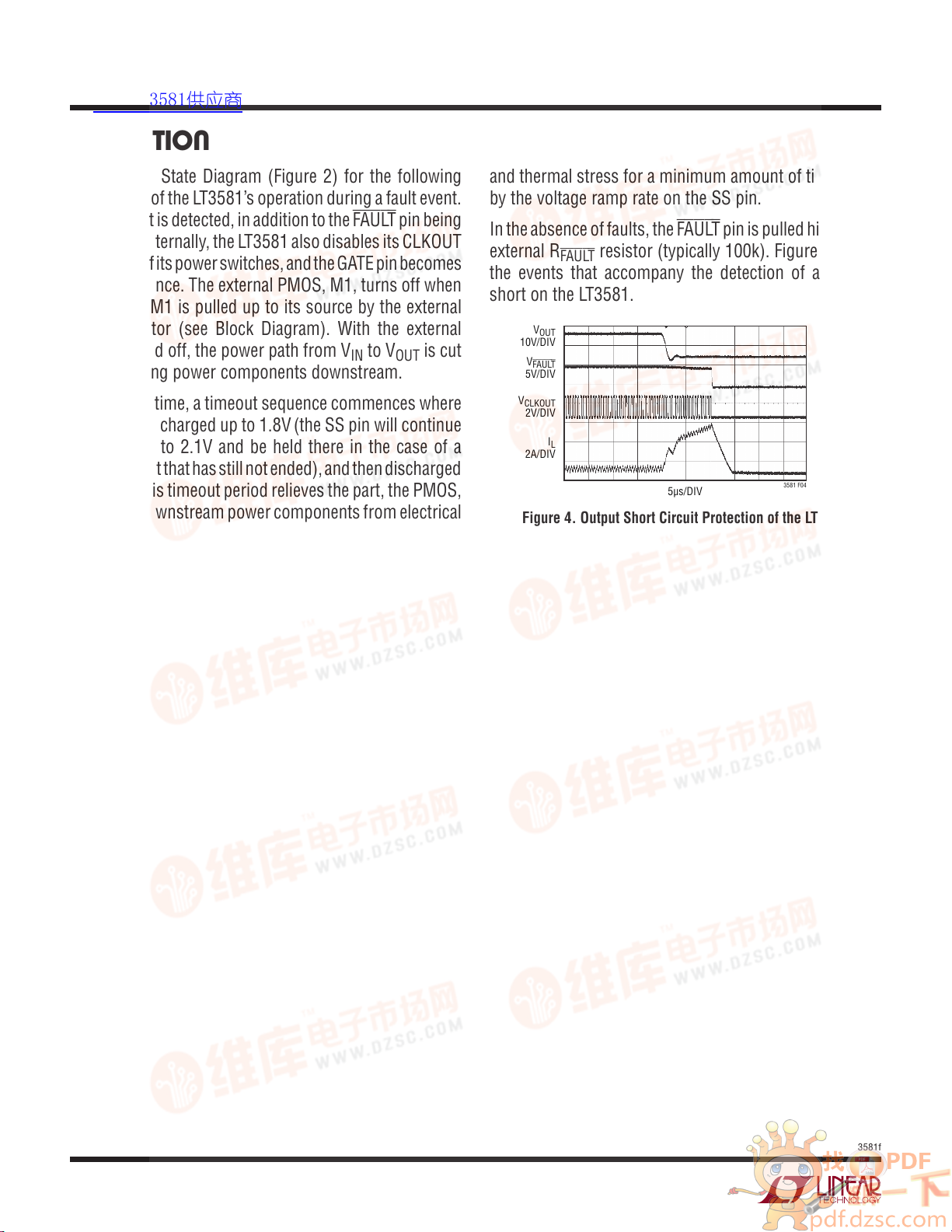

Refer to the State Diagram (Figure 2) for the following

description of the LT3581’s operation during a fault event.

When a fault is detected, in addition to the FAULT pin being

pulled low internally, the LT3581 also disables its CLKOUT

pin, turns off its power switches, and the GATE pin becomes

high impedance. The external PMOS, M1, turns off when

the gate of M1 is pulled up to its source by the external

resistor (see Block Diagram). With the external

R

GATE

PMOS turned off, the power path from V

IN

to V

OUT

is cut

off, protecting power components downstream.

At the same time, a timeout sequence commences where

the SS pin is charged up to 1.8V (the SS pin will continue

charging up to 2.1V and be held there in the case of a

FAULT1 event that has still not ended), and then discharged

to 50mV. This timeout period relieves the part, the PMOS,

and other downstream power components from electrical

and thermal stress for a minimum amount of time as set

by the voltage ramp rate on the SS pin.

In the absence of faults, the FAULT pin is pulled high by the

external R

resistor (typically 100k). Figure 4 shows

FAULT

the events that accompany the detection of an output

short on the LT3581.

Figure 4. Output Short Circuit Protection of the LT3581

3581f

12

D1

20V, 2A

V

IN

5V

R

GATE

6.04k

R

FAULT

100k

R

FB

130k

R

T

43.2k

C

IN

4.7µF

L1

1.5µH

C

C

1nF

C

OUT2

4.7µF

3581 F05

C

SS

0.1µF

R

C

10.5k

C

OUT1

4.7µF

V

OUT

12V

I

OUT

< 0.83A

SW1 SW2

FB

CLKOUT

GATE

V

C

SS

V

IN

RT

GND

SYNC

FAULT

SHDN

LT3581

C

F

56pF

OPTIONAL

PMOS

DC

V V V

V V V

OUT IN

OUT

≅

+

+

– .

. – .

0 5

0 5 0 3

L

V V DC

f A

L

V V

TYP

IN

OSC

MIN

IN

=

( )

•

•

=

( )

• •

– .

– .

0 3

1

0 3 2

DDC

A f DC

L

V V DC

f

OSC

MAX

IN

O

–

. –

– .

1

2 2 1

0 3

( )

• •

( )

=

( )

•

SSC

A• 0 35.

I

V V DC

f L

RIPPLE

IN

OSC

=

( )

•

•

– .0 3

1

I A

I

DC

OUT

RIPPLE

=

•

( )

3 3

2

1. – –

V V I I

R OUT AVG OUT

> >;

C C

I DC

f V I

OUT OUT

OUT

OSC OUT OUT

1 2

0 01 0 50

= ≥

•

. • – . • •

RR

DSON PMOS_

C C C

A DC

f V

I

IN VIN PWR

OSC IN

RIP

≥ + ≥

•

• • •

+

3 3

45 0 005..

PPLE

OSC IN

f V8 0 005• • . •

R

V V

µA

FB

OUT

=

– ..1 215

83 3

R

f

f in MHz and R in k

T

OSC

OSC T

=

87 61.

– ; Ω

查询LT3581供应商

applicaTions inForMaTion

LT3581

BOOST CONVERTER COMPONENT SELECTION

Figure 5. Boost Converter – The Component Values and Voltages

Given Are Typical Values for a 2MHz, 5V to 12V Boost

The LT3581 can be configured as a Boost converter as

in Figure 5. This topology allows for positive output volt-

ages that are higher than the input voltage. An external

PMOS (optional) driven by the GATE pin of the LT3581 can

achieve input or output disconnect during a fault event.

A single feedback resistor sets the output voltage. For

output voltages higher than 40V, see the Charge Pump

Aided Regulators section.

Table 1 is a step-by-step set of equations to calculate

component values for the LT3581 when operating as a

boost converter. Input parameters are input and output

voltage, and switching frequency (V

IN

OUT

and f

OSC

re-

, V

spectively). Refer to the Appendix for further information

on the design equations presented in Table 1.

Table 1. Boost Design Equations

PARAMETERS/EQUATIONS

Step 1:

Inputs

Step 2:

DC

Step 3:

L1

Step 4:

I

RIPPLE

Step 5:

I

OUT

Step 6:

D1

Step 7:

C

C

Pick V

, V

, and f

IN

OUT

to calculate equations below.

OSC

• Pick L1 out of a range of inductor values where the minimum

value of the range is set by L

The maximum value of the range is set by L

on how to choose current rating for inductor value chosen.

,

OUT1

OUT2

• If PMOS is not used, then use just one capacitor where

C

= C

+ C

OUT

OUT1

OUT2

.

TYP

or L

, whichever is higher.

MIN

. See appendix

MAX

(1)

(2)

(3)

Variable Definitions:

= Input Voltage

V

IN

= Output Voltage

V

OUT

DC = Power Switch Duty Cycle

= Switching Frequency

f

OSC

= Maximum Average Output Current

I

OUT

I

R

using PMOS)

= Inductor Ripple Current

RIPPLE

DSON_PMOS

= R

DSON

of External PMOS (set to 0 if not

Step 8:

C

IN

• Refer to Input Capacitor Selection in Appendix for definition of

C

VIN

and C

PWR

.

Step 9:

R

FB

Step 10:

R

T

Step 11:

PMOS

Only needed for input or output disconnect. See PMOS Selection

in the Appendix for information on sizing the PMOS, R

picking appropriae UVLO components.

GATE

and

Note 1: The maximum design target for peak switch current is 3.3A and is

used in this table.

, C

Note 2: The final values for C

above equations in order to obtain desired load transient performance.

OUT1

and CIN may deviate from the

OUT2

3581f

13

LT3581

DC

V V

V V V V

OUT

IN OUT

≅

+

+ +

0 5

0 5 0 3

.

. – .

L

V V DC

f A

L

V V

TYP

IN

OSC

MIN

IN

=

( )

•

•

=

( )

• •

– .

– .

0 3

1

0 3 2

DDC

A f DC

L

V V DC

f

OSC

MAX

IN

O

–

. –

– .

1

2 2 1

0 3

( )

• •

( )

=

( )

•

SSC

A• 0 35.

I

V V DC

f L

RIPPLE

IN

OSC

=

( )

•

•

– .0 3

I A

I

DC

OUT

RIPPLE

=

•

( )

3 3

2

1. – –

V V V I I

R IN OUT AVG OUT

> + >;

C µF V V

RATING IN

1 1≥ ≥;

C

I DC

f V

OUT

OUT

OSC OUT

≥

•

• •0 005.

C C C

A DC

f V

I

IN VIN PWR

OSC IN

RIP

≥ + ≥

•

• • •

+

3 3

45 0 005..

PPLE

OSC IN

f V8 0 005• • . •

R

V V

µA

FB

OUT

=

– ..1 215

83 3

R

f

f in MHz and R in k

T

OSC

OSC T

=

87 61.

– ; Ω

D1

30V, 2A

V

IN

3V TO 16V

R

FAULT

100k

R

T

124k

L1

3.3µH

3581 F06

C

SS

1µF

C

OUT

22µF

s2

L2

3.3µH

C

IN

22µF

V

OUT

5V

I

OUT

< 0.9A (VIN = 3V)

I

OUT

< 1.5A (VIN = 12V)

SW1 SW2

FB

CLKOUT

GATE

V

C

SS

V

IN

RT

GND

SYNC

FAULT

SHDN

ENABLE

LT3581

C

F

100pF

C1

1µF

R

FB

45.3k

•

•

C

C

2.2nF

R

C

7.87k

查询LT3581供应商

applicaTions inForMaTion

SEPIC CONVERTER COMPONENT SELECTION

(COUPLED OR UN-COUPLED INDUCTORS)

Figure 6. SEPIC Converter – The Component Values and Voltages

Given Are Typical Values for a 700kHz, Wide Input Range (3V to

16V) SEPIC Converter with 5V Out

The LT3581 can also be configured as a SEPIC as shown in

Figure 6. This topology allows for positive output voltages

that are lower, equal, or higher than the input voltage. Out-

put disconnect is inherently built into the SEPIC topology,

meaning no DC path exists between the input and output

due to capacitor C1. This implies that a PMOS controlled

by the GATE pin is not required in the power path.

Table 2 is a step-by-step set of equations to calculate

component values for the LT3581 when operating as a

SEPIC converter. Input parameters are input and output

voltage, and switching frequency (V

IN

OUT

and f

OSC

re-

, V

spectively). Refer to the Appendix for further information

on the design equations presented in Table 2.

Variable Definitions:

Table 2. SEPIC Design Equations

PARAMETERS/EQUATIONS

Step 1:

Inputs

Step 2:

DC

Step 3:

L

Step 4:

I

RIPPLE

Step 5:

I

OUT

Step 6:

D1

Step 7:

C1

Step 8:

C

OUT

Pick V

, V

, and f

IN

OUT

to calculate equations below.

OSC

• Pick L out of a range of inductor values where the minimum

value of the range is set by L

The maximum value of the range is set by L

Appendix on how to choose current rating for inductor value

chosen.

• Pick L1 = L2 = L for coupled inductors.

• Pick L1L2 = L for un-coupled inductors.

• L = L1 = L2 for coupled inductors.

• L = L1L2 for un-coupled inductors.

TYP

or L

, whichever is higher.

MIN

MAX

(1)

(2)

(3)

. See

= Input Voltage

V

IN

= Output Voltage

V

OUT

DC = Power Switch Duty Cycle

= Switching Frequency

f

OSC

= Maximum Average Output Current

I

OUT

I

14

= Inductor Ripple Current

RIPPLE

Step 9:

C

IN

• Refer to Input Capacitor Selection in Appendix for definition

of C

VIN

and C

PWR

.

Step 10:

R

FB

Step 11:

R

T

Note 1: The maximum design target for peak switch current is 3.3A and is

used in this table.

Note 2: The final values for C

equations in order to obtain desired load transient performance.

, CIN and C1 may deviate from the above

OUT

3581f

DC

V V

V V V V

OUT

IN OUT

≅

+

+ +

| | .

| | . – .

0 5

0 5 0 3

L

V V DC

f A

L

V V

TYP

IN

OSC

MIN

IN

=

( )

•

•

=

( )

• •

– .

– .

0 3

1

0 3 2

DDC

A f DC

L

V V DC

f

OSC

MAX

IN

O

–

. –

– .

1

2 2 1

0 3

( )

• •

( )

=

( )

•

SSC

A• 0 35.

I

V V DC

f L

RIPPLE

IN

OSC

=

( )

•

•

– .0 3

I A

I

DC

OUT

RIPPLE

=

•

( )

3 3

2

1. – –

V V V I I

R IN OUT AVG OUT

> + >| | ;

C µF V V V

RATING IN OUT

1 1≥ ≥ +; | |

C

I

f V

OUT

RIPPLE

OSC OUT

≥

• •

( )

8 0 005. | |

C C C

A DC

f V

I

IN VIN PWR

OSC IN

RIP

≥ + ≥

•

• • •

+

3 3

45 0 005..

PPLE

OSC IN

f V8 0 005• • . •

R

V mV

µA

FB

OUT

=

+| |.5

83 3

R

f

f in MHz and R in k

T

OSC

OSC T

=

87 61.

– ; Ω

L2

3.3µH

D1

20V

1A

V

IN

5V

R

FAULT

100k

R

T

43.2k

L1

3.3µH

3581 F07

C

SS

100nF

C

OUT

4.7µF

C

IN

3.3µF

V

OUT

–12V

I

OUT

< 625mA

SW1 SW2

FB

CLKOUT

GATE

V

C

SS

V

IN

RT

GND

SYNC

FAULT

SHDN

ENABLE

LT3581

C

F

47pF

R

FB

143k

•

•

C

C

1nF

R

C

11k

C1

1µF

查询LT3581供应商

applicaTions inForMaTion

LT3581

DUAL INDUCTOR INVERTING CONVERTER COMPONENT

SELECTION (COUPLED OR UN-COUPLED INDUCTORS)

Figure 7. Dual Inductor Inverting Converter – The Component

Values and Voltages Given Are Typical Values for a 2MHz, 5V to

–12V Inverting Topology Using Coupled Inductors

Due to its unique FB pin, the LT3581 can work in a Dual

Inductor Inverting configuration as in Figure 7. Changing

the connections of L2 and the Schottky diode in the SEPIC

topology results in generating negative output voltages.

This solution results in very low output voltage ripple

due to inductor L2 being in series with the output. Output

disconnect is inherently built into this topology due to the

capacitor C1.

Table 3. Dual Inductor Inverting Design Equations

PARAMETERS/EQUATIONS

, V

Step 1: Inputs Pick V

Step 2: DC

Step 3: L

• Pick L out of a range of inductor values where the

minimum value of the range is set by L

whichever is higher. The maximum value of the range

is set by L

rating for inductor value chosen.

• Pick L1 = L2 = L for coupled inductors.

• Pick L1L2 = L for un-coupled inductors.

Step 4: I

RIPPLE

• L = L1 = L2 for coupled inductors.

• L = L1L2 for un-coupled inductors.

Step 5: I

OUT

Step 6: D1

, and f

IN

OUT

MAX

to calculate equations below.

OSC

TYP

. See Appendix on how to choose current

or L

MIN

(1)

(2)

(3)

,

Table 3 is a step-by-step set of equations to calculate

component values for the LT3581 when operating as a

dual inductor inverting converter. Input parameters are

input and output voltage, and switching frequency (V

and f

V

OUT

OSC

further information on the design equations presented

in Table 3.

Variable Definitions:

= Input Voltage

V

IN

= Output Voltage

V

OUT

DC = Power Switch Duty Cycle

= Switching Frequency

f

OSC

I

I

= Maximum Average Output Current

OUT

= Inductor Ripple Current

RIPPLE

respectively). Refer to the Appendix for

IN

Step 7: C1

Step 8: C

,

Step 9: C

Step 10: R

Step 11: R

Note 1: The maximum design target for peak switch current is 3.3A and is

used in this table.

Note 2: The final values for C

equations in order to obtain desired load transient performance.

OUT

IN

• Refer to Input Capacitor Selection in Appendix for

definition of C

FB

T

and C

VIN

, CIN and C1 may deviate from the above

OUT

PWR

.

3581f

15

LT3581

3581 F08

V

OUT

C

IN

B

A

SYNC

GND

A: RETURN C

IN

GROUND DIRECTLY TO LT3581 EXPOSED PAD PIN 17. IT IS ADVISED TO NOT

COMBINE C

IN

GROUND WITH GND EXCEPT AT THE EXPOSED PAD.

B: RETURN C

OUT

AND C

OUT1

GROUND DIRECTLY TO LT3581 EXPOSED PAD PIN 17. IT IS ADVISED

TO NOT COMBINE C

OUT

AND C

OUT1

GROUND WITH GND EXCEPT AT THE EXPOSED PAD.

SHDN

CLKOUT

+

–

V

IN

+

–

L1

17

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

C

OUT1

R

GATE

C

OUT

D1

M1

D2

3581 F09

V

OUT

C

IN

C1

D1

B

A

SYNC

GND

A: RETURN C

IN

AND L2 GROUND DIRECTLY TO LT3581 EXPOSED PAD PIN 17. IT IS ADVISED

TO NOT COMBINE C

IN

AND L2 GROUND WITH GND EXCEPT AT THE EXPOSED PAD.

B: RETURN C

OUT

GROUNDS DIRECTLY TO LT3581 EXPOSED PAD PIN 17. IT IS ADVISED

TO NOT COMBINE C

OUT

GROUND WITH GND EXCEPT AT THE EXPOSED PAD.

L1, L2: MOST COUPLED INDUCTOR MANUFACTURERS USE CROSS PINOUT FOR IMPROVED

PERFORMANCE.

C

OUT

SHDN

CLKOUT

+

–

V

IN

+

–

•

•

L2

L1

17

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

查询LT3581供应商

applicaTions inForMaTion

LAYOUT GUIDELINES FOR BOOST, SEPIC, AND DUAL

INDUCTOR INVERTING TOPOLOGIES

General Layout Guidelines

• To optimize thermal performance, solder the exposed

ground pad of the LT3581 to the ground plane, with

multiple vias around the pad connecting to additional

ground planes.

• A

ground plane should be used under the switcher circuitry

to prevent interplane coupling and overall noise.

• High

speed switching path (see specific topology for

more information) must be kept as short as possible.

• The

V

, FB, and RT components should be placed as

C

close to the LT3581 as possible, while being as far

away as practically possible from the switch node. The

ground for these components should be separated from

the switch current path.

• Place the bypass capacitor for the V

pin as close as

IN

possible to the LT3581.

• Place the bypass capacitor for the inductor as close as

possible to the inductor.

• The

load should connect directly to the positive and

negative terminals of the output capacitor for best load

regulation.

Boost Topology Specific Layout Guidelines

• Keep length of loop (high speed switching path) governing switch, diode D1, output capacitor C

OUT1

, and

ground return as short as possible to minimize parasitic

inductive spikes at the switch node during switching.

SEPIC Topology Specific Layout Guidelines

• Keep

length of loop (high speed switching path) governing switch, flying capacitor C1, diode D1, output

capacitor C

, and ground return as short as possible

OUT

to minimize parasitic inductive spikes at the switch node

during switching.

Inverting Topology Specific Layout Guidelines

• Keep

ground return path from the cathode of D1 (to

chip) separated from output capacitor C

OUT

’s ground

return path (to chip) in order to minimize switching

noise coupling into the output.

• Keep length of loop (high speed switching path) governing switch, flying capacitor C1, diode D1, and ground

return as short as possible to minimize parasitic inductive spikes at the switch node during switching.

Figure 8. Suggested Component Placement for Boost Topology

(MSOP Shown, DFN Similar, Not to Scale.) Pin 15 on DFN or

Pin 17 on MSOP Is the Exposed Pad Which Must Be Soldered

Directly to the Local Ground Plane for Adequate Thermal

Performance. Multiple Vias to Additional Ground Planes Will

Improve Thermal Performance

16

Figure 9. Suggested Component Placement for SEPIC Topology

(MSOP Shown, DFN Similar, Not to Scale.) Pin 15 on DFN or

Pin 17 on MSOP Is the Exposed Pad Which Must Be Soldered

Directly to the Local Ground Plane for Adequate Thermal

Performance. Multiple Vias to Additional Ground Planes Will

Improve Thermal Performance

3581f

DC

V V V

V V V

OUT IN D

OUT D CESAT

=

+

+––

DC

V V V

V V V

=

+

+

12 5 0 45

12 0 45 0 21

– .

. – .

I

V I

V

IN

OUT OUT

IN

=

•

• η

I

V A

V

IN

=

•

•

12 0 83

5 0 88..

P DC I R

SWDC IN SW

= • •

2

P A m

SWDC

= • •0 609 2 3 90

2

. ( . ) Ω

P ns I V f

SWAC IN OUT OSC

= • • •13

P ns A V MHz

SWAC

=

( )

• • •

( )

13 2 3 12 2.

P

V I DC

BDC

IN IN

=

• •

45

P

V A

BDC

=

• •5 2 3 0 609

45

. .

P mA V

INP IN

= •9

P mA V

INP

= •9 5

3581 F10

C

IN

B

A

C

SYNC

GND

A: RETURN C

IN

GROUND DIRECTLY TO LT3581 EXPOSED PAD PIN 17. IT IS ADVISED

TO NOT COMBINE C

IN

GROUND WITH GND EXCEPT AT THE EXPOSED PAD.

B: RETURN C

OUT

GROUND DIRECTLY TO LT3581 EXPOSED PAD PIN 17. IT IS ADVISED

TO NOT COMBINE C

OUT

GROUND WITH GND EXCEPT AT THE EXPOSED PAD.

C: RETURN D1 GROUND DIRECTLY TO LT3581 EXPOSED PAD PIN 17. IT IS ADVISED

TO NOT COMBINE D1 GROUND WITH GND EXCEPT AT THE EXPOSED PAD.

L1, L2: MOST COUPLED INDUCTOR MANUFACTURERS USE CROSS PINOUT FOR

IMPROVED PERFORMANCE.

C

OUT

SHDN

CLKOUT

– V

OUT

GND

V

IN

+

–

•

•

L2

L1

17

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

C1

D1

查询LT3581供应商

applicaTions inForMaTion

LT3581

the heat generated within the package. This can be

accomplished by taking advantage of the thermal pad on

the underside of the IC. It is recommended that multiple

vias in the printed circuit board be used to conduct heat

away from the IC and into a copper plane with as much

area as possible.

Power and Thermal Calculations

Power dissipation in the LT3581 chip comes from four

2

primary sources: switch I

R losses, switch dynamic

losses, NPN base drive DC losses, and miscellaneous

input current losses. These formulas assume continuous

mode operation, so they should not be used for calculating

thermal losses or efficiency in discontinuous mode or at

light load currents.

The following example calculates the power dissipa-

Figure 10. Suggested Component Placement for Dual Inductor

Inverting Topology (MSOP Shown, DFN Similar, Not to Scale.)

Pin 15 on DFN or Pin 17 on MSOP Is the Exposed Pad Which

Must Be Soldered Directly to the Local Ground Plane for

Adequate Thermal Performance. Multiple Vias to Additional

Ground Planes Will Improve Thermal Performance

THERMAL CONSIDERATIONS

Overview

For the

LT3581 to deliver its full output power, it is imp-

tion in the LT3581 for a particular boost application

(V

IN

V

CESAT

= 5V, V

= 0.21V).

OUT

= 12V, I

OUT

= 0.83A, f

= 2MHz, VD = 0.45V,

OSC

To calculate die junction temperature, use the appropriate

thermal resistance number and add in worst-case ambient

temperature:

= TA + θJA • P

T

J

TOTAL

erative that a good thermal path be provided to dissipate

Table 4. Power Calculations Example for Boost Converter with VIN = 5V, V

DEFINITION OF VARIABLES EQUATIONS DESIGN EXAMPLE VALUE

DC = SWITCH DUTY CYCLE

OUT

= 12V, I

= 0.83A, f

OUT

= 2MHz, VD = 0.45V, V

OSC

= 0.21V

CESAT

DC = 60.9%

= Average Switch Current

I

IN

η = Power Conversion Efficiency

(typically 88% at high currents)

= Switch I2R Loss (DC)

P

SWDC

R

= Switch Resistance (typically

SW

90mΩ combined SW1 and SW2)

= Switch Dynamic Loss (AC)

P

SWAC

= Base Drive Loss (DC)

P

BDC

= Input Power Loss

P

INP

IIN = 2.3A

P

SWDC

P

SWAC

P

BDC

P

INP

P

TOTAL

= 290mW

= 718mW

= 156mW

= 45mW

= 1.209W

3581f

17

LT3581

T

DC

J

CLKOUT

=

– %

. %

35

0 3

f

R

OSC

T

=

+

87 61.

R

f

T

OSC

=

87 61.

–

查询LT3581供应商

applicaTions inForMaTion

where TJ = Die Junction Temperature, TA = Ambient Tem-

perature, P

shown in Table 4, and θ

is the final result from the calculations

TOTAL

is the thermal resistance from

JA

the silicon junction to the ambient air.

The published (http://www.linear.com/designtools/packag-

ing/Linear_Technology_Thermal_Resistance_Table.pdf)

value is 43°C/W for the 4mm × 3mm 14-pin DFN

θ

JA

package and 45°C/W for the 16-lead MSOP package. In

practice, lower θ

values are realizable if board layout is

JA

performed with appropriate grounding (accounting for heat

sinking properties of the board) and other considerations

listed in the Layout Guidelines section. For instance, a

value of ~24°C/W was consistently achieved for both

θ

JA

MSE and DFN packages of the LT3581 (at V

12V, I

= 0.83A, f

OUT

= 2MHz) when board layout was

OSC

= 5V, V

IN

OUT

=

optimized as per the suggestions in the Board Layout

Guidelines section.

Junction Temperature Measurement

The duty cycle of the CLKOUT signal is linearly propor-

tional to die junction temperature, T

. To get a temperature

J

reading, measure the duty cycle of the CLKOUT signal and

use the following equation to approximate the junction

temperature:

Thermal Lockout

A fault condition occurs when the die temperature exceeds

165°C (see Operation Section), and the part goes into

thermal lockout. The fault condition ceases when the die

temperature drops by ~5°C (nominal).

WITCHING

S

FREQUENCY

There are several considerations in selecting the operating frequency of the converter. The first is staying clear

of sensitive frequency bands, which cannot tolerate any

spectral noise. For example, in products incorporating RF

communications, the 455kHz IF frequency is sensitive to

any noise, therefore switching above 600kHz is desired.

Some communications have sensitivity to 1.1MHz and in

that case a 1.5MHz switching converter frequency may be

employed. The second consideration is the physical size

of the converter. As the operating frequency goes up, the

inductor and filter capacitors go down in value and size.

The tradeoff is efficiency, since the losses due to switching dynamics (see Thermal Considerations), Schottky

diode charge, and other capacitive loss terms increase

proportionally with frequency.

Oscillator Timing Resistor (R

)

T

where DC

CLKOUT

is the CLKOUT duty cycle in % and TJ

is the die junction temperature in °C. Although the actual

die temperature can deviate from the above equation by

±15°C, the relationship between change in CLKOUT duty

cycle and change in die temperature is well defined. Basi-

cally a 1% change in CLKOUT duty cycle corresponds to a

3.33°C change in die temperature. Note that the CLKOUT

pin is only meant to drive capacitive loads up to 50pF.

The operating frequency of the LT3581 can be set by the

internal free-running oscillator. When the SYNC pin is driven

low (< 0.4V), the frequency of operation is set by a resistor

from the R

pin to ground. An internally trimmed timing

T

capacitor resides inside the IC. The oscillator frequency

is calculated using the following formula:

where f

is in MHz and RT is in k. Conversely, RT (in k)

OSC

can be calculated from the desired frequency (in MHz)

using:

3581f

18

ENABLE

1.5µH

1.5µH

6.8µF

4.7µF

4.7µF

2.2µF

100pF

SW1 SW2

GATE FB

V

C

SS

GND

SYNC

CLKOUTV

IN

RT

SHDN

FAULT

LT3581

SLAVE

SW1 SW2

GATE CLKOUT

V

C

SS

GND

SYNC

FBV

IN

RT

FAULT

SHDN

LT3581

MASTER

143k

V

OUT

–12V

450mA

V

IN

5V

V

OUT

12V

830mA

10k

10.5k

2.2nF

0.1µF

0.1µF

130k

43.2k

56pF

1nF

43.2k

100k

10k

3581 F11

6.8µF

查询LT3581供应商

LT3581

applicaTions inForMaTion

Clock Synchronization

The operating frequency of the LT3581 can be set by an

external source by simply providing a digital clock signal

into the SYNC pin (R

will revert to its internal free-running oscillator clock (set

by the R

resistor) when the SYNC pin is driven below

T

0.4V for a few free-running clock periods.

Driving SYNC high for an extended period of time effec-

tively stops the operating clock and prevents latch SR1

from becoming set (see Block Diagram). As a result, the

switching operation of the LT3581 will stop and the CLKOUT

pin will be held at ground.

The duty cycle of the SYNC signal must be between 20%

and 80% for proper operation. Also, the frequency of the

SYNC signal must meet the following two criteria:

SYNC may not toggle outside the frequency range of

(1)

200kHz to 2.5MHz unless it is stopped low (below

0.4V) to enable the free-running oscillator.

(2) The SYNC frequency can always be higher than the

free-running oscillator frequency (as set by the R

resistor), f

below f

OSC

CLOCK SYNCHRONIZATION OF ADDITIONAL

REGULATORS

The CLKOUT pin of the LT3581 can be used to synchronize

one or more other compatible switching regulator ICs as

shown in Figure 11.

The frequency of the master LT3581 is set by the external

resistor. The SYNC pin of the slave LT3581 is driven

R

T

by the CLKOUT pin of the master LT3581. Note that the

RT pin of the slave LT3581 must have a resistor tied to

ground. It takes a few clock cycles for the CLKOUT signal

to begin oscillating, and it’s preferable for all LT3581s to

have the same internal free-running frequency. Therefore,

in general, use the same value R

synchronized LT3581s.

resistor still required). The LT3581

T

, but should not be less than 25%

OSC

.

resistor for all of the

T

Figure 11. A Single Inductor Inverting Topology Is Synchronized

with a Boost Regulator to Generate –12V and 12V Outputs. The

External PMOS Helps Disconnect the Input from the Power Paths

During Fault Events

T

Also, the FAULT pins can be tied together so that a fault

condition from one LT3581 causes all of the LT3581s to

enter fault, until the fault condition disappears.

HARGE

C

PUMP AIDED REGULATORS

Designing charge pumps with the LT3581 can offer efficient solutions with fewer components than traditional

circuits because of the master/slave switch configuration

on the IC. Although the slave switch, SW2, operates in

phase with the master switch, SW1, it is only the current

through the master switch (SW1) that is sensed by the

current comparator (A4 in Block Diagram) as part of the

current feedback loop. This method of operation by the

master/slave switches can offer the following benefits to

charge pump designs:

3581f

19

LT3581

V

IN

12V

V

OUT2

97V

140mA

V

OUT1

65V

70mA

24k

2.2µF

10µH

2.2µF

2.2µF

0.47µF

43.2k

100pF

1nF

100k

2.2µF

370k

SW1 SW2

FB

V

C

SS

GND

SYNC

GATE

CLKOUT

V

IN

RT

FAULT

SHDN

LT3581

3581 F12

8.06k

2.2µF

2.2µF

2.2µF

ENABLE

C

VC2

V

IN

C

OUT

V

OUT

< 0V

AND |V

OUT

| > |VIN|

SW1 SW2

GATE FB

V

C

SS

GND

SYNC

CLKOUTV

IN

RT

FAULT

SHDN

LT3581

100k

L1

D1

D2

D3

C1

R

FB

C

VC1

C

SS

C

IN

R

VC

R

T

3579 F13

查询LT3581供应商

applicaTions inForMaTion

• The slave switch, by not performing a current sense

operation like the master switch, can sustain fairly large

current spikes when the flying capacitors charge up.

Since this current spike flows through SW2, it does

not affect the operation of the current comparator (A4

in Block Diagram).

The

•

• Since the slave switch can sustain large current spikes,

master switch, immune from the capacitor current

spike (seen only by the slave switch) can sense the

inductor current more accurately.

the diodes that feed current into the flying capacitors do

not need current limiting resistors, leading to efficiency

and thermal improvements.

High V

Charge Pump Topology

OUT

The LT3581 can be used in a charge-pump topology as

shown in Figure 12, multiplying the output of an inductive

boost converter. The master switch (SW1) can be used to

drive the inductive boost converter (first stage of charge

pump), while the slave switch (SW2) can be used to drive

one or more other charge pump stages. This topology is

useful for high voltage applications including VFD bias

supplies.

Single Inductor Inverting Topology

If there is a need to use just one inductor to generate a

negative output voltage whose magnitude is greater than

, the single inductor inverting topology (shown in Figure

V

IN

13) can be used. Since the master and slave switches are

isolated by a Schottky diode, the current spike through C1

will flow only through the slave switch, thereby preventing

the current comparator, (A4 in the Block Diagram), from

falsely tripping. Output disconnect is inherently built into

the single inductor topology.

Figure 12. High V

Charge Pump Topology Can Be Used to

OUT

Build VFD Bias Supplies

Figure 13. Single Inductor Inverting Topology

20

3581f

V

OUT

10V/DIV

SS

1V/DIV

I

L

5A/DIV

V

IN

5V/DIV

3581 F14

1s/DIV

查询LT3581供应商

applicaTions inForMaTion

LT3581

HOT-PLUG

The high inrush current associated with hot-plugging V

IN

can be largely rejected with the use of an external PMOS. A

simple hot-plug controller can be designed by connecting

an external PMOS in series with V

, with the gate of the

IN

PMOS being driven by the GATE pin of the LT3581. Since

the GATE pin pull-down current is linearly proportional to

the SS voltage, and the SS charge up time is relatively slow,

the GATE pin pull-down current will increase gradually,

thereby turning on the external PMOS slowly. Controlled

in this manner, the PMOS acts as an input current limiter

when V

hot-plugs or ramps up sharply.

IN

Likewise, when the PMOS is connected in series with the

output, inrush currents into the output capacitor can be

limited during a hot-plug event. To illustrate this, the circuit

in Figure 18 was re-configured by adding a large 1500µF

capacitor to the output. An 18Ω resistive load was used

and a 2.2µF capacitor was placed on SS. Figure 14 shows

the results of hot-plugging this re-configured circuit. Notice

how the inductor current is well behaved.

Figure 14. Inrush Current Is Well Controlled in Spite Of HotPlugging the Re-configured Boost Converter in Figure 18

3581f

21

LT3581

R

V V

µA

FB

OUT FB

=

| – |

.83 3

DC

T MinOffTime

T

MAX

P

P

=

( )

•–%100

DC

MinOnTime

T

MIN

P

=

( )

•100%

DC

V V V

V V V

BOOST

OUT IN D

OUT D CESAT

≅

+

+––

DC

V V

V V V V

SEPIC INVERT

D OUT

IN OUT D CE

_&_

| |

| |

≅

+

+ + −

SSAT

DC

V V V V

V

SI INVERT

OUT IN CESAT D

OUT

_

| |

| |

=

− + + •

+ •33

VV

D

查询LT3581供应商

appenDix

SETTING THE OUTPUT VOLTAGE

The output voltage is set by connecting a resistor (R

from V

to the FB pin. RFB is determined by using the

OUT

FB

)

following equation:

where VFB is 1.215V (typical) for non-inverting topologies

(i.e. boost and SEPIC regulators) and 5mV (typical) for

inverting topologies.

OWER

P

SWITCH DUTY CYCLE

In order to maintain loop stability and deliver adequate

current to the load, the power NPNs (Q1 and Q2 in the

Block Diagram) cannot remain “on” for 100% of each clock

cycle. The maximum allowable duty cycle is given by:

where TP is the clock period and MinOffTime (found in the

Electrical Characteristics) is typically 60ns.

Conversely, the power NPNs (Q1 and Q2 in the Block Dia-

gram) cannot remain “off” for 100% of each clock cycle,

and will turn on for a minimum on time (MinOnTime) when

in regulation. This MinOnTime governs the minimum al-

lowable duty cycle given by:

Where TP is the clock period and MinOnTime (found in

the Electrical Characteristics) is typically 100ns.

The application should be designed such that the operating

duty cycle is between DC

MIN

and DC

MAX

.

Duty cycle equations for several common topologies are given

below where V

is the diode forward voltage drop and V

D

CESAT

is the collector to emitter saturation voltage of the switch.

, with SW1 and SW2 tied together, is typically 250mV

V

CESAT

when the combined switch current (I

SW1

+ I

) is 2.75A.

SW2

For the boost topology (see Figure 5):

For the SEPIC or Dual Inductor Inverting topology (see

Figures 6 and 7):

For the Single Inductor Inverting topology (see Figure 13):

The LT3581 can be used in configurations where the duty

cycle is higher than DC

, but it must be operated in

MAX

the discontinuous conduction mode so that the effective

duty cycle is reduced.

NDUCTOR

I

SELECTION

General Guidelines: The high frequency operation of the

LT3581 allows for the use of small surface mount inductors.

For high efficiency, choose inductors with high frequency

core material, such as ferrite, to reduce core losses. Also

to improve efficiency, choose inductors with more volume

for a given inductance. The inductor should have low

2

DCR (copper-wire resistance) to reduce I

R losses, and

must be able to handle the peak inductor current without

saturating. Note that in some applications, the current

handling requirements of the inductor can be lower, such

as in the SEPIC topology where each inductor only carries

one half of the total switch current. Molded chokes or chip

inductors usually do not have enough core area to support

peak inductor currents in the 2A to 6A range. To minimize

radiated noise, use a toroidal or shielded inductor. See

Table 5 for a list of inductor manufacturers.

Table 5. Inductor Manufacturers

Sumida CDR6D28MN and CDR7D28MN

Coilcraft MSD7342 Series www.coilcraft.com

Vishay IHLP-1616BZ-01, IHLP-2020BZ-01

Taiyo Yuden NR Series www.t-yuden.com

Wurth WE-PD Series www.we-online.com

TDK VLF, SLF and RLF Series www.tdk.com

Series

and IHLP-2525CZ-01 Series

www.sumida.com

www.vishay.com

22

3581f

L

DC V V

f I

V I

BOOST

IN CESAT

OSC PK

OUT OU

>

• −

( )

• • −

•

2

| |

TT

IN

DUAL

IN CESAT

OSC

V

or

L

DC V V

f

•

>

• −

( )

• •

η

2 II

V I

V

I

PK

OUT OUT

IN

OUT

−

•

•

−

| |

η

Boost

Topology

SEPIC

or

Inverting

Topologies

L

V V DC

A f DC

MIN

IN CESAT

OSC

=

−

( )

• • −

( )

• • −

( )

2 1

2 2 1.

L

V V

mA

DC

f

MAX

IN CESAT

OSC

=

−

•

350

查询LT3581供应商

appenDix

LT3581

Minimum Inductance

Although there can be a tradeoff with efficiency, it is often

desirable to minimize board space by choosing smaller

inductors. When choosing an inductor, there are three

conditions that limit the minimum inductance: (1) provid-

ing adequate load current, (2) avoidance of subharmonic

oscillations and (3) supplying a minimum ripple current

to avoid false tripping of the current comparator.

Adequate Load Current

Small value inductors result in increased ripple currents and

thus, due to the limited peak switch current, decrease the

average current that can be provided to the load. In order

to provide adequate load current, L should be at least:

Negative values of L

put load current, I

OUT

BOOST

or L

indicate that the out-

DUAL

, exceeds the switch current limit

capability of the LT3581.

Avoiding Sub-Harmonic Oscillations