LT3572

Dual Full-Bridge Piezo Driver

with 900mA Boost Converter

FEATURES

■

2.7V to 10V Input Voltage Range

■

900mA Boost Converter

■

Dual Full-Bridge Piezo Drivers

■

Programmable Switching Frequency from

500kHz to 2.25MHz

■

Synchronizable Up to 2.5MHz

■

Soft-Start

■

Separate Enable for Each Piezo Driver and Boost

Converter

■

Available in a 4mm × 4mm 20-Pin QFN Package

APPLICATIONS

■

Piezo Motor Drive

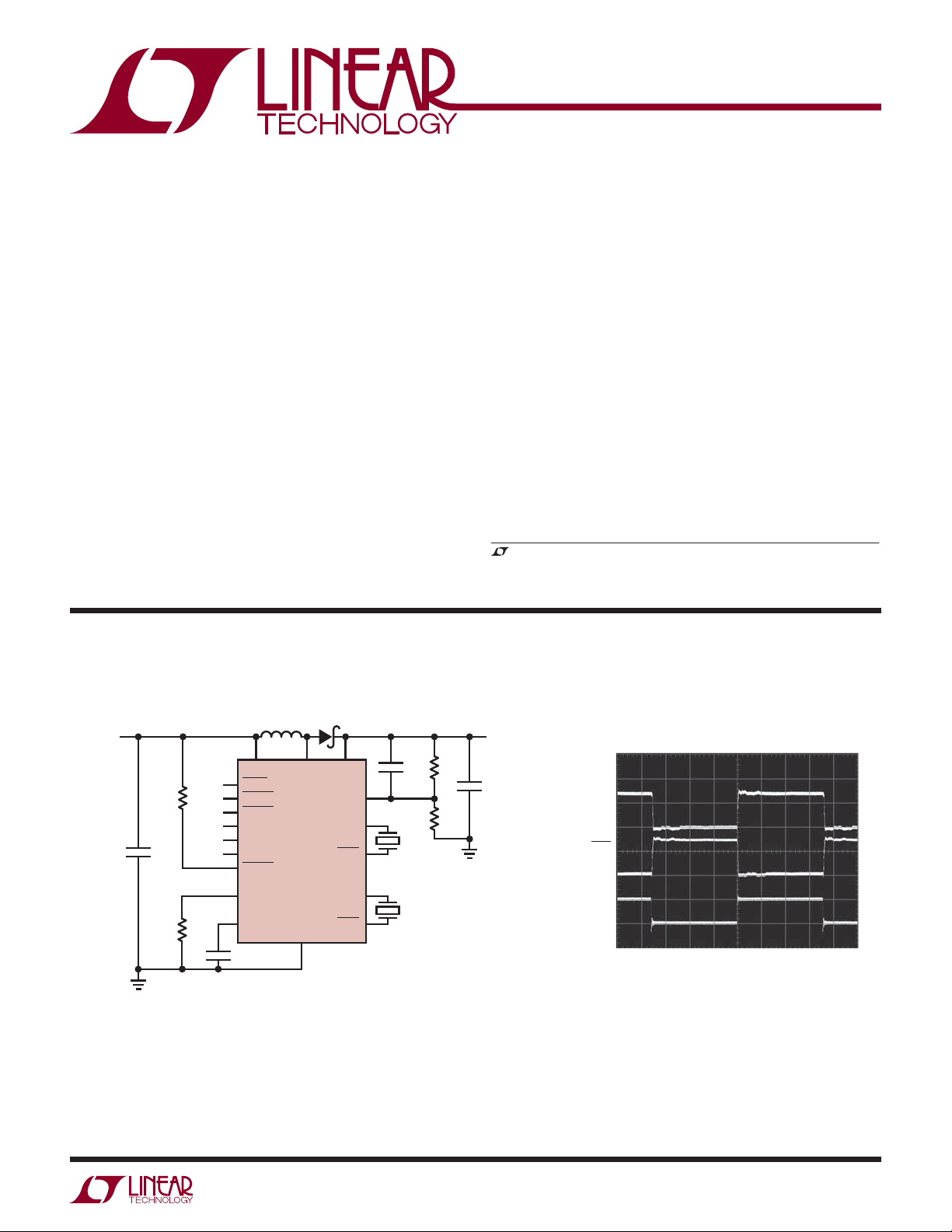

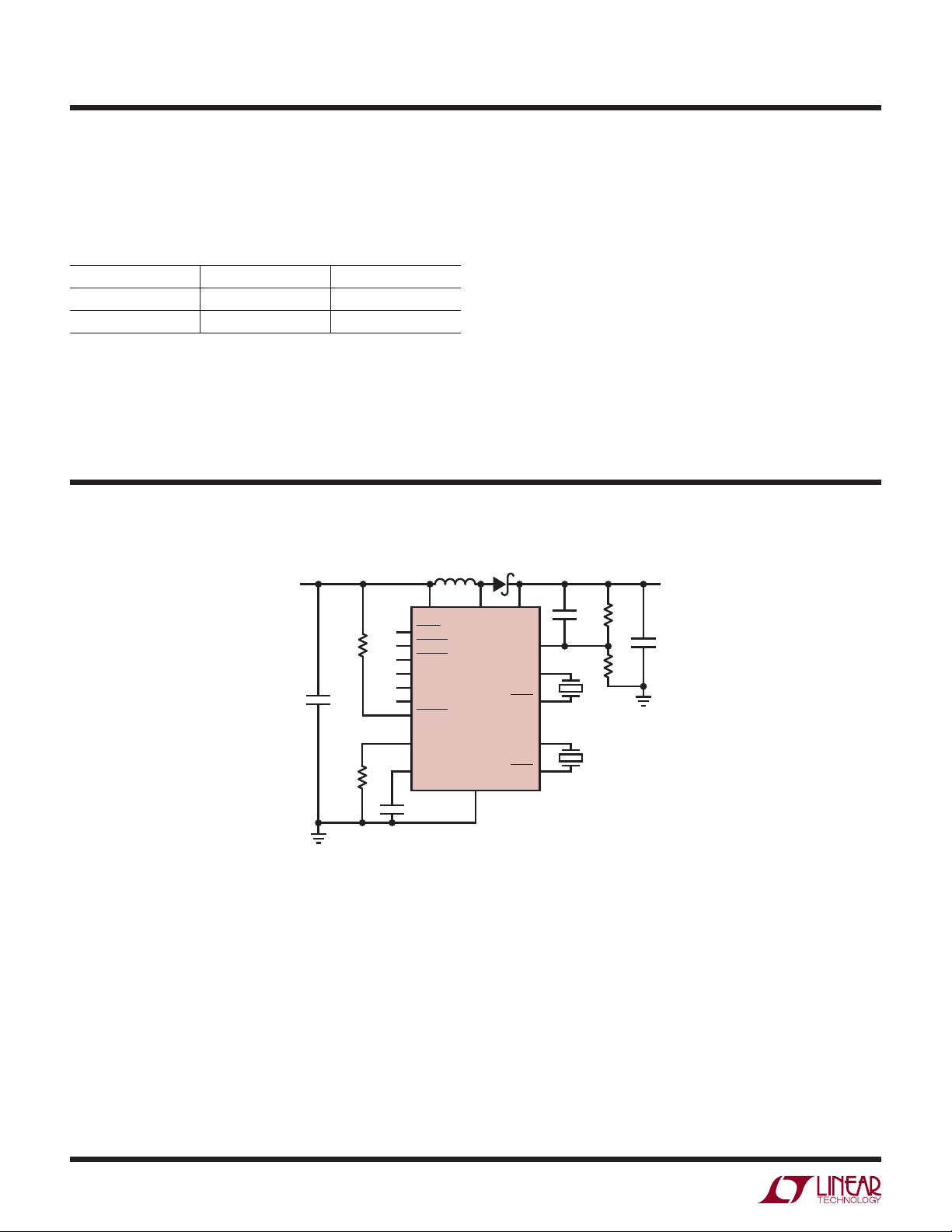

TYPICAL APPLICATION

DESCRIPTION

The LT®3572 is a highly integrated dual Piezo motor driver

capable of driving two Piezo motors at up to 40V from a

5V supply. Each Piezo driver can be independently turned

on or off along with the boost converter.

The boost regulator has a soft-start capability that limits the

inrush current at start-up. The boost regulator switching

frequency is set by an external resistor or the frequency can

be synchronized by an external clock. A PGOOD pin indicates

when the output of the boost converter is in regulation and

the Piezo drivers are allowed to start switching.

The LT3572 is available in a (4mm × 4mm) 20-pin QFN

package.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

V

3V TO 5V

Dual Piezo Driver

SHDN

SHDNA

SHDNB

PWMA

PWMB

SYNC

PGOOD

RT

SS

10nF

10μH

15pF

V

SW

GND

V

OUT

OUTA

OUTA

OUTB

OUTB

FB

IN

LT3572

576k

24.3k

IN

100k

4.7μF

42.2k

V

30V

50mA

10μF

3572 TA01a

OUT

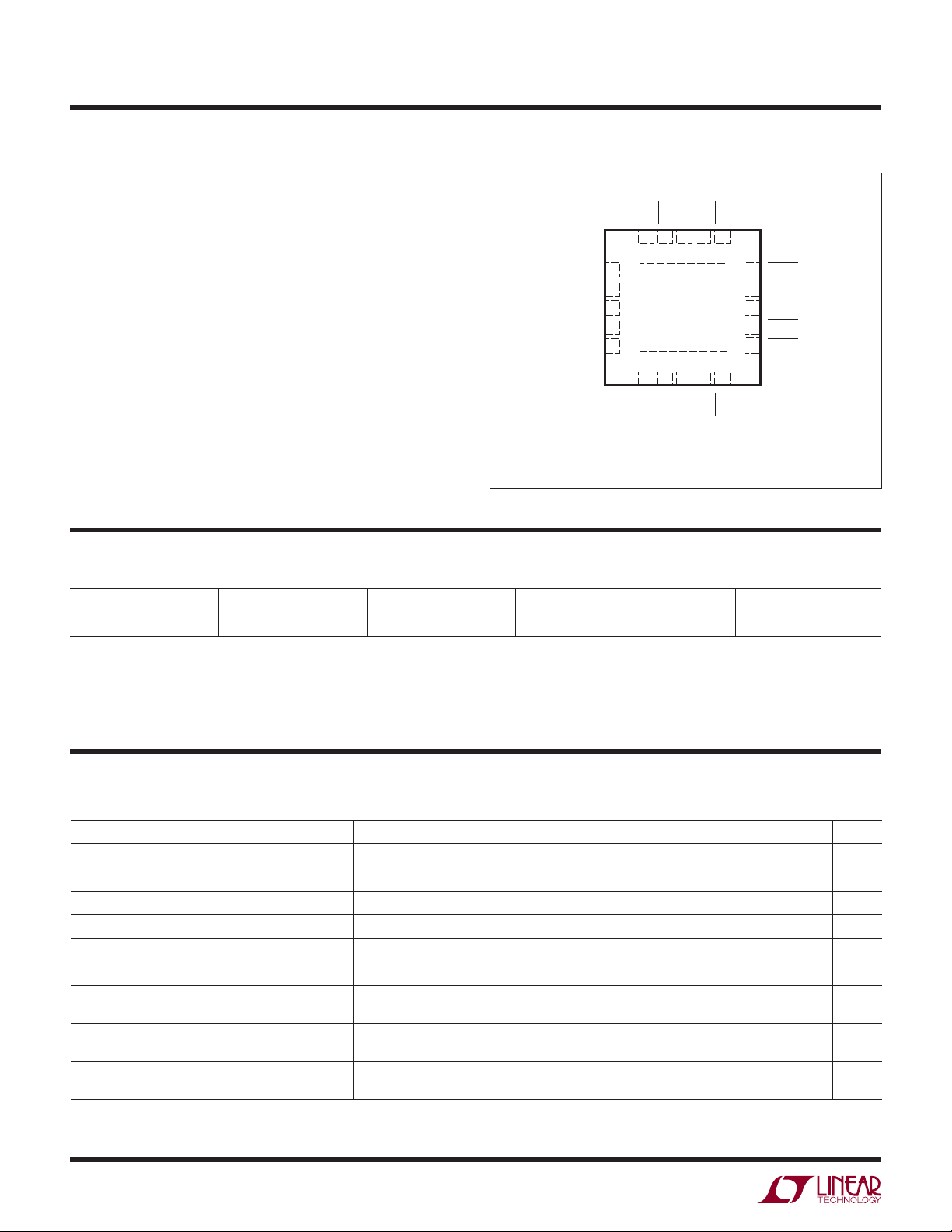

Response Driving Piezo Motor at 70kHz

V

OUTA

20V/DIV

V

OUTA

20V/DIV

PWMA

2V/DIV

2μs/DIV

3572 TA01b

3572fa

1

LT3572

ABSOLUTE MAXIMUM RATINGS

(Note 1)

V

Voltage .............................................................40V

OUT

OUTA, OUTA, OUTB, OUTB Voltage ...........................40V

SW Voltage ...............................................................42V

RT, SS, SYNC ..............................................................2V

FB ............................................................................... 3V

All Other Pins ............................................................10V

Maximum Junction Temperature........................... 125°C

Operating Temperature Range (Note 2).... –40°C to 85°C

Storage Temperature Range ...................–65°C to 125°C

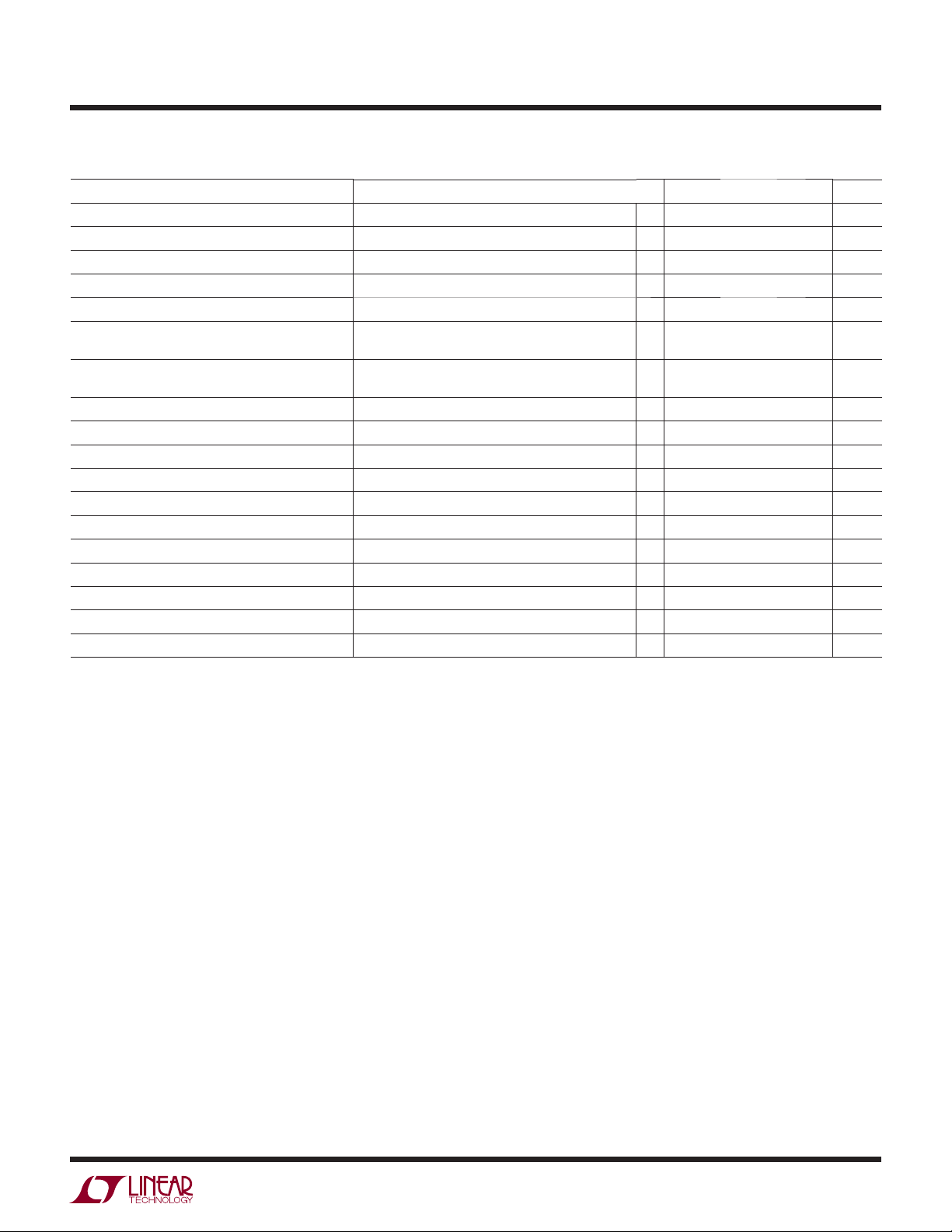

ORDER INFORMATION

PIN CONFIGURATION

TOP VIEW

GND

OUTA

OUTA

OUTB

20 19 18 17 16

1

SW

V

2

IN

SYNC

3

RT

4

GND

5

20-LEAD (4mm s 4mm) PLASTIC QFN

T

EXPOSED PAD (PIN 21) IS GND, MUST BE SOLDERED TO PCB

JMAX

21

6 7 8

PWMB

= 125°C, θJA = 37°C/W

OUT

V

PWMA

UF PACKAGE

9 10

GND

OUTB

SHDN

PGOOD

15

SS

14

FB

13

SHDNB

12

SHDNA

11

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3572EUF#PBF LT3572EUF#TRPBF 3572 20-Lead (4mm × 4mm) Plastic DFN –40°C to 85°C

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

Consult LTC Marketing for information on non-standard lead based fi nish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifi cations, go to: http://www.linear.com/tapeandreel/

ELECTRICAL CHARACTERISTICS

The ● denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at TA = 25°C. VIN = 5V, V

SHDNA

= V

SHDNB

= V

5V, unless otherwise noted.

SHDN =

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage

Quiescent Current VFB = 1.3V 3.4 4 mA

V

IN

Shutdown Current V

V

IN

SHDN

= V

SHDNA

= V

= 0V 0 1 μA

SHDNB

●

2.5 2.7 V

SHDN Pin Threshold 0.3 1.5 V

SHDNA Pin Threshold 0.3 1.5 V

SHDNB Pin Threshold 0.3 1.5 V

SHDN Pin Bias Current V

SHDNA Pin Bias Current V

SHDNB Pin Bias Current V

V

V

V

SHDN

SHDN

SHDN

SHDN

SHDN

SHDN

= 5V, V

= 0V, V

= 0V, V

= 0V, V

= 0V, V

= 0V, V

SHDNA

SHDNA

SHDNA

SHDNA

SHDNA

SHDNA

= 0V, V

= 0V, V

= 5V, V

= 0V, V

= 0V, V

= 0V, V

SHDNB

SHDNB

SHDNB

SHDNB

SHDNB

SHDNB

= 0V

= 0V

= 0V

= 0V

= 5V

= 0V

8

0.1

8

0.1

8

0.1

15

15

15

1

μA

μA

μA

1

μA

μA

1

μA

2

3572fa

LT3572

ELECTRICAL CHARACTERISTICS

The ● denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

PWMA Pin Threshold 0.3 1.5 V

PWMB Pin Threshold 0.3 1.5 V

PGOOD Rising Threshold (Note 3)

PGOOD Falling Threshold (Note 4)

PGOOD Resistance

Switching Frequency RT = 75.0kΩ

Maximum Duty Cycle RT = 75.0kΩ

Synchronization Frequency 575 2500 kHz

SYNC Pin Thresholds (Note 5) 0.3 1.5 V

SS Current 4.5 μA

FB Pin Voltage

FB Pin Voltage Line Regulation V

FB Pin Bias Current V

SW Current Limit (Note 7) 0.9 1.3 1.7 A

SW V

CESAT

SW Leakage Current SW = 40V 0.2 5 μA

OUTx Rise Time C = 2.2nF, V

OUTx Fall Time C = 2.2nF, V

= 25°C. VIN = 5V, V

A

RT = 13.0kΩ

RT = 13.0kΩ

= 2.5V to 10V 0.01 0.05 %/V

IN

= 1.225V (Note 6) 50 200 nA

FB

ISW = 800mA 310 450 mV

= 30V (Note 8) 120 ns

OUT

= 30V (Note 8) 120 ns

OUT

SHDNA

= V

SHDNB

= V

5V, unless otherwise noted.

SHDN =

●

1.12 1.16 1.19 V

●

1.01 1.04 1.065 V

●

●

425

●

1.9

●

95

●

85

●

1.195 1.225 1.255 V

500

2.25

13 kΩ

575

2.6

kHz

MHz

%

%

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LT3572 is guaranteed to meet specifi ed performance from

0°C to 70°C operating junction temperature. Specifi cations over the

–40°C to 85°C operating junction temperature range are assured by

design, characterization and correlation with statistical process controls.

Note 3: Rising threshold voltage on FB pin that pulls PGOOD low.

Note 4: Falling threshold voltage on FB pin that causes a high impedance

on PGOOD.

Note 5: Minimum pulse width is 100ns. Maximum off pulse width is 100ns.

Note 6: Current fl ows into the pin.

Note 7: Current limit guaranteed by design and/or correlation to static test.

Note 8: OUTx refers to OUTA, OUTA, OUTB, OUTB.

3572fa

3

LT3572

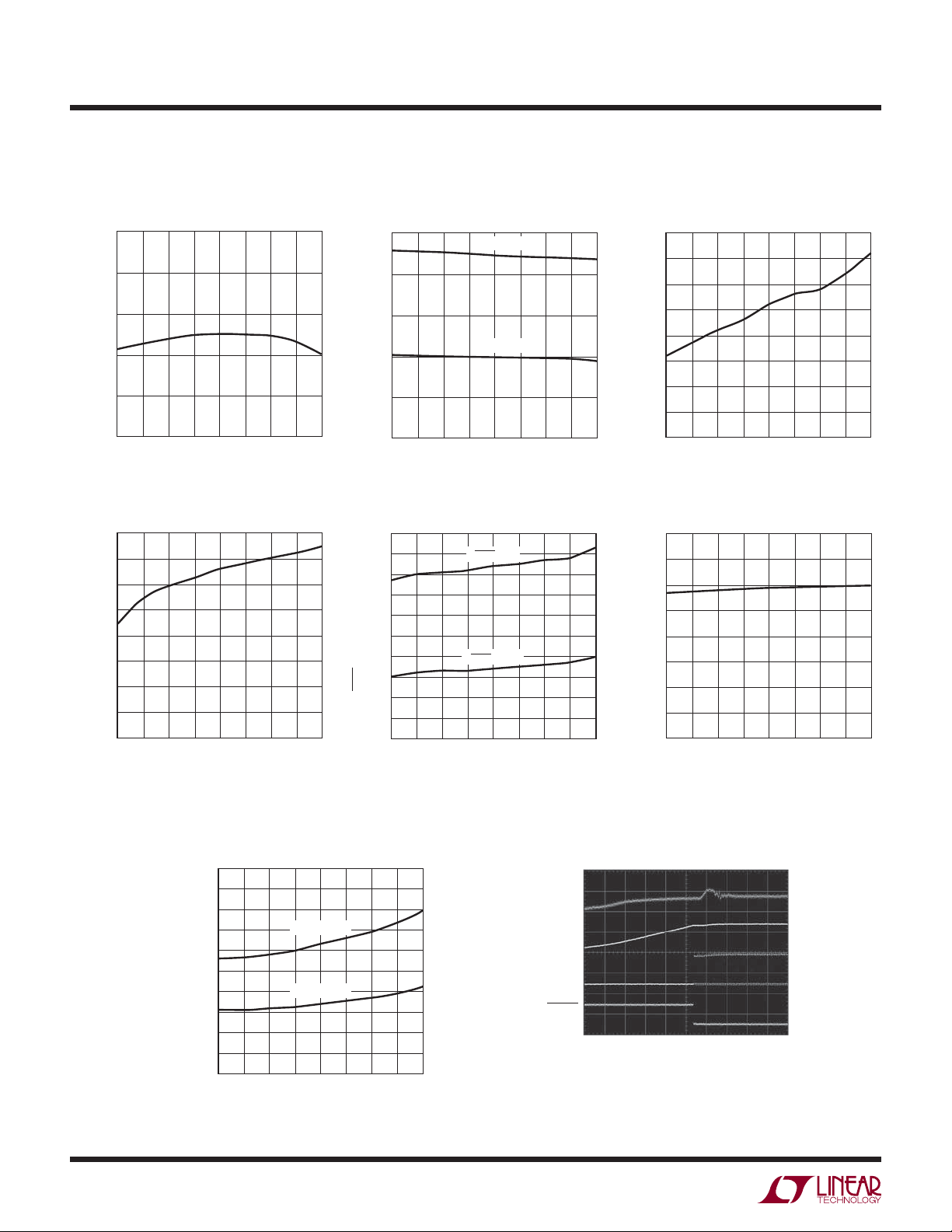

TYPICAL PERFORMANCE CHARACTERISTICS

Feedback Pin Voltage vs

Temperature

1.25

1.24

1.23

1.22

FEEDBACK VOLTAGE (V)

1.21

1.20

–50

–25 0

25 75 150

TEMPERATURE (°C)

50

100 125

3572 G01

Oscillator Frequency vs

Temperature

2.5

2.0

1.5

1.0

FREQUENCY (MHz)

0.5

0

–50

–25 0

25 75 150

TEMPERATURE (°C)

RT = 13k

RT = 35k

50

Quiescent Current vs Temperature SHDN Pin Current vs Temperature

4.0

3.5

3.0

2.5

2.0

1.5

1.0

QUIESCENT CURRENT (mA)

0.5

0

–25

–50

0

25

TEMPERATURE (°C)

50

75

100

125

150

3572 G04

10

9

8

7

6

5

4

3

SHDN PIN CURRENT (μA)

2

1

0

–50

–25 25

0

TEMPERATURE (°C)

V

V

SHDN

SHDN

= 5V

= 2.5V

50

75

100 125

125

100

3572 G02

3572 G05

150

SS Pin Current vs Temperature

8

7

6

5

4

3

SS PIN CURRENT (μA)

2

1

0

–25

–50

0

50

25

TEMPERATURE (°C)

75

SW Current Limit vs Temperature

1.6

1.4

1.2

1.0

0.8

0.6

PEAK CURRENT (A)

0.4

0.2

0

–25

–50

0

50

25

TEMPERATURE (°C)

75

100

100

125

125

150

3572 G03

150

3572 G06

4

SW Saturation Voltage vs

Temperature

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

SWITCH SATURATION VOLTAGE (V)

0.05

0

–50

–25 25

ISW = 800mA

ISW = 400mA

0

50

TEMPERATURE (°C)

Start-Up

I

IN

200mA/DIV

V

OUT

20V/DIV

V

OUTA

20V/DIV

PGOOD

5V/DIV

200μs/DIV

125

100

75

150

3572 G07

3572 G08

3572fa

PIN FUNCTIONS

LT3572

SW (Pin 1): Switch Node. This pin connects to the collector of an internal NPN power switch.

(Pin 2): Input Supply Pin. This pin must be locally

V

IN

bypassed with a capacitor.

SYNC (Pin 3): Synchronization Pin. This pin is used to

synchronize the internal oscillator to an external signal.

The synchronizing range is 15% above the free running

frequency set by the RT pin up to 2.5MHz. If not used,

this pin must be tied to GND.

RT (Pin 4): Frequency Set Pin. Place a resistor to GND

to set the internal frequency. The range of oscillation is

500kHz to 2.25MHz.

GND (Pins 5, 9, 20): Ground.

PWMB (Pin 6): Logic Input for the Driver. A high signal

on this input sets OUTB high and OUTB low.

PWMA (Pin 7): Logic Input for the Driver. A high signal

on this input sets OUTA high and OUTA low.

(Pin 8): Output for the Switching Regulator and the

V

OUT

Input Supply for the Drivers.

SHDN (Pin 10): Shutdown Pin. Tie to 1.5V or more to

enable the switcher. Pull low to disable the switcher.

SHDNA (Pin 11): Shutdown Pin. Tie to 1.5V or more to

enable OUTA and OUTA. Pull low to place OUTA and OUTA

in a high impedance state.

SHDNB (Pin 12): Shutdown Pin. Tie to 1.5V or more to

enable OUTB and OUTB. Pull low to place OUTB and OUTB

in a high impedance state.

FB (Pin 13): Feedback Pin. The LT3572 regulates this pin

to 1.225V. Connect the feedback resistors to this pin to

set the output voltage for the switching regulator.

SS (Pin 14): Soft-Start Pin. Place a soft-start capacitor

here. A capacitor on the soft-start pin slowly ramps the

current limit of the part from 0A to 1.3A.

PGOOD (Pin 15): This pin is an open-drain output that

pulls low when the FB pin is within 95% of its regulation

value.

OUTB (Pin 16): The Output Driver. This node switches

between V

OUTB (Pin 17): The Output Driver. This node switches

between V

OUTA (Pin 18): The Output Driver. This node switches

between V

OUTA (Pin 19): The Output Driver. This node switches

between V

Exposed Pad (Pin 21): Ground. The Exposed Pad of the

package provides both electrical contact to ground and

good thermal contact to the printed circuit board. The

Exposed Pad must be soldered to the circuit board for

proper operation.

and GND and is inverted from OUTB.

OUT

and GND.

OUT

and GND .

OUT

and GND and is inverted from OUTA.

OUT

3572fa

5

LT3572

BLOCK DIAGRAM

8

V

OUT

OUTA

18

Q2

Q3

7

PWMA

+

A2

A6

10

SHDN

START-UP/

INTERNAL BIAS

A4

S

Q

R

11

SHDNA12SHDNB

V

IN

2

L1

SW

1

Q1

–

OUTA

19

OUTB

17

OUTB

16

Q4

Q5

Q6

OSCILLATOR

Q7

Q8

Q9

A5

R

C

C

C

Q10

+

GND

A3

R5

–

1.225V

+

A1

–

95%/85%

–

A7

GND

GND

GND

5

9

20

21

FB

13

SS

14

+

D1

V

OUT

R1

R2

C2

R4

C1

PWMB4RT3SYNC

6

R3

PGOOD

15

3572 F01

Figure 1. Block Diagram

6

3572fa

OPERATION

LT3572

Switching Regulator

The LT3572 uses a constant frequency, current mode,

control scheme to provide excellent line and load regulation

for the output drivers. Operation can be best understood

by referring to the Block Diagram in Figure 1. A pulse

from the oscillator sets the RS fl ip-fl op, A4, and turns on

the internal NPN bipolar power switch, Q1. Current in Q1

and the external inductor, L1, begins to increase. When

this current exceeds a level determined by the voltage at

the output of the error amplifi er A1, comparator A2 resets

A4, turning Q1 off. The current in L1 fl ows through the

external Schottky diode D1 and begins to decrease. The

cycle begins again at the next pulse from the oscillator.

In this way, the voltage at the output of the error amplifi er

controls the current through the indictor to the output. The

soft-start capacitor, C2, clamps the output of the error

amplifi er causing the current limit to slowly increase. This

helps reduce overshoot on the output and helps minimize

inrush current on the input.

Output Drivers

The function of the driver section is to level shift the

input of the PWM pins to the voltage of the V

drivers operate in an H-bridge fashion, where the OUTA

and OUTB pins are the same polarity as the PWMA and

PWMB pins respectively and the OUTA and OUTB are

inverted from PWMA and PWMB respectively. The OUT

pins will be high impedance until the FB pin is within

95% of its regulated voltage. The OUT pins will follow

PWMA and PWMB as long as FB stays within 85% of the

regulated voltage. If FB drops below 85%, the OUT pins

will go high impedance.

pin. The

OUT

3572fa

7

LT3572

APPLICATIONS INFORMATION

Duty Cycle

The typical maximum duty cycle of the LT3572 is 95% at

1MHz. This maximum duty cycle reduces as the switching frequency is increased. The duty cycle for a given

application is given by:

VVV

++–

DC

OUT D IN

=

VVV

OUT D CESAT

–

where VD is the diode forward drop, typically 0.5V and

V

is, in the worst case, 310mV at 0.8A. The LT3572

CESAT

can be used at higher duty cycles, but must be operated

in the discontinuous mode so that the actual duty cycle

is reduced.

FB Resistor Network

The output voltage is programmed with a resistor divider

between the output and the FB pin. Choose the resistors

according to:

RR

12

⎛

⎜

⎝

1 225

.

OUT

⎞

1=

–

⎟

⎠

V

V

Shutdown Pins

When held below 0.3V, SHDNA and SHDNB prevent the

drivers from switching and keep the outputs in a high

impedance state. If SHDN is held below 0.3V then the

switching regulator is prevented from turning on. When

any one of these pins are pulled above 1.5V the internal

circuitry is turned on and the respective output is allowed

to operate. When the LT3572 is not in use all three pins

should be pulled low.

Oscillator

The LT3572 can operate at switching frequencies from

500kHz up to 2.25MHz by changing the value of the resistor R3 on the RT pin. Figure 2 shows a graph of RT vs

Switching Frequency.

The oscillator can be synchronized with an external clock

applied to the SYNC pin. When synchronizing the oscillator, the free running frequency must be set approximately

10000

1000

SWITCHING FREQUENCY (kHz)

100

10

Figure 2. RT Resistance vs Switching Frequency

RT RESISTANCE (kΩ)

100

3572 F02

15% lower than the desired synchronized frequency. If

the sync function is not used the SYNC pin must be tied

to ground.

PGOOD

The part has a power good feature that detects when the

output boost converter is up and in regulation. When the

part is turned off or not in regulation the PGOOD pin is

in a high impedance state. When the part is within 95%

of regulation the PGOOD pin is pulled low signaling that

the output is valid. If the output then falls below 85% of

regulation the PGOOD pin is put back in a high impedance

state. Whenever the output is not in regulation the output

pins in the driver aren’t allowed to switch and are placed

in a high impedance state. The PGOOD pin is an open

drain of an NMOS devices with an impedance of 1kΩ and

should be tied to V

through a resistor.

IN

Soft-Start

The soft-start feature limits the inrush current drawn from

the supply upon start-up. An internal current source with a

nominal 4.5μA current source charges an external capacitor

C2. The voltage on the soft-start pin is used to control the

output of the error amplifi er, which limits the maximum

peak current through the inductor and the inrush current

drawn from the supply during start-up.

8

3572fa

APPLICATIONS INFORMATION

LT3572

PWM

The LT3572 can PWM the output drivers at a very high

frequency. The limitation on the frequency is determined

by the internal rise in die temperature that occurs when

driving the motor. The power delivered to the piezo motor

2

is propotional to V

, the capacitance of the motor, and

OUT

the PWM frequency. When any of these are increased the

power dissipated in the part increases causing the internal

die temperature to increase. Driving two 2.2nF capacitors

with V

at 30V, the maximum PWM frequency should be

OUT

less than 80 kHz. The LT3572 can run at a higher frequency

but either V

needs to be reduced or the capacitance

OUT

needs to be lowered. A piezo motor has an associated

capacitance that cannot be reduced so the output voltage

2

must be lowered. Since the power is proportional to V

reduction of V

to 25V from 30V will allow the LT3572 to

OUT

OUT

a

run at a maxim frequency of 115 kHz. If a different motor is

used the maximum PWM frequency will need to be adjusted

inversely to the equivolent capacitance of the motor.

Inductor Selection

A 10μH inductor is recommended for most LT3572 applications. Choose an inductor that will handle at least

1A without saturating, and ensure that the inductor has a

2

low DCR (copper-wire resistance) to minimize I

R power

losses. Table 1 lists several inductor manufacturers.

Table 1. Inductor Manufacturers

Sumida (847) 956-0666 www.sumida.com

TDK (847) 803-6100 www.tdk.com

Murata (714) 852-2001 www.murata.com

FDK (408) 432-8331 www.tdk.co.jp

Capacitor Selection

The small size of ceramic capacitors makes them ideal

for LT3572 applications. Only X5R or X7R types should

be used because they retain their capacitance over wider

voltage and temperature ranges than other types such as

Y5V or Z5U. A 4.7μF to 15μF output capacitor is suffi cient

for stable transient response, however, more output capacitance can help limit the voltage droop on V

OUT

during

transients.

Ceramic capacitors also make a good choice for the input

decoupling capacitor, which should be placed as close as

possible to the LT3572. A 1μF to 4.7μF input capacitor

is suffi cient for most applications. Table 2 shows a list

OUTB

OUTA

C1

PWMB

OUTA

20

6

PWMA

19

GND

7

V

OUT

D1

L1

1

SW

V

2

C3

IN

3

SYNC

4

RT

GND

5

R4

OUTB

18

17

16

PGOOD

15

SS

14

13

FB

12

SHDNB

11

8

9

10

SHDN

SHDNA

C2

R2

R1

C

FF

3572 BD LAYOUT

3572fa

9

LT3572

APPLICATIONS INFORMATION

of several ceramic capacitor manufacturers. Consult the

manufacturers for detailed information on their entire

selection of ceramic parts.

Table 2. Ceramic Capacitor Manufacturers

Taiyo Yuden (408) 573-4150 www.t-yuden.com

AVX (803) 448-9411 www.avxcorp.com

Murata (714) 852-2001 www.murata.com

Diode Selection

A Schottky diode is recommended for use with the LT3572.

The Philips PMEG 3005 is a good choice. If the switch

voltage exceeds 30V, a PMEG 4005 (a 40V diode) can be

TYPICAL APPLICATION

L1

V

3V TO 5V

IN

R4

100k

C3

4.7μF

R3

34k

12μH

218

10

11

12

15

14

7

6

3

4

C2

10nF

V

SHDN

SHDNA

SHDNB

PWMA

PWMB

SYNC

PGOOD

RT

SS

SW

IN

LT3572

GND

used. These diodes are rated to handle an average forward

current of 0.5A. For higher effi ciency, use a diode with better thermal characteristics such as the On Semiconductor

MBRM140 (a 40V diode).

Layout Hints

As with all switching regulators, careful attention must be

paid to the PCB board layout and component placement.

To maximize effi ciency, switch rise and fall times are made

as short as possible. Note the vias under the Exposed Pad.

These should connect to a local ground plane for better

thermal performance.

D1

V

OUT

OUTA

OUTA

OUTB

OUTB

5, 9, 20, 21

C4

R1

20pF

576k

13

FB

18

19

17

16

R2

24.9k

V

30V

50mA

C1

10μF

3572 TA02

OUT

10

3572fa

PACKAGE DESCRIPTION

4.50 p 0.05

3.10 p 0.05

2.00 REF

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

APPLY SOLDER MASK TO AREAS THAT ARE NOT SOLDERED

4.00 p 0.10

2.45 p 0.05

2.45 p 0.05

4.00 p 0.10

PIN 1

TOP MARK

(NOTE 6)

UF Package

20-Lead Plastic QFN (4mm × 4mm)

(Reference LTC DWG # 05-08-1710 Rev A)

0.70 p0.05

PACKAGE OUTLINE

0.25 p0.05

0.50 BSC

0.75 p 0.05

R = 0.05

TYP

2.00 REF

BOTTOM VIEW—EXPOSED PAD

R = 0.115

TYP

2.45 p 0.10

2019

LT3572

PIN 1 NOTCH

R = 0.20 TYP

OR 0.35 s 45o

CHAMFER

0.40 p 0.10

1

2

0.200 REF

0.00 – 0.05

NOTE:

1. DRAWING IS PROPOSED TO BE MADE A JEDEC PACKAGE OUTLINE MO-220

VARIATION (WGGD-1)—TO BE APPROVED

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON THE TOP AND BOTTOM OF PACKAGE

2.45 p 0.10

(UF20) QFN 01-07 REV A

0.25 p 0.05

0.50 BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3572fa

11

LT3572

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1160 Half-/Full-Bridge N-Channel MOSFET Driver V

LT3469 Piezo Microactuator Driver with Boost Regulator V

LT3479 3A, Full Featured DC/DC Converter with Soft-Start and Inrush

Current Protection

LT3580 42V, 2A, 2.5MHz High Effi ciency Step-Up DC/DC Converter VIN: 2.5V to 32V, V

: 10V to 15V, V

IN

: 2.5V to 16V, V

IN

Piezo Microactuator

: 2.5V to 24V, V

V

IN

DFN, TSSOP Packages

3mm × 3mm DFN8 and MS8E Packages

= 60V, 24-Lead SO Package

OUT(MAX)

= 35V Maximum, 40mA Current Limit for

OUT

= 40V, IQ = Analog/PWM, ISD < 1μA,

OUT(MAX)

= 40V, IQ = 1mA, ISD < 1μA,

OUT(MAX)

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

3572fa

LT 0408 REV A • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2007

Loading...

Loading...