Application Note 5

December 1984

Thermal Techniques in Measurement and Control Circuitry

Jim Williams

Designers spend much time combating thermal effects in

circuitry. The close relationship between temperature and

electronic devices is the source of more design headaches

than any other consideration.

In fact, instead of eliminating or compensating for thermal

parasitics in circuits, it is possible to utilize them. In particular, applying thermal techniques to measurement and

control circuits allows novel solutions to diffi cult problems.

The most obvious example is temperature control. Familiarity with thermal considerations in temperature control

loops permits less obvious, but very useful, thermallybased circuits to be built.

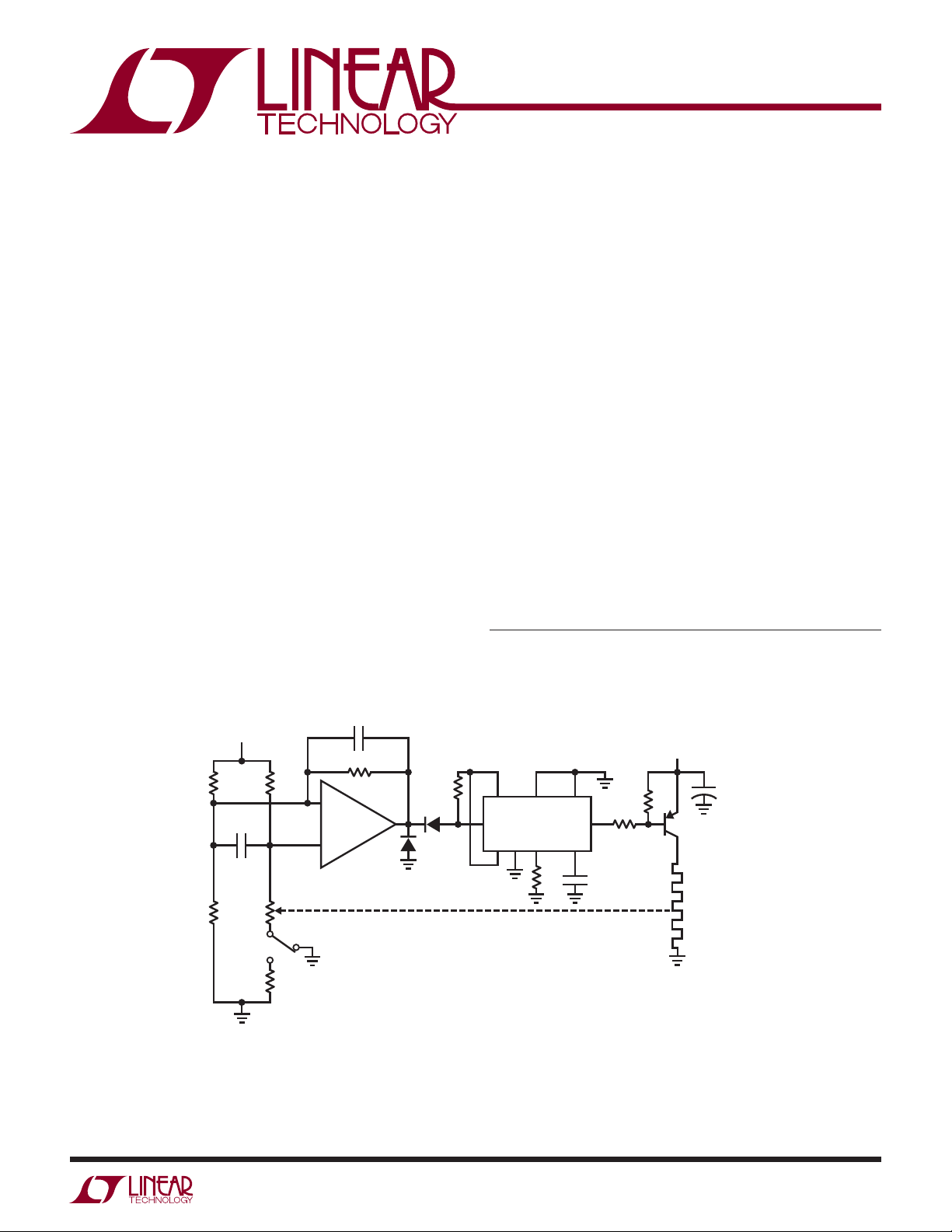

Temperature Controller

Figure 1 shows a precision temperature controller for

a small components oven. When power is applied, the

thermistor, a negative TC device, is at a high value. A1

®

saturates positive. This forces the LT

15V

100k*

100k*

0.05

100k*

R

T

3525A switching

0.02

100M

–

+

A1

LT1012

1N914

1N914

10k

THERMAL FEEDBACK

regulator’s output low, biasing Q1. As the heater warms,

the thermistor ’s value decreases. When its inputs fi nally

balance, A1 comes out of saturation and the LT3525A pulse

width modulates the heater via Q1, completing a feedback

path. A1 provides gain and the LT3523A furnishes high

effi ciency. The 2kHz pulse width modulated heater power

is much faster than the thermal loop’s response and the

oven sees an even, continuous heat fl ow.

The key to high performance control is matching the gain

bandwidth of A1 to the thermal feedback path. Theoretically, it is a simple matter to do this using conventional

servo-feedback techniques. Practically, the long time

constants and uncertain delays inherent in thermal systems

present a challenge. The unfortunate relationship between

servo systems and oscillators is very apparent in thermal

control systems.

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Linear

Technology Corporation. All other trademarks are the property of their respective owners.

15V

141116

LT3525A

12 6 5

5k

139

0.015

≈2kHz

1k

2k

+

47

Q1

2N5023

20Ω HEATER

50Ω

STEP TEST

50Ω ≈ 0.01°C

*TRW MAR-6 RESISTOR

= YSI #44014 RT = 300k AT 25°C

R

T

Figure 1. Precision Temperature Controller

AN05 F01

an5f

AN5-1

Application Note 5

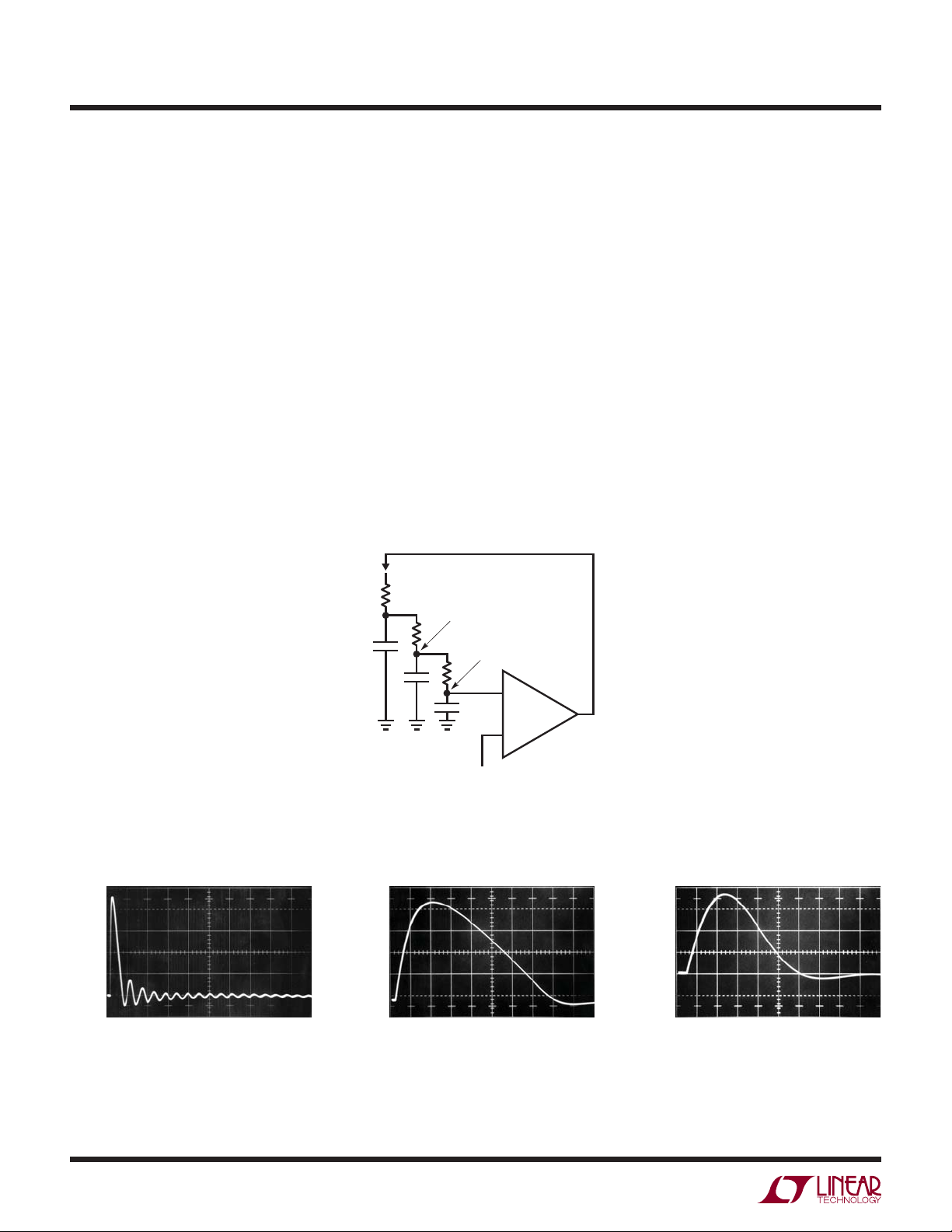

The thermal control loop can be very simply modeled as

a network of resistors and capacitors. The resistors are

equivalent to the thermal resistance and the capacitors

equivalent to thermal capacity. In Figure 2 the heater,

heater-sensor interface, and sensor all have RC factors

that contribute to a lumped delay in the ability of a thermal system to respond. To prevent oscillation, A1’s gain

bandwidth must be limited to account for this delay. Since

high gain bandwidth is desirable for good control, the

delays must be minimized. The physical size and electrical resistivity of the heater selected give some element of

control over the heater’s time constant. The heater-sensor

interface time constant can be minimized by placing the

sensor in intimate contact with the heater.

The sensor ’s RC product can be minimized by selecting a

sensor of small size relative to the capacity of its thermal

environment. Clearly, if the wall of an oven is 6" thick

aluminum, the tiniest sensor available is not an absolute

necessity. Conversely, if one is controlling the temperature

of 1/16" thick glass microscope slide, a very small sensor

(i.e., fast) is in order.

After the thermal time constants relating to the heater and

sensor have been minimized, some form of insulation for

the system must be chosen. The function of insulation

is to keep the loss rate down so the temperature control

device can keep up with the losses. For any given system, the higher the ratio between the heater-sensor time

constants and the insulation time constants, the better

the performance of the control loop.

After these thermal considerations have been attended

to, the control loop’s gain bandwidth can be optimized.

Figures 3A, 3B and 3C show the effects of different compensation values at A1. Compensation is trimmed by applying small steps in temperature setpoint and observing

the loop response at A1’s output. The 50Ω resistor and

2V/DIV

HEATER

OR CURRENT CORRESPONDING TO TEMPERATURE)

Figure 2. Thermal Control Loop Model

0.5V/DIV

5 SECONDS/DIV

ABC

AN05 F03a

HEATER-SENSOR INTERFACE

SENSOR

TEMPERATURE REFERENCE

(CAN BE A RESISTANCE, VOLTAGE

2 SECONDS/DIV

AN05 F02

AN05 F03b

0.5V/DIV

HORIZONTAL = 0.5 SECONDS/DIV

AN05 F03c

AN5-2

Figure 3. Loop Response for Various Gain Bandwidths

an5f

Application Note 5

switch in the thermistor leg of the bridge furnish a 0.01°C

step generator. Figure 3A shows the effects of too much

gain bandwidth. The step change forces a damped, ringing

response over 50 seconds in duration! The loop is marginally stable. Increasing A1’s gain bandwidth (GBW) will force

oscillation. Figure 3B shows what happens when GBW is

reduced. Settling is much quicker and more controlled. The

waveform is overdamped, indicating that higher GBW is

achievable without stability compromises. Figure 3C shows

the response for the compensation values given and is a

nearly ideal critically damped recovery. Settling occurs

within 4 seconds. An oven optimized in this fashion will

easily attenuate external temperature shifts by a factor of

thousands without overshoots or excessive lags.

Thermally Stabilized PIN Photodiode Signal

Conditioner

PIN photodiodes are frequently employed in wide range

photometric measurements. The photodiode specifi ed in

Figure 4 responds linearly to light intensity over a 100dB

range. Digitizing the diode’s linearly amplifi ed output

would require an A/D converter with 17 bits of range.

This requirement can be eliminated by logarithmically

compressing the diode’s output in the signal conditioning circuity. Logarithmic amplifi ers utilize the logarithmic

relationship between V

and collector current in transis-

BE

tors. This characteristic is very temperature sensitive and

requires special components and layout considerations

to achieve good results. Figure 4’s circuit logarithmically

signal conditions the photodiode’s output with no special

components or layout.

A1 and Q4 convert the diode’s photocurrent to a voltage

output with a logarithmic transfer function. A2 provides

offsetting and additional gain. A3 and its associated components form a temperature control loop which maintains

Q4 at constant temperature (all transistors in this circuit

are part of a CA3096 monolithic array). The 0.033μF value

at A3’s compensation pins gives good loop damping if the

circuit is built using the array’s transistors in the locations

shown. These locations have been selected for optimal

control at Q4, the logging transistor. Because of the array

15V

LT1021-10V

OUT

IN

Q4

500pF

50k*

1M

750k*

1M

FULL-SCALE

TRIM

0.01

46

10

5

11

Q5

2k

12

50k

DARK

TRIM

–

A1

10k*

LT1012

+

10k*

2k

15

14

Q1 Q3

13

–

A3

LM301A

+

0.033

3k

33Ω

7

8

9

15V

I

P

–

A2

LM107

+

1

2

3

Q2

AN05 F04

= HP-5082-4204 PIN PHOTODIODE

Q1 TO Q5 = CA3096

CONNECT SUBSTRATE OF CA3096

ARRAY TO Q4’s EMITTER

*1% RESISTOR

E

OUT

LIGHT

(900 NANOMETERS)

1mW

100μW

10μW

1μW

100nW

10nW

RESPONSE DATA

DIODE CURRENT

350μA

35μA

3.5μA

350nA

35nA

3.5nA

CIRCUIT OUTPUT

10.0V

7.85V

5.70V

3.55V

1.40V

–0.75V

Figure 4. 100dB Range Logarithmic Photodiode Amplifi er

an5f

AN5-3

Application Note 5

die’s small size, response is quick and clean. A full-scale

step requires only 250ms to settle (photo, Figure 5) to fi nal

value. To use this circuit, fi rst set the thermal control loop.

To do this, ground Q3’s base and set the 2k pot so A3’s

negative input voltage is 55mV below its positive input. This

places the servo’s setpoint at about 50°C (25°C ambient

+ 2.2mV/°C • 25°C rise = 55mV = 50°C). Unground Q3’s

base and the array will come to temperature. Next, place

the photodiode in a completely dark environment and

adjust the “dark trim” so A2’s output is 0V. Finally, apply

or electrically simulate (see chart, Figure 4) 1mW of light

and set the “full-scale” trim to 10V out. Once adjusted,

this circuit responds logarithmically to light inputs from

10nW to 1mW with an accuracy limited by the diode’s

1% error.

0.2V/DIV

50MHz Bandwidth Thermal RMS→DC Converter

Conversion of AC waveforms to their equivalent DC power

value is usually accomplished by either rectifying and

averaging or using analog computing methods. Rectifi cation averaging works only for sinusoidal inputs. Analog

computing methods are limited to use below 500kHz.

Above this frequency, accuracy degrades beyond the

point of usefulness in instrumentation applications. Additionally, crest factors greater than 10 cause signifi cant

reading errors.

A way to achieve wide bandwidth and high crest factor

performance is to measure the true power value of the

waveform directly. The circuit of Figure 6 does this by

measuring the DC heating power of the input waveform.

15V

90k*

90k*

10k

0.01

INPUT

*0.1% RESISTOR

T1, T2 = YELLOW SPRINGS INST. CO.

THERMISTOR COMPOSITE

#44018

1μF = MYLAR

T1A

REDBRN

T1

T1B

10k

T2

T2B

GRNGRN

Figure 6. 50MHz Thermal RMS→DC Converter

HORIZONTAL = 50ms/DIV

AN05 F05

Figure 5. Figure 4’s Thermal Loop Response

100k*

BRNRED

T2A

1μF

300Ω*

1μF

–

+

–

+

0.01

A1

LT1002

100k*

0.01

A2

LT1002

10k* 10k*

–

10k*

15k

+

10k*

–

+

A3

LT1001

20k

FULL-SCALE

TRIM

A4

LT1001

1N4148

OUT

0V TO 10V

AN05 F06

an5f

AN5-4

Application Note 5

By using thermal techniques to integrate the input waveform, 50MHz bandwidth is easily achieved with 2% accuracy. Additionally, because the thermal integrator’s output

is at low frequency, no wideband circuitry is required.

The circuit uses standard components and requires no

special trimming techniques. It is based on measuring

the amount of power required to maintain two similar but

thermally decoupled masses at the same temperature.

The input is applied to T1, a dual thermistor bead. The

power dissipated in one leg (T1A) of this bead forces the

other section (T1B) to shift down in value, unbalancing

the bridge formed by the other bead and the 90k resistors.

This imbalance is amplifi ed by the A1-A2-A3 combination. A3’s output is applied to a second thermistor bead,

T2. T2A heats, causing T2B to decay in value. As T2B’s

resistance drops, the bridge balances. A3’s output adjusts

drive to T2A until T1B and T2B have equal values. Under

these conditions, the voltage at T2A is equal to the RMS

value of the circuit’s input. In fact, slight mass imbalances between T1 and T2 contribute a gain error, which

is corrected at A4. RC fi lters at A1 and A2 and the 0.01μF

capacitor eliminate possible high frequency error due to

capacitive coupling between T1A and T1B. The diode in

A3’s output line prevents circuit latch-up.

Figure 7 details the recommended thermal arrangement

for the thermistors. The Styrofoam block provides an

isothermal environment and coiling the thermistor leads

attenuates heat pipe effects to the outside ambient. The

2-inch distance between the devices allows them to see

identical thermal conditions without interaction. To calibrate this circuit, apply 10V

to the input and adjust the

DC

full-scale trim for 10V out at A4. Accuracy remains within

2% from DC to 50MHz for inputs of 300mV to 10V. Crest

factors of 100:1 contribute less than 0.1% additional error

and response time to rated accuracy is fi ve seconds.

Low Flow Rate Thermal Flowmeter

Measuring low fl ow rates in fl uids presents diffi culties.

“Paddle wheel” and hinged vane type transducers have low

and inaccurate outputs at low fl ow rates. If small diameter

tubing is required, as in medical or biochemical work,

such transduction techniques also become mechanically

impractical. Figure 8 shows a thermally-based fl owmeter

which features high accuracy at rates as low as 1mL/minute

and has a frequency output which is a linear function of

fl ow rate. This design measures the differential temperature

between two sensors (Figure 9). One sensor, T1, located

before the heater resistor, assumes the fl uid’s temperature

before it is heated by the resistor. The second sensor, T2,

picks up the temperature rise induced into the fl uid by the

resistor’s heating. The sensor ’s difference signal appears

at A1’s output. A2 amplifi es this difference with a time

constant set by the 10MΩ adjustment. Figure 10 shows

A2’s output versus fl ow rate. The function has an inverse

relationship. A3 and A4 linearize this relationship, while simultaneously providing a frequency output (Figure 10). A3

functions as an integrator which is biased from the LT1004

and the 383k input resistor. Its output is compared to A2’s

output at A4. Large inputs from A2 force the integrator to

run for a long time before A4 can go high, turning on Q1

and resetting A3. For small inputs from A2, A3 does not

have to integrate very long before resetting action occurs.

Thus, the confi guration oscillates at a frequency which is

inversely proportional to A2’s output voltage. Since this

voltage is inversely related to fl ow rate, the oscillation

frequency linearly corresponds to fl ow rate.

Several thermal considerations are important in this circuit.

The amount of power dissipated into the stream should be

constant to maintain calibration. Ideally, the best way to

do this is to measure the VI product at the heater resistor

and construct a control loop to maintain constant wattage

4"

BOTTOMTOP

2"

THERMISTORS

Figure 7. Thermal Arrangement for RMS→DC Converter

AN05 F07

2"

Styrofoam

0.5"

BLOCKS

AN5-5

an5f

Application Note 5

1M*

–15V

3.2k**

3.2k**

15V

15Ω

R

HEATER

100k

0.1

2.7k

383k*

LT1004-1.2V

*1% FILM RESISTOR

**SUPPLIED WITH YSI THERMISTOR NETWORK

YSI THERMISTOR NETWORK = #44201

R

HEATER

= DALE HL-25

–

LT1012

+

A3

6.25k**6.25k**

T2T1

Q1

2N4391

1M*

1M*

100k

–

+

1M*

1N4148

A1

LT1002

+

–

300pF

A4

LT1011

1

–15V

4

Figure 8. Liquid Flowmeter

100k

10M

RESPONSE

TIME

4.7k

100k

15V

OUTPUT

0Hz TO 300Hz =

0 TO 300mL/MIN

1μF

–

LT1002

+

A2

6.98k*

5k

FLOW

CALIBRATION

1k*

AN05 F08

IN

MIXING GRID

PREVENTS

LAMINER FLOW

FLOW

SENSOR T1

HEATER RESISTOR

15V

STAINLESS TUBING

OUT

SENSOR T2

SIZE TUBING O.D.

TO FIT RESISTOR I.D.

USE THERMAL COMPOUND

FOR GOOD HEAT TRANSFIER

AN05 F09

Figure 9. Flowmeter Transducer Details

dissipation. However, if the resistor specifi ed is used, its

drift with temperature is small enough to assume constant

dissipation with a fi xed voltage drive. Additionally, the fl uid’s

specifi c heat will affect calibration. The curves shown are

for distilled water. To calibrate this circuit, set a fl ow rate

of 10mL/minute and adjust the fl ow calibration trim for

10Hz output. The response time adjustment is convenient

for fi ltering fl ow aberrations due to mechanical limitations

in the pump driving the system.

280

240

200

T1-T2 (A2 OUTPUT)

VS FLOW CURVE

160

120

0.05V

80

40

FLOW FOR DISTILLED WATER (mL/MINUTE)

0

0

40 80

FREQUENCY VS FLOW CURVE

0.1V

0.22V

160

120 200

FREQUENCY (Hz)

0.66V0.44V

240 280

AN05 F10

Figure 10. Flowmeter Response Data

Thermally-Based Anemometer (Air Flowmeter)

Figure 11 shows another thermally-based fl owmeter, but

this design is used to measure air or gas fl ow. It works

by measuring the energy required to maintain a heated

resistance wire at constant temperature. The positive

temperature coeffi cient of a small lamp, in combination

with its ready availability, makes it a good sensor. A type

AN5-6

an5f

Application Note 5

2k 15V

Q1

27Ω

500k*

1W

AIR FLOW

RECOMMENDED

LAMP

ORIENTATION

Q1 = 2N6533

Q2 TO Q5 = CA3046 ARRAY [TIE PIN 13 (SUBSTRATE) TO –15V]

*1% RESISTOR

100k

100k*

–

LT1002

+

150k*

A1

0.1μF

500pF

1N4148

2k

33k

1k

ZERO

FLOW

Figure 11. Thermal Anemometer

328 lamp is modifi ed for this circuit by removing its glass

envelope. The lamp is placed in a bridge which is monitored

by A1. A1’s output is current amplifi ed by Q1 and fed back

to drive the bridge. The capacitors and 220Ω resistor

ensure stability. The 2k resistor furnishes start-up. When

power is applied, the lamp is at a low resistance and Q1’s

emitter tries to come full on. As current fl ows through the

lamp, its temperature quickly rises, forcing its resistance

to increase. This action increases A1’s negative input potential. Q1’s emitter voltage decreases and the circuit fi nds

a stable operating point. To keep the bridge balanced, A1

acts to force the lamp’s resistance, hence its temperature,

constant. The 10k-2k bridge values have been chosen so

that the lamp operates just below the incandescence point.

This high temperature minimizes the effects of ambient

temperature shifts on circuit operation. Under these conditions, the only physical parameter which can signifi cantly

infl uence the lamp’s temperature is a change in dissipation

characteristic. Air fl ow moving by the lamp provides this

change. Moving air by the lamp tends to cool it and A1

increases Q1’s output to maintain the lamp’s temperature.

The voltage at Q1’s emitter is nonlinearly, but predictably,

related to air fl ow by the lamp. A2, A3 and the array transistors form a circuit which squares and amplifi es Q1’s

emitter voltage to give a linear, calibrated output versus

air fl ow rate. To use this circuit, place the lamp in the air

fl ow so that its fi lament is a 90° angle to the fl ow. Next,

either shut off the air fl ow or shield the lamp from it and

adjust the zero fl ow potentiometer for a circuit output of

0V. Then, expose the lamp to air fl ow of 1000 feet/minute

and trim the full fl ow potentiometer for 10V output. Repeat

1N4148

Q2 Q3 Q5

1000pF

2k

–

A2

LT1002

+

150k*

500k

1μF

12k

3.3k

–15V

2M

FULL-SCALE

FLOW

–

LT1004-1.2V

+

A3

LM107

OUTPUT

0V TO 10V =

AN05 F11

0 TO 1000FT/MIN

these adjustments until both points are fi xed. With this

procedure completed, the air fl owmeter is accurate within

3% over the entire 0 to 1000 foot/minute range.

Low Distortion, Thermally Stabilized Wien Bridge

Oscillator

The positive temperature coeffi cient of lamp fi laments is

employed in a modern adaptation of a classic circuit in

Figure 12. In any oscillator it is necessary to control the

gain as well as the phase shift at the frequency of interest.

If gain is too low, oscillation will not occur. Conversely,

too much gain will cause saturation limiting. Figure 12

uses a variable Wien Bridge to provide frequency tuning

from 20Hz to 20kHz. Gain control comes from the positive

temperature coeffi cient of the lamp. When power is applied, the lamp is at a low resistance value, gain is high and

oscillation amplitude builds. As amplitude builds, the lamp

current increases, heating occurs and its resistance goes

up. This causes a reduction in amplifi er gain and the circuit

fi nds a stable operating point. The lamp’s gain-regulating

behavior is fl at within 0.25dB over the 20Hz-20kHz range

of the circuit. The smooth, limiting nature of the lamp’s

operation, in combination with its simplicity, gives good

results. Trace A, Figure 13 shows circuit output at 10kHz.

Harmonic distortion is shown in Trace B and is below

0.003%. The trace shows that most of the distortion is

due to second harmonic content and some crossover

disturbance is noticeable. The low resistance values in the

Wein network and the 3.8nV√Hz noise specifi cation of the

LT1037 eliminate amplifi er noise as an error term.

an5f

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

AN5-7

Application Note 5

At low frequencies, the thermal time constant of the small

normal mode lamp begins to introduce distortion levels

above 0.01%. This is due to “hunting” as the oscillator’s

frequency approaches the lamp thermal time constant.

This effect can be eliminated, at the expense of reduced

output amplitude and longer amplitude settling time, by

switching to the low frequency, low distortion mode. The

four large lamps give a longer thermal time constant and

distortion is reduced. Figure 14 plots distortion versus

frequency for the circuit.

References

1. Multiplier Application Guide, pp. 7-9, “Flowmeter,”

Analog Devices, Inc., Norwood, Massachusetts.

LOW FREQ (<50Hz)

LOW DISTORTION MODE

NORMAL

MODE

L2-L5 #1891

L1 #327

100Ω

430Ω

2. Olson, J.V., “A High Stability Temperature Controlled

Oven,” S.B. Thesis M.I.T., Cambridge, Massachusetts,

1974.

3. PIN Photodiodes—5082-4200 Series, pp. 332-335,

Optoelectronics Designers’ Catalog, 1981, Hewlett

Packard Company, Palo Alto, California.

4. Y.S.I. Thermilinear Thermistor, #44018 Data Sheet,

Yellow Springs Instrument Company, Yellow Springs,

Ohio.

5. Hewlett, William R., “A New Type Resistance-Capacitor

Oscillator,” M.S. Thesis, Stanford University, Palo Alto,

California, 1939.

*1% FILM RESISTOR

10k DUAL POTENTIOMETER-

MATCH TRACKING 0.1%

MATCH ALL LIKE CAPACITOR

VALUES 0.1%

–

A = 10V/DIV

B = 0.01V/DIV

(0.003% DISTORTION)

20Hz-200Hz

0.82

953*

10k

HORIZONTAL = 20μs/DIV

200Hzm2kHz 2kHzm20kHz

0.082

0.0082

Figure 12. Low Distortion Sinewave Oscillator

AN05 F13

LT1037 OUTPUT

+

0.82

953*

10k

0.050

0.045

0.040

0.035

0.030

0.025

0.020

0.015

PERCENT DISTORTION

0.010

0.005

0

0

0.082 0.0082

NORMAL MODE

LOW FREQUENCY

LOW DISTORTION

MODE

20

FREQUENCY (Hz)

AN05 F12

200

2k

20k

AN05 F14

AN5-8

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

Figure 14. Oscillator Distortion vs FrequencyFigure 13. Oscillator Waveforms

an5f

IM/GP 0885 10K • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 1984

Loading...

Loading...