Page 1

LT3518

Full-Featured LED Driver

with 2.3A Switch Current

FEATURES

n

3000:1 True Color PWM™ Dimming Ratio

n

2.3A, 45V Internal Switch

n

100mV High Side Current Sense

n

Open LED Protection

n

Adjustable Frequency: 250kHz to 2.5MHz

n

Wide Input Voltage Range:

Operation from 3V to 30V

Transient Protection to 40V

n

Operates in Boost, Buck Mode and Buck-Boost Mode

n

Gate Driver for PMOS LED Disconnect*

n

Constant-Current and Constant-Voltage Regulation

n

CTRL Pin Provides 10:1 Analog Dimming

n

Low Shutdown Current: <1μA

n

Available in (4mm × 4mm) 16-Lead QFN and 16-Pin

TSSOP Packages

APPLICATIONS

n

Display Backlighting

n

Automotive and Avionic Lighting

n

Illumination

n

Scanners

DESCRIPTION

The LT®3518 is a current mode DC/DC converter with an

internal 2.3A, 45V switch specifi cally designed to drive

LEDs. The LT3518 operates as a LED driver in boost, buck

mode and buck-boost mode. It combines a traditional

voltage loop and a unique current loop to operate as a

constant-current source or constant-voltage source. Programmable switching frequency allows optimization of the

external components for effi ciency or component size. The

switching frequency of the LT3518 can be synchronized

to an external clock signal. The LED current is externally

programmable with a 100mV sense resistor. The external

PWM input provides 3000:1 LED dimming. The CTRL pin

provides further 10:1 dimming ratio.

The LT3518 is available in the tiny footprint 16-Lead QFN

(4mm × 4mm) and the 16-Pin TSSOP package. The LT3518

provides a complete solution for both constant-voltage

and constant-current applications.

L, LT, LTC and LTM are registered trademarks of Linear Technology Corporation. True Color

PWM is a trademark of Linear Technology Corporation. Patent Pending. All other trademarks are

the property of their respective owners. *Patents Pending.

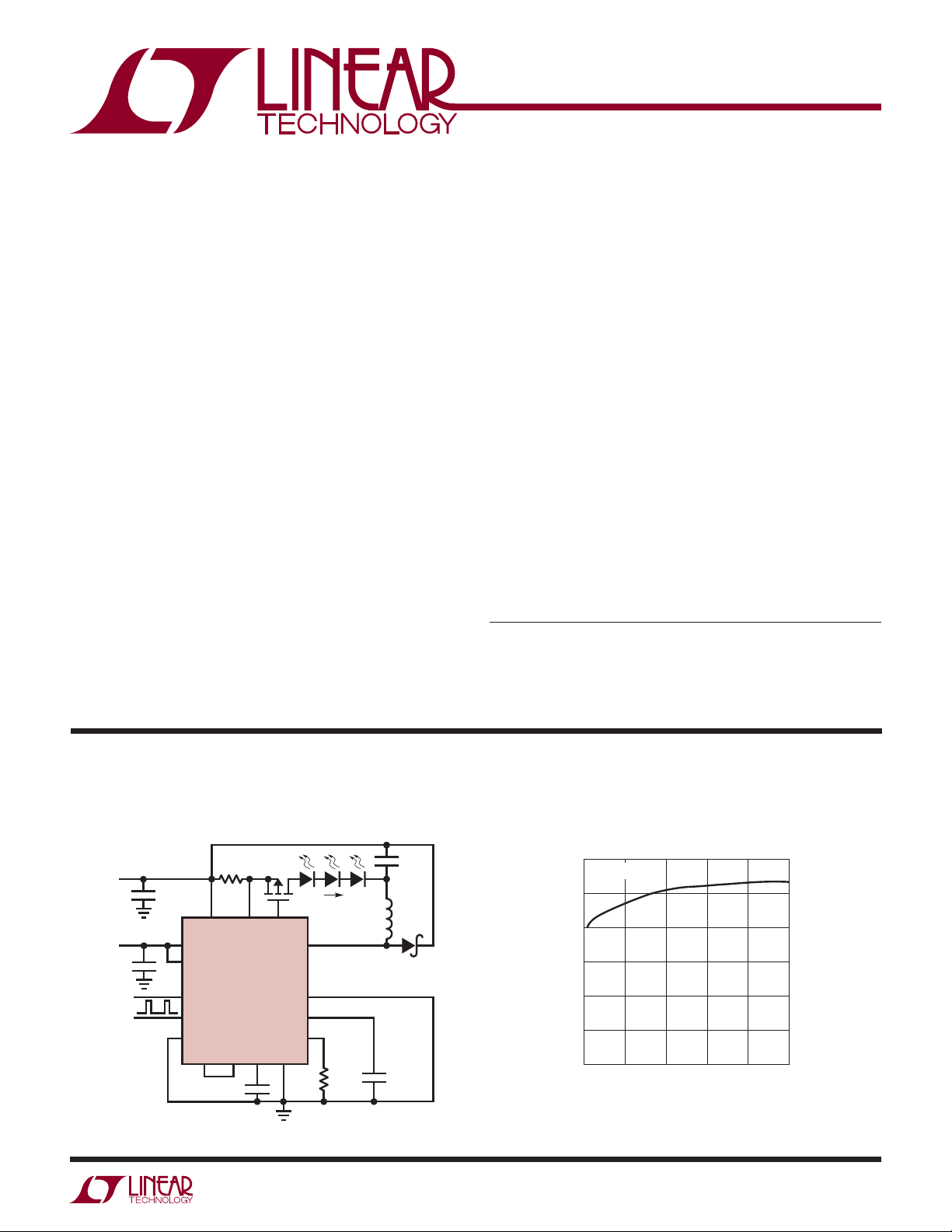

TYPICAL APPLICATION

1.5A Buck Mode LED Driver

ISP

V

IN

SHDN

CTRL

PWM

SYNC

TGEN GNDV

68mΩ M1

ISN

TG

LT3518

REFVC

0.1μF

SW

FB

SS

R

T

PV

24V

V

3.3V

IN

IN

2.2μF

V

REF

PWM

2.2μF

1.5A

16.9k

1MHz

15μH

0.1μF

10μF

3518 TA01a

100

CTRL = V

90

80

70

EFFICIENCY (%)

60

50

40

0

Effi ciency

REF

20 40 60 80

PWM DUTY CYCLE (%)

100

3518 TA01b

3518fb

1

Page 2

LT3518

ABSOLUTE MAXIMUM RATINGS

VIN, SHDN, PWM, TGEN (Note 3)..............................40V

SW, ISP, ISN, TG ........................................................45V

TG Pin Below ISP Pin ................................................10V

FB, SYNC, SS, CTRL ...................................................6V

V

C

, RT, V

.................................................................3V

REF

Operating Junction Temperature Range (Notes 2, 4)

LT3518E .............................................–40°C to 125°C

LT3518I .............................................. –40°C to 125°C

LT3518H ............................................ –40°C to 150°C

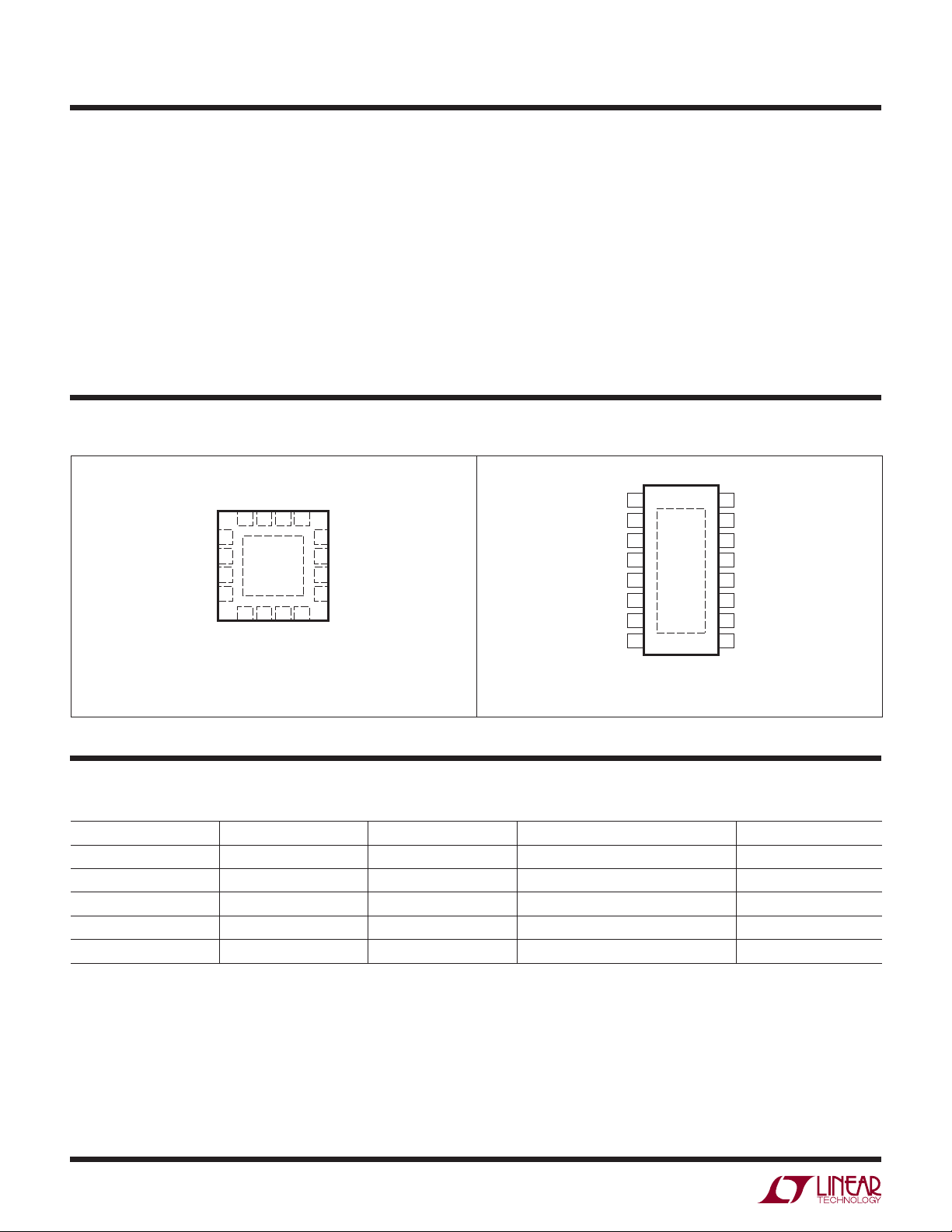

PIN CONFIGURATION

TOP VIEW

TG

ISP

ISN

TGEN

16 15 14 13

FB

1SW

SW

2

V

IN

SHDN

16-LEAD (4mm × 4mm) PLASTIC QFN

T

EXPOSED PAD (PIN 17) IS GND, MUST BE SOLDERED TO PCB

JMAX

17

3

4

5 6 7 8

R

REF

V

UF PACKAGE

= 125°C, θJA = 36°C/W

12

V

11

C

CTRL

10

PWM

9

T

SS

SYNC

(Note 1)

Storage Temperature Range

QFN .................................................... –65°C to 125°C

TSSOP ............................................... –65°C to 150°C

Lead Temperature (Soldering, 10 sec)

TSSOP .............................................................. 300°C

TOP VIEW

1

V

IN

2

SHDN

3

V

REF

4

R

T

5

SYNC

6

SS

7

PWM

8

CTRL

16-LEAD PLASTIC TSSOP

T

= 150°C, θJA = 40°C/W, θ

JMAX

17

GND

FE PACKAGE

16

15

14

13

12

11

10

9

JC(PAD)

SW

SW

TG

ISP

ISN

TGEN

FB

V

C

= 10°C/W

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3518EUF#PBF LT3518EUF#TRPBF 3518

LT3518IUF#PBF LT3518IUF#TRPBF 3518

16-Lead (4mm × 4mm) Plastic QFN

16-Lead (4mm × 4mm) Plastic QFN

–40°C to 125°C

–40°C to 125°C

LT3518EFE#PBF LT3518EFE#TRPBF 3518FE 16-Lead Plastic TSSOP –40°C to 125°C

LT3518IFE#PBF LT3518IFE#TRPBF 3518FE 16-Lead Plastic TSSOP –40°C to 125°C

LT3518HFE#PBF LT3518HFE#TRPBF 3518HFE 16-Lead Plastic TSSOP –40°C to 150°C

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges. *The temperature grade is identifi ed by a label on the shipping container.

Consult LTC Marketing for information on non-standard lead based fi nish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifi cations, go to: http://www.linear.com/tapeandreel/

3518fb

2

Page 3

LT3518

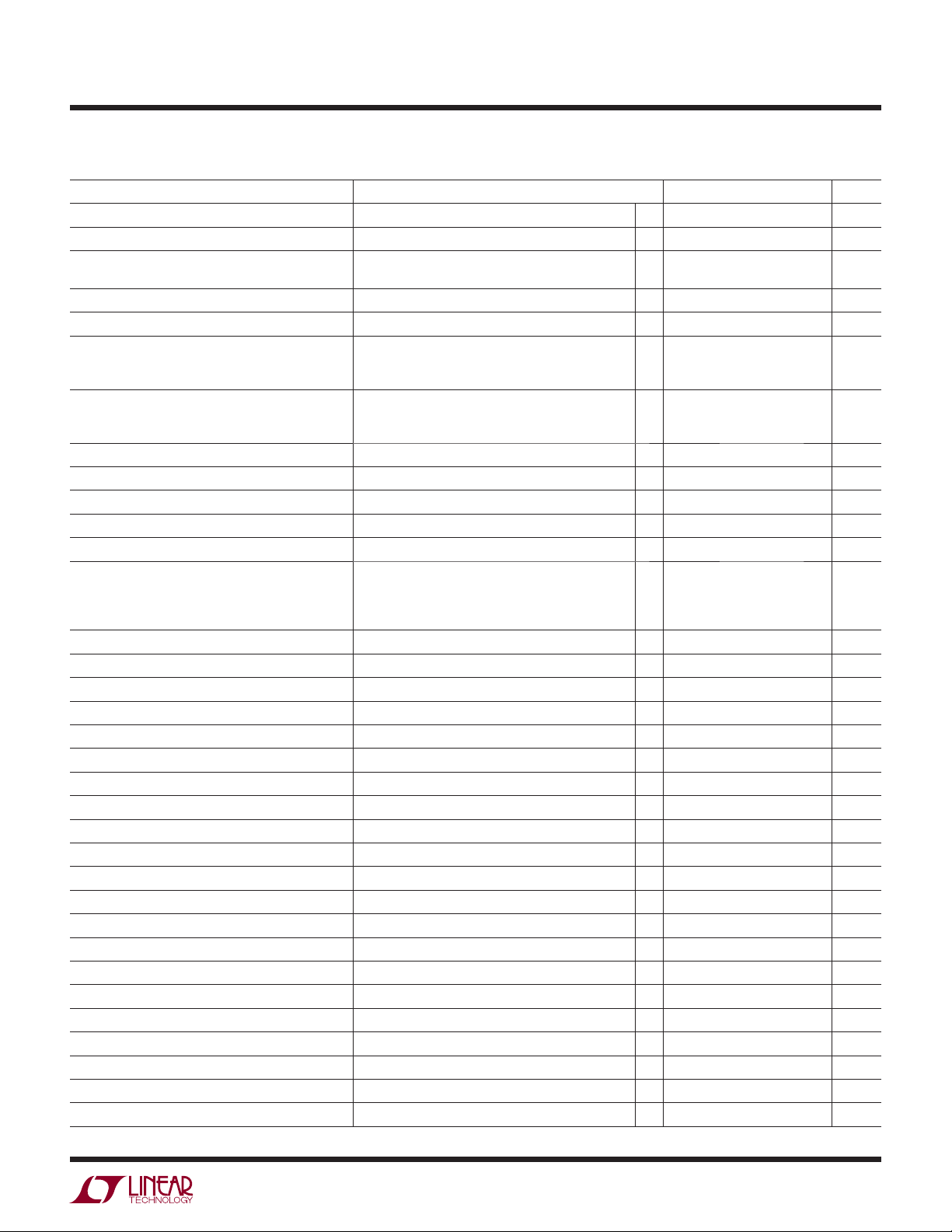

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum VIN Operating Voltage 3V

Maximum V

Current Sense Voltage (V

10% Scale Current Sense Voltage (V

Current Sense Voltage Line Regulation 2V < V

Supply Current PWM > 1.5V, VC = 0V

V

IN

Switching Frequency R

R

Voltage 1V

T

Soft-Start Pin Current SS = 0.5V, Out of Pin 6 9 12 μA

SYNC Pull-Down Current (Into the Pin) V

SYNC Input Low 0.4 V

SYNC Input High 1.5 V

Maximum Duty Cycle R

Switch Current Limit 2.3 2.8 3.5 A

Switch V

Switch Leakage Current V

CTRL Input Bias Current Current Out of Pin, V

Error Amplifi er Transconductance 550 μS

Output Impedance 1000 kΩ

V

C

Idle Input Bias Current PWM = 0, VC = 1V –20 0 20 nA

V

C

FB Pin Input Bias Current Current Out of Pin, V

FB Pin Threshold

, ISN Idle Input Bias Current PWM = 0V 300 nA

ISP

ISP , ISN Full-Scale Input Bias Current ISP Tied to ISN, V

SHDN Voltage High 1.5 V

SHDN Voltage Low 0.4 V

SHDN Pin Bias Current 60 100 μA

PWM Input High Voltage 1.5 V

PWM Input Low Voltage 0.4 V

PWM Pin Bias Current 60 120 μA

TGEN Input High Voltage 1.5 V

TGEN Input Low Voltage 0.4 V

TGEN Pin Bias Current TGEN = 5V 100 200 μA

Pin Voltage I

V

REF

Operating Voltage Continuous Operation (Note 3) 30 V

IN

– V

ISP

CESAT

)V

ISN

– V

ISP

)V

ISN

= 25°C. (Note 2) VIN = 5V, SHDN = 5V, PWM = 5V unless otherwise noted.

A

l

l

l

96 100

0.85

2.25

220

95

94

85

100

6

4.5

0.1

1.0

2.5

250

97

96

90

74

103 mV

mV

10

mA

mA

1

1.15

2.7

270

MHz

MHz

kHz

μA

V

CTRL

CTRL

CTRL

= 2V, V

= 2V, V

= 100mV, V

ISP

= 24V, VC = 1V

ISP

= 0V, VC = 1V

ISP

= 24V, VC = 1V 9 mV

ISP

< 45V 0.03 %/V

PWM = 0V

SHDN = 0V

= 16.7k

T

R

= 4.03k

T

R

= 91.5k

T

= 2V 60 μA

SYNC

= 91.5k (250kHz)

T

SYNC = 300kHz Clock Signal, R

R

= 16.7k (1MHz)

T

R

= 4.03k (2.5MHz)

T

= 91.5k

T

ISW = 1.5A 400 mV

= 45V, PWM = 0V 2 μA

SW

= 0.1V 20 100 nA

CTRL

= 0.5V 20 100 nA

FB

l

0.98 1.01 1.04 V

= –100μA

REF

= 24V, V

ISP

= 2V 20 μA

CTRL

l

1.96 2 2.04 V

%

%

%

%

3518fb

3

Page 4

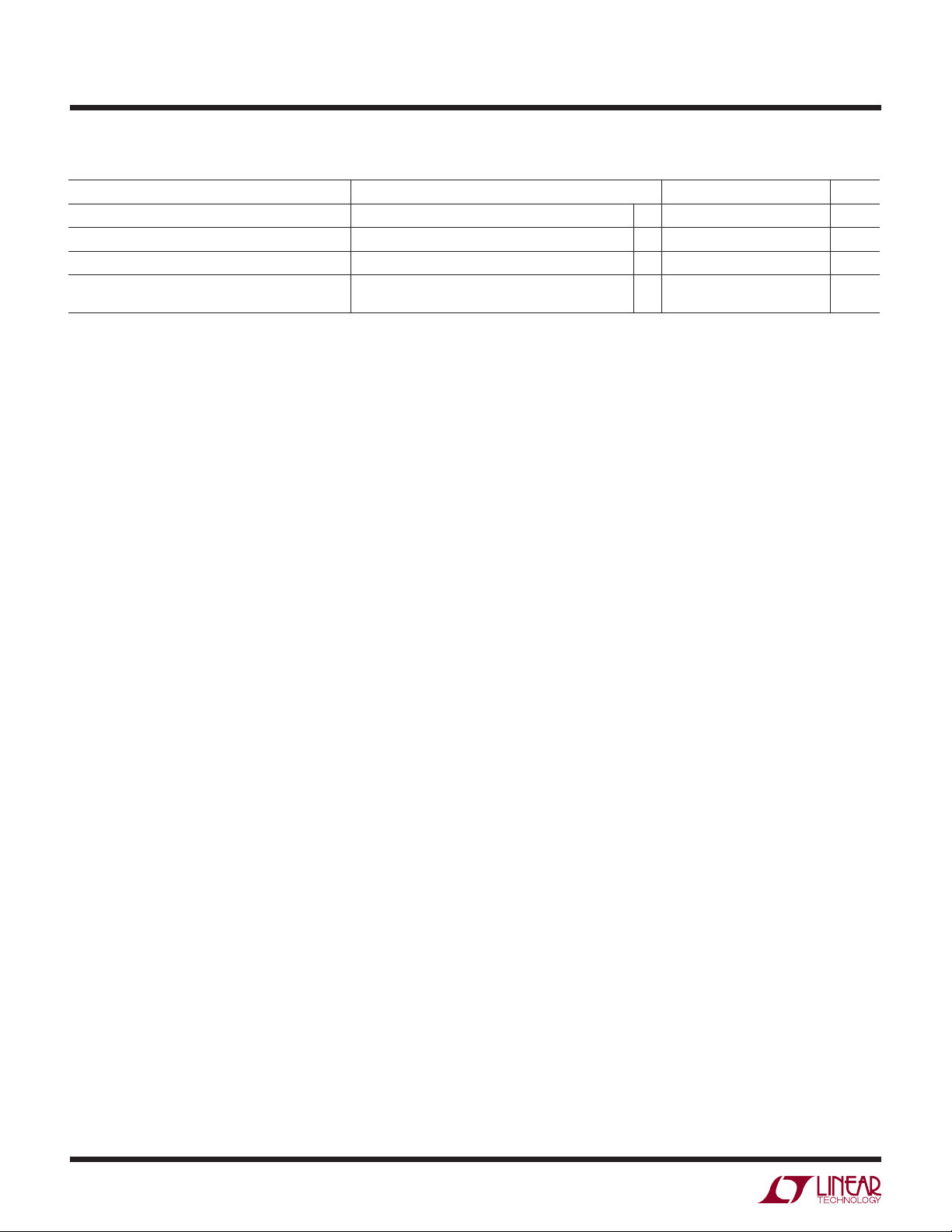

LT3518

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

V

Pin Voltage Line Regulation 3V < VIN < 40V 0.03 %/V

REF

Gate Turn-On Delay C

Gate Turn-Off Delay C

(V

Top Gate Drive V

– VTG)V

GS

ISP

= 25°C. (Note 2) VIN = 5V, SHDN = 5V, PWM = 5V unless otherwise noted.

A

= 1nF Between ISP and TG 200 ns

LOAD

= 1nF Between ISP and TG 200 ns

LOAD

= 24V, TGEN = 5V

ISP

PWM = 0V

7

0 0.3

V

V

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LT3518E is guaranteed to meet performance specifi cations

from 0°C to 125°C junction temperature. Specifi cations over the –40°C

to 125°C operating junction temperature range are assured by design,

characterization and correlation with statistical process controls. The

LT3518I is guaranteed over the full –40°C to 125°C operating junction

temperature range. The LT3518H is guaranteed over the full –40°C to

150°C operating junction temperature range. Operating lifetime is derated

at junction temperatures greater than 125°C.

Note 3: Absolute maximum voltage at VIN, SHDN, PWM and TGEN pins

is 40V for nonrepetitive 1 second transients and 30V for continuous

operation.

Note 4: This IC includes overtemperature protection that is intended

to protect the device during momentary overload conditions. Junction

temperature will exceed the maximum operating junction temperature

when overtemperature protection is active. Continuous operation above

the specifi ed maximum operating junction temperature may impair device

reliability.

4

3518fb

Page 5

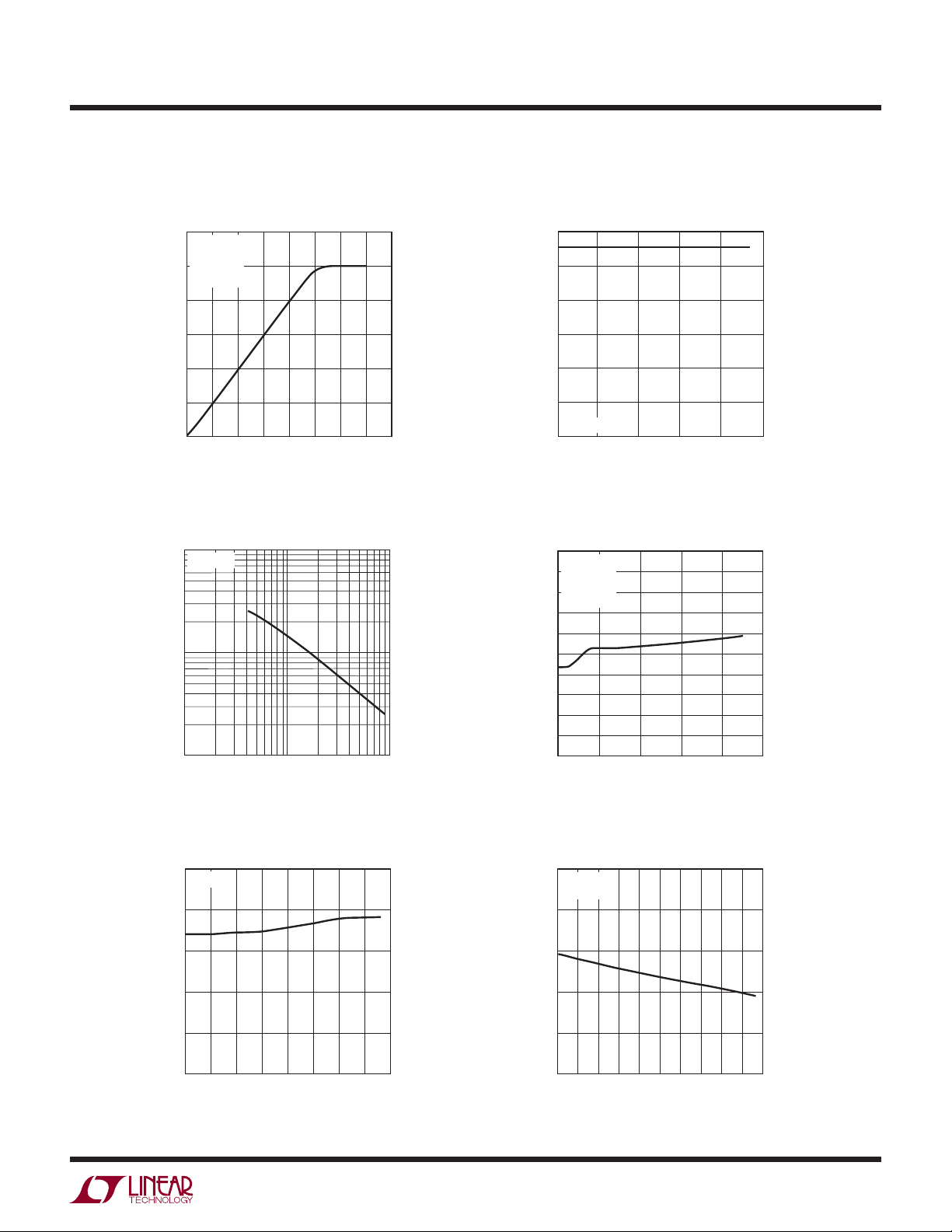

TYPICAL PERFORMANCE CHARACTERISTICS

V

– V

Threshold vs V

ISN

= 24V

CTRL

3.0

2.5

2.0

120

100

80

ISP

VIN = 5V

V

ISP

= 1V

V

C

= 25°C

T

A

LT3518

Switch Current Limit

vs Duty Cycle

60

THRESHOLD (mV)

ISN

40

– V

ISP

V

20

0

0

0.4 0.8

0.2 0.6

V

CTRL

Oscillator Frequency vs R

10000

TA = 25°C

1000

OSCILLATOR FREQUENCY (kHz)

100

1

RT (kΩ)

1.2

1.0

(V)

1.4

3518 G01

T

10 100

3518 G03

1.6

1.5

1.0

CURRENT LIMIT (A)

0.5

TA = 25°C

0

0

20 40 60 80

V

– V

ISP

Temperature

105

V

= 2V

CTRL

104

= 5V

V

IN

= 25°C

T

A

103

= 1V

V

C

102

101

100

THRESHOLD (mV)

99

ISN

98

– V

ISP

V

97

96

95

10

0

DUTY CYCLE (%)

Threshold vs

ISN

20

V

(V)

ISP

100

3518 G02

30

40

50

3518 G04

Switch Current Limit vs

Temperature

3.0

VIN = 5V

2.8

2.6

2.4

CURRENT LIMIT (A)

2.2

2.0

–40 –15

35

–10

TEMPERATURE (°C)

Oscillator Frequency vs

Temperature

2.5

VIN = 5V

= 6.04k

R

T

2.3

2.1

1.9

1.7

OSCILLATOR FREQUENCY (MHz)

60

85

110 135 160

3518 G05

1.5

–40 –20

40

20

0

TEMPERATURE (°C)

60

80

160100 120 140

3518 G06

3518fb

5

Page 6

LT3518

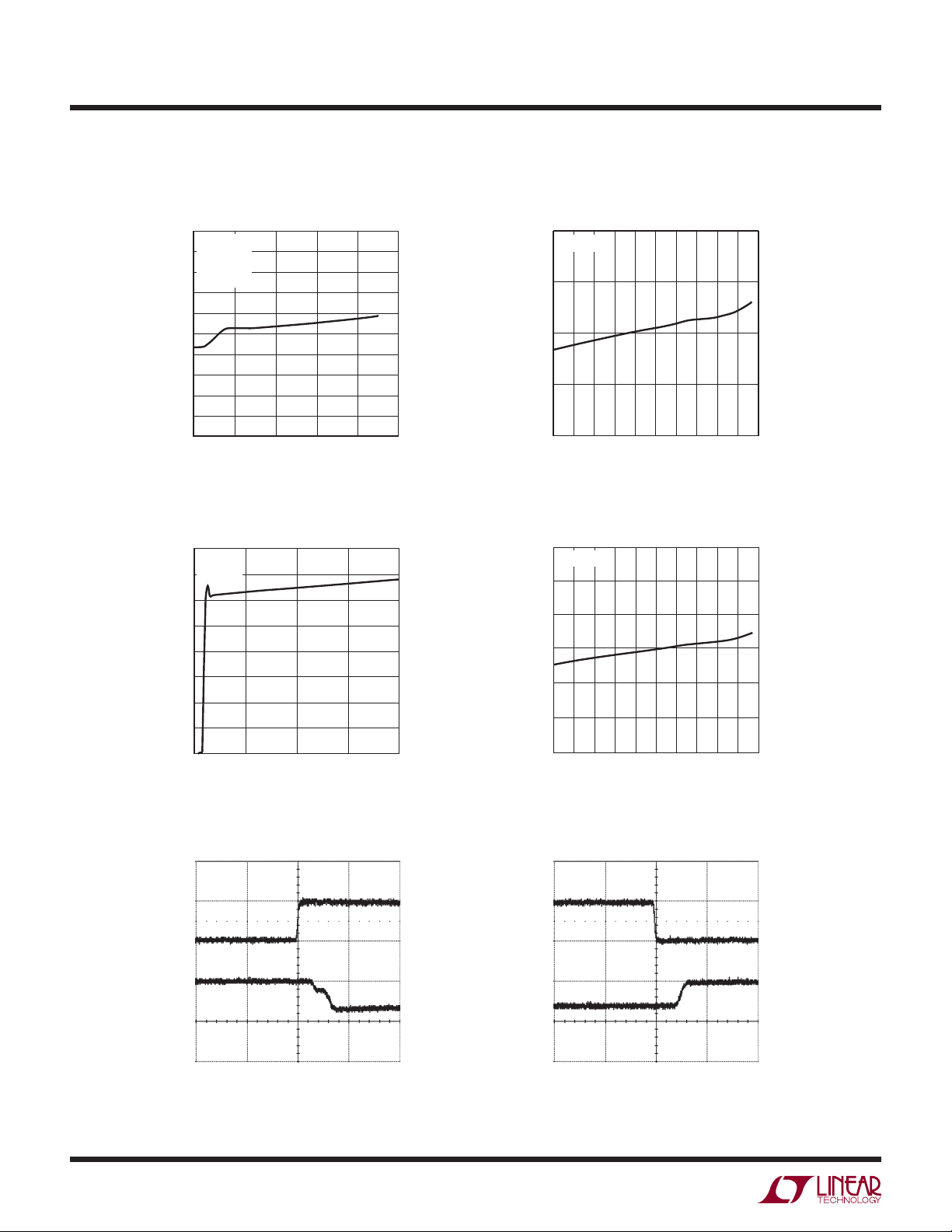

TYPICAL PERFORMANCE CHARACTERISTICS

V

– V

ISN

= 2V

= 5V

10

Threshold vs V

30

20

V

(V)

ISP

ISP

40

3518 G07

2.02

2.01

(V)

2.00

REF

V

1.99

50

1.98

ISP

105

V

CTRL

104

V

IN

= 25°C

T

A

103

= 1V

V

C

102

101

100

THRESHOLD (mV)

99

ISN

98

– V

ISP

V

97

96

95

0

Reference Voltage vs

Temperature

VIN = 5V

–40

–20 0 20 40

60 80 100 120 140 160

TEMPERATURE (°C)

3518 G08

Quiescent Current vs V

8

TA = 25°C

= 0V

V

C

7

6

5

4

CURRENT (mA)

3

IN

V

2

1

0

0

10

VIN (V)

IN

1.04

1.03

1.02

1.01

1.00

FB PIN THRESHOLD (V)

0.99

0.98

20

30

40

3518 G09

–40

PMOS Turn-On PMOS Turn-Off

5V

PWM

0V

5V

PWM

0V

FB Pin Threshold vs Temperature

VIN = 5V

–20 0 20 40

60 80 140 160100 120

TEMPERATURE (°C)

3518 G10

6

40V

TG

30V

ISP

= 40V

200ns/DIVV

3518 G11

40V

TG

30V

ISP

= 40V

200ns/DIVV

3518 G12

3518fb

Page 7

PIN FUNCTIONS

LT3518

SW: Switch Pin. Minimize trace at this pin to reduce

EMI.

: Input Supply Pin. Must be locally bypassed.

V

IN

SHDN: Shutdown Pin. Tie to 1.5V or higher to enable

device or 0.4V or less to disable device.

: Reference Output Pin. This pin can supply up to

V

REF

100μA.

: Switching Frequency Adjustment Pin. Set switching

R

T

frequency using a resistor to GND (see Typical Performance

Characteristics for values). For SYNC function, choose

the resistor to program a frequency 20% slower than the

SYNC pulse frequency. Do not leave this pin open.

SYNC: Frequency Synchronization Pin. Tie an external

clock signal here. R

gram a switching frequency 20% slower than SYNC pulse

frequency. Synchronization (power switch turn-on) occurs

a fi xed delay after the rising edge of SYNC. Tie the SYNC

pin to ground if this feature is not used.

SS: Soft-Start Pin. Place a soft-start capacitor here. Leave

the pin open if not in use.

PWM: Pulse Width Modulated Input Pin. Signal low turns

off channel, disables the main switch and makes the TG

pin high. Tie the PWM pin to SHDN pin if not used. There

is an equivalent 50k resistor from PWM pin to ground

internally.

resistor should be chosen to pro-

T

CTRL: LED Current Adjustment Pin. Sets voltage across

sense resistor between ISP and ISN. Connect directly to

for full-scale threshold of 100mV, or use signal values

V

REF

between GND and 1V to modulate LED current. Tie the CTRL

pin to the V

: gm Error Amplifi er Output Pin. Stabilize the loop with

V

C

an RC network or compensating C.

FB: Voltage Loop Feedback Pin. Works as overvoltage

protection for LED drivers. If FB is higher than 1V, the

main switch is turned off.

TGEN: Top Gate Enable Input Pin. Tie to 1.5V or higher

to enable the PMOS driver function. Tie the TGEN pin to

ground if TG function is not used. There is an equivalent

40k resistor from TGEN pin to ground internally.

ISN: Current Sense (–) Pin. The inverting input to the

current sense amplifi er.

ISP: Current Sense (+) Pin. The noninverting input to the

current sense amplifi er. Also serves as positive rail for

TG pin driver.

TG: Top Gate Driver Output. An inverted PWM signal drives series PMOS device between V

– 7V). An internal 7V clamp protects the V

(V

ISP

gate. Leave TG unconnected if not used.

Ground: Exposed Pad. Solder paddle directly to ground

plane.

pin if not used.

REF

ISP

PMOS

ISP

and

3518fb

7

Page 8

LT3518

BLOCK DIAGRAM

C

R

SHDN

SENSE

ISP ISN

+

–

X10

CURRENT

SENSE

AMPLIFIER

PV

IN

–

CTRL

FB

V

C

SYNC

1.01V

+

A1

+

1V

+

A2

–

IN

TG

V

MOSFET DRIVER

ERROR

AMPLIFIER

+

A3

+

SS

+

A5

1V

–

V

IN

1V

SS

R

T

10μA

+

A6

+

–

FREQ

ADJUST

2.5MHz TO 250kHz

Q2

LED ARRAY

V

ISP

– 7V

ISP

RAMP

GENERATOR

OSCILLATOR

+

A4

–

PWM

COMPARATOR

V

IN

TGEN

C

FILT

PWM

MAIN SWITCH

DRIVER

R

Q

S

SW SW

Q1

MAIN

SWITCH

+

A8

–

100μA

GND

V

IN

V

REF

+

A7

2V

–

3518 F01

8

Figure 1. Buck Mode LED Driver

3518fb

Page 9

OPERATION

LT3518

The LT3518 is a constant frequency, current mode regulator with an internal power switch. Operation can be best

understood by referring to the Block Diagram in Figure 1. At

the start of each oscillator cycle, the SR latch is set, which

turns on the Q1 power switch. A voltage proportional to

the switch current is added to a stabilizing ramp and the

resulting sum is fed into the positive terminal of the PWM

comparator, A4. When this voltage exceeds the level at the

negative input of A4, the SR latch is reset, turning off the

power switch. The level at the negative input of A4 is set

by the error amplifi er A3. A3 has two inputs, one from the

voltage feedback loop and the other one from the current

loop. Whichever feedback input is lower takes precedence,

and forces the converter into either constant-current or

constant-voltage mode. The LT3518 is designed to transition cleanly between these two modes of operation. The

current sense amplifi er senses the voltage across R

and provides a pre-gain to amplifi er A1. The output of A1

is simply an amplifi ed version of the difference between

the voltage across R

or 100mV. In this manner, the error amplifi er sets the

correct peak switch current level to regulate the current

and the lower of V

SENSE

CTRL

SENSE

/10

through R

more current is delivered to the output; if it decreases,

less current is delivered. The current regulated in R

can be adjusted by changing the input voltage V

The current sense amplifi er provides rail-to-rail current

sense operation. The FB voltage loop is implemented by

the amplifi er A2. When the voltage loop dominates, the

error amplifi er and the amplifi er A2 regulate the FB pin to

1.01V (constant-voltage mode).

Dimming of the LED array is accomplished by pulsing the

LED current using the PWM pin. When the PWM pin is

low, switching is disabled and the error amplifi er is turned

off so that it does not drive the V

loads on the V

of the V

capacitor. This feature reduces transient recovery time.

When the PWM input again transitions high, the demand

current for the switch returns to the value just before

PWM last transitioned low. To further reduce transient

recovery time, an external PMOS is used to disconnect

the LED array current loop when PWM is low, stopping

C

FILT

pin will be saved on the external compensation

C

from discharging.

. If the error amplifi er’s output increases,

SENSE

pin. Also, all internal

C

pin are disabled so that the charge state

C

SENSE

CTRL

.

3518fb

9

Page 10

LT3518

APPLICATIONS INFORMATION

Dimming Control

There are two methods to control the current source for

dimming using the LT3518. The fi rst method uses the

PWM pin to modulate the current source between zero

and full current to achieve a precisely programmed average current. To make this method of current control more

accurate, the switch demand current is stored on the V

C

node during the quiescent phase. This feature minimizes

recovery time when the PWM signal goes high. To further

improve the recovery time, a disconnect switch is used in

the LED current path to prevent the output capacitor from

discharging in the PWM signal low phase. The minimum

PWM on or off time will depend on the choice of operating

frequency through R

input pin or SYNC pin. When using

T

the SYNC function, the SYNC and PWM signals must have

the aligned rising edges to achieve the optimized high PWM

dimming ratio. For best current accuracy, the minimum

PWM low or high time should be at least six switching

cycles (3μs for f

= 2MHz). Maximum PWM period is

SW

determined by the system and is unlikely to be longer than

12ms. The maximum PWM dimming ratio (PWM

be calculated from the maximum PWM period (t

the minimum PWM pulse width (t

t

MAX

=

t

MIN

PWM

RATIO

) as follows:

MIN

RATIO

MAX

) can

) and

(1)

Example:

t

MAX

PWM

= 9ms, t

RATIO

= 3μs (fSW = 2MHz)

MIN

= 9ms/3μs = 3000:1

When V

is higher than 1V, the LED current is clamped

CTRL

to be:

LED

100mV

=

R

SENSE

(3)

I

The LED current programming feature possibly increases

V

REF

2V

45.3k

5k

PTC

Figure 2

49.9k

CTRL

3518 F02

total dimming range by a factor of ten.

The CTRL pin should not be left open (tie to V

REF

if not

used). The CTRL pin can also be used in conjunction with

a PTC thermistor to provide overtemperature protection

for the LED load.

Setting Output Voltage

For a boost application, the output voltage can be set by

selecting the values of R1 and R2 (see Figure 3) according

to the following equation:

R1

OUT

=

V

R2

+ 1

• 1.01V

(4)

The second method of dimming control uses the CTRL

pin to linearly adjust the current sense threshold during

the PWM high state. When the CTRL pin voltage is less

than 1V, the LED current is:

V

=

10 •R

CTRL

SENSE

(2)

I

LED

10

LT3518

Figure 3

V

OUT

R1

FB

R2

3518 F03

3518fb

Page 11

APPLICATIONS INFORMATION

LT3518

For a buck or a buck-boost confi guration, the output

voltage is typically level-shifted to a signal with respect

to GND as illustrated in the Figure 4. The output can be

expressed as:

OUT

R1

=

R2

• 1.01V + V

LT3518

FB

BE(Q1)

+

R1

V

–

R2

3518 F04

Figure 4

OUT

(5)

R

SENSE

LED

ARRAY

V

Inductor Selection

The inductor used with the LT3518 should have a saturation current rating of 2A or greater. For buck mode LED

drivers, the inductor value should be chosen to give a

ripple current “ΔI” of ~30% to 40% of the LED current.

In the buck mode, the inductor value can be estimated

using the formula:

Table 1 provides some recommended inductor vendors.

Table 1. Inductor Manufacturers

VENDOR PHONE WEB

Sumida (408) 321-9660 www.sumida.com

Toko (408) 432-8281 www.toko.com

Cooper (561) 998-4100 www.cooperet.com

Vishay (402) 563-6866 www.vishay.com

Input Capacitor Selection

For proper operation, it is necessary to place a bypass

capacitor to GND close to the V

pin of the LT3518. A

IN

1μF or greater capacitor with low ESR should be used. A

ceramic capacitor is usually the best choice.

In the buck mode confi guration, the capacitor at the input

to the power converter has large pulsed currents due to

the current returned though the Schottky diode when the

switch is off. For best reliability, this capacitor should have

low ESR and ESL and have an adequate ripple current

rating. The RMS input current is:

I

IN(RMS)

= I

•(1–D)•D

LED

(8)

where D is the switch duty cycle. A 2.2μF ceramic type

capacitor is usually suffi cient.

D

LµH

()

D

BUCK

BUCK•tSW

=

V

LED

=

V

IN

is the voltage across the LED string, VIN is the input

V

LED

voltage to the converter, and t

(µs) • VIN–V

()

LED

I

is the switching period.

SW

(6)

In the boost confi guration, the inductor can be estimated

using the formula:

LµH

()

D

BOOST

D

BOOST•tSW

=

V

LED–VIN

=

V

LED

I

(µs) • V

IN

(7)

Output Capacitor Selection

The selection of output capacitor depends on the load

and converter confi guration, i.e., step-up or step-down.

For LED applications, the equivalent resistance of the LED

is typically low, and the output fi lter capacitor should be

sized to attenuate the current ripple.

To achieve the same LED ripple current, the required fi lter

capacitor value is larger in the boost and buck-boost mode

applications than that in the buck mode applications. For

LED buck mode applications, a 1μF ceramic capacitor

is usually suffi cient. For the LED boost and buck-boost

mode applications, a 2.2μF ceramic capacitor is usually

suffi cient. Very high performance PWM dimming applications may require a larger capacitor value to support

the LED voltage during PWM transitions.

3518fb

11

Page 12

LT3518

APPLICATIONS INFORMATION

Use only ceramic capacitors with X7R, X5R or better dielectric as they are best for temperature and DC bias stability

of the capacitor value. All ceramic capacitors exhibit loss

of capacitance value with increasing DC voltage bias, so

it may be necessary to choose a higher value capacitor

to get the required capacitance at the operation voltage.

Always check that the voltage rating of the capacitor is

suffi cient. Table 2 shows some recommended capacitor

vendors.

Table 2. Ceramic Capacitor Manufacturers

VENDOR PHONE WEB

Taiyo Yuden (408) 573-4150 www.t-yuden.com

AVX (843) 448-9411 www.avxcorp.com

Murata (770) 436-1300 www.murata.com

TDK (847) 803-6100 www.tdk.com

Loop Compensation

The LT3518 uses an internal transconductance error

amplifi er whose V

output compensates the control loop.

C

The external inductor, output capacitor, and the compensation resistor and capacitor determine the loop stability.

The inductor and output capacitor are chosen based on

performance, size and cost. The compensation resistor

and capacitor at V

are selected to optimize control loop

C

stability. For typical LED applications, a 10nF compensation

capacitor at V

is adequate, and a series resistor is not

C

required. A compensation resistor may be used to increase

the slew rate on the V

of LED current during fast transients on V

pin to maintain tighter regulation

C

or CTRL.

IN

Table 3. Schottky Diodes

PART NUMBER VR (V) I

On Semiconductor

MBRS260T3 60 2

Diodes Inc.

DFLS140L 40 1

Zetex

ZLLS2000TA 40 2.2

International Rectifi er

10MQ060N 60 1.5

AVE

(A)

Board Layout

The high speed operation of the LT3518 demands careful

attention to board layout and component placement. The

Exposed Pad of the package is the only GND terminal of

the IC and is also important for thermal management of

the IC. It is crucial to achieve a good electrical and thermal

contact between the Exposed Pad and the ground plane of

the board. To reduce electromagnetic interference (EMI),

it is important to minimize the area of the SW node. Use

a GND plane under SW and minimize the length of traces

in the high frequency switching path between SW and

GND through the diode and the capacitors. Since there is

a small DC input bias current to the ISN and ISP inputs,

resistance in series with these inputs should be minimized

and matched, otherwise there will be an offset. Finally, the

bypass capacitor on the V

be placed as close as possible to the V

supply to the LT3518 should

IN

terminal of the

IN

device.

Diode Selection

The Schottky diode conducts current during the interval

when the switch is turned off. Select a diode rated for

the maximum SW voltage. If using the PWM feature for

dimming, it is important to consider diode leakage, which

increases with the temperature, from the output during the

PWM low interval. Therefore, choose the Schottky diode

with suffi ciently low leakage current. Table 3 has some

recommended component vendors.

12

Soft-Start

For many applications, it is necessary to minimize the

inrush current at start-up. The built-in soft-start circuit

signifi cantly reduces the start-up current spike and

output voltage overshoot. A typical value for the soft-start

capacitor is 0.1μF.

3518fb

Page 13

APPLICATIONS INFORMATION

LT3518

Switching Frequency

There are two methods to set the switching frequency of

LT3518. Both methods require a resistor connected at R

pin. Do not leave the R

pin open. Also, do not load this pin

T

T

with a capacitor. A resistor must always be connected for

proper operation. One way to set the frequency is simply

connecting an external resistor between the R

See Table 4 below or see the Oscillator Frequency vs R

pin and GND.

T

T

graph in the Typical Performance Characteristics for resistor values and corresponding switching frequencies.

Table 4. Switching Frequency vs R

Switching Frequency (kHz) RT ( kΩ )

250 90.9

500 39.2

1000 16.9

1500 9.53

2000 6.04

2500 4.02

T

The other way is to make the LT3518 synchronize with

an external clock via SYNC pin. For proper operation, a

resistor should be connected at the R

pin and be able

T

to generate a switching frequency 20% lower than the

external clock when external clock is absent.

In general, a lower switching frequency should be used

where either very high or very low switching duty cycle

operation is required, or high effi ciency is desired. Selection

of a higher switching frequency will allow use of smaller

value external components and yield a smaller solution

size and profi le.

Thermal Considerations

The LT3518 is rated to a maximum input voltage of 30V

for continuous operation, and 40V for nonrepetitive one

second transients. Careful attention must be paid to the

internal power dissipation of the LT3518 at higher input

voltages to ensure that the maximum junction temperature

is not exceeded. This junction limit is especially important

when operating at high ambient temperatures. The Exposed

Pad on the bottom of the package must be soldered to a

ground plane. This ground should then be connected to

an internal copper ground plane with thermal vias placed

directly under the package to spread out the heat dissipated

by the LT3518.

3518fb

13

Page 14

LT3518

TYPICAL APPLICATIONS

Buck Mode 1.5A LED Driver

R

SENSE

ISP

V

IN

SHDN

CTRL

PWM

SYNC

TGEN GNDV

68mΩ

LT3518

REFVC

C4

0.1μF

PV

IN

24V

V

IN

3.3V

2.2μF

V

PWM

C1: KEMET C0805C225K4RAC

C2: MURATA GRM31MR71E225KA93

C3: MURATA GRM32DR71E106KA12B

C4, C5: MURATA GRM21BR71H104KA01B

D1: ZETEX ZLLS2000TA

L1: TOKO B992AS-150M

LEDS: LUXEON K2 (WHITE)

M1: ZETEX ZXMP6A13GTA

C2

2.2μF

C1

REF

ISN

M1

TG

SW

SS

R

1.5A

FB

T

R

T

16.9k

1MHz

C3

10μF

L1

15μH

D1

C5

0.1μF

3518 TA02a

500mA, 5V to 12V Boost Converter with Accurate Input Current Limit

PWM

5V/DIV

I

LED

1A/DIV

1A/DIV

1000:1 PWM Dimming at 120Hz

I

L

f

I

OSC

LED

= 24V

IN

= 1MHz

= 1.5A

2μs/DIVPV

3518 TA02b

V

IN

5V

C2

2.2MF

V

CTRL

PWM

SHDN

C1: KEMET C0805C225K4RAC

C2: KEMET C1206C106K4RAC

C3: MURATA GRM21BR71H104KA01B

C4: MURATA GCM033R71A103KA03

D1: ZETEX ZLLS2000TA

L1: TOKO B992AS-4R3N

SHDN

TGEN

V

10k

C4

10nF

SENSE

TGISP

LT3518

GND SS

ISN

L1

4.3MH

SW

SYNC

FB

R

T

C3

0.1MF

100

Effi ciency

300

200

I

(mA)

LOAD

400

500

3518 TA03b

D1

R1

549k

R2

49.9k

R

T

6.04k

2MHz

3518 TA03a

C2

10MF

V

OUT

12V

500mA

90

80

70

EFFICIENCY (%)

60

50

0

R

50m7

IN

REF

V

C

R3

14

3518fb

Page 15

TYPICAL APPLICATIONS

LT3518

Buck-Boost Mode LED Driver

V

8V TO 16V

IN

SHDN

PWM

C1

2.2μF

C1: KEMET C0806C225K4RAC

C2: KEMET C1206C475K3RAC

C3, C4: MURATA GRM21BR71H104KA01B

C5: MURATA GRM21BR71H224KA01B

D1: ZETEX ZLLS2000TA

L1: TOKO B992AS-4R3N

LEDS: LUXEON I (WHITE)

M1: ZETEX ZXMP6A13GTA

0.1μF

PWM

TGEN

V

REF

CTRL

SYNC

V

C4

C

6.04k

2MHz

R

V

T

IN

LT3518

L1

4.3μH

C3

0.1μF

SW

D1

C2

4.7μF

C5

0.22μF

3518 TA04a

R1

FB

ISP

ISN

TG

GNDRTSS

3.92M

R2

124k

300mA

R

SENSE

330mΩ

M1

PWM

5V/DIV

I

LED

200mA/DIV

1A/DIV

3000:1 PWM Dimming at 120Hz Effi ciency

90

VIN = 10V

CTRL = V

80

70

I

L1

IN

f

OSC

I

LED

= 10V

= 2MHz

= 300mA

500ns/DIVV

3518 TA04b

60

50

EFFICIENCY (%)

40

30

20

0

20 40 60 100

REF

80

PWM DUTY CYCLE (%)

3518 TA04c

3518fb

15

Page 16

LT3518

TYPICAL APPLICATIONS

Buck Mode 1A LED Driver with Open LED Protection and Sync Input

PV

IN

32V

V

3.3V

IN

2.2μF

V

PWM

SYNC

C1

REF

3.3V, 1.2MHz

C2

2.2μF

V

SHDN

CTRL

PWM

SYNC

R

100mΩ

ISP

IN

TGEN GNDV

SENSE

LT3518

REFVC

0.1μF

M1

D1

C5

0.1μF

3518 TA05a

R1

49.9k

Q1

R2

2.00k

C3

10μF

FB

C1: KEMET C0806C225K4RAC

C2: MURATA GRM31MR71E225KA93

C3: MURATA GRM32DR71E106KA12B

C4, C5: MURATA GRM21BR71H104KA01B

D1: ZETEX ZLLS2000TA

L1: TOKO B992AS-100M

LEDS: LUXEON III (WHITE)

M1: ZETEX ZXMP6A13GTA

M2: PHILIPS PMBT3906

LED1

1A

LED6

R3

5.62k

L1

ISN

TG

SW

SS

C4

10μH

FB

FB

R

T

R

T

16.7k

1MHz

PWM

5V/DIV

I

LED

1A/DIV

I

1A/DIV

1000:1 PWM Dimming at 120Hz Effi ciency

100

CTRL = V

90

80

L1

70

EFFICIENCY (%)

IN

f

OSC

I

LED

= 32V

= 1.2MHz

= 1A

2μs/DIVPV

3518 TA05b

60

50

40

0

20 40 60 80

REF

100

PWM DUTY CYCLE (%)

3518 TA05c

16

3518fb

Page 17

TYPICAL APPLICATIONS

LT3518

Boost 300mA LED Driver with LED Open Protection

PWM

5V/DIV

I

LED

200mA/DIV

1A/DIV

V

8V TO 16V

L1

R

V

T

8.2μH

IN

LT3518

SW

ISP

ISN

TG

FB

GNDRTSS

C3

0.1μF

IN

C4

0.1μF

SHDN

PWM

TGEN

V

REF

CTRL

SYNC

V

C

16.9k

1MHz

PWM

C1

2.2μF

D1

R1

1M

300mA

R2

30.1k

R

SENSE

330mΩ

M1

C2

6.8μF

LED1

C1: KEMET C1206C225K2RAC

LED2

C2: TDK C5750X7R1H685M

C3, C4: MURATA GRM21BR71H104KA01B

D1: ZETEX ZLLS2000TA

L1: TOKO B992AS-8R2N

LED8

LEDS: LUXEON I (WHITE)

M1: ZETEX ZXMP6A13GTA

3518 TA06a

3000:1 PWM Dimming at 100Hz Effi ciency

100

90

80

70

I

L1

3518 TA06b

f

I

IN

OSC

LED

= 12V

= 1MHz

= 300mA

1μs/DIVV

60

50

EFFICIENCY (%)

40

30

20

0

20

60

40

PWM DUTY CYCLE (%)

VIN = 12V

CTRL = V

80

REF

100

3518 TA06c

3518fb

17

Page 18

LT3518

PACKAGE DESCRIPTION

UF Package

16-Lead Plastic QFN (4mm × 4mm)

(Reference LTC DWG # 05-08-1692)

0.72 ±0.05

4.35 ± 0.05

2.90 ± 0.05

2.15 ± 0.05

(4 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

4.00 ± 0.10

(4 SIDES)

PIN 1

TOP MARK

(NOTE 6)

NOTE:

1. DRAWING CONFORMS TO JEDEC PACKAGE OUTLINE MO-220 VARIATION (WGGC)

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON THE TOP AND BOTTOM OF PACKAGE

0.30 ±0.05

0.65 BSC

PACKAGE OUTLINE

0.75 ± 0.05

2.15 ± 0.10

(4-SIDES)

0.200 REF

0.00 – 0.05

BOTTOM VIEW—EXPOSED PAD

R = 0.115

TYP

1615

PIN 1 NOTCH R = 0.20 TYP

OR 0.35 × 45° CHAMFER

0.55 ± 0.20

1

2

(UF16) QFN 1004

0.30 ± 0.05

0.65 BSC

18

3518fb

Page 19

PACKAGE DESCRIPTION

2.74

(.108)

FE Package

16-Lead Plastic TSSOP

(Reference LTC DWG # 05-08-1663)

16 1514 13 12 11

4.90 – 5.10*

(.193 – .201)

2.74

(.108)

LT3518

10 9

6.60 ±0.10

4.50 ±0.10

RECOMMENDED SOLDER PAD LAYOUT

0.09 – 0.20

(.0035 – .0079)

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

SEE NOTE 4

0.65 BSC

4.30 – 4.50*

(.169 – .177)

0.50 – 0.75

(.020 – .030)

MILLIMETERS

(INCHES)

(.108)

0.45 ±0.05

2.74

1.05 ±0.10

1345678

2

0.25

REF

0° – 8°

0.65

(.0256)

BSC

0.195 – 0.30

(.0077 – .0118)

TYP

4. RECOMMENDED MINIMUM PCB METAL SIZE

FOR EXPOSED PAD ATTACHMENT

*DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.150mm (.006") PER SIDE

2.74

(.108)

1.10

(.0433)

MAX

0.05 – 0.15

(.002 – .006)

FE16 (BA) TSSOP 0204

6.40

(.252)

BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3518fb

19

Page 20

LT3518

TYPICAL APPLICATION

5.5V SEPIC Converter with Short-Circuit Protection

C5

10μF

SW

FB

TG

ISP

ISN

R

T

C3

0.1μF

2.4μH

R

T

6.04k

2MHz

D1

L2

V

IN

3V

C2

2.2μF

SHDN

C4

10nF

C1: KEMET C0805C225K4RAC

C2, C5: KEMET C1206C106K4RAC

C3: MURATA GRM21BR71H104KA01B

C4: MURATA GCM033R71A103KA03

D1: ZETEX ZLLS2000TA

L1, L2: TOKO 962BS-2R4M

PWM

V

IN

CTRL

SYNC

SHDN

LT3518

TGEN

V

REF

VCGND SS

R3

10k

L1

2.4μH

C2

10μF

R

SENSE

0.15Ω

3518 TA07a

R1

221k

R2

49.9k

V

OUT

5.5V

500mA

100

90

80

70

60

EFFICIENCY (%)

50

40

30

0

Effi ciency

100 200 300 500

I

LOAD

400

(mA)

3518 TA07b

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1618 Constant Current, 1.4MHz, 1.5A Boost Converter V

: 5V to 18V, V

IN

MSOP10 Package

LT3003 3-Channel LED Ballaster with PWM Dimming VIN: 3V to 48V, Dimming = 3000:1 True Color PWM, ISD < 5μA,

MSOP10 Package

LT3474 36V, 1A (I

LT3475 Dual 1.5A (I

LT3476 Quad Output 1.5A, 36V, 2MHz High Current LED Driver

with 1,000:1 Dimming

LT3477 3A, 42V, 3MHz Boost, Buck-Boost, Buck LED Driver V

), 2MHz, Step-Down LED Driver VIN: 4V to 36V, V

LED

), 36V 2MHz Step-Down LED Driver VIN: 4V to 36V, V

LED

I

< 1μA, TSSOP16E Package

SD

I

< 1μA, TSSOP20E Package

SD

: 2.8V to 16V, V

V

IN

I

< 10μA, 5mm × 7mm QFN Package

SD

: 2.5V to 25V, V

IN

QFN, TSSOP20E Packages

LT3478/LT3478-1 4.5A, 42V, 2.5MHz High Current LED Driver with 3,000:1

Dimming

LT3479 3A, Full Featured DC/DC Converter with Soft-Start and

Inrush Current Protection

VIN: 2.8V to 36V, V

I

< 3μA, TSSOP16E Packages

SD

: 2.5V to 24V, V

V

IN

DFN and TSSOP Packages

LT3486 Dual 1.3A, 2MHz High Current LED Driver VIN: 2.5V to 24V, V

I

< 1μA, 5mm × 3mm DFN, TSSOP16E

SD

LT3496 Triple Output LED Driver V

: 3V to 40V, V

IN

I

< 10μA, 4mm × 5mm QFN Package

SD

LT3517 Full-Featured LED Driver with 1.5A Switch Current VIN: 3V to 40V, V

ISD < 1μA, 4mm × 4mm QFN and TSSOP Packages

LT3590 48V Buck Mode 50mA LED Driver V

LT3595 16 Channel Buck LED Driver Mode V

: 4.5V to 55V, Drives Up to 10 LEDs, 200:1 Dimming,

IN

I

= 15mA, 2mm × 2mm DFN SC70

SO

: 4.5V to 45V, Drives Up to 160 LEDs, 5000:1 Dimming,

IN

5mm × 9mm QFN

LT C®3783 High Current LED Controller VIN: 3V to 36V, V

I

< 20μA, 5mm × 4mm QFN10, TSSOP16E Packages

SD

= 36V, Dimming = Analog/PWM, ISD < 1μA,

OUT(MAX)

= 13.5V, Dimming = 400:1 True Color PWM,

OUT(MAX)

= 13.5V, Dimming = 3000:1 True Color PWM,

OUT(MAX)

= 36V, Dimming = 1000:1 True Color PWM,

OUT(MAX)

= 40V, Dimming = Analog/PWM, ISD < 1μA,

OUT(MAX)

= 42V, Dimming = 3000:1 True Color PWM,

OUT(MAX)

= 40V, IQ = 6.5mA, ISD < 1μA,

OUT(MAX)

= 36V, Dimming = 1000:1 True Color PWM,

OUT(MAX)

= 45V, Dimming = 3000:1 True Color PWM,

OUT(MAX)

= 45V, Dimming = 5000:1 True Color PWM,

OUT(MAX)

= Ext FET, Dimming = 3000:1 True Color PWM,

OUT(MAX)

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

3518fb

LT 0308 REV B • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2007

Loading...

Loading...