查询LT3511供应商

LT3511

Monolithic High Voltage

Isolated Flyback Converter

FEATURES

n

4.5V to 100V Input Voltage Range

n

Internal 240mA, 150V Power Switch

n

Boundary Mode Operation

n

No Transformer Third Winding or

Opto-Isolator Required for Regulation

n

Improved Primary-Side Winding Feedback

Load Regulation

n

V

Set with Two External Resistors

OUT

n

BIAS Pin for Internal Bias Supply and Power

Switch Driver

n

No External Start-Up Resistor

n

16-Lead MSOP Package

APPLICATIONS

n

Isolated Telecom Power Supplies

n

Isolated Auxiliary/Housekeeping Power Supplies

n

Isolated Industrial, Automotive and Medical Power

Supplies

DESCRIPTION

The LT3511 is a high voltage monolithic switching regulator specifically designed for the isolated flyback topology.

No third winding or opto-isolator is required for regulation as the part senses output voltage directly from the

primary-side flyback waveform. The device integrates a

240mA, 150V power switch, high voltage circuitry, and

control into a high voltage 16-lead MSOP package with

four leads removed.

The LT3511 operates from an input voltage range of 4.5V

to 100V and delivers up to 2.5W of isolated output power.

Two external resistors and the transformer turns ratio

easily set the output voltage. Off-the-shelf transformers

are available for several applications. The high level of

integration and the use of boundary mode operation results

in a simple, clean, tightly regulated application solution to

the traditionally tough problem of isolated power delivery.

L, LT, LTC, LTM, Burst Mode, Linear Technology and the Linear logo are registered trademarks

and No R

property of their respective owners. Protected by U.S. Patents, including 5438499, 7471522.

is a trademark of Linear Technology Corporation. All other trademarks are the

SENSE

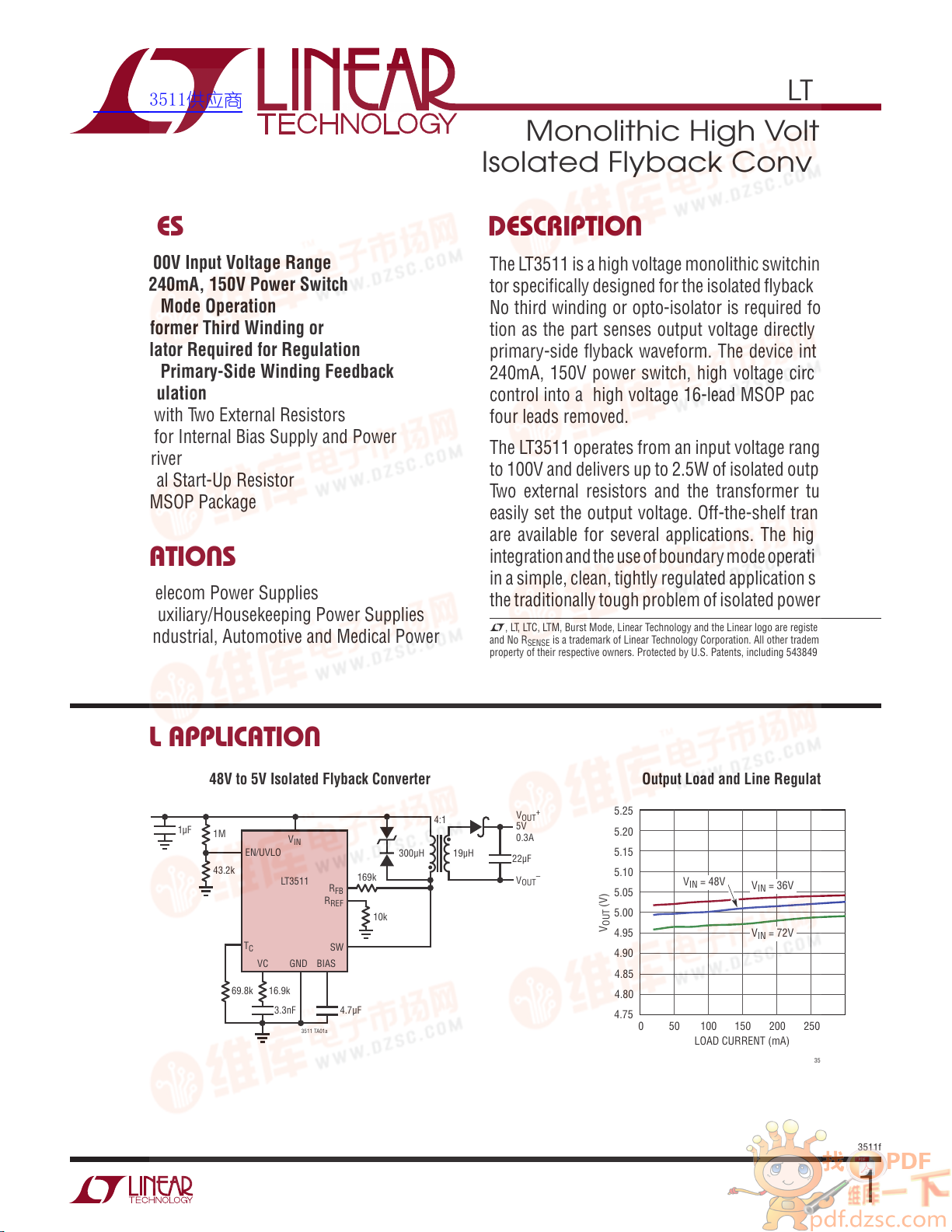

TYPICAL APPLICATION

48V to 5V Isolated Flyback Converter

V

IN

36V TO 72V

1

µF

1M

43.2k

69.8k

V

EN/UVLO

T

IN

LT3511

C

VC GND BIAS

16.9k

3.3nF

3511 TA01a

Output Load and Line Regulation

+

V

22

5V

0.3A

V

OUT

µF

OUT

–

4:1

•

19

µH300µH

169k

R

FB

R

REF

10k

SW

4.7µF

•

(V)

OUT

V

5.25

5.20

5.15

5.10

5.05

5.00

4.95

4.90

4.85

4.80

4.75

VIN = 48V

50

0

100

LOAD CURRENT (mA)

VIN = 36V

VIN = 72V

150 200

250

300

3511 TA01b

3511f

1

LT3511

查询LT3511供应商

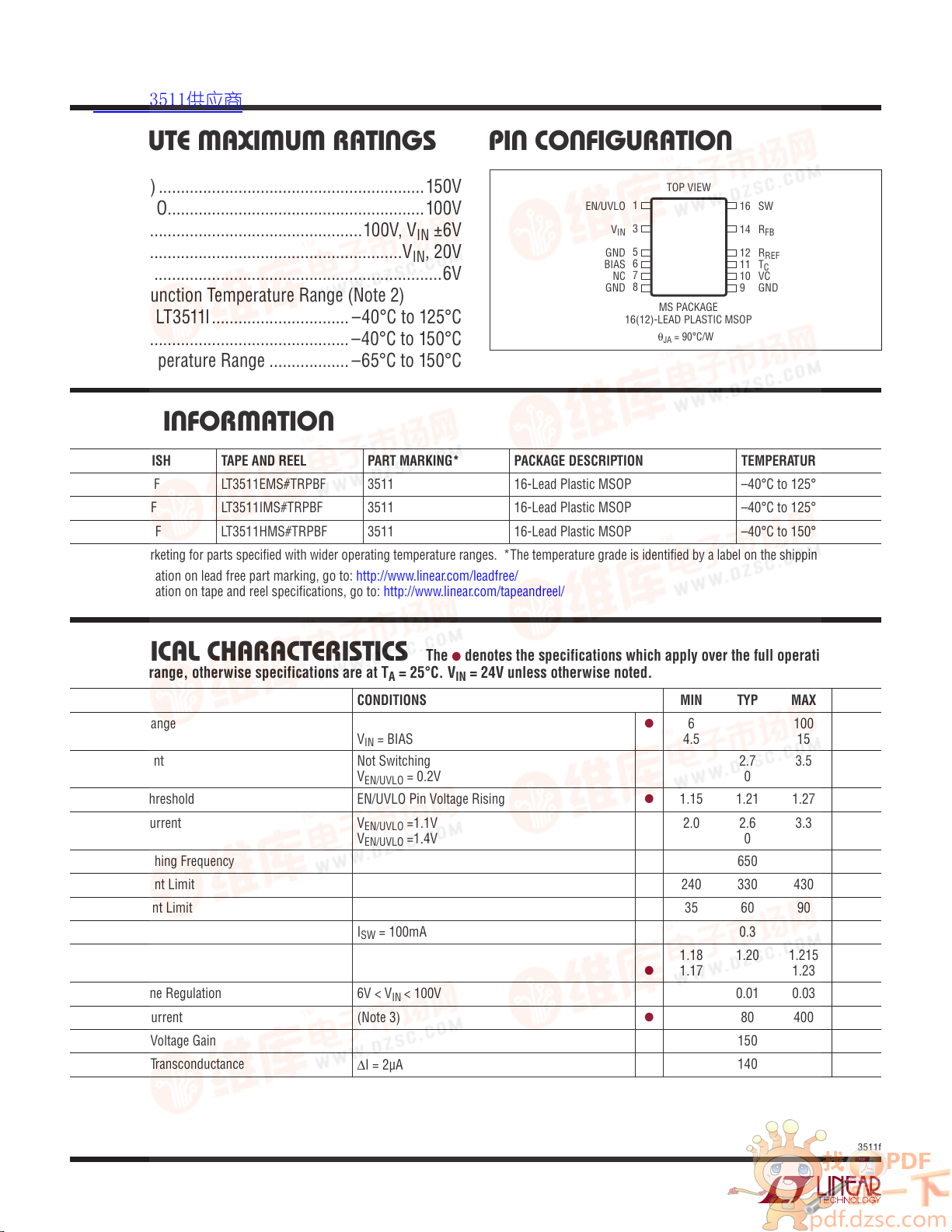

PIN CONFIGURATIONABSOLUTE MAXIMUM RATINGS

(Note 1)

SW (Note 4) ............................................................150V

, EN/UVLO ..........................................................100V

V

IN

............................................................100V, VIN ±6V

R

FB

...................................................................VIN, 20V

BIAS

R

, VC .................................................................6V

REF,TC

Operating Junction Temperature Range (Note 2)

LT3511E, LT3511I ............................... –40°C to 125°C

LT3511H ............................................. –40°C to 150°C

Storage Temperature Range

.................. –65°C to 150°C

EN/UVLO

V

GND

BIAS

NC

GND

IN

TOP VIEW

1

3

5

6

7

8

MS PACKAGE

16(12)-LEAD PLASTIC MSOP

θJA = 90°C/W

SW

16

R

14

FB

12

R

REF

11

T

C

10

VC

9

GND

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3511EMS#PBF LT3511EMS#TRPBF 3511 16-Lead Plastic MSOP –40°C to 125°C

LT3511IMS#PBF LT3511IMS#TRPBF 3511 16-Lead Plastic MSOP –40°C to 125°C

LT3511HMS#PBF LT3511HMS#TRPBF 3511 16-Lead Plastic MSOP –40°C to 150°C

Consult LTC Marketing for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifications, go to: http://www.linear.com/tapeandreel/

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VIN = 24V unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

l

Input Voltage Range

Quiescent Current Not Switching

EN/UVLO Pin Threshold EN/UVLO Pin Voltage Rising

EN/UVLO Pin Current V

Maximum Switching Frequency 650 kHz

Maximum Current Limit 240 330 430 mA

Minimum Current Limit 35 60 90 mA

Switch V

CESAT

Voltage

R

REF

Voltage Line Regulation 6V < V

R

REF

Pin Bias Current (Note 3)

R

REF

Error Amplifier Voltage Gain 150 V/V

Error Amplifier Transconductance

= BIAS

V

IN

V

= 0.2V

EN/UVLO

=1.1V

EN/UVLO

V

=1.4V

EN/UVLO

ISW = 100mA 0.3 V

< 100V 0.01 0.03 %/V

IN

∆I = 2µA

6

4.5

2.7

0

l

1.15 1.21 1.27 V

l

l

2.0 2.6

1.18

1.17

0

1.20 1.215

80 400 nA

140 μmhos

100

15

3.5 mA

μA

3.3 μA

μA

1.23

V

V

V

V

2

3511f

V

(V)

查询LT3511供应商

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full operating

LT3511

temperature range, otherwise specifications are at TA = 25°C. VIN = 24V unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Switching Frequency 40 kHz

Current into R

T

C

REF

BIAS Pin Voltage Internally Regulated 3 3.1 3.2 V

RTC = 53.6k 9.5 μA

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LT3511E is guaranteed to meet performance specifications

from 0°C to 125°C junction temperature. Specifications over the –40°C

to 125°C operating junction temperature range are assured by design,

characterization and correlation with statistical process controls. The

125°C operating junction temperature range. The LT3511H is guaranteed

over the full –40°C to 150°C operating junction temperature range. High

junction temperatures degrade operating lifetimes. Operating lifetime is

derated at junction temperatures greater than 125°C.

Note 3: Current flows out of the R

Note 4: The SW pin is rated to 150V for transients. Operating waveforms

of the SW pin should keep the pedestal of the flyback waveform below

100V as shown in Figure 5.

LT3511I is guaranteed to meet performance specifications from –40°C to

= 25°C, unless otherwise noted.

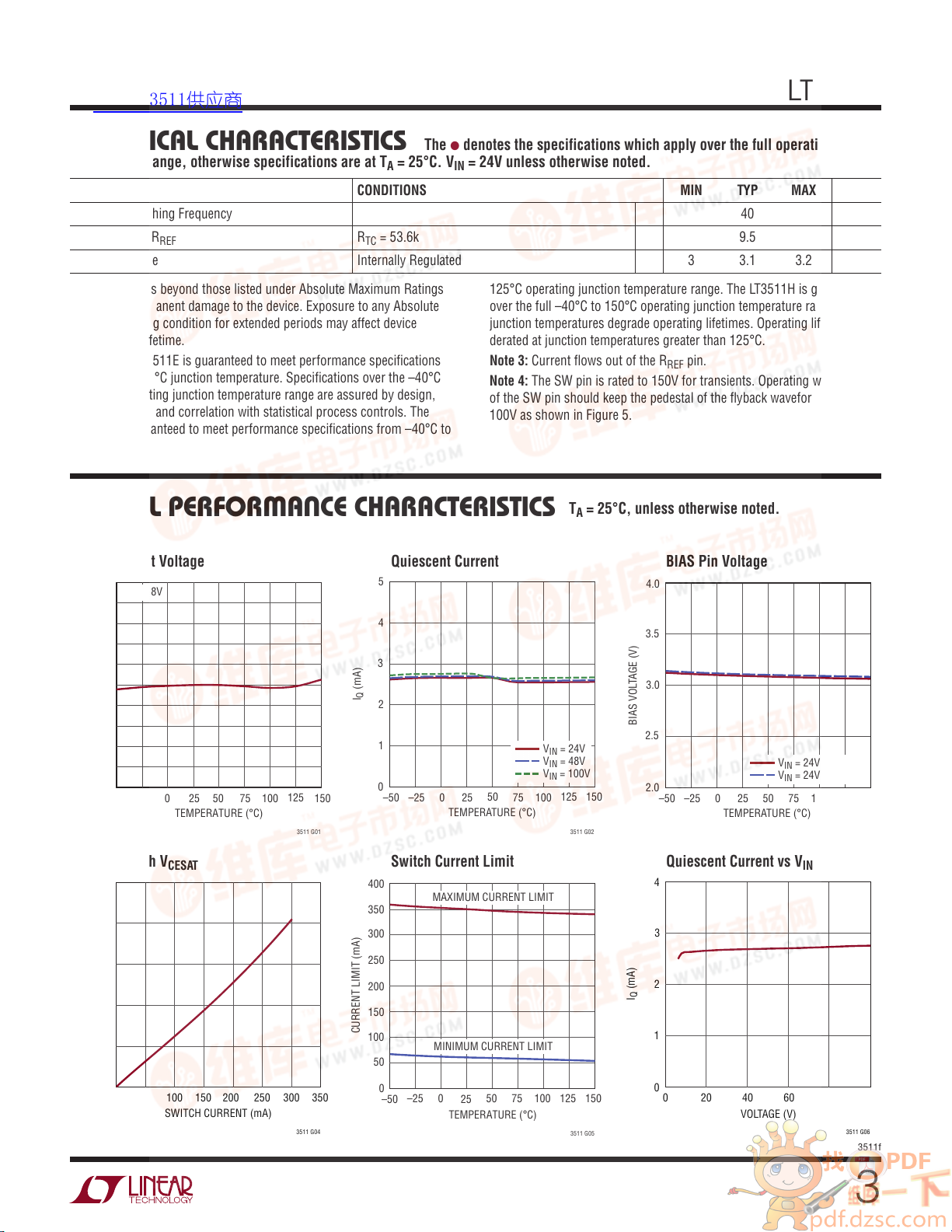

TYPICAL PERFORMANCE CHARACTERISTICS

T

A

Output Voltage Quiescent Current BIAS Pin Voltage

5

4

3

(mA)

Q

I

2

1

0

–50 –25

0

Switch Current Limit

400

350

300

MAXIMUM CURRENT LIMIT

50

25

TEMPERATURE (°C)

75

VIN = 24V

= 48V

V

IN

= 100V

V

IN

100

3511 G02

4.0

3.5

3.0

BIAS VOLTAGE (V)

2.5

150125

2.0

–50

4

3

OUT

1000

5.25

5.20

5.15

5.10

5.05

5.00

4.95

4.90

4.85

4.80

4.75

800

VIN = 48V

–50

–25 25

Switch V

0

50

TEMPERATURE (°C)

CESAT

125

100

75

150

3511 G01

pin.

REF

VIN = 24V, 10mA

= 24V, NO LOAD

V

IN

–25 0 25 50

TEMPERATURE (°C)

75 100 150125

Quiescent Current vs V

3511 G03

IN

600

VOLTAGE (mV)

400

CESAT

200

SWITCH V

0

0 50

150

200

250

100

SWITCH CURRENT (mA)

300

3511 G04

350

250

200

150

CURRENT LIMIT (mA)

100

50

0

–50

MINIMUM CURRENT LIMIT

–25 0 50

25

TEMPERATURE (°C)

75 100 150125

3511 G05

(mA)

Q

I

2

1

0

20

0

40

VOLTAGE (V)

60

80

100

3511 G06

3511f

3

LT3511

查询LT3511供应商

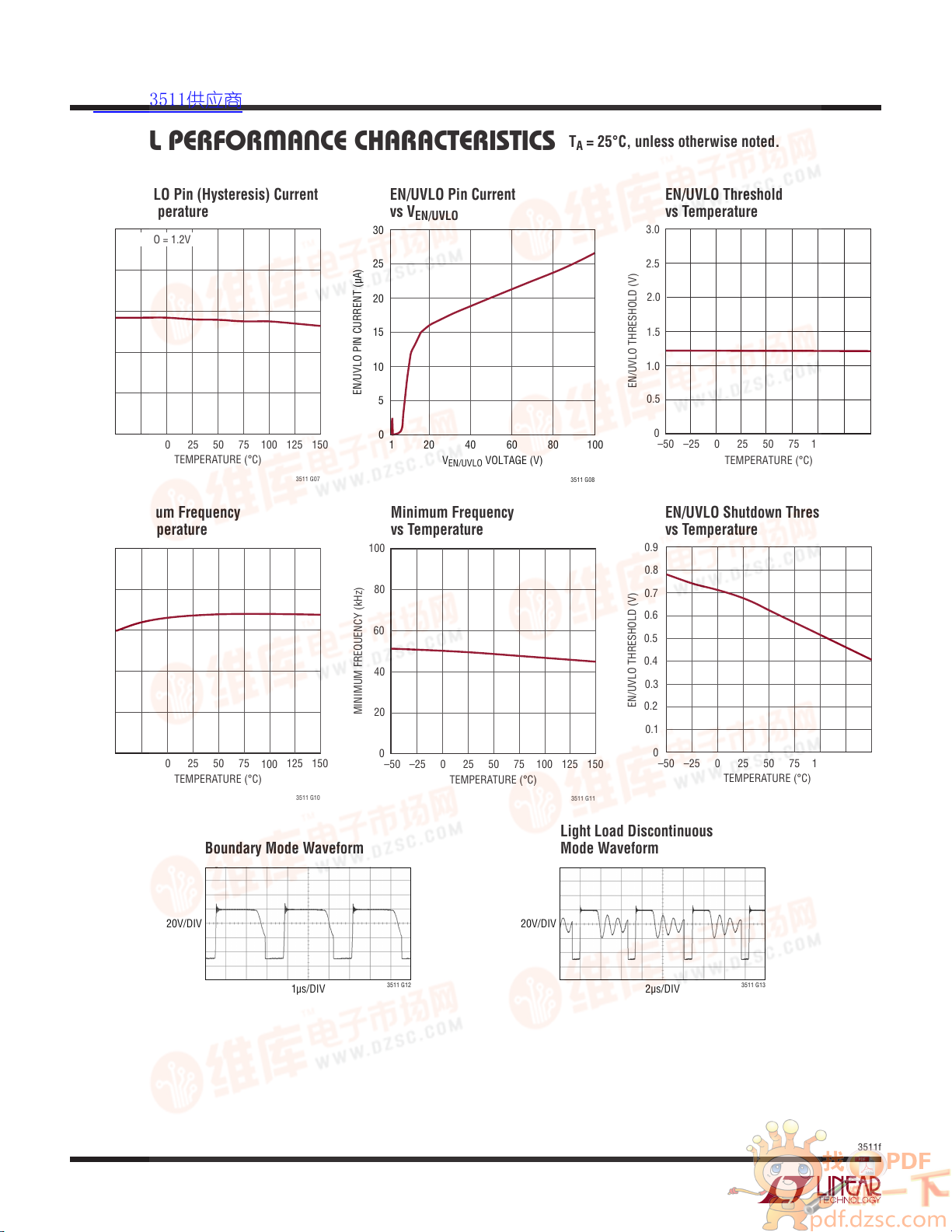

TYPICAL PERFORMANCE CHARACTERISTICS

EN/UVLO Pin (Hysteresis) Current

vs Temperature

5

EN/UVLO = 1.2V

4

3

2

EN/UVLO PIN CURRENT (µA)

1

0

–50 –25

0

50

25

TEMPERATURE (°C)

75

100

Maximum Frequency

vs Temperature

1000

800

600

400

MAXIMUM FREQUENCY (kHz)

200

0

–50 –25

0

50

25

TEMPERATURE (°C)

75

100

150125

3511 G07

150125

3511 G10

EN/UVLO Pin Current

vs V

EN/UVLO

30

25

20

15

10

EN/UVLO PIN CURRENT (µA)

5

0

1

20 40 60 80

V

EN/UVLO

Minimum Frequency

vs Temperature

100

80

60

40

MINIMUM FREQUENCY (kHz)

20

0

–50 –25

0

25

TEMPERATURE (°C)

VOLTAGE (V)

50

75

100

TA = 25°C, unless otherwise noted.

EN/UVLO Threshold

vs Temperature

3.0

2.5

2.0

1.5

1.0

EN/UVLO THRESHOLD (V)

0.5

3511 G08

100

0

–50

–25 0

50 100 150125

25 75

TEMPERATURE (°C)

EN/UVLO Shutdown Threshold

vs Temperature

0.9

0.8

0.7

0.6

0.5

0.4

0.3

EN/UVLO THRESHOLD (V)

0.2

0.1

3511 G11

0

150125

–50

–25

0

25 150125

50

TEMPERATURE (°C)

3511 G09

75 100

3511 G14

4

Boundary Mode Waveform

20V/DIV

1µs/DIV

3511 G12

Light Load Discontinuous

Mode Waveform

20V/DIV

2µs/DIV

3511 G13

3511f

查询LT3511供应商

PIN FUNCTIONS

LT3511

EN/UVLO (Pin 1): Enable/Undervoltage Lockout. The EN/

UVLO pin is used to start up the LT3511. Pull the pin to 0V

to shut down the LT3511. This pin has an accurate 1.21V

threshold and can be used to program an undervoltage

lockout (UVLO) threshold using a resistor divider from

supply to ground. A 2.6μA pin current hysteresis allows

the programming of undervoltage lockout (UVLO) hys-

teresis. EN/UVLO can be directly connected to V

. If left

IN

open circuit the part will not power up.

(Pin 3): Input Supply Pin. This pin supplies current to

V

IN

the internal start-up circuitry, and serves as a reference

voltage for the DCM comparator and feedback circuitry.

Must be locally bypassed with a capacitor.

GND (Pin 5, 8, 9): Ground Pins. All three pins should be

tied directly to the local ground plane.

BIAS (Pin 6): Bias Voltage. This pin supplies current to

the switch driver and internal circuitry of the LT3511.

This pin may also be connected to V

is not used and if V

to 4.5V when BIAS and V

< 20V. The part can operate down

IN

are connected together. If a

IN

if a third winding

IN

third winding is used, the BIAS voltage should be lower

than the input voltage and greater than 3.3V for proper

operation. BIAS must be bypassed with a 4.7µF capacitor

placed close to the pin.

VC (Pin 10): Compensation Pin for Internal Error Amplifier.

Connect a series RC from this pin to ground to compensate

the switching regulator. An additional 100pF capacitor from

this pin to ground helps eliminate noise.

(Pin 11): Output Voltage Temperature Compensa-

T

C

tion. Connect a resistor to ground to produce a current

proportional to absolute temperature to be sourced into

REF

node.

the R

ITC = 0.55V/RTC.

(Pin 12): Input Pin for External Ground-Referred

R

REF

Reference Resistor. The resistor at this pin should be 10k.

For nonisolated applications, a traditional resistor voltage

divider from V

(Pin 14): Input Pin for External Feedback Resistor.

R

FB

This pin is connected to the transformer primary (V

The ratio of this resistor to the R

may be connected to this pin.

OUT

resistor, times the

REF

SW

).

internal bandgap reference, determines the output voltage (plus the effect of any non-unity transformer turns

ratio). For nonisolated applications, this pin should be

connected to V

IN

.

SW (Pin 16): Switch Pin. Collector of the internal power

switch. Minimize trace area at this pin to minimize EMI

and voltage spikes.

3511f

5

LT3511

查询LT3511供应商

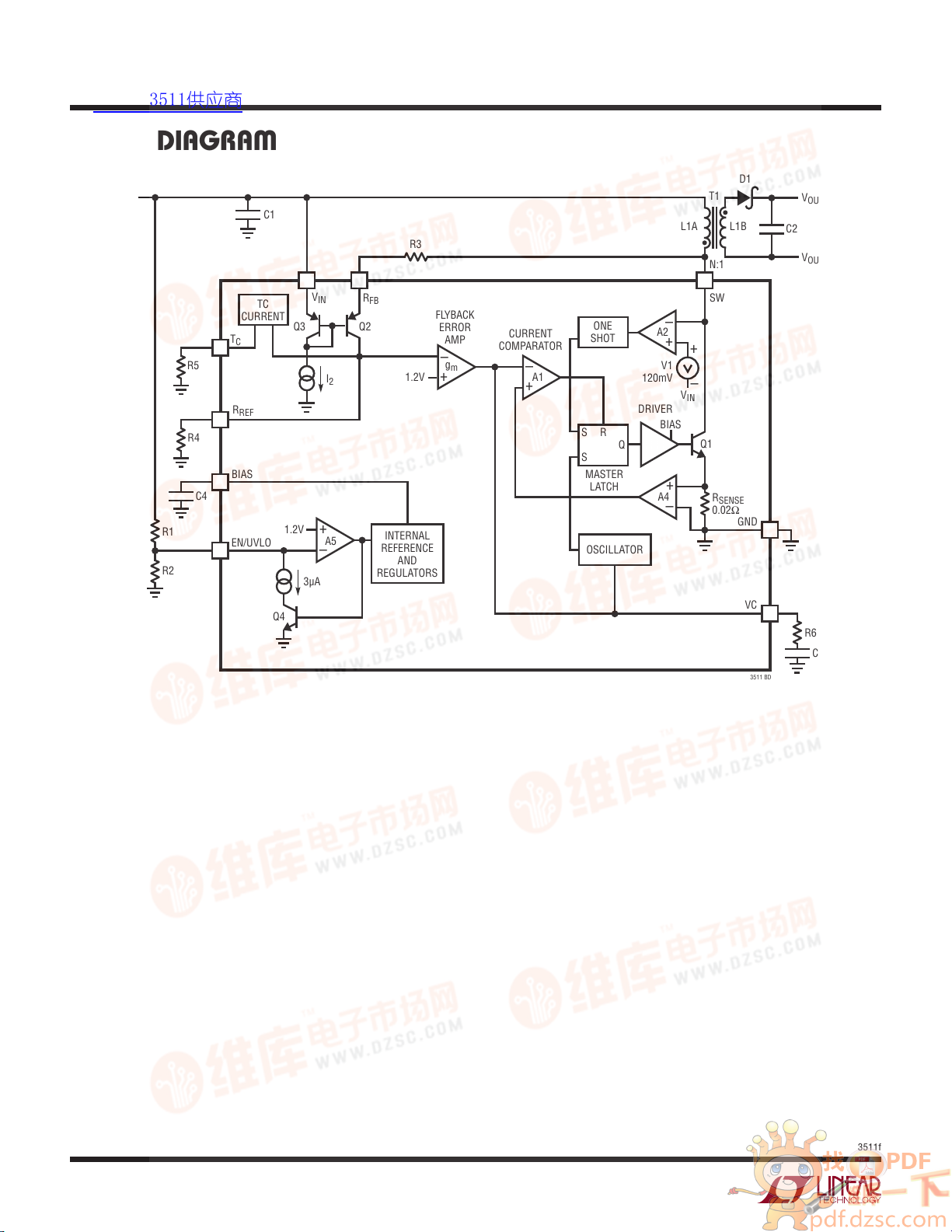

BLOCK DIAGRAM

Q1

T1

N:1

SW

R

SENSE

0.02Ω

D1

GND

V

C

3511 BD

V

IN

C1

R3

TC

CURRENT

T

C

R5

R

REF

R4

BIAS

C4

R1

R2

EN/UVLO

V

Q3

1.2V

3µA

Q4

R

IN

+

–

FB

Q2

I

2

A5

INTERNAL

REFERENCE

REGULATORS

AND

1.2V

FLYBACK

ERROR

AMP

–

g

m

+

CURRENT

COMPARATOR

–

A1

+

ONE

SHOT

RQS

S

MASTER

LATCH

OSCILLATOR

A2

120mV

DRIVER

BIAS

A4

L1A L1B

–

+

+

V1

–

V

IN

+

–

+

V

OUT

C2

–

V

OUT

R6

C3

6

3511f

查询LT3511供应商

OPERATION

LT3511

The LT3511 is a current mode switching regulator IC de-

signed specifically for the isolated flyback topology. The

key problem in isolated topologies is how to communicate

information regarding the output voltage from the isolated

secondary side of the transformer to the primary side.

Historically, optoisolators or extra transformer windings

communicate this information across the transformer.

Optoisolator circuits waste output power, and the extra

components increase the cost and physical size of the

power supply. Optoisolators can also exhibit trouble due

to limited dynamic response, nonlinearity, unit-to-unit

variation and aging over life. Circuits employing an extra

transformer winding also exhibit deficiencies. Using an

extra winding adds to the transformer’s physical size and

cost, and dynamic response is often mediocre.

In the LT3511, the primary-side flyback pulse provides

information about the isolated output voltage. In this man-

ner, neither optoisolator nor extra transformer winding is

required for regulation. Two resistors program the output

voltage. Since this IC operates in boundary mode, the part

calculates output voltage from the switch pin when the

secondary current is almost zero.

The Block Diagram shows an overall view of the system.

Many of the blocks are similar to those found in traditional

switching regulators including internal bias regulator, os-

cillator, logic, current amplifier, current comparator, driver,

and output switch. The novel sections include a special

flyback error amplifier and a temperature compensation

circuit. In addition, the logic system contains additional

logic for boundary mode operation.

The LT3511 features boundary mode control, where the part

operates at the boundary between continuous conduction

mode and discontinuous conduction mode. The VC pin

controls the current level just as it does in normal current

mode operation, but instead of turning the switch on at the

start of the oscillator period, the part turns on the switch

when the secondary-side winding current is zero.

Boundary Mode Operation

Boundary mode is a variable frequency, current mode

switching scheme. The switch turns on and the inductor

current increases until a VC pin controlled current limit.

After the switch turns off, the voltage on the SW pin rises

to the output voltage divided by the secondary-to-primary

transformer turns ratio plus the input voltage. When the

secondary current through the diode falls to zero, the SW

pin voltage falls below V

mode (DCM) comparator detects this event and turns the

switch back on.

Boundary mode returns the secondary current to zero every

cycle, so parasitic resistive voltage drops do not cause load

regulation errors. Boundary mode also allows the use of a

smaller transformer compared to continuous conduction

mode and does not exhibit subharmonic oscillation.

At low output currents, the LT3511 delays turning on the

switch, and thus operates in discontinuous mode. Unlike

traditional flyback converters, the switch has to turn on

to update the output voltage information. Below 0.6V on

the VC pin, the current comparator level decreases to

its minimum value, and the internal oscillator frequency

decreases. With the decrease of the internal oscillator,

the part starts to operate in DCM. The output current is

able to decrease while still allowing a minimum switch off

time for the flyback error amplifier. The typical minimum

internal oscillator frequency with VC equal to 0V is 40kHz.

. A discontinuous conduction

IN

3511f

7

LT3511

查询LT3511供应商

APPLICATIONS INFORMATION

PSUEDO DC THEORY

In the Block Diagram, R

(R4) and RFB (R3) are external

REF

resistors used to program the output voltage. The LT3511

operates similar to traditional current mode switchers,

except in the use of a unique error amplifier, which derives

its feedback information from the flyback pulse.

Operation is as follows: when the output switch, Q1, turns

off, its collector voltage rises above the V

rail. The am-

IN

plitude of this flyback pulse, i.e., the difference between

it and V

V

, is given as:

IN

= (V

FLBK

OUT

+ VF + I

• ESR) • N

SEC

PS

VF = D1 forward voltage

= Transformer secondary current

I

SEC

ESR = Total impedance of secondary circuit

= Transformer effective primary-to-secondary turns

N

PS

ratio

and Q2 convert the flyback voltage into a current. Nearly

R

FB

all of this current flows through R

to form a ground-

REF

referred voltage. The resulting voltage forms the input

to the flyback error amplifier. The flyback error amplifier

samples the voltage information when the secondary side

winding current is zero. The bandgap voltage, 1.20V, acts

as the reference for the flyback error amplifier.

the effect of nonzero secondary output impedance (ESR).

Boundary control mode minimizes the effect of this impedance term.

Temperature Compensation

The first term in the V

equation does not have tem-

OUT

perature dependence, but the diode forward drop has a

significant negative temperature coefficient. A positive

temperature coefficient current source connects to the

pin to compensate. A resistor to ground from the

R

REF

pin sets the compensation current.

T

C

The following equation explains the cancellation of the

temperature coefficient:

dV

dT

R

TC

R

F

= −

=

−R

N

R

FB

TC

FB

PS

1

dV

•

N

PS

1

•

dV

/ dT

F

TC

•

or,

dT

dV

•

dT

TC

R

FB

≈

N

PS

(dVF/dT) = Diode’s forward voltage temperature coefficient

/dT) = 2mV

(dV

TC

= 0.55V

V

TC

Experimentally verify the resulting value of R

and adjust as

TC

necessary to achieve optimal regulation over temperature.

The relatively high gain in the overall loop will then cause

the voltage at R

reference voltage V

and VBG approximately equals:

V

FLBK

V

FL BK

R

FB

=

to be nearly equal to the bandgap

REF

. The resulting relationship between

BG

V

BG

or V

R

RE F

FL BK

= V

BG

R

FB

R

RE F

VBG = Internal bandgap reference

Combination of the preceding expression with earlier

derivation of V

V

= V

OU T

The expression defines V

results in the following equation:

FLBK

1

N

PS

in terms of the internal ref-

OUT

− V

− I

F

BG

R

FB

R

RE F

SE C

(ESR)

erence, programming resistors, transformer turns ratio

and diode forward voltage drop. Additionally, it includes

8

The addition of a temperature coefficient current modifies

the expression of output voltage as follows:

FB

PS

1

− V

F

N

PS

– I

SE C

(ESR)

V

= V

OU T

BG

V

−

R

TC

TC

R

FB

R

RE F

R

•

N

Output Power

A flyback converter has a complicated relationship between the input and output current compared to a buck

or a boost. A boost has a relatively constant maximum

input current regardless of input voltage and a buck has a

relatively constant maximum output current regardless of

input voltage. This is due to the continuous nonswitching

behavior of the two currents. A flyback converter has both

discontinuous input and output currents which makes it

3511f

( )

查询LT3511供应商

APPLICATIONS INFORMATION

LT3511

similar to a nonisolated buck-boost. The duty cycle will

affect the input and output currents, making it hard to

predict output power. In addition, the winding ratio can

be changed to multiply the output current at the expense

of a higher switch voltage.

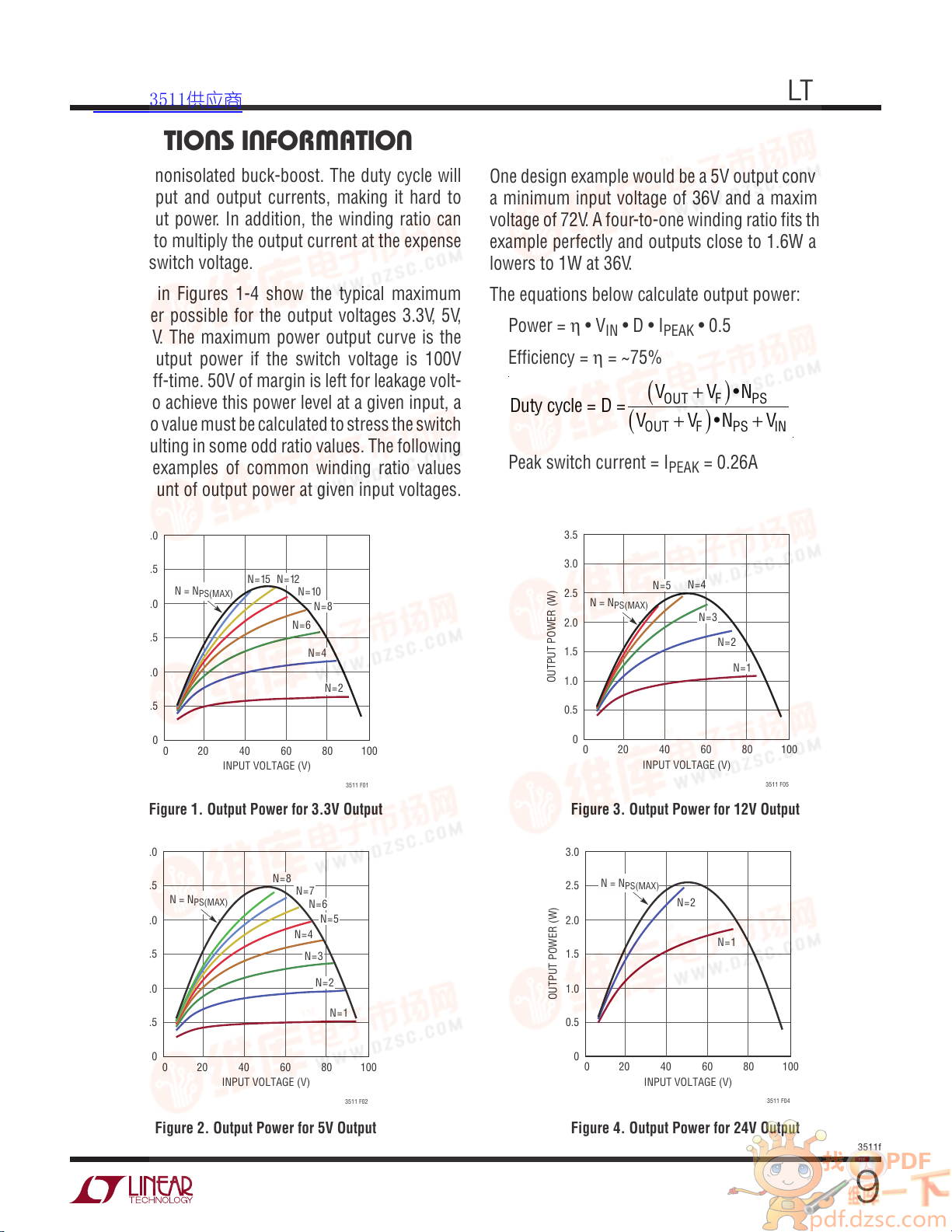

The graphs in Figures 1-4 show the typical maximum

output power possible for the output voltages 3.3V, 5V,

12V and 24V. The maximum power output curve is the

calculated output power if the switch voltage is 100V

during the off-time. 50V of margin is left for leakage volt-

age spike. To achieve this power level at a given input, a

winding ratio value must be calculated to stress the switch

to 100V, resulting in some odd ratio values. The following

curves are examples of common winding ratio values

and the amount of output power at given input voltages.

3.0

2.5

N = N

2.0

1.5

1.0

OUTPUT POWER (W)

0.5

PS(MAX)

N = 15

N = 12

N = 10

N = 8

N = 6

N = 4

N = 2

One design example would be a 5V output converter with

a minimum input voltage of 36V and a maximum input

voltage of 72V. A four-to-one winding ratio fits this design

example perfectly and outputs close to 1.6W at 72V but

lowers to 1W at 36V.

The equations below calculate output power:

Power = η • VIN • D • I

PEAK

• 0.5

Efficiency = η = ~75%

+ V

V

Duty cycle = D =

OUT

V

( )

OUT

Peak switch current = I

3.5

3.0

2.5

N = N

2.0

1.5

OUTPUT POWER (W)

1.0

0.5

N = 5

PS(MAX)

+ V

PEAK

F

• NPS+ V

F

= 0.26A

N = 4

N = 3

N = 2

• N

N = 1

PS

IN

0

0

20 40 60 80

INPUT VOLTAGE (V)

3511 F01

Figure 1. Output Power for 3.3V Output

3.0

2.5

N = N

PS(MAX)

2.0

1.5

1.0

OUTPUT POWER (W)

0.5

0

0

20 40 60 80

INPUT VOLTAGE (V)

N = 8

N = 7

N = 6

N = 5

N = 4

N = 3

N = 2

N = 1

3511 F02

Figure 2. Output Power for 5V Output

100

100

0

20 40 60 80

0

INPUT VOLTAGE (V)

3511 F05

Figure 3. Output Power for 12V Output

3.0

N = N

2.5

2.0

1.5

1.0

OUTPUT POWER (W)

0.5

0

PS(MAX)

0

20 40 60 80

INPUT VOLTAGE (V)

N = 2

N = 1

3511 F04

Figure 4. Output Power for 24V Output

100

100

3511f

9

LT3511

查询LT3511供应商

APPLICATIONS INFORMATION

TRANSFORMER DESIGN CONSIDERATIONS

Successful application of the LT3511 relies on proper

transformer specification and design. Carefully consider

the following information in addition to the traditional

Linear Technology has worked with several leading magnetic component manufacturers to produce pre-designed

flyback transformers for use with the LT3511. Table 1

shows the details of these transformers.

guidelines associated with high frequency isolated power

supply transformer design.

Table 1. Predesigned Transformers

TRANSFORMER

PART NUMBER L

750311558 300 1.5 4:1:1 1500 500 Würth Elektronik 48V to 5V, 0.3A

750311019 400 5 6:1:2 1500 750 Würth Elektronik 24V to 5V, 0.26A

750311659 300 2 1:1:0.2 1500 560 Würth Elektronik 48V to 24V, 0.07A

750311660 350 3 2:1:0.33 1500 520 Würth Elektronik 48V to 15V, 0.13A

750311838 350 3 2:1:1 1500 520 Würth Elektronik 48V to ±15V, 0.055A

750311963 200 0.4 1:5:5 1500 650 Würth Elektronik 12V to ±70V, 0.005A

750311966 120 0.45 1:5:0.5 1500 900 Würth Elektronik 12V to +120V and

10396-T024 300 2.0 4:1:1 1500 500 Sumida 48V to 5V, 0.3A

10396-T026 300 2.5 6:1:2 1500 500 Sumida 24V to 5V, 0.26A

01355-T057 250 2.0 1:1:0.2 1500 500 Sumida 48V to 24V, 0.07A

10396-T022 300 2.0 2:1:0.33 1500 500 Sumida 48V to 15V, 0.13A

10396-T028 300 2.5 2:1:1 1500 500 Sumida 48V to ±15V, 0.055A

(µH) LEAKAGE (µH) NP:NS:N

PRI

B

ISOLATION (V)

SATURATION

CURRENT (mA) VENDOR

TARGET

APPLICATIONS

24V to 5V, 0.2A

12V to 5V, 0.15A

48V to 3.3V, 0.33A

24V to 3.3V, 0.28A

12V to 3.3V, 0.18A

12V to 5V, 0.17A

48V to 3.3V, 0.43A

24V to 3.3V, 0.35A

12V to 3.3V, 0.21A

48V to 12V, 0.14A

24V to 15V, 0.1A

12V to 15V, 0.058A

48V to ±12V, 0.07A

24V to ±15V, 0.045A

12V to ±100V, 0.004A

12V to ±150V, 0.003A

–12V, 0.005A

24V to 5V, 0.2A

12V to 5V, 0.15A

48V to 3.3V, 0.33A

24V to 3.3V, 0.28A

12V to 3.3V, 0.18A

12V to 5V, 0.17A

48V to 3.3V, 0.43A

24V to 3.3V, 0.35A

12V to 3.3V, 0.21A

48V to 12V, 0.14A

24V to 15V, 0.1A

12V to 15V, 0.058A

48V to ±12V, 0.07A

24V to ±15V, 0.045A

3511f

10

150V – V

– V

( )

查询LT3511供应商

APPLICATIONS INFORMATION

LT3511

Turns Ratio

Note that when using an R

FB/RREF

resistor ratio to set

output voltage, the user has relative freedom in selecting

a transformer turns ratio to suit a given application. In

contrast, the use of simple ratios of small integers, e.g.,

1:1, 2:1, 3:2, provides more freedom in setting total turns

and mutual inductance.

Typically, choose the transformer turns to maximize avail-

able output power. For low output voltages (3.3V or 5V), a

N:1 turns ratio can be used with multiple primary windings

relative to the secondary to maximize the transformer’s

current gain (and output power). However, remember that

the SW pin sees a voltage that is equal to the maximum

input supply voltage plus the output voltage multiplied by

the turns ratio. In addition, leakage inductance will cause

a voltage spike (V

LEAKAGE

) on top of this reflected voltage.

This total quantity needs to remain below the absolute

maximum rating of the SW pin to prevent breakdown of

the internal power switch. Together these conditions place

an upper limit on the turns ratio, N, for a given application.

Choose a turns ratio low enough to ensure:

N <

IN(MAX )

V

OU T

+ V

LEAK AGE

F

For larger N:1 values, a transformer with a larger physical

size is needed to deliver additional current and provide a

large enough inductance value to ensure that the off-time

is long enough to accurately measure the output voltage.

For larger N:1 values, choose a transformer with a larger

physical size to deliver additional current. In addition,

choose a large enough inductance value to ensure that

the off-time is long enough to measure the output voltage.

For lower output power levels, choose a 1:1 or 1:N

transformer for the absolute smallest transformer size. A

1:N transformer will minimize the magnetizing inductance

(and minimize size), but will also limit the available output

power. A higher 1:N turns ratio makes it possible to have

very high output voltages without exceeding the breakdown

voltage of the internal power switch.

The turns ratio is an important element in the isolated

feedback scheme. Make sure the transformer manufacturer

guarantees turns ratio accuracy within ±1%.

Saturation Current

The current in the transformer windings should not exceed its rated saturation current. Energy injected once the

core is saturated will not be transferred to the secondary

and will instead be dissipated in the core. Information on

saturation current should be provided by the transformer

manufacturers. Table 1 lists the saturation current of the

transformers designed for use with the LT3511.

Primary Inductance Requirements

The LT3511 obtains output voltage information from the

reflected output voltage on the switch pin. The conduction

of secondary winding current reflects the output voltage

on the primary. The sampling circuitry needs a minimum

of 400ns to settle and sample the reflected output voltage.

In order to ensure proper sampling, the secondary winding

needs to conduct current for a minimum of 400ns. The

following equation gives the minimum value for primaryside magnetizing inductance:

L

PRI

t

OFF(MIN)

I

PEAK(MIN)

t

OFF(MIN)

≥

= 400ns

= 55mA

• NPS• V

I

PEAK(MIN)

OUT

+ V

F

Leakage Inductance and Clamp Circuits

Transformer leakage inductance (on either the primary or

secondary) causes a voltage spike to appear at the primary

after the output switch turns off. This spike is increasingly

prominent at higher load currents where more stored energy must be dissipated. When designing an application,

adequate margin should be kept for the effect of leakage

voltage spikes. In most cases the reflected output voltage

on the primary plus V

should be kept below 100V. This

IN

leaves at least 50V of margin for the leakage spike across

line and load conditions. A larger voltage margin will be

needed for poorly wound transformers or for excessive

leakage inductance. Figure 5 illustrates this point. Minimize

transformer leakage inductance.

A clamp circuit is recommended for most applications.

3511f

11

LT3511

查询LT3511供应商

APPLICATIONS INFORMATION

V

SW

<150V

V

LEAKAGE

<100V

t

> 400ns

OFF

t

< 150ns

SP

without Clamp

Figure 5. Maximum Voltages for SW Pin Flyback Waveform

TIME

Two circuits that can protect the internal power switch

include the RCD (resistor-capacitor-diode) clamp and the

DZ (diode-Zener) clamp. The clamp circuits dissipate the

stored energy in the leakage inductance. The DZ clamp

is the recommended clamp for the LT3511. Simplicity of

design, high clamp voltages, and low power levels make the

DZ clamp the preferred solution. Additionally, a DZ clamp

ensures well defined and consistent clamping voltages.

Figure 5 shows the clamp effect on the switch waveform

and Figure 6 shows the connection of the DZ clamp.

Proper care must be taken when choosing both the diode

and the Zener diode. Schottky diodes are typically the best

choice, but some PN diodes can be used if they turn on

fast enough to limit the leakage inductance spike. Choose

a diode that has a reverse-voltage rating higher than the

maximum input voltage. The Zener diode breakdown volt-

age should be chosen to balance power loss and switch

voltage protection. The best compromise is to choose the

largest voltage breakdown. Use the following equation to

make the proper choice:

V

ZENER(MAX)

≤ 150V – V

IN(MAX)

For an application with a maximum input voltage of 72V,

choose a 68V V

ZENER

which has V

ZENER(MAX)

at 72V, which

will be below the 78V maximum.

The power loss in the clamp will determine the power rat-

ing of the Zener diode. Power loss in the clamp is highest

at maximum load and minimum input voltage. The switch

V

SW

<150V

<140V

<100V

t

> 400ns

OFF

TIME

t

SP

< 150ns

with Clamp

Z

D

Figure 6. DZ Clamp

3511 F05

L

S

3511 F06

current is highest at this point along with the energy stored

in the leakage inductance. A 0.5W Zener will satisfy most

applications when the highest V

a low value for V

will cause excessive power loss as

ZENER

is chosen. Choosing

ZENER

shown in the following equations:

DZ Power Loss=

1

• L•I

2

1+

PK( VIN(MIN))

N

PS

V

ZENER–NPS

2

• fSW•

• V

+ V

( )

OUT

• V

( )

OUT

+ V

F

F

L = Leakage Inductance

I

PK( VIN(MIN))

fSW=

tON+ t

V

OFF

OUT•IOUT

η • V

IN(MIN)

=

L

PRI•IPK( VIN(MIN))

=

1

• D

V

IN(MIN)

• 2

VIN(MIN)

1

L

PRI•IPK( VIN(MIN))

+

NPS• V

( )

OUT

+ V

F

12

3511f

查询LT3511供应商

APPLICATIONS INFORMATION

LT3511

Table 2 and 3 show some recommended diodes and Zener

diodes.

Table 2. Recommended Zener Diodes

V

ZENER

PART

MMSZ5266BT1G 68 0.5 SOD-123 On Semi

MMSZ5270BT1G 91 0.5 SOD-123

CMHZ5266B 68 0.5 SOD-123 Central

CMHZ5267B 75 0.5 SOD-123

BZX84J-68 68 0.5 SOD323F NXP

BZX100A 100 0.5 SOD323F

Table 3. Recommended Diodes

PART I (A)

BAV19W 0.625 100 SOD-123 Diodes Inc.

BAV20W 0.625 150 SOD-123

(V)

POWER

(W) CASE VENDOR

Semiconductor

V

REVERSE

(V) CASE VENDOR

Leakage Inductance Blanking

When the power switch turns off, the flyback pulse ap-

pears. However, a finite time passes before the trans-

former primary-side voltage waveform approximately

represents the output voltage. Rise time on the SW node

and transformer leakage inductance cause the delay. The

leakage inductance also causes a very fast voltage spike

on the primary side of the transformer. The amplitude of

the leakage spike is largest when power switch current is

highest. Introduction of an internal fixed delay between

switch turn-off and the start of sampling provides im-

munity to the phenomena discussed above. The LT3511

sets internal blanking to 150ns. In certain cases leakage

inductance spikes last longer than the internal blanking,

but will not significantly affect output regulation.

Secondary Leakage Inductance

In addition to primary leakage inductance, secondary leak-

age inductance exhibits an important effect on application

design. Secondary leakage inductance forms an inductive

divider on the transformer secondary. The inductive divider

effectively reduces the size of the primary-referred flyback

pulse. The smaller flyback pulse results in a higher regulated

output voltage. The inductive divider effect of secondary

leakage inductance is load independent. R

FB/RREF

ratio

adjustments can accommodate this effect to the extent

secondary leakage inductance is a constant percentage

of mutual inductance (over manufacturing variations).

Winding Resistance Effects

Resistance in either the primary or secondary will reduce

overall efficiency (P

OUT/PIN

). Good output voltage regulation will be maintained independent of winding resistance

due to the boundary mode operation of the LT3511.

Bifilar Winding

A bifilar, or similar winding technique, is a good way to

minimize troublesome leakage inductances. However, remember that this will also increase primary-to-secondary

capacitance and limit the primary-to-secondary breakdown

voltage, so bifilar winding is not always practical. The

Linear Technology applications group is available and

extremely qualified to assist in the selection and/or design

of the transformer.

APPLICATION DESIGN CONSIDERATIONS

Iterative Design Process

The LT3511 uses a unique sampling scheme to regulate

the isolated output voltage. The use of this isolated scheme

requires a simple iterative process to choose feedback

resistors and temperature compensation. Feedback resistor values and temperature compensation resistance

is heavily dependent on the application, transformer and

output diode chosen.

Once resistor values are fixed after iteration, the values

will produce consistent output voltages with the chosen

transformer and output diode. Remember, the turns ratio

of the transformer must be guaranteed within ±1%. The

transformer vendors mentioned in this data sheet can

build transformers to this specification.

3511f

13

LT3511

( )

R2

查询LT3511供应商

APPLICATIONS INFORMATION

Selecting RFB and R

Resistor Values

REF

The following section provides an equation for setting

R

FB

and R

values. The equation should only serve

REF

as a guide. Follow the procedure outlined in the Design

, R

Procedure to set accurate values for R

FB

and RTC

REF

using the iterative design procedure.

Rearrangement of the expression for V

in the Tempera-

OUT

ture Compensation section, developed in the Operations

section, yields the following expression for R

• N

PSVOU T

+ V

+ V

F

TC

V

BG

RFB=

R

RE F

:

FB

where:

V

= Output voltage

OUT

VF = Switching diode forward voltage

NPS = Effective primary-to-secondary turns ratio

VTC = 0.55V

This equation assumes:

R

RTC=

FB

N

PS

The equation assumes the temperature coefficients of

the diode and V

are equal, which is a good first order

TC

approximation.

Strictly speaking, the above equation defines R

absolute value, but as a ratio of R

is, what is the proper value for R

should be approximately 10k. The LT3511 is trimmed

R

REF

and specified using this value of R

varies considerably from 10k, additional errors will

R

REF

result. However, a variation in R

. So the next question

REF

? The answer is that

REF

. If the impedance of

REF

of several percent is

REF

not as an

FB

acceptable. This yields a bit of freedom in selecting stan-

dard 1% resistor values to yield nominal R

FB/RREF

ratios.

Undervoltage Lockout (UVLO)

A resistive divider from V

to the EN/UVLO pin imple-

IN

ments undervoltage lockout (UVLO). Figure 7 shows this

configuration. The EN/UVLO pin threshold is set at 1.21V.

V

IN

R1

EN/UVLO

LT3511

GND

Figure 7. Undervoltage Lockout (UVLO)

R2

RUN/STOP

CONTROL

(OPTIONAL)

3511 F07

In addition, the EN/UVLO pin draws 2.6µA when the voltage at the pin is below 1.21V. This current provides user

programmable hysteresis based on the value of R1. The

effective UVLO thresholds are:

V

IN(UVLO,RISING)

V

IN(UVLO,FA L L ING)

1.2V • (R1+ R2)

=

R2

1.2V • (R1+ R2)

=

+ 2.6µA • R1

Figure 7 also shows the implementation of external shutdown control while still using the UVLO function. The

NMOS grounds the EN/UVLO pin when turned on, and

puts the LT3511 in shutdown with quiescent current draw

of less than 1µA.

Minimum Load Requirement

The LT3511 recovers output voltage information using the

flyback pulse. The flyback pulse occurs once the switch

turns off and the secondary winding conducts current. In

order to regulate the output voltage, the LT3511 needs to

sample the flyback pulse. The LT3511 delivers a minimum

amount of energy even during light load conditions to

ensure accurate output voltage information. The minimum

delivery of energy creates a minimum load requirement

of 10mA to 15mA depending on the specific application.

Verify minimum load requirements for each application.

A Zener diode with a Zener breakdown of 20% higher

than the output voltage can serve as a minimum load if

pre-loading is not acceptable. For a 5V output, use a 6V

Zener with cathode connected to the output.

3511f

14

查询LT3511供应商

APPLICATIONS INFORMATION

LT3511

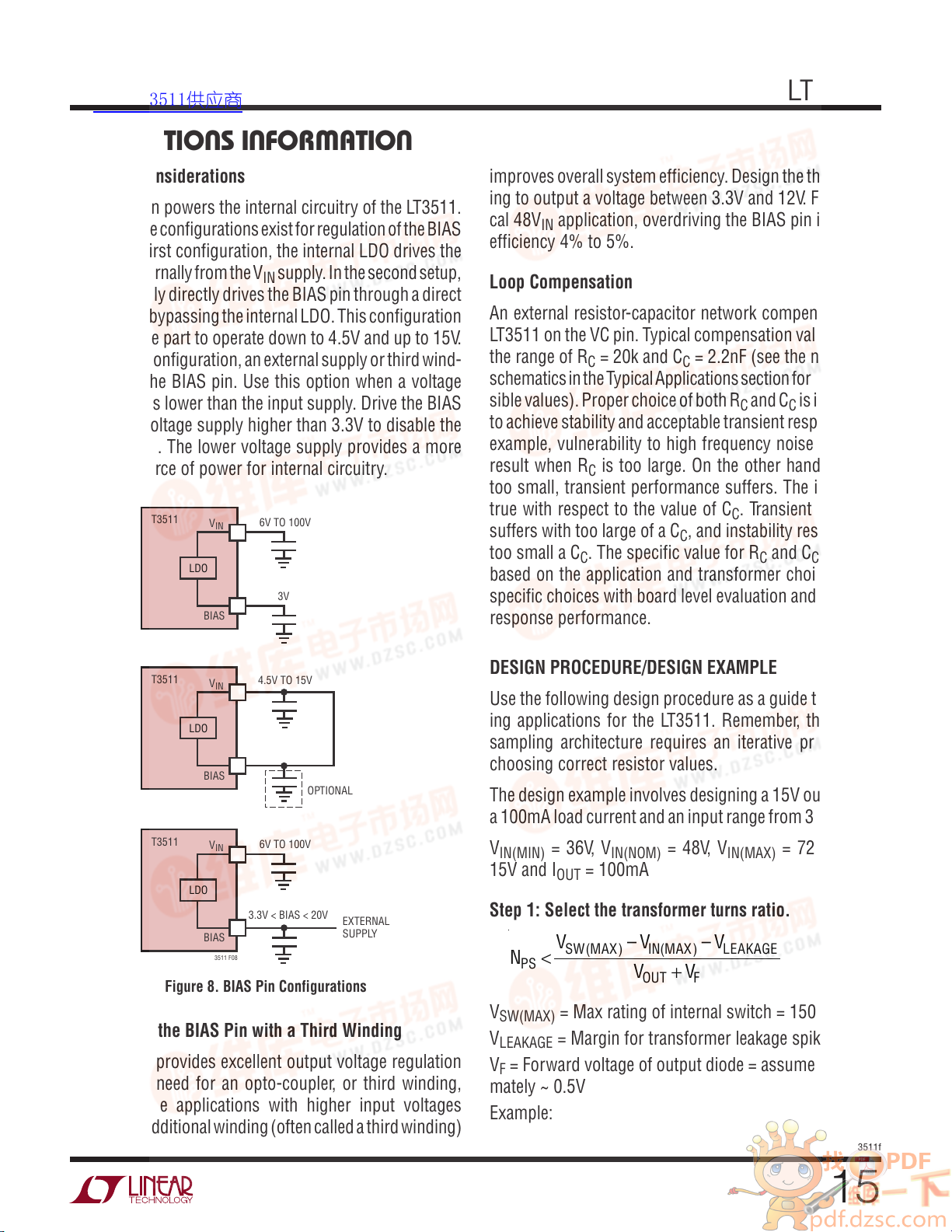

BIAS Pin Considerations

The BIAS pin powers the internal circuitry of the LT3511.

Three unique configurations exist for regulation of the BIAS

pin. In the first configuration, the internal LDO drives the

BIAS pin internally from the V

supply directly drives the BIAS pin through a direct

the V

IN

supply. In the second setup,

IN

connection bypassing the internal LDO. This configuration

will allow the part to operate down to 4.5V and up to 15V.

In the third configuration, an external supply or third wind-

ing drives the BIAS pin. Use this option when a voltage

supply exists lower than the input supply. Drive the BIAS

pin with a voltage supply higher than 3.3V to disable the

internal LDO. The lower voltage supply provides a more

efficient source of power for internal circuitry.

LT3511

V

LDO

BIAS

6V TO 100V

IN

3V

improves overall system efficiency. Design the third winding to output a voltage between 3.3V and 12V. For a typical 48V

application, overdriving the BIAS pin improves

IN

efficiency 4% to 5%.

Loop Compensation

An external resistor-capacitor network compensates the

LT3511 on the VC pin. Typical compensation values are in

the range of R

= 20k and CC = 2.2nF (see the numerous

C

schematics in the Typical Applications section for other possible values). Proper choice of both R

and CC is important

C

to achieve stability and acceptable transient response. For

example, vulnerability to high frequency noise and jitter

result when R

is too large. On the other hand, if RC is

C

too small, transient performance suffers. The inverse is

true with respect to the value of C

suffers with too large of a C

too small a C

. The specific value for RC and CC will vary

C

, and instability results from

C

. Transient response

C

based on the application and transformer choice. Verify

specific choices with board level evaluation and transient

response performance.

LT3511

LT3511

V

LDO

BIAS

V

LDO

BIAS

Figure 8. BIAS Pin Configurations

IN

IN

3511 F08

4.5V TO 15V

OPTIONAL

6V TO 100V

3.3V < BIAS < 20V

EXTERNAL

SUPPLY

Overdriving the BIAS Pin with a Third Winding

The LT3511 provides excellent output voltage regulation

without the need for an opto-coupler, or third winding,

but for some applications with higher input voltages

(>20V), an additional winding (often called a third winding)

DESIGN PROCEDURE/DESIGN EXAMPLE

Use the following design procedure as a guide to designing applications for the LT3511. Remember, the unique

sampling architecture requires an iterative process for

choosing correct resistor values.

The design example involves designing a 15V output with

a 100mA load current and an input range from 36V to 72V.

V

IN(MIN)

= 36V, V

15V and I

= 100mA

OUT

IN(NOM)

= 48V, V

IN(MAX)

= 72V, V

OUT

=

Step 1: Select the transformer turns ratio.

V

NPS<

SW(MAX)

V

SW(MAX)

V

LEAKAGE

= Forward voltage of output diode = assume approxi-

V

F

= Max rating of internal switch = 150V

= Margin for transformer leakage spike = 40V

– V

V

OUT

IN(MAX)

+ V

– V

F

LEAKAGE

mately ~ 0.5V

Example:

3511f

15

LT3511

( )

( )

( )

( )

查询LT3511供应商

APPLICATIONS INFORMATION

150V –72V – 40V

NPS<

15V + 0.5V

NPS< 2.45

= 2

N

PS

The choice of turns ratio is critical in determining output

power as shown earlier in the Output Power section. At

this point, a third winding can be added to the transformer

to drive the BIAS pin of the LT3511 for higher efficiencies.

Choose a turns ratio that sets the third winding voltage

to regulate between 3.3V and 6V for maximum efficiency.

Choose a third winding ratio to drive BIAS winding with

5V. (Optional)

Example:

N

THIRD

N

V

THIRD

=

S

V

OUT

=

5V

15V

= 0.33

The turns ratio of the transformer chosen is as follows

N

PRIMARY

: N

SECONDARY

: N

THIRD

= 2:1:0.33.

Step 2: Calculate maximum power output at minimum

VIN.

P

OUT(VIN(MIN))

I

PEAK

D=

( )

• 0.5

V

OUT

V

+ V

OUT

= η • V

+ V

F

• NPS+ V

F

IN(MIN)

• N

• IIN = η • V

PS

IN(MIN)

IN(MIN)

• D •

η = Efficiency = ~75%

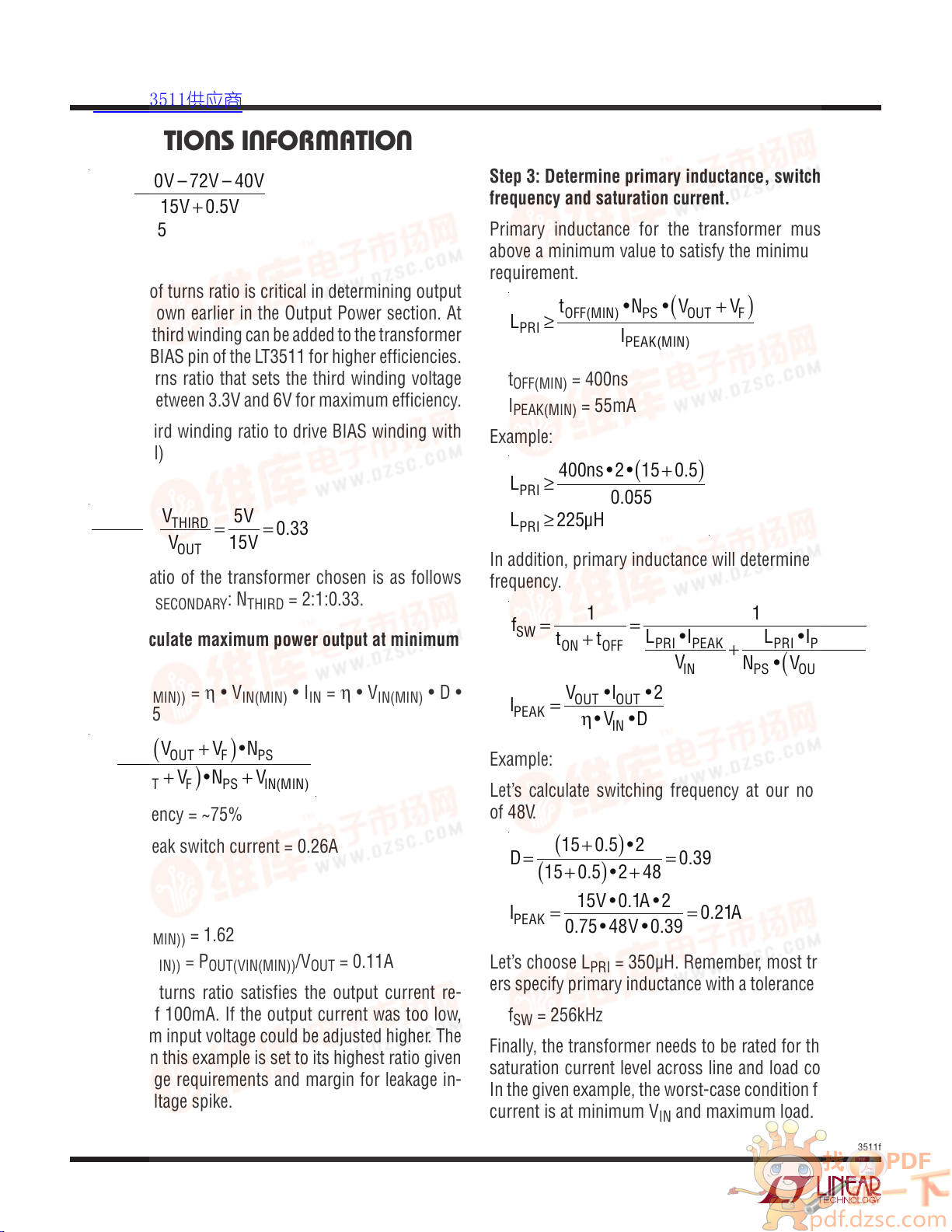

Step 3: Determine primary inductance, switching

frequency and saturation current.

Primary inductance for the transformer must be set

above a minimum value to satisfy the minimum off time

requirement.

L

PRI

t

OFF(MIN)

I

PEAK(MIN)

t

OFF(MIN)

≥

= 400ns

= 55mA

• NPS• V

I

PEAK(MIN)

OUT

+ V

F

Example:

400ns• 2 • 15+ 0.5

L

≥

PRI

L

≥ 225µH

PRI

0.055

In addition, primary inductance will determine switching

frequency.

fSW=

I

PEAK

tON+ t

V

OUT•IOUT

=

1

η • V

OFF

IN

=

L

PRI•IPEAK

• 2

• D

V

IN

1

+

NPS• V

L

PRI•IPEAK

( )

OUT

+ V

F

Example:

Let’s calculate switching frequency at our nominal V

IN

of 48V.

I

= Peak switch current = 0.26A

PEAK

Example:

D = 0.46

P

OUT(VIN(MIN))

I

OUT(VIN(MIN))

= 1.62

= P

OUT(VIN(MIN))/VOUT

= 0.11A

The chosen turns ratio satisfies the output current re-

quirement of 100mA. If the output current was too low,

the minimum input voltage could be adjusted higher. The

turns ratio in this example is set to its highest ratio given

switch voltage requirements and margin for leakage in-

ductance voltage spike.

D=

15+ 0.5

15+ 0.5

( )

I

PEAK

15V • 0.1A • 2

=

0.75 • 48V • 0.39

Let’s choose L

ers specify primary inductance with a tolerance of ±20%.

fSW = 256kHz

Finally, the transformer needs to be rated for the correct

saturation current level across line and load conditions.

In the given example, the worst-case condition for switch

current is at minimum V

• 2

= 0.39

• 2+ 48

= 0.21A

= 350µH. Remember, most transform-

PRI

and maximum load.

IN

3511f

16

0.75 • 36V • 0.46

2

查询LT3511供应商

APPLICATIONS INFORMATION

LT3511

I

PEAK

I

PEAK

V

OUT•IOUT

=

η • V

15V • 0.1A • 2

=

• 2

• D

IN

= 0.24A

Ensure that the saturation current covers steady-state

operation, start-up and transient conditions. To satisfy

these conditions, choose a saturation current 50% or more

higher than the steady-state calculation. In this example, a

saturation current between 400mA and 500mA is chosen.

Table 1 presents a list of pre-designed flyback transform-

ers. For this application, the Würth 750311660 transformer

will be used.

Step 4: Choose the correct output diode.

The two main criteria for choosing the output diode include

forward current rating and reverse voltage rating. The

maximum load requirement is a good first-order guess

at the average current requirement for the output diode.

A better metric is RMS current.

1–D

I

RMS

= I

PEAK(VIN(MIN))

• NPS•

VIN(MIN)

3

Example:

I

= 0.24 • 2 •

RMS

1– 0.46

3

= 0.2A

Next calculate reverse voltage requirement using maxi-

mum V

IN

V

REVERSE

:

V

= V

OUT

+

IN(MAX)

N

PS

Step 5: Choose an output capacitor.

The output capacitor choice should minimize output voltage

ripple and balance the trade-off between size and cost for

a larger capacitor. Use the equation below at nominal V

• D

I

∆V

OUT

OUT

• f

SW

C =

IN

:

Example:

Design for ripple levels below 50mV.

0.1A • 0.39

C =

0.05V • 256kHz

= 3.1µF

A 10µF, 25V output capacitor is chosen. Remember ceramic capacitors lose capacitance with applied voltage.

The capacitance can drop to 40% of quoted capacitance

at the max voltage rating.

Step 6: Design clamp circuit.

The clamp circuit protects the switch from leakage inductance spike. A DZ clamp is the preferred clamp circuit. The

Zener and the diode need to be chosen.

The maximum Zener value is set according to the maximum V

V

:

IN

ZENER(MAX)

≤ 150V – V

IN(MAX)

Example:

V

ZENER(MAX)

V

ZENER(MAX)

≤ 150V – 72V

≤ 78V

In addition, power loss in the clamp circuit is inversely

related to the clamp voltage as shown previously. Higher

clamp voltages lead to lower power loss.

Example:

A 68V Zener with a maximum of 72V will provide optimal

protection and minimize power loss. Half-watt Zeners will

72V

= 51V

V

REVERSE

= 15V +

A 0.5A, 60V diode from Diodes Inc. (SBR0560S1) will

be used.

satisfy most clamp applications involving the LT3511.

Power loss can be calculated using the equations presented

in the Leakage Inductance and Clamp Circuit section.

The Zener chosen is a 68V 0.5W Zener from On Semiconductor (MMSZ5266BT1G).

3511f

17

LT3511

( )

( )

查询LT3511供应商

APPLICATIONS INFORMATION

Choose a diode that is fast and has sufficient reverse

voltage breakdown:

V

REVERSE

> V

IN(MAX)

Example:

V

REVERSE

> 72V

The diode needs to handle the peak switch current of the

switch which was determined to be 0.24A. A 100V, 0.6A

diode from Diodes Inc. (BAV19W) is chosen.

Step 7: Compensation.

Compensation will be optimized towards the end of the

design procedure. Connect a resistor and capacitor from

the VC node to ground. Use a 20k resistor and a 2.2nF

capacitor.

Step 8: Select R

and RTC Resistors.

FB

Use the following equations to choose starting values for

and RTC. Set R

R

FB

RFB=

V

OUT

to 10k.

REF

+ VF+ 0.55V

• NPS• R

REF

1.2V

R

= 10k

REF

R

FB

=

R

TC

N

PS

Example:

RFB=

15+ 0.5 + 0.55V

• 2• 10k

= 267k

1.2V

267k

=

R

TC

= 133k

2

Step 9: Adjust RFB based on output voltage.

Power up the application with application components

connected and measure the regulated output voltage.

Readjust R

R

FB(NEW)

based on the measured output voltage.

FB

V

=

OUT

V

OUT(MEAS)

• R

FB(OLD)

Example:

=

16.8V

15V

• 267k = 237k

R

FB(NEW)

Step 10: Remove RTC and measure output voltage

over temperature.

Measure output voltage in a controlled temperature environment like an oven to determine the output temperature

coefficient. Measure output voltage at a consistent load

current and input voltage, across the temperature range

of operation. This procedure will optimize line and load

regulation over temperature.

Calculate the temperature coefficient of V

∆V

OUT

∆Temp

V

=

OUT(HOT )

T

HOT(°C)

– V

OUT(COLD)

– T

COLD(°C)

OUT

:

Example:

V

measured at 100mA and 48V

OUT

∆V

OUT

∆Temp

15.70V –15.37V

=

125°C– −50°C

( )

IN

= 1.9mV °C

3511f

18

°

( )

查询LT3511供应商

APPLICATIONS INFORMATION

LT3511

Step 11: Calculate new value for RTC.

R

TC(NEW )

=

•

N

PS

∆V

1.85mV

R

FB

∆Temp

C

OUT

Example:

R

TC(NEW )

=

237k

Step 12: Place new value for RTC, measure V

readjust R

R

FB(NEW)

due to RTC change.

FB

=

V

1.85

•

2

1.9

V

OUT

OUT(MEAS)

= 118k

• R

FB(OLD)

OUT

, and

Example:

=

15V

• 237k = 237k

15V

R

FB(NEW)

Step 13: Verify new values of RFB and RTC over

temperature.

Measure output voltage over temperature with R

TC

connected.

Step 14: Optimize compensation.

Now that values for R

and RTC are fixed, optimize the

FB

compensation. Compensation should be optimized for

transient response to load steps on the output. Check

transient response across the load range.

Example:

The optimal compensation for the application is:

RC = 22.1k, CC = 4.7nF

Step 15: Ensure minimum load.

Check minimum load requirement at maximum input

voltage. The minimum load occurs at the point where the

output voltage begins to climb up as the converter delivers

more energy than what is consumed at the output.

Example:

The minimum load at an input voltage of 72V is:

7mA

Step 16: EN/UVLO resistor values.

Determine amount of hysterysis required.

Voltage hysteresis = 2.6µA • R1

Example:

Choose 2V of hysteresis.

2V

R1=

2.6µA

= 768k

Determine UVLO Threshold.

1.2V • R1+R2

V

IN(UVLO,FALLING)

R2=

V

IN(UVLO,FALLING)

=

R2

1.2V • R1

– 1.2V

Set UVLO falling threshold to 30V.

1.2V • 768k

R2=

= 32.4k

30V –1.2V

1.2V • R1+R2

V

IN(UVLO,FALLING)

=

1.2V • 768k + 32.4k

=

( )

R2

( )

32.4k

= 30V

V

IN(UVLO,RISING)

= V

IN(UVLO,FALLING)

+ 2.6µA • R1 = 30V

+ 2.6µA • 768k = 32V

3511f

19

LT3511

C4: MURATA GRM32ER71H475KA88B

查询LT3511供应商

TYPICAL APPLICATIONS

V

IN

36V TO 72V

V

36V TO 72V

C1

R1

µF

1

1M

R2

43.2k

IN

C1

R1

µF

1

1M

R2

43.2k

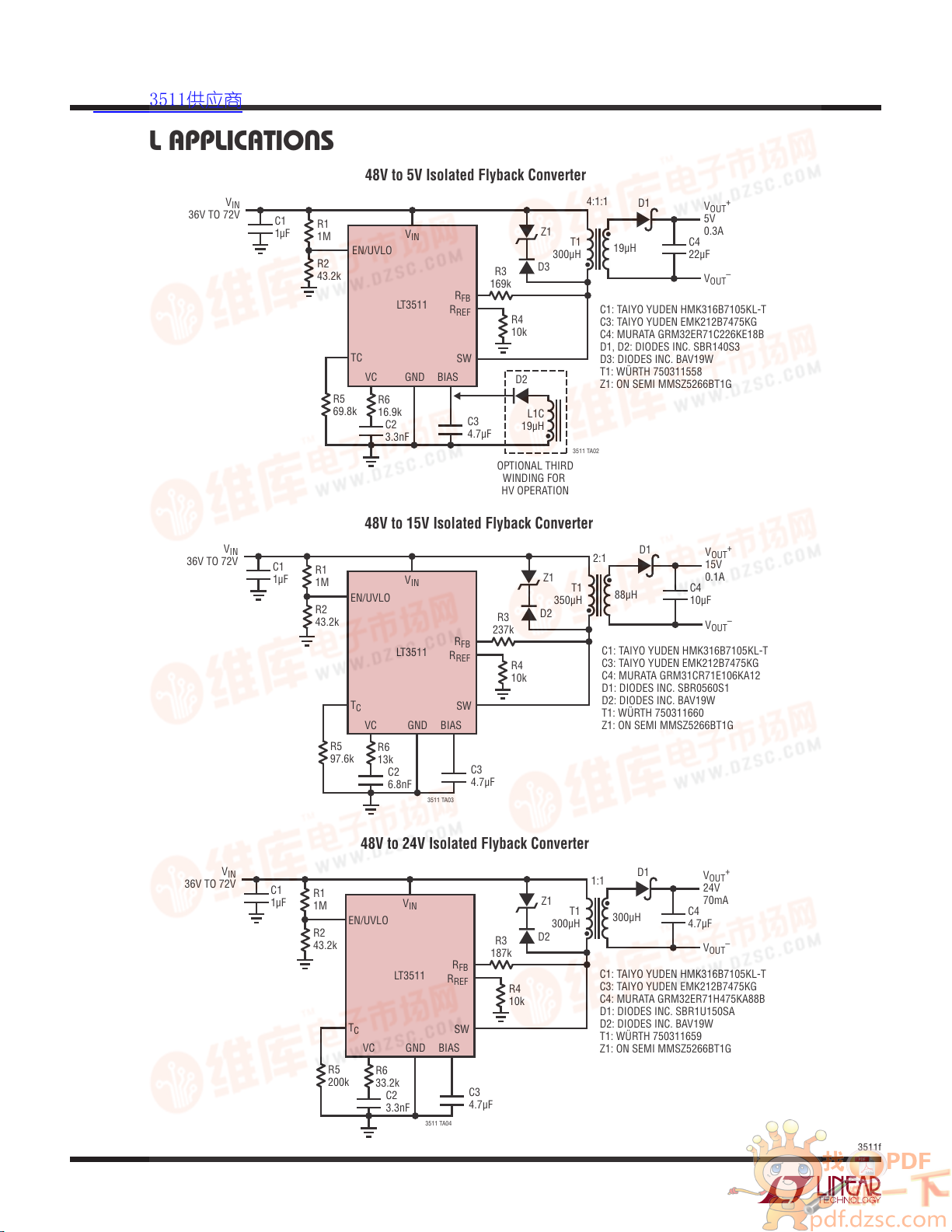

48V to 5V Isolated Flyback Converter

V

EN/UVLO

TC

R5

69.8k

IN

LT3511

VC GND BIAS

R6

16.9k

C2

3.3nF

R3

169k

R

FB

R

REF

SW

C3

4.7µF

OPTIONAL THIRD

WINDING FOR

HV OPERATION

R4

10k

D2

19µH

48V to 15V Isolated Flyback Converter

V

IN

LT3511

VC GND BIAS

R6

13k

C2

6.8nF

R

3511 TA03

R

REF

SW

R3

237k

FB

R4

10k

C3

4.7µF

R5

97.6k

EN/UVLO

T

C

L1C

4:1:1

Z1

T1

µH

300

D3

3511 TA02

Z1

T1

µH

350

D2

D1

19

µH

C1: TAIYO YUDEN HMK316B7105KL-T

C3: TAIYO YUDEN EMK212B7475KG

C4: MURATA GRM32ER71C226KE18B

D1, D2: DIODES INC. SBR140S3

D3: DIODES INC. BAV19W

T1: WÜRTH 750311558

Z1: ON SEMI MMSZ5266BT1G

D1

2:1

88

µH

C1: TAIYO YUDEN HMK316B7105KL-T

C3: TAIYO YUDEN EMK212B7475KG

C4: MURATA GRM31CR71E106KA12

D1: DIODES INC. SBR0560S1

D2: DIODES INC. BAV19W

T1: WÜRTH 750311660

Z1: ON SEMI MMSZ5266BT1G

+

V

OUT

5V

0.3A

C4

22

µF

–

V

OUT

+

V

OUT

15V

0.1A

C4

10

µF

–

V

OUT

20

V

36V TO 72V

48V to 24V Isolated Flyback Converter

C4

4.7

V

OUT

24V

70mA

µF

V

OUT

+

–

3511f

IN

C1

R1

µF

1

1M

EN/UVLO

R2

43.2k

T

C

R5

200k

V

IN

LT3511

VC GND BIAS

R6

33.2k

C2

3.3nF

3511 TA04

187k

R

FB

R

REF

SW

C3

4.7µF

Z1

T1

µH

300

D2

R3

R4

10k

D1

1:1

300

µH

C1: TAIYO YUDEN HMK316B7105KL-T

C3: TAIYO YUDEN EMK212B7475KG

D1: DIODES INC. SBR1U150SA

D2: DIODES INC. BAV19W

T1: WÜRTH 750311659

Z1: ON SEMI MMSZ5266BT1G

查询LT3511供应商

TYPICAL APPLICATIONS

LT3511

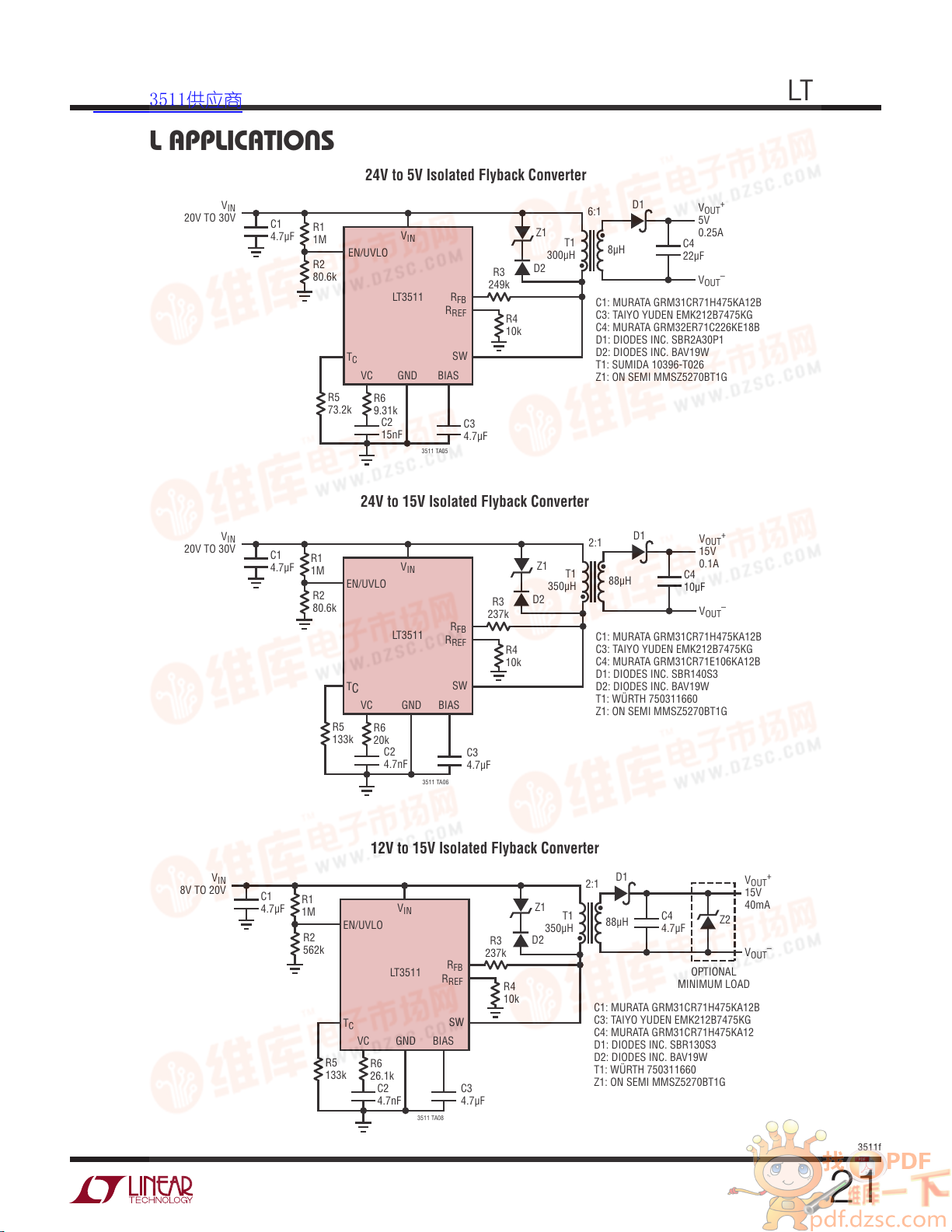

24V to 5V Isolated Flyback Converter

V

20V TO 30V

V

20V TO 30V

IN

C1

4.7

R1

µF

1M

EN/UVLO

R2

80.6k

T

C

R5

73.2k

V

IN

LT3511

VC GND BIAS

R6

9.31k

C2

15nF

R

3511 TA05

249k

R

FB

REF

SW

C3

4.7µF

Z1

T1

µH

300

D2

R3

R4

10k

D1

6:1

8

µH

C1: MURATA GRM31CR71H475KA12B

C3: TAIYO YUDEN EMK212B7475KG

C4: MURATA GRM32ER71C226KE18B

D1: DIODES INC. SBR2A30P1

D2: DIODES INC. BAV19W

T1: SUMIDA 10396-T026

Z1: ON SEMI MMSZ5270BT1G

+

V

OUT

5V

0.25A

C4

µF

22

–

V

OUT

24V to 15V Isolated Flyback Converter

IN

C1

4.7

R1

µF

1M

EN/UVLO

R2

80.6k

T

C

R5

133k

V

IN

LT3511

VC GND BIAS

R6

20k

C2

4.7nF

R

3511 TA06

R

237k

FB

REF

SW

C3

4.7µF

Z1

T1

µH

350

D2

R3

R4

10k

D1

2:1

88

µH

C1: MURATA GRM31CR71H475KA12B

C3: TAIYO YUDEN EMK212B7475KG

C4: MURATA GRM31CR71E106KA12B

D1: DIODES INC. SBR140S3

D2: DIODES INC. BAV19W

T1: WÜRTH 750311660

Z1: ON SEMI MMSZ5270BT1G

+

V

OUT

15V

0.1A

C4

µF

10

–

V

OUT

V

8V TO 20V

12V to 15V Isolated Flyback Converter

IN

C1

4.7

R1

µF

1M

EN/UVLO

R2

562k

T

C

R5

133k

V

IN

LT3511

VC GND BIAS

R6

26.1k

C2

4.7nF

3511 TA08

237k

R

FB

R

REF

SW

C3

4.7µF

Z1

T1

µH

350

D2

R3

R4

10k

D1

2:1

88

C1: MURATA GRM31CR71H475KA12B

C3: TAIYO YUDEN EMK212B7475KG

C4: MURATA GRM31CR71H475KA12

D1: DIODES INC. SBR130S3

D2: DIODES INC. BAV19W

T1: WÜRTH 750311660

Z1: ON SEMI MMSZ5270BT1G

C4

µH

4.7

Z2

µF

OPTIONAL

MINIMUM LOAD

V

OUT

15V

40mA

V

OUT

+

–

3511f

21

LT3511

查询LT3511供应商

TYPICAL APPLICATIONS

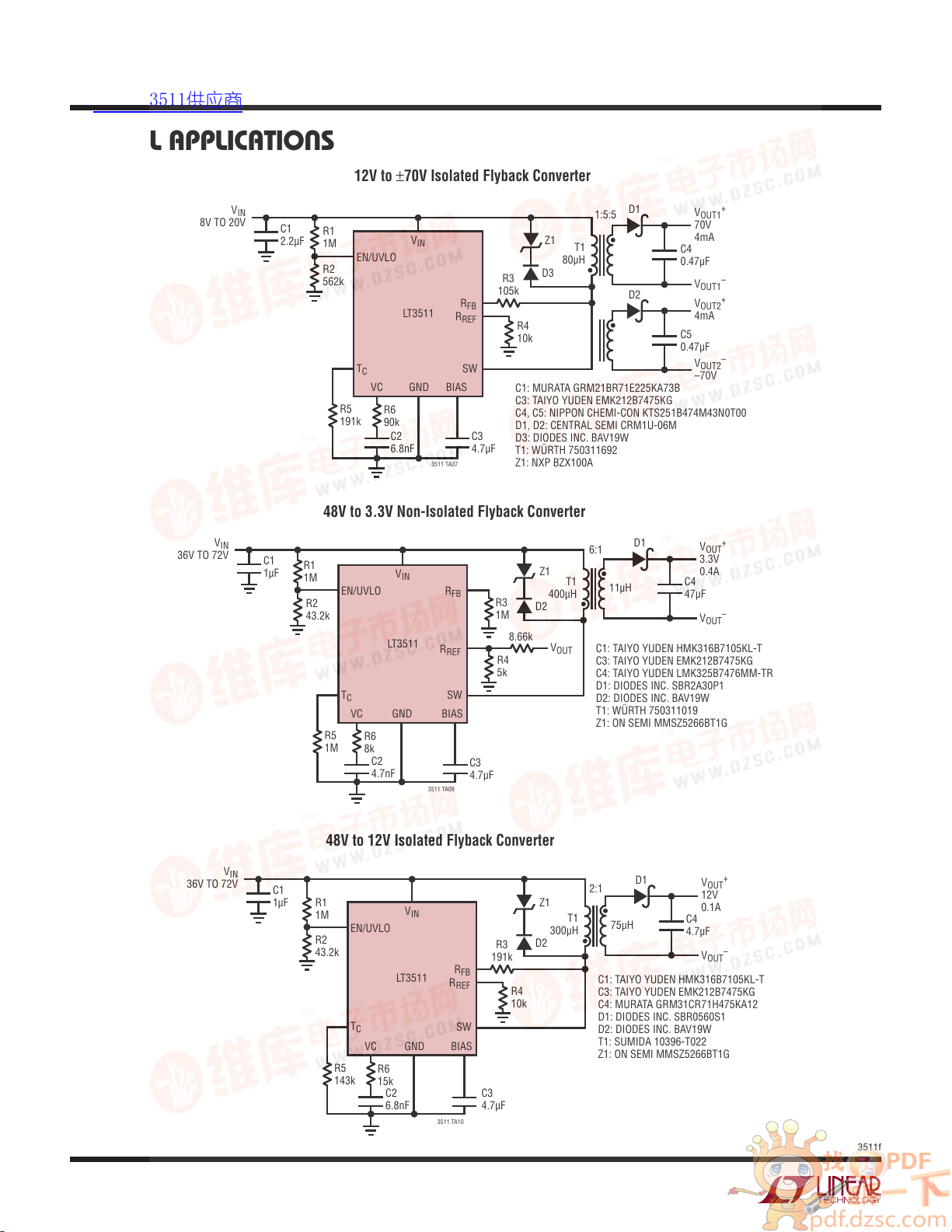

12V to ±70V Isolated Flyback Converter

8V TO 20V

V

36V TO 72V

V

IN

C1

2.2

R1

µF

1M

EN/UVLO

R2

562k

T

C

R5

191k

V

IN

LT3511

VC GND BIAS

R6

90k

C2

6.8nF

R

3511 TA07

R

REF

SW

FB

C3

4.7µF

Z1

T1

µH

80

D3

R3

105k

R4

10k

C1: MURATA GRM21BR71E225KA73B

C3: TAIYO YUDEN EMK212B7475KG

C4, C5: NIPPON CHEMI-CON KTS251B474M43N0T00

D1, D2: CENTRAL SEMI CRM1U-06M

D3: DIODES INC. BAV19W

T1: WÜRTH 750311692

Z1: NXP BZX100A

1:5:5

D1

D2

V

70V

4mA

C4

0.47µF

V

V

4mA

C5

0.47µF

V

–70V

OUT1

OUT1

OUT2

OUT2

+

–

+

–

48V to 3.3V Non-Isolated Flyback Converter

IN

C1

R1

µF

1

1M

EN/UVLO

R2

43.2k

T

C

R5

1M

V

IN

R

LT3511

VC GND BIAS

R6

8k

C2

4.7nF

R

3511 TA09

REF

SW

FB

C3

4.7µF

R3

1M

Z1

T1

µH

400

D2

8.66k

V

R4

5k

OUT

D1

6:1

11

µH

C1: TAIYO YUDEN HMK316B7105KL-T

C3: TAIYO YUDEN EMK212B7475KG

C4: TAIYO YUDEN LMK325B7476MM-TR

D1: DIODES INC. SBR2A30P1

D2: DIODES INC. BAV19W

T1: WÜRTH 750311019

Z1: ON SEMI MMSZ5266BT1G

+

V

OUT

3.3V

0.4A

C4

47

µF

–

V

OUT

22

V

36V TO 72V

48V to 12V Isolated Flyback Converter

IN

C1

µF

1

R1

1M

R2

43.2k

R5

143k

EN/UVLO

T

C

V

IN

LT3511

VC GND BIAS

R6

15k

C2

6.8nF

R

3511 TA10

R

REF

SW

191k

FB

C3

4.7µF

Z1

T1

µH

300

D2

R3

R4

10k

D1

2:1

75

µH

C1: TAIYO YUDEN HMK316B7105KL-T

C3: TAIYO YUDEN EMK212B7475KG

C4: MURATA GRM31CR71H475KA12

D1: DIODES INC. SBR0560S1

D2: DIODES INC. BAV19W

T1: SUMIDA 10396-T022

Z1: ON SEMI MMSZ5266BT1G

C4

4.7

V

12V

0.1A

µF

V

OUT

OUT

+

–

3511f

1.0

查询LT3511供应商

PACKAGE DESCRIPTION

LT3511

MS Package

Varitation: MS16 (12)

16-Lead Plastic MSOP with 4 Pins Removed

(Reference LTC DWG # 05-08-1847 Rev A)

(.0197)

0° – 6° TYP

0.53 ± 0.152

(.021 ± .006)

0.889 ± 0.127

(.035 ± .005)

3.20 – 3.45

(.126 – .136)

0.50

BSC

SEATING

PLANE

4.90 ± 0.152

(.193 ± .006)

(.043)

0.17 –0.27

(.007 – .011)

TYP

1.10

MAX

4.039 ± 0.102

(.159 ± .004)

(NOTE 3)

16 14 12 1110

1 3 5 6 7 8

1.0

(.0394)

BSC

0.50

(.0197)

BSC

(.0394)

BSC

5.23

(.206)

MIN

0.305 ± 0.038

(.0120 ± .0015)

TYP

RECOMMENDED SOLDER PAD LAYOUT

0.254

(.010)

GAUGE PLANE

0.18

(.007)

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

DETAIL “A”

DETAIL “A”

0.280 ± 0.076

(.011 ± .003)

9

3.00 ± 0.102

(.118 ± .004)

(NOTE 4)

(.034)

MSOP (MS12) 0510 REV A

REF

0.86

REF

0.1016 ± 0.0508

(.004 ± .002)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3511f

23

LT3511

查询LT3511供应商

TYPICAL APPLICATION

V

IN

36V TO 72V

C1

µF

1

RELATED PARTS

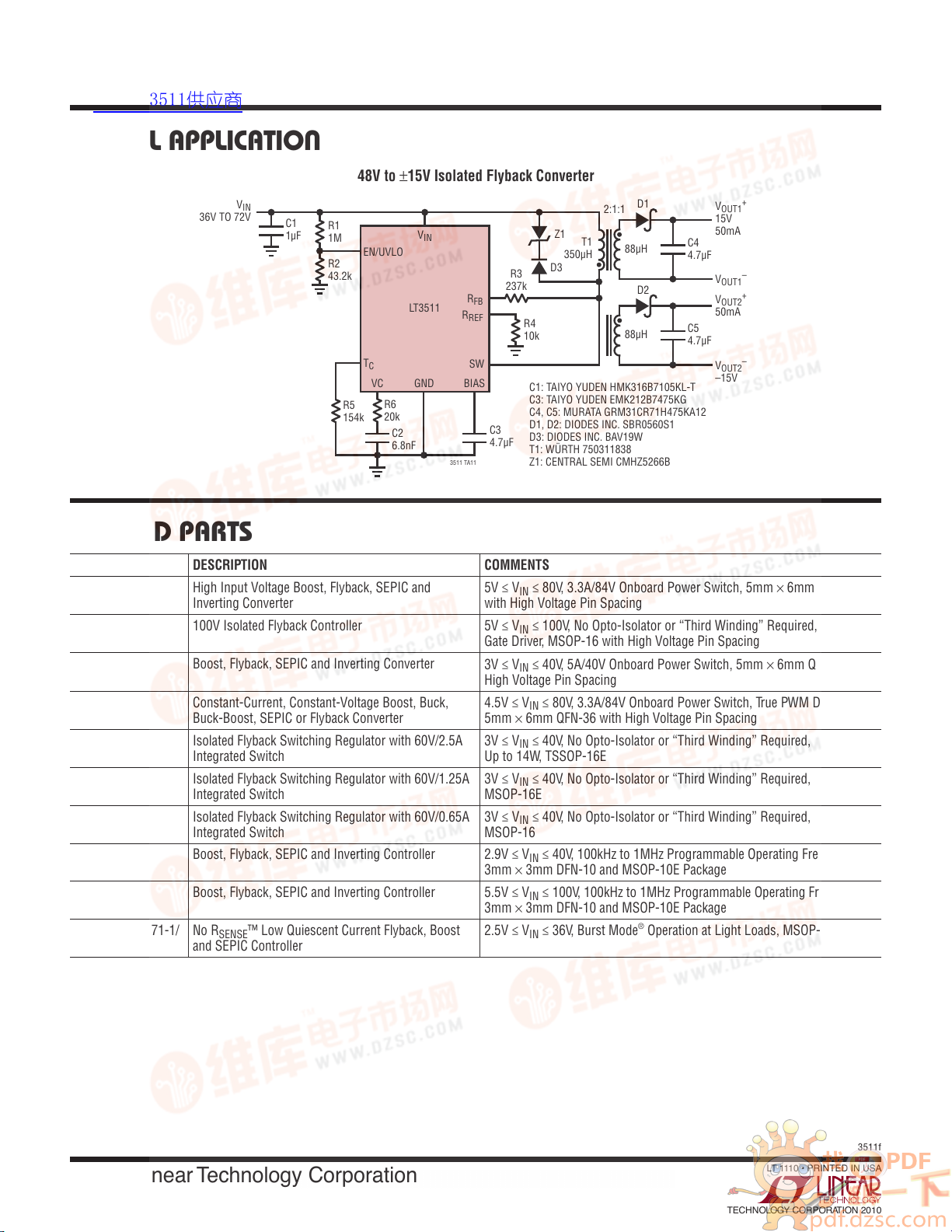

48V to ±15V Isolated Flyback Converter

R1

1M

R2

43.2k

R5

154k

EN/UVLO

T

C

V

IN

LT3511

VC GND BIAS

R6

20k

C2

6.8nF

R

3511 TA11

R

REF

SW

R3

237k

FB

R4

10k

C1: TAIYO YUDEN HMK316B7105KL-T

C3: TAIYO YUDEN EMK212B7475KG

C4, C5: MURATA GRM31CR71H475KA12

D1, D2: DIODES INC. SBR0560S1

C3

D3: DIODES INC. BAV19W

4.7µF

T1: WÜRTH 750311838

Z1: CENTRAL SEMI CMHZ5266B

D1

2:1:1

Z1

T1

88

µH

350

D3

µH

D2

88µH

C4

4.7

C5

4.7

+

V

OUT1

15V

50mA

µF

–

V

OUT1

+

V

OUT2

50mA

µF

–

V

OUT2

–15V

PART NUMBER DESCRIPTION COMMENTS

LT3958 High Input Voltage Boost, Flyback, SEPIC and

Inverting Converter

LT3748 100V Isolated Flyback Controller 5V ≤ V

≤ 80V, 3.3A/84V Onboard Power Switch, 5mm × 6mm QFN-36

5V ≤ V

IN

with High Voltage Pin Spacing

≤ 100V, No Opto-Isolator or “Third Winding” Required, Onboard

IN

Gate Driver, MSOP-16 with High Voltage Pin Spacing

LT3957 Boost, Flyback, SEPIC and Inverting Converter

3V ≤ VIN ≤ 40V, 5A/40V Onboard Power Switch, 5mm × 6mm QFN-36 with

High Voltage Pin Spacing

LT3956 Constant-Current, Constant-Voltage Boost, Buck,

Buck-Boost, SEPIC or Flyback Converter

LT3575 Isolated Flyback Switching Regulator with 60V/2.5A

Integrated Switch

LT3573 Isolated Flyback Switching Regulator with 60V/1.25A

Integrated Switch

LT3574 Isolated Flyback Switching Regulator with 60V/0.65A

Integrated Switch

4.5V ≤ V

5mm × 6mm QFN-36 with High Voltage Pin Spacing

3V ≤ V

Up to 14W, TSSOP-16E

3V ≤ V

MSOP-16E

3V ≤ V

MSOP-16

LT3757 Boost, Flyback, SEPIC and Inverting Controller 2.9V ≤ V

≤ 80V, 3.3A/84V Onboard Power Switch, True PWM Dimming,

IN

≤ 40V, No Opto-Isolator or “Third Winding” Required,

IN

≤ 40V, No Opto-Isolator or “Third Winding” Required, Up to 7W,

IN

≤ 40V, No Opto-Isolator or “Third Winding” Required, Up to 3W,

IN

≤ 40V, 100kHz to 1MHz Programmable Operating Frequency,

IN

3mm × 3mm DFN-10 and MSOP-10E Package

LT3758 Boost, Flyback, SEPIC and Inverting Controller 5.5V ≤ V

≤ 100V, 100kHz to 1MHz Programmable Operating Frequency,

IN

3mm × 3mm DFN-10 and MSOP-10E Package

LTC1871/LTC1871-1/

LTC1871-7

No R

™ Low Quiescent Current Flyback, Boost

SENSE

and SEPIC Controller

2.5V ≤ VIN ≤ 36V, Burst Mode® Operation at Light Loads, MSOP-10

24

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

3511f

LT 1110 • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2010

Loading...

Loading...