LT3510

Monolithic Dual Tracking

2A Step-Down Switching

Regulator

FEATURES

n

Wide Input Range: 3.1V to 25V

n

Two Switching Regulators with 2A Output Capability

n

Independent Supply to Each Regulator

n

Adjustable/Synchronizable Fixed Frequency

Operation from 250kHz to 1.5MHz

n

Antiphase Switching

n

Outputs Can be Paralleled

n

Independent, Sequential, Ratiometric or Absolute

Tracking Between Outputs

n

Independent Soft-Start and Power Good Pins

n

Enhanced Short-Circuit Protection

n

Low Dropout: 95% Maximum Duty Cycle

n

Low Shutdown Current: <10μA

n

20-Lead TSSOP Package with Exposed Leadframe

APPLICATIONS

n

DSP Power Supplies

n

Disc Drives

n

DSL/Cable Modems

n

Wall Transformer Regulation

n

Distributed Power Regulation

n

PCI Cards

, LT, LTC, and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

DESCRIPTION

The LT®3510 is a dual current mode PWM step-down

DC/DC converter with two internal 2.5A switches. Independent input voltage, feedback, soft-start and power

good pins for each channel simplify complex power

supply tracking/sequencing requirements.

Both converters are synchronized to either a common

external clock input or a resistor programmable fi xed

250kHz to 1.5MHz internal oscillator. At all frequencies, a

180° phase relationship between channels is maintained,

reducing voltage ripple and component size. Programmable

frequency allows for optimization between effi ciency and

external component size.

Minimum input-to-output voltage ratios are improved

by allowing the switch to stay on through multiple clock

cycles, only switching off when the boost capacitor needs

recharging, resulting in ~95% maximum duty cycle.

Each output can be independently disabled using its own

soft-start pin, or by using the SHDN pin the entire part can

be placed in a low quiescent current shutdown mode.

The LT3510 is available in a 20-lead TSSOP package with

exposed leadframe for low thermal resistance.

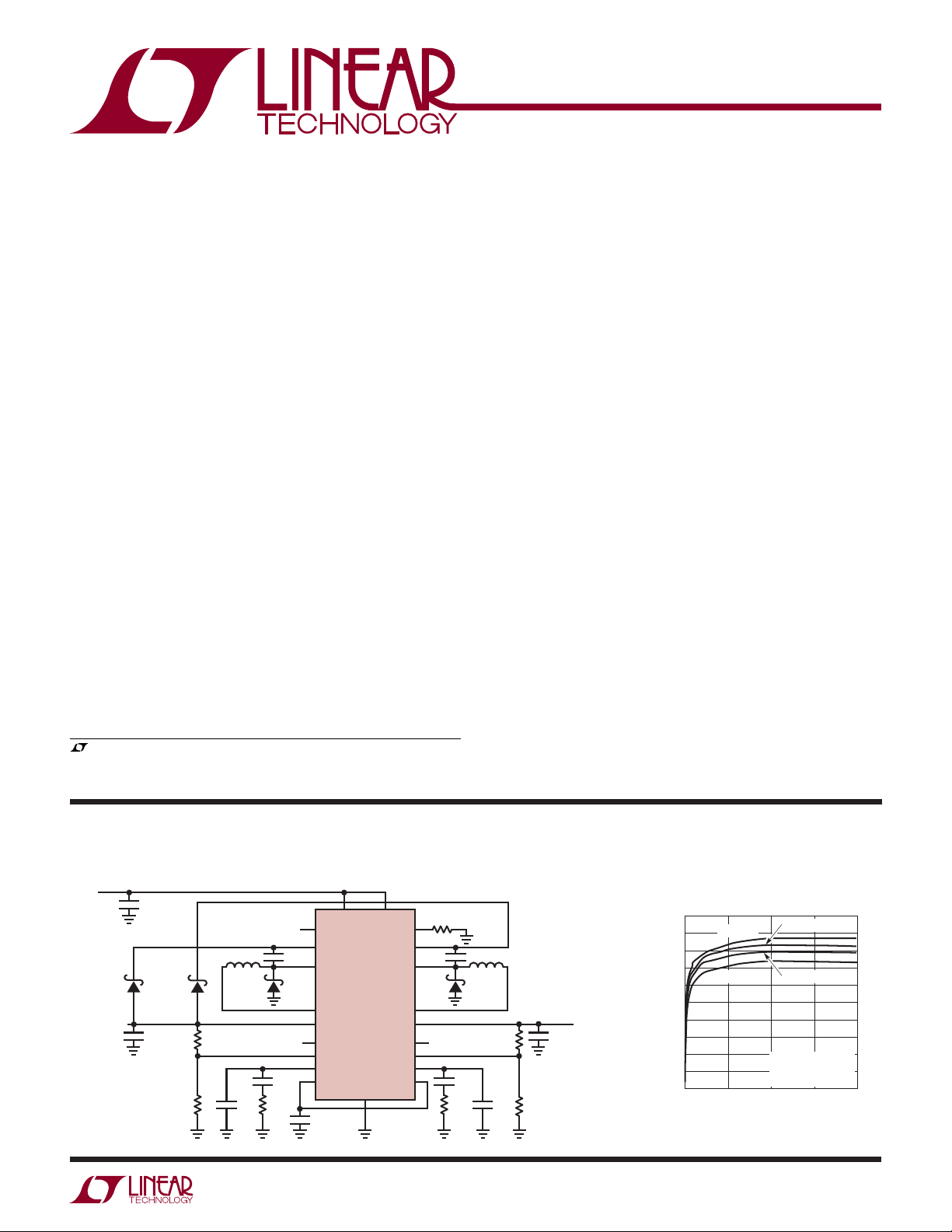

TYPICAL APPLICATION

3.3V and 1.8V Dual 2A Step-Down Converter with Output Tracking

V

IN

12V

4.7μF

PMEG4005

V

OUT1

3.3V

2A

4.7μH

PMEG4005

47μF 100μF

24.9k

8.06k

0.47μF

B360A B360A

470pF

40.2k

10pF 47pF

SHDN

BST1

SW1

IND1

V

OUT1

PG1

FB1

V

C1

SS/TRACK1

0.1μF

Effi ciency

V

IN1

LT3510

GND

V

IN2

R

/SYNC

T

BST2

SW2

IND2

V

OUT2

PG2

FB2

V

SS/TRACK2

61.9k

470pF

40.2k

3.3μH

10k

8.06k

3510 TA01a

V

1.8V

2A

OUT2

0.47μF

C2

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0

V

= 5V

OUT

V

= 1.8V

OUT

0.5

LOAD CURRENT (A)

V

= 3.3V

OUT

V

= 2.5V

OUT

VIN = 12V

= 0A

I

OUT2

FREQUENCY = 500kHz

1.5

1

3510 TA01b

2

3510fc

1

LT3510

ABSOLUTE MAXIMUM RATINGS

PIN CONFIGURATION

(Note 1)

V

, SHDN, PG1/2 ...................................... 25V/–0.3V

IN1/2

SW1/2 .................................................................... V

IN1/2

BST1/2 ........................................................... 35V/–0.3V

BST1/2 Pins Above SW1/2 ........................................25V

IND1/2 .....................................................................±4A

V

FB1/2, SS1/2, R

V

........................................................ V

OUT1/2

/SYNC ............................................5.5V

T

......................................................................±1mA

C1/2

IN1/2

/–0.3V

Operating Junction Temperature Range

LT3510EFE (Notes 2, 8) ..................... –40°C to 125°C

LT3510IFE (Notes 2, 8) ...................... –40°C to 125°C

Storage Temperature Range ...................–65°C to 150°C

Lead Temperature (Soldering, 10 sec) ..................300°C

V

IN1

SW1

IND1

V

OUT1

PG1

PG2

V

OUT2

IND2

SW2

V

IN2

T

= 125°C, θJA = 45°C/W, θ

JMAX

EXPOSED PAD (PIN 21) IS GND, MUST BE SOLDERED TO PCB

TOP VIEW

1

2

3

4

5

6

7

8

9

10

FE PACKAGE

20-LEAD PLASTIC TSSOP

20

19

18

17

16

21

15

14

13

12

11

JC(PAD)

BST1

SS/TRACK1

V

C1

FB1

R

/SYNC

T

SHDN

FB2

V

C2

SS/TRACK2

BST2

= 10°C/W

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3510EFE#PBF LT3510EFE#TRPBF LT3510FE 20-Lead TSSOP –40°C to 125°C

LT3510IFE#PBF LT3510IFE#TRPBF LT3510FE 20-Lead TSSOP –40°C to 125°C

LEAD BASED FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3510EFE LT3510EFE#TR LT3510FE 20-Lead TSSOP –40°C to 125°C

LT3510IFE LT3510IFE#TR LT3510FE 20-Lead TSSOP –40°C to 125°C

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges. *The temperature grade is identifi ed by a label on the shipping container.

For more information on lead free part marking, go to:

For more information on tape and reel specifi cations, go to:

http://www.linear.com/leadfree/

http://www.linear.com/tapeandreel/

The

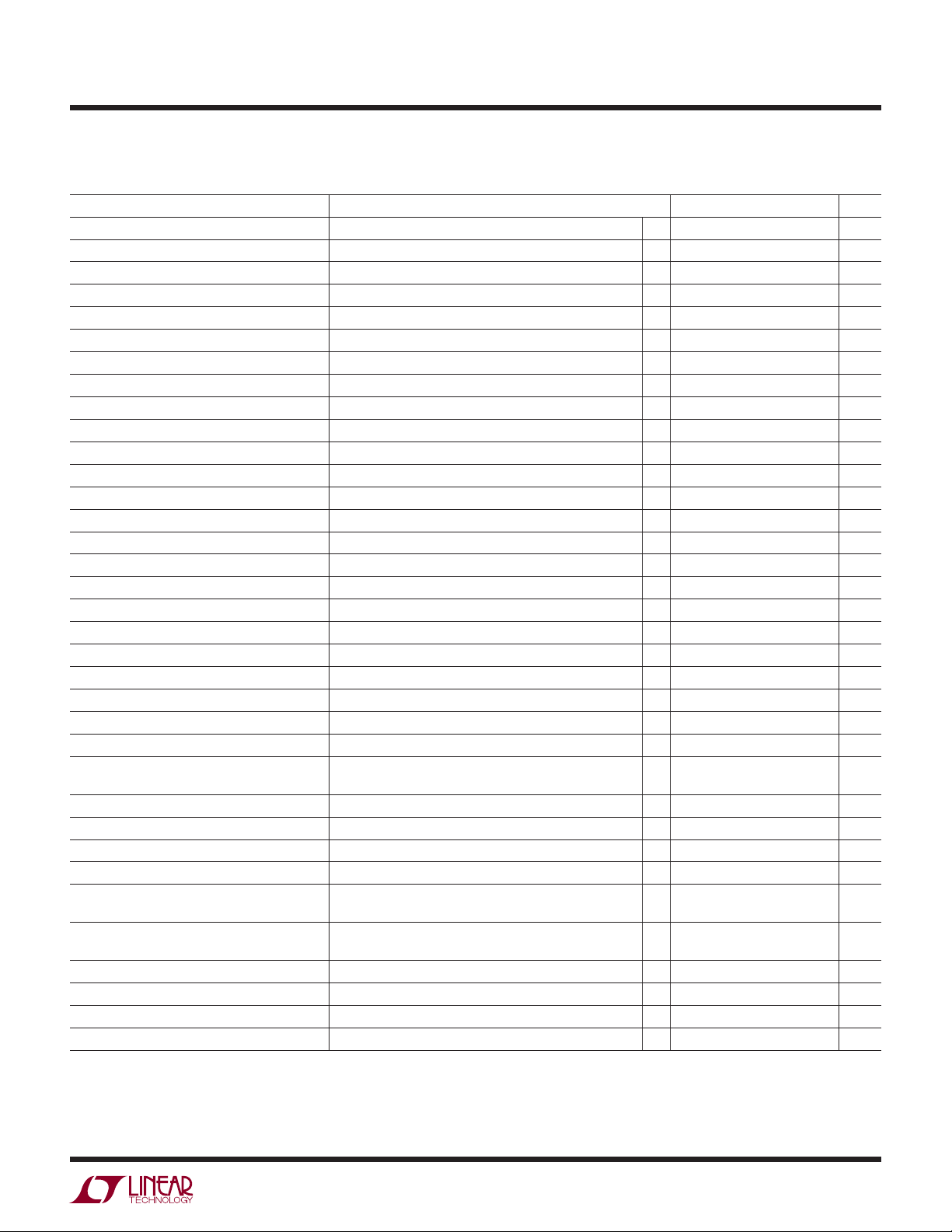

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at TJ = 25°C. V

l denotes the specifi cations which apply over the full operating

VIN1/2

= 15V, V

BST1/2

= open, V

RT/SYNC

= 2V, V

VOUT1/2

= open,

unless otherwise specifi ed.

PARAMETER CONDITIONS MIN TYP MAX UNITS

SHDN Threshold V

SHDN Input Current V

Minimum Input Voltage Ch 1 (Note 3) V

Minimum Input Voltage Ch 2 V

Supply Shutdown Current Ch 1 V

Supply Shutdown Current Ch 2 V

Supply Quiescent Current Ch 1 V

Supply Quiescent Current Ch 2 V

Feedback Voltage Ch 1/2 V

= 0V, RT/SYNC = 133k

OUT1/2

= 1.375V

SHDN

V

= 1.225V

SHDN

= 0V, V

FB1/2

= 0V, V

FB1/2

= 0V

SHDN

= 0V 0 5 μA

SHDN

= 0.9V 3.5 5 mA

FB1/2

= 0.9V 200 500 μA

FB1/2

= 1V

VC1/2

VOUT1/2

VOUT1/2

= 0V, V

= 0V, V

= 0V, RT/SYNC = 133k 2.8 3 V

IND1/2

= 0V 2.8 3 V

IND1/2

l

1.23 1.28 1.37 V

7

2

l

l

0.784 0.8 0.816 V

10

13

3

930 μA

5

μA

3510fc

μA

2

LT3510

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

unless otherwise specifi ed.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Feedback Voltage Line Regulation V

Feedback Voltage Offset Ch 1 to Ch 2 V

Feedback Bias Current Ch 1/2 V

Error Amplifi er g

Ch 1/2 V

m

Error Amplifi er Gain Ch 1/2 1000 V/V

Error Amplifi er to Switch Gain Ch 1/2 2.2 A/V

Error Amplifi er Source Current Ch 1/2 V

Error Amplifi er Sink Current Ch 1/2 V

Error Amplifi er High Clamp Ch 1/2 V

Error Amplifi er Switching Threshold Ch 1/2 V

Soft-Start Source Current Ch 1/2 V

Soft-Start V

Ch 1/2 V

OH

Soft-Start Sink Current Ch 1/2 V

Soft-Start V

Ch 1/2 V

OL

Soft-Start to Feedback Offset Ch 1/2 V

Soft-Start Sink Current Ch 1/2 POR V

Soft-Start POR Threshold Ch 1/2 V

Soft-Start Switching Threshold Ch 1/2 V

Power Good Leakage Ch 1/2 V

Power Good Threshold Ch 1/2 V

Power Good Hysteresis Ch 1/2 V

Power Good Sink Current Ch 1/2 V

Power Good Shutdown Sink Current Ch 1/2 V

/SYNC Reference Voltage V

R

T

Switching Frequency R

Switching Phase Angle Ch A to Ch B R

Minimum Boost for 100% Duty Cycle Ch 1/2 V

SYNC Frequency Range V

SYNC Switching Phase Angle Ch A to Ch B SYNC = 250kHz, V

IND + V

IND to V

Current Ch 1/2 V

OUT

Maximum Current Ch 1/2 V

OUT

Switch Leakage Current Ch 1/2 V

Switch Saturation Voltage Ch 1/2 I

Boost Current Ch 1/2 I

Minimum Boost Voltage Ch 1/2 I

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

VIN1/2

VC1/2

FB1/2

VC1/2

FB1/2

FB1/2

FB1/2

OUT1/2

FB1/2

FB1/2

FB1/2

FB1/2

VC1/2

SS1/2

FB1/2

FB1/2

FB1/2

FB1/2

FB1/2

FB1/2

VIN1/2

FB1/2

T

R

T

T

FB1/2

BST1/2

VOUT1/2

V

VOUT1/2

VOUT1/2

V

VOUT1/2

SW1/2

SW1/2

SW1/2

SW1/2

= 25°C. V

J

= 3V to 25V

= 1V

= 0.8V, V

= 1V, I

= 0.6V, V

= 1V, V

VC1/2

VC1/2

VC1/2

VC1/2

= ±5μA

= 1V 15 20 30 μA

VIN1/2

= 1V

= 15V, V

BST1/2

= open, V

RT/SYNC

l

l

l

l

= 2V, V

VOUT1/2

= open,

–1 0 1 %

–16 0 16 mV

–200 75 200 nA

150 275 450 μmho

= 1V 10 15 25 μA

= 0.7V 1.75 2.0 2.25 V

= 5V, RT/SYNC = 133k 0.5 0.7 1.0 V

= 0.6V, V

SS1/2

= 0.4V

l

2.5 3.25 4 μA

= 0.9V 1.9 2 2.4 V

= 0.6V, V

= 1V 200 600 1000 μA

SS1/2

= 0V 50 80 125 mV

= 1V, V

SS1/2

= 0.4V

l

–16 0 16 mV

= 0.4V (Note 4), VVC = 1V 0.5 1.5 2 mA

= 0V (Note 4) 55 80 105 mV

= 0V 30 50 70 mV

= 0.9V, V

Rising, PG1/2 = 20k to 5V

PG1/2

= 25V, V

VIN1/2

= 25V, V

= 5V 0 1 μA

OUT

l

87 90 93 %

Falling, PG1/2 = 20k to 5V 20 30 50 mV

= 0.65V, V

= 2V, V

= 0.9V, I

/SYNC = 133k, V

/SYNC = 15.4k, V

/SYNC = 133k, V

= 0.7V, I

= 0.4V 400 800 1200 μA

PG1/2

= 0V, V

FB1/2

= –40μA 0.93 0.975 1 V

RT/SYNC

FB1/2

FB1/2

FB1/2

= –35μA (Note 5), V

RT/SYNC

= 0.4V 10 50 100 μA

PG1/2

= 0.6V, V

= 0.6V, V

= 0.6V, V

= VSW + 3V

BST1/2

= VSW + 3V

BST1/2

= VSW + 3V 120 180 210 Deg

BST1/2

= 0V 1.7 2 V

OUT

200

1.2

250

1.5

300

1.8

= VSW + 3V 250 1500 kHz

= VSW + 3V 120 180 210 Deg

BST1/2

= 0V, V

= 5V

= 0.5V (Note 6), V

= 5V (Note 6), RT/SYNC = 133k, V

= 0V, V

= 2A, V

= 2A, V

= 2A, V

= 0.9V

FB1/2

VIN1/2 = 25V

= 20V, V

BST1/2

= 20V, V

BST1/2

= 20V, V

BST1/2

40 70

100

0

= 0.7V, V

FB1/2

= 0.7V

FB1/2

= 0.7V 25 50 100 mA

FB1/2

= 0.7V (Note 7) 1.4 2.5 V

FB1/2

BST1/2

BST1/2

= 20V

= 20V

2.25

2.5

l

l

2.8

2.8

050 μA

250 400 mV

1

4

4

Note 2: The LT3510EFE is guaranteed to meet performance specifi cations

from 0°C to 125°C junction temperature. Specifi cations over the –40°C

to 125°C operating junction temperature range are assured by design,

characterization and correlation with statistical process controls. The

kHz

MHz

μA

μA

A

A

3510fc

3

LT3510

ELECTRICAL CHARACTERISTICS

LT3510IFE is guaranteed and tested over the full –40°C to 125°C operating

junction temperature range.

Note 3: Minimum input voltage is defi ned as the voltage where internal

bias lines are regulated so that the reference voltage and oscillator remain

constant. Actual minimum input voltage to maintain a regulated output

will depend upon output voltage and load current. See Applications

Information.

Note 4: An internal power-on reset (POR) latch is set on the positive

transition of the SHDN pin through its threshold. The output of the latch

activates current sources on each SS pin which typically sink 1.5mA,

discharging the SS capacitor. The latch is reset when both SS pins are

driven below the soft-start POR threshold or the SHDN pin is taken below

its threshold.

Note 5: To enhance dropout operation, the output switch will be turned off

for the minimum off time only when the voltage across the boost capacitor

drops below the minimum boost for 100% duty cycle threshold.

Note 6: The IND to V

current fl owing from the IND pin to the V

latch when the V

Note 7: This is the minimum voltage across the boost capacitor needed to

guarantee full saturation of the internal power switch.

Note 8: This IC includes overtemperature protection that is intended

to protect the device during momentary overload conditions. Junction

temperature will exceed 125°C when overtemperature protection is active.

Continuous operation above the specifi ed maximum operating junction

temperature may impair device reliability.

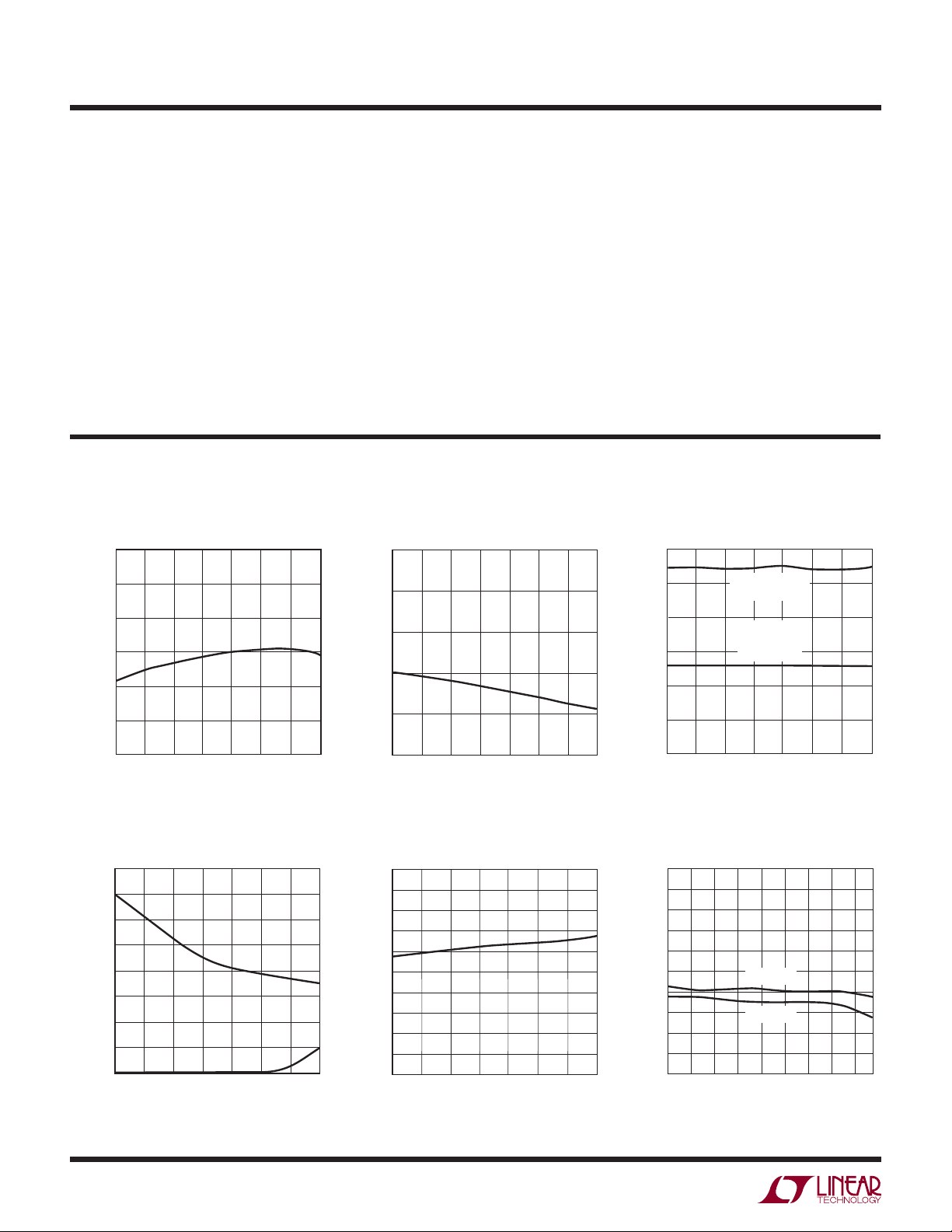

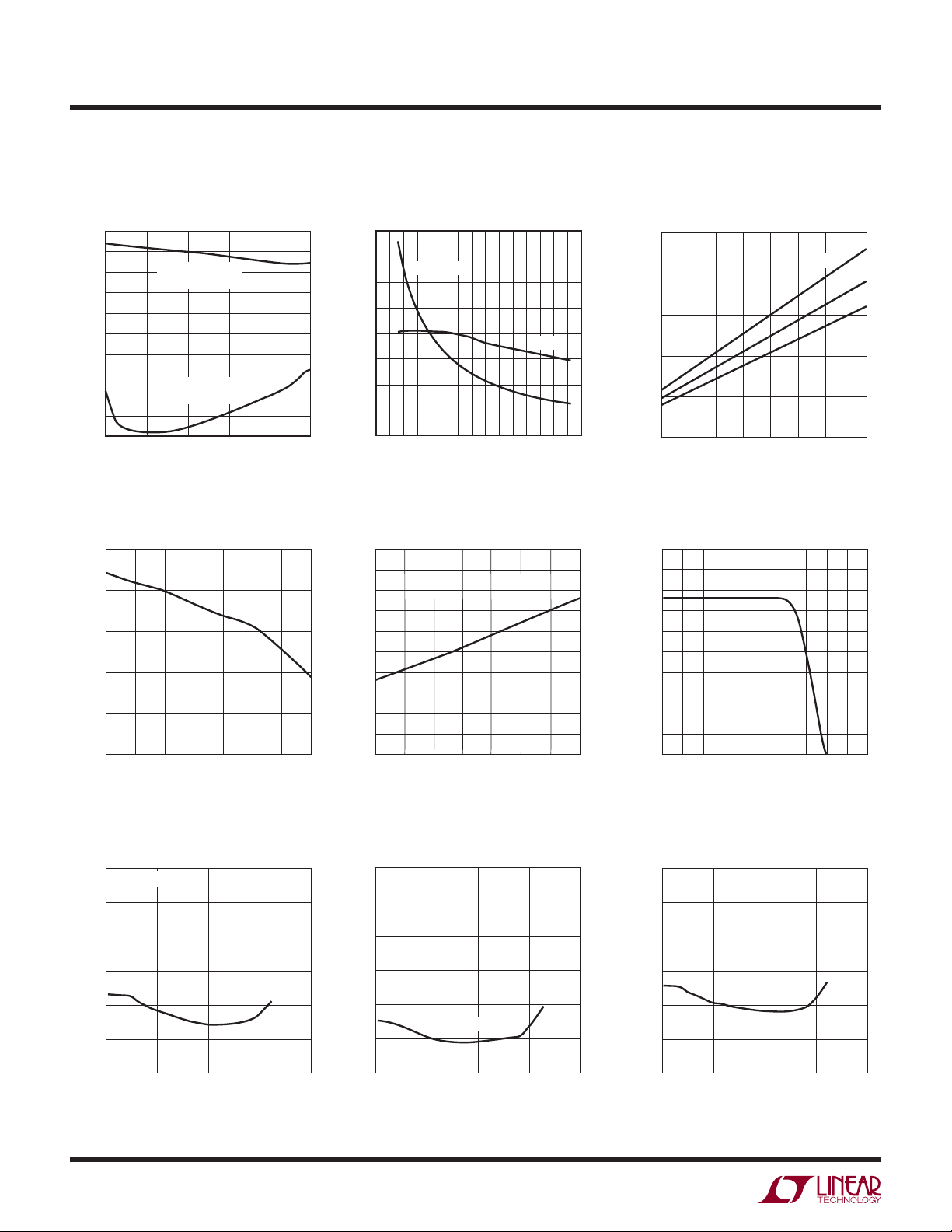

TYPICAL PERFORMANCE CHARACTERISTICS

Feedback Voltage vs Temperature RT/SYNC Voltage vs Temperature

0.816

0.811

0.806

0.801

VOLTAGE (V)

0.796

1.05

1.03

1.01

0.99

VOLTAGE (V)

maximum current is defi ned as the value of

OUT

pin is at its high clamp.

C

pin which resets the switch

OUT

Shutdown Threshold and Minimum

Input Voltage vs Temperature

3.0

2.5

2.0

1.5

VOLTAGE (V)

1.0

MINIMUM INPUT

VOLTAGE

SHUTDOWN

THRESHOLD

VOLTAGE

0.791

0.786

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

Shutdown Quiescent Current

vs Temperature

16

14

12

10

CURRENT (μA)

V

VIN1

8

6

4

2

0

–25 0 50

–50

25

TEMPERATURE (°C)

3510 G02

V

VIN2

75 100 125

3510 G05

0.97

0.95

–50 –25

25

0

TEMPERATURE (°C)

Soft-Start Source Current

vs Temperature

4.0

3.8

3.6

3.4

3.2

3.0

2.8

CURRENT (μA)

2.6

2.4

2.2

2.0

–50

–25

25

0

TEMPERATURE (°C)

0.5

0

–50

50

75

100

125

3510 G03

–25 0

IND to V

TEMPERATURE (°C)

OUT

50 100 125

25 75

3510 G04

Maximum Current vs

Temperature

4.0

3.8

3.6

3.4

3.2

3.0

2.8

CURRENT (A)

2.6

2.4

2.2

2.0

–30 10

50

75

100

125

3510 G07

–50

V

OUT

V

OUT

–10

30

TEMPERATURE (°C)

= 5V

= 0V

50

90

110

70

3510 G30

3510fc

4

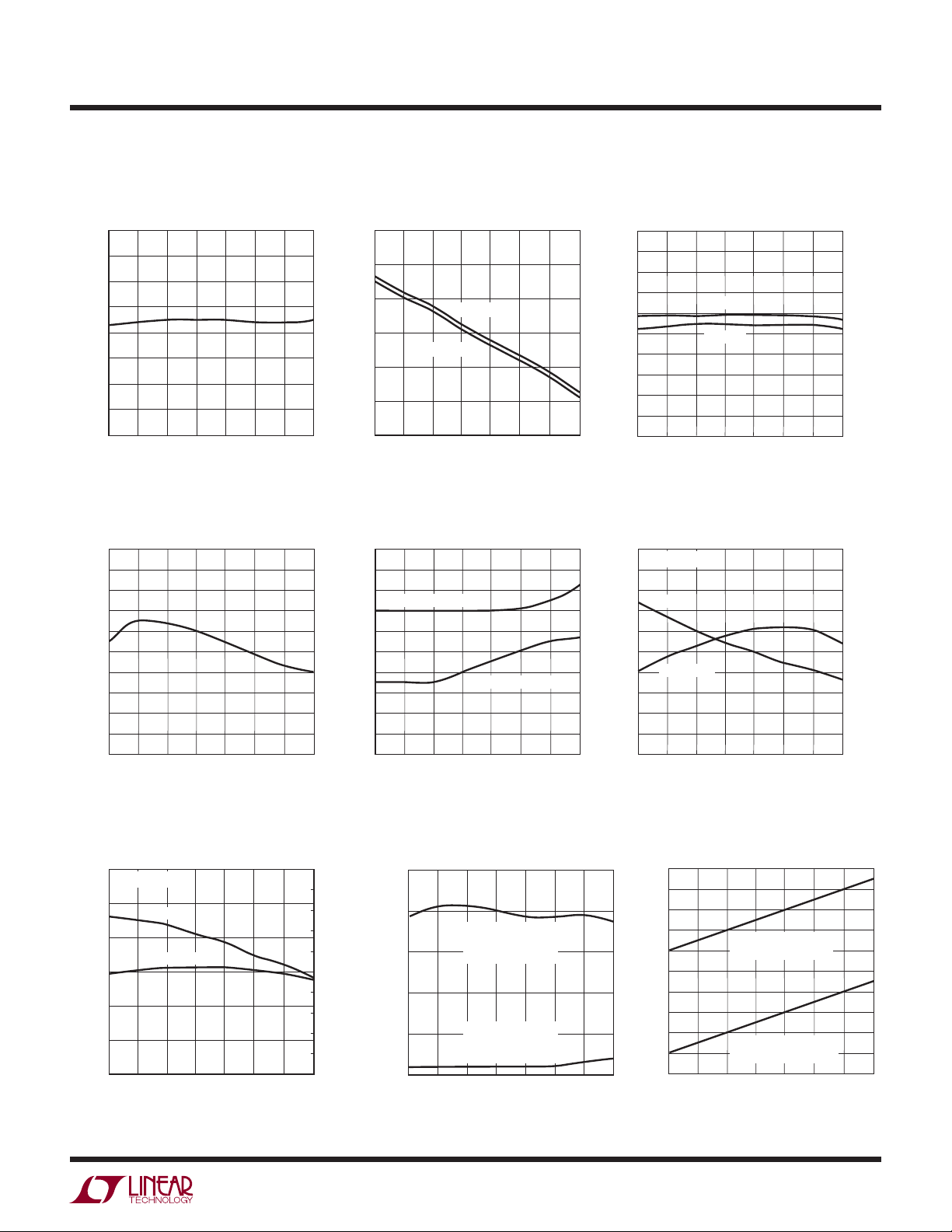

TYPICAL PERFORMANCE CHARACTERISTICS

LT3510

Soft-Start to Feedback Offset

Voltage vs Temperature

4

3

2

1

0

–1

VOLTAGE (mV)

–2

–3

–4

–25 0 50

–50

25

TEMPERATURE (°C)

Power Good Sink Current

vs Temperature

1000

950

900

850

800

750

700

CURRENT (μA)

650

600

550

500

–50

0

–25

TEMPERATURE (°C)

50

25

75 100 125

3510 G08

100

125

3510 G11

75

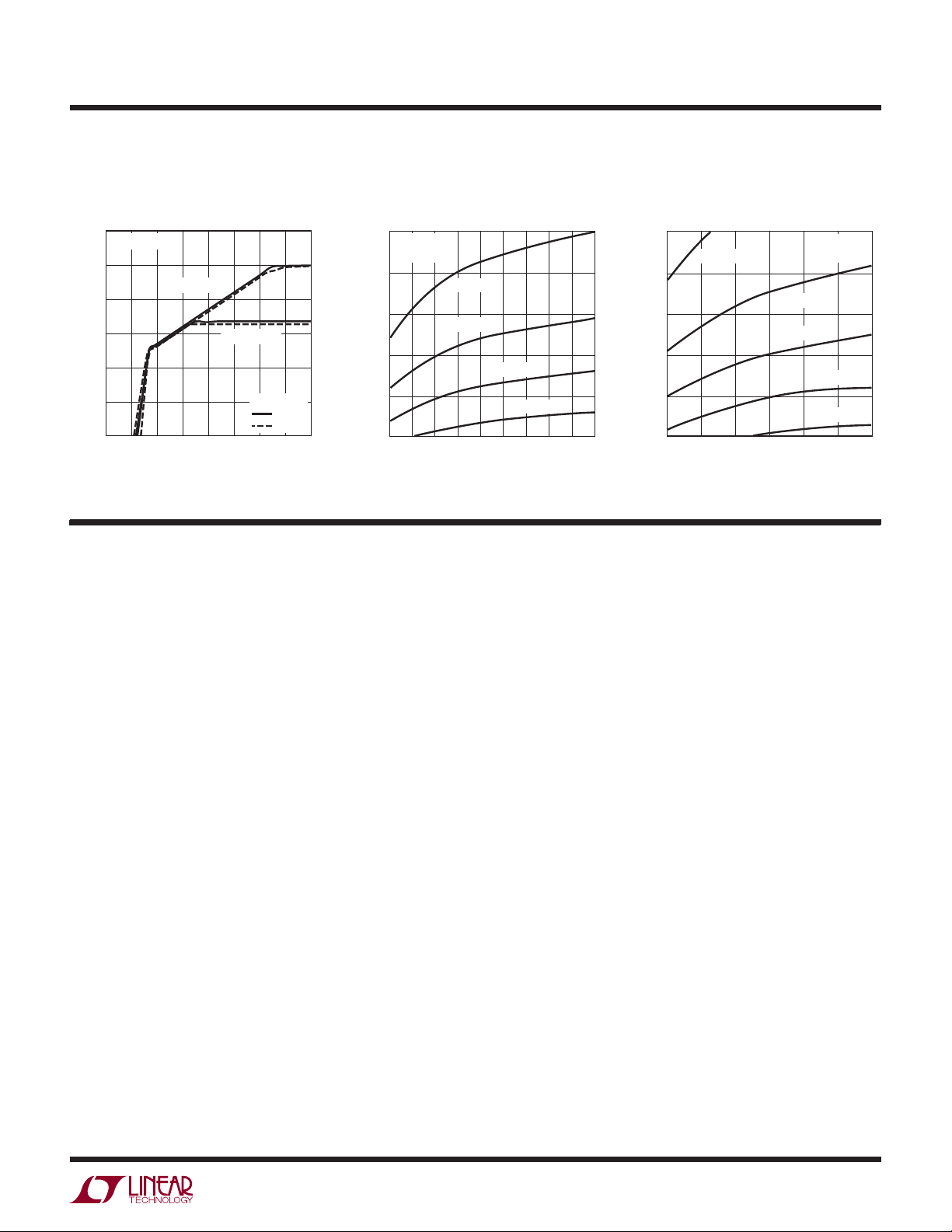

Switching Threshold Voltage

V

C

vs Temperature

1000

900

800

700

VOLTAGE (V)

600

500

400

–50

–25 0

V

OUT

V

= 0V

OUT

25 75

TEMPERATURE (°C)

Minimum Switching Times

vs Temperature

250

230

210

MINIMUM ON TIME

190

170

150

TIME (ns)

130

110

90

70

50

–50

–25

MINIMUM OFF TIME

25

0

TEMPERATURE (°C)

= 5V

50 100 125

3510 G09

50

75

100

3510 G12

125

Power Good Threshold Voltage

vs Temperature

800

780

760

740

720

700

680

VOLTAGE (V)

660

640

620

600

–50

–25

RISING

FALLING

50

25

0

TEMPERATURE (°C)

75

Switching Frequency and Channel

Phase vs Temperature

300

RT/SYNC = 133k

290

280

PHASE

270

260

250

FREQUENCY

240

FREQUENCY (kHz)

230

220

210

200

–50

–25

0

TEMPERATURE (°C)

50

25

75

100

100

3510 G10

3510 G13

125

125

200

190

180

170

PHASE (DEG)

160

150

140

130

120

110

100

Switching Frequency and Channel

Phase vs Temperature

1650

RRT/SYNC = 15.4k

1600

1550

1500

1450

FREQUENCY (kHz)

1400

1350

–50

PHASE

FREQUENCY

–25 0

50 100 125

25 75

TEMPERATURE (°C)

3510 G14

200

195

190

185

PHASE (DEG)

180

175

170

165

160

155

150

Synchronization Clock Frequency

Range vs Temperature

2500

2000

MAXIMUM

1500

1000

FREQUENCY (kHz)

500

0

–50 –25

SYNCHRONIZATION

FREQUENCY

MINIMUM

SYNCHRONIZATION

FREQUENCY

50

25

0

TEMPERATURE (°C)

Channel Phase vs Temperature

with External Synchronization

188

186

164

182

180

178

176

PHASE (DEG)

174

172

170

168

100

125

3510 G15

75

–50

SYNCHRONIZATION

FREQUENCY = 250kHz

SYNCHRONIZATION

FREQUENCY = 1500kHz

0

–25

TEMPERATURE (°C)

50

25

75

100

125

3510 G16

3510fc

5

LT3510

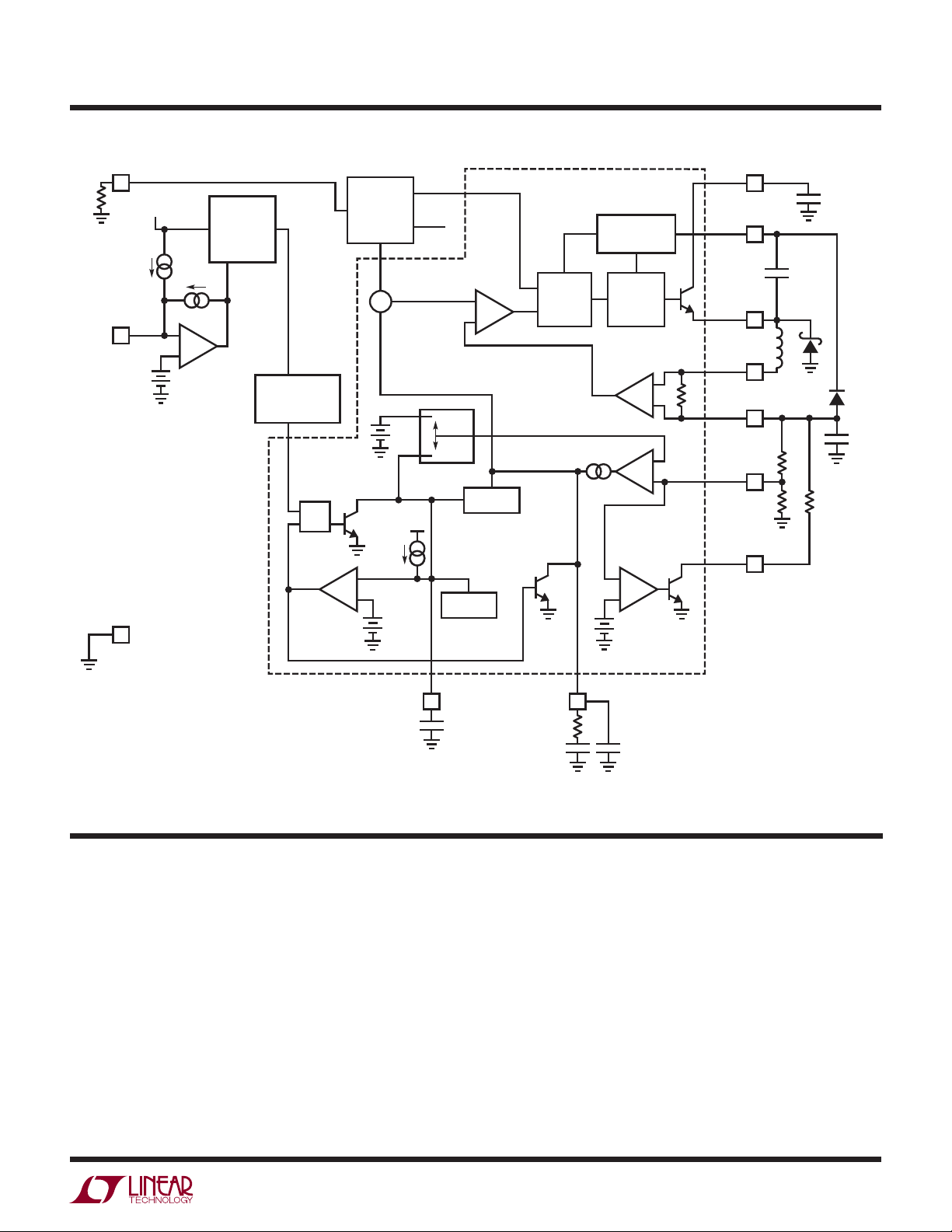

TYPICAL PERFORMANCE CHARACTERISTICS

External Sync Duty Cycle Range

vs External Sync Frequency

100

90

80

70

60

50

40

DUTY CYCLE (%)

30

20

10

0

250

MAXIMUM CLOCK

DUTY CYCLE

MINIMUM CLOCK

DUTY CYCLE

500

750

FREQUENCY (kHz)

1000

Minimum Boost Voltage

vs Temperature

2.5

2.0

1.5

1.0

VOLTAGE (V)

0.5

0

–50 –25

0

TEMPERATURE (°C)

50

25

Frequency and Phase vs RT/SYNC

Pin Resistance

1250

3510 G17

1500

1600

1400

1200

1000

800

600

FREQUENCY (kHz)

400

200

100

FREQUENCY

0 20 40 60 80 100 120 140

RESISTANCE (kΩ)

V

+ IND Current

OUT

PHASE

3510 G18

190

185

180

PHASE (DEG)

175

170

165

160

155

150

vs Temperature

100

95

90

85

80

75

70

CURRENT (μA)

65

60

55

100

125

3510 G21

75

50

–50

–25

0

TEMPERATURE (°C)

50

25

75

100

125

3510 G22

Switch Saturation Voltage

vs Switch Current

250

200

150

100

VOLTAGE (mV)

50

0

0.5

0.7 0.9

V

OUT

vs V

100

90

80

70

60

50

40

CURRENT (μA)

30

20

10

0

0

OUT

1.1 1.5

CURRENT (A)

+ IND Current

Voltage

0.40.2

0.80.6

VOLTAGE (V)

1.3

1.2 1.4 1.8

1.0

125°C

25°C

–50°C

1.7 1.9

1.6

3510 G19

2.0

3510 G23

Minimum Input Voltage

vs Load Current

5.0

V

= 2.5V

OUT

4.5

4.0

3.5

VOLTAGE (V)

3.0

2.5

2.0

1

10 100 1000 10000

6

CURRENT (mA)

RUNNING

3510 G24

Minimum Input Voltage

vs Load Current

6.0

V

= 3.3V

OUT

5.5

5.0

4.5

VOLTAGE (V)

4.0

3.5

3.0

1

10 100 1000 10000

CURRENT (mA)

RUNNING

3510 G25

Minimum Input Voltage

vs Load Current

7.5

V

= 5V

OUT

7.0

6.5

6.0

VOLTAGE (V)

5.5

5.0

4.5

1

10 100 1000 10000

CURRENT (mA)

RUNNING

3510 G26

3510fc

TYPICAL PERFORMANCE CHARACTERISTICS

LT3510

Inductor Value vs Frequency for

Dropout Operation

6

LOAD = 1A

5

4

3

2

OUTPUT VOLTAGE (V)

1

0

2

34

2.5 3.5

V

= 5V

OUT

V

OUT

INPUT VOLTAGE (V)

4.5

= 3.3V

FREQUENCY

1.5MHz

250kHz

5

5.5

6

3510 G27

2A Maximum Load Current

1500

V

= 3.3V

OUT

= 1A

I

RIPPLE

1250

1000

750

FREQUENCY (kHz)

500

250

7

L = 2.2μH

L = 3.3μH

913

11

INPUT VOLTAGE (V)

PIN FUNCTIONS

V

(Pin 1): The V

IN1

circuitry for both channels and is monitored by the

undervoltage lockout comparator. The V

connected to the collector of channel 1’s on-chip power

NPN switch. The V

be decoupled to ground close to the pin of the device.

SW1/SW2 (Pins 2, 9): The SW pin is the emitter of the onchip power NPN. At switch off, the inductor will drive this

pin below ground with a high dV/dt. An external Schottky

catch diode to ground, close to the SW pin and respective

decoupling capacitor’s ground, must be used to prevent

V

IN

this pin from excessive negative voltages.

IND1/IND2 (Pins 3, 8): The IND pin is the input to the

on-chip sense resistor that measures current fl owing in

the inductor. When the current in the resistor exceeds

the current dictated by the V

reset, disabling the output switch. Bias current fl ows out

of the IND pin when IND is less than 1.6V.

pin powers the internal control

IN1

pin is also

IN1

pin has high dI/dt edges and must

IN1

pin, the SW latch is held in

C

Inductor Value vs Frequency for

2A Maximum Load Current

L = 4.7μH

L = 6.8μH

17 25

19

15

1500

L = 2.2μH

1250

1000

750

FREQUENCY (kHz)

500

250

21

23

3510 G28

10

15 17.5 20

12.5

INPUT VOLTAGE (V)

L = 3.3μH

L = 4.7μH

V

= 5V

OUT

I

RIPPLE

L = 6.8μH

L = 10μH

22.5 25

= 1A

3510 G29

PG1/PG2 (Pins 5, 6): The power good pin is an open-collector output that sinks current when the feedback falls

below 90% of its nominal regulating voltage. For V

IN1

above 1V, its output state remains true, although during

shutdown, V

undervoltage lockout or thermal shutdown,

IN1

its current sink capability is reduced. The PG pins can be

left open circuit or tied together to form a single power

good signal.

(Pin 10): The V

V

IN2

on-chip power NPN switch. This pin is independent of V

pin is the collector of channel 2’s

IN2

IN1

and may be connected to the same or a separate supply. In

either case, high dI/dt edges are present and decoupling

to ground must be used close to this pin.

SS1/SS2 (Pins 19, 12): The SS1/2 pins control the softstart and sequence of their respective outputs. A single

capacitor from the SS pin to ground determines the outpt

ramp rate. For soft-start and output tracking/sequencing

details, see the Applications Information section.

V

OUT1/VOUT2

(Pins 4, 7): The V

pin is the output to

OUT

the on-chip sense resistor that measures current fl owing

in the inductor. When the current in the resistor exceeds

the current dictated by the V

pin, the SW latch is held in

C

reset, disabling the output switch. Bias current fl ows out

of the V

pin when V

OUT

is less than 1.6V.

OUT

V

(Pins 18, 13): The VC pin is the output of the

C1/VC2

error amplifi er and the input to the peak switch current

comparator. It is normally used for frequency compensation, but can also be used as a current clamp or control

loop override. If the error amplifi er drives V

above the

C

maximum switch current level, a voltage clamp activates.

3510fc

7

LT3510

PIN FUNCTIONS

This indicates that the output is overloaded and current is

pulled from the SS pin, reducing the regulation point.

FB1/FB2 (Pins 17, 14): The FB pin is the negative input

to the error amplifi er. The output switches regulate this

pin to 0.8V, with respect to the exposed ground pad. Bias

current fl ows out of the FB pin.

SHDN (Pin 15): The shutdown pin is used to turn off both

channels and control circuitry to reduce quiescent current

to a typical value of 9μA. The accurate 1.28V threshold and

input current hysteresis can be used as an undervoltage

lockout, preventing the regulator from operating until the

input voltage has reached a predetermined level. Force

the SHDN pin above its threshold or let it fl oat for normal

operation.

/SYNC (Pin 16): This RT/SYNC pin provides two modes

R

T

of setting the constant switch frequency.

Connecting a resistor from the R

will set the R

resultant switching frequency will be set by the resistor

value. The minimum value of 15.4k and maximum value of

133k sets the switching frequency to 1.5MHz and 250kHz

respectively.

Driving the R

synchronize the switch to the applied frequency. Synchronization occurs on the rising edge of the clock signal after

/SYNC pin to a typical value of 0.975V. The

T

/SYNC pin with an external clock signal will

T

/SYNC pin to ground

T

the clock signal is detected, with switch 1 in phase with

the synchronization signal. Each rising clock edge initiates

an oscillator ramp reset. A gain control loop servos the

oscillator charging current to maintain a constant oscillator

amplitude. Hence, the slope compensation and channel

phase relationship remain unchanged. If the clock signal

is removed, the oscillator reverts to resistor mode and

reapplies the 0.975V bias to the R

synchronization detection circuitry times out. The clock

source impedance should be set such that the current out

of the R

roughly equivalent to the synchronization frequency.

BST1/BST2 (Pins 20, 11): The BST pin provides a higher

than V

switch drop. A comparator to V

off time on the SW pin if the BST pin voltage drops too

low. Forcing a SW off time allows the boost capacitor to

recharge.

Exposed Pad (Pin 21): GND. The Exposed Pad GND pin is

the only ground connection for the device. The Exposed

Pad should be soldered to a large copper area to reduce

thermal resistance. The GND pin is common to both channels and also serves as small-signal ground. For ideal

operation all small-signal ground paths should connect

to the GND pin at a single point, avoiding any high current

ground returns.

/SYNC pin in resistor mode generates a frequency

T

base drive to the power NPN to ensure a low

IN

/SYNC pin after the

T

imposes a minimum

IN

8

3510fc

BLOCK DIAGRAM

/SYNC

R

T

R3

3μA

SHDN

1.28V

GND

V

IN1

+

INTERNAL

REGULATOR

AND

REFERENCE

7μA

+

–

SHUTDOWN

COMPARATOR

UNDERVOLTAGE

POR

TSD

S

RQ

SOFT-START

RESET

COMPARATOR

OSCILLATOR

AND

AGC

SLOPE

COMPENSATION

3

+

0.8V

3.25A

–

+

+

80mV

CLK1

CLK2

LOWEST

VOLTAGE

SS

ONE CHANNEL

–

+

VC CLAMP

SS CLAMP

LT3510

V

IN

C

DROPOUT

ENHANCEMENT

PRE

S

R

Q

DRIVER

CIRCUITRY

+

–

+

–

POWER GOOD

COMPARATOR

–

+

+

0.72V

V

C

BST

SW

IND

V

OUT

PGOOD

3510 BD

C3

D

L1

D

C

FB

R1

R2

C

Figure 1. Block Diagram (One of Two Switching Regulators Shown)

APPLICATIONS INFORMATION

The LT3510 is dual channel, constant frequency, current

mode buck converter with internal 2A switches. Each

channel is identical with a common shutdown pin, internal

regulator, oscillator, undervoltage detect, thermal shutdown

and power-on reset.

If the SHDN pin is taken below its 1.28V threshold the

LT3510 will be placed in a low quiescent current mode.

In this mode the LT3510 typically draws 9μA from V

and <1μA from V

with a typical sink capability of 50μA for V

. In shutdown mode the PG is active

IN2

voltage

IN1

greater than 2V.

IN1

When the SHDN pin is opened or driven above 1.28V,

the internal bias circuits turn on generating an internal

regulated voltage, 0.8V

, 0.975V RT/SYNC references,

FB

and a POR signal which sets the soft-start latch.

As the R

/SYNC pin reaches its 0.975V regulation point,

T

the internal oscillator will start generating two clock signals 180° out of phase for each regulator at a frequency

determined by the resistor from the R

/SYNC pin to ground.

T

Alternatively, if a synchronization signal is detected by the

LT3510 at the R

/SYNC pin, clock signals 180° out of phase

T

3510fc

9

LT3510

APPLICATIONS INFORMATION

will be generated at the incoming frequency on the rising

edge of the synchronization pulse with switch 1 in phase

with the synchronization signal. In addition, the internal

slope compensation will be automatically adjusted to prevent subharmonic oscillation during synchronization.

The two regulators are constant frequency, current mode

step-down converters. Current mode regulators are controlled by an internal clock and two feedback loops that

control the duty cycle of the power switch. In addition to

the normal error amplifi er, there is a current sense amplifi er

that monitors switch current on a cycle-by-cycle basis.

This technique means that the error amplifi er commands

current to be delivered to the output rather than voltage.

A voltage fed system will have low phase shift up to the

resonant frequency of the inductor and output capacitor,

then an abrupt 180°, shift will occur. The current fed system will have 90° phase shift at a much lower frequency,

but will not have the additional 90° shift until well beyond

the LC resonant frequency. This makes it much easier to

frequency compensate the feedback loop and also gives

much quicker transient response.

The Block Diagram in Figure 1 shows only one of the

switching regulators whose operation will be discussed

below. The additional regulator will operate in a similar

manner with the exception that its clock will be 180° out

of phase with the other regulator.

When, during power up, the POR signal sets the soft-start

latch, both SS pins will be discharged to ground to ensure

proper start-up operation. When the SS pin voltage drops

below 80mV, the V

pin is driven low disabling switching

C

and the soft-start latch is reset. Once the latch is reset the

soft-start capacitor starts to charge with a typical value

of 3.25μA.

As the voltage rises above 80mV on the SS pin, the V

pin

C

will be driven high by the error amplifi er. When the voltage

on the V

pin exceeds 0.7V, the clock set pulse sets the

C

driver fl ip-fl op which turns on the internal power NPN

switch. This causes current from V

, through the NPN

IN

switch, inductor and internal sense resistor, to increase.

When the voltage drop across the internal sense resistor

exceeds a predetermined level set by the voltage on the

pin, the fl ip-fl op is reset and the internal NPN switch

V

C

is turned off. Once the switch is turned off the inductor

will drive the voltage at the SW pin low until the external

Schottky diode starts to conduct, decreasing the current

in the inductor. The cycle is repeated with the start of each

clock cycle. However, if the internal sense resistor voltage

exceeds the predetermined level at the start of a clock cycle,

the fl ip-fl op will not be set resulting in a further decrease in

inductor current. Since the output current is controlled by

voltage, output regulation is achieved by the error

the V

C

amplifi er continually adjusting the V

pin voltage.

C

The error amplifi er is a transconductance amplifi er that

compares the FB voltage to the lowest voltage present at

either the SS pin or an internal 0.8V reference. Compensation of the loop is easily achieved with a simple capacitor

or series resistor/capacitor from the V

pin to ground.

C

Since the SS pin is driven by a constant current source, a

single capacitor on the soft-start pin will generate controlled

linear ramp on the output voltage.

If the current demanded by the output exceeds the maximum current dictated by the V

pin clamp, the SS pin

C

will be discharged, lowering the regulation point until the

output voltage can be supported by the maximum current.

When overload is removed, the output will soft-start from

the overload regulation point.

undervoltage detection or thermal shutdown will

V

IN1

set the soft-start latch, resulting in a complete soft-start

sequence.

The switch driver operates from either the V

or BST volt-

IN

age. An external diode and capacitor are used to generate

a drive voltage higher than V

to saturate the output NPN

IN

and maintain high effi ciency. If the BST capacitor voltage

is suffi cient, the switch is allowed to operate to 100% duty

cycle. If the boost capacitor discharges towards a level

insuffi cient to drive the output NPN, a BST pin comparator forces a minimum cycle off time, allowing the boost

capacitor to recharge.

A power good comparator with 30mV of hysteresis trips

at 90% of regulated output voltage. The PG output is an

open-collector NPN that is off when the output is in regulation allowing a resistor to pull the PG pin to a desired

voltage.

10

3510fc

APPLICATIONS INFORMATION

LT3510

Choosing the Output Voltage

The output voltage is programmed with a resistor divider

between the output and the FB pin. Choose the 1% resistors according to:

RR

12

⎛

OUT

•

⎜

⎝

08

.

⎞

1=

–

⎟

⎠

V

V

R2 should be 10k or less to avoid bias current errors. Reference designators refer to the Block Diagram in Figure 1.

Choosing the Switching Frequency

The LT3510 switching frequency is set by resistor R3 in

Figure 1. The R

Setting resistor R3 sets the current in the R

/SYNC pin is internally regulated at 0.975V.

T

/SYNC pin

T

which determines the oscillator frequency as illustrated

in Figure 2.

The switching frequency is typically set as high as possible to reduce overall solution size. The LT3510 employs

techniques to enhance dropout at high frequencies but

effi ciency and maximum input voltage decrease due to

switching losses and minimum switch on times. The

maximum recommended frequency can be approximated

by the equation:

1600

1400

1200

1000

800

600

FREQUENCY (kHz)

400

200

100

Figure 2. Frequency and Phase vs RT/SYNC Resistance

FREQUENCY

PHASE

0 20 40 60 80 100 120 140

RESISTANCE (kΩ)

3510 F02

190

185

180

PHASE (DEG)

175

170

165

160

155

150

The following example along with the data in Table 1

illustrates the tradeoffs of switch frequency selection.

Example.

= 25V, V

V

IN

OUT

= 3.3V, I

OUT

= 2.5A,

Temperature = 0°C to 85°C

t

ON(MIN)

Characteristics graph), V

Max Frequency

= 200ns (85°C from the Typical Performance

= 0.6V, V

D

..

+

33 06

–. .

25 04 06

+

= 0.4V (85°C)

SW

1

•~=

200e-9

750

kkHz

Frequency Hz

()

=

+

OUT D

VV Vt

–

IN SW D ON MIN

+

•

1

()

VV

where VD is the forward voltage drop of the catch diode (D1

Figure 2), V

and t

ON(MIN)

is the voltage drop of the internal switch,

SW

in the minimum on time of the switch, all at

maximum load current.

Table 1. Effi ciency and Size Comparisons for Different R

Output

FREQUENCY RT/SYNC

1.2MHz 20.5k 79.0% 16 1.5μH 22μF 63mm

1.0MHz 26.7k 80.9% 18 2.2μH 47μF 66mm

750kHz 38.3k 81.2% 22 3.3μH 47μF 66mm

500kHz 61.9k 82.0% 24 4.7μH 47μF 66mm

250kHz 133k 83.9% 24 10μH 100μF 172mm

†

V

is defi ned as the highest input voltage that maintains constant output voltage ripple.

IN(MAX)

*Inductor and capacitor values chosen for stability and constant ripple current.

EFFICIENCY

V

= 12V V

VIN1/2

/~( )42 2

R SYNC k Figure

T

Input Voltage Range

Once the switching frequency has been determined, the

input voltage range of the regulator can be determined.

The minimum input voltage is determined by either the

LT3510’s minimum operating voltage of ~2.8V, or by its

Values. 3.3V

RT/SYNC

†

IN(MAX)

L* C* L + C AREA

2

2

2

2

2

3510fc

11

LT3510

APPLICATIONS INFORMATION

maximum duty cycle. The duty cycle is the fraction of time

that the internal switch is on during a clock cycle. Unlike

most fi xed frequency regulators, the LT3510 will not switch

off at the end of each clock cycle if there is suffi cient voltage across the boost capacitor (C3 in Figure 1) to fully

saturate the output switch. Forced switch off for a minimum

time will only occur at the end of a clock cycle when the

boost capacitor needs to be recharged. This operation

has the same effect as lowering the clock frequency for a

fi xed off time, resulting in a higher duty cycle and lower

minimum input voltage. The resultant duty cycle depends

on the charging times of the boost capacitor and can be

approximated by the following equation:

DC

MAX

=

1

+11

B

where B is 2A divided by the typical boost current from

the Electrical Characteristics.

This leads to a minimum input voltage of:

VV

+

V

IN MIN

OUT D

DC

MAX

VV

–=

+

DSW()

6.0

V

= 3.3V

OUT

5.5

5.0

4.5

VOLTAGE (V)

4.0

3.5

3.0

1

Figure 3. Minimum Input Voltage vs Load Current

START-UP

RUNNING

10 100 1000 10000

CURRENT (mA)

3510 F03

Example:

V

OUT

= 3.3V, I

= 1A, Frequency = 1MHz, Temperature

OUT

= 25°C

= 0.1V, B = 40 (from boost characteristics specifi ca-

V

SW

tion), V

DC

MAX

= 0.4V, t

D

=

1

ON(MIN)

1

+

1

=

98

= 200ns

%

40

where VSW is the voltage drop of the internal switch.

Figure 3 shows a typical graph of minimum input voltage

vs load current for the 3.3V and 1.8V application on the

fi rst page of this data sheet. The maximum input voltage

is determined by the absolute maximum ratings of the V

IN

and BST pins and by the frequency and minimum duty

cycle. The minimum duty cycle is defi ned as :

DC

MIN

= t

ON(MIN)

• Frequency

Maximum input voltage as:

VV

+

OUT D

DC

MIN

VV

–=

+

DSW()

V

IN MAX

Note that the LT3510 will regulate if the input voltage is

taken above the calculated maximum voltage as long as

maximum ratings of the V

and BST pins are not violated.

IN

However operation in this region of input voltage will exhibit

pulse skipping behavior.

+

33 04

V

IN MIN

()

DC t f

MIN MIN ON

V

()

IN MAX

..

=

==

33

=

098

.

()

004

+

.

0 200

.

04 0

–. .

0 200

•.

.

04 01 182

–. . .+= V

11348

+

=

V

.

Inductor Selection and Maximum Output Current

A good fi rst choice for the inductor value is:

–•

VV V

()

IN OUT OUT

L

=

•

Vf

IN

where f is frequency in MHz and L is in μH.

With this value the maximum load current will be ~2A,

independent of input voltage. The inductor’s RMS current

rating must be greater than your maximum load current

12

3510fc

APPLICATIONS INFORMATION

LT3510

and its saturation current should be about 30% higher. To

keep effi ciency high, the series resistance (DCR) should

be less than 0.05Ω.

For applications with a duty cycle of about 50%, the inductor value should be chosen to obtain an inductor ripple

current less than 40% of peak switch current.

Of course, such a simple design guide will not always

result in the optimum inductor for your application. A

larger value provides a slightly higher maximum load

current, and will reduce the output voltage ripple. If your

load is lower than 2A, then you can decrease the value of

the inductor and operate with higher ripple current. This

allows you to use a physically smaller inductor, or one

with a lower DCR resulting in higher effi ciency.

The current in the inductor is a triangle wave with an

average value equal to the load current. The peak switch

current is equal to the output current plus half the peak-topeak inductor ripple current. The LT3510 limits its switch

current in order to protect itself and the system from

overload faults. Therefore, the maximum output current

that the LT3510 will deliver depends on the current limit,

the inductor value, switch frequency, and the input and

output voltages. The inductor is chosen based on output

current requirements, output voltage ripple requirements,

size restrictions and effi ciency goals.

2.5A over the entire duty cycle range. The maximum output

current is a function of the chosen inductor value:

II

ΔΔ

II

OUT MAX LIM

()

LL

–.–==

25

2

2

If the inductor value is chosen so that the ripple current

is small, then the available output current will be near the

switch current limit.

One approach to choosing the inductor is to start with the

simple rule given above, look at the available inductors

and choose one to meet cost or space goals. Then use

these equations to check that the LT3510 will be able to

deliver the required output current. Note again that these

equations assume that the inductor current is continuous.

Discontinuous operation occurs when I

/2 as calculated above.

I

L

is less than

OUT

Figure 4 illustrates the inductance value needed for a 3.3V

output with a maximum load capability of 2A. Referring

to Figure 4, an inductor value between 3.3μH and 4.7μH

will be suffi cient for a 15V input voltage and a switch

frequency of 750kHz. There are several graphs in the

Typical Performance Characteristics section of this data

sheet that show inductor selection as a function of input

voltage and switch frequency for several popular output

voltages and output ripple currents. Also, low inductance

When the switch is off, the inductor sees the output voltage plus the catch diode drop. This gives the peak-to-peak

ripple current in the inductor:

1–

DC V V

()

ΔI

=

L

+

()

OUT D

•

Lf

where f is the switching frequency of the LT3510 and L

is the value of the inductor. The peak inductor and switch

current is:

I

Δ

III

SW PK

==+

()

LPK OUT

L

2

To maintain output regulation, this peak current must be

. I

less than the LT3510’s switch current limit I

LIM

LIM

is

1500

L = 2.2μH

1250

1000

750

FREQUENCY (kHz)

500

250

10

Figure 4. Inductor Values for 2A Maximum Load Current

vs Frequency and Input Voltage

15 17.5 20

12.5

INPUT VOLTAGE (V)

L = 3.3μH

L = 4.7μH

V

= 5V

OUT

I

RIPPLE

L = 6.8μH

L = 10μH

22.5 25

= 1A

3510 F04

3510fc

13

LT3510

APPLICATIONS INFORMATION

may result in discontinuous mode operation, which is

okay, but further reduces maximum load current. For

details of maximum output current and discontinuous

mode operation, see Linear Technology Application Note

44. Finally, for duty cycles greater than 50% (V

> 0.5), there is a minimum inductance required to avoid

subharmonic oscillations. See Application Note 19 for

more information.

Input Capacitor Selection

Bypass the inputs of the LT3510 circuit with a 4.7μF or

higher ceramic capacitor of X7R or X5R type. A lower

value or a less expensive Y5V type can be used if there

is additional bypassing provided by bulk electrolytic or

tantalum capacitors. The following paragraphs describe

the input capacitor considerations in more detail.

Step-down regulators draw current from the input supply in

pulses with very fast rise and fall times. The input capacitor is required to reduce the resulting voltage ripple at the

LT3510 and to force this very high frequency switching

current into a tight local loop, minimizing EMI. The input

capacitor must have low impedance at the switching frequency to do this effectively, and it must have an adequate

ripple current rating. With two switchers operating at the

same frequency but with different phases and duty cycles,

calculating the input capacitor RMS current is not simple.

However, a conservative value is the RMS input current for

the channel that is delivering most power (V

This is given by:

I

CIN RMS

()

IV VV

OUT OUT IN OUT

=

•–

()

V

IN

OUT/VIN

• I

OUT

I

OUT

<

2

OUT

).

ments of the input capacitor. Determine the worst-case

condition for input ripple current and then size the input

capacitor such that it reduces input voltage ripple to an

acceptable level. Typical values for input capacitors run

from 10μF at low frequencies to 2.2μF at higher frequencies.

The combination of small size and low impedance (low

equivalent series resistance or ESR) of ceramic capacitors

make them the preferred choice. The low ESR results in

very low voltage ripple and the capacitors can handle plenty

of ripple current. They are also comparatively robust and

can be used in this application at their rated voltage. X5R

and X7R types are stable over temperature and applied

voltage, and give dependable service. Other types (Y5V and

Z5U) have very large temperature and voltage coeffi cients

of capacitance, so they may have only a small fraction of

their nominal capacitance in your application. While they

will still handle the RMS ripple current, the input voltage

ripple may become fairly large, and the ripple current may

end up fl owing from your input supply or from other bypass capacitors in your system, as opposed to being fully

sourced from the local input capacitor. An alternative to a

high value ceramic capacitor is a lower value along with

a larger electrolytic capacitor, for example a 1μF ceramic

capacitor in parallel with a low ESR tantalum capacitor.

For the electrolytic capacitor, a value larger than 10μF will

be required to meet the ESR and ripple current requirements. Because the input capacitor is likely to see high

surge currents when the input source is applied, tantalum

capacitors should be surge rated. The manufacturer may

also recommend operation below the rated voltage of the

capacitor. Be sure to place the 1μF ceramic as close as

possible to the V

noise immunity.

and GND pins on the IC for optimal

IN

and is largest when VIN = 2V

the second, lower power channel draws input current,

the input capacitor’s RMS current actually decreases as

the out-of-phase current cancels the current drawn by the

higher power channel. Considering that the maximum load

current from a single channel is ~2A, RMS ripple current

will always be less than 1A.

The frequency, VIN to V

rent requirement of the LT3510 along with the input supply

source impedance, determine the energy storage require-

ratio, and maximum load cur-

OUT

(50% duty cycle). As

OUT

14

When the LT3510’s input supplies are operated at different

input voltages, an input capacitor sized for that channel

should be placed as close as possible to the respective

pins.

V

IN

A fi nal caution regarding the use of ceramic capacitors

at the input. A ceramic input capacitor can combine with

stray inductance to form a resonant tank circuit. If power

is applied quickly (for example by plugging the circuit

into a live power source) this tank can ring, doubling the

input voltage and damaging the LT3510. The solution is to

3510fc

APPLICATIONS INFORMATION

LT3510

either clamp the input voltage or dampen the tank circuit

by adding a lossy capacitor in parallel with the ceramic

capacitor. For details, see Application Note 88.

Output Capacitor Selection

Typically step-down regulators are easily compensated with

an output crossover frequency that is 1/10 of the switching frequency. This means that the time that the output

capacitor must supply the output load during a transient

step is ~2 or 3 switching periods. With an allowable 5%

drop in output voltage during the step, a good starting

value for the output capacitor can be expressed by:

C

VOUT

Max Load Step

=

Frequency V

•. •005

OUT

Example:

= 3.3V, Frequency = 1MHz, Max Load Step = 2A

V

OUT

C

==

VOUT

eV

16 005 33

2

•. •.

12

F

μ

The calculated value is only a suggested starting value.

Increase the value if transient response needs improvement

or reduce the capacitance if size is a priority.

The output capacitor fi lters the inductor current to generate

an output with low voltage ripple. It also stores energy in

order to satisfy transient loads and to stabilize the LT3510’s

control loop. The switching frequency of the LT3510 determines the value of output capacitance required. Also, the

current mode control loop doesn’t require the presence

of output capacitor series resistance (ESR). For these

reasons, you are free to use ceramic capacitors to achieve

very low output ripple and small circuit size.

Estimate output ripple with the following equations:

V

RIPPLE

= ΔIL/(8f C

) for ceramic capacitors,

OUT

and

V

= ΔIL ESR for electrolytic capacitors (tantalum

RIPPLE

and aluminum)

where ΔI

is the peak-to-peak ripple current in the

L

inductor.

The RMS content of this ripple is very low, and the RMS

current rating of the output capacitor is usually not of

concern.

Another constraint on the output capacitor is that it must

have greater energy storage than the inductor; if the stored

energy in the inductor is transferred to the output, you

would like the resulting voltage step to be small compared

to the regulation voltage. For a 5% overshoot, this requirement becomes:

I

LIM

OUT

2

⎞

⎟

⎠

CL

⎛

>

10

OUT

⎜

V

⎝

Finally, there must be enough capacitance for good transient

performance. The last equation gives a good starting point.

Alternatively, you can start with one of the designs in this

data sheet and experiment to get the desired performance.

This topic is covered more thoroughly in the section on

loop compensation.

The high performance (low ESR), small size and robustness

of ceramic capacitors make them the preferred type for

LT3510 applications. However, all ceramic capacitors are

not the same. As mentioned above, many of the high value

capacitors use poor dielectrics with high temperature and

voltage coeffi cients. In particular, Y5V and Z5U types lose

a large fraction of their capacitance with applied voltage

and temperature extremes. Because the loop stability and

transient response depend on the value of C

, you may

OUT

not be able to tolerate this loss. Use X7R and X5R types.

You can also use electrolytic capacitors. The ESRs of most

aluminum electrolytics are too large to deliver low output

ripple. Tantalum and newer, lower ESR organic electrolytic

capacitors intended for power supply use, are suitable

and the manufacturers will specify the ESR. The choice of

capacitor value will be based on the ESR required for low

ripple. Because the volume of the capacitor determines

its ESR, both the size and the value will be larger than a

ceramic capacitor that would give you similar ripple performance. One benefi t is that the larger capacitance may

give better transient response for large changes in load

current. Table 2 lists several capacitor vendors.

3510fc

15

LT3510

APPLICATIONS INFORMATION

Table 2

VENDOR TYPE SERIES

Taiyo Yuden Ceramic X5R, X7R

AVX Ceramic X5R, X7R

Tantalum

Kemet Tantalum

TA Organic

AL Organic

Sanyo TA/AL Organic POSCAP

Panasonic AL Organic SP CAP

TDK Ceramic X5R, X7R

T491, T494, T495

T520

A700

Catch Diode

The diode D1 conducts current only during switch off

time. Use a Schottky diode to limit forward voltage drop to

increase effi ciency. The Schottky diode must have a peak

reverse voltage that is equal to regulator input voltage and

sized for average forward current in normal operation.

Average forward current can be calculated from:

I

OUT

V

VV

•–=

()

IN

IN OUT()

I

D AVG

The only reason to consider a larger diode is the worstcase condition of a high input voltage and shorted output.

With a shorted condition, diode current will increase to a

typical value of 3A, determined by the peak switch current

limit of the LT3510. This is safe for short periods of time,

but it would be prudent to check with the diode manufacturer if continuous operation under these conditions

can be tolerated.

BST Pin Considerations

The capacitor and diode tied to the BST pin generate

a voltage that is higher than the input voltage. In most

cases a 0.47μF capacitor and fast switching diode (such

as the CMDSH-3 or FMMD914) will work well. Almost

any type of fi lm or ceramic capacitor is suitable, but the

ESR should be <1Ω to ensure it can be fully recharged

during the off time of the switch. The capacitor value can

be approximated by:

IDC

C

=

BST

OUT MAX

•– •

BV V f

()

OUT BST MIN

•

()

()

where I

V

BST(MIN)

OUT(MAX)

is the minimum boost voltage to fully saturate

is the maximum load current, and

the switch.

Figure 5 shows four ways to arrange the boost circuit. The

BST pin must be more than 1.4V above the SW pin for

full effi ciency. Generally, for outputs of 3.3V and higher

the standard circuit (Figure 5a) is the best. For outputs

between 2.8V and 3.3V, replace the D2 with a small Schottky

diode such as the PMEG4005. For lower output voltages

the boost diode can be tied to the input (Figure 5b). The

circuit in Figure 5a is more effi cient because the BST

pin current comes from a lower voltage source. Figure

5c shows the boost voltage source from available DC

sources that are greater than 3V. The highest effi ciency is

attained by choosing the lowest boost voltage above 3V.

For example, if you are generating 3.3V and 1.8V and the

3.3V is on whenever the 1.8V is on, the 1.8V boost diode

can be connected to the 3.3V output. In any case, you

must also be sure that the maximum voltage at the BST

pin is less than the maximum specifi ed in the Absolute

Maximum Ratings section.

The boost circuit can also run directly from a DC voltage

that is higher than the input voltage by more than 3V, as

in Figure 5d. The diode is used to prevent damage to the

LT3510 in case V

is held low while VIN is present. The

X

circuit saves several components (both BST pins can be

tied to D2). However, effi ciency may be lower and dissipation in the LT3510 may be higher. Also, if V

is absent, the

X

LT3510 will still attempt to regulate the output, but will do

so with very low effi ciency and high dissipation because

the switch will not be able to saturate, dropping 1.5V to

2V in conduction.

The minimum input voltage of an LT3510 application is

limited by the minimum operating voltage (<3V) and by

the maximum duty cycle as outlined above. For proper

start-up, the minimum input voltage is also limited by

the boost circuit. If the input voltage is ramped slowly, or

the LT3510 is turned on with its SS pin when the output

is already in regulation, then the boost capacitor may not

be fully charged. Because the boost capacitor is charged

with the energy stored in the inductor, the circuit will rely

on some minimum load current to get the boost circuit

running properly. This minimum load will depend on

3510fc

16

(5d)(5c)

APPLICATIONS INFORMATION

LT3510

D2

V

BST

V

BST(MAX)

V

IN

– VSW = V

= VIN+ V

OUT

OUT

BST

GND

SW

IND

V

OUT

V

IN

LT3510

C3

D2

V

OUT

(5a)

= VIN + V

= 3V

D2

BST

V

IN

LT3510

X

X

GND

SW

IND

V

OUT

C3

V

< 3V

OUT

VX = LOWEST V

OR V

> 3V

OUT

V

BST

V

BST(MAX)

V

X(MIN)

IN

V

IN

– VSW = V

Figure 5. BST Pin Considerations

input and output voltages, and on the arrangement of the

boost circuit. The Typical Performance Characteristics

section shows plots of the minimum load current to start

and to run as a function of input voltage for 3.3V and 5V

outputs. In many cases the discharged output capacitor

will present a load to the switcher which will allow it to

start. The plots show the worst-case situation where V

IN

is

ramping very slowly. Use a Schottky diode for the lowest

start-up voltage.

Frequency Compensation

The LT3510 uses current mode control to regulate the

output. This simplifi es loop compensation. In particular, the

LT3510 does not require the ESR of the output capacitor

for stability so you are free to use ceramic capacitors to

achieve low output ripple and small circuit size.

Frequency compensation is provided by the components

tied to the V

pin. Generally a capacitor and a resistor in

C

series to ground determine loop gain. In addition, there

is a lower value capacitor in parallel. This capacitor is not

C3

V

< 3V

OUT

V

V

BST

V

BST(MAX)

IN

– VSW = V

= 2 •V

BST

GND

SW

IND

V

OUT

V

IN

LT3510

IN

IN

(5b)

D2

VX > VIN + 3V

BST

V

IN

V

– VSW = V

BST

V

BST(MAX)

V

X(MIN)

= V

= VIN + 3V

V

IN

LT3510

X

X

GND

SW

IND

V

V

OUT

3510 F05

OUT

< 3V

part of the loop compensation but is used to fi lter noise

at the switching frequency.

Loop compensation determines the stability and transient

performance. Designing the compensation network is a bit

complicated and the best values depend on the application

and in particular the type of output capacitor. A practical

approach is to start with one of the circuits in this data

sheet that is similar to your application and tune the compensation network to optimize the performance. Stability

should then be checked across all operating conditions,

including load current, input voltage and temperature.

The LT1375 data sheet contains a more thorough discussion of loop compensation and describes how to test the

stability using a transient load.

Figure 6 shows an equivalent circuit for the LT3510 control

loop. The error amp is a transconductance amplifi er with

fi nite output impedance. The power section, consisting of

the modulator, power switch and inductor, is modeled as

a transconductance amplifi er generating an output current proportional to the voltage at the V

pin. Note that

C

3510fc

17

LT3510

APPLICATIONS INFORMATION

LT3510

CURRENT MODE

POWER STAGE

= 2.2mho

g

m

V

C

R

C

C

C

3.6M

C

F

Figure 6. Model for Loop Response

= 275μmho

g

m

ERROR

AMP

SW

C

R1 ESR

–

+

FB

+

0.8V

R2

PL

TANTALUM

OR

POLYMER

OUTPUT

C1 C1

CERAMIC

3510 F06

the output capacitor integrates this current, and that the

capacitor on the V

pin (CC) integrates the error ampli-

C

fi er output current, resulting in two poles in the loop. In

most cases a zero is required and comes from either the

output capacitor ESR or from a resistor in series with C

.

C

This simple model works well as long as the value of the

inductor is not too high and the loop crossover frequency

is much lower than the switching frequency. A phase lead

capacitor (C

) across the feedback divider may improve

PL

the transient response.

Synchronization

/SYNC pin can be used to synchronize the regulators

The R

T

to an external clock source. Driving the RT/SYNC resistor

with a clock source triggers the synchronization detection

circuitry. Once synchronization is detected, the rising edge

of SW1 will be synchronized to the rising edge of the

RT/SYNC pin signal. An AGC loop will adjust the internal

oscillators to maintain a 180 degree phase between SW1

and SW2, and also adjust slope compensation to avoid

subharmonic oscillation.

The synchronizing clock signal input to the LT3510 must

have a frequency between 250kHz and 1.5MHz, a duty

cycle between 20% and 80%, a low state below 0.5V and

a high state above 1.6V. Synchronization signals outside

of these parameters will cause erratic switching behavior.

The RT/SYNC resistor should be set such that the free

running frequency ((V

RT/SYNC

– V

SYNCLO

)/R

RT/SYNC

) is

approximately equal to the synchronization frequency. If

the synchronization signal is halted, the synchronization

detection circuitry will timeout in typically 10μs at which

V

OUT1

LT3510 SYNCHRONIZATION

PG1

RT/SYNC

Figure 7. Synchronous Signal Powered from Regulator’s Output

V

CC

CIRCUITRY

CLK

3510 F07

time the LT3510 reverts to the free-running frequency

based on the current through R

/SYNC. If the RT/SYNC

T

resistor is held above 2V at any time, switching will be

disabled.

If the synchronization signal is not present during regulator start-up (for example, the synchronization circuitry is

powered from the regulator output) the R

/SYNC pin must

T

see an equivalent resistance to ground between 15.4k and

133k until the synchronization circuitry is active for proper

start-up operation.

If the synchronization signal powers up in an undetermined

state (V

, VOH, Hi-Z), connect the synchronization clock

OL

to the LT3510 as shown in Figure 7. The circuit as shown

will isolate the synchronization signal when the output

voltage is below 90% of the regulated output. The LT3510

will start-up with a switching frequency determined by the

resistor from the R

/SYNC pin to ground.

T

If the synchronization signal powers up in a low impedance

state (V

), connect a resistor between the RT/SYNC pin

OL

and the synchronizing clock. The equivalent resistance

seen from the R

/SYNC pin to ground will set the start-up

T

frequency.

3510fc

18

APPLICATIONS INFORMATION

LT3510

If the synchronization signal powers up in a high impedance

state (Hi-Z), connect a resistor from the R

ground. The equivalent resistance seen from the R

/SYNC pin to

T

/SYNC

T

pin to ground will set the start-up frequency.

If the synchronization signal changes between high and

low impedance states during power up (V

, Hi-Z), connect

OL

the synchronization circuitry to the LT3510 as shown in

the Typical Applications section. This will allow the LT3510

to start-up with a switching frequency determined by the

equivalent resistance from the R

/SYNC pin to ground.

T

Shutdown and Undervoltage Lockout

Figure 8 shows how to add undervoltage lockout (UVLO)

to the LT3510. Typically, UVLO is used in situations where

the input supply is current limited, or has a relatively high

source resistance. A switching regulator draws constant

power from the source, so source current increases as

source voltage drops. This looks like a negative resistance

load to the source and can cause the source to current limit

or latch low under low source voltage conditions. UVLO

prevents the regulator from operating at source voltages

where these problems might occur.

An internal comparator will force the part into shutdown

below the minimum V

of 2.8V. This feature can be

IN1

used to prevent excessive discharge of battery-operated

systems.

Since V

not monitored, care must be taken to insure that V

supplies the output stage of channel 2 and is

IN2

IN2

is

present before channel 2 is allowed to switch.

If an adjustable UVLO threshold is required, the SHDN

pin can be used. The threshold voltage of the SHDN

pin comparator is 1.28V. A 3μA internal current source

LT3510

V

V

> 2.8V

IN1

V

OR V

IN1

IN2

IN1

1.28V

–

+

INTERNAL

REGULATOR

3510 F08

+

7μA

3μA

R1

SHDN

R2C1

defaults the open-pin condition to be operating (see Typical

Performance Characteristics). Current hysteresis is added

above the SHDN threshold. This can be used to set voltage

hysteresis of the UVLO using the following:

VV

–

HL

R

1

=

R

2

A

7

μ

128

–.

H

128

R

1

.

A

3

+

μ

=

V

VH = Turn-on threshold

= Turn-off threshold

V

L

Example: switching should not start until the input is above

4.75V and is to stop if the input falls below 3.75V.

= 4.75V

V

H

= 3.75V

V

L

475 375

R

R

.–.

1

=≅

2

=

A

7

μ

128

.

475 128

.–.

k

143

+

143

3

μAA

k

k≅ 47

Keep the connections from the resistors to the SHDN

pin short and make sure that the interplane or surface

capacitance to switching nodes is minimized. If high resistor values are used, the SHDN pin should be bypassed

with a 1nF capacitor to prevent coupling problems from

the switch node.

Soft-Start

The output of the LT3510 regulates to the lowest voltage

present at either the SS pin or an internal 0.8V reference.

A capacitor from the SS pin to ground is charged by an

internal 3.25μA current source resulting in a linear output

ramp from 0V to the regulated output whose duration is

given by:

CV

•..08

t

RAMP

=

SS

325μ

A

Figure 8. Undervoltage Lockout

3510fc

19

LT3510

APPLICATIONS INFORMATION

At power-up, a reset signal sets the soft-start latch and

discharges both SS pins to approximately 0V to ensure

proper start-up. When both SS pins are fully discharged

the latch is reset and the internal 3.25μA current source

starts to charge the SS pin.

When the SS pin voltage is below 50mV, the VC pin is pulled

low which disables switching. This allows the SS pin to be

used as an individual shutdown for each channel.

As the SS pin voltage rises above 50mV, the VC pin is released and the output is regulated to the SS voltage. When

the SS pin voltage exceeds the internal 0.8V reference, the

output is regulated to the reference. The SS pin voltage

will continue to rise until it is clamped at 2V.

In the event of a V

undervoltage lockout, the SHDN

IN1

pin driven below 1.28V, or the internal die temperature

exceeding its maximum rating during normal operation, the

soft-start latch is set, triggering a start-up sequence.

In addition, if the load exceeds the maximum output switch

current, the output will start to drop causing the VC pin

clamp to be activated. As long as the VC pin is clamped,

the SS pin will be discharged. As a result, the output will

be regulated to the highest voltage that the maximum

output current can support. For example, if a 6V output

is loaded by 1Ω the SS pin will drop to 0.4V, regulating

the output at 3V ( 3A • 1Ω ). Once the overload condition

is removed, the output will soft-start from the temporary

voltage level to the normal regulation point.

Since the SS pin is clamped at 2V and has to discharge

to 0.8V before taking control of regulation, momentary

overload conditions will be tolerated without a soft-start

recovery. The typical time before the SS pin takes control

is:

•.=12

CV

t

SS CONTROL

()

SS

700μ

A

Power Good Indicators

The PG pin is the open-collector output of an internal

comparator. The comparator compares the FB pin voltage

to 90% of the reference voltage with 30mV of hysteresis.

The PG pin has a sink capability of 800μA when the FB pin

is below the threshold and can withstand 25V when the

threshold is exceeded. The PG pin is active (sink capability

is reduced in shutdown and undervoltage lockout mode)

as long as the V

pin voltage exceeds 1V.

IN1

Output Tracking/Sequencing

Complex output tracking and sequencing between channels can be implemented using the LT3510’s SS and PG

pins. Figure 9 shows several confi gurations for output

tracking/sequencing for a 3.3V and 1.8V application.

Independent soft-start for each channel is shown in

Figure 9a. The output ramp time for each channel is set

by the soft-start capacitor as described in the soft-start

section.

Ratiometric tracking is achieved in Figure 9b by connecting

both SS pins together. In this confi guration, the SS pin

source current is doubled (6.5μA) which must be taken

into account when calculating the output rise time.

By connecting a feedback network from V

pin with the same ratio that sets V

voltage, absolute

OUT2

to the SS2

OUT1

tracking shown in Figure 9c is implemented. The minimum

value of the top feedback resistor (R1) should be set such

that the SS pin can be driven all the way to ground with

700μA of sink current when V

In addition, a small V

OUT2

is at its regulated voltage.

OUT1

voltage offset will be present

due to the SS2 3.25μA source current. This offset can be

corrected for by slightly reducing the value of R2.

Figure 9d illustrates output sequencing. When V

OUT1

is

within 10% of its regulated voltage, PG1 releases the SS2

soft-start pin allowing V