DESIGN FEATURES L

V

IN1

BOOST1 UVLO

OVLO

BOOST2

SW2

FB2

V

C2

BIAS

DRIVE

FB4

PGOOD1

PGOOD2

PGOOD3

PGOOD1

PGOOD2

PGOOD3

SW1

FB1

V

C1

TRK/SS1

BOOST3

0.22µF

22µF

100µF

D1

18.7k

680pF

470pF

18.7k

4.7µH

V

OUT1

1.8V

2.4A

V

IN

6V TO 36V

V

OUT3

5V

1.5A

15µH

10µH

V

IN2VIN3VINSW

1k

49.9k

18.2k

100k

V

OUT1

15k

SW3

FB3

V

C3

RT/SYNC TRK/SS4

GND

LT3507

RUN1

RUN2

RUN3

0.22µF

0.22µF

22µF

22µF

D2

D3

24.3k

16.2k

SHDN

680pF

0.01µF

1000pF

53.6k

L1: WÜRTH WE-PD 744 778 9004

L2: WÜRTH WE-PD 744 778 9115

L3: WÜRTH WE-PD 744 778 910

D1, D2, D3: DIODES, INC. B240A

Q1: ON SEMICONDUCTOR NSS30101LT1G

11.5k

11.5k

24.3k

105k

fSW = 450kHz

10.2k

2.2nF

22µF

BAS70

100k 100k

V

OUT2

3.3V

1.3A

V

OUT4

2.5V

0.2A

35.7k

TRK/SS3

TRK/SS2 TRK/SS2

V

OUT2

V

OUT2

CMDSH-4E

CMDSH-4E

CMDSH-4E

15k

18.7k

35.7k

11.5k

TRK/SS2

SYNC SOURCE

POWERED FROM

3.3V OUTPUT, V

OUT2

Q1

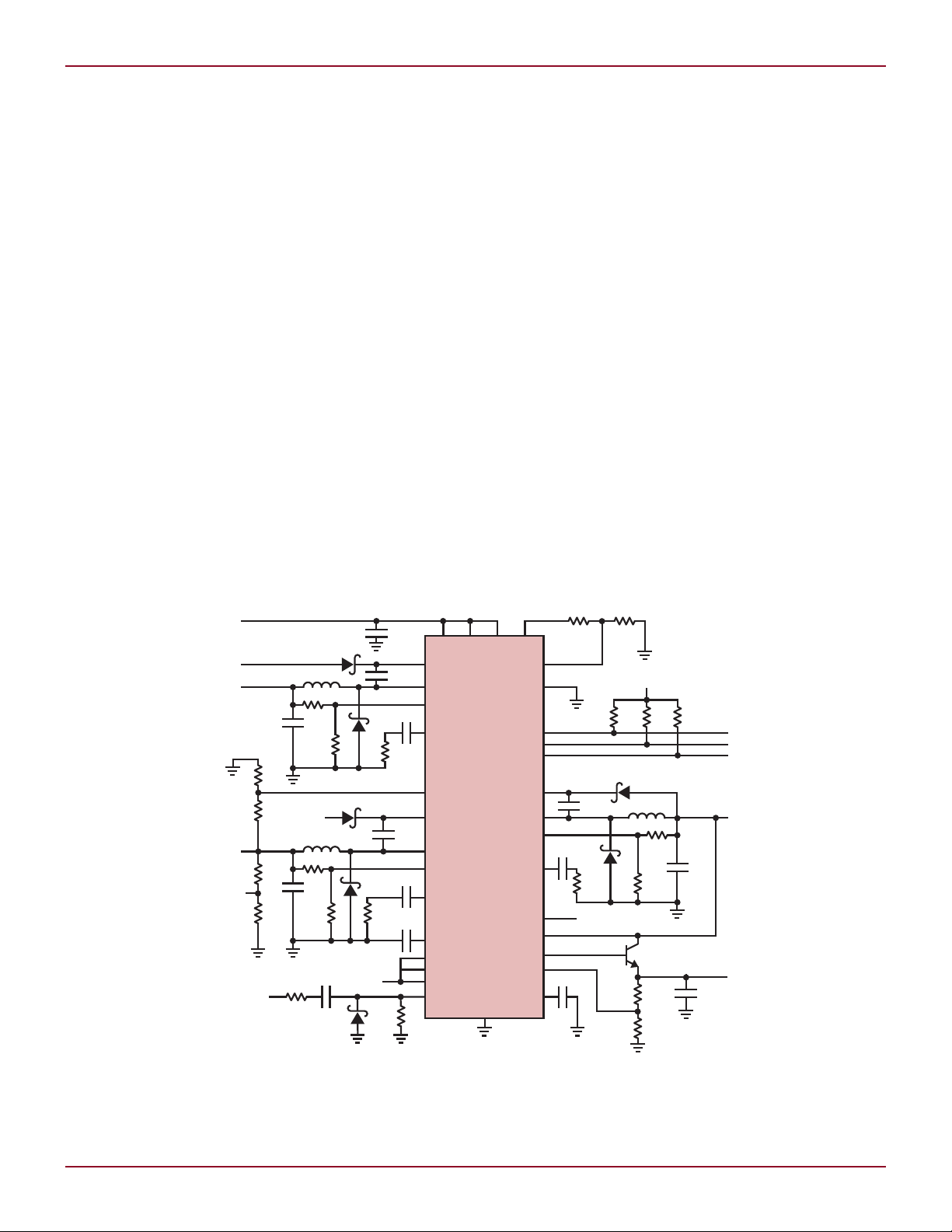

Quad Output Regulator Meets Varied

Demands of Multiple Power Supplies

Introduction

Many modern electronic devices require a number of power domains to

satisfy the needs of a wide variety of devices and subsystems. A power supply

designer’s job would be relatively easy

if the design contraints were limited to

simply providing well-regulated voltages, but power supply requirements

are typically much more complicated.

For example, multiple power rails must

be sequenced and/or track each other

to ensure proper system behavior.

High power sections of the design

are often powered down when not

in use, requiring multiple shutdown

options. Powering analog circuitry

adds the demand for clean, low noise

supplies—no switching transients

or excessive voltage ripple allowed.

And, of course, all supplies must be

generated as efficiently as possible to

minimize power consumption.

The LT3507 meets these requirements by combining three switching

regulators and a low dropout linear

regulator in a compact 5mm × 7mm

QFN package. The switching regulators have internal power switches,

independent input supplies, run and

track/soft-start controls, and power

good indicators. The LDO requires

an external NPN pass transistor and

includes track/soft-start control.

Three Independent

Switching Regulators…

The LT3507 includes three independent, monolithic switching regulators

to achieve a space saving solution.

Channel 1 is capable of providing up

by Michael Nootbaar

to 2.4A of output current. Channels 2

and 3 are each capable of providing up

to 1.6A of output current. Each of the

three switching regulators has its own

input supply pin to the power switch.

The regulators may be operated from

different supplies in order to maximize

system efficiency.

The maximum voltage on any of the

VIN pins is 36V. The LT3507 internal

circuitry is powered from V

requires a minimum operating voltage

for V

voltage for V

V

of 4V. The minimum operating

IN1

powers the internal circuitry, it

IN1

and V

IN2

IN3

must always be at least 4V when any

channel is running, even if Channel 1

is off.

All three regulators use a current mode, c o ns t an t frequency

, which

IN1

is 3V. Since

Linear Technology Magazine • June 2008

Figure 1. The LT3507 in a wide input range, quad output application

25

EFFICIENCY (%)

LOAD CURRENT (A)

2.50

90

50

0.5 1 1.5 2

70

60

80

CHANNEL 3

5V

OUT

CHANNEL 2

3.3V

OUT

CHANNEL 1

1.8V

OUT

VIN = 12V

V

OUT2

20mV/DIV

LDO

V

OUT4

20mV/DIV

2µs/DIV

L DESIGN FEATURES

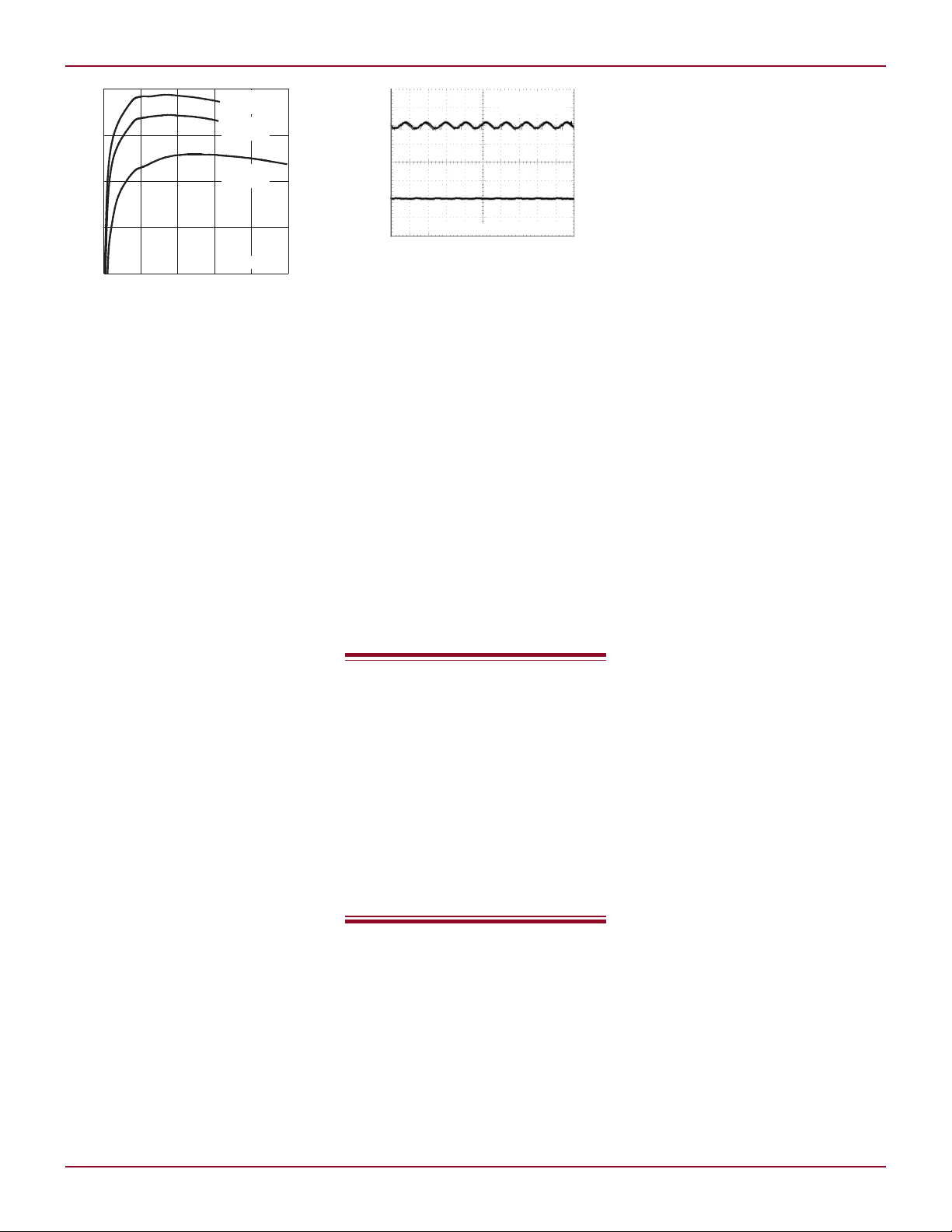

Figure 2. Switching regulator efficiency

architecture, which simplifies loop

compensation. External compensation allows custom tailoring of loop

bandwidth, transient response and

phase margin. The feedback reference

is 0.8V, allowing output voltages as

low as 0.8V.

The regulators share a master oscillator that is resistor programmable

from 250kHz to 2.5MHz, or can be

synchronized to an external frequency

in the same range. Each regulator features frequency foldback in overload

conditions to improve short circuit

tolerance. Channel 1 operates 180° out

of phase with respect to channels 2 and

3 to reduce input current ripple.

…and a Low Dropout

Linear Regulator

The LT3507 also includes an LDO

linear regulator that uses an external

NPN pass transistor to provide up

to 0.5A of output current. The base

drive can supply up to 10mA of base

current to the pass transistor and is

current limited. The LDO is internally

compensated and is stable with output

capacitance of 2.2µF or greater. It uses

the same 0.8V feedback reference as

the switching regulators.

The LDO drive current is drawn

from the BIAS pin if it’s at least 1.5V

higher than the DRIVE pin voltage,

otherwise it’s drawn from V

reduces the power consumption of

the LDO, especially when V

high voltages.

The LDO does not have a separate

RUN pin; it is powered up when any of

the RUN pins are high. The LDO can

be shut down when it is not used by

pulling the FB pin above 1.25V with at

26

. This

IN1

is at

IN1

Figure 3. The LT3507’s built-in

LDO offers a low noise output

least 30µA. If independent control of

the LDO is needed, the LDO output can

be forced to 0V by pulling the TRK/SS4

pin low. If the track or soft-start functions are needed, use an open drain

output in parallel with the track or

soft-start circuitry described below. If

track and soft-start are not necessary,

then a standard CMOS output (from

1.8V to 5V) is sufficient.

Run Control

Each of the switching regulators has

a RUN pin to allow flexibility in shutting off power domains. The RUN pin

The LT3507 includes three

independent, monolithic

switching regulators to

achieve a space saving

solution. Each of the three

switching regulators has its

own input supply pin to the

power switch. The regulators

may be operated from

different supplies in order to

maximize system efficiency.

is a wide range logic input and can be

driven from 1.8V CMOS logic, directly

from VIN (up to 36V), or anywhere in

between. The RUN pin draws a small

amount of current to bring the reference up. This current is about 3µA at

1.8V and 40µA at 36V. The RUN pin

should be pulled low (not left floating)

when the regulator is to be shut down.

When all three RUN pins are pulled

low, the LT3507 goes into a low power

shut down state and draws less than

1µA from the input supply.

Track/Soft-Start Control

Each regulator and the LDO has its

own track/soft-start (TRK/SS) pin.

When this pin is below the 0.8V reference, the regulator forces its feedback

pin to the TRK/SS pin voltage rather

than to the reference voltage. The

TRK/SS pin has a 1.25µA pull-up

current source. The soft-start function

requires a capacitor from the TRK/SS

pin to ground. At start-up, this capacitor is at 0V, which forces the regulator

outputs to 0V. The current source

slowly charges the capacitor voltage

up and the regulator outputs ramp

up proportionally. Once the capacitor

voltage reaches 0.8V, the regulator

locks onto the internal reference instead of the TRK/SS voltage.

The tracking function is achieved

by connecting the slave regulator’s

TRK/SS pin to a resistor divider from

the master regulator output. The

master regulator uses a normal softstart capacitor as described above to

generate the start-up ramp that controls the other regulators. The resistor

divider ratio sets the type of tracking,

either coincident (ratio equal to slave

feedback divider ratio) or ratiometric

(ratio equal to master feedback divider

ratio plus a small offset).

Undervoltage and

Overvoltage Protection

Each switching regulator has its

own input undervoltage shutdown

to prevent the circuit from operating

erratically in undervoltage conditions.

V

shuts down at 4.0V, and because

IN1

it’s the primary input voltage, it turns

off the entire LT3507. V

shut off at 3.0V and only shut off the

switch on the affected channel.

The LT3507 also has a user

programmable undervoltage and

overvoltage lockout. The undervoltage

lockout can protect against pulse

stretching and regulator dropout.

It can also protect the input source

from excessive current since the buck

regulator is a constant power load and

draws more current when the input

source is low. The overvoltage lockout

Linear Technology Magazine • June 2008

and V

IN2

IN3

DESIGN FEATURES L

1V/DIV

V

OUT3

V

OUT2

V

OUT4

V

OUT1

1ms/DIV

Authors can be contacted

at (408) 432-1900

can protect the rectifier diodes from

excessive reverse voltage and can

prevent pulse-skipping by limiting the

minimum duty cycle. Both of these

lockouts shut off all four regulators

when tripped.

These functions are realized with

a pair of built in comparators at

inputs UVLO and OVLO. A resistor

divider from the VINSW pin to each

comparator input sets the trip voltage

and hysteresis. The VINSW pin pulls

up to V

when any RUN pin is pulled

IN1

high, and is open when all three RUN

pins are low. This reduces shutdown

current by disconnecting the resistor

dividers from the input voltage. These

comparators have a 1.2V threshold

and also have 10µA of hysteresis.

The UVLO hysteresis is a current sink

while the OVLO hysteresis is a current

source. UVLO should be connected to

VINSW and OVLO connected to ground

if these functions aren’t used.

Frequency Control

The switching frequency is set by a

single resistor to the RT/SYNC pin.

The value is adjustable from 250kHz

to 2.5MHz. Higher frequencies allow

smaller inductors and capacitors, but

efficiency is lower and the supply has

a smaller allowable range of step-down

ratios due to the minimum on and off

time constraints.

The frequency can also be synchronized to an external clock by

connecting it to the RT/SYNC pin. The

clock source must supply a clock signal

whenever the LT3507 is powered up.

This leads to a dilemma if the clock

source is to be powered from one of the

LT3507 regulators: there is no clock

until the regulator comes up, but the

regulator won’t come up until there’s a

clock! This situation is easily overcome

with a capacitor, a low leakage diode

and a couple of resistors. The capacitor isolates the clock source from the

RT/SYNC pin until the power is up

and the resistor on the RT/SYNC pin

sets the initial clock frequency. The

application in Figure 1 shows how

this is done.

Typical Application

Figure 1 shows a typical LT3507 application. This application allows a

very wide input range, from 6V to 36V.

It generates four outputs: 5V, 3.3V,

2.5V and 1.8V. Efficiencies for three

of the outputs are shown in Figure 2.

The LDO produces a particularly low

noise output at 2.5V, as shown in

Figure 3.

The outputs are set to coincident

tracking using the 5V supply as the

Figure 4. Coincident tracking waveforms

master. But wait, there’s no resistor

divider on the TRK/SS4 pin! It’s no

mistake; the LDO output coincidently

tracks the supply it’s sourced from

(the 3.3V supply in this case) as long

as Q1 is a low V

transistor, such

CESAT

as the NSS30101 used here. Just

remember that this little cheat only

works for coincident tracking. Figure 4

shows the start-up waveforms of the

four outputs.

In this application, the clock is

synchronized to an external source

that is powered from the 3.3V output.

A capacitor isolates the clock until the

3.3V supply is good, and then passes

the clock signal to the RT/SYNC pin.

It should be noted that the LDO can

actually supply up to 0.5A as long as

I

OUT4

+ I

OUT2

≤ 1.5A.

Conclusion

The LT3507 provides a compact

solution for four power supplies. Its

tiny 5mm × 7mm QFN package includes three highly efficient switching

regulators and a low dropout linear

regulator. Just a few small inductors

and ceramic capacitors are needed to

create four high efficiency step-down

regulators. Plenty of options insure

that the LT3507 meets the needs of

a wide variety of multiple output applications.

L

LT5575, continued from page 13

signals as shown in Figure 6. One of

these is a –48dBm CW tone, and the

other is a –48dBm WCDMA carrier.

These are offset in frequency so that

the resulting 3rd order product appears centered about DC. Compute the

intermodulation product generated in

the I/Q demodulator:

q

RF gain preceding LT5575: 20dB

q

Signals entering LT5575: –28dBm

q

LT5575 IIP3, 2-tone: 22.6dBm

q

LT5575 a3: 0.0244

A MATLAB simulation performed

using a pseudo-random channel pre-

Linear Technology Magazine • June 2008

dicts distortion at LT5575 output of

–135.8dBm. This result agrees well

with the equation 8, which predicts a

distortion power of –135.7dBm.

Refer this signal back to the receiver

input:

q

RF gain preceding LT5575: 20dB

q

Equivalent interference level at

Rx input: –155.8dBm

q

Thermal noise at receiver input:

–101.2dBm

The equivalent interference in this

case is 54.6dB below the thermal noise

at the receiver input. The resulting

degradation in sensitivity is <0.1dB,

so the receiver easily meets the specification of –121dBm.

Conclusion

The calculations given here using the

LT5575 I/Q demodulator show that a

WCDMA wide area basestation receiver

can be successfully implemented using

a direct conversion architecture. The

high 2nd order linearity and input 1dB

compression point of the LT5575 are

critical to meeting the performance

requirements of such a design.

L

27

Loading...

Loading...