FEATURES

LT3486

Dual 1.3A White LED

Step-Up Converters with

Wide Dimming

U

DESCRIPTIO

■

Wide (1000:1) PWM Dimming Range with No

ColorShift

■

Independent Dimming and Shutdown Control of the

LED Drivers

■

Drives Up to 16 White LEDs at 25mA (8 per Driver)

from a Single Li-Ion Cell

■

Drives Up to 16 White LEDs at 100mA (8 per Driver)

from 12V Supply

■

±3% LED Current Programming Accuracy

■

Open LED Protection: 36V Clamp Voltage

■

Fixed Frequency Operation: Up to 2.5MHz

■

Wide Input Voltage Range: 2.5V to 24V

■

Low Shutdown Current: I

■

Overtemperature Protection

■

Available in (5mm × 3mm × 0.75mm) 16-Pin DFN

CC

< 1µA

and 16-Pin Thermally Enhanced TSSOP Packages

U

APPLICATIO S

■

Notebook PC Display

■

LED Camera Light for Cell Phones

■

Car Dashboard Lighting

■

Avionics Displays

The LT®3486 is a dual step-up DC/DC converter

specifi cally designed to drive up to 16 White LEDs (8 in

series per converter) at constant current from a single

Li-Ion cell. Series connection of the LEDs provides identical LED currents resulting in uniform brightness. The two

independent converters are capable of driving asymmetric

LED strings.

The dimming of the two LED strings can be controlled

independently via the respective CTRL pins. An internal

dimming system allows the dimming range to be extended

up to 1000:1 by feeding a PWM signal to the respective

PWM pins. The LT3486 operating frequency can be set with

an external resistor over a 200kHz to 2.5MHz range. A low

200mV feedback voltage (±3% accuracy) minimizes power

loss in the current setting resistor for better effi ciency.

Additional features include output voltage limiting when

LEDs are disconnected and overtemperature protection.

The LT3486 is available in a space saving 16-pin DFN

(5mm × 3mm × 0.75mm) and 16-pin thermally enhanced

TSSOP packages.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

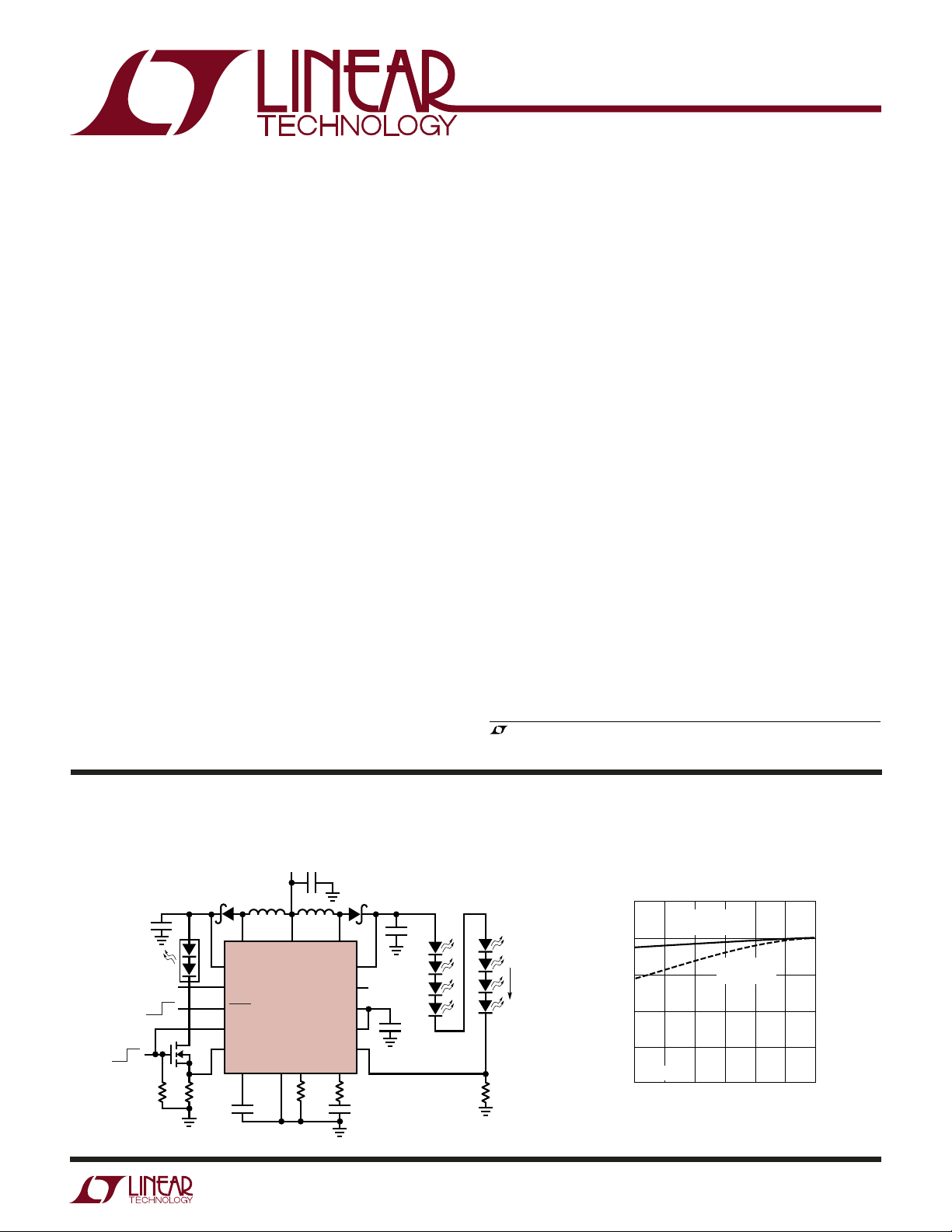

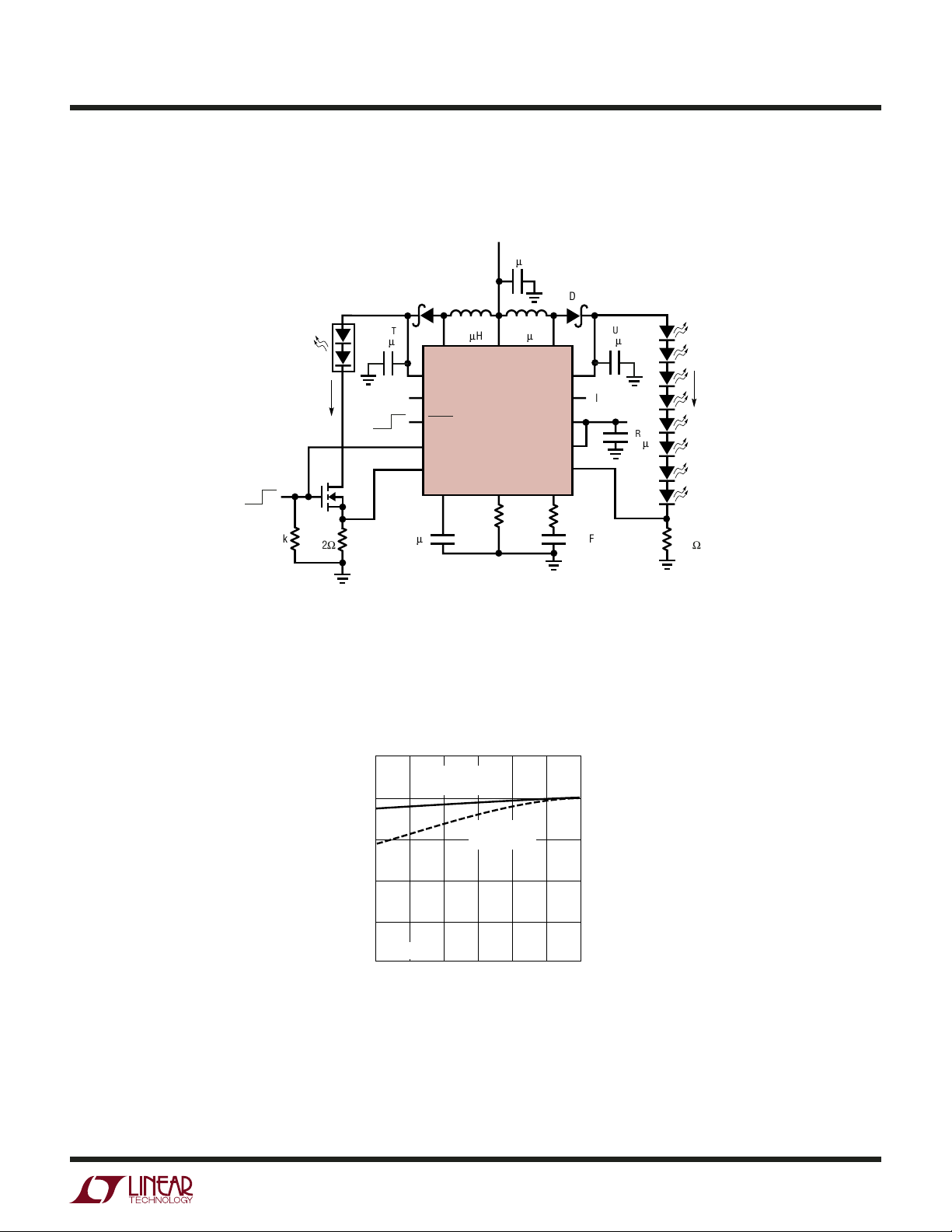

TYPICAL APPLICATIO

Li-Ion Powered Driver for Camera Flash and LCD Backlighting

V

IN

3V TO 4.2V

2.2µF

AOT3218

OFF ON

LED1

DIMMING 1

OFF ON

100k

R

FB1

0.62Ω

L1

10µHL210µH

SW1 SW2

OVP1

CTRL1

SHDN

PWM1

FB1

V

V

IN

LT3486

C1

0.1µF

RTGND

10µF

63.4k

U

CTRL2

PWM2

OVP2

REF

FB2

V

C2

2.8k

4.7nF

DIMMING 2

2.2µF

0.1µF

R

FB2

8.06Ω

3486 TA01a

8 LEDs

25mA

90

85

80

75

EFFICIENCY (%)

70

8 LEDS/25mA

65

3

Effi ciency vs V

MOVIE MODE

= 175mA

I

LED1

I

3.4 3.6 3.8

3.2

VIN (V)

FLASH MODE

= 320mA

LED1

IN

4 4.2

3486 TA01b

3486fa

1

LT3486

WW

W

ABSOLUTE AXI U RATI GS

U

(Note 1)

Input Voltage (VIN) ...................................................25V

⎯S⎯H⎯D⎯

N Voltage ..........................................................25V

SW1, SW2 Voltages .................................................40V

OVP1, OVP2 Voltages ...............................................40V

CTRL1, CTRL2 Voltages ...........................................10V

PWM1, PWM2 Voltages ...........................................10V

FB1, FB2 Voltages .....................................................10V

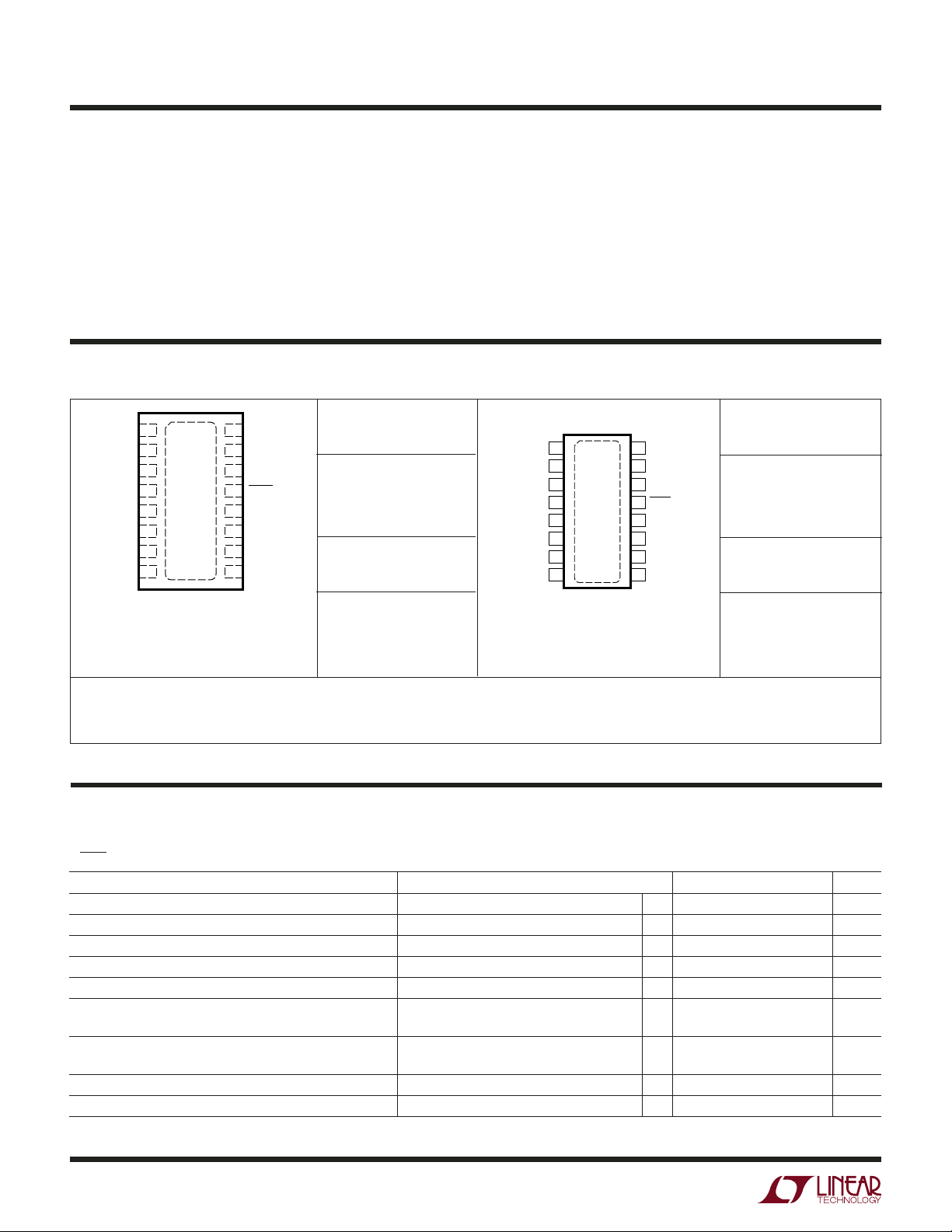

UUW

FOR ATIOPACKAGE/ORDER I

SW1

1

V

2

IN

OVP1

3

R

4

T

V

5

C1

FB1

6

CTRL1

7

PWM1

8

16-LEAD (5mm × 3mm) PLASTIC DFN

T

JMAX

DHC PACKAGE

EXPOSED PAD (PIN 17) IS GND

MUST BE SOLDERED TO PCB

= 125°C, θJA = 43°C/W, θJC = 4°C/W

16

SW2

15

REF

14

OVP2

13

17

SHDN

12

V

FB2

11

CTRL2

10

PWM2

9

C2

ORDER PART

NUMBER

LT3486EDHC

DHC PART

MARKING

3486

Operating Temperature Range (Note 2) ...–40°C to 85°C

Storage Temperature Range

DFN ...................................................– 65°C to 125°C

TSSOP ............................................... –65°C to 150°C

Maximum Junction Temperature .......................... 125°C

Lead Temperature (Soldering, 10sec, TSSOP) ...... 300°C

TOP VIEW

1

SW1

2

V

IN

3

OVP1

4

R

T

V

C1

FB1

CTRL1

PWM1

EXPOSED PAD IS GND (PIN 17)

MUST BE SOLDERED TO PCB

= 125°C, θJA = 38°C/W, θJC = 10°C/W

T

JMAX

17

5

6

7

8

FE PACKAGE

16-LEAD PLASTIC TSSOP

16

SW2

15

REF

14

OVP2

SHDN

13

V

12

C2

FB2

11

CTRL2

10

PWM2

9

ORDER PART

NUMBER

LT3486EFE

FE PART

MARKING

3486EFE

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

The

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

= 3V, unless otherwise noted.

V

SHDN

= 25°C. VIN = 3V, V

A

●

denotes the specifi cations which apply over the full operating

CTRL1

= 3V, V

CTRL2

= 3V, V

PWM1

= 3V, V

PWM2

= 3V,

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage 2.5 V

Maximum Operating Voltage 24 V

●

Feedback Voltage (FB1, FB2)

194 200 206 mV

Offset between FB1 and FB2 VOS = |FB1-FB2| 0 3 6 mV

Feedback Pin Bias Current (FB1, FB2) V

Quiescent Current V

= V

FB1

FB1

⎯S⎯H⎯D⎯

= 0.2V (Note 3) 10 45 100 nA

FB2

= V

= 1V 9 14 mA

FB2

N = 0V, CTRL1 = CTRL2 = 0V 0.1 1 µA

Switching Frequency RT = 53.6k 0.75 1 1.25 MHz

R

= 20.5k

T

●

1.7 2.2 2.7 MHz

Oscillator Frequency Range (Typical Value) (Note 4) 200 2500 kHz

Nominal RT Pin Voltage RT = 53.6k 0.54 V

2

3486fa

LT3486

The

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

= 3V, unless otherwise noted.

V

SHDN

= 25°C. VIN = 3V, V

A

●

denotes the specifi cations which apply over the full operating

CTRL1

= 3V, V

CTRL2

= 3V, V

PWM1

= 3V, V

PWM2

= 3V,

PARAMETER CONDITIONS MIN TYP MAX UNITS

Maximum Duty Cycle R

R

R

= 53.6k

T

= 20.5k 90 %

T

= 309k 98 %

T

●

90 96 %

Switch Current Limit (SW1, SW2) 1 1.3 A

Switch V

Switch Leakage Current V

I

CESAT

SW1

SW1

= I

= 0.75A 300 mV

SW2

= V

= 10V 0.1 5 µA

SW2

Error Amplifi er Transconductance ∆I = ±5µA 220 µA/V

Error Amplifi er Voltage Gain 120

VC1, VC2 Switching Threshold 0.85 V

VC1, VC2 Clamp Voltage 1.5 V

VC1, VC2 Source Current V

VC1, VC2 Sink Current V

VC1, VC2 Pin Leakage Current VC1 = VC2 = 1V, V

FB1

FB1

= V

= 0V 25 µA

FB2

= V

= 1V 25 µA

FB2

PWM1

= V

= 0V 1 10 nA

PWM2

OVP1, OVP2 Overvoltage Threshold Voltage 34 36 38 V

CTRL1, CTRL2 Voltages to Turn Off LED1, 2 Currents

●

75 mV

CTRL1, CTRL2 Voltages to Turn On LED1, 2 Currents 150 mV

CTRL1, CTRL2 Voltages for Full LED1, 2 Currents 1.8 V

CTRL1, CTRL2 Pin Bias Current V

PWM1, PWM2 Voltage High

PWM1, PWM2 Voltage Low

PWM1, PWM2 Pin Bias Current V

CTRL1

PWM1

= V

= V

= 3V

CTRL2

= 3V 0.1 1 µA

PWM2

●

20 30 40 µA

●

0.9 V

●

0.4 V

SHDN Voltage High 1.6 V

SHDN Voltage Low 0.4 V

SHDN Pin Bias Current V

REF Voltage I

REF Source Current

= 3V 20 µA

SHDN

= 10µA 1.2 1.25 1.3 V

REF

●

50 80 µA

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LT3486E is guaranteed to meet specifi ed performance from

0°C to 70°C and is designed, characterized and expected to meet these

extended temperature limits, but is not tested at –40°C and 85°C.

Note 3: Current fl ows out of the pin.

Note 4: Guaranteed by design and test correlation, not production tested.

3486fa

3

LT3486

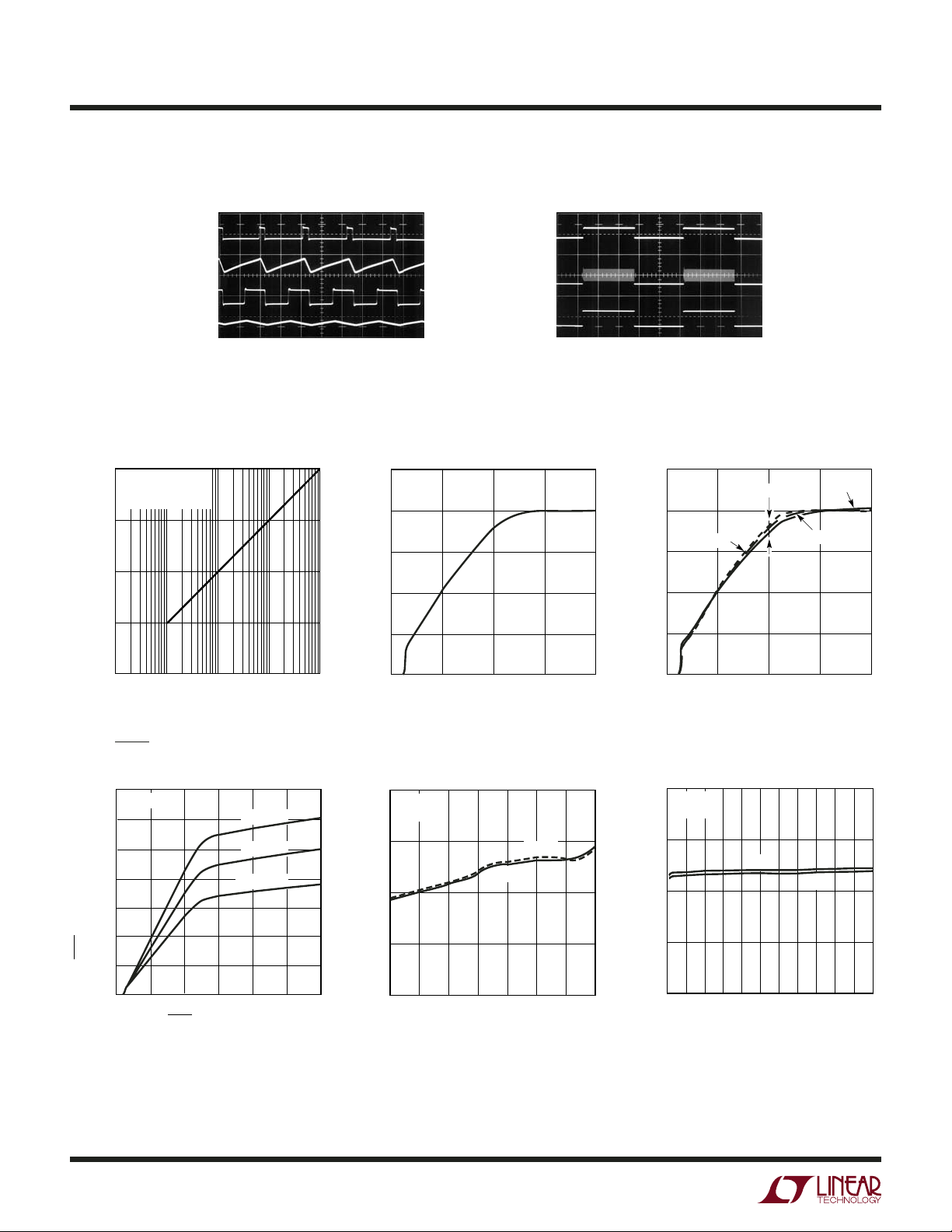

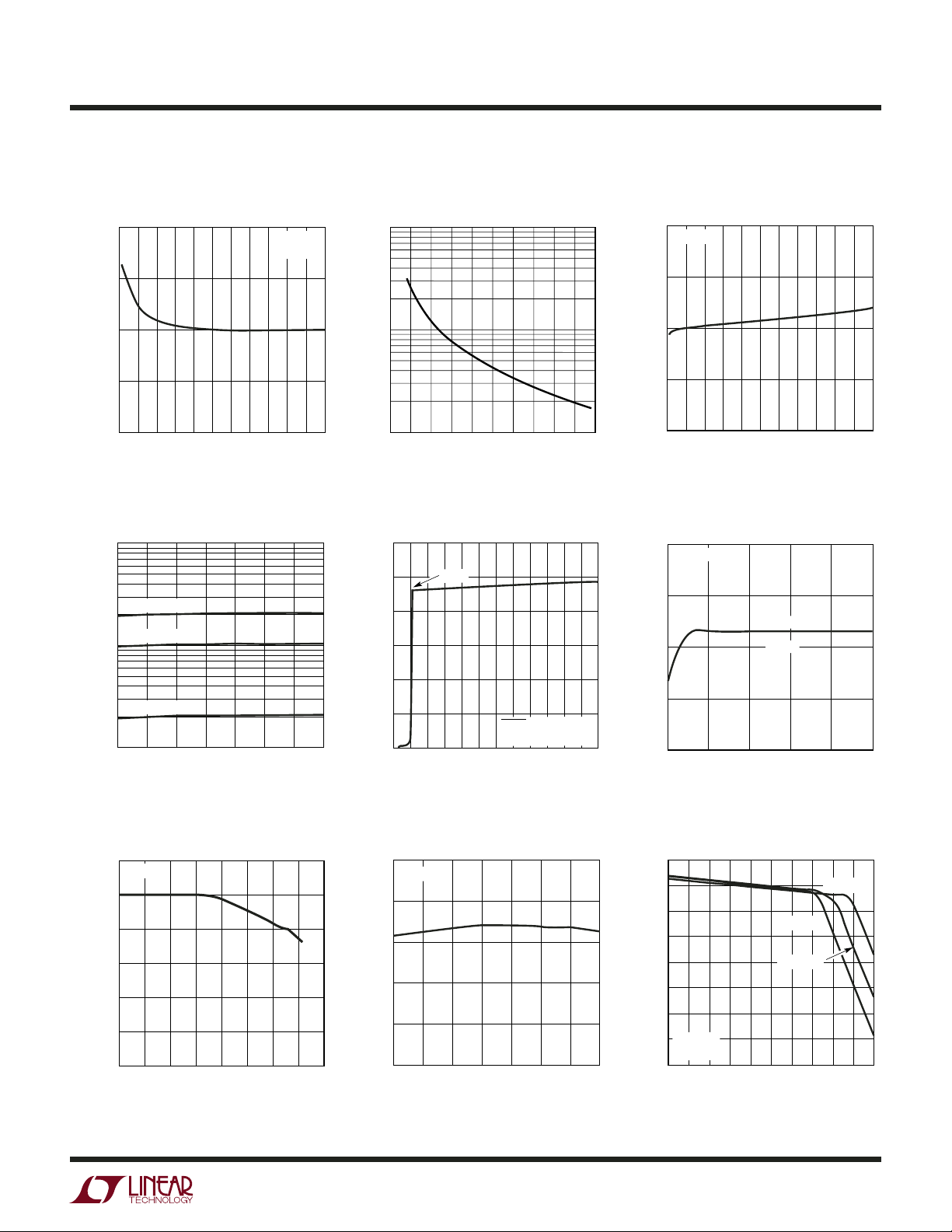

TYPICAL PERFOR

Switching Waveforms PWM Dimming Wavforms

UW

CE CHARACTERISTICSA

TA = 25°C unless otherwise specifi ed.

V

SW2

50V/DIV

I

L2

500mA/DIV

V

SW1

10V/DIV

I

L1

1A/DIV

VIN = 3.6V

8 LEDs/25mA

2 LEDs/320mA

CIRCUIT OF FRONT PAGE APPLICATION

LED Current vs PWM Duty Cycle

Wide Dimming Range (1000:1)

100

VIN = 12V

8/8 LEDs

PWM FREQ = 100Hz

10

(mA)

1

LED

I

0.1

0.01

0.01 1 10 100

0.1

PWM DUTY CYCLE (%)

0.5µs/DIV

3486 G01

3486 G17

vs V

V

FB

CTRL

250

VIN = 3.6V

= 25°C

T

A

200

150

100

FEEDBACK VOLTAGE (mV)

50

0

0

0.5

CONTROL VOLTAGE (V)

200mA/DIV

500mA/DIV

1

I

LED

PWM

5V/DIV

1.5

I

L

VIN = 12V

8/8 LEDs

PWM FREQ = 1kHz

2

3486 G03

0.2ms/DIV

VFB vs V

3486 G18

CTRL

(Temperature Variation)

250

200

TA = –50°C

150

100

FEEDBACK VOLTAGE (mV)

50

0

0

0.5

CONTROL VOLTAGE (V)

± 5mV

1

TA = 85°C

TA = 25°C

1.5

2

3486 G04

SHDN Pin Bias Current

(CTRL1 = CTRL2 = 3V)

140

VIN = 3.6V

120

100

80

60

40

SHDN PIN BIAS CURRENT (µA)

20

0

01220

48

SHDN PIN VOLTAGE (V)

TA = 50°C

TA = 25°C

TA = 100°C

16 24

4

3486 G05

Open-Circuit Output Clamp

Voltage vs Temperature

37

= 3.6V

V

IN

= 63.4k

R

T

36

35

34

OUTPUT CLAMP VOLTAGE (V)

33

–50

–25 0 25 50

TEMPERATURE (°C)

V

OUT1

V

OUT2

75 100 125

3486 G06

Open-Circuit Output Clamp

Voltage vs V

37

= 3.6V

V

IN

= 63.4k

R

T

36

35

34

OUTPUT CLAMP VOLTAGE (V)

33

4

2

IN

V

OUT1

6

12

8

10

V

IN

(V)

V

OUT2

18

14

16

22 24

20

3486 G07

3486fa

UW

0

TYPICAL PERFOR A CE CHARACTERISTICS

Input Current with Output 1 and

Output 2 Open Circuit

20

15

T

A

R

= 25°C

= 63.4k

T

R

vs Oscillator Frequency Oscillator Frequency vs V

T

1000

LT3486

TA = 25°C unless otherwise specifi ed.

1100

1050

R

= 53.6k

T

IN

10

INPUT CURRENT (mA)

5

0

4

6

2

12

8

10

VIN (V)

Oscillator Frequency vs

Temperature

10000

= 22.1k

R

T

= 53.6k

R

1000

OSCILLATOR FREQUENCY (kHz)

T

= 309k

R

T

100

–50

–25 0 25 50 75 100

TEMPERATURE (°C)

100

(kΩ)

T

R

10

0

14

16

18

22 24

20

3486 G08

QUIESCENT CURRENT (mA)

125

3486 G11

500 2500200015001000

OSCILLATOR FREQUENCY (kHz)

Quiescent Current vs V

12

10

8

6

4

2

0

0

UVLO

10 14 18 22 24

81216

6

4

V

IN

3486 G09

IN

SHDN = 3V

CTRL1 = CTRL2 = 3V

202

(V)

3486 G12

1000

950

OSCILLATOR FREQUENCY (kHz)

900

6

4

2

12

10

8

VIN (V)

PWM Pin Input Bias Current

1.0

V

= 3.6V

IN

0.5

PWM 1

PWM 2

4

PWM PIN CURRENT (µA)

–0.5

–1.0

0

2

0

PWM PIN VOLTAGE (V)

18

14

16

6

22 24

20

3486 G10

8

1

Switch Current Limit vs

Duty Cycle

1800

V

= 3.6V

IN

1700

1600

1500

1400

CURRENT LIMIT (mA)

1300

1200

20

40 60

30 50

DUTY CYCLE (%)

REF Voltage vs Temperature

1.30

V

= 3.6V

IN

1.28

1.26

1.24

REF VOLTAGE (V)

1.22

1.20

80

70

90

3486 G14

100

–50 –25

0

TEMPERATURE (°C)

50

25

75

100

125

3486 G15

REF Voltage Load Regulation

1.30

1.25

1.20

1.15

1.10

1.05

REF VOLTAGE (V)

1.00

0.95

V

= 3.6V

IN

T

= 25°C

A

0.90

0

40 80 120 20014020 60 100 180

REF LOAD CURRENT (µA)

TA = 25°C

TA = –50°C

TA = 85°C

160

3468 G16

3486fa

5

LT3486

PI FU CTIO S

UUU

SW1, SW2 (Pins 1, 16): The SW Pins are the Collectors

of the Internal Power Transistors. Connect the inductors

and Schottky diodes to these pins. Minimize trace area

at these pins to minimize EMI.

(Pin 2): Input Supply Pin. Must be locally bypassed

V

IN

with an X5R or X7R type ceramic capacitor.

OVP1, OVP2 (Pins 3, 14): Output Overvoltage Protection

Pins. Connect these pins to the output capacitors. The

on-chip voltage detectors monitor the voltages at these

pins and limit it to 36V (typ) by turning off the respective

switcher and pulling its V

(Pin 4): Timing Resistor to Program the Switching

R

T

Frequency. The switching frequency can be programmed

from 200kHz to 2.5MHz.

, VC2 (Pins 5, 12): The VC Pins are the Outputs of the

V

C1

Internal Error Amplifi er. The voltages at these pins control

the peak switch currents. Connect a resistor and capacitor

compensation network from these pin to ground.

FB1, FB2 (Pins 6, 11): The LT3486 regulates the voltage

at each feedback pin to 200mV. Connect the cathode of

the lowest LED in the string and the feedback resistor

) to the respective feedback pin. The LED current in

(R

FB

each string can be programmed by:

≅ 200mV/RFB, when V

I

LED

I

LED

≅ V

/(5RFB), when V

CTRL

pin low.

C

CTRL

CTRL

> 1.8V

< 1V

CTRL1, CTRL2 (Pins 7, 10): The CTRL pins are used to

provide dimming and shutdown control for the individual

switching converters. Connecting these to ground shuts

down the respective converter. As the voltages on these

pins is ramped from 0V to 1.8V, the LED current in each

converter ramps from 0 to I

age above 1.8V does not affect the LED current.

PWM1, PWM2 (Pins 8, 9): The PWM control pins can

be used to extend the dimming range for the individual

switching converter. The LED current in each string can

be controlled down to µA levels by feeding a PWM signal

to these pins. When the PWM pin voltage is taken below

0.4V, the respective converter is turned off and its V

is disconnected from the internal circuitry. Taking it higher

than 0.9V resumes normal operation. Connect these pins

to 0.9V supply or higher, if not in use.

SHDN (Pin 13): Shutdown Pin for the Device. Connect it

to 1.6V or higher to enable device; 0.4V or less to disable

device.

REF (Pin 15): The internal bandgap reference (1.25V) is

available at this pin. Bypass with a 0.1µF X5R or X7R ceramic capacitor. Draw no more than 50µA from this pin.

Exposed Pad (Pin 17): Ground. The exposed pad of the

package provides an electrical contact to ground and good

thermal connection to the printed circuit board (PCB).

Solder the exposed pad to the PCB system ground.

= (200mV/RFB). Any volt-

LED

pin

C

6

3486fa

BLOCK DIAGRA

LT3486

W

R

4

OSC

RAMP

GEN

T

OVP1

3

OVERVOLT

DETECTION

OV1

EN1

PWM

LOGIC

OSC

SW1

1

CONVERTER1 CONVERTER2

Q1 Q2

+

R

SNS1

A3

–

PWM

COMP

V

C1

5

OV1 OV2

CONVERTER1

+

A2

–

CONTROL

8

7

CTRL1PWM1 FB1

++

EA

A1 A1

0.2V

+

–

+

SHDN

20k

6

V

IN

2

OSC

REF 1.25V

START-UP

CONTROL

13

SHDN REF FB2

0.2V

15

SW2

16

DRIVER

+

A3

R

SNS2

–

PWM

COMP

+

A2

EA

+

–

–

+

EN2EN1

80k80k

20k

11

CONVERTER 2

CONTROL

10

CTRL2

PWM2

9

PWM

LOGIC

OVERVOLT

DETECTION

OSC

OV2

EN2

17

14

EXPOSED

PAD

12

3486 F01

OVP2

V

C2

Figure 1. LT3486 Block Diagram

3486fa

7

LT3486

OPERATIO

U

Main Control Loop

The LT3486 uses a constant frequency, current mode

control scheme to provide excellent line and load regulation.

It incorporates two identical, but fully independent PWM

converters. Operation can be best understood by referring

to the block diagram in Figure 1. The oscillator, start-up

bias and the bandgap reference are shared between the two

converters. The control circuitry, power switch, dimming

control etc., are all identical for both converters.

At power-up, the output capacitors of both converters are

charged up to V

(input supply voltage) via their respective

IN

inductor and the Schottky diode. If the SHDN pin is taken

above 1.6V, the bandgap reference, start-up bias and the

oscillator are turned on. Grounding the SHDN pin shuts

down the part.

The CTRL1 and CTRL2 pins perform independent dimming

and shutdown control for the two converters. Taking

the CTRL pins high, enables the respective converters.

Connecting these pins to ground, shuts down each

converter by pulling their respective V

pin low.

C

Working of the main control loop can be understood by

following the operation of converter 1. At the start of

each oscillator cycle, the power switch Q1 is turned on.

A voltage proportional to the switch current is added to

a stabilizing ramp and the resulting sum is fed into the

positive terminal of the PWM comparator A2. When this

voltage exceeds the level at the negative input of A2, the

PWM logic turns off the power switch. The level at the

negative input of A2 is set by the error amplifi er A1, and

is simply an amplifi ed version of the difference between

the feedback voltage and the 200mV reference voltage. In

this manner, the error amplifi er A1 regulates the feedback

voltage to 200mV reference voltage. The output of the

error amplifi er A1 sets the correct peak current level in

inductor L1 to keep the output in regulation. The CTRL1

pin voltage is used to adjust the reference voltage.

The PWM1, 2 control pins are used to extend the dimming

range for the individual converter. The LED current in each

string can be controlled down to µA levels by feeding

a PWM signal to these pins. Refer to the Applications

Information section for more detail.

If only one of the converters is turned on, the other converter

will stay off and its output will remain charged up to V

IN

(input supply voltage).

Minimum Output Current

The LT3486 can drive an 8-LED string at 4mA LED current

without pulse skipping. As current is further reduced, the

device may begin skipping pulses. This will result in some

low frequency ripple, although the LED current remains

regulated on an average basis down to zero. The photo

in Figure 2 shows circuit operation with 8 white LEDs

at 4mA current driven from 3.6V supply. Peak inductor

current is less than 200mA and the regulator operates in

discontinuous mode implying that the inductor current

reached zero during the discharge phase. After the inductor

current reaches zero, the switch pin exhibits ringing due to

the LC tank circuit formed by the inductor in combination

with switch and diode capacitance. This ringing is not

harmful; far less spectral energy is contained in the ringing

than in the switch transitions. The ringing can be damped

by application of a 300Ω resistor across the inductors,

although this will degrade effi ciency.

V

OUT2

10mV/DIV

V

SW2

20V/DIV

I

L2

200mA/DIV

VIN = 3.6V

= 4mA (8 LEDs)

I

LED2

CIRCUIT OF FRONT PAGE APPLICATION

Figure 2. Switching Waveforms

0.5µs/DIV

3486 F02

Open-Circuit Protection

The LT3486 has internal open-circuit protection for both

the converters. Connect the overvoltage protection pins

(OVP1, OVP2) to the output of the respective converter.

When the LEDs are disconnected from the circuit or fail

open, the on-chip voltage detectors monitor the voltages at

the OVP1 and OVP2 pins and limits these voltages to 36V

(typ) by turning off the respective switcher. The converter

will then switch at a very low frequency to minimize the

input current. Output voltage and input current during

3486fa

8

OPERATIO

LT3486

U

output open circuit are shown in the Typical Performance

Characteristics graphs.

Figure 3a shows the transient response of switcher 1 with

the LEDs disconnected from the output. When the LED1

string is disconnected from the output, the voltage at

the feedback pin (FB1) drops to 0V. As a result, the error

amplifi er charges up the V

node to the clamp voltage

C

level of 1.5V (typ). The converter starts switching at peak

current limit and ramps up the output voltage. When the

output voltage reaches the OVP clamp voltage level of

36V (typ), the LT3486 shuts off the converter by pulling

node to ground. The converter then regulates the

the V

C

output voltage at 36V (typ) by switching at a very low

frequency.

In the event one of the converters has an output opencircuit, its output voltage will be clamped at 36V (typ).

However, the other converter will continue functioning

properly. The photo in Figure 3b shows circuit operation

with converter 1 output open-circuit and converter 2 driving

I

L1

1A/DIV

eight LEDs at 25mA. Converter 1 starts switching at a very

low frequency, reducing its input current.

Soft-Start

The LT3486 has a separate internal soft-start circuitry for

each converter. Soft-start helps to limit the inrush current

during start-up. Soft-start is achieved by clamping the

output of the error amplifi er during the soft-start period.

This limits the peak inductor current and ramps up the

output voltage in a controlled manner.

The converter enters into soft-start mode whenever the

respective CTRL pin is pulled from low to high. Figure 4

shows the start-up waveforms with converter 2 driving

eight LEDs at 25mA. The fi ltered input current, as shown

in Figure 4, is well controlled. The soft-start circuit is more

effective when driving a smaller number of LEDs.

Undervoltage Lockout

The LT3486 has an undervoltage lockout circuit which

shuts down both the converters when the input voltage

drops below 2.1V (typ). This prevents the converter to

operate in an erratic mode when powered from low supply

voltages.

V

OUT1

20V/DIV

Overtemperature Protection

The maximum allowable junction temperature for LT3486 is

V

C1

2V/DIV

VIN = 3.6V

CIRCUIT OF

FRONT PAGE

APPLICATION

100µs/DIV

LED1 DISCONNECTED

AT THIS INSTANT

3486 F03a

Figure 3a. Transient Response of Switcher 1 with LED1

Disconnected from the Output

I

L1

1A/DIV

V

OUT1

1V/DIV

AC COUPLED

I

L2

500mA/DIV

VIN = 3.6V

CIRCUIT OF FRONT PAGE APPLICATION

LED1 DISCONNECTED

2ms/DIV

3486 F03b

Figure 3b. Switching Waveforms with Output 1 Open Circuit Figure 4. Start-Up Waveforms

125°C. In normal operation, the IC’s junction temperature

should be kept below 125°C at an ambient temperature of

85°C or less. If the junction temperature exceeds 150°C, the

internal thermal shutdown circuitry kicks in and turns-off

both the converters. The converters will remain off until

the die temperature falls below 150°C.

I

IN

200mA/DIV

V

OUT2

10V/DIV

V

FB2

200mV/DIV

CTRL2

5V/DIV

VIN = 3.6V

8 LEDs, 25mA

CIRCUIT OF FRONT PAGE APPLICATION

0.5ms/DIV

3486 F04

3486fa

9

LT3486

U

WUU

APPLICATIO S I FOR ATIO

Duty Cycle

The duty cycle for a step-up converter is given by:

VVV

++–

D

where:

V

OUT

V

D

V

CESAT

V

IN

The maximum duty cycle achievable for LT3486 is 96%

(typ) when running at 1MHz switching frequency. It increases to 98% (typ) when run at 200kHz and drops to

90% (typ) at 2MHz. Always ensure that the converter is

not duty-cycle limited when powering the LEDs at a given

switching frequency.

Setting the Switching Frequency

OUT D IN

=

VVV

OUT D CESAT

–

= Output voltage

= Schottky forward voltage drop

= Saturation voltage of the switch

= Input battery voltage

Operating Frequency Selection

The choice of operating frequency is determined by several factors. There is a tradeoff between effi ciency and

component size. Higher switching frequency allows the

use of smaller inductors albeit at the cost of increased

switching losses and decreased effi ciency.

Another consideration is the maximum duty cycle

achievable. In certain applications the converter needs to

operate at the maximum duty cycle in order to light up

the maximum number of LEDs. The LT3486 has a fi xed

oscillator off-time and a variable on-time. As a result, the

maximum duty cycle increases as the switching frequency

is decreased.

The circuit of Figure 6a is operated with different values of

timing resistor (R

at 800kHz (R

= 21.5k). The CTRL pins are used to provide dimming

(R

T

). RT is chosen so as to run the converters

T

= 63.4k), 1.25MHz (RT = 39.1k) and 2MHz

T

for the respective LED strings. The effi ciency comparison

for different R

values is shown in Figure 6b.

T

The LT3486 uses a constant frequency architecture that

can be programmed over a 200kHz to 2.5MHz range

with a single external timing resistor from the R

ground. The nominal voltage on the R

pin is 0.54V, and the

T

pin to

T

current that fl ows into the timing resistor is used to charge

and discharge an internal oscillator capacitor. A graph for

selecting the value of R

for a given operating frequency

T

is shown in the Figure 5.

1000

100

(kΩ)

T

R

10

0

500 2500200015001000

OSCILLATOR FREQUENCY (kHz)

3486 G09

D1 D2

C

OUT1

2.2µF

SW1 SW2V

, C

REF

OUT2

OVP1

CTRL1

SHDN

PWM1

FB1

V

C1

: 35V, X5R

25mA

OFF ON

CIN: 10V, X7R

C

OUT1

D1, D2: ZETEX ZHCS400

L1, L2: TOKO D53LC TYPE A

Figure 6a. 5V to 8/8 White LEDs

C

IN

5V

10µF

L1

10µH

2.8k 2.8k

4.7nF 4.7nF

IN

LT3486

GND

L2

10µH

R

T

CTRL2

PWM2

R

T

OVP2

REF

FB2

V

C2

C

OUT2

2.2µF

25mA

1.25V

C

REF

0.1µF

8.06Ω8.06Ω

3486 F06a

10

Figure 5. Timing Resistor (RT) Value

3486fa

LT3486

U

WUU

APPLICATIO S I FOR ATIO

90

VIN = 5V

8/8 LEDs

80

70

60

EFFICIENCY (%)

50

40

30

0

Figure 6b. Effi ciency Comparison for Different RT Resistors

Inductor Selection

The choice of the inductor will depend on the selection of

switching frequency of LT3486. The switching frequency

can be programmed from 200kHz to 2.5MHz. Higher

switching frequency allows the use of smaller inductors

albeit at the cost of increased switching losses.

The inductor current ripple (ΔI

the Schottky diode and the switch, is given by:

VV V

IN MIN OUT MAX IN MIN

∆=

I

L

() ( ) ()

where:

L = Inductor

f = Operating frequency

V

V

The ΔI

= Minimum input voltage

IN(MIN)

OUT(MAX)

= Maximum output voltage

is typically set to 20% to 40% of the maximum

L

inductor current.

The inductor should have a saturation current rating greater

than the peak inductor current required for the application.

Also, ensure that the inductor has a low DCR (copper wire

resistance) to minimize I

inductor values range from 4.7µH to 22µH.

RT = 63.4k

RT = 21.5k

RT = 39.1k

5101520

LED CURRENT (mA)

), neglecting the drop across

L

•–

()

VfL

OUT MAX

••

()

2

R power losses. Recommended

25

3486 F06b

Several inductors that work well with the LT3486 are listed

in Table 1. Consult each manufacturer for more detailed information and for their entire selection of related parts.

Table 1. Recommended Inductors

MAX CURRENT

L DCR RATING

PART (µH) (Ω) (A) VENDOR

LQH55DN150M 15 0.150 1.40 Murata

LQH55DN220M 22 0.190 1.20 (814) 237-1431

www.murata.com

A915AY-4R7M 4.7 0.045 2.49 Toko

A915AY-6R8M 6.8 0.068 2.01 (847) 297-0070

A915AY-100M 10 0.090 1.77 www.toko.com

A918CY-100M 10 0.098 1.22

A918CY-150M 15 0.149 0.94

CDRH4D28-100 10 0.048 1.30 Sumida

CDRH5D18-150 15 0.145 0.97 (847) 956-0666

www.sumida.com

Capacitor Selection

The small size of ceramic capacitors make them ideal

for LT3486 applications. Use only X5R and X7R types

because they retain their capacitance over wider voltage

and temperature ranges than other types such as Y5V

or Z5U. A 4.7µF or larger input capacitor is suffi cient for

most applications. Always use a capacitor with suffi cient

voltage rating.

Table 2 shows a list of several ceramic capacitor manufacturers. Consult the manufacturers for detailed information

on their entire selection of ceramic parts.

Table 2. Ceramic Capacitor Manufacturers

Taiyo Yuden (408) 573-4150

www.t-yuden.com

AVX (803) 448-9411

www.avxcorp.com

Murata (714) 852-2001

www.murata.com

Diode Selection

Schottky diodes with their low forward voltage drop and

fast reverse recovery, are the ideal choices for LT3486

applications. The diode conducts current only during the

switch off time. The peak reverse voltage that the diode

must withstand is equal to the regulator output voltage.

3486fa

11

LT3486

U

WUU

APPLICATIO S I FOR ATIO

The average forward current in normal operation is equal

to the output current, and the peak current is equal to the

peak inductor current. A Schottky diode rated at 1A is suffi cient for most LT3486 applications. Some recommended

Schottky diodes are listed in Table 3.

Table 3. Recommended Schottky Diodes

PART NUMBER VR (V) I

MBR0530 30 0.5 On Semiconductor

MBRM120E 20 1 www.onsemi.com

ZLLS400 40 0.4 Zetex

ZLLS1000 40 1 www.zetex.com

ZHCS400 40 0.4

ZHCS1000 40 1

When the LT3486 is set up for PWM dimming operation,

choose a Schottky diode with low reverse leakage current.

During PWM dimming operation, the output capacitor is

required to hold up the charge in the PWM “off” period.

A low reverse leakage Schottky helps in that mode of operation. The Zetex ZLLS400 and ZLLS1000 are available

in a small surface mount package and are a good fi t for

this application.

MOSFET Selection

(A) MANUFACTURER

AVG

200

R

FB

1

R

FB

2

Table 4. RFB Value Selection

I

5 40.2

10 20.0

15 13.3

20 10.0

25 8.06

mV

=

I

LED

1

200

mV

=

I

LED

2

(mA) RFB (Ω)

LED

Most low power white LEDs are driven at maximum currents of 15mA to 25mA. The LT3486 can be used to power

high power LEDs as well. Refer to the Typical Applications

for more detail.

Dimming Control

The dimming of the two LED strings can be controlled

independently by modulating the respective CTRL and

PWM pins. There are two ways to control the intensity

of the LEDs.

The power MOSFET used in LT3486 applications with wide

dimming range requirements should be chosen based on

the maximum drain-source voltage. The maximum drain

current I

D(MAX)

and gate-to-source voltages should also

be considered when choosing the FET.

Choose a MOSFET with maximum V

(drain source) volt-

DS

age greater than the output clamp voltage i.e., 36V (typ).

Fairchild Semiconductor’s FDN5630 (60V, 1.7A N-channel

FET) is a good fi t for most LT3486 applications. For dimming low current LEDs (~25mA), Fairchild 2N7002 is a

good alternative.

Programming LED Current

The current in each LED string can be set independently

by the choice of resistors R

FB1

and R

respectively

FB2

(see front page application). The feedback reference is

200mV. In order to have accurate LED current, precision

resistors are preferred (1% is recommended).

Adjusting the LED Current Value

Controlling the current fl owing through the LEDs controls

the intensity of the LEDs.This is the easiest way to control

the intensity of the LEDs. The LED forward current can be

controlled by modulating the DC voltage at the respective

CRTL pin. The PWM pins are not in use when appying

this scheme. They must be connected to a 0.9V supply or

higher. The DC voltage at the CTRL pin can be modulated

in two ways.

(a) Using a DC Voltage Source

For some applications, the preferred method of brightness

control is a variable DC voltage fed to the CTRL pins. The

CTRL1, CTRL2 pin voltage can be modulated to set the

dimming of the respective LED string. As the voltage on

the CTRL1, CTRL2 pin increases from 0V to 1.8V, the LED

current increases from 0 to I

. As the CTRL1, CTRL2

LED

pin voltage increases beyond 1.8V, it has no effect on the

LED current.

3486fa

12

LT3486

3486 F07

C1

1µF

PWM

10kHz TYP

R1

10k

LT3486

CTRL1,2

U

WUU

APPLICATIO S I FOR ATIO

The LED current can be set by:

≈ (200mV/RFB), when V

I

LED

I

LED

≈ (V

/5 • RFB), when V

CTRL

Feedback voltage variation versus control voltage is given

in the Typical Performance Characteristics graphs.

(b) Using a Filtered PWM Signal

A variable duty cycle PWM can be used to control the

brightness of the LED string. The PWM signal is fi ltered

(Figure 7) by an RC network and fed to the CTRL1, CTRL2

pins.

The corner frequency of R1, C1 should be much lower

than the frequency of the PWM signal. R1 needs to be

much smaller than the internal impedance in the CTRL

pins, which is 100kΩ.

CTRL

CTRL

> 1.8V

< 1V

Pulse-Width Modulation (PWM)

Adjusting the forward current fl owing in the LEDs changes

the intensity of the LEDs, as explained in the previous section. However, a change in forward current also changes the

color of the LEDs. The chromaticity of the LEDs changes

with the change in forward current. Many applications cannot tolerate any shift in the color of the LEDs. Controlling

the intensity of the LEDs via applying a PWM signal allows

dimming of the LEDs without changing the color.

Dimming the LEDs via a PWM signal essentially involves

turning the LEDs on and off at the PWM frequency. The

human eye has a limit of 60 frames per second. By increasing the PWM frequency to say, 80Hz, the eye can

be deceived into believing that the pulsed light source is

continously on. Additionally by modulating the duty cycle

(amount of “on-time”), the intensity of the LEDs can be

controlled. The color of the LEDs remains unchanged in

this scheme since the LED current value is either zero or

a constant value.

Figure 7. Dimming Control Using a Filtered PWM Signal

12V (TYP)

9V TO 15V

L1

10µH

C

OUT1

D1

2.2µF

LUXEON

LEDs

LXCL-PWF1

100mA

DIMMING

INPUT 1

PWM

FREQ

1kHz

100k 100k

OFF ON

Q1

R

C

FB1

OUT1

2Ω

C

IN

C1: 10V, X5R OR X7R

C

REF

SW1 SW2

OVP1

V

CTRL1

IN

SHDN

PWM1

FB1

V

C1

3.65k

2.2nF

, C

: 35V, X5R OR X7R

OUT2

: 25V, X5R OR X7R

: 6.3V, X5R OR X7R

LT3486

21.5k

C

IN

10µF

L2

µH

10

5V

V

R

C1 1µF

IN

T

D2

OVP2

CTRL2

REF

PWM2

FB2

V

C2

22pF

3.65k

2.2nF

D1, D2: ZETEX ZLLS1000

L1, L2: TOKO D53LC (TYPE A)

Q1, Q2: FAIRCHILD FDN5630

C

OUT2

2.2µF

V

IN

C

REF

0.1µF

Figure 8(a) shows a 12V to 8/8 white LED driver. The PWM

dimming control method requires an external NMOS tied

to the cathode of the lowest LED in the string, as shown in

LUXEON

LEDs

LXCL-PWF1

100mA

DIMMING

INPUT 2

Q2

R

FB2

2Ω

3486 TA10a

PWM

FREQ

1kHz

I

LED

200mA/DIV

I

L

500mA/DIV

PWM

5V/DIV

VIN = 12V

8/8 LEDs

PWM FREQ = 1kHz

0.2ms/DIV

Figure 8b. PWM Dimming Waveforms

3486 G18

Figure 8a. 12V to 8/8 White LEDs

3486fa

13

LT3486

U

WUU

S I FOR ATIOAPPLICATIO

the fi gure. A PWM logic input is applied to the gate of the

NMOS and the PWM pin of the LT3486. When the PWM

input is taken high, the LEDs are connected to the R

resistor and a current I

= 200mV/RFB fl ows through

LED

the LEDs. When the PWM input is taken low, the LEDs are

disconnected and turn off. The low PWM input applied to

the LT3486 ensures that the respective converter turns

off and its V

the capacitor connected to the V

pin goes high impedance. This ensures that

C

pin retains its voltage

C

which in turn allows the LEDs to turn on faster, as shown

in Figure 8(b). The CTRL pin is not used to modulate the

LED current in the scheme. It can be connected to a supply

voltage greater than 1.8V.

The dimming control pins (PWM1, PWM2) can be used

to extend the dimming range for the individual switching

converters. The LED current can be controlled down to

µA levels by feeding a PWM signal with frequencies in the

range of 80Hz to 50kHz. The LED current can be controlled

by PWM frequencies above 50kHz but the controllable

current decreases with increasing frequency. Pulling the

PWM pins below 0.4V disables the respective switcher.

Taking it higher than 0.9V resumes normal operation.

Connect these pins to 0.9V or higher if not in use.

FB

Figure 9 shows the LED current variation vs PWM duty

cycle. The LED current is controlled by applying a PWM

of frequency 100Hz, 1kHz and 25kHz to the circuit of

Figure 8a. As seen in the curves, the LED string is able to

get a wide (1000:1) dimming range with PWM frequency of

100Hz. The dimming range decreases as PWM frequency

goes up.

Board Layout Consideration

As with all switching regulators, careful attention must be

paid to the PCB board layout and component placement.

To prevent electromagnetic interference (EMI) problems,

proper layout of high frequency switching paths is essential.

Minimize the length and area of all traces connected to the

switching node pins (SW1 and SW2). Keep the feedback

pins (FB1 and FB2) away from the switching nodes.

The DFN and FE packages both have an exposed paddle

that must be connected to the system ground. The ground

connection for the feedback resistors should be tied directly

to the ground plane and not shared with any other component, except the R

resistor, ensuring a clean, noise-free

T

connection. Recommended component placement for the

DFN package is shown in the Figure 10.

100

10

1

LED CURRENT (mA)

0.1

PWM FREQ = 100Hz

PWM FREQ = 1kHz

0.01

0.01 1 10 100

0.1

PWM DUTY CYCLE (%)

PWM FREQ = 25kHz

3486 F09

Figure 9. LED Current Variation vs PWM Duty Cycle

LED1

VIAs TO VIN PLANE

V

OVP1

R

V

PWM1

OUT1

T

C1

FB1

CTRL1 CTRL2

PLANE

IN

SW1 SW2

V

IN

16

1

15

2

14

3

17

13

4

12

5

11

6

10

7

9

8

V

IN

Figure 10. Recommended Layout for LT3486

V

OUT2

V

IN

VIAs TO GROUND PLANEVIAs TO V

LED2

OVP2

SHDN

PWM2

REF

V

C2

FB2

3486 F10

3486fa

14

TYPICAL APPLICATIO S

Li-Ion Cell Powered Driver for Camera Flash and LCD Backlighting

U

V

IN

3V TO 5V

C

10mF

LT3486

IN

0V

OFF ON

LED1

AOT3218

5V

100k

C

OUT1

2.2mF

320mA

OFF ON

Q1

R

FB1

0.62

W

C

: 6.3V, X5R OR X7R DIELECTRIC

IN

, C

C

OUT1

D1: ZETEX ZHCS1000

D2: ZETEX ZHCS400

: 35V, X5R OR X7R

OUT2

D1

L1

10mH

SW1 SW2

OVP1

CTRL1

SHDN

PWM1

FB1

V

0.1mF

LT3486

C1

63.4k

Effi ciency vs V

D2

L2

10mH

V

IN

OVP2

CTRL2

PWM2

R

T

L1, L2: TOKO D53LC (TYPE A)

Q1: FAIRCHILD FDN5630

DIMMING 2DIMMING 1

REF

FB2

V

C2

2.8k

4.7nF

IN

C

OUT2

2.2mF

C

REF

0.1mF

R

FB2

8.06

3486 TA02a

25mA

W

90

85

80

75

EFFICIENCY (%)

70

8 LEDS/25mA

65

3

3.2

MOVIE MODE

= 175mA

I

LED1

FLASH MODE

= 320mA

I

LED1

3.4 3.6 3.8

VIN (V)

4 4.2

3486 TA01b

3486fa

15

LT3486

LED C

Effi ci

PWM Duty Cycl

Wide (250:1) Dimmi

PWM Dimmi

TYPICAL APPLICATIO S

U

1 Li-Ion Cell to 8/8 White LEDs

3V TO 5V

C

IN

10µF

urrent and

85

VIN = 3.6V

8/8 LEDs

80

75

EFFICIENCY

70

65

EFFICIENCY (%)

60

55

PWM1

100Hz

D1

C

OUT1

2.2µF

8 LEDs 8 LEDs

V

IN

25mA

5V

100k

8.06Ω 8.06Ω

ency vs

LED CURRENT

OFF ON

Q1

C

OUT1

C

: 10V, X5R OR X7R

IN

35

30

25

20

15

10

5

4.7nF

, C

OUT2

e

LED CURRENT (mA)

L1

10

µHL210µH

SW1 SW2

OVP1

CTRL1

SHDN

PWM1

FB1

V

C1

2.8k

: 35V, X5R OR X7R

63.4k

V

IN

LT3486

R

T

D2

C

OUT2

2.2µF

OVP2

CTRL2

PWM2

D1, D2: ZETEX ZLLS400

L1, L2: TOKO D53LC (TYPE A)

Q1, Q2: FAIRCHILD 2N7002

V

IN

REF

FB2

V

C2

2.8k

4.7nF

(LED Current 0.1mA to 25mA)

100

VIN = 3.6V

8/8 LEDs

PWM FREQ = 100Hz

10

1

LED CURRENT (mA)

0.10

C

REF

0.1µF

Q2

25mA

PWM2

100Hz

100k

3486 TA05A

ng Range

16

50

20 40 60 100

0

PWM DUTY CYCLE (%)

LED CURRENT

80

3486 TA05b

20mA/DIV

200mA/DIV

PWM

5V/DIV

0

I

L

VIN = 3.6V

CTRL1 = 3.6V

8 LEDs/25mA

PWM FREQ = 100Hz

ng Waveforms

2ms/DIV

0.01

3486 TA05c

0.1

1 10 100

DUTY CYCLE (%)

3486 TA05d

3486fa

TYPICAL APPLICATIO S

LED C

Effi ci

PWM Duty Cycl

PWM Dimmi

LT3486

U

5V to 16/16 White LEDs

PWM FREQ

200Hz

100k

16 LEDs

25mA

D5 D6

C3

1mF

C

Q1

8.06

W

C

C

C1-C4: 50V, X5R OR X7R

C

D3 D4

C1

0.1mF

D1

OUT1

2.2mF

V

IN

OFF ON

4.02k 4.02k

4.7nF 4.7nF

: 6.3V, X5R OR X7R

IN

, C

OUT1

OUT2

: 6.3V, X5R OR X7R

REF

5V

L1

15mH

SW1 SW2

OVP1

CTRL1

SHDN

PWM1

FB1

V

C1

: 35V, X5R OR X7R

63.4k

V

IN

LT3486

R

T

22pF

C

IN

1mF

L2

15mH

OVP2

CTRL2

REF

PWM2

FB2

V

C2

D1, D2: ZETEX ZLLS400

D3-D6: PHILIPS BAV99W

L1, L2: TOKO D53LC (TYPE A)

Q1, Q2: FAIRCHILD 2N7002

C2

0.1mF

D2

V

C4

1mF

C

OUT2

2.2mF

IN

C

0.1mF

REF

8.06

16 LEDs

25mA

Q2

W

3486 TA08a

PWM FREQ

200Hz

100k

urrent and

85

VIN = 5V

16/16 LEDs

80

75

70

65

EFFICIENCY (%)

60

55

50

0

ency vs

EFFICIENCY

LED CURRENT

20 40 60 100

PWM DUTY CYCLE (%)

80

3486 TA08b

e

35

30

LED CURRENT (mA)

25

20

15

10

5

0

I

LED

50mA/DIV

500mA/DIV

PWM

5V/DIV

I

L

L = 15µH

PWM FREQ = 200Hz

ng Waveforms

1ms/DIV

3486 TA08c

3486fa

17

LT3486

PACKAGE DESCRIPTIO

U

DHC Package

16-Lead Plastic DFN (5mm × 3mm)

(Reference LTC DWG # 05-08-1706)

0.65 ±0.05

3.50 ±0.05

1.65 ±0.05

(2 SIDES)2.20 ±0.05

4.40 ±0.05

(2 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

5.00 ±0.10

(2 SIDES)

PIN 1

TOP MARK

(SEE NOTE 6)

0.200 REF

NOTE:

1. DRAWING PROPOSED TO BE MADE VARIATION OF VERSION (WJED-1) IN JEDEC

PACKAGE OUTLINE MO-229

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE

TOP AND BOTTOM OF PACKAGE

0.25 ± 0.05

0.50 BSC

PACKAGE

OUTLINE

3.00 ±0.10

(2 SIDES)

0.75 ±0.05

R = 0.20

1.65 ± 0.10

(2 SIDES)

0.00 – 0.05

TYP

R = 0.115

TYP

0.25 ± 0.05

0.50 BSC

4.40 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

169

18

0.40 ± 0.10

PIN 1

NOTCH

(DHC16) DFN 1103

18

3486fa

PACKAGE DESCRIPTIO

3.58

(.141)

U

FE Package

16-Lead Plastic TSSOP (4.4mm)

(Reference LTC DWG # 05-08-1663)

Exposed Pad Variation BB

4.90 – 5.10*

(.193 – .201)

3.58

(.141)

16 1514 13 12 11

LT3486

10 9

6.60 ±0.10

4.50 ±0.10

RECOMMENDED SOLDER PAD LAYOUT

0.09 – 0.20

(.0035 – .0079)

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

SEE NOTE 4

0.65 BSC

4.30 – 4.50*

(.169 – .177)

0.50 – 0.75

(.020 – .030)

MILLIMETERS

(INCHES)

(.116)

0.45 ±0.05

2.94

1.05 ±0.10

1345678

2

0.25

REF

0° – 8°

0.65

(.0256)

BSC

0.195 – 0.30

(.0077 – .0118)

TYP

4. RECOMMENDED MINIMUM PCB METAL SIZE

FOR EXPOSED PAD ATTACHMENT

*DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.150mm (.006") PER SIDE

2.94

(.116)

1.10

(.0433)

MAX

0.05 – 0.15

(.002 – .006)

FE16 (BB) TSSOP 0204

6.40

(.252)

BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3486fa

19

LT3486

TYPICAL APPLICATIO

12V to 8/8 White LEDs

U

12V (TYP)

9V TO 15V

C

10µF

IN

L1

µH

10

C

OUT1

D1

2.2µF

LUXEON

LEDs

LXCL-PWF1

100mA

DIMMING

INPUT 1

PWM

FREQ

1kHz

100k 100k

OFF ON

Q1

R

C

FB1

OUT1

2Ω

C

IN

C1: 10V, X5R OR X7R

C

REF

SW1 SW2

OVP1

V

CTRL1

IN

SHDN

PWM1

FB1

V

C1

3.65k

2.2nF

, C

: 35V, X5R OR X7R

OUT2

: 25V, X5R OR X7R

: 6.3V, X5R OR X7R

21.5k

L2

µH

10

5V

C1 1µF

V

IN

OVP2

CTRL2

LT3486

R

T

REF

PWM2

FB2

V

C2

22pF

D1, D2: ZETEX ZLLS1000

L1, L2: TOKO D53LC (TYPE A)

Q1, Q2: FAIRCHILD FDN5630

D2

3.65k

2.2nF

C

OUT2

2.2µF

V

IN

C

REF

0.1µF

RELATED PARTS

LED Current and Effi ciency

vs PWM Duty Cycle

90

EFFICIENCY

85

LUXEON

LEDs

LXCL-PWF1

100mA

DIMMING

INPUT 2

Q2

R

FB2

2Ω

3486 TA10a

PWM

FREQ

1kHz

80

75

EFFICIENCY (%)

70

65

60

0

LED CURRENT

20 40 60 80

PWM DUTY CYCLE (%)

V

8/8 LEDs

= 12V

IN

3486 TA10b

120

100

LED CURRENT (mA)

80

60

40

20

0

100

PART NUMBER DESCRIPTION COMMENTS

LT1618 Constant Current, Constant Voltage 1.24MHz, High Effi ciency Up to 16 White LEDs, VIN: 1.6V to 18V, V

Boost Regulator I

LT1932 Constant Current, 1.2MHz, High Effi ciency White LED Boost Up to 8 White LEDs, VIN: 1V to 10V, V

Regulator I

= 1.8mA, ISD < 1µA, MS Package

Q

= 1.2mA, ISD < 1µA, ThinSOT

Q

TM

Package

OUT(MAX)

LT1937 Constant Current, 1.2MHz, High Effi ciency White LED Boost Up to 4 White LEDs, VIN: 2.5V to 10V, V

Regulator I

LTC3200 Low Noise, 2MHz, Regulated Charge Pump White LED Driver Up to 6 White LEDs, V

= 1.9mA, ISD < 1µA, ThinSOT, SC70 Packages

Q

: 2.7V to 4.5V, IQ = 8mA, ISD < 1µA,

IN

MS Package

LTC3200-5 Low Noise, 2MHz, Regulated Charge Pump White LED Driver Up to 6 White LEDs, V

: 2.7V to 4.5V, IQ = 8mA, ISD < 1µA,

IN

ThinSOT Package

LTC3201 Low Noise, 1.7MHz, Regulated Charge Pump White LED Driver Up to 6 White LEDs, V

: 2.7V to 4.5V, IQ = 6.5mA, ISD < 1µA,

IN

MS Package

LTC3202 Low Noise, 1.5MHz, Regulated Charge Pump White LED Driver Up to 8 White LEDs, V

: 2.7V to 4.5V, IQ = 5mA, ISD < 1µA,

IN

MS Package

LTC3205 High Effi ciency, Multidisplay LED Controller Up to 4 (Main), 2 (Sub) and RGB, V

I

= 50µA, ISD < 1µA, QFN-24 Package

Q

: 2.8V to 4.5V,

IN

LT3465/LT3465A Constant Current, 1.2MHz/2.7MHz, High Effi ciency White LED Up to Six White LEDs, VIN: 2.7V to 16V, V

Boost Regulator with Integrated Schottky Diode I

= 1.9mA, ISD < 1µA, ThinSOT Package

Q

LT3466 Dual Full Function White LED Boost Regulator with Integrated Drives Up to 20 LEDs, VIN: 2.7V to 24V, V

Schottky Diode I

Linear Technology Corporation

20

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX: (408) 434-0507

●

www.linear.com

= 5mA, ISD < 16µA, DFN Package

Q

© LINEAR TECHNOLOGY CORPORATION 2005

LT 0506 REV A • PRINTED IN USA

OUT(MAX)

OUT(MAX)

OUT(MAX)

OUT(MAX)

= 34V,

= 34V,

= 34V,

= 34V,

= 40V,

3486fa

Loading...

Loading...