查询LT1617-1供应商

FEATURES

■

Internal 40V Schottky Diode

■

One Resistor Feedback (Other Resistor Inside)

■

Internal 40V, 200mA Power Switch

■

Generates Regulated Negative Outputs to –38V

■

Low Quiescent Current:

40µA in Active Mode

<1µA in Shutdown Mode

■

Low V

■

Wide Input Range: 2.5V to 16V

■

Uses Small Surface Mount Components

■

Output Short-Circuit Protected

■

Available in a 6-Lead SOT-23 Package

Switch: 200mV at 150mA

CESAT

U

APPLICATIO S

■

LCD Bias

■

Handheld Computers

■

Battery Backup

■

Digital Cameras

■

OLED Bias

LT3483

Inverting Micropower

DC/DC Converter with

Schottky in ThinSOT Package

U

DESCRIPTIO

The LT®3483 is a micropower inverting DC/DC converter

with integrated Schottky and one resistor feedback. The

small package size, high level of integration and use of tiny

surface mount components yield a solution size as small

as 40mm

40µA at no load, which further reduces to 0.1µA in

shutdown. A current limited, fixed off-time control scheme

conserves operating current, resulting in high efficiency

over a broad range of load current. A precisely trimmed

10µA feedback current enables one resistor feedback and

virtually eliminates feedback loading of the output. The

40V switch enables voltage outputs up to –38V to be

generated without the use of costly transformers. The

LT3483’s low 300ns off-time permits the use of tiny low

profile inductors and capacitors to minimize footprint and

cost in space-conscious portable applications.

The LT3483 is available in the low profile (1mm) SOT-23

(ThinSOTTM) package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

ThinSOT is a trademark of Linear Technology Corporation.

Patent pending.

2

. The device features a quiescent current of only

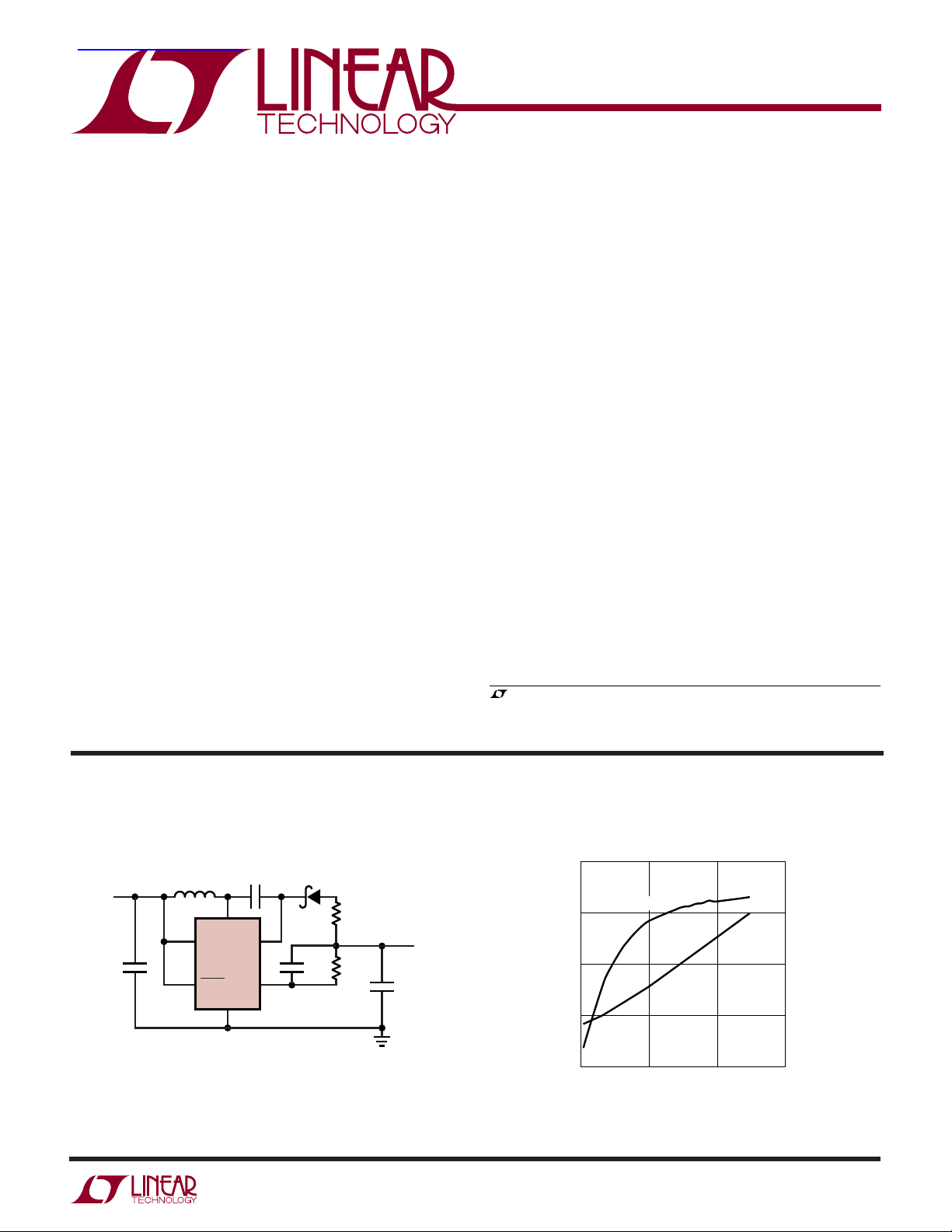

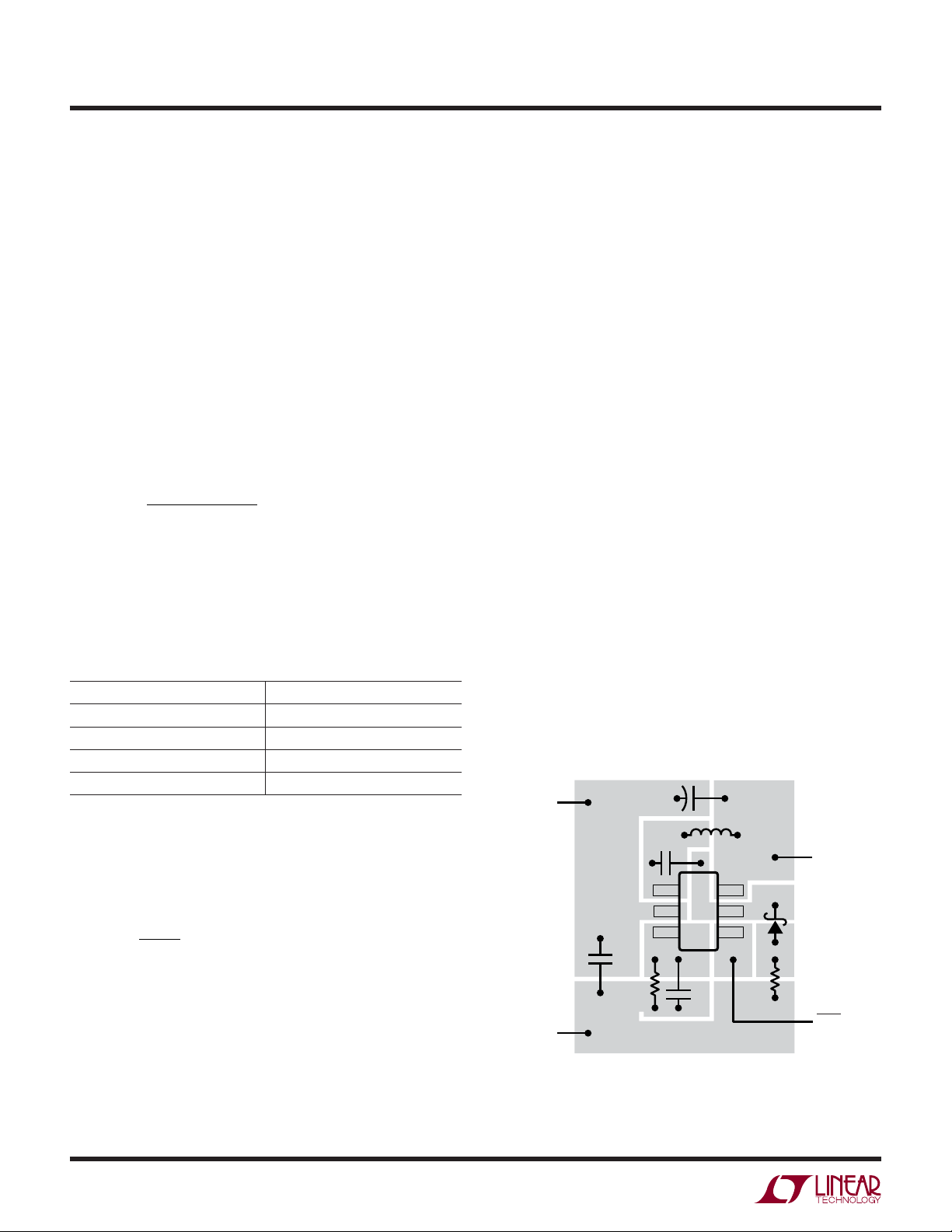

TYPICAL APPLICATIO

3.6V to –8V DC/DC Converter

V

IN

LT3483

SHDN

0.22µF

SW

D

FB

GND

V

3.6V

4.7µF

IN

10µH

U

10Ω

806k5pF

2.2µF

3483 TA01a

V

OUT

–8V

25mA

Efficiency and Power Loss

75

= 3.6V

V

IN

70

65

EFFICIENCY (%)

60

55

0.1

EFFICIENCY

POWER

LOSS

110

LOAD CURRENT (mA)

3483 TA01b

1000

100

POWER LOSS (mW)

10

1

0.1

100

3483f

1

LT3483

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

VIN Voltage ............................................................. 16V

SW Voltage ............................................................. 40V

D Voltage .............................................................. –40V

FB Voltage ............................................................. 2.5V

SHDN Voltage ......................................................... 16V

Operating Ambient Temperature Range

(Note 2) .................................................. – 40°C to 85°C

Junction Temperature.......................................... 125°C

Storage Temperature Range ................ –65°C to 150°C

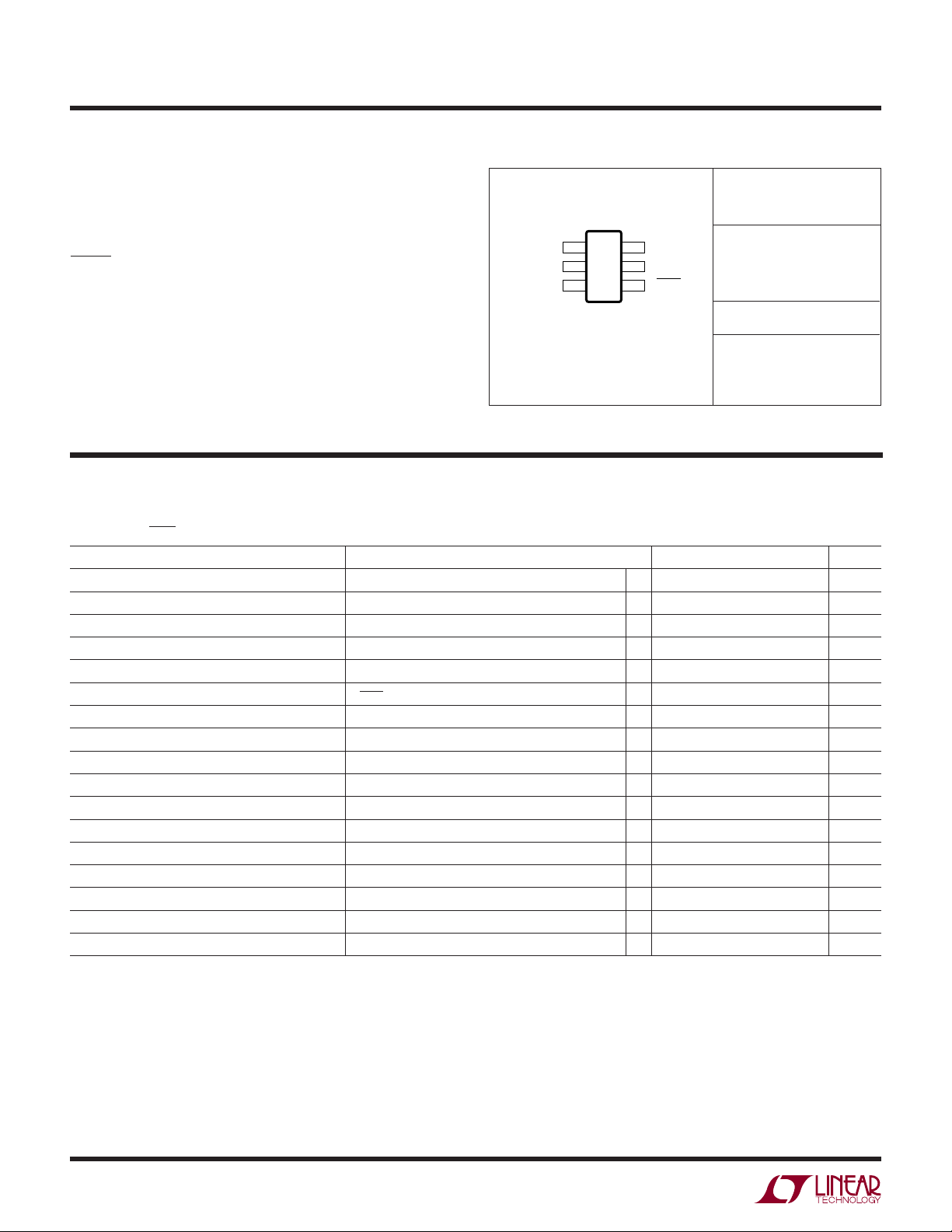

PACKAGE/ORDER I FOR ATIO

TOP VIEW

SW 1

GND 2

FB 3

S6 PACKAGE

6-LEAD PLASTIC TSOT-23

T

= 125°C, θJA = 256°C/W IN FREE AIR

JMAX

= 120°C/W ON BOARD OVER GROUND PLANE

θ

JA

6 V

5 D

4 SHDN

UU

W

ORDER PART

NUMBER

IN

LT3483ES6

S6 PART MARKING

LTBKX

Lead Temperature (Soldering, 10 sec)................. 300°C

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VIN = 3.6V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

VIN Operating Range 2.5 16 V

VIN Undervoltage Lockout 2 2.4 V

FB Comparator Trip Voltage to GND (VFB) FB Falling ● 0512 mV

FB Output Current (Note 3) FB = VFB – 5mV ● –10.15 –10 –9.75 µA

FB Comparator Hysteresis FB Rising 10 mV

Quiescent Current in Shutdown V

Quiescent Current (Not Switching) FB = –0.05V 40 50 µA

IFB Line Regulation 2.5V ≤ VIN ≤ 16V 0.07 %/V

Switch Off-Time 300 ns

Switch Current Limit 170 200 230 mA

Switch V

CESAT

Switch Leakage Current SW = 40V 1 µA

Rectifier Leakage Current D = – 40V 4 µA

Rectifier Forward Drop ID = 150mA to GND 0.64 V

SHDN Input Low Voltage 0.4 V

SHDN Input High Voltage 1.5 V

SHDN Pin Current 610 µA

= 3.6V unless otherwise specified.

SHDN

= GND 1 µA

SHDN

ISW = 150mA to GND 200 mV

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC3483E is guaranteed to meet specifications from 0°C to

70°C. Specifications over the –40°C to 85°C operating temperature range

are assured by design, characterization and correlation with statistical

process controls.

2

Note 3: Current flows out of the pin.

3483f

UW

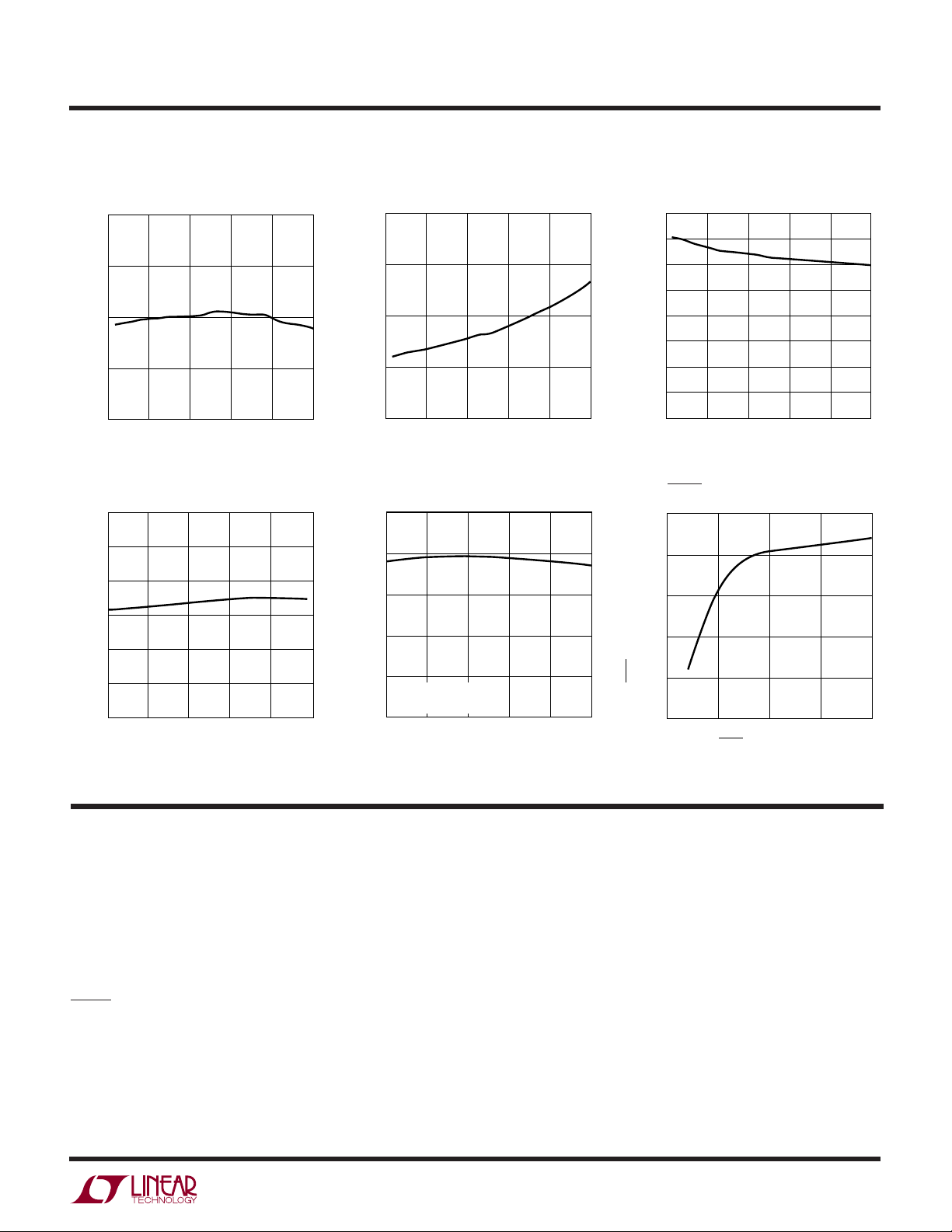

TYPICAL PERFOR A CE CHARACTERISTICS

LT3483

CURRENT (µA)

V

FB

10.2

10.1

10.0

9.9

9.8

–50

VFB Current

–20

40

10

TEMPERATURE (°C)

70

100

3483 G01

VFB Voltage Switch Off Time

12

9

6

VOLTAGE (mV)

FB

V

3

0

–50

–20

10

TEMPERATURE (°C)

40

70

100

3483 G02

400

350

300

250

200

150

SWITCH OFF TIME (ns)

100

50

0

–50

–20 10 70

TEMPERATURE (°C)

Switch Current Limit Quiescent Current SHDN Pin Bias Current

230

220

210

200

190

SWITCH CURRENT LIMIT (mA)

180

170

–50

–20 10 40 70

TEMPERATURE (°C)

100

3483 G04

50

40

30

20

QUIESCENT CURRENT (µA)

10

0

–50

NOT SWITCHING

= –0.05V

V

FB

–20

TEMPERATURE (°C)

10

= 25°C

T

A

8

6

4

2

SHDN PIN BIAS CURRENT (µA)

40

70

10

100

3483 G05

0

0

4

SHDN PIN VOLTAGE (V)

40

8

12

100

3483 G03

16

3483 G06

U

UU

PI FU CTIO S

SW: Switch. Connect to external inductor L1 and positive

terminal of transfer capacitor.

GND: Ground.

FB: Feedback. Place resistor to negative output here. Set

resistor value R1 = V

SHDN: Shutdown. Connect to GND to turn device off.

Connect to supply to turn device on.

OUT

/10µA.

D: Anode Terminal of Integrated Schottky Diode. Connect to negative terminal of transfer capacitor and external inductor L2 (flyback configuration) or to cathode of

external Schottky diode (inverting charge pump

configuration).

VIN: Input Supply. Must be locally bypassed with 1µF or

greater.

3483f

3

LT3483

BLOCK DIAGRA

W

V

IN

6

V

1.250V

REFERENCE

125k

R1

V

OUT

FB

3

+

A3

300ns

DELAY

S

Q

RQ

–

IN

+

A1

–

GND

2

OPTIONAL CHARGE PUMP CONFIGURATION.

L1B REPLACED WITH:

D2

D

R2

V

OUT

••

C

FLY

1

SW D

Q1

0.1Ω 0.1Ω

20mV

L1BL1A

5

D1

25mV

V

OUT

C

OUT

+

A2

–

3483 BD

U

OPERATIO

The LT3483 uses a constant off-time control scheme to

provide high efficiency over a wide range of output currents. Operation can be best understood by referring to the

Block Diagram. When the voltage at the FB pin is approximately 0V, comparator A3 disables most of the internal circuitry. Output current is then provided by external capacitor

C

, which slowly discharges until the voltage at the FB

OUT

pin goes above the hysteresis point of A3. Typical hysteresis at the FB pin is 10mV. A3 then enables the internal

circuitry, turns on power switch Q1, and the currents in

external inductors L1A and L1B begin to ramp up. Once the

switch current reaches 200mA, comparator A1 resets the

latch, which turns off Q1 after about 80ns. Inductor current flows through the internal Schottky D1 to GND, charging the flying capacitor. Once the 300ns off-time has

elapsed, and internal diode current drops below 250mA

(as detected by comparator A2), Q1 turns on again and

ramps up to 200mA. This switching action continues until

the output capacitor charge is replenished (until the FB pin

decreases to 0V), then A3 turns off the internal circuitry

and the cycle repeats. The inverting charge pump topology

replaces L1B with the series combination D2 and R2.

4

3483f

WUUU

APPLICATIO S I FOR ATIO

LT3483

CHOOSING A REGULATOR TOPOLOGY

Inverting Charge Pump

The inverting charge pump regulator combines an inductor-based step-up with an inverting charge pump. This

configuration usually provides the best size, efficiency and

output ripple and is applicable where the magnitude of

V

is greater than VIN. Negative outputs to –38V can be

OUT

produced with the LT3483 in this configuration. For cases

where the magnitude of V

is less than or equal to VIN,

OUT

use a 2-inductor or transformer configuration such as the

inverting flyback.

In the inverting charge pump configuration, a resistor is

added in series with the Schottky diode between the

negative output and the D pin of the LT3483. The purpose

of this resistor is to smooth/reduce the current spike in the

flying capacitor when the switch turns on. A 10Ω resistor

works well for a Li

+

to –8V application, and the impact to

converter efficiency is less than 3%. The resistor values

recommended in the applications circuits also limit the

switch current during a short-circuit condition at the

output.

Inverting Flyback

The inverting flyback regulator, shown in the –5V application circuit, uses a coupled inductor and is an excellent

choice where the magnitude of the output is less than or

equal to the supply voltage. The inverting flyback also

performs well in a step-up/invert application, but it occupies more board space compared with the inverting charge

pump. Also, the maximum |V

| using the flyback is less

OUT

than can be obtained with the charge pump—it is reduced

from 38V by the magnitudes of VIN and ringing at the

switch node. Under a short-circuit condition at the output,

a proprietary technique limits the switch current and

prevents damage to the LT3483 even with supply voltage

as high as 16V. As an option, a 0.47µF capacitor may be

added between terminals D and SW of LT3483 to suppress

ringing at SW.

Inductor Selection

Several recommended inductors that work well with the

LT3483 are listed in Table 1, although there are many other

manufacturers and devices that can be used. Consult each

manufacturer for more detailed information and for their

entire selection of related parts. Many different sizes and

shapes are available. For inverting charge pump regulators with input and output voltages below 7V, a 4.7µH or

6.8µH inductor is usually the best choice. For flyback

regulators or for inverting charge pump regulators where

the input or output voltage is greater than 7V, a 10µH

inductor is usually the best choice. A larger value inductor

can be used to slightly increase the available output

current, but limit it to around twice the value recommended, as too large of an inductance will increase the

output voltage ripple without providing much additional

output current.

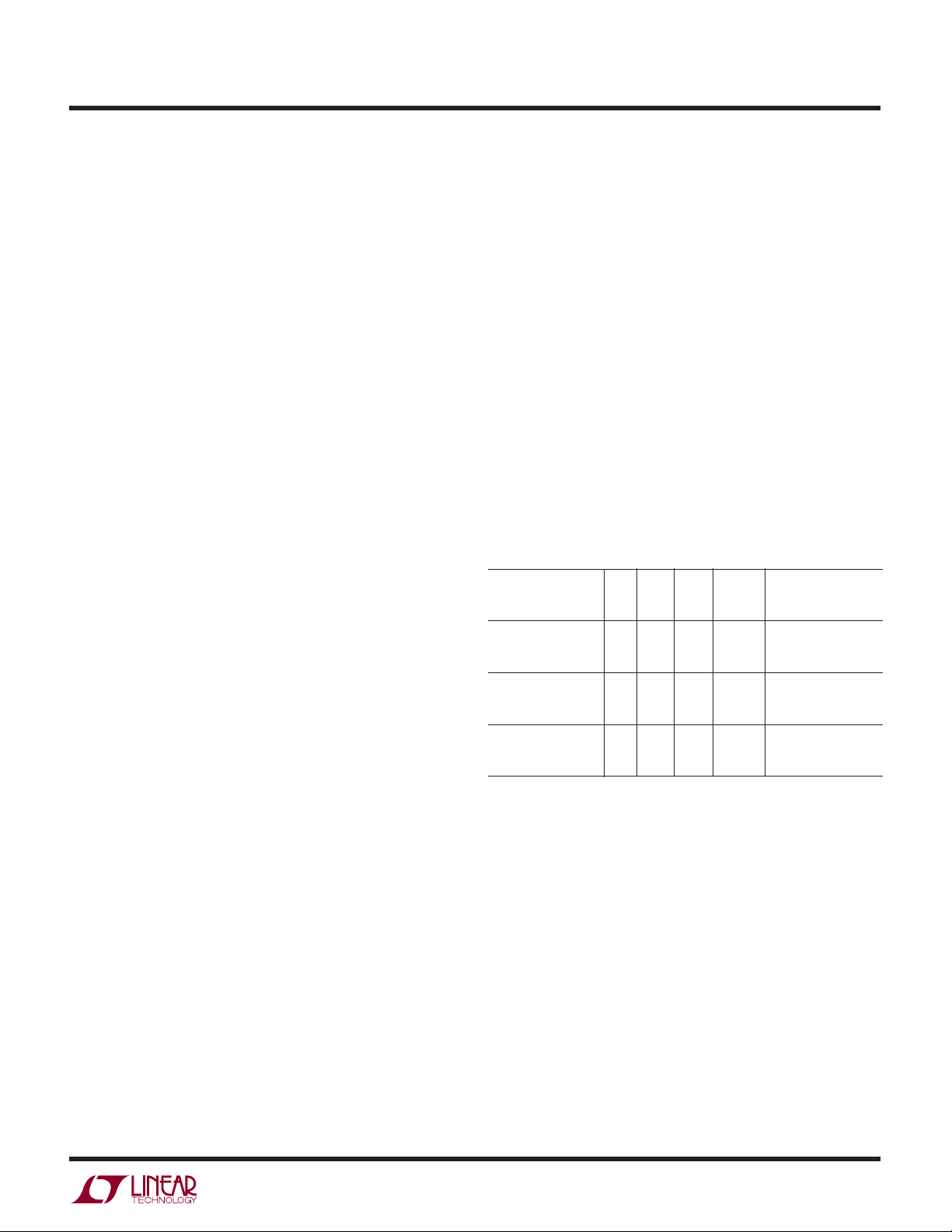

Table 1. Recommended Inductors

MAX

LIDCDCR HEIGHT

µ

PART (

LQH2MCN4R7M02L 4.7 300 0.84 0.95 Murata

LQH2MCN6R8M02L 6.8 255 1.0 www.murata.com

LQH2MCN100M02L 10 225 1.2

SDQ12 10 980 0.72 1.2 Cooper Electronics

Coupled 15 780 1.15 Tech

Inductor www.cooperet.com

744876 10 550 0.46 1.2 Würth Elektronik

Coupled www.we-online.com

Inductor

H) (mA) (Ω) (mm) MANUFACTURER

Capacitor Selection

The small size and low ESR of ceramic capacitors make

them ideal for LT3483 applications. Use of X5R and X7R

types is recommended because they retain their capacitance

over wider voltage and temperature ranges than other dielectric types. Always verify the proper voltage rating. Table

2 shows a list of several ceramic capacitor manufacturers.

Consult the manufacturers for more detailed information

on their entire selection of ceramic capacitors.

A 4.7µF ceramic bypass capacitor on the VIN pin is

recommended where the distance to the power supply or

battery could be more than a couple inches. Otherwise, a

1µF is adequate.

3483f

5

LT3483

WUUU

APPLICATIO S I FOR ATIO

A capacitor in parallel with feedback resistor R1 is recommended to reduce the output voltage ripple. Use a 5pF

capacitor for the inverting charge pump, and a 22pF value

for the inverting flyback or other dual inductor configurations. Output voltage ripple can be reduced to 20mV in some

cases using this capacitor in combination with an appropriately selected output capacitor.

The output capacitor is selected based on desired output

voltage ripple. For low output voltage ripple in the inverting

flyback configuration, use a 4.7µF to 10µF capacitor. The

inverting charge pump utilizes values ranging from 0.22µF

to 4.7µF. The following formula is useful to estimate the

output capacitor value needed:

2

LI

•

C

OUT

where I

=

–•

= 0.25A and ∆V

SW

SW

VV

∆

OUT OUT

OUT

= 30mV. The flying capacitor in the inverting charge pump configuration ranges

from 0.1µF to 0.47µF. Multiply the value predicted by the

above equation for C

by 1/10 to determine the value

OUT

needed for the flying capacitor.

Table 2. Recommended Ceramic Capacitor Manufacturers

MANUFACTURER URL

AVX www.avxcorp.com

Kemet www.kemet.com

Murata www.murata.com

Taiyo Yuden www.tyuden.com

Setting the Output Voltage

The output voltage is programmed using one feedback

resistor according to the following formula:

V

R

110=µ–

OUT

A

Inrush Current

When VIN is increased from ground to operating voltage,

an inrush current will flow through the input inductor and

integrated Schottky diode to charge the flying capacitor.

Conditions that increase inrush current include a larger,

more abrupt voltage step at VIN, a larger flying capacitor,

and an inductor with a low saturation current.

While the internal diode is designed to handle such events,

the inrush current should not be allowed to exceed 1.5A.

For circuits that use flying capacitors within the recommended range and have input voltages less than 5V,

inrush current remains low, posing no hazard to the

device. In cases where there are large steps at V

, inrush

IN

current should be measured to ensure operation within the

limits of the device.

Board Layout Considerations

As with all switching regulators, careful attention must be

given to the PCB board layout and component placement.

Proper layout of the high frequency switching path is

essential. The voltage signals of the SW and D pins have

sharp rising and falling edges. Minimize the length and

area of all traces connected to the SW and D pins. In

particular, it is desirable to minimize the trace length to

and from the flying capacitor, since current in this capacitor switches directions within a cycle. Always use a

ground plane under the switching regulator to minimize

interplane coupling.

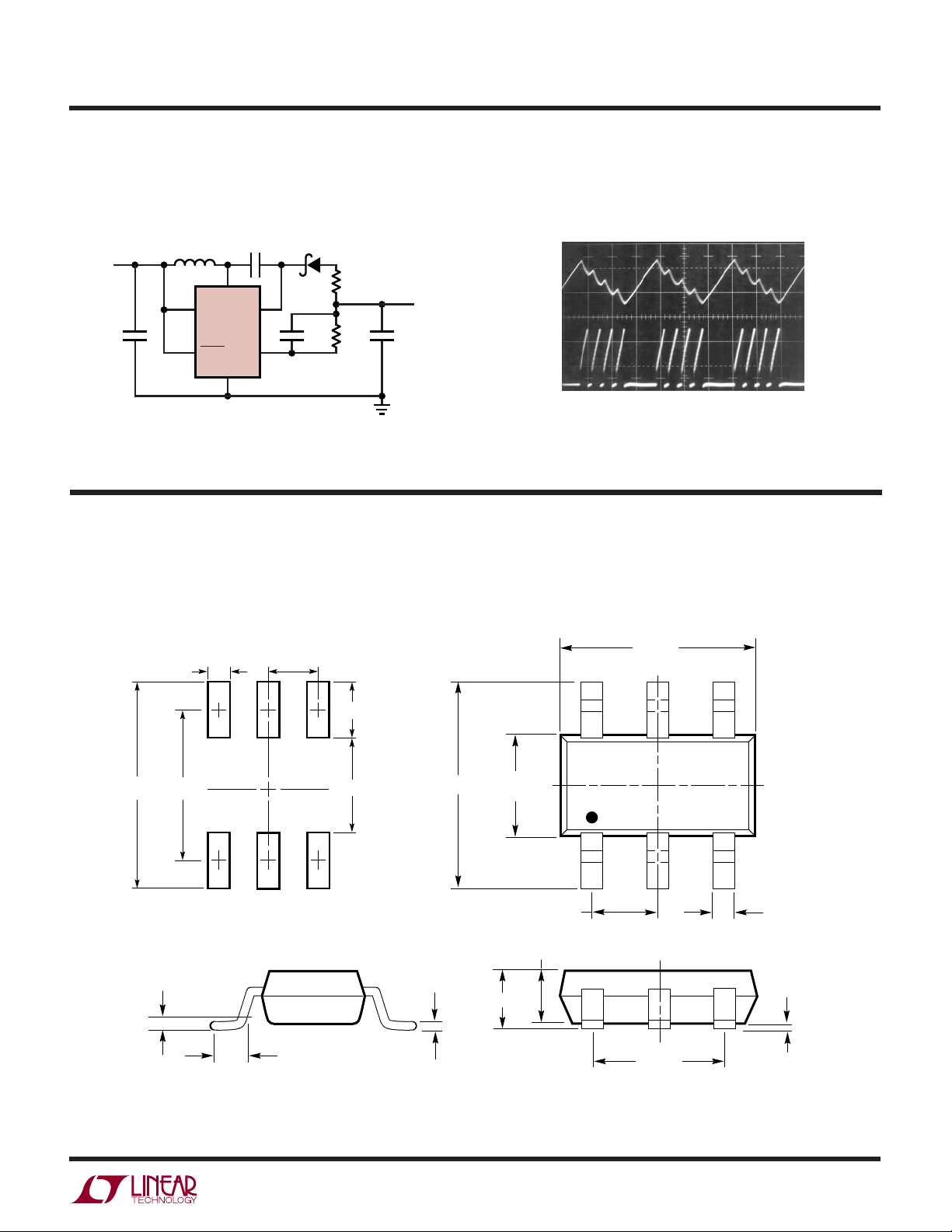

Suggested Layout (SOT-23)

for Inverting Charge Pump

+

GND

V

OUT

C

OUT

C

IN

L1

C

FLY

1

2

3

R1

6

5

4

3483 AI01

V

IN

SHDN

6

3483f

TYPICAL APPLICATIO

3.6V to –8V DC/DC Converter

Low Profile, Small Footprint

LT3483

U

SW

IN

LT3483

GND

C2

0.22µF

D

FB

D1

5pF

L1

V

IN

3.6V

C1

4.7µF

C1: MURATA GRM219R61A475KE34B

C2: TAIYO YUDEN LMK107BJ224

C3: MURATA GRM219R61C225KA88B

D1: PHILIPS PMEG2005EB

L1: MURATA LQH2MCN100K02L

10µH

V

SHDN

PACKAGE DESCRIPTIO

0.62

MAX

0.95

REF

10Ω

R1

806k

C3

2.2µF

3483 TA04a

V

OUT

–8V

25mA

U

S6 Package

6-Lead Plastic TSOT-23

(Reference LTC DWG # 05-08-1636)

V

OUT

20mV/DIV

I

SW

100mA/DIV

Switching Waveform

2µs/DIV

2.90 BSC

(NOTE 4)

3483 TA04b

3.85 MAX

2.62 REF

RECOMMENDED SOLDER PAD LAYOUT

PER IPC CALCULATOR

0.20 BSC

DATUM ‘A’

NOTE:

1. DIMENSIONS ARE IN MILLIMETERS

2. DRAWING NOT TO SCALE

3. DIMENSIONS ARE INCLUSIVE OF PLATING

1.22 REF

1.4 MIN

0.30 – 0.50 REF

2.80 BSC

0.09 – 0.20

(NOTE 3)

4. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

5. MOLD FLASH SHALL NOT EXCEED 0.254mm

6. JEDEC PACKAGE REFERENCE IS MO-193

1.50 – 1.75

(NOTE 4)

PIN ONE ID

0.95 BSC

0.80 – 0.90

1.00 MAX

1.90 BSC

0.30 – 0.45

6 PLCS (NOTE 3)

0.01 – 0.10

S6 TSOT-23 0302

3483f

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

7

LT3483

TYPICAL APPLICATIO S

U

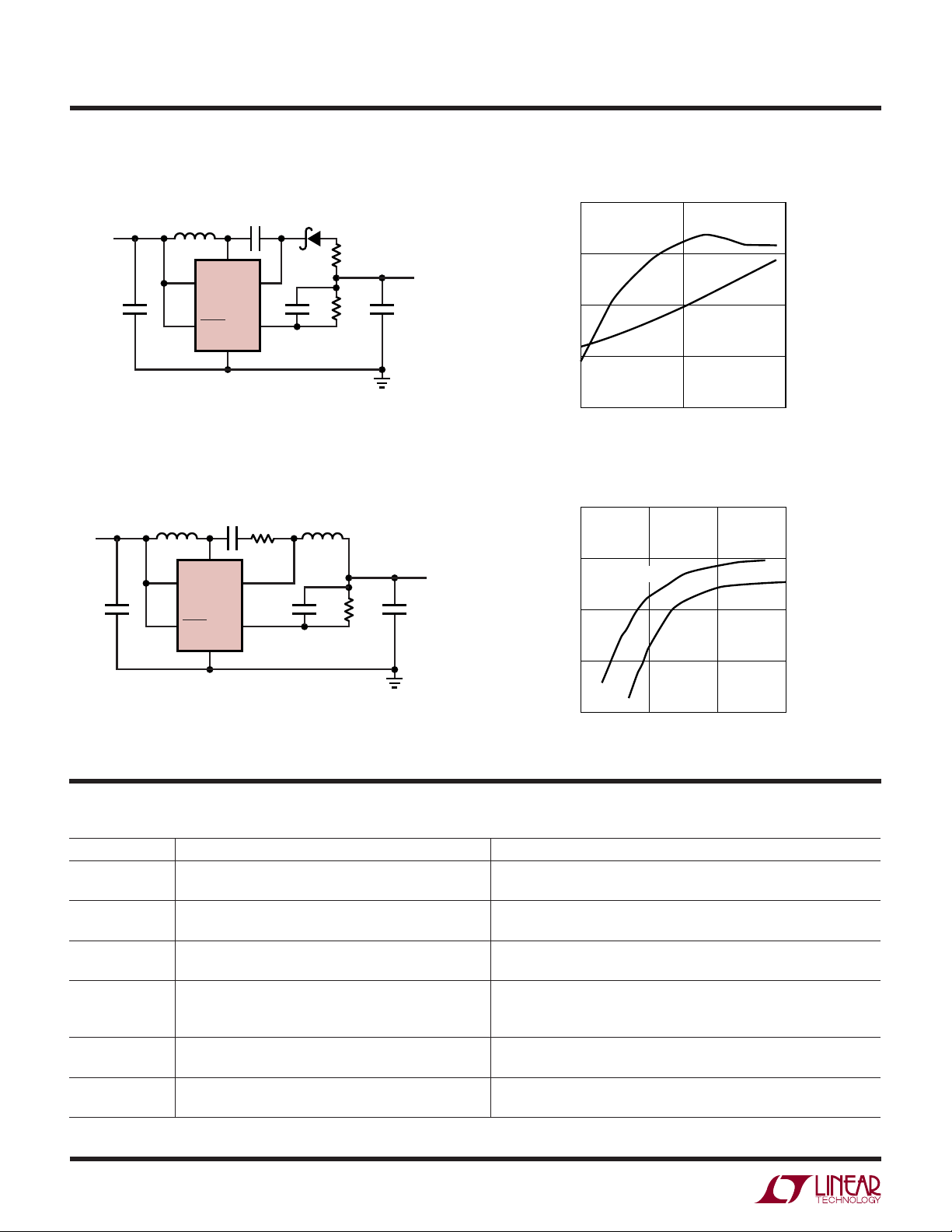

3.6V to –22V DC/DC Converter

L1A

10µH

10µH

V

SHDN

V

IN

3.6V

C1

4.7µF

C1: TAIYO YUDEN LMK316BJ475MD

C2: TAIYO YUDEN TMK107BJ104 (X5R)

C3: TAIYO YUDEN TMK316BJ105MD

D1: PHILIPS PMEG3002AEB

L1: MURATA LQH2MCN100K02L

V

IN

C1

4.7µF

C1: TAIYO YUDEN EMK316BJ475ML

C2: TAIYO YUDEN JMK316BJ106ML

L1A, L1B: WURTH 744876100

SW

IN

LT3483

GND

C2

0.1µF

D

FB

D1

R

S

30Ω

R1

5pF

2.2M

L1

V

SHDN

–5V DC/DC Converter

1nF

10Ω

••

SW

D

IN

LT3483

FB

GND

L1B

10µH

22pF

511k

C3

1µF

3483 TA02a

C2

10µF

3483 TA03a

V

OUT

–22V

8mA

V

–5V

OUT

3.6V to –22V Converter Efficiency and Power Loss

75

70

65

EFFICIENCY (%)

60

55

0.1

EFFICIENCY

POWER

LOSS

1

LOAD CURRENT (mA)

3483 TA02b

1000

100

POWER LOSS (mW)

10

1

0.1

10

–5V Efficiency

75

70

65

EFFICIENCY (%)

60

55

0.1

VIN = 5V

= 12V

V

IN

110

LOAD CURRENT (mA)

100

3483 TA03b

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1617/LT1617-1 350mA/100mA (ISW) High Efficiency VIN: 1.2V to 15V, V

Micropower Inverting DC/DC Converter ThinSOT Package

LT1931/LT1931A 1A (ISW), 1.2MHz/2.2MHz, High Efficiency VIN: 2.6V to 16V, V

Micropower Inverting DC/DC Converter ThinSOT Package

LT1945 Dual Output, Boost/Inverter, 350mA (ISW), Constant VIN: 1.2V to 15V, V

Off-Time, High Efficiency Step-Up DC/DC Converter MS10 Package

LT3463 Dual Output, Boost/Inverter, 250mA (ISW), Constant VIN: 2.3V to 15V, V

Off-Time, High Efficiency Step-Up DC/DC Converter DFN Package

with Integrated Schottky Diodes

LT3464 85mA (ISW), High Efficiency Step-Up DC/DC Converter VIN: 2.3V to 10V, V

with Integrated Schottky and PNP Disconnect ThinSOT Package

LT3472 Boost (350mA) and Inverting (400mA) DC/DC Converter VIN: 2.3V to 15V, V

for CCD Bias with Integrated Schottkys DFN Package

Linear Technology Corporation

8

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

= –34V, IQ = 20µA, ISD < 1µA

OUT(MAX)

= –34V, IQ = 5.8mA, ISD < 1µA

OUT(MAX)

= ±34V, IQ = 40µA, ISD < 1µA,

OUT(MAX)

= ±40V, IQ = 40µA, ISD < 1µA

OUT(MAX)

= 34V, IQ = 25µA, ISD < 1µA

OUT(MAX)

= ±40V, IQ = 2.8mA, ISD < 1µA

OUT(MAX)

© LINEAR TECHNOLOGY CORPORATION 2004

3483f

LT/TP 1004 1K • PRINTED IN THE USA

Loading...

Loading...