FEATURES

■

True Color PWM™ Dimming Delivers Constant LED

Color with Up to 3000:1 Range

■

Wide Input Voltage Range: 2.8V to 36V

■

4.5A, 60mΩ, 42V Internal Switch

■

Drives LEDs in Boost, Buck-Boost or Buck Modes

■

Integrated Resistors for Inductor and LED Current

Sensing

■

Program LED Current:

100mA to 1050mA (LT3478-1)

(10mV to 105mV)/R

■

Program LED Current De-Rating vs Temperature

■

Separate Inductor Supply Input

■

Inrush Current Protection

■

Programmable Soft-Start

■

Fixed Frequency Operation from 200kHz to 2.25MHz

■

Open LED Protection (Programmable OVP)

■

Accurate Shutdown/UVLO Threshold with

SENSE

(LT3478)

Programmable Hysteresis

■

16-Pin Thermally Enhanced TSSOP Package

U

APPLICATIO S

LT3478/LT3478-1

4.5A Monolithic LED

Drivers with True Color

PWM Dimming

U

DESCRIPTIO

The LT®3478/LT3478-1 are 4.5A step-up DC/DC converters designed to drive LEDs with a constant current over

a wide programmable range. Series connection of the

LEDs provides identical LED currents for uniform brightness without the need for ballast resistors and expensive

factory calibration.

The LT3478-1 reduces external component count and cost

by integrating the LED current sense resistor. The LT3478

uses an external sense resistor to extend the maximum

programmable LED current beyond 1A and also to achieve

greater accuracy when programming low LED currents.

Operating frequency can be set with an external resistor

from 200kHz up to 2.25MHz. Unique circuitry allows a

PWM dimming range up to 3000:1 while maintaining

constant LED color. The LT3478/LT3478-1 are ideal for

high power LED driver applications such as automotive TFT

LCD backlights, courtesy lighting and heads-up displays.

One of two CTRL pins can be used to program maximum

LED current. The other CTRL pin can be used to program

a reduction in maximum LED current vs temperature to

maximize LED usage and improve reliability.

■

High Power LED Driver

■

Automotive Lighting

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners. Patents Pending.

U

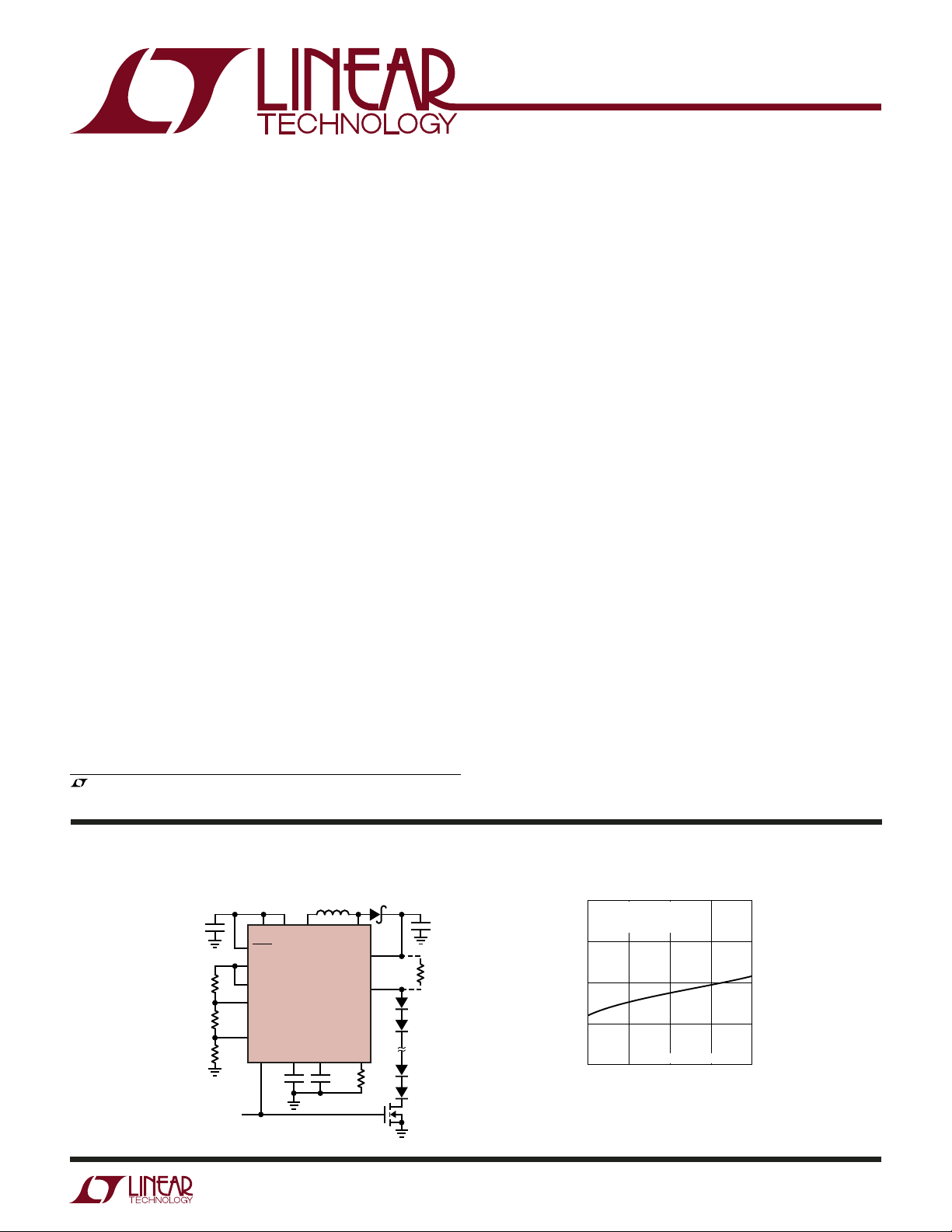

TYPICAL APPLICATIO

Automotive TFT LCD Backlight

LT3478-1

10µH

C

OUT

LED

R

T

0.1µF1µF

69.8k

4.7µF

45.3k

54.9k

130k

PWM DIMMING

CONTROL

8V TO 16V

V

IN

VINVSLSW

SHDN

V

REF

CTRL2

OVPSET

CTRL1

PWM SS V

10µF

0.1Ω

R

SENSE

(LT3478)

700mA

15W

6 LEDs

(WHITE)

3478 TA01

Additional features include inrush current protection,

programmable open LED protection and programmable

soft-start. Each part is available in a 16-pin thermally

enhanced TSSOP Package.

Effi ciency vs V

100

I

= 700mA

LED

= 500kHz

f

OSC

PWM DUTY CYCLE = 100%

95

90

EFFICIENCY (%)

85

80

8

6 LEDs LUXEON III (WHITE)

VIN (V)

IN

14 16

1210

3478 TA01b

34781f

1

LT3478/LT3478-1

WW

W

U

ABSOLUTE AXI U RATI GS

(Note 1)

SW ............................................................................42V

, LED ..................................................................42V

V

OUT

, VS, VL, ⎯S⎯H⎯D⎯N (Note 5) .......................................36V

V

IN

PWM .........................................................................15V

CTRL1, 2 .....................................................................6V

, VC, V

SS, R

T

Operating Junction Temperature Range

(Notes 2, 3, 4) .................................... –40°C to 125°C

Storage Temperature Range ................... –65°C to 150°C

Lead Temperature (Soldering, 10 Sec) .................. 300°C

, OVPSET ............................................2V

REF

UUW

PACKAGE/ORDER I FOR ATIO

TOP VIEW

1

SW

2

SW

3

V

IN

4

V

S

L

V

OUT

LED

OVPSET

16-LEAD PLASTIC TSSOP

T

EXPOSED PAD (PIN 17) IS PGND, MUST BE SOLDERED TO PCB.

JMAX

17

5

6

7

8

FE PACKAGE

= 125°C, θJA = 35°C/W

ORDER PART NUMBER FE PART MARKING

LT3478EFE

LT3478EFE-1

LT3478IFE

LT3478IFE-1

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

SS

16

R

15

T

PWM

14

CTRL2

13

CTRL1

12

SHDN

11

V

10

REF

V

9

C

3478FE

3478FE-1

3478FE

3478FE-1

●

The

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

PWM = CTRL1, CTRL2 = 1.25V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage (Rising)

Operational Input Voltage V

Quiescent Current VC = 0V (No Switching) 6.1 mA

V

IN

Shutdown Current

V

IN

⎯S⎯H⎯D⎯

N Pin Threshold (V

⎯S⎯H⎯D⎯

N Pin Threshold (V

⎯S⎯H⎯D⎯

N Pin Current

Voltage I(V

V

REF

Line Regulation I(V

V

REF

Load Regulation 0 < I(V

V

REF

Frequency: f

Frequency: f

200kHz RT = 200k 0.18 0.2 0.22 MHz

OSC

1MHz RT = 31.6k

OSC

) (Micropower)

SD_µp

) (Switching) 1.3 1.4 1.5 V

SD_UVLO

= open, VC = open, RT = 31.6k.

REF

S

VIN (Note 5)

⎯S⎯H⎯D⎯

N = 0V 3 6 µA

⎯S⎯H⎯D⎯

N = V

⎯S⎯H⎯D⎯

SD_UVLO

N = V

SD_UVLO

) = 0µA, VC = 0V

REF

) = 0µA, 2.7V < VIN < 36V 0.005 0.015 %/V

REF

) < 100µA (Max) 8 12 mV

REF

= 25°C. SW = open, VIN = VS = L = V

A

– 50mV

+ 50mV

denotes the specifi cations which apply over the full operating

= ⎯S⎯H⎯D⎯N = 2.7V, LED = open, SS = open,

OUT

●

2.8

2.8

●

0.1 0.4 0.7 V

810012 µA

●

1.213 1.240 1.263 V

●

0.88 1.12 MHz

2.4 2.8 V

36

36

µA

34781f

V

V

2

LT3478/LT3478-1

The

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

PWM = CTRL1, CTRL2 = 1.25V, V

= open, VC = open, RT = 31.6k.

REF

= 25°C. SW = open, VIN = VS = L = V

A

●

denotes the specifi cations which apply over the full operating

= ⎯S⎯H⎯D⎯N = 2.7V, LED = open, SS = open,

OUT

PARAMETER CONDITIONS MIN TYP MAX UNITS

Frequency: f

Line Regulation f

Nominal R

Maximum Duty Cycle R

LED Current to V

LED Current to V

to Switch Current Gain 13 A/V

V

C

Source Current (Out of Pin) CTRL1 = 0.4V, VC = 1V 40 µA

V

C

Sink Current CTRL1 = 0V, VC = 1V 40 µA

V

C

Switching Threshold 0.65 V

V

C

High Level (VOH) CTRL1 = 0.4V 1.5 V

V

C

Low Level (VOL) CTRL1 = 0V 0.2 V

V

C

Inductor Current Limit 2.7V < V

Switch Current Limit

Switch V

Switch Leakage Current SW = 42V, V

Overvoltage Protection (OVP)

V

OUT

(Rising)

Full Scale LED Current (LT3478-1) CTRL1 = V

700mA LED Current (LT3478-1) CTRL1 = 700mV, Current Out of LED Pin

2.25MHz RT = 9.09k 2 2.25 2.6 MHz

OSC

OSC

Pin Voltage 0.64 V

T

Current Gain (Note 6) 770 µA/A

C

Voltage Gain (Note 6) 400 V/A

C

SAT ISW = 4.5A 270 mV

CE

RT = 31.6k, 2.7V < VIN < 36V 0.05 0.2 %/V

= 31.6k

T

R

= 200k

T

R

= 9.09k

T

< 36V

S

= 0V 1 µA

C

OVPSET = 1V

OVPSET = 0.3V

, Current Out of LED Pin 1010 1050 1090 mA

REF

●

80 88

97

73

●

4.5 6 6.8 A

●

4.5 6.3 7.5 A

41

12.3

●

655 700 730 mA

%

%

%

350mA LED Current (LT3478-1) CTRL1 = 350mV, Current Out of LED Pin 325 350 375 mA

100mA LED Current (LT3478-1) CTRL1 = 100mV, Current Out of LED Pin 70 100 130 mA

Full Scale LED Current V

CTRL1 = 700mV, V

CTRL1 = 350mV, V

CTRL1 = 100mV, V

SENSE

SENSE

SENSE

(LT3478) CTRL1 = V

SENSE

(LT3478) CTRL1 = 700mV, V

(LT3478) CTRL1 = 350mV, V

(LT3478) CTRL1 = 100mV, V

CTRL1, 2 Input Currents CTRL1 = 100mV, CTRL2 = 1.25V or

REF

, V

SENSE

SENSE

SENSE

SENSE

= V

= V

= V

= V

VOUT

VOUT

VOUT

VOUT

– V

LED

– V

– V

– V

LED

LED

LED

101 105 109 mV

●

67 70.5 74 mV

33 35.5 38 mV

71013 mV

40 nA

CTRL2 = 100mV, CTRL1 = 1.25V (Current Out of Pin)

OVPSET Input Current OVPSET = 1V, V

= 41V (Current Out of Pin) 200 nA

OUT

PWM Switching Threshold 0.8 1 1.2 V

Pin Current in PWM Mode VC = 1V, PWM = 0 1 50 nA

V

C

OUT Pin Current in PWM Mode PWM = 0 1 100 nA

SS Low Level (V

)I

OL

SS Reset Threshold V

SS High Level (V

)V

OH

Soft-Start (SS) Pin Charge Current SS = 1V, Current Out of Pin, V

Soft-Start (SS) Pin Discharge Current SS = 0.5V, V

= 20µA 0.15 V

(SS)

= 0V 0.25 V

C

= 0V 1.5 V

C

= 0V 12 µA

C

= 0V 350 µA

C

V

V

34781f

3

LT3478/LT3478-1

ELECTRICAL CHARACTERISTICS

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LT3478EFE/LT3478EFE-1 are guaranteed to meet performance

specifi cations from 0°C to 125°C junction temperature. Specifi cations over

the –40°C to 125°C operating junction temperature range are assured by

design, characterization and correlation with statistical process controls.

The LT3478IFE/LT3478IFE-1 are guaranteed over the full –40°C to 125°C

operating junction temperature range.

Note 3: This IC includes over-temperature protection that is intended

temperature will exceed 125°C when over-temperature protection is active.

Continuous operation above the specifi ed maximum operating junction

temperature may impair device reliability.

Note 4: For maximum operating ambient temperature, see the “Thermal

Calculations” section in the Applications Information section.

Note 5: The maximum operational voltage for V

effi ciency considerations. Power switch base current is delivered from V

and should therefore be driven from the lowest available power supply in

the system. See “Thermal Calculations” in the Applications Information

section.

Note 6: For LT3478, parameter scales • (R

to protect the device during momentary overload conditions. Junction

UW

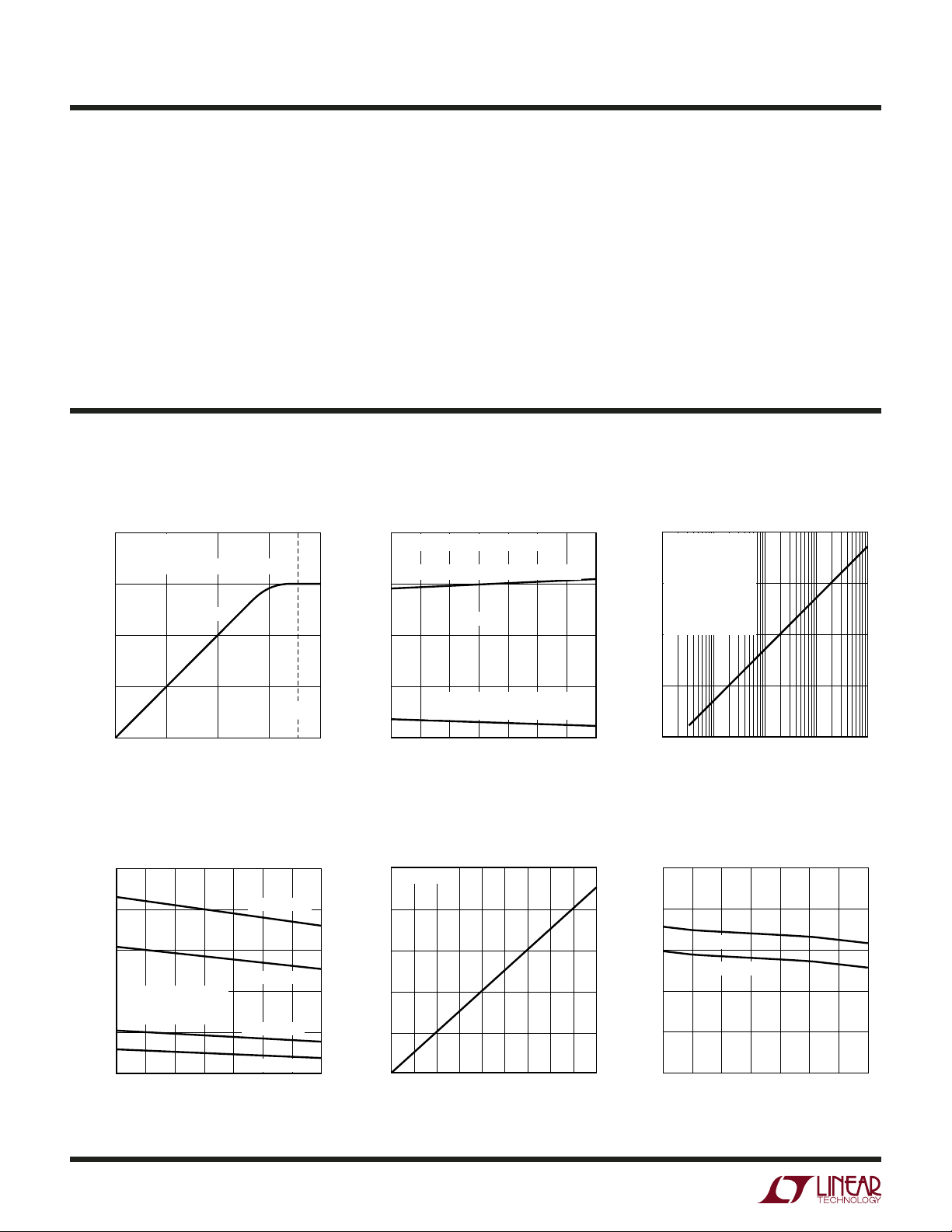

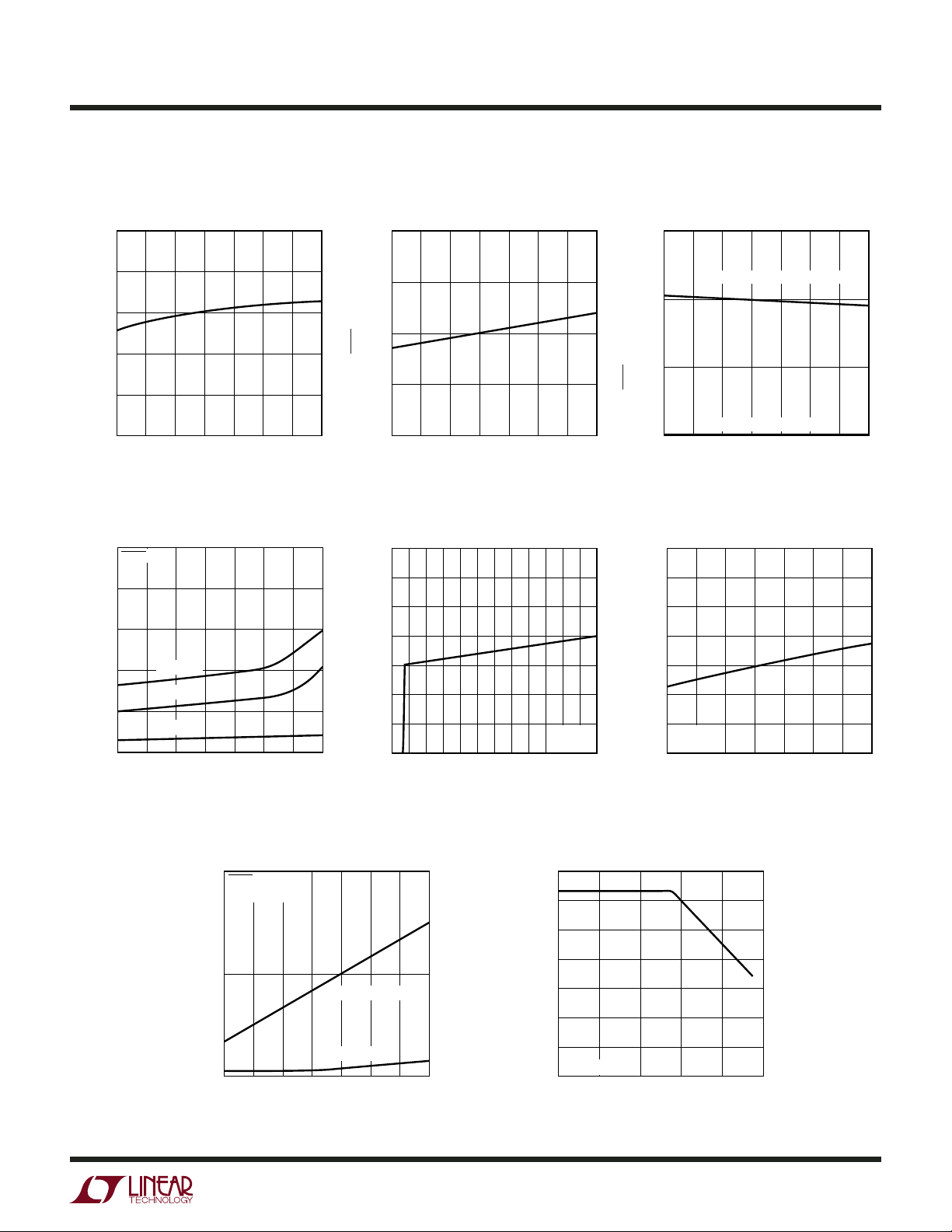

TYPICAL PERFOR A CE CHARACTERISTICS

LED Current vs CTRL1 LED Current vs Temperature

1400

TA = 25°C

CTRL2 = V

REF

(FOR LT3478 SCALE BY 0.1Ω/R

1050

700

LT3478-1

SENSE

)

1400

(FOR LT3478 SCALE BY 0.1Ω/R

I

= 1050mA, CTRL1 = CTRL2 = V

1050

LED

700

SENSE

LT3478-1

is limited by thermal and

SENSE

IN

/0.1Ω).

IN

LED Current vs PWM Duty Cycle

Wide PWM Dimming Range

(3000:1)

1000

)

REF

TA = 25°C

= VS = 12V

V

IN

6 LEDS AT 500mA

PWM FREQ = 100Hz

100

CTRL1 = 0.5V

CTRL2 = V

F

= 1.6MHz

OSC

L = 2.2µH

10

REF

LED CURRENT (mA)

350

0

0

0.35 0.70 1.05

CTRL1 (V)

CTRL1 Pin Current vs

Temperature

50

40

30

20

CTRL2 = V

CTRL1 AND CTRL2 PINS

INTERCHANGEABLE

10

CTRL1 PIN CURRENT X (–1) (nA)

0

–50

REF

–25 0 25

JUNCTION TEMPERATURE (°C)

V

REF

1.40

3478 G01

CTRL1 = 0.1V

CTRL1 = 0.35V

CTRL1 = 0.7V

CTRL1 = 0.9V

50 75 100 125

3478 G04

LED CURRENT (mA)

350

0

–50

I

LED

CTRL2 = V

–25 0 25

JUNCTION TEMPERATURE (°C)

Switch V

Current

240

TA = 25°C

210

180

(SAT) (mV)

CE

120

SWITCH V

60

0

0.5 1.5 3.0 3.5 4.0

1.0 2.0 2.5 4.5

0.0

= 100mA, CTRL1 = 100mV,

REF

50 75 100 125

(SAT) vs Switch

CE

SWITCH CURRENT (A)

3478 G02

3478 G05

LED CURRENT (mA)

1

0

0.01 1 10 100

0.1

PWM DUTY CYCLE (%)

Switch and Inductor Peak Current

Limits vs Temperature

7.0

6.5

6.0

5.5

CURRENT LIMIT (A)

5.0

4.5

–50

SWITCH

INDUCTOR

–25 0 25

JUNCTION TEMPERATURE (°C)

50 75 100 125

3478 G03

3478 G06

4

34781f

UW

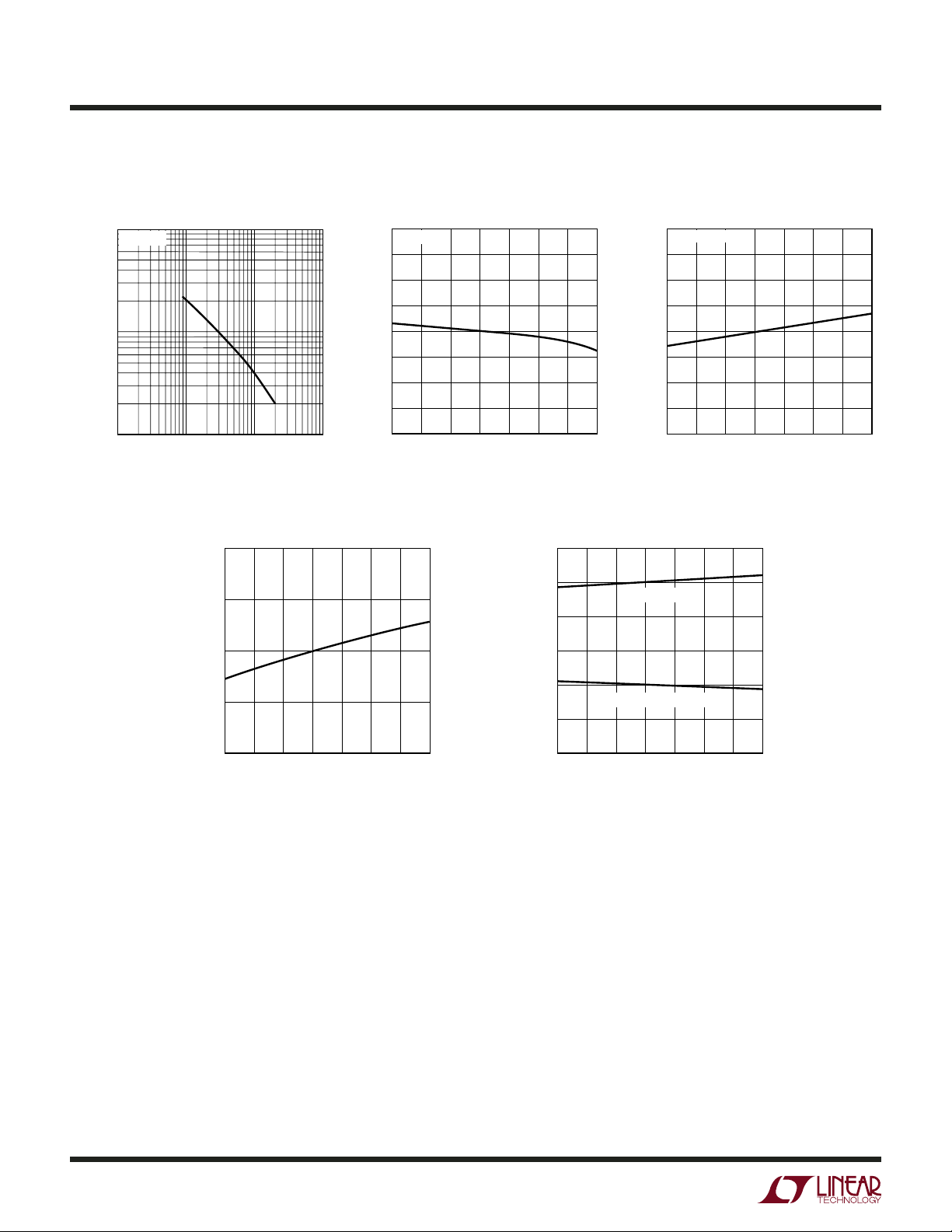

TYPICAL PERFOR A CE CHARACTERISTICS

1.28

V

vs Temperature

REF

1.60

⎯S⎯H⎯D⎯

N Threshold vs Temperature

LT3478/LT3478-1

⎯S⎯H⎯D⎯

N Pin (Hysteresis) Current vs

Temperature

15

1.26

1.24

(V)

REF

V

1.22

1.20

1.18

–50

–25 0 25

JUNCTION TEMPERATURE (°C)

Shutdown Current vs

V

IN

50 75 100 125

3478 G07

Temperature V

50

SHDN = 0V

40

30

20

CURRENT (µA)

IN

V

10

0

–50

VIN = 36V

VIN = 20V

VIN = 2.8V

–25 0 25

JUNCTION TEMPERATURE (°C)

50 75 100 125

3478 G10

1.50

1.40

SHDN (V)

1.30

1.20

–50

IN

14

12

10

8

6

CURRENT (mA)

IN

V

4

2

0

36 12

0

–25 0 25

JUNCTION TEMPERATURE (°C)

50 75 100 125

Quiescent Current vs V

18 272491521 303336

VIN (V)

3478 G08

IN

TA= 25°C

= 0V

V

C

3478 G11

JUST BEFORE PART TURNS ON

10

5

SHDN PIN CURRENT (µA)

0

–50

AFTER PART TURNS ON

–25 0 25

JUNCTION TEMPERATURE (°C)

VIN Quiescent Current vs

Temperature

14

12

10

8

6

CURRENT (mA)

IN

V

4

2

VIN = 2.8V

= 0V

V

C

0

–50

–25 0 25

JUNCTION TEMPERATURE (°C)

50 75 100 125

3478 G09

50 75 100 125

3478 G12

VS, L, SW Shutdown Currents vs

Temperature

4

SHDN = 0V

= L = SW = 36V

V

S

2

I(VS PIN) = I(L PIN)

PIN CURRENT (µA)

I(SW PIN)

0

–50

–25 0 25

JUNCTION TEMPERATURE (°C)

50 75 100 125

3478 G18

Switch Peak Current Limit

vs Duty Cycle

7

6

5

4

3

2

1

SWITCH PEAK CURRENT LIMIT (A)

TA= 25°C

0

20

0

40 60 80 100

DUTY CYCLE (%)

3478 G19

34781f

5

LT3478/LT3478-1

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Switching Frequency vs R

10000

TA = 25°C

1000

SWITCHING FREQUENCY (kHz)

100

1

10 100 1000

RT (kΩ)

T

3478 G13

SS Pin Charge Current vs

Temperature

14

13

Switching Frequency vs

Temperature

1.20

RT = 31.6k

1.15

1.10

1.05

1.00

0.95

0.90

SWITCHING FREQUENCY (MHz)

0.85

0.80

–25 0 25

–50

JUNCTION TEMPERATURE (°C)

50 75 100 125

3478 G14

Pin Active and Clamp Voltages

V

C

vs Temperature

1.8

1.5

1.2

Open-Circuit Output Clamp

Voltage vs Temperature

43.0

OVPSET = 1V

42.5

42.0

41.5

41.0

CLAMP (V)

40.5

OUT

V

40.0

39.5

39.0

–25 0 25

–50

JUNCTION TEMPERATURE (°C)

VC CLAMP

50 75 100 125

3478 G15

12

11

SS PIN CURRENT (µA) (OUT OF PIN)

10

–50

–25 0 25

JUNCTION TEMPERATURE (°C)

50 75 100 125

3478 G16

(V)

C

V

0.9

0.6

0.3

0

–50

VC ACTIVE THRESHOLD

–25 0 25

JUNCTION TEMPERATURE (°C)

50 75 100 125

3478 G17

6

34781f

PI FU CTIO S

LT3478/LT3478-1

UUU

SW (Pins 1, 2): Switch Pin. Collector of the internal NPN

power switch. Both pins are fused together inside the IC.

Connect the inductor and diode here and minimize the

metal trace area connected to this pin to minimize EMI.

(Pin 3): Input Supply. Must be locally bypassed with

V

IN

a capacitor to ground.

(Pin 4): Inductor Supply. Must be locally bypassed

V

S

with a capacitor to ground. Can be shorted to V

if only

IN

one supply is available (see L (Pin 5) function).

L (Pin 5): Inductor Pin. An internal resistor between V

S

and L pins monitors inductor current to protect against

inrush current. Exceeding 6A immediately turns off the

internal NPN power switch and discharges the soft-start

pin. Input current monitoring can be disabled by connecting the inductor power supply directly to the L pin and

leaving the V

to GND on L pin; not V

(Pin 6): Output voltage of the converter. Connect a

V

OUT

pin open (requires local bypass capacitor

S

pin).

S

capacitor from this pin to ground. Internal circuitry monitors V

for protection against open LED faults.

OUT

LED (Pin 7): Connect the LED string from this pin to

ground. An internal (LT3478-1)/external (LT3478) resistor

between the V

and LED pins senses LED current for

OUT

accurate control.

OVPSET (Pin 8): Programs V

overvoltage protection

OUT

level (OVP) to protect against open LED faults. OVP =

(OVPSET • 41)V. OVPSET range is 0.3V to 1V for an OVP

range of typically 12.3V to 41V.

(Pin 9): Output of the transconductance error amplifi er

V

C

and compensation pin for the converter regulation loop.

(Pin 10): Bandgap Voltage Reference. This pin can

V

REF

supply up to 100µA. Can be used to program CTRL1,

CTRL2, OVPSET pin voltages using resistor dividers to

ground.

⎯S⎯H⎯D⎯

N (Pin 11): The ⎯S⎯H⎯D⎯N pin has an accurate 1.4V

threshold and can be used to program an undervoltage

lockout (UVLO) threshold for system input supply using a

resistor divider from supply to ground. A 10µA pin current

hysteresis allows programming of undervoltage lockout

⎯S⎯H⎯D⎯

(UVLO) hysteresis.

and removes a 10µA sink current from the pin.

reduces V

to V

IN

current < 3µA. ⎯S⎯H⎯D⎯N can be directly connected

IN

. If left open circuit the part will be turned off.

N above 1.4V turns the part on

⎯S⎯H⎯D⎯

N = 0V

CTRL1 (Pin 12): CTRL1 pin voltage is used to program

maximum LED current (CTRL2 = V

can be set by a resistor divider from V

). CTRL1 voltage

REF

or an external

REF

voltage source. Maximum LED current is given by:

(LT3478-1) Max LED Current = Min(CTRL1, 1.05) Amps

()

LT Max LED Current

3478

(,.)•

Min CTRL

105

01

R

SE

(linear for 0.1V < CTRL1< 0.95V ; CTRL2 = V

mum LED current, short CTRL1 and CTRL2 pins to V

.

NNSE

=

Amps

) For maxi-

REF

REF

.

CTRL2 (Pin 13): The CTRL2 pin is available for programming a decrease in LED current versus temperature

(setting temperature breakpoint and slope). This feature

allows the output LED(s) to be programmed for maximum

allowable current without damage at higher temperatures.

This maximizes LED usage and increases reliability. A

CTRL2 voltage with negative temperature coeffi cient is

created using an external resistor divider from V

REF

with

temperature dependant resistance. If not used, CTRL2

should be tied to V

REF

.

PWM (Pin 14): Input pin for PWM dimming control. Above

1V allows converter switching and below 1V disables

switching with V

pin level maintained. With an external

C

MOSFET placed in series with the ground side of the LED

string, a PWM signal driving the PWM pin and MOSFET

gate provides accurate dimming control. The PWM signal

can be driven from 0V to 15V. If unused, the pin should

be connected to V

(Pin 15): A resistor to ground programs switching

R

T

REF

.

frequency between 200kHz and 2.25MHz.

SS (Pin 16): Soft-Start Pin. Placing a capacitor here programs soft-start timing to limit inductor inrush current

during start-up due to the converter. When inductor current

34781f

7

LT3478/LT3478-1

UUU

PI FU CTIO S

exceeds 6A or V

exceeds OVP, an internal soft-start

OUT

latch is set, the power NPN is immediately turned off and

the SS pin is discharged. The soft-start latch is also set

and/or ⎯S⎯H⎯D⎯N do not meet their turn on thresholds.

if V

IN

The SS pin only recharges when all faults are removed

and the pin has been discharged below 0.25V.

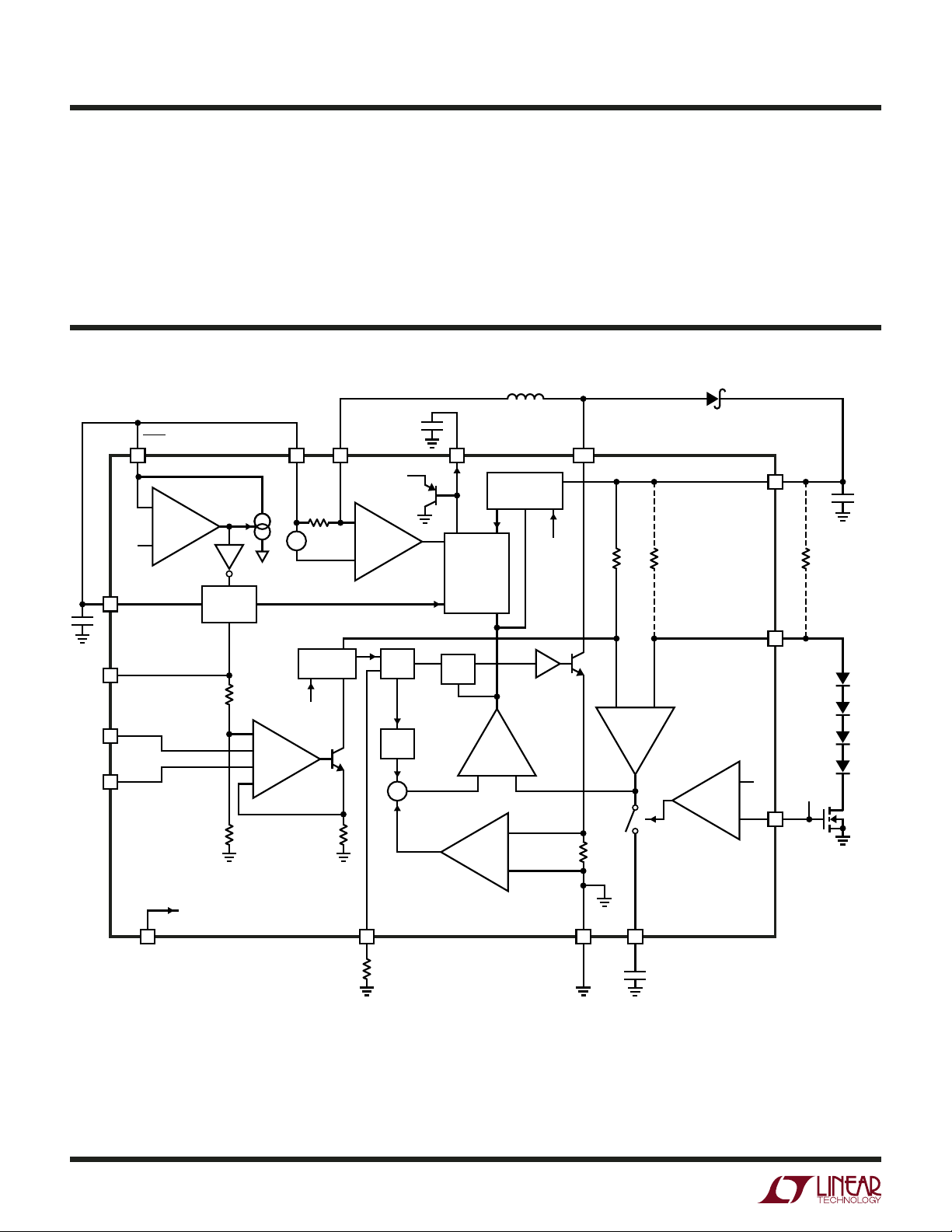

W

BLOCK DIAGRA

SHDN

11

10µA

4

–

UVLO

+

–

1.4V

+

V

IN

3

V

REF

10

REF

1.24V

V

S

5

9.5mΩ

57mV

INRUSH

CURRENT

PROTECTION

PWM

DETECT

L

V

C

–

+

OSC SQ Q1

SS

16

SOFT-START

R

Exposed Pad (Pin 17): The ground for the IC and the converter. The FE package has an Exposed Pad underneath the

IC which is the best path for heat out of the package. Pin 17

should be soldered to a continuous copper ground plane

under the device to reduce die temperature and increase

the power capability of the LT3478/LT3478-1.

SW

OVERVOLTAGE

DETECT

OVPSET

1, 2

100Ω R

SENSE

0.1Ω

(INTERNAL FOR

LT3478-1)

V

OUT

6

LED

7

R

SENSE

(EXTERNAL FOR

LT3478)

LED

CTRL1

CTRL2

–

12

13

8

OVPSET

1.05V

TO OVERVOLTAGE

DETECT CIRCUIT

PWM

+

+

+

–

1000Ω

SLOPE

COMP

Q2

Σ

+

–

+

R

–

15

R

T

EXPOSED PAD

S

17

(GND)

+

GM

–

1V

PWM

+

14

9

V

C

3478 F01

LED

LED

LED

Figure 1

34781f

8

OPERATIO

LT3478/LT3478-1

U

The LT3478/LT3478-1 are high powered LED drivers with

a 42V, 4.5A internal switch and the ability to drive LEDs

with up to 1050mA for LT3478-1 and up to 105mV/R

for LT3478.

The LT3478/LT3478-1 work similarly to a conventional

current mode boost converter but use LED current (instead

of output voltage) as feedback for the control loop. The

Block Diagram in Figure 1 shows the major functions of

the LT3478/LT3478-1.

For the part to turn on, the V

⎯S⎯H⎯D⎯

the

allows programming of an undervoltage lockout (UVLO)

threshold for the system input supply using a simple

resistor divider. A 10µA current fl ows into the

before part turn on and is removed after part turn on. This

current hysteresis allows programming of hysteresis for

the UVLO threshold. See “Shutdown Pin and Programming

Undervoltage Lockout” in the Applications Information

Section. For micropower shutdown the

reduces V

Each LED driver is a current mode step-up switching regulator. A regulation point is achieved when the

boosted output voltage V

high enough to create current in the LED(s) equal to the

programmed LED current. A sense resistor connected in

series with the LED(s) provides feedback of LED current

to the converter loop.

The basic loop uses a pulse from an internal oscillator to set

the RS fl ip-fl op and turn on the internal power NPN switch

Q1 connected between the switch pin, SW, and ground.

Current increases in the external inductor until switch

current limit is exceeded or until the oscillator reaches

its maximum duty cycle. The switch is then turned off,

causing inductor current to lift the SW pin and turn on an

external Schottky diode connected to the output. Inductor

current fl ows via the Schottky diode charging the output

capacitor. The switch is turned back on at the next reset

cycle of the internal oscillator. During normal operation

N pin must exceed 1.4V. The ⎯S⎯H⎯D⎯N pin threshold

supply current to approximately 3µA.

IN

pin must exceed 2.8V and

IN

⎯S⎯H⎯D⎯

⎯S⎯H⎯D⎯

N pin at 0V

across the output LED(s) is

OUT

SENSE

N pin

voltage controls the peak switch current limit and

the V

C

hence the inductor current available to the output LED(s).

As with all current mode converters, slope compensation

is added to the control path to ensure stability.

The CTRL1 pin is used to program maximum LED current

via Q2. The CTRL2 pin can be used to program a decrease

in LED current versus temperature for maximum reliability

and utilization of the LED(s). A CTRL2 voltage with negative

temperature coeffi cient can be created using an external

resistor divider from V

resistance. Unused CTRL2 is tied to V

For True Color PWM dimming, the LT3478/LT3478-1

provide up to a 3000:1 wide PWM dimming range by allowing the duty cycle of the PWM pin (connected to the

IC and an external N-channel MOSFET in series with the

LED(s)) to be reduced from 100% to as low as 0.033%

for a PWM frequency of 100Hz. Dimming by PWM duty

cycle, allows for constant LED color to be maintained over

the entire dimming range.

For robust operation, the LT3478/LT3478-1 monitor system

performance for any of the following faults : V

pin voltages too low and/or inductor current too high

and/or boosted output voltage too high. On detection of

any of these faults, the LT3478/LT3478-1 stop switching

immediately and a soft-start latch is set discharging the

SS pin (see Timing Diagram for SS pin in Figure 11). All

faults are detected internally and do not require external

components. When all faults no longer exist, an internal

12µA supply charges the SS pin with a timing programmed

using a single external capacitor. A gradual ramp up of SS

pin voltage limits switch current during startup.

For optimum component sizing, duty cycle range and effi ciency the LT3478/LT3478-1 allow for a separate inductor

supply V

from 200kHz up to 2.25MHz using a resistor from the R

pin to ground. The advantages of these options are covered

in the Applications Informations section.

and for switching frequency to be programmed

S

with temperature dependant

REF

.

REF

or ⎯S⎯H⎯D⎯N

IN

T

34781f

9

LT3478/LT3478-1

U

WUU

APPLICATIO S I FOR ATIO

Inductor Selection

Several inductors that work well with the LT3478/LT3478-1

are listed in Table 1. However, there are many other manufacturers and inductors that can be used. Consult each

manufacturer for more detailed information and their entire

range of parts. Ferrite cores should be used to obtain the

best effi ciency. Choose an inductor that can handle the

necessary peak current without saturating. Also ensure

that the inductor has a low DCR (copper-wire resistance)

to minimize I

22µH will suffi ce for most applications.

Inductor manufacturers specify the maximum current

rating as the current where inductance falls by a given

percentage of its nominal value. An inductor can pass a

current greater than its rated value without damaging it.

Aggressive designs where board space is precious will

exceed the maximum current rating of the inductor to save

space. Consult each manufacturer to determine how the

maximum inductor current is measured and how much

more current the inductor can reliably conduct.

2

R power losses. Values between 4.7µH and

Capacitor Selection

Low ESR (equivalent series resistance) ceramic capacitors should be used at the output to minimize the output

ripple voltage. Use only X5R or X7R dielectrics, as these

materials retain their capacitance over wider voltage and

temperature ranges than other dielectrics. A 4.7µF to

10µF output capacitor is suffi cient for most high output

current designs. Some suggested manufacturers are

listed in Table 2.

Diode Selection

Schottky diodes, with their low forward voltage drop and

fast switching speed, are ideal for LT3478/LT3478-1 applications. Table 3 lists several Schottky diodes that work

well. The diode’s average current rating must exceed the

application’s average output current. The diode’s maximum

reverse voltage must exceed the application’s output voltage. A 4.5A diode is suffi cient for most designs. For PWM

dimming applications, be aware of the reverse leakage

current of the diode. Lower leakage current will drain the

output capacitor less, allowing for higher dimming range.

The companies below offer Schottky diodes with high

voltage and current ratings.

Table 1. Suggested Inductors

MANUFACTURER PART NUMBER IDC (A) INDUCTANCE (µH) MAX DCR (mΩ)L × W × H (mm) MANUFACTURER

CDRH104R-100NC

CDRH103RNP-4R7NC-B

CDRH124R-100MC

CDRH104R-5R2NC

FDV0630-4R7M 4.2 4.7 49 7.0 × 7.7 × 3.0 Toko

UP4B-220 7.6 22 34 22 × 15 × 7.9 Cooper

Table 2. Ceramic Capacitor Manufacturers

MANUFACTURER PHONE NUMBER WEB

Taiyo Yuden (408) 573-4150 www.t-yuden.com

AVX (803) 448-9411 www.avxcorp.com

Murata (714) 852-2001 www.murata.com

Table 3. Suggested Diodes

MANUFACTURER PART NUMBER MAX CURRENT (A) MAX REVERSE VOLTAGE WEB

UPS340 3 40 Microsemi

B520C

B530C

B340A

B540C

PDS560

3.8

4

4.5

5.5

5

5

3

5

5

10

4.7

10

5.2

35

30

28

22

30

30

40

40

60

10.5 × 10.3 × 4.0

10.5 × 10.3 × 3.1

12.3 × 12.3 × 4.5

10.5 × 10.3 × 4.0

Sumida

www.sumida.com

www.toko.com

www.cooperet.com

www.microsemi.com

Diodes, Inc.

www.diodes.com

34781f

10

LT3478/LT3478-1

U

WUU

APPLICATIO S I FOR ATIO

Shutdown and Programming Undervoltage Lockout

The LT3478/LT3478-1 have an accurate 1.4V shutdown

⎯S⎯H⎯D⎯

threshold at the

conjunction with a resistor divider from the system input

supply to defi ne an accurate undervoltage lockout (UVLO)

threshold for the system (Figure 2).

hysteresis allows programming of hysteresis voltage for

this UVLO threshold. Just before part turn on, 10µA fl ows

⎯S⎯H⎯D⎯

into the

⎯S⎯H⎯D⎯

N pin. Calculation of the on/off thresholds for a system

N pin. After part turn on, 0µA fl ows from the

input supply using the LT3478/LT3478-1

be made as follows:

V

SUPPLY

V

SUPPLY

OFF = 1.4 [1 + R1/R2)]

ON = V

An open drain transistor can be added to the resistor

divider network at the

the turn off of the LT3478/LT3478-1.

N pin. This threshold can be used in

⎯S⎯H⎯D⎯

N pin current

⎯S⎯H⎯D⎯

N pin can

OFF + (10µA • R1)

SUPPLY

⎯S⎯H⎯D⎯

N pin to independently control

Programming Switching Frequency

The switching frequency is programmed using an external

resistor (R

) connected between the RT pin and ground. The

T

internal free-running oscillator is programmable between

200kHz and 2.25MHz. Table 4 shows the typical R

values

T

required for a range of switching frequencies.

Selecting the optimum switching frequency depends

on several factors. Inductor size is reduced with higher

frequency but effi ciency drops due to higher switching

losses. In addition, some applications require very high duty

cycles to drive a large number of LEDs from a low supply.

Low switching frequency allows a greater operational duty

cycle and hence a greater number of LEDs to be driven.

In each case the switching frequency can be tailored to

provide the optimum solution. When programming the

switching frequency the total power losses within the IC

should be considered. See “Thermal Calculations” in the

Applications Information section.

V

SUPPLY

R1

R2

ONOFF

Figure 2. Programming Undervoltage Lockout (UVLO)

with Hysteresis

SHDN

11

1.4V

10µA

–

+

3478 F02

With the ⎯S⎯H⎯D⎯N pin connected directly to the VIN pin, an

internal undervoltage lockout threshold exists for the V

IN

pin (2.8V max). This prevents the converter from operating in an erratic mode when supply voltage is too low.

The LT3478/LT3478-1 provide a soft-start function when

⎯S⎯H⎯D⎯

recovering from such faults as

N <1.4V and/or VIN

<2.8V. See details in the Applications Information section

“Soft-Start”.

10000

TA = 25°C

1000

SWITCHING FREQUENCY (kHz)

100

1

Figure 3. Switching Frequency vs RT Resistor Value

Table 4. Switching Frequencies vs R

SWITCHING FREQUENCY (MHz) RT (kΩ)

2.25 9.09

0.2 200

10 100 1000

RT (kΩ)

Values

T

1 31.6

3478 F03

34781f

11

LT3478/LT3478-1

U

WUU

APPLICATIO S I FOR ATIO

Programming Maximum LED current

Maximum LED current can be programmed using the CTRL1

pin with CTRL2 tied to the V

The maximum allowed LED current is defi ned as:

(LT3478-1) Max LED Current = Min(CTRL1, 1.05) Amps

()

LT Max LED Current

3478

.

(,.)•

Min CTRL

1105

01

R

S

EENSE

LED current vs CTRL1 is linear for approximately

0.1V < CTRL1 < 0.95V

For maximum possible LED current, connect CTRL1 and

CTRL2 to the V

1400

1050

pin.

REF

TA = 25°C

CTRL2 = V

REF

(FOR LT3478 SCALE

BY 0.1Ω/R

SENSE

pin (see Figures 4 and 5).

REF

=

Amps

)

maximum allowed LED current versus temperature to

warn against exceeding this current limit and damaging

the LED (Figure 6).

Luxeon V (Maximum) and LT3478-1

(Programmed) Current Derating

Curves vs Temperature

900

800

700

600

500

EXAMPLE

400

LT3478-1

300

PROGRAMMED LED

FORWARD CURRENT (mA)

f

I

CURRENT DERATING CURVE

200

100

0

0

LUXEON V EMITTER

(GREEN, CYAN, BLUE, ROYAL BLUE)

θ

25

TA AMBIENT TEMPERATURE (°C)

= 20°C/W

JA

LUXEON V EMITTER

CURRENT DERATING

CURVE

50 75 100

3478 F06

700

LED CURRENT (mA)

350

0

0

LT3478-1

0.35 0.70 1.05

CTRL1 (V)

V

REF

1.40

3478 F04

Figure 4. LED Current vs CTRL1 Voltage

LT3478/LT3478-1

10

V

REF

R2 R

R1

13

CTRL2

12

CTRL1

V

LED

3478 F05

(LT3478)

OUT

SENSE

Figure 5. Programming LED Current

Programming LED Current Derating vs Temperature

A useful feature of the LT3478/LT3478-1 is the ability

to program a derating curve for maximum LED current

versus temperature. LED data sheets provide curves of

Figure 6. LED Current Derating Curve vs Ambient Temperature

Without the ability to back off LED current as temperature

increases, many LED drivers are limited to driving the

LED(s) at only 50% or less of their maximum rated currents.

This limitation requires more LEDs to obtain the intended

brightness for the application. The LT3478/LT3478-1 allow the output LED(s) to be programmed for maximum

allowable current while still protecting the LED(s) from

excessive currents at high temperature. This is achieved

by programming a voltage at the CTRL2 pin with a negative temperature coeffi cient using a resistor divider with

temperature dependent resistance (Figures 7 and 8).

CTRL2 voltage is programmed higher than CTRL1 voltage.

This allows initial LED current to be defi ned by CTRL1.

As temperature increases, CTRL2 voltage will fall below

CTRL1 voltage causing LED currents to be controlled by

CTRL2 pin voltage. The choice of resistor ratios and use

of temperature dependent resistance in the divider for the

CTRL2 pin will defi ne the LED current curve breakpoint

and slope versus temperature (Figure 8).

A variety of resistor networks and NTC resistors with different temperature coeffi cients can be used for programming

12

34781f

LT3478/LT3478-1

U

WUU

APPLICATIO S I FOR ATIO

CTRL2 to achieve the desired CTRL2 curve vs temperature.

The current derating curve shown in Figure 6 uses the

resistor network shown in option C of Figure 7.

10

V

REF

R4

R2

R1

R

NTC

R3

R

NTC

OPTION A TO D

Figure 7. Programming LED Current Derating Curve

vs Temperature (R

1100

1000

900

800

700

600

500

400

300

200

LED CURRENT = MINIMUM

CTRL1, CTRL2 PIN VOLTAGES (mV)

OF CTRL1, CTRL2

100

R3 = OPTION C

0

0

Located on LEDs PCB)

NTC

25

TA AMBIENT TEMPERATURE (°C)

Figure 8. CTRL1, 2 Programmed Voltages vs Temperature

LT3478/LT3478-1

13

CTRL2

12

CTRL1

R

Y

R

R

X

NTC

50 75 100

CTRL1

CTRL2

R

NTC

DCBA

3478 F08

R

Y

3478 F07

R

X

to obtain a resistor’s exact values over temperature from

the manufacturer. Hand calculations of CTRL2 voltage

can then be performed at each given temperature and the

resulting CTRL2 curve plotted versus temperature. Several

iterations of resistor value calculations may be required

to achieve the desired breakpoint and slope of the LED

current derating curve.

Table 5. NTC Resistor Manufacturers/Distributors

MANUFACTURER

Murata Electronics North America www.murata.com

TDK Corporation www.tdk.com

Digi-key www.digikey.com

If calculation of CTRL2 voltage at various temperatures

gives a downward slope that is too strong, alternative

resistor networks can be chosen (B, C, D in Figure 7)

which use temperature independent resistance to reduce

the effects of the NTC resistor over temperature.

Murata Electronics provides a selection of NTC resistors

with complete data over a wide range of temperatures. In

addition, a software tool is available which allows the user

to select from different resistor networks and NTC resistor

values and then simulate the exact output voltage curve

(CTRL2 behavior) over temperature. Referred to as the

‘Murata Chip NTC Thermistor Output Voltage Simulator’,

users can log onto www.murata.com/designlib and download the software followed by instructions for creating an

output voltage V

). At any time during selection of circuit parameters

(V

REF

(CTRL2) from a specifi ed VCC supply

OUT

the user can access data on the chosen NTC resistor by

clicking on a link to the Murata catalog.

Table 5 shows a list of manufacturers/distributors of NTC

resistors. There are several other manufacturers available

and the chosen supplier should be contacted for more

detailed information. To use an NTC resistor to indicate

LED temperature it is only effective if the resistor is connected as close as possible to the LED(s). LED derating

curves shown by manufacturers are listed for ambient

temperature. The NTC resistor should be submitted to

the same ambient temperature as the LED(s). Since the

temperature dependency of an NTC resistor can be nonlinear over a wide range of temperatures it is important

The following example uses hand calculations to derive

the resistor values required for CTRL1 and CTRL2 pin

voltages to achieve a given LED current derating curve.

The resistor values obtained using the Murata simulation

tool are also provided and were used to create the derating

curve shown in Figure 6. The simulation tool illustrates

the non-linear nature of the NTC resistor temperature

coeffi cient at temperatures exceeding 50°C ambient. In

addition, the resistor divider technique using an NTC

resistor to derive CTRL2 voltage inherently has a fl attening characteristic (reduced downward slope) at higher

temperatures. To avoid LED current exceeding a maximum

34781f

13

LT3478/LT3478-1

U

WUU

APPLICATIO S I FOR ATIO

allowed level at higher temperatures, the CTRL2 voltage

curve may require a greater downward slope between

25°C and 50°C to compensate for that loss of slope at

higher temperatures.

Example: Calculate the resistor values required for generating CTRL1 and CTRL2 from V

requirements:

(a) I

(b) I

(c) I

= 700mA at 25°C

LED

derating curve breakpoint occurs at 25°C

LED

derating curve has a slope of –200mA/25°C be-

LED

tween 25°C and 50°C ambient temperature

Step1: Choose CTRL1 = 700mV for I

CTRL1 = V

R2 = R1 • [(V

For V

REF

/(1 + R2/R1)

REF

/CTRL1) – 1]

REF

= 1.24V and choosing R1 = 22.1k,

R2 = 22.1k [(1.24/0.7) – 1]

R2 = 17k (choose 16.9k)

based on the following

REF

= 700mA

LED

R

R

R

NTC

NTC

NTC

(50°C) = R

(25°C).e

NTC

(50°C) = 22k • 0.358

(50°C) = 7.9k

–1.026

CTRL2(50°C) = 1.24/(1 + 16.9/7.9) = 395mV

CTRL2 slope (25°C to 50°C) = [CTRL2(50°C)

– CTRL2(25°C)]/25°C

= (395 – 701)/25

= –306mV/25°C

I

The required I

slope = –306mA/25°C

LED

slope is –200mA/25°C. To reduce the

LED

slope of CTRL2 versus temperature it is easier to keep

the exact same NTC resistor value and B-constant (there

are limited choices) and simply adjust R4 and the type

of resistor network used for the CTRL2 pin. By changing

the resistor network to option C it is possible to place a

temperature independent resistor in series with R

reduce the effects of R

on the CTRL2 pin voltage over

NTC

NTC

to

temperature.

CTRL1 = 1.24/(1 + (16.9/22.1))

CTRL1 = 703mV (I

= 703mA)

LED

Step 2: Choose resistor network option A (Figure 7) and

CTRL2 = CTRL1 for 25°C breakpoint

start with R4 = R2 = 16.9k, R

= 22k (closest value

NTC

available)

CTRL2 = 701mV (I

= Min(CTRL1, CTRL2) • 1A =

LED

701mA)

Step 3: Calculate CTRL2 slope between 25°C and 50°C

CTRL2 (T) = 1.24/(1 + R4/R

at T = T

at T = 50°C, R

= 25°C, CTRL2 = 701mV

O

(T) = R

NTC

NTC

(T))

NTC

(TO).ex, x = B [(1/(T + 273)

– 1/298)]

(B = B-constant; linear over the 25°C to 50°C temperature

range)

For R

B-constant = 3950 and T = 50°C

NTC

x = 3950 [(1/323) – 1/298] = –1.026

Step 4: Calculate the resistor value required for R

resistor network option (c) (Figure 7) to provide an I

Y

LED

in

slope of –200mA/25°C between 25°C and 50°C ambient

temperature.

CTRL2 (25°C) = 0.7V = 1.24/(1 + (R4/(R

))

R

Y

R4 = 0.77 (R

(25°C) + RY) (a)

NTC

(25°C)+

NTC

for –200mA/25°C slope ≥ CTRL2(50°C) = 0.7 – 0.2 =

0.5

CTRL2(50°C) = 0.5V = 1.24/(1 + (R4/(R

R4 = 1.48 (R

Equating (a) = (b) and knowing R

(50°C) = 7.9k gives,

R

NTC

0.77 (22k + R

17k + 0.77 R

(50°C) + RY) (b)

NTC

(25°C) = 22k and

NTC

) = 1.48 (7.9k + RY)

Y

= 11.7 k + 1.48 R

Y

Y

NTC

+ RY))

RY = (17k – 11.7k)/(1.48 – 0.77)

R

= 7.5k

Y

14

34781f

LT3478/LT3478-1

U

WUU

APPLICATIO S I FOR ATIO

The value for R4 can now be solved using equation (a)

where,

R4 = 0.77 (R

R4 = 22.7k (choose 22.6k)

slope can now be calculated from,

I

LED

slope = [CTRL2(50°C) – CTRL2(25°C)]/25°C

I

LED

where CTRL2 (50°C) = 1.24/(1 + 22.6/(7.9 + 7.5)) =

503mV

and CTRL2 (25°C) = 1.24/(1 + 39.2/(22 + 28.7)) =

699mV

giving I

LED

= 503mV – 699mV/25°C

= –196mV/25°C => I

Using the Murata simulation tool for the resistor network

and values in the above example shows a CTRL2 voltage curve that fl attens out as temperatures approach

100°C ambient. The fi nal resistor network chosen for the

derating curve in Figure 6 used option C network with

R4 = 19.3k, R

= 3.01k. Although the CTRL2 downward slope is greater

than –200mA/25°C initially, the slope is required to avoid

exceeding maximum allowed LED currents at high ambient

temperatures (see Figure 6).

PWM Dimming

Many LED applications require an accurate control of the

brightness of the LED(s). In addition, being able to maintain a constant color over the entire dimming range can

be just as critical. For constant color LED dimming, the

LT3478/LT3478-1 provide a PWM pin and special internal

circuitry to allow up to a 3000:1 wide PWM dimming

range. With an N-channel MOSFET connected between

the LED(s) and ground and a PWM signal connected to

the gate of the MOSFET and the PWM pin (Figure 9), it

is possible to control the brightness of the LED(s) based

on PWM signal duty cycle only. This form of dimming is

superior to dimming control using an analog input voltage

(reducing CTRL1 voltage) because it allows constant color

to be maintained during dimming. The maximum current

(25°C) + RY) = 0.77 (22k + 7.5k)

NTC

slope (from 25°C to 50°C)

slope = –196mA/25°C

LED

= 22k (NCP15XW223J0SRC) and RY

NTC

for the output LED(s) is programmed for a given brightness/color and “chopped” over a PWM duty cycle range

(Figure 10) from 100% to as low as 0.033%.

D2

C

(LT3478)

R

SENSE

D1

3478 F09

OUT

3478 F10

VSLSW

V

IN

SHDN

V

REF

CTRL2

CTRL1

OVPSET

Figure 9. PWM Dimming Control Using the LT3478/LT3478-1

PWM

INDUCTOR

CURRENT

LED

CURRENT

Figure 10. PWM Dimming Waveforms Using the

LT3478/LT3478-1

LT3478/

LT3478-1

R

C

T

PWM DIMMING

CONTROL

TON

MAX I

PWM

LED

T

PWM

V

OUT

LED

PWMV

(= 1/f

)

PWM

Some general guidelines for LED Current Dimming using

the PWM pin (see Figure 10):

(1) PWM Dimming Ratio (PDR) = 1/(PWM duty cycle) =

1/(TON

PWM

• f

(2) Lower f

(use minimum f

)

PWM

allows higher PWM Dimming Ratios

PWM

= 100Hz to avoid visible fl icker and

PWM

to maximize PDR)

(3) Higher f

value improves PDR (allows lower TON

OSC

PWM

)

but will reduce effi ciency and increase internal heating. In

general, minimum operational TON

PWM

= 3 • (1/f

OSC

).

(4) Lower inductor value improves PDR

34781f

15

LT3478/LT3478-1

U

WUU

APPLICATIO S I FOR ATIO

(5) Higher output capacitor value improves PDR

(6) Choose the schottky diode (D2, Figure 9) for minimum

reverse leakage

See Typical Performance Characteristics graph “LED Current vs PWM Duty Cycle”.

Soft-Start

To limit inrush current and output voltage overshoot during startup/recovery from a fault condition, the LT3478/

LT3478-1 provide a soft-start pin SS. The SS pin is used

to program switch current ramp up timing using a capacitor to ground. The LT3478/LT3478-1 monitor system

parameters for the following faults: V

inductor current >6A and boosted output voltage >OVP.

On detection of any of these faults, the LT3478/LT3478-1

stop switching immediately and a soft-start latch is set

causing the SS pin to be discharged (see Timing Diagram

for the SS pin in Figure 11). When all faults no longer exist and the SS pin has been discharged to at least 0.25V,

the soft-start latch is reset and an internal 12µA supply

charges the SS pin. A gradual ramp up of SS pin voltage

is equivalent to a ramp up of switch current limit until SS

exceeds V

.

C

The ramp rate of the SS pin is given by:

ΔV

SW

SS

FAULTS TRIGGERING

SOFT-START LATCH

WITH SW TURNED OFF

IMMEDIATELY:

V

IN

SHDN < 1.4V OR

V

OUT

I

(INDUCTOR)

/Δt = 12µA/C

SS

< 2.8V OR

> OVP OR

> 6A

Figure 11. LT3478 Fault Detection and SS Pin Timing Diagram

SS

SOFT-START

LATCH SET:

<2.8V, ⎯S⎯H⎯D⎯N <1.4,

IN

0.65V (ACTIVE THRESHOLD)

0.25V (RESET THRESHOLD)

0.15V

SOFT-START LATCH RESET:

SS < 0.25V AND

> 2.8V AND

V

IN

SHDN > 1.4V AND

< OVP AND

V

OUT

I

(INDUCTOR)

< 6A

3478 F11

To limit inductor current overshoot to <0.5A when SS

charges past the V

level required for loop control, the CSS

C

capacitor should be chosen using the following formula:

C

SS(MIN)

Example: V

C

SS(MIN)

= 0.1µF (7.35 – 0.6(1.05 • 16/8))

= CC (7.35 – 0.6(I

= 8V, V

S

OUT

= 16V, I

• V

LED

OUT/VS

= 1.05A, CC = 0.1µF,

LED

))

= 0.612µF (choose 0.68µF).

High Inductor Current “Inrush” Protection

The LT3478/LT3478-1 provide an integrated resistor

between the V

and L pins to monitor inductor current

S

(Figure 1). During startup or “hotplugging” of the inductor supply, it is possible for inductor currents to exceed

the maximum switch current limit. When inductor current

exceeds 6A, the LT3478/LT3478-1 protect the internal

power switch by turning it off and triggering a soft-start

latch. This protection prevents the switch from repetitively

turning on during excessive inductor currents by delaying switching until the fault has been removed. To defeat

inductor current sensing the inductor supply should be

connected to the L pin and the V

pin left open. See details

S

in the Applications Information section “Soft-Start”.

LED Open Circuit Protection and Maximum PWM

Dimming Ratios

The LT3478/LT3478-1 LED drivers provide optimum protection from open LED faults by clamping the converter

output to a programmable overvoltage protection level

(OVP). In addition, the programmable OVP feature draws

zero current from the output during PWM = 0 to allow

higher PWM dimming ratios. This provides an advantage

over other LED driver applications which connect a resistor

divider directly from V

OUT

.

An open LED fault occurs when the connection to the

LED(s) becomes broken or the LED(s) fails open. For an

LED driver using a step-up switching regulator, an open

circuit LED fault can cause the converter output to exceed

the voltage capabilities of the regulator’s power switch,

causing permanent damage. When V

exceeds OVP, the

OUT

16

34781f

LT3478/LT3478-1

U

WUU

APPLICATIO S I FOR ATIO

LT3478/LT3478-1 immediately stop switching, a soft-start

latch is set and the SS pin is discharged. The SS latch can

only be reset when V

has been discharged below 0.25V (Figure 11). If the LED(s)

simply go open circuit and are reconnected, however, the

OVP used to protect the switch might be too high for the

reconnected LED(s). The LT3478/LT3478-1 therefore allow

OVP to be programmable to protect both the LED driver

switch and the LED(s). (The minimum allowable OVP for

normal operation for a given LED string depends on the

number of LEDs and their maximum forward voltage ratings.) OVP is programmed using the OVPSET pin (front

page), given by,

OVP = (OVPSET • 41)V

where the programmable range for the OVPSET pin is 0.3V

to 1V resulting in an OVP range of 12.3V to 41V.

The OVPSET pin can be programmed with a single resistor

by tapping off of the resistor divider from V

program CTRL1. If both CTRL1 and CTRL2 are connected

directly to V

(maximum LED current setting) then OVP-

REF

SET requires a simple 2 resistor divider from V

falls below OVP and the SS pin

OUT

used to

REF

REF

.

= inductor supply input

V

S

D = switch duty cycle = (V

= forward voltage drop of external Schottky diode

V

F

V

SAT

= I

L(AVE)

• R

SW

(2) Switch AC loss = P

= t

= effective switch current and switch VCE voltage

t

EFF

EFF

OUT

SW(AC)

(1/2)I

+ VF – VS)/(V

L(AVE)(VOUT

+ VF – V

OUT

+ VF)(F

overlap time during turn on and turn off = 2 • (t

)

t

VSW

t

t

f

= I

ISW

SWITCH

= SW fall/rise time = (V

VSW

= switching frequency

OSC

(3) Current sensing loss = P

P

SENSE(IL)

P

P

+ P

SENSE(IL)

SENSE(ILED)

(4) Input quiescent loss = P

rise/fall time = I

SENSE(ILED)

L(AVE)

= I

LED

2

2

• 9.5mΩ

• 0.1Ω

= I

• 2ns

L(AVE)

+ VF) • 0.7ns

OUT

=

SENSE

= VIN • IQ where

Q

OSC

ISW

SAT

)

)

+

Thermal Calculations

To maximize output power capability in an application

without exceeding the LT3478/LT3478-1 125°C maximum

operational junction temperature, it is useful to be able

to calculate power dissipation within the IC. The power

dissipation within the IC comes from four main sources:

switch DC loss, switch AC loss, Inductor and LED current sensing and input quiescent current. These formulas

assume a boost converter architecture, continuous mode

operation and no PWM dimming.

(1) Switch DC loss = P

= (RSW • I

R

I

P

= switch resistance = 0.07Ω (at TJ = 125°C)

SW

= P

L(AVE)

OUT

= V

OUT

OUT

• I

η = converter effi ciency = P

SW(DC)

/(η • VS)

LED

L(AVE)

OUT

2

/(P

• D)

OUT

+ P

LOSS

)

= (6.2mA + (100mA • D))

I

Q

Example (Using LT3478-1):

For V

V

= VS = 8V, I

IN

= 0.5V and f

F

OSC

= 700mA, V

LED

= 0.2Mhz,

= 24.5V (7 LEDs),

OUT

η = 0.89 (initial assumption)

I

= (24.5 • 0.7)/(0.89 • 8) = 2.41A

L(AVE)

D = (24.5 + 0.5 – 8)/(24.5 + 0.5 – 0.17) = 0.684

T

= 2 • ((2.41 • 2)ns + (24.5 + 0.5) • 0.7)ns = 45ns

EFF

Total Power Dissipation:

= P

P

IC

P

SW(DC)

P

SW(AC)

P

SENSE

= 8 • (6.2mA + (100mA • 0.684)) = 0.597W

P

Q

= 0.278 + 0.271 + 0.104 + 0.597 = 1.25W

P

IC

SW(DC)

+ P

SW(AC)

+ P

SENSE

+ P

Q

= 0.07 • (2.41)2 • 0.684 = 0.278W

= 45ns • 0.5 • 2.41 • 25 • 0.2MHz = 0.271W

= ((2.41)2 • 0.0095) + ((0.7)2 • 0.1) = 0.104W

34781f

17

LT3478/LT3478-1

U

WUU

APPLICATIO S I FOR ATIO

Local heating from the nearby inductor and Schottky diode

will also add to the fi nal junction temperature of the IC.

Based on empirical measurements, the effect of diode and

inductor heating on the LT3478-1 junction temperature

can be approximated as:

(LT3478-1) = 5°C/W • (P

ΔT

J

P

= (1 – D) • VF • I

DIODE

L(AVE)

1 – D = 0.316

= 0.5V

V

F

I

P

P

= 2.41

L(AVE)

= 0.316 • 0.5 • 2.41 = 0.381W

DIODE

INDUCTOR

= I

L(AVE)

2

• DCR

DCR = inductor DC resistance (assume 0.05Ω)

P

INDUCTOR

= (2.41)2 • 0.05 = 0.29W

The LT3478/LT3478-1 use a thermally enhanced FE package. With proper soldering to the Exposed Pad on the

underside of the package combined with a full copper plane

underneath the device, thermal resistance (θ

about 35°C/W. For an ambient temperature of T

the junction temperature of the LT3478-1 for the example

application described above, can be calculated as:

(LT3478-1)

T

J

= T

+ θJA(P

A

TOT

) + 5(P

DIODE

= 70 + 35(1.25) + 5(0.671)

= 70 + 44 + 4

= 118°C

In the above example, effi ciency was initially assumed to

be η = 0.89. A lower effi ciency (η) for the converter will

increase I

. η can be calculated as:

for T

J

η = P

OUT

and hence increase the calculated value

L(AVE)

/(P

OUT

+ P

LOSS

)

DIODE

+ P

+ P

INDUCTOR

INDUCTOR

JA

)

)

) will be

= 70°C,

A

If an application is built, the inductor current can be measured and a new value for junction temperature estimated.

Ideally a thermal measurement should be made to achieve

the greatest accuracy for T

.

J

Note: The junction temperature of the IC can be reduced

if a lower V

inductor supply V

from an available 3V source (instead of V

supply is available – separate from the

IN

. In the above example, driving VIN

S

= 8V) reduces

S

input quiescent losses in item(4) from 0.597W to 0.224W,

resulting in a reduction of T

from 118°C to 105°C.

J

Layout Considerations

As with all switching regulators, careful attention must be

given to PCB layout and component placement to achieve

optimal thermal,electrical and noise performance (Figure

12). The exposed pad of the LT3478/LT3478-1 (Pin 17)

is the only GND connection for the IC. The exposed pad

should be soldered to a continuous copper ground plane

underneath the device to reduce die temperature and

maximize the power capability of the IC. The ground path

for the R

resistor and VC capacitor should be taken from

T

nearby the analog ground connection to the exposed pad

(near Pin 9) separate from the power ground connection

to the exposed pad (near Pin 16). The bypass capacitor

for V

should be placed as close as possible to the VIN

IN

pin and the analog ground connection. SW pin voltage rise

and fall times are designed to be as short as possible for

maximum effi ciency. To reduce the effects of both radiated

and conducted noise, the area of the SW trace should be

kept as small as possible. Use a ground plane under the

switching regulator to minimize interplane coupling. The

schottky diode and output capacitor should be placed as

close as possible to the SW node to minimize this high

frequency switching path. To minimize LED current sensing

errors for the LT3478, the terminals of the external sense

resistor R

should be tracked to the V

SENSE

OUT

and LED

pins separate from any high current paths.

P

OUT

P

LOSS

= V

• I

OUT

= 17.15W

LED

(estimated) = PIC + P

DIODE

η = 17.15/(17.15 + 1.92) = 0.9

18

+ P

INDUCTOR

= 1.92W

34781f

LT3478/LT3478-1

U

WUU

APPLICATIO S I FOR ATIO

V

C

VS

C

VIN

SW

INDUCTOR

L

Figure 12. Recommended Layout for LT3478/LT3478-1 (Boost Confi guration)

S

V

IN

SCHOTTKY

R

SENSE

(LT3478 ONLY)

DIODE

(CONNECT MULTIPLE GROUND PLANES

THROUGH VIAS UNDERNEATH THE IC)

V

OUT

LT3478/LT3478-1

1

SW

2

SW

3

V

IN

4

V

S

5

L

6

V

OUT

EXPOSED PAD

7

LED

OVPSET

R

R

8

C

OUTPUT CAPACITOR

POWER GND

PIN 17

ANALOG GND

V

BYPASS CAP

IN

SOLDER THE EXPOSED PAD (PIN 17)

TO THE ENTIRE COPPER GROUND PLANE

UNDERNEATH THE DEVICE

SS

16

R

15

T

PWM

14

CTRL2

13

CTRL1

12

SHDN

11

V

10

REF

V

9

C

C

R

GND

F

C

C

SS

R

T

R

R

R

R

C

C

3252 F08

U

TYPICAL APPLICATIO S

V

IN

8V TO 16V

L1: CDRH104R-100NC

D1: PDS560

Q1: Si2318DS

LEDs: LUXEON III (WHITE)

3.3V

C1

4.7µF

25V

R1

45.3k

R4

54.9k

R2

130k

0V

100Hz

PWM

DIMMING RATIO = 1000:1

VINVSLSW

SHDN

V

REF

CTRL2

OVPSET

CTRL1

PWM SS V

C

1µF

LT3478-1

SS

15W, 6 LEDs at 700mA, Boost LED Driver

L1

10µH

C

f

OSC

C

0.1µF

OUT

LED

R

C

= 500kHz

R3

10k

T

D1

700mA

R

T

69.8k

C2

10µF

25V

Q1

PWM

5V/DIV

INDUCTOR

CURRENT

1A/DIV

I

LED

0.5A/DIV

LT3478-1 PWM Dimming

Waveforms

f

= 100Hz

PWM

PWM DIMMING RATIO = 1000:1

(SEE EFFICIENCY ON PAGE 1)

2µs/DIV

3478 TA02b

3478 TA02a

34781f

19

LT3478/LT3478-1

U

TYPICAL APPLICATIO S

17W, 15 LEDs at 350mA, Boost LED Driver plus LT3003

V

S

V

3.3V

C1

4.7µF

16V

IN

3.3µF

10V

100k

3.3V

0V

C3

R1

24k

R2

100Hz

PWM

DIMMING RATIO = 3000:1

VINVSLSW

SHDN

V

REF

CTRL2

CTRL1

OVPSET

PWM SS V

C

1µF

LT3478-1

SS

8V TO 14V

L1: CDRH104R-5R2

D1: PDS560

LEDs: LUXEON I (WHITE)

C

L1

5.2µH

V

C

C

0.1µF

f

OSC

C

= 1MHz

V

OUT

V

IN

OUT

LED

R

D1

V

OUT

1.05A

T

R

T

31.6k

LED1 LED2 LED3

V

MAX

V

IN

PWM

GND V

C2

3.3µF

25V

LT3003

Effi ciency vs Input V

90

VIN = 3.3V

= 350mA

I

LED

= 1MHz

f

OSC

PWM DUTY CYCLE = 100%

85

80

EFFICIENCY (%)

75

15 LEDs

(5 SERIES x 3 CHANNELS)

70

8

OT1

V

OT2

EE

C

3478 TA03a

LUXEON I (WHITE)

10 1412

VS (V)

S

3478 TA03b

V

S

12V TO 16V

V

IN

5V

L1: CDRH105R-8R2

D1: PDS560

D2: 7.5V ZENER

LEDs: LUXEON I (WHITE)

C1

4.7µF

25V

C3

3.3µF

10V

100k

3.3V

0V

R1

24k

R2

100Hz

PWM

DIMMING RATIO = 200:1

16W, 12 LEDs at 350mA, Buck-Boost Mode LED Driver plus LT3003

L1

8.2µH

VINVSLSW

SHDN

V

REF

CTRL2

CTRL1

OVPSET

PWM SS V

C

1µF

SS

LT3478-1

C

C4

1µF

V

C

C

0.1µF

f

OSC

D2

OUT

LED

C

= 500kHz

V

OUT

D1

V

OUT

1.05A

R

T

R

T

69.8k

LED1 LED2 LED3

V

MAX

V

IN

PWM

C2

10µF

50V

LT3003

GND V

OT1

V

OT2

EE

C

3478 TA04a

Effi ciency vs Input V

90

VIN = 5V

= 350mA

I

LED

85

= 500kHz

f

OSC

PWM DUTY CYCLE = 100%

80

75

70

65

EFFICIENCY (%)

60

55

50

12 14 161513

S

12 LEDs

(4 SERIES x 3 CHANNELS)

LUXEON I (WHITE)

VS (V)

3478 TA04b

34781f

20

U

TYPICAL APPLICATIO S

V

IN

3.8V TO 6.5V

NiMH 4×

L1: CDRH105R-6R8

D1: B320

Q1: Si2302ADS

Q2: Si2315BDS

LED: LUXEON III (WHITE)

3.3V

C1

10µF

10V

VINVSLSW

OFFON

R1

100k

R2

34k

0V

1kHz

SHDN

V

REF

CTRL2

CTRL1

OVPSET

PWM SS V

PWM

DIMMING RATIO = 200:1

C

1µF

LT3478-1

SS

4W, 1 LED at 1A, Buck-Boost Mode LED Driver

C

L1

6.8µH

C

C

0.1µF

f

OSC

OUT

LED

R

T

= 500kHz

D1

R

T

69.8k

C2

4.7µF

16V

1A

510Ω

510Ω

R3

10k

Q2

R4

R5

Q1

LT3478/LT3478-1

80

I

= 1A

LED

f

= 500kHz

OSC

PWM DUTY CYCLE = 100%

75

70

65

EFFICIENCY (%)

60

55

50

35764

Effi ciency vs V

VIN (V)

IN

SINGLE LED

LUXEON III (WHITE)

3478 TA06b

3478 TA06a

34781f

21

LT3478/LT3478-1

U

TYPICAL APPLICATIO S

PV

32V

TYPICAL EFFICIENCY = 90%

FOR CONDITIONS/COMPONENTS SHOWN

(PWM DUTY CYCLE = 100%, T

24W, 4 LEDs at 1.5A, Buck Mode LED Driver

IN

3.3µF

50V

C1

=25°C)

A

R

SENSE

0.068Ω

1.5A

Q2

4 LEDs

R4

365Ω

C3

10µF

25V

V

IN

3.3V

L1: CDRH105R-100

D1: PDS560

Q1: 2N7002

Q2: Si2319DS

LEDs: LXK2 (WHITE)

4.7µF

10V

C2

R1

24k

R2

100k

VINVSL OUT LED SW

SHDN

V

REF

CTRL2

CTRL1

OVPSET

C

1µF

LT3478

SS V

C

SS

C

C

0.1µF

= 500kHz

f

OSC

L1

10µH

D1

PWM

R3

10k

PWM

DIMMING RATIO = 3000:1

3.3V

R

0V

T

R

T

69.8k

3478 TA07a

R5

510Ω

Q1

100Hz

22

34781f

PACKAGE DESCRIPTIO

3.58

(.141)

U

FE Package

16-Lead Plastic TSSOP (4.4mm)

(Reference LTC DWG # 05-08-1663)

Exposed Pad Variation BC

4.90 – 5.10*

(.193 – .201)

3.58

(.141)

16 1514 13 12 11

LT3478/LT3478-1

10 9

6.60 ±0.10

4.50 ±0.10

RECOMMENDED SOLDER PAD LAYOUT

0.09 – 0.20

(.0035 – .0079)

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

SEE NOTE 4

0.65 BSC

4.30 – 4.50*

(.169 – .177)

0.50 – 0.75

(.020 – .030)

MILLIMETERS

(INCHES)

(.116)

0.45 ±0.05

2.94

1.05 ±0.10

1345678

2

0.25

REF

0° – 8°

0.65

(.0256)

BSC

0.195 – 0.30

(.0077 – .0118)

TYP

4. RECOMMENDED MINIMUM PCB METAL SIZE

FOR EXPOSED PAD ATTACHMENT

*DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.150mm (.006") PER SIDE

2.94

(.116)

1.10

(.0433)

MAX

0.05 – 0.15

(.002 – .006)

FE16 (BC) TSSOP 0204

6.40

(.252)

BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

34781f

23

LT3478/LT3478-1

TYPICAL APPLICATIO

V

S

V

3.3V

0V

IN

4.7µF

25V

3.3µF

10V

8.25k

100Hz

C1

C3

R1

R2

10k

PWM

DIMMING RATIO = 1000:1

VINVSLSW

SHDN

V

REF

CTRL2

CTRL1

OVPSET

PWM SS V

C

SS

1µF

8V TO 16V

L1: CDRH6D28

D1: ZLLS1000

Q1: Si2318DS

LEDs: LUXEON I (WHITE)

3.3V

U

6W, 6 LEDs at 250mA, Boost LED Driver

LT3478

C

L1

10µH

C

0.1µF

f

OSC

C

OUT

LED

R

= 2MHz

R3

10k

D1

C2

3.3µF

25V

R

SENSE

0.42Ω

250mA

T

R

T

10k

Q1

Effi ciency vs Input V

100

VIN = 3.3V

= 250mA

I

LED

95

= 2MHz

f

OSC

PWM DUTY CYCLE = 100%

90

85

80

75

EFFICIENCY (%)

70

65

60

8

S

6 LEDs = LUXEON I (WHITE)

12 161410

VS (V)

3478 TA05b

3478 TA05a

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1618 Constant Current, 1.4MHz, 1.5A Boost Converter with Analog/PWM

Dimming

LT3003 Three Channel LED Ballaster with 3,000:1 True Color PWM Dimming V

LT3474 36V, 1A (I

), 2MHz,Step-Down LED Driver with 400:1 True Color

LED

PWM Dimming

LT3475 Dual 1.5A(I

), 36V, 2MHz,Step-Down LED Driver 3,000:1 True

LED

Color PWM Dimming

LT3476 Quad Output 1.5A, 2MHz High Current LED Driver with 1,000:1 True

Color PWM Dimming

LT3477 42V, 3A, 3.5MHz Boost, Buck-Boost, Buck LED Driver with Analog/

PWM Dimming

LT3479 3A, 3.5MHz Full Featured DC/DC Converter with Soft-Start and

Inrush Current Protection and Analog/PWM Dimming

LT3486 Dual 1.3A , 2MHz High Current LED Driver with 1,000:1 True Color

PWM Dimming

LTC3783 High Current LED Controller with 3,000:1 True Color PWM Dimming V

: 5V to 18V, V

V

IN

: 3V to 48V, ISD <5µA, MSOP10 Package

IN

VIN: 4V to 36V, V

VIN: 4V to 36V, V

V

: 2.8V to 16V, V

IN

Package

: 2.5V to 25V, V

V

IN

Packages

V

: 2.5V to 24V, V

IN

TSSOP16E Packages

VIN: 2.5V to 24V, V

TSSOP16E Packages

: 3V to 36V, V

IN

DFN, TSSOP16E Packages

= 36V, ISD <1µA, MS10 Package

OUT(MAX)

= 13.5V, ISD <1µA, TSSOP16E Package

OUT(MAX)

= 13.5V, ISD <1µA, TSSOP20E Package

OUT(MAX)

= 36V, ISD <10µA, 5mm × 7mm QFN

OUT(MAX)

= 40V, ISD <1µA, QFN, TSSOP20E

OUT(MAX)

= 40V, ISD <1µA, 4mm × 3mm DFN,

OUT(MAX)

= 36V, ISD <1µA, 5mm × 3mm DFN,

OUT(MAX)

= Ext FET, ISD <20µA, 5mm × 4mm

OUT(MAX)

24

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

34781f

LT 0107 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2007

Loading...

Loading...