FEATURES

www.BDTIC.com/LINEAR

■

Drives Up to 10 White LEDs from a 3.6V Supply

■

Two Independent Step-Up DC/DC Converters

■

Independent Dimming and Shutdown Control

of the Outputs

■

±1.5% Output Voltage Accuracy (Boost Converter)

■

±4% LED Current Programming Accuracy

■

Internal Schottky Diodes

■

Internal Soft-Start Eliminates Inrush Current

■

Output Overvoltage Protection (39.5V Max V

■

Fixed Frequency Operation Up to 2MHz

■

83% Efficiency Driving 8 White LEDs at 15mA

OUT

from a 3.6V Supply

■

Wide Input Voltage Range: 2.7V to 24V

■

Tiny (3mm × 3mm) 10-Lead DFN Package

U

APPLICATIO S

■

White LED and OLED Displays

■

Digital Cameras, Sub-Notebook PCs

■

PDAs, Handheld Computers

■

TFT - LCD Bias Supply

■

Automotive

LT3466-1

White LED Driver and Boost

Converter in 3mm × 3mm

DFN Package

U

DESCRIPTIO

LT®3466-1 is a dual switching regulator that combines a

white LED driver and a boost converter in a low profile,

small footprint (3mm × 3mm × 0.75mm) DFN package.

The LED driver can be configured to drive up to 10 White

LEDs in series and the boost converter can be used for

generating the LCD bias voltages or driving a secondary

OLED display. Series connection of the LEDs provides

identical LED currents resulting in uniform brightness and

)

eliminating the need for ballast resistors and expensive

factory calibration.

The LT3466-1 provides independent dimming and shutdown control of the two converters. The operating frequency can be set with an external resistor over a 200kHz

to 2MHz range. The white LED driver features a low 200mV

reference, thereby minimizing power loss in the current

setting resistor for better efficiency. The boost converter

achieves ±1.5% output voltage accuracy by the use of a

precision 0.8V reference. Protection features include output overvoltage protection and internal soft-start. Wide

input supply range allows operation from 2.7V to 24V.

, LTC and LT are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

U

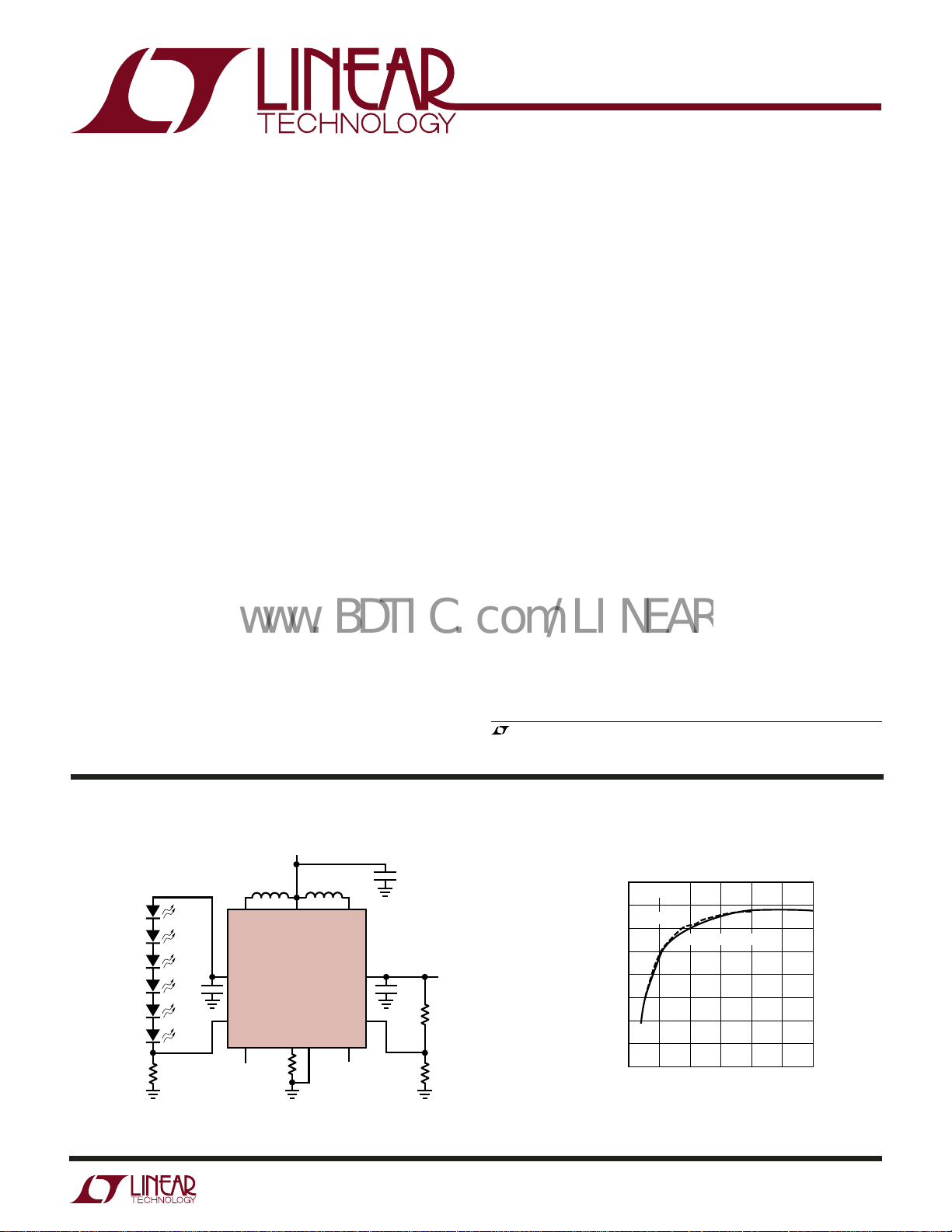

TYPICAL APPLICATIO

3V TO 5V

1µF

IN

LT3466-1

R

T

33µH

V

SHUTDOWN

AND DIMMING

CONTROL 2

OUT2

FB2

16V

30mA

475k

24.9k

34661 F01a

6 LEDs

33µH

SW1 SW2V

V

1µF1µF

10Ω

OUT1

FB1

CTRL1 GND CTRL2

SHUTDOWN

AND DIMMING

CONTROL 1

63.4k

Figure 1. Li-Ion Powered Driver for 6 White LEDs and OLED Display

90

VIN = 3.6V

85

LED DRIVER

80

75

70

65

EFFICIENCY (%)

60

55

50

0

Conversion Efficiency

BOOST CONVERTER

51015

OUTPUT CURRENT (mA)

302520

34661 F01b

34661f

1

LT3466-1

www.BDTIC.com/LINEAR

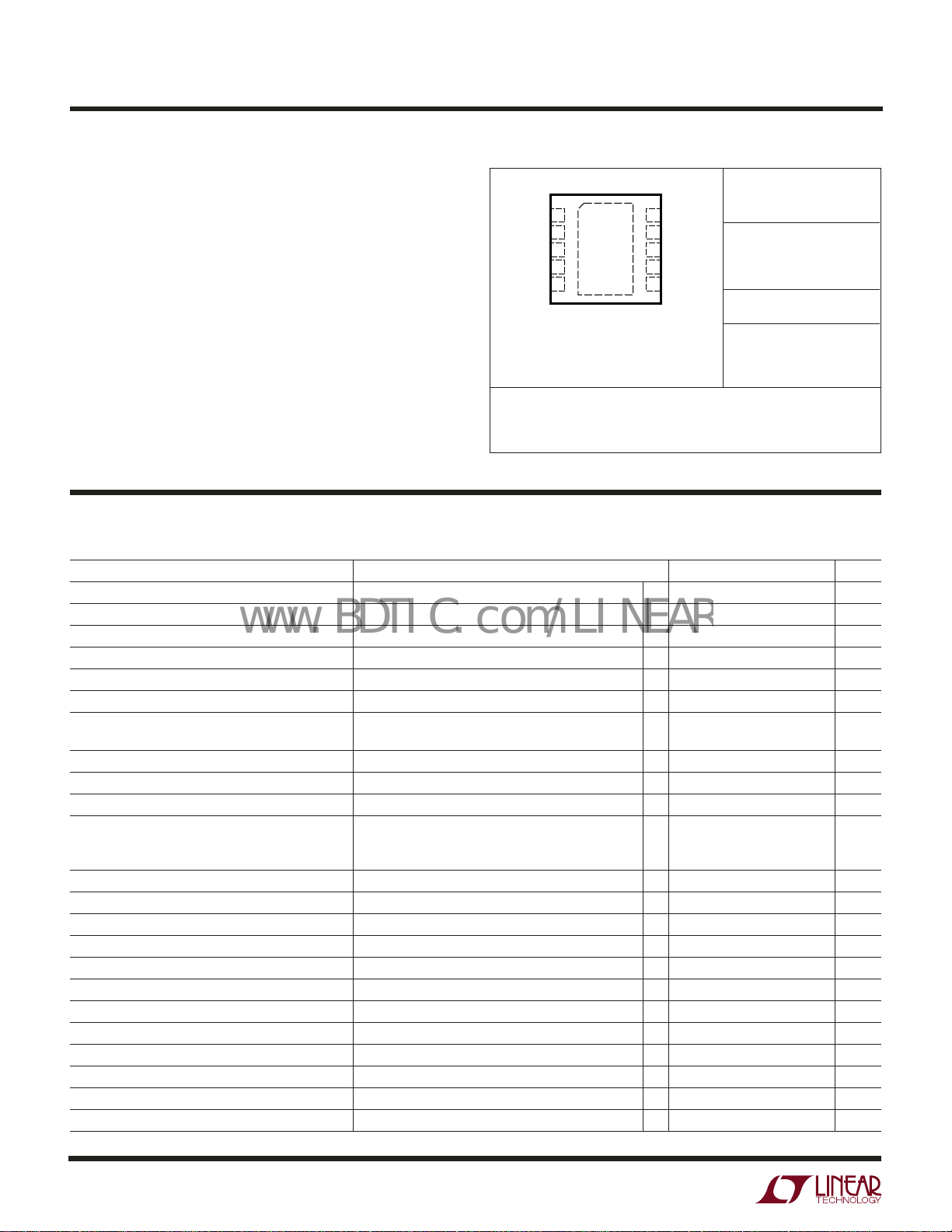

WWWU

ABSOLUTE AXI U RATI GS

PACKAGE/ORDER I FOR ATIO

UU

W

(Note 1)

Input Voltage (VIN) ................................................... 24V

SW1, SW2 Voltages ................................................ 44V

V

OUT1

, V

Voltages ............................................. 44V

OUT2

CTRL1, CTRL2 Voltages ........................................... 24V

FB1, FB2 Voltages ...................................................... 2V

Operating Temperature Range (Note 2) ... –40°C to 85°C

Storage Temperature Range .................. –65°C to 125°C

Junction Temperature .......................................... 125°C

ELECTRICAL CHARACTERISTICS

range, otherwise specifications are at TA = 25°C. VIN = 3V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage 2.7 V

Maximum Operating Voltage 22 V

FB1 Voltage ● 192 200 208 mV

FB2 Voltage ● 788 800 812 mV

FB1 Pin Bias Current V

FB2 Pin Bias Current V

Quiescent Current V

Switching Frequency RT = 48.7k 0.75 1 1.25 MHz

Oscillator Frequency Range (Note 4) 200 2000 kHz

Nominal RT Pin Voltage RT = 48.7k 0.54 V

Maximum Duty Cycle RT = 48.7k ● 90 96 %

Converter 1 Current Limit ● 310 400 mA

Converter 2 Current Limit ● 310 400 mA

Converter 1 V

Converter 2 V

Switch 1 Leakage Current V

Switch 2 Leakage Current V

CTRL1 Voltage for Full LED Current ● 1.8 V

CTRL2 Voltage for Full Feedback Voltage ● 1V

CTRL1 or CTRL2 Voltage to Turn On the IC 150 mV

CTRL1 and CTRL2 Voltages to Shut Down Chip 70 mV

CTRL1 Pin Bias Current V

CTRL2 Pin Bias Current V

CESAT

CESAT

FB1

FB2

FB1

CTRL1 = CTRL2 = 0V 16 25 µA

R

= 20.5k 92 %

T

RT = 267k 99 %

I

SW1

I

SW2

SW1

SW2

CTRL1

CTRL2

The ● denotes specifications that apply over the full operating temperature

= 3V, V

CTRL1

= 0.2V (Note 3) 10 50 nA

= 0.8V (Note 3) 10 50 nA

= V

= 1V 5 7.5 mA

FB2

= 300mA 320 mV

= 300mA 320 mV

= 10V 0.01 5 µA

= 10V 0.01 5 µA

= 1V ● 6 9 12.5 µA

= 1V (Note 3) ● 10 120 nA

V

OUT1

SW1

V

IN

SW2

V

OUT2

10-LEAD (3mm × 3mm) PLASTIC DFN

T

JMAX

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specified with wider operating temperature ranges.

CTRL2

TOP VIEW

10

9

8

7

6

FB1

CTRL1

R

T

CTRL2

FB2

DD PART MARKING

1

2

11

3

4

5

DD PACKAGE

= 125°C, θJA = 43°C/W, θJC = 3°C/W

EXPOSED PAD (PIN 11) IS GND

MUST BE SOLDERED TO PCB

= 3V, unless otherwise specified.

ORDER PART

NUMBER

LT3466EDD-1

LBRX

34661f

2

LT3466-1

www.BDTIC.com/LINEAR

ELECTRICAL CHARACTERISTICS

range, otherwise specifications are at TA = 25°C. VIN = 3V, V

The ● denotes specifications that apply over the full operating temperature

CTRL1

= 3V, V

= 3V, unless otherwise specified.

CTRL2

PARAMETER CONDITIONS MIN TYP MAX UNITS

V

Overvoltage Threshold 39.5 V

OUT1

V

Overvoltage Threshold 39.5 V

OUT2

Schottky 1 Forward Drop I

Schottky 2 Forward Drop I

Schottky 1 Reverse Leakage V

Schottky 2 Reverse Leakage V

SCHOTTKY1

SCHOTTKY2

OUT1

OUT2

= 300mA 0.85 V

= 300mA 0.85 V

= 20V 5 µA

= 20V 5 µA

Soft-Start Time (Switcher 1) 600 µs

Soft-Start Time (Switcher 2) 600 µs

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 3: Current flows out of the pin.

Note 4: Guaranteed by design and test correlation, not production tested.

Note 2: The LTC3466-1E is guaranteed to meet specified performance

from 0°C to 70°C. Specifications over the –40°C to 85°C operating range

are assured by design, characterization and correlation with statistical

process controls.

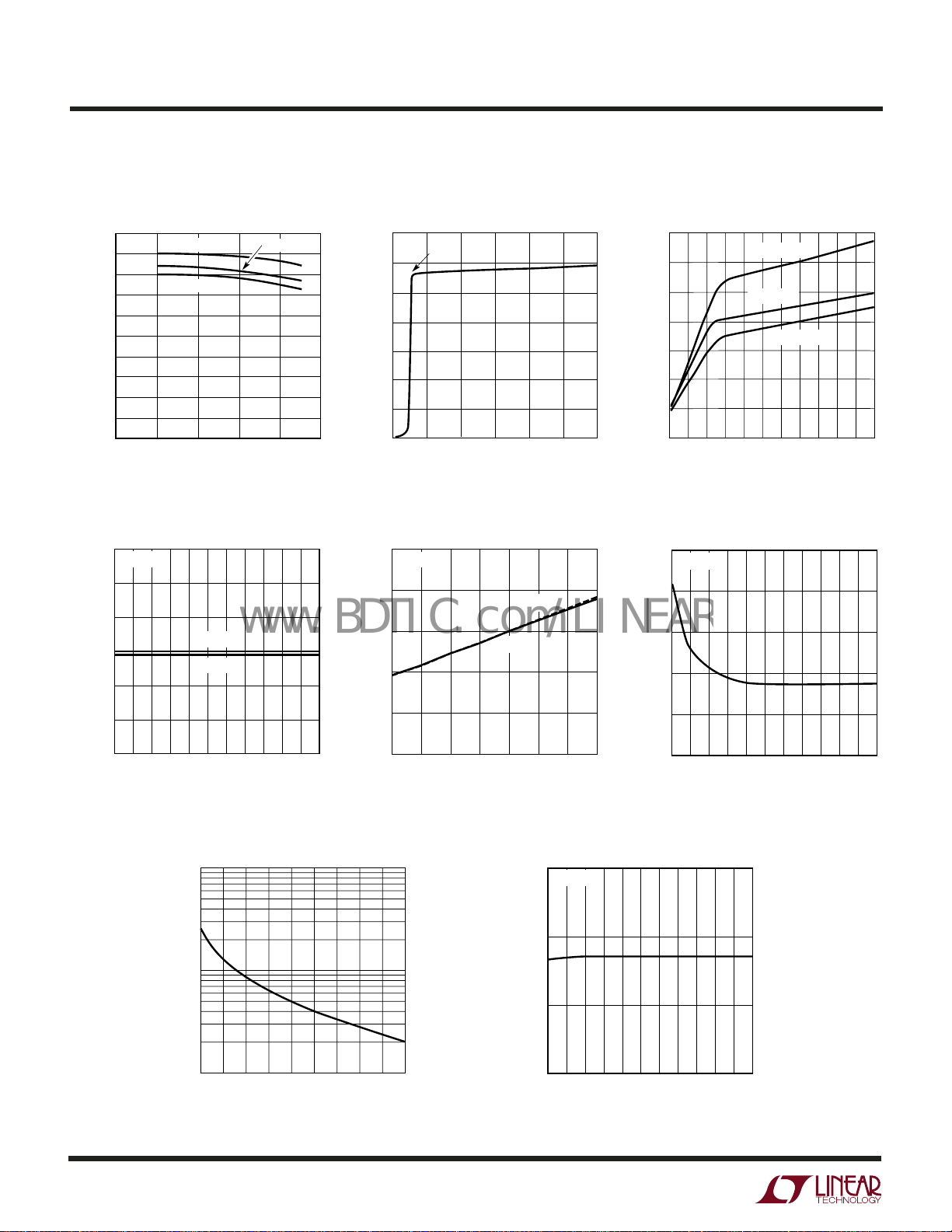

UW

TYPICAL PERFOR A CE CHARACTERISTICS

TA = 25°C unless otherwise specified

V

OUT1

100mV/DIV

(AC-COUPLED)

V

SW1

20V/DIV

I

100mA/DIV

250

200

150

(mV)

FB1

V

100

Switching Waveforms

(LED Driver)

L1

V

= 3.6V 0.5µs/DIV 34661 G01

IN

6 LEDs AT 20mA

CIRCUIT OF FIGURE 1

V

vs V

50

0

0

FB1

VIN = 3.6V

6 LEDs

0.5

CTRL1

V

CTRL1

1

(V)

1.5

34661 G03

Switching Waveforms

(Boost Converter)

V

OUT2

100mV/DIV

(AC-COUPLED)

V

SW2

20V/DIV

I

L2

100mA/DIV

VIN = 3.6V 0.5µs/DIV 34661 G02

V

= 16V/30mA

OUT2

CIRCUIT OF FIGURE 1

V

vs V

FB2

900

VIN = 3.6V

V

800

700

600

500

(mV)

FB2

400

V

300

200

100

2

0

0

OUT2

= 16V

0.5

CTRL2

V

CTRL2

1

(V)

1.5

34661 G16

2

34661f

3

LT3466-1

VIN (V)

2

0

SHUTDOWN CURRENT (µA)

10

30

40

50

70

4

12

16

34661 G06

20

60

10

20

2422

6

8

14 18

TA = –50°C

TA = 25°C

TA = 100°C

www.BDTIC.com/LINEAR

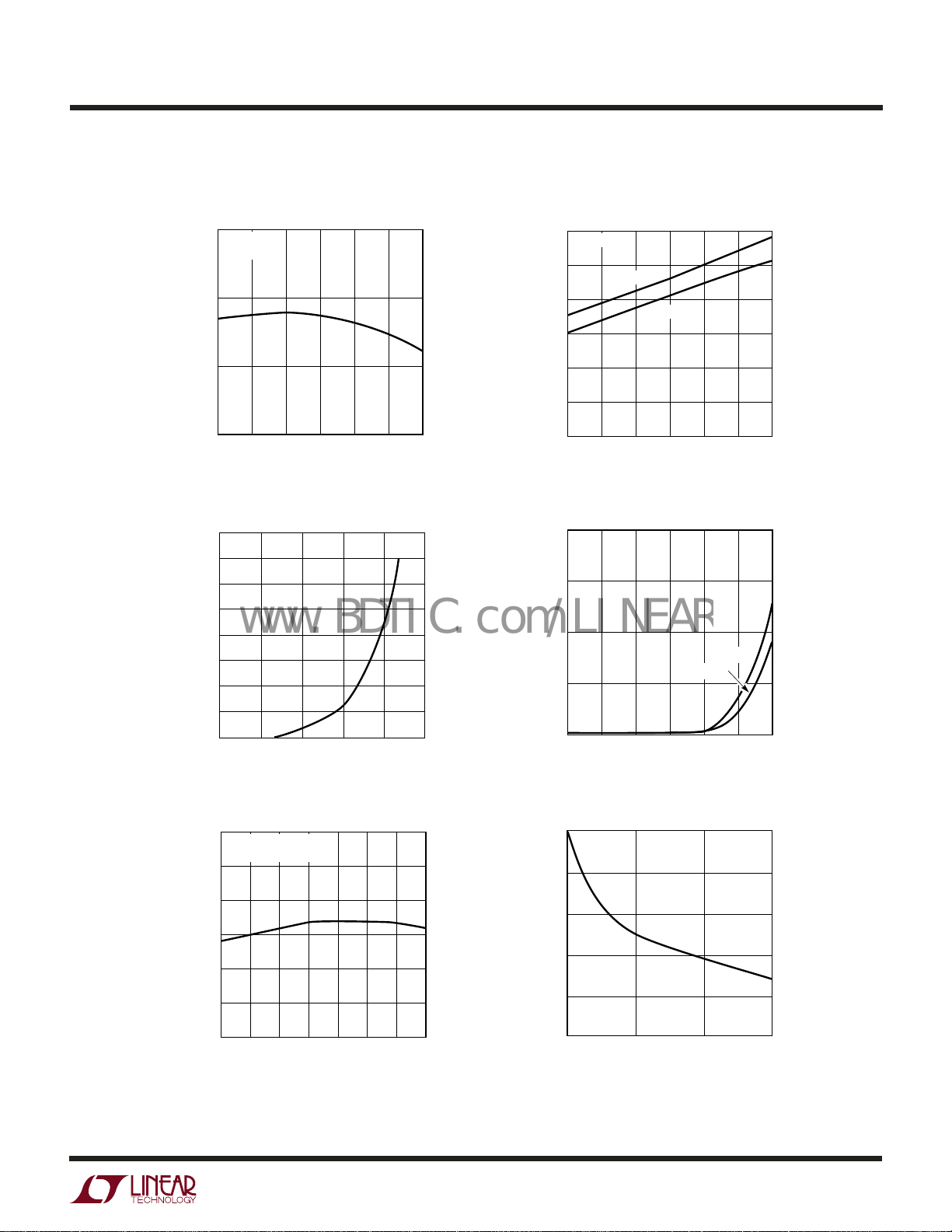

UW

TYPICAL PERFOR A CE CHARACTERISTICS

TA = 25°C unless otherwise specified

500

450

400

350

300

250

200

150

CURRENT LIMIT (mA)

100

50

0

0

TA = –50°C

T

A

20

DUTY CYCLE (%)

= 85°C

40

Open-Circuit Output Clamp

Voltage

41.00

RT = 63.4k

40.50

40.00

39.50

39.00

OUTPUT CLAMP VOLTAGE (V)

38.50

V

V

OUT2

OUT1

60

TA = 25°C

80

34661 G05

100

Quiescent Current

(CTRL1 = CTRL2 = 3V)Switch Current Limit vs Duty Cycle

7

0

UVLO

48

VIN (V)

12 20

6

5

4

3

2

QUIESCENT CURRENT (mA)

1

0

Open-Circuit Output Clamp

Voltage

42

RT = 63.4k

41

40

39

38

OUTPUT CLAMP VOLTAGE (V)

16 24

V

OUT2

V

OUT1

34661 G04

Shutdown Current

(CTRL1 = CTRL2 = 0V)

Input Current with Output 1 and

Output 2 Open Circuit

20

RT = 63.4k

16

12

8

INPUT CURRENT (mA)

4

38.00

6 101418

VIN (V)

2442 8 12 16 20 22

34661 G07

37

–50 –25

0

TEMPERATURE (°C)

RT vs Oscillator Frequency

1000

100

4

(kΩ)

T

R

10

600 180014001000

200

OSCILLATOR FREQUENCY (kHz)

34661 G10

50

25

75

100

Oscillator Frequency vs V

1100

RT = 48.7k

1000

900

OSCILLATOR FREQUENCY (kHz)

800

VIN (V)

0

2

125

34661 G08

8121620

468

IN

34661 G11

10 12

24462 10141822

14 16 20

VIN (V)

18

2422

34661 G09

34661f

UW

www.BDTIC.com/LINEAR

TYPICAL PERFOR A CE CHARACTERISTICS

LT3466-1

TA = 25°C unless otherwise specified

Oscillator Frequency

vs Temperature

1100

VIN = 3.6V

= 48.7k

R

T

1000

900

OSCILLATOR FREQUENCY (kHz)

800

–50

–25 0 25 50

TEMPERATURE (°C)

75

100

34661 G12

CTRL Voltages to Shut Down

the IC

150

= 3.6V

V

IN

125

100

75

50

CTRL VOLTAGE (mV)

25

0

–50

CTRL1

02550

–25

TEMPERATURE (°C)

CTRL2

Schottky Forward Voltage Drop Schottky Leakage Current

400

350

300

250

200

150

100

50

SCHOTTKY FORWARD CURRENT (mA)

0

200 400 800

0

SCHOTTKY FORWARD DROP (mV)

600

1000

34661 G14

8

6

4

2

SCHOTTKY LEAKAGE CURRENT (µA)

0

–50

–25 0 25 50

TEMPERATURE (°C)

75 100

34661 G13

VR = 36V

VR = 20V

75 100

34661 G015

FB2 Pin Voltage vs Temperature

0.810

VIN = 3V

= 16V/30mA

V

OUT2

0.805

0.800

0.795

FB2 VOLTAGE (V)

0.790

0.785

0.780

–50

02550

–25

TEMPERATURE (°C)

75 125100

34661 G17

FB2 Pin Load Regulation

0

–0.20

(%)

–0.40

OUT2

/V

–0.60

OUT2

∆V

–0.80

–1.00

0

10 20

LOAD CURRENT (mA)

V

V

IN

OUT2

= 3V

= 16V

30

34661 G18

34661f

5

LT3466-1

www.BDTIC.com/LINEAR

U

UU

PI FU CTIO S

V

(Pin 1): Output of Converter 1. This pin is connected

OUT1

to the cathode of the internal Schottky diode. Connect an

output capacitor from this pin to ground.

SW1 (Pin 2): Switch Pin for Converter 1. Connect the

inductor at this pin.

VIN (Pin 3): Input Supply Pin. Must be locally bypassed

with a 1µF, X5R or X7R type ceramic capacitor.

SW2 (Pin 4): Switch Pin for Converter 2. Connect the

inductor at this pin.

V

(Pin 5): Output of Converter 2. This pin is connected

OUT2

to the cathode of the internal Schottky diode. Connect an

output capacitor from this pin to ground.

FB2 (Pin 6): Feedback Pin for Converter 2. The nominal

voltage at this pin is 800mV. Connect the resistor divider

to this pin. The feedback voltage can be programmed

as:

V

≈ V

FB2

V

= 0.8V, when V

FB2

CTRL2

, when V

CTRL2

CTRL2

> 1V

< 0.8V

CTRL2 (Pin 7): Dimming and Shutdown Pin for Converter 2. As the pin voltage is ramped from 0V to 1V, the

FB2 pin voltage tracks the CTRL2 voltage and ramps up to

0.8V. Any voltage above 1V does not affect the feedback

voltage. Do not leave the pin floating. It must be connected

to ground to disable converter 2.

RT (Pin 8): Timing Resistor to Program the Switching

Frequency. The switching frequency can be programmed

from 200KHz to 2MHz.

CTRL1 (Pin 9): Dimming and Shutdown Pin for Converter 1. Connect this pin to ground to disable the converter. As the pin voltage is ramped from 0V to 1.8V, the

LED current ramps from 0 to I

voltage above 1.8V does not affect the LED current.

FB1 (Pin 10): Feedback Pin for Converter 1. The nominal

voltage at this pin is 200mV. Connect cathode of the lowest

LED and the feedback resistor at this pin. The LED current

can be programmed by :

I

≈ (V

LED1

I

≈ (200mV/R

LED1

CTRL1

/5 • R

FB1

), when V

FB1

), when V

(= 200mV/R

LED1

CTRL1

CTRL1

< 1V

> 1.8V

FB1

). Any

Exposed Pad (Pin 11): The Exposed Pad must be soldered

to the PCB system ground.

6

34661f

BLOCK DIAGRA

–

+

–

+

Σ

–

+

+

EAEA

PWM

COMP

R

SNS1

R

SNS2

OSC

C3

V

OUT2

DRIVER

L2

SW2

0.8V

EXPOSED

PAD

20k

FB1

CONVERTER 1 CONVERTER 2

0.2V

80k

SHDN

CTRL2

7

11

CTRL1

9

–

+

–

+

+

START-UP

CONTROL

REF 1.25V

PWM

LOGIC

5

4

V

IN

V

IN

R

T

3

R

T

8

FB2

R2

R1

R

FB1

34661 F02

6

–

+

Σ

OSC

SW1

C1

L1

DRIVER

1

2

10

V

OUT1

C2

PWM

LOGIC

OSC

RAMP

GEN

OSC

OVERVOLT

DETECTION

OVERVOLT

DETECTION

Q1 Q2

A2

A1 A1

A2

A3

PWM

COMP

A3

www.BDTIC.com/LINEAR

LT3466-1

W

Figure 2. Block Diagram

34661f

7

LT3466-1

www.BDTIC.com/LINEAR

OPERATIO

U

Main Control Loop

The LT3466-1 uses a constant frequency, current mode

control scheme to provide excellent line and load regulation. It incorporates two similar, but fully independent PWM

converters. Operation can be best understood by referring

to the Block Diagram in Figure 2. The oscillator, start-up

bias and the bandgap reference are shared between the

two converters. The control circuitry, power switch, Schottky diode etc., are similar for both converters.

At power-up, the output voltages V

charged up to V

(input supply voltage) via their respec-

IN

OUT1

and V

OUT2

are

tive inductor and the internal Schottky diode. If either

CTRL1 and CTRL2 or both are pulled high, the bandgap

reference, start-up bias and the oscillator are turned on.

Working of the main control loop can be understood by

following the operation of converter 1. At the start of each

oscillator cycle, the power switch Q1 is turned on. A

voltage proportional to the switch current is added to a

stabilizing ramp and the resulting sum is fed into the

positive terminal of the PWM comparator A2. When this

voltage exceeds the level at the negative input of A2, the

PWM logic turns off the power switch. The level at the

negative input of A2 is set by the error amplifier A1, and is

simply an amplified version of the difference between the

feedback voltage and the 200mV reference voltage. In this

manner, the error amplifier A1 regulates the voltage at the

FB1 pin to 200mV. The output of the error amplifier A1 sets

the correct peak current level in inductor L1 to keep the

output in regulation. The CTRL1 pin voltage is used to

adjust the feedback voltage.

The working of converter 2 is similar to converter 1 with

the exception that the feedback 2 reference voltage is

800mV. The error amplifier A1 in converter 2 regulates the

voltage at the FB2 pin to 800mV. If only one of the

converters is turned on, the other converter will stay off

and its output will remain charged up to VIN (input supply

voltage). The LT3466-1 enters into shutdown, when both

CTRL1 and CTRL2 are pulled lower than 70mV. The CTRL1

and CTRL2 pins perform independent dimming and shutdown control for the two converters.

Minimum Output Current

The LT3466-1 can drive a 6-LED string at 3mA LED current

without pulse skipping. As current is further reduced, the

device may begin skipping pulses. This will result in some

low frequency ripple, although the LED current remains

regulated on an average basis down to zero. The photo in

Figure 3 shows circuit operation with 6 white LEDs at 3mA

current driven from 3.6V supply. Peak inductor current is

less than 50mA and the regulator operates in discontinuous mode implying that the inductor current reached zero

during the discharge phase. After the inductor current

reaches zero, the switch pin exhibits ringing due to the LC

tank circuit formed by the inductor in combination with

switch and diode capacitance. This ringing is not harmful;

far less spectral energy is contained in the ringing than in

the switch transitions. The ringing can be damped by

application of a 300Ω resistor across the inductors, although this will degrade efficiency.

V

OUT1

20mV/DIV

(AC-COUPLED)

V

SW1

20V/DIV

I

L1

50mA/DIV

V

= 3.6V 0.5µs/DIV 34661 F03

IN

I

= 3mA

LED1

CIRCUIT OF FIGURE 1

Figure 3. Switching Waveforms

Overvoltage Protection

The LT3466-1 has internal overvoltage protection for both

converters. In the event the white LEDs are disconnected

from the circuit or fail open, the converter 1 output voltage

is clamped at 39.5V (typ). Figure 4(a) shows the transient

response of the circuit in Figure 1 with LED1 disconnected.

With the white LEDs disconnected, the converter 1 starts

switching at the peak current limit. The output of converter

1 starts ramping up and finally gets clamped at 39.5V (typ).

The converter 1 will then switch at low inductor current to

regulate the output voltage. Output voltage and input

current during output open circuit are shown in the Typical

Performance Characteristics graphs.

8

34661f

OPERATIO

www.BDTIC.com/LINEAR

LT3466-1

U

In the event one of the converters has an output open-circuit,

its output voltage will be clamped at 39.5V. However, the

other converter will continue functioning properly. The photo

in Figure 4b shows circuit operation with converter 1 output

open-circuit and converter 2 driving the OLED display. Converter 1 starts switching at a lower inductor current and

begins skipping pulses, thereby reducing its input current.

Converter 2 continues functioning properly.

V

OUT1

10V/DIV

I

L1

200mA/DIV

200µs/DIV

LED1 DISCONNECTED AT THIS POINT

V

= 3.3V

IN

CIRCUIT OF FIGURE 1

Figure 4a. Transient Response of Switcher 1 with LED1

Disconnected from the Output

34661 F04a

Soft-Start

The LT3466-1 has a separate internal soft-start circuitry

for each converter. Soft-start helps to limit the inrush

current during start-up. Soft-start is achieved by clamping

the output of the error amplifier during the soft-start

period. This limits the peak inductor current and ramps up

the output voltage in a controlled manner.

The converter enters into soft-start mode whenever the

respective CTRL pin is pulled from low to high. Figure 5

shows the start-up waveforms with converter 1 driving six

LEDs at 20mA. The filtered input current, as shown in

Figure 5, is well controlled. The soft-start circuitry is less

effective when driving a higher number of LEDs.

Undervoltage Lockout

The LT3466-1 has an undervoltage lockout circuit which

shuts down both converters when the input voltage drops

below 2.1V (typ). This prevents the converter from switching in an erratic mode when powered from low supply

voltages.

V

SW1

50V/DIV

100mA/DIV

V

SW2

50V/DIV

100mA/DIV

I

IN

200mA/DIV

I

L1

I

L2

V

= 3.6V

IN

CIRCUIT OF FIGURE 1

1µs/DIV

34661 F04b

V

OUT1

20V/DIV

V

FB1

200mV/DIV

CTRL1

5V/DIV

V

= 3.6V

IN

6 LEDs, 20mA

CIRCUIT OF FIGURE 1

200µs/DIV

Figure 4b. Output 1 Open-Circuit Waveforms Figure 5. Start-Up Waveforms

34661 F05

34661f

9

LT3466-1

www.BDTIC.com/LINEAR

WUUU

APPLICATIO S I FOR ATIO

DUTY CYCLE

The duty cycle for a step-up converter is given by:

VVV

++–

D

OUT D IN

=

VVV

OUT D CESAT

–

where:

= Output voltage

V

OUT

V

= Schottky forward voltage drop

D

V

= Saturation voltage of the switch

CESAT

= Input battery voltage

V

IN

The maximum duty cycle achievable for LT3466

-1

is 96%

(typ) when running at 1MHz switching frequency. It increases to 99% (typ) when run at 200kHz and drops to

92% (typ) at 2MHz. Always ensure that the converter is not

duty-cycle limited when powering the LEDs or OLED at a

given switching frequency.

SETTING THE SWITCHING FREQUENCY

OPERATING FREQUENCY SELECTION

The choice of operating frequency is determined by several factors. There is a tradeoff between efficiency and

component size. Higher switching frequency allows the

use of smaller inductors albeit at the cost of increased

switching losses and decreased efficiency.

Another consideration is the maximum duty cycle achievable. In certain applications, the converter needs to operate at the maximum duty cycle in order to light up the

-1

maximum number of LEDs. The LT3466

has a fixed

oscillator off-time and a variable on-time. As a result, the

maximum duty cycle increases as the switching frequency

is decreased.

The circuit of Figure 1 is operated with different values of

timing resistor (RT). RT is chosen so as to run the

converters at 800kHz (RT = 63.4k), 1.25MHz (RT = 38.3k)

and 2MHz (RT = 20.5k). The efficiency comparison for

different RT values is shown in Figure 7.

INDUCTOR SELECTION

The LT3466-1 uses a constant frequency architecture that

can be programmed over a 200KHz to 2MHz range with a

single external timing resistor from the R

The nominal voltage on the R

pin is 0.54V, and the

T

pin to ground.

T

current that flows into the timing resistor is used to

charge and discharge an internal oscillator capacitor. A

graph for selecting the value of R

for a given operating

T

frequency is shown in the Figure 6.

1000

100

(kΩ)

T

R

10

600 180014001000

200

OSCILLATOR FREQUENCY (kHz)

34661 F06

The choice of the inductor will depend on the selection of

switching frequency of LT3466-1. The switching frequency can be programmed from 200kHz to 2MHz. Higher

switching frequency allows the use of smaller inductors

albeit at the cost of increased switching losses.

90

CIRCUIT OF FIGURE 1

= 3.6V

V

IN

6 LEDs

80

70

60

EFFICIENCY (%)

50

40

0

5

LED CURRENT (mA)

RT = 63.4k

RT = 38.3k

10

RT = 20.5k

15

20

34661 F07

Figure 6. Timing Resistor (RT) Value

10

Figure 7. Efficiency Comparison for Different RT Resistors

34661f

WUUU

www.BDTIC.com/LINEAR

APPLICATIO S I FOR ATIO

LT3466-1

The inductor current ripple (∆IL), neglecting the drop

across the Schottky diode and the switch, is given by :

VV V

∆ =

IN MIN OUT MAX IN MIN

I

L

•–

() ( ) ()

()

VfL

OUT MAX

••

()

where:

L = Inductor

f = Operating frequency

V

V

= Minimum input voltage

IN(MIN)

OUT(MAX)

= Maximum output voltage

The ∆IL is typically set to 20% to 40% of the maximum

inductor current.

The inductor should have a saturation current rating

greater than the peak inductor current required for the

application. Also, ensure that the inductor has a low DCR

(copper wire resistance) to minimize I2R power losses.

Recommended inductor values range from 10µH to 68µH.

Several inductors that work well with the LT3466-1 are listed

in Table 1. Consult each manufacturer for more detailed

information and for their entire selection of related parts.

Table 1. Recommended Inductors

MAX CURRENT

L DCR RATING

PART (µH) (Ω) (mA) VENDOR

LQH32CN100 10 0.44 300 Murata

LQH32CN150 15 0.58 300 (814) 237-1431

LQH43CN330 33 1.00 310 www.murata.com

ELL6RH330M 33 0.38 600 Panasonic

ELL6SH680M 68 0.52 500 (714) 373-7939

www.panasonic.com

A914BYW330M 33 0.45 440 Toko

A914BYW470M 47 0.73 360 www.toko.com

A920CY680M 68 0.40 400

CDRH2D18150NC 15 0.22 0.35A Sumida

CDRH4D18-330 33 0.51 0.31A (847) 956-0666

CDRH5D18-680 68 0.84 0.43A www.sumida.com

CAPACITOR SELECTION

The small size of ceramic capacitors make them ideal for

LT3466-1 applications. Use only X5R and X7R types

because they retain their capacitance over wider voltage

and temperature ranges than other types such as Y5V or

Z5U. A 1µF input capacitor is sufficient for most applica-

tions. Always use a capacitor with sufficient voltage rating.

Table 2 shows a list of several ceramic capacitor manufacturers. Consult the manufacturers for detailed information

on their entire selection of ceramic parts.

Table 2. Ceramic Capacitor Manufacturers

Taiyo Yuden (408) 573-4150

www.t-yuden.com

AVX (803) 448-9411

www.avxcorp.com

Murata (714) 852-2001

www.murata.com

INRUSH CURRENT

The LT3466-1 has built-in Schottky diodes. When supply

voltage is applied to the VIN pin, an inrush current flows

through the inductor and the Schottky diode and charges

up the output capacitor. Both Schottky diodes in the

LT3466-1 can sustain a maximum of 1A current. The

selection of inductor and capacitor value should ensure

the peak of the inrush current to be below 1A.

For low DCR inductors, which is usually the case for this

application, the peak inrush current can be simplified as

follows:

V

–.:06

PK

IN

=

ω

L

I

where

1

=

ω

LC

OUT

Table 3 gives inrush peak current for some component

selections.

Table 3. Inrush Peak Current

VIN (V) L (µH) C

5 15 0.47 0.78

5 33 1.00 0.77

5 47 2.2 0.95

5 68 1.00 0.53

9 47 0.47 0.84

12 33 0.22 0.93

(µF) IP (A)

OUT

34661f

11

LT3466-1

VV

R

R

OUT2

08 1

1

2

=+

⎛

⎝

⎜

⎞

⎠

⎟

.

www.BDTIC.com/LINEAR

WUUU

APPLICATIO S I FOR ATIO

Typically peak inrush current will be less than the value

calculated above. This is due to the fact that the DC

resistance in the inductor provides some damping resulting in a lower peak inrush current.

SETTING THE LED CURRENT

The current in the LED string can be set by the choice of the

resistor R

(Figure 1). The feedback reference is 200mV.

FB1

In order to have accurate LED current, precision resistors

are preferred (1% is recommended).

FB

200

=

I

LED11

Value Selection

FB1

I

(mA) R

LED1

5 40.2

10 20.0

15 13.3

20 10.0

25 8.06

FB1

(Ω)

R

Table 4. R

mV

Most White LEDs are driven at maximum currents of

15mA to 20mA.

Feedback voltage variation versus control voltage is given

in the Typical Performance Characteristics graphs.

Using a Filtered PWM Signal

A variable duty cycle PWM can be used to control the

brightness of the LED string. The PWM signal is filtered

(Figure 8) by an RC network and fed to the CTRL1 pin.

The corner frequency of R1, C1 should be much lower than

the frequency of the PWM signal. R1 needs to be much

smaller than the internal impedance in the CTRL pin, which

is 100kΩ.

C1

1µF

LT3466-1

CTRL1

34661 F08

R1

10k

PWM

10kHz TYP

Figure 8. Dimming Control Using a Filtered PWM Signal

SETTING THE BOOST OUTPUT VOLTAGE

The LT3466-1 regulates the voltage at the FB2 pin to 0.8V.

The output voltage of the boost converter (V

OUT2

) is set by

a resistor divider according to the formula:

DIMMING WHITE LEDS

The LED current in the driver can be set by modulating the

CTRL1 pin. There are two different ways to control the

intensity of white LEDs.

Using a DC Voltage

For some applications, the preferred method of brightness

control is a variable DC voltage to adjust the LED current.

The CTRL1 pin voltage can be modulated to set the

dimming of the LED string. As the voltage on the CTRL1

pin increases from 0V to 1.8V, the LED current increases

from 0 to I

. As the CTRL1 pin voltage increases

LED1

beyond 1.8V, it has no effect on the LED current.

The LED current can be set by:

I

≈ (V

LED1

I

≈ (200mV/R

LED1

CTRL1

/5 • R

FB1

), when V

FB1

), when V

CTRL1

CTRL1

< 1V

> 1.8V

Choose 1% resistors for better accuracy. The FB2 input

bias current is quite low, on the order of 10nA (typ). Large

resistor values (R1 ~ 1MΩ) can be used in the divider

network maximizing efficiency.

PROGRAMMING THE BOOST OUTPUT VOLTAGE

The output voltage of the boost converter can be modulated by applying a variable DC voltage at the CTRL2 pin

The nominal voltage at the FB2 pin is 800mV. As the

voltage on the CTRL2 pin is ramped from 0V to 1V, the FB2

pin voltage ramps up to 0.8V. The feedback voltage can be

programmed as:

V

≈ V

FB2

V

≈ 0.8V, when V

FB2

CTRL2

, when V

CTRL2

CTRL2

> 1V

< 0.8V

34661f

12

WUUU

VIRVVV

IN MAX BASE BASE BE Q OUT CE Q( ) () ()

+• + = +

121

www.BDTIC.com/LINEAR

APPLICATIO S I FOR ATIO

LT3466-1

Figure 9 shows the feedback voltage variation versus the

control voltage. As seen in Figure 9, the linearity of the

graph allows the feedback voltage to be set accurately via

the control voltage.

The boost converter output voltage (V

R

1

VV

=+

OUT FB22

⎛

⎜

⎝

⎞

1

⎟

⎠

R

2

) is given by:

OUT2

Thus a linear change in the feedback (FB2) voltage results

in a linear change in the boost output voltage (V

OUT2

).

Connect the CTRL2 pin to ground to disable converter 2.

Do not leave the pin floating. Unlike the CTRL1 pin, which

has an internal 100k pull-down resistor, the CTRL2 pin

input impedance is very high (>100MΩ). A small amount

of board leakage current is sufficient to turn on the

converter 2.

900

VIN = 3.6V

= 16V

V

OUT2

800

700

600

500

(mV)

FB2

400

V

300

200

100

0

0

0.8

0.4

V

CTRL2

Figure 9. V

FB2

(V)

vs V

1.61.2

CTRL2

2

34661 F09

OUTPUT DISCONNECT

The LT3466-1 can be used for powering white LEDs

(Channel 1) and an OLED display or, LCD bias (Channel 2).

Some OLED displays require load isolation in order to

reduce the current drained from the battery in shutdown.

The LT3466-1 output can be configured to provide output

disconnect by the use of only one resistor, R

BASE

, and a

PNP transistor, Q1, as shown in Figure 10.

As a design example, we target a Li-Ion powered driver for

6 white LEDs and an OLED display (16V at 30mA). We can

choose a general purpose PNP switching transistor like

Philips BC807 (Q1) to provide isolation.

3V TO 5V

C

IN

I

R

C

OUT1

1µF

R

FB1

10Ω

: TAIYO YUDEN JMK107BJ105

C

IN

: TAIYO YUDEN GMK316BJ105

C

OUT1

, C

C

OUT2

L1, L2: TOKO D52LC

Q1: PHILIPS BC807

: TAIYO YUDEN TMK316BJ474

OUT3

L1

33µH

SW1 SW2V

IN

V

OUT1

LT3466-1

FB1

R

CTRL1 CTRL2

T

1µF

63.4k

1%

V

BASE

L2

33µH

OUT2

FB2

ONOFFONOFF

BASE

Q1

+–

V

CE(SAT)

R1

475k

C

OUT2

0.47µF

Figure 10. Li-Ion Powered Driver for 6 White LEDs and a

Secondary OLED Display with Output Disconnect

The R

I

LOAD

I

BASE

I

BASE

all conditions. The h

resistor can be calculated as:

BASE

= 30mA

I

LOAD

=

h

04.

FE MIN

()

must be chosen such that Q1 is in saturation under

can be obtained from the

FE(MIN)

Philips BC807 data sheet as:

h

This yields worst case I

I

BASE

R

BASE

≅ 100

FE(MIN)

= ≅

0 4 100

is given by:

mA

30

.( )

BASE

075

.

as:

mA

Thus R

;

BASE

VV V V

=

––

211

OUT IN MAX CE Q BE Q

+

( ) () ()

I

B

AASE

R2

24.9k

34661 F10

16V

30mA

C

OUT3

0.47µF

34661f

13

LT3466-1

www.BDTIC.com/LINEAR

WUUU

APPLICATIO S I FOR ATIO

The V

CE(SAT)

and V

BE(SAT)

values for the transistor Q1 can

be obtained from the Philips BC807 data sheet:

R

R

BASE

BASE

VV

=

= 13.6k

+1650109

–.–.

mA

075

.

Picking the closest 1% resistor value yields:

R

= 14k

BASE

BOARD LAYOUT CONSIDERATION

As with all switching regulators, careful attention must be

paid to the PCB board layout and component placement.

To prevent electromagnetic interference (EMI) problems,

proper layout of high frequency switching paths is essential. Minimize the length and area of all traces connected to

the switching node pins (SW1 and SW2). Keep the feedback pins (FB1 and FB2) away from the switching nodes.

The DFN package has an exposed paddle that must be

connected to the system ground. The ground connection

for the feedback resistors should be tied directly to the

ground plane and not shared with any other component,

except the R

resistor, ensuring a clean, noise-free con-

T

nection. Recommended component placement is shown

in the Figure 11.

GND

C

IN

V

GND

C

OUT1

R

FB1

L1

IN

L2

C

OUT2

Figure 11. Recommended Component Placement

1

2

11

3

4

5

10

9

8

7

6

R2

R1

CTRL1

R

T

CTRL2

34661 F10

14

34661f

U

www.BDTIC.com/LINEAR

TYPICAL APPLICATIO S

Li-Ion Powered 4 White LEDs Driver and 12V Boost Converter

3V TO 5V

C

IN

1µF

12V

30mA AT V

60mA AT V

R1

R2

64.9k

34661 TA01a

4 LEDs

C

OUT1

0.47µF

R

FB1

10Ω

C

: TAIYO YUDEN JMK107BJ105

IN

: TAIYO YUDEN EMK212BJ474

C

OUT1

: TAIYO YUDEN EMK212BJ105

C

OUT2

L1, L2: MURATA LQH32CN150K53

L1

15µH

SW1 SW2V

IN

V

OUT1

LT3466-1

FB1

R

CTRL1 CTRL2

T

38.3k

1%

V

OUT2

FB2

L2

15µH

909k

C

OUT2

1µF

ONOFFONOFF

IN

IN

= 3V

= 5V

Efficiency vs Load Current

90

4 LEDs/20mA

V

OUT2

85

80

75

EFFICIENCY (%)

70

65

60

0

10

= 12V

VIN = 3V

20 30 40

LOAD CURRENT (mA)

LT3466-1

VIN = 5V

50 60

34661 TA01b

Li-Ion Powered Driver for 6 White LEDs and OLED Display

3V TO 5V

6 LEDs

R

FB1

10Ω

: TAIYO YUDEN JMK107BJ105

C

IN

C

OUT1

L1, L2: 33µH TOKO D52LC

SW1 SW2V

V

C

OUT1

1µF

, C

OUT2

OUT1

FB1

CTRL1 GND CTRL2

SHUTDOWN

AND DIMMING

CONTROL 1

: TAIYO YUDEN GMK316BJ105

L1

33µH

63.4k

IN

LT3466-1

R

T

L2

33µH

V

SHUTDOWN

AND DIMMING

CONTROL 2

OUT2

FB2

1µF

C

1µF

OUT2

16V

30mA

R1

475k

R2

24.9k

34661 TA02a

90

85

LED DRIVER

80

75

70

65

EFFICIENCY (%)

60

VIN = 3.6V

55

6 LEDs

V

OUT2

50

0

Conversion Efficiency

BOOST CONVERTER

= 16V

51015

OUTPUT CURRENT (mA)

302520

34661 TA02b

34661f

15

LT3466-1

www.BDTIC.com/LINEAR

TYPICAL APPLICATIO S

Li-Ion Powered Driver for 6 White LEDs and OLED with Output Disconnect

U

V

OUT2

20V/DIV

6 LEDs

L1

33µH

C

OUT1

1µF

R

FB1

10Ω

: TAIYO YUDEN JMK107BJ105

C

IN

: TAIYO YUDEN GMK316BJ105

C

OUT1

, C

C

OUT2

OUT3

L1, L2: 33µH TOKO D52LC

Q1: PHILIPS BC807

V

FB1

CTRL1 CTRL2

: TAIYO YUDEN TMK316BJ474

3V TO 5V

SW1 SW2V

OUT1

LT3466-1

14k

C

IN

1µF

L2

33µH

IN

V

OUT2

FB2

R

T

63.4k

1%

ONOFFONOFF

C

OUT3

0.47µF

C

OUT2

0.47µF

Q1

16V

30mA

R1

475k

R2

24.9k

34661 TA03a

Conversion Efficiency

90

VIN = 3.6V

= 16V

V

OUT2

80

200mA/DIV

CTRL2

5V/DIV

I

L2

34661 TA03c

V

= 3.6V

IN

OUT2

= 16V

2ms/DIVV

70

60

EFFICIENCY (%)

50

40

0

10 15 20

5

LOAD CURRENT (mA)

25 30

34661 TA03b

34661f

16

TYPICAL APPLICATIO S

www.BDTIC.com/LINEAR

Li-Ion Powered Driver for 6 White LEDs and OLED with Output Disconnect

6 LEDs

U

R

FB1

10Ω

C

OUT1

1µF

3V TO 5V

L1

33µH

SW1 SW2V

V

OUT1

LT3466-1

FB1

R

CTRL1 CTRL2

IN

T

63.4k

1%

C

1µF

V

IN

OUT2

FB2

L2

33µH

LT3466-1

16V

Q1

C

OUT3

0.47µF

C

OUT2

0.47µF

ONOFFONOFF

30mA

R1

475k

R2

24.9k

34661 TA04a

V

OUT2

20V/DIV

I

200mA/DIV

CTRL2

5V/DIV

: TAIYO YUDEN JMK107BJ105

C

IN

: TAIYO YUDEN GMK316BJ105

C

OUT1

, C

C

OUT2

L1, L2: 33µH TOKO D52LC

Q1: SILICONIX TPO610

: TAIYO YUDEN TMK316BJ474

OUT3

NOTE: ENSURE THAT V

OUT2

> V

IN(MAX)

+ 5V

Conversion Efficiency

90

VIN = 3.6V

= 16V

V

OUT2

85

80

L2

34661 TA04c

V

= 3.6V

IN

OUT2

= 16V

2ms/DIVV

75

70

65

EFFICIENCY (%)

60

55

50

0

510 20

15

LOAD CURRENT (mA)

25

34661 TA04b

30

34661f

17

LT3466-1

www.BDTIC.com/LINEAR

U

TYPICAL APPLICATIO S

Li-Ion to 10 White LEDs and LCD Bias (±8V) with Output Disconnect

10 LEDs

R

FB1

16.5Ω

: TAIYO YUDEN JMK107BJ105

C

IN

: TAIYO YUDEN UMK325BJ105

C

OUT1

, C

C

OUT2

C1, C2: TAIYO YUDEN UMK212BJ104

D1, D2: PHILIPS BAT54S

L1: 68µH TOKO D52LC

L2: 33µF TOKO D52LC

L1

68µH

SW1 SW2V

V

C

OUT1

1µF

: TAIYO YUDEN GMK316BJ105

OUT3

OUT1

FB1

CTRL1 CTRL2

ONOFF

3V TO 5V

IN

LT3466-1

R

T

147k

1µF

V

C

OUT2

IN

FB2

L2

33µH

ONOFF

C1

0.1µF

C2

0.1µF

D1

–8V

10mA

C

OUT2

1µF

D2

909k

10k

34661 TA05a

C

1µF

8V

10mA

OUT3

+8V OUTPUT

10V/DIV

–8V OUTPUT

10V/DIV

CTRL2

5V/DIV

= 3.6V

IN

+8V/10mA

–8V/10mA

Conversion Efficiency

84

VIN = 3.6V

10 LEDs

82

+8V/10mA

–8V/10mA

80

78

EFFICIENCY (%)

76

2ms/DIVV

34661 TA05c

74

72

0

468

2

LED CURRENT (mA)

10 12

34661 TA05b

18

34661f

PACKAGE DESCRIPTIO

www.BDTIC.com/LINEAR

LT3466-1

U

DD Package

10-Lead Plastic DFN (3mm × 3mm)

(Reference LTC DWG # 05-08-1699)

0.675 ±0.05

3.50 ±0.05

1.65 ±0.05

(2 SIDES)2.15 ±0.05

PACKAGE

OUTLINE

0.25 ± 0.05

2.38 ±0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

PIN 1

TOP MARK

(SEE NOTE 6)

0.200 REF

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WEED-2).

CHECK THE LTC WEBSITE DATA SHEET FOR CURRENT STATUS OF VARIATION ASSIGNMENT

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE

TOP AND BOTTOM OF PACKAGE

0.50

BSC

(2 SIDES)

3.00 ±0.10

(4 SIDES)

0.75 ±0.05

1.65 ± 0.10

(2 SIDES)

0.00 – 0.05

R = 0.115

TYP

2.38 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

106

15

0.25 ± 0.05

0.50 BSC

0.38 ± 0.10

(DD10) DFN 1103

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

34661f

19

LT3466-1

www.BDTIC.com/LINEAR

TYPICAL APPLICATIO

Li-Ion to 8 White LEDs and ±15V TFT LCD Bias Supply

3V TO 5V

L1

33µH

SW1 SW2V

8 LEDs

C

OUT1

1µF

V

OUT1

FB1

CTRL1 CTRL2

IN

LT3466-1

R

T

1µF

V

U

C

IN

OUT2

FB2

L2

33µH

C1

0.1µF

475k

26.7k

Conversion Efficiency

D1

–15V

10mA

C

OUT3

1µF

15V

10mA

C

OUT2

1µF

86

VIN = 3.6V

8 LEDs

84

+15V/10mA

–15V/10mA

82

80

EFFICIENCY (%)

78

76

R

FB1

13.3Ω

CIN: TAIYO YUDEN JMK107BJ105

, C

C

OUT1

OUT2

C1: TAIYO YUDEN UMK212BJ104

L1, L2: 33µH TOKO D52LC

D1: PHILIPS BAT54S

ONOFF

, C

: TAIYO YUDEN GMK316BJ105

OUT3

63.4k

ONOFF

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1618 Constant Current, Constant Voltage 1.4MHz, High Efficiency VIN: 1.6V to 18V, V

Boost Regulator MS/EDD Packages

LT1932 Constant Current, 1.2MHz, High Efficiency White LED Boost VIN: 1V to 10V, V

Regulator ThinSOT

LT1937 Constant Current, 1.2MHz, High Efficiency White LED Boost VIN: 2.5V to 10V, V

Regulator ThinSOT, SC70 Packages

LTC®3200-5 Low Noise, 2MHz, Regulated Charge Pump White LED Driver VIN: 2.7V to 4.5V, V

LTC3202 Low Noise, 1.5MHz, Regulated Charge Pump White LED Driver VIN: 2.7V to 4.5V, V

LTC3205 High Efficiency, Multidisplay LED Controller VIN: 2.8V to 4.5V, V

LTC3216 1A Low Noise High Current LED Charge Pump with Independent VIN: 2.9V to 4.4V, V

Flash/Torch Current Control DFN Package

LTC3453 500mA Synchronous Buck-Boost High Current LED Driver VIN: 2.7V to 5.5V, V

in Q FN QFN Package

LT3465/LT3465A Constant Current, 1.2MHz/2.7MHz, High Efficiency White LED VIN: 2.7V to 16V, V

Boost Regulator with Integrated Schottky Diode ThinSOT Package

LT3466 Dual Constant Current, 2MHz High Efficiency White LED Boost VIN: 2.7V to 24V, V

Regulator with Integrated Schottky Diode DFN Package

LT3479 3A, Full Featured DC/DC Converter with Soft-Start and Inrush VIN: 2.5V to 24V, V

Current Protection DFN/TSSOP Packages

ThinSOT is a trademark of Linear Technology Corporation.

Linear Technology Corporation

20

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

34661 TA06a

74

TM

Package

ThinSOT Package

MS/EDD Packages

QFN-24 Package

0

2.5

OUT(MAX)

OUT(MAX)

OUT(MAX)

OUT(MAX)

OUT(MAX)

OUT(MAX)

OUT(MAX)

OUT(MAX)

OUT(MAX)

OUT(MAX)

OUT(MAX)

5 7.5 10

LED CURRENT (mA)

12.5 15

34661 TA06b

= 34V, IQ = 1.8mA, ISD < 1µA,

= 34V, IQ = 1.2mA, ISD < 1µA,

= 34V, IQ = 1.9mA, ISD < 1µA,

= 5V, IQ = 8mA, ISD < 1µA,

= 5.5V, IQ = 5mA, ISD < 1µA,

= 6V, IQ = 50µA, ISD < 1µA,

= 5.5V, IQ = 300µA, ISD < 2.5µA,

= 5.5V, IQ = 0.6mA, ISD < 6µA,

= 34V, IQ = 1.9mA, ISD < 1µA,

= 40V, IQ = 5mA, ISD < 16µA,

= 40V, IQ = 6.5mA, ISD < 1µA,

34661f

LT/TP 0705 500 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2005

Loading...

Loading...