查询LT3463A供应商

FEATURES

LT3463/LT3463A

Dual Micropower

DC/DC Converters

with Schottky Diodes

U

DESCRIPTIO

■

Generates Well-Regulated Positive and

Negative Outputs

■

Low Quiescent Current:

20µA (per Converter) in Active Mode

<1µA in Shutdown Mode

■

Internal 42V Power Switches

■

Internal 42V Schottky Diodes

■

Low V

■

Input Voltage Range: 2.4V to 15V

■

High Output Voltages: Up to ±40V

■

Low Profile (0.8mm) 3mm x 3mm DFN Package

Switch: 180mV at 150mA

CESAT

U

APPLICATIO S

■

CCD Bias

■

LCD Bias

■

Handheld Computers

■

Digital Cameras

U

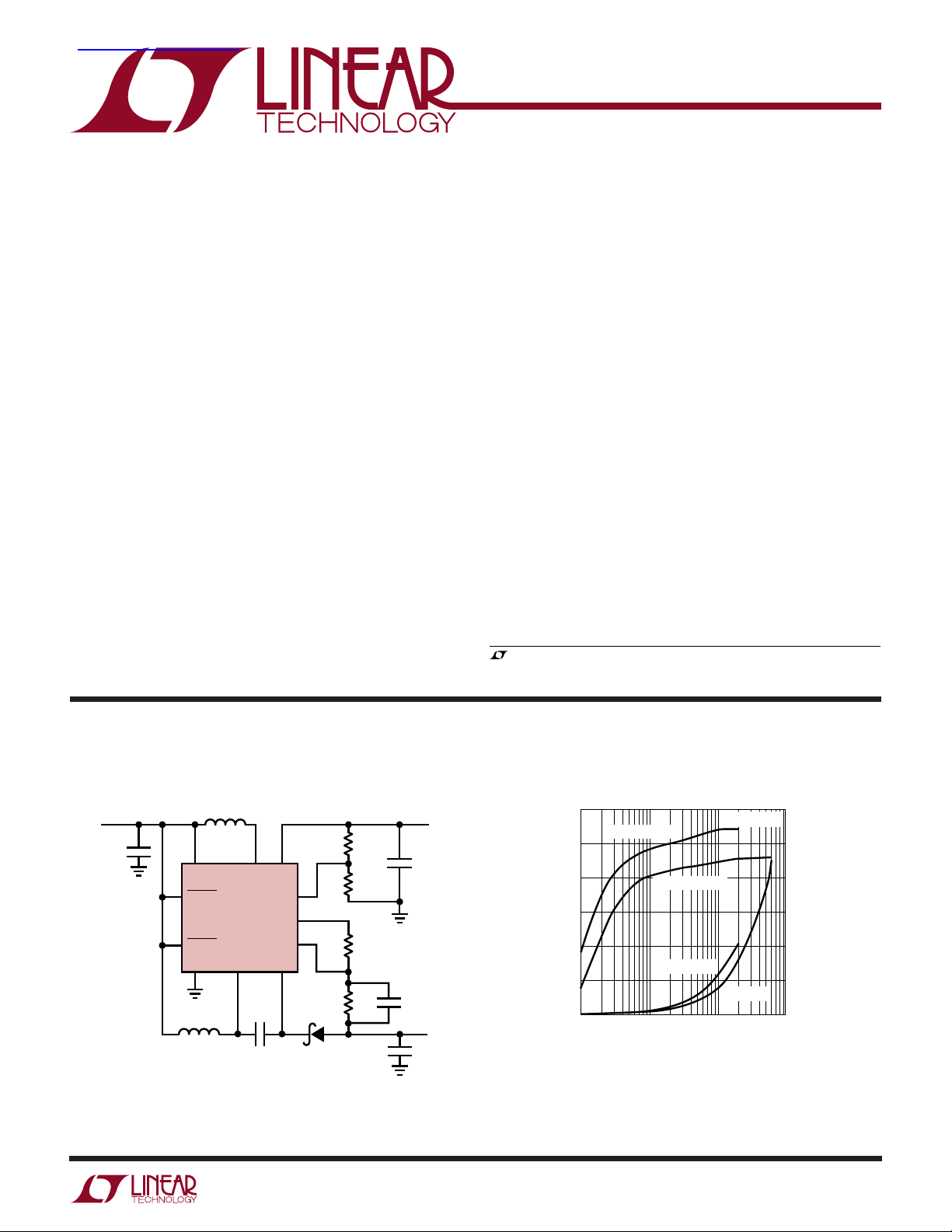

TYPICAL APPLICATIO

The LT®3463/LT3463A are dual micropower DC/DC converters with internal Schottky diodes in a 10-lead 3mm ×

3mm DFN package. Negative and positive LT3463 converters have a 250mA current limit. The LT3463A positive

converter also has a 250mA limit, while the negative

converter has a 400mA limit. Both devices have an input

voltage range of 2.4V to 15V, making them ideal for a wide

variety of applications. Each converter features a quiescent current of only 20µA, which drops to under 1µA in

shutdown. A current limited, fixed off-time control scheme

conserves operating current, resulting in high efficiency

over a broad range of load current. The 42V switch enables

high voltage outputs up to ±40V to be easily generated

without the use of costly transformers. The low 300ns offtime permits the use of tiny, low profile inductors and

capacitors to minimize footprint and cost in space-conscious portable applications.

, LTC and LT are registered trademarks of Linear Technology Corporation.

V

2.7V

TO 5V

IN

4.7µF

CCD Bias Supply (15V, –8V)

10µH

V

IN

SHDN2

GND SW2 D2

10µH

SW1

LT3463A

1µF

V

OUT1

FB1SHDN1

V

REF

FB2

1M

90.9k

154k

1M 10pF

4.7µF

3463 TA01a

2.2µF

V

OUT1

15V

10mA

V

OUT2

–8V

50mA

Efficiency and Power Loss

80

15V EFFICIENCY

75

70

65

EFFICIENCY (%)

60

55

50

0.1

VIN = 3.6V

–8V EFFICIENCY

15V LOSS

–8V LOSS

1 10 100

LOAD CURRENT (mA)

3463 TA01b

240

200

POWER LOSS (mW)

160

120

80

40

0

3463f

1

LT3463/LT3463A

TOP VIEW

DD PACKAGE

10-LEAD (3mm × 3mm) PLASTIC DFN

10

9

6

7

8

4

5

3

2

1

FB1

SHDN1

SHDN2

V

REF

FB2

V

OUT1

SW1

V

IN

SW2

D2

11

ABSOLUTE AXI U RATI GS

(Note 1)

VIN, SHDN1, SHDN2 Voltage ................................... 15V

SW1, SW2, V

D2 Voltage ............................................................. –42V

FB1, FB2 Voltage Range .............................. –0.3V to 2V

Junction Temperature........................................... 125°C

Operating Ambient Temperature Range

(Note 2) .............................................. –40°C to 85°C

Storage Temperature Range ................. –65°C to 125°C

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 2.5V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Input Voltage 2.2 2.4 V

Total Quiescent Current For Both Switchers, Not Switching 40 60 µA

Shutdown Current V

V

Pin Voltage With 124kΩ to GND ● 1.23 1.25 1.27 V

REF

V

Pin Voltage Line Regulation With 124kΩ to GND 0.05 0.10 %/V

REF

FB1 Comparator Trip Voltage High to Low Transition ● 1.225 1.25 1.275 V

FB1 Comparator Hysteresis 8mV

FB1 Line Regulation 2.5V < VIN < 15V 0.05 0.10 %/V

FB1 Pin Bias Current (Note 3) V

FB2 Comparator Trip Voltage Low to High Transition ● 0312mV

FB2 Comparator Hysteresis 8mV

FB2 Line Regulation (V

FB2 Pin Bias Current (Note 4) V

SW1 Switch Off Time V

SW2 Switch Off Time V

Switch V

CESAT

Switch Current Limit (SW1) 180 250 320 mA

Switch Current Limit (SW2) LT3463 180 250 320 mA

Swith Leakage Current (SW1, SW2) Switch Off, VSW = 42V 0.01 1 µA

Schottky Forward Voltage (V

Schottky Reverse Leakage Current V

SHDN1 Pin Current V

SHDN2 Pin Current V

SHDN1/SHDN2 Start-Up Threshold 0.3 1 1.5 V

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LT3463/LT3463A are guaranteed to meet performance

specifications from 0°C to 70°C. Specifications over the –40°C to 85°C

2

W

Voltage ....................................... 42V

OUT1

– V

REF

(SW1, SW2) I

) 2.5V < VIN < 15V 0.05 0.10 %/V

FB2

, D2) ID = 150mA 750 mV

OUT1

WW

U

UUW

PACKAGE/ORDER I FOR ATIO

ORDER PART

NUMBER

LT3463EDD

LT3463AEDD

DD PART MARKING

T

= 125°C, θJA = 43°C/W, θJC = 3°C/W

JMAX

EXPOSED PAD (PIN 11) IS GND

AND MUST BE SOLDERED TO PCB

Consult LTC Marketing for parts specified with wider operating temperature ranges.

The ● denotes the specifications which apply over the full operating

= 2.5V unless otherwise noted.

SHDN

= V

SHDN1

= 1.3V ● 20 50 nA

FB1

= –0.1V ● 20 50 nA

FB2

– VIN = 4V 300 ns

OUT1

– VIN = 0V 1.5 µs

V

OUT1

< 0.1V 300 ns

FB2

= 1V 1.5 µs

V

FB2

= 150mA 180 mV

SW

LT3463A 320 400 460 mA

– VSW = 42V 1 5 µA

OUT1

= –42V 1 5 µA

V

D2

= 2.5V 4 10 µA

SHDN1

= 2.5V 4 10 µA

SHDN2

= 0V 0.1 1 µA

SHDN2

operating ambient temperature range are assured by design,

characterization and correlation with statistical process controls.

Note 3: Bias current flows into the FB1 pin.

Note 4: Bias current flows out of the FB2 pin.

LAFC

LBJK

3463f

UW

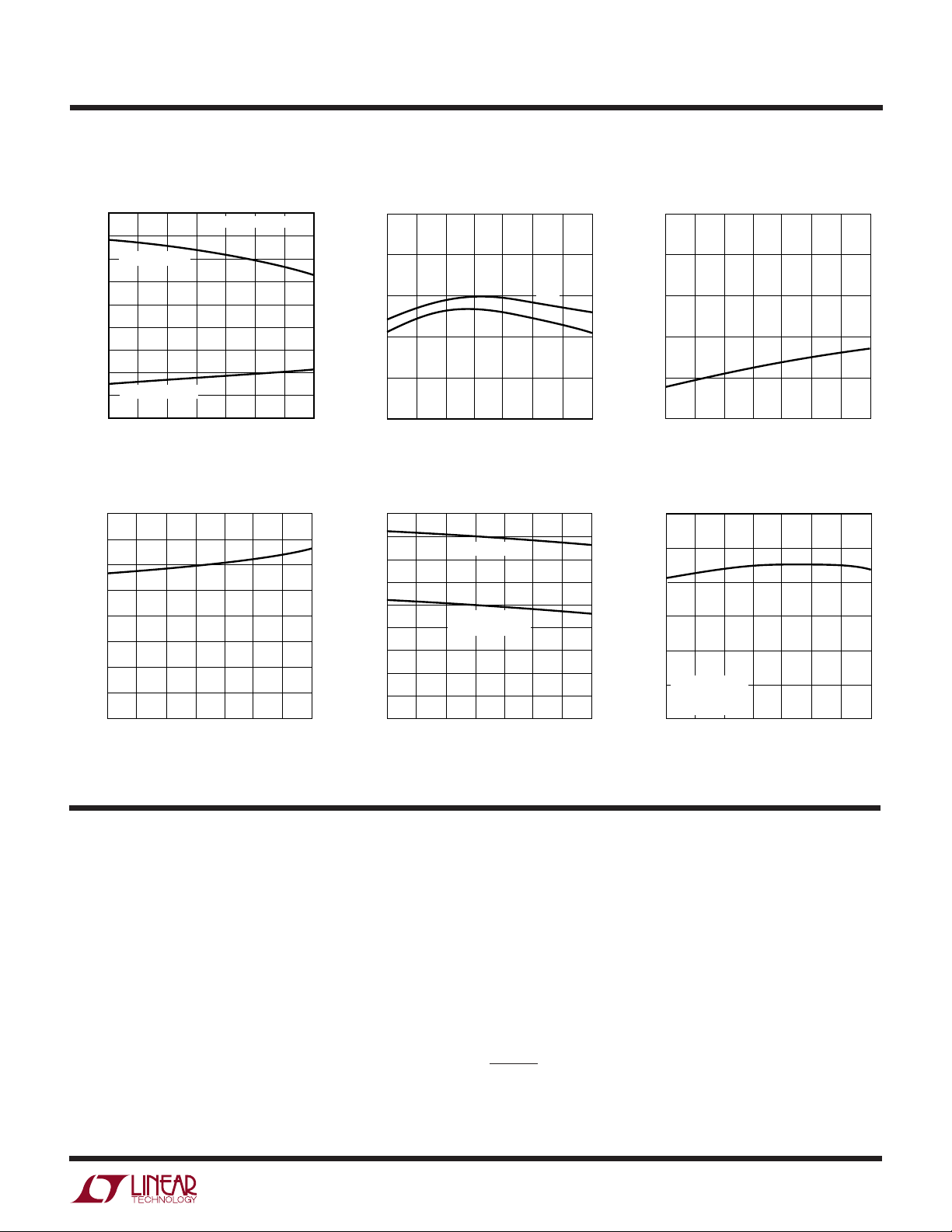

TYPICAL PERFOR A CE CHARACTERISTICS

V

and V

CESAT

900

800

I

700

600

VOLTAGE (V)

500

DIODE

400

300

AND V

200

CESAT

V

100

0

= 150mA

DIODE

I

= 150mA

SWITCH

–50 100

050–25 25 75 125

TEMPERATURE (°C)

Voltage

DIODE

FOR BOTH SWITCHERS

3463 G01

V

and V

REF

1.27

1.26

1.25

VOLTAGE (V)

FB1

1.24

AND V

REF

V

1.23

1.22

–50 100

Voltage V

FB1

V

FB1

050–25 25 75 125

TEMPERATURE (°C)

V

REF

3463 G02

LT3463/LT3463A

Voltage

FB2

10

8

6

4

VOLTAGE (mV)

FB2

V

2

0

–50 25 75

–25 0

TEMPERATURE (°C)

50 100 125

3463 G03

Switch Off Time

400

350

300

250

200

150

SWITCH OFF TIME (ns)

100

50

0

–50

050

–25 25 75 125

100

TEMPERATURE (°C)

3463 G04

Switch Current Limit

450

400

350

300

250

200

150

100

SWITCH CURRENT LIMIT (mA)

50

0

–25 25 75 125

–50

LT3463A SW2

LT3463 SW1, SW2

LT3463A SW1

050

TEMPERATURE (°C)

UUU

PI FU CTIO S

V

(Pin 1): Output Voltage Switcher 1. This is the

OUT1

cathode of an internal Schottky diode whose anode is

connected to the SW1 pin.

Quiescent Current

60

50

40

30

20

QUIESCENT CURRENT (µA)

NOT SWITCHING

10

= 1.3V

V

FB1

V

= –0.1V

FB2

100

3463 G05

0

–50

–25 0

50 100 125

25 75

TEMPERATURE (°C)

3463 G06

D2 (Pin 5): Diode for Switcher 2. This is the anode of an

internal Schottky diode whose cathode connected to the

GND pin.

SW1 (Pin 2): Switch Pin for Switcher 1. This is the

collector of the internal NPN switch. Minimize the metal

trace area connected to this pin to minimize EMI.

VIN (Pin 3): Input Supply Pin. Bypass this pin with a

capacitor as close to the device as possible.

SW2 (Pin 4): Switch Pin for Switcher 2. This is the

collector of the internal NPN switch. Minimize the metal

trace area connected to this pin to minimize EMI.

FB2 (Pin 6): Feedback Pin for Switcher 2. Set the output

voltage by selecting values for R3 and R4.

V

(Pin 7): Voltage Reference Pin (1.25V). This pin is

REF

used along with FB2 to set the negative output voltage for

Switcher 2.

SHDN2 (Pin 8): Shutdown Pin for Switcher 2. Pull this pin

above 1.5V to enable Switcher 2. Pull below 0.3V to turn

it off. Do not leave this pin floating.

3463f

3

LT3463/LT3463A

U

UU

PI FU CTIO S

SHDN1 (Pin 9): Shutdown Pin for Switcher 1. Pull this pin

above 1.5V to enable Switcher 1. Pull below 0.3V to turn

it off. Do not leave this pin floating.

FB1 (Pin 10): Feedback Pin for Switcher 1. Set the output

voltage by selecting values for R1 and R2.

W

BLOCK DIAGRA

V

OUT1

V

IN

C1

3

V

IN

9

SHDN1SHDN1

L1

300ns

ONE-SHOT

V

2

SW1

OUT1

V

OUT2

C2

C3

1

V

OUT1

D1

Q1

GND (Pin 11): Exposed Pad. Solder this exposed pad

directly to the local ground plane. This pad must be

electrically connected for proper operation.

C4

D3

5

D2

D2

L2

V

IN

4

SW2

8

Q2

300ns

ONE-SHOT

1.25V

V

REF

7

SHDN2SHDN2

R2

FB1

10

R1

LT3463: R

LT3463A: R

–

+

= RS2 = 0.1Ω

S1

= 0.1Ω, RS2 = 0.063Ω

S1

A2A1

SWITCHER 1

+

R

S1

–

25mV

Figure 1. Block Diagram

U

OPERATIO

The LT3463 uses a constant off-time control scheme to

provide high efficiency over a wide range of output current. Operation can be best understood by referring to the

block diagram in Figure 1. When the voltage at the FB1 pin

is slightly above 1.25V, comparator A1 disables most of

the internal circuitry. Output current is then provided by

capacitor C2, which slowly discharges until the voltage at

the FB1 pin goes below the hysteresis point of A1 (typical

hysteresis at the FB1 pin is 8mV). A1 then enables the

internal circuitry, turns on power switch Q1, and the

FB2

+

+

R

S2

25mV1.25V

GND

11

–

A4 A3

SWITCHER 2

6

–

3463 F01

V

OUT2

current in inductor L1 begins ramping up. Once the switch

current reaches 250mA, comparator A2 resets the oneshot, which turns off Q1 for 300ns. Q1 turns on again and

the inductor currents ramp back up to 250mA, then A2

again resets the one-shot. This switching action continues

until the output voltage is charged up (until the FB1 pin

reaches 1.25V), then A1 turns off the internal circuitry and

the cycle repeats. The second switching regulator is an

inverting converter (which generates a negative output)

but the basic operation is the same.

R3

R4

4

3463f

LT3463/LT3463A

L

VV

I

t

OUT D

LIM

OFF

=

+

2

U

WUU

APPLICATIO S I FOR ATIO

Choosing an Inductor

Several recommended inductors that work well with the

LT3463 are listed in Table 1, although there are many other

manufacturers and devices that can be used. Consult each

manufacturer for more detailed information and for their

entire selection of related parts. Many different sizes and

shapes are available. Use the equations and recommendations in the next few sections to find the correct inductance

value for your design.

Table 1. Recommended Inductors

MAX MAX HEIGHT

µ

PART L (

CMD4D06 4.7 750 0.22 0.8 Sumida

CDRH3D16 10 500 0.19 1.8 Sumida

LPO4812 4.7 600 0.16 1.2 Coilcraft

LQH32C 10 450 0.39 1.8 Murata

LQH31C 4.7 340 0.85 1.8 Murata

Inductor Selection—Boost Regulator

The formula below calculates the appropriate inductor

value to be used for a boost regulator using the LT3463 (or

at least provides a good starting point). This value provides a good tradeoff in inductor size and system performance. Pick a standard inductor close to this value. A

larger value can be used to slightly increase the available

output current, but limit it to around twice the value

calculated below, as too large of an inductance will increase the output voltage ripple without providing much

additional output current. A smaller value can be used

(especially for systems with output voltages greater than

12V) to give a smaller physical size. Inductance can be

calculated as:

VV V

OUT

L

=

where VD = 0.5V (Schottky diode voltage), I

(or 400mA) and t

H) IDC (mA) DCR(Ω) (mm) MANUFACTURER

10 500 0.46 (847) 956-0666

22 310 1.07 www.sumida.com

22 310 0.36

10 400 0.30 (847) 639-6400

22 280 0.64 www.coilcraft.com

15 300 0.75 (714) 852-2001

22 250 0.92 www.murata.com

−+

IN MIN

()

I

LIM

= 300ns; for designs with varying V

OFF

D

t

OFF

= 250mA

LIM

IN

such as battery powered applications, use the minimum

VIN value in the above equation. For most regulators with

output voltages below 7V, a 4.7µH inductor is the best

choice, even though the equation above might specify a

smaller value.

For higher output voltages, the formula above will give

large inductance values. For a 3V to 20V converter (typical

LCD Bias application), a 21µH inductor is called for with

the above equation, but a 10µH inductor could be used

without much reduction in the maximum output current.

Inductor Selection—Inverting Regulator

The formula below calculates the appropriate inductor

value to be used for an inverting regulator using the

LT3463 (or at least provides a good starting point). This

value provides a good tradeoff in inductor size and system

performance. Pick a standard inductor close to this value

(both inductors should be the same value). A larger value

can be used to slightly increase the available output

current, but limit it to around twice the value calculated

below, as too large of an inductance will increase the

output voltage ripple without providing much additional

output current. A smaller value can be used (especially for

systems with output voltages greater than 12V) to give a

smaller physical size. Inductance can be calculated as:

where VD = 0.5V (Schottky diode voltage), I

(or 400mA) and t

= 300ns.

OFF

= 250mA

LIM

For higher output voltages, the formula above will give

large inductance values. For a 3V to 20V converter (typical

LCD bias application), a 49µH inductor is called for with

the above equation, but a 10µH or 22µH inductor could be

used without much reduction in the maximum output

current.

Inductor Selection—Inverting Charge Pump Regulator

For the inverting regulator, the voltage seen by the internal

power switch is equal to the sum of the absolute value of

the input and output voltages, so that generating high

3463f

5

LT3463/LT3463A

VV

R

R

VV

R

R

OUT

OUT12

125 1

2

1

125

4

3

=+

=

.

–.

U

WUU

APPLICATIO S I FOR ATIO

output voltages from a high input voltage source will often

exceed the 50V maximum switch rating. For instance, a

12V to – 40V converter using the inverting topology would

generate 52V on the SW pin, exceeding its maximum

rating. For this application, an inverting charge pump is

the best topology.

The formula below calculates the approximate inductor

value to be used for an inverting charge pump regulator

using the LT3463. As for the boost inductor selection, a

larger or smaller value can be used. For designs with

varying VIN such as battery powered applications, use the

minimum VIN value in the equation below.

VV V

−+

OUT

L

=

Capacitor Selection

The small size and low ESR of ceramic capacitors makes

them ideal for LT3463 applications. Use only X5R and X7R

types because they retain their capacitance over wider

voltage and temperature ranges than other ceramic types.

A 1µF input capacitor and a 0.22µF or 0.47µF output

capacitor are sufficient for most applications. Table 2

shows a list of several ceramic capacitor manufacturers.

Consult the manufacturers for more detailed information

on their entire selection of ceramic capacitors. For applications needing very low output voltage ripple, larger

output capacitor values can be used.

IN MIN

()

I

LIM

D

t

OFF

inrush current include a larger more abrupt voltage step at

VIN, a larger output capacitor tied to the outputs, and an

inductor with a low saturation current.

While the internal diode is designed to handle such events,

the inrush current should not be allowed to exceed 1 amp.

For circuits that use output capacitor values within the

recommended range and have input voltages of less than

5V, inrush current remains low, posing no hazard to the

device. In cases where there are large steps at VIN and/or

a large capacitor is used at the outputs, inrush current

should be measured to ensure safe operation.

Setting the Output Voltages

The output voltages are programmed using two feedback

resistors. As shown in Figure 1, resistors R1 and R2

program the positive output voltage (for Switcher 1), and

resistors R3 and R4 program the negative output voltage

(for Switcher 2) according to the following formulas:

R1 and R3 are typically 1% resistors with values in the

range of 50k to 250k.

Board Layout Considerations

Table 2. Recommended Ceramic Capacitor Manufacturers

MANUFACTURER PHONE URL

AVX 843-448-9411 www.avxcorp.com

Kemet 408-986-0424 www.kemet.com

Murata 814-237-1431 www.murata.com

Taiyo Yuden 408-573-4150 www.t-yuden.com

Inrush Current

When VIN is increased from ground to operating voltage

while the output capacitor is discharged, an inrush current

will flow through the inductor and integrated Schottky

diode into the output capacitor. Conditions that increase

6

As with all switching regulators, careful attention must be

paid to the PCB board layout and component placement.

To maximize efficiency, switch rise and fall times are made

as short as possible. To prevent electromagnetic interference (EMI) problems, proper layout of the high frequency

switching path is essential. The voltage signal of the SW

pin has sharp rising and falling edges. Minimize the length

and area of all traces connected to the SW pin and always

use a ground plane under the switching regulator to

minimize interplane coupling. In addition, the ground

connection for the feedback resistor R1 should be tied

directly to the GND pin and not shared with any other

component, ensuring a clean, noise-free connection.

3463f

TYPICAL APPLICATIO

V

IN

2.7V

TO 5V

PACKAGE DESCRIPTIO

U

1µF

LT3463/LT3463A

Dual Output ±20V Converter

L1

10µH

C1

321

V

SW1

OUT1

10

FB1

LT3463

SW2

11

4

C4

0.1µF

7

V

REF

6

FB2

D2

5

9

8

V

IN

SHDN1

SHDN2

GND

L2

10µH

R2

1M

R1

66.5k

R3

61.9k

R4

1M

D1

C3

0.47µF

C2

0.47µF

3463 TA02

V

OUT1

20V

9mA

V

OUT2

–20V

9mA

U

10-Lead Plastic DFN (3mm × 3mm)

(Reference LTC DWG # 05-08-1699)

0.675 ±0.05

3.50 ±0.05

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WEED-2).

CHECK THE LTC WEBSITE DATA SHEET FOR CURRENT STATUS OF VARIATION ASSIGNMENT

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

1.65 ±0.05

(2 SIDES)2.15 ±0.05

PACKAGE

OUTLINE

0.25 ± 0.05

2.38 ±0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

(2 SIDES)

0.50

BSC

TOP MARK

(SEE NOTE 6)

DD Package

PIN 1

0.200 REF

R = 0.115

TYP

3.00 ±0.10

(4 SIDES)

0.75 ±0.05

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE

TOP AND BOTTOM OF PACKAGE

1.65 ± 0.10

(2 SIDES)

0.00 – 0.05

2.38 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

106

15

0.25 ± 0.05

0.50 BSC

0.38 ± 0.10

(DD10) DFN 1103

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3463f

7

LT3463/LT3463A

TYPICAL APPLICATIO

2.7V

TO 5V

U

CCD Bias Supply

L1

V

IN

C1

4.7µF

C1: TAIYO YUDEN JMK212BJ475MG

C2: TAIYO YUDEN EMK316BJ225ML

C3: TAIYO YUDEN LMK316BJ475ML

C4: TAIYO YUDEN EMK212BJ105MG

C5: AVX 06035A100KAT2A

D1: DIODES, INC B0540W

L1, L2: MURATA LQH32CN100K53

10µH

321

V

11

SW1

LT3463A

SW2

4

C4

1µF

OUT1

FB1

V

REF

FB2

D2

9

8

V

IN

SHDN1

SHDN2

GND

L2

10µH

R2

1M

10

7

6

5

R1

90.9k

R3

154k

R4

1M

D1

C3

4.7µF

C2

2.2µF

C5

10pF

3463 TA01a

V

OUT1

15V

10mA

V

OUT2

–8V

50mA

Typical Waveforms for 15V Output Typical Waveforms for –8V Output

V

V

SW1

10V/DIV

V

OUT1

AC-COUPLED

50mV/DIV

200mA/DIV

I

L1

2µs/DIV

3463 TA04

SW2

5V/DIV

V

OUT2

AC-COUPLED

50mV/DIV

I

200mA/DIV

L2

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1615/LT1615-1 300mA/80mA (ISW), High Efficiency Step-Up DC/DC Converters VIN: 1V to 15V, V

ThinSOT Package

LT1944 Dual Output 350mA (ISW), Constant Off-Time, VIN: 1.2V to 15V, V

High Efficiency Step-Up DC/DC Converter MS Package

LT1944-1 Dual Output 150mA (ISW), Constant Off-Time, VIN: 1.2V to 15V, V

High Efficiency Step-Up DC/DC Converter MS Package

LT1945 Dual Output, Pos/Neg, 350mA (ISW), VIN: 1.2V to 15V, V

Constant Off-Time, High Efficiency Step-Up DC/DC Converter MS Package

LT3464 85mA (ISW), High Efficiency Step-Up DC/DC Converter VIN: 2.3V to 10V, V

with Integrated Schottky and PNP Disconnect ThinSOT Package

OUT(MAX)

2µs/DIV

: 34V, IQ: 20µA, ISD: <1µA,

: 34V, IQ: 20µA, ISD: <1µA,

OUT(MAX)

: 34V, IQ: 20µA, ISD: <1µA,

OUT(MAX)

: ±34V, IQ: 20µA, ISD: <1µA,

OUT(MAX)

: 34V, IQ: 25µA, ISD: <1µA,

OUT(MAX)

3463 TA05

8

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

3463f

LT/TP 0404 1K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2003

Loading...

Loading...