查询LT3420EDD供应商

Chargers with Automatic Refresh

FEATURES

■

Charges 220µF to 320V in 3.7 Seconds

from 5V (LT3420)

■

Charges 100µF to 320V in 3.5 Seconds

from 5V (LT3420-1)

■

Charges Any Size Photoflash Capacitor

■

Supports Operation from Two AA Cells or Any

Supply from 1.8V to 16V

■

Controlled Peak Switch Current: 1.4A (LT3420)

1.0A (LT3420-1)

■

Controlled Input Current: 840mA (LT3420)

450mA (LT3420-1)

■

Uses Standard Transformers

■

Efficient Flyback Operation (>75% Typical)

■

Adjustable Output

■

Automatic Refresh

■

Charge Complete Indicator

■

No High Voltage Zener Diode Required

■

No Output Voltage Divider Required

■

Small 10-Lead MSOP Package

■

Small 10-Lead (3mm × 3mm) DFN Package

U

APPLICATIO S

■

Digital Camera Flash Unit

■

Film Camera Flash Unit

■

High Voltage Power Supplies

LT3420/LT3420-1

Photoflash Capacitor

U

DESCRIPTIO

The LT®3420/LT3420-1 charge high voltage photoflash

capacitors quickly and efficiently. Designed for use in both

digital and film cameras, these devices use a flyback

topology to achieve efficiencies up to four times better

than competing flash modules. A unique adaptive off-time

control algorithm* maintains current-limited continuous

mode transformer operation throughout the entire charge

cycle, eliminating the high inrush current often found in

modules.

The LT3420/LT3420-1 output voltage sensing scheme*

monitors the flyback voltage to indirectly regulate the

output voltage, eliminating an output resistor divider or

discrete zener diode. This feature allows the capacitor to

be held at a fully charged state without excessive power

consumption. Automatic refresh (which can be defeated)

allows the capacitor to remain charged while consuming

an average input current of about 2mA, at a user-defined

refresh rate. A logic high on the CHARGE pin initiates

charging, while the DONE pin signals that the capacitor is

fully charged.

The LT3420/LT3420-1 are available in 10-Lead MSOP and

(3mm × 3mm) DFN packages.

, LTC and LT are registered trademarks of Linear Technology Corporation. All other

trademarks are the property of their respective owners. *Protected by U.S. Patents

including 6518733.

U

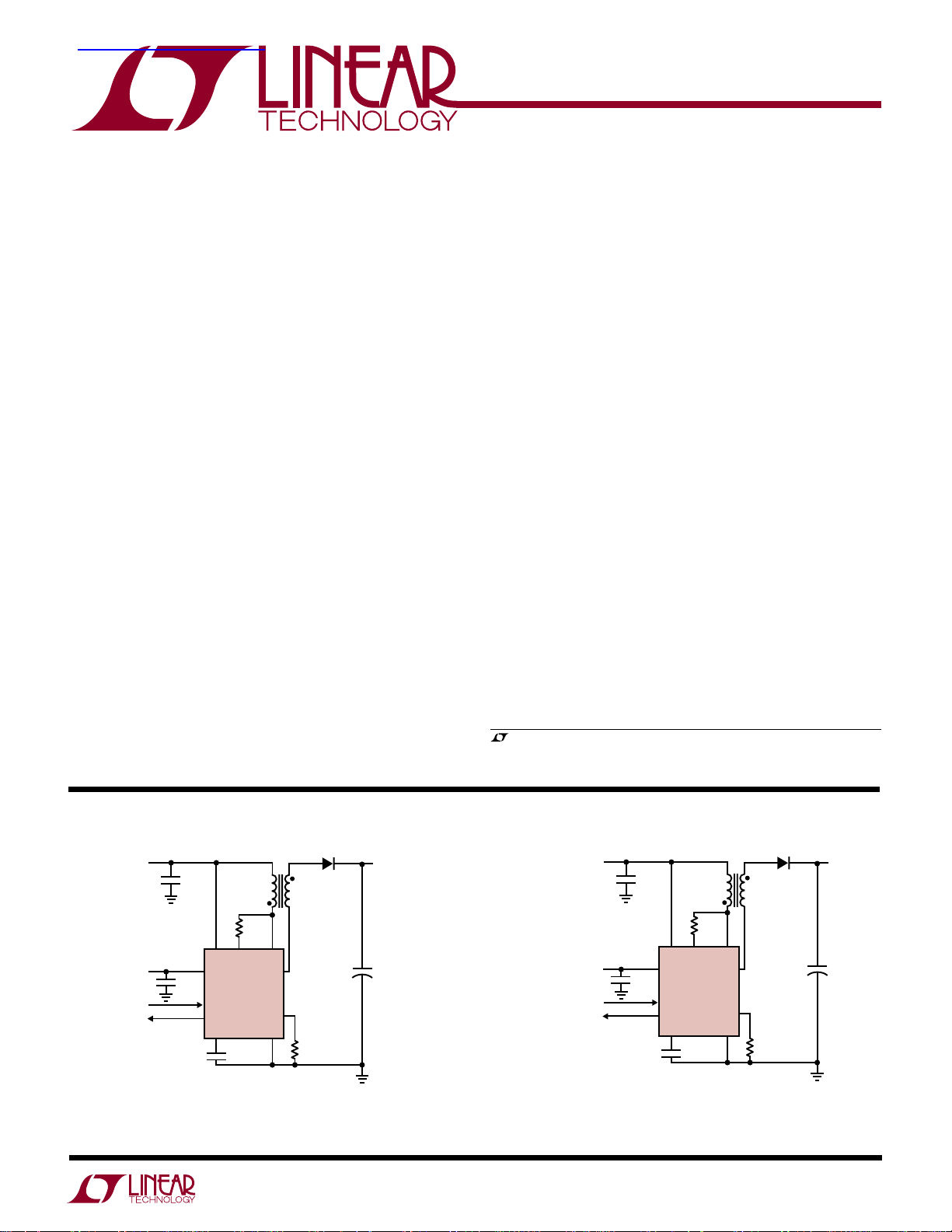

TYPICAL APPLICATIO

T1

LT3420

0.1µF

51.1k

1:12

8

5,6

3,4

632

SW

SEC

R

REF

GND

1

7

PHOTOFLASH

1

2k

D1

220µF

330V

CAPACITOR

C3

+

V

BAT

1.8V TO 6V

INPUT CURRENT

≈350mA

V

2.5V TO 10V

CHARGE

DONE

C1, C2: 4.7µF, X5R or X7R, 10V

C3: RUBYCON 220µF PHOTOFLASH CAPACITOR

T1: TDK SRW10EPC-U01H003 FLYBACK TRANSFORMER

D1: VISHAY GSD2004S SOT-23

DUAL DIODE. DIODES CONNECTED IN SERIES

C1

4.7µF

V

BATRFB

C2

4.7µF

4

V

9

CHARGE

8

DONE

C

CC

T

10 5

CC

Figure 1. High Charge Rate LT3420 Photoflash Circuit

320V

DANGER HIGH VOLTAGE

OPERATION BY HIGH VOLTAGE

3420 F01

TRAINED PERSONNEL ONLY

T1

60.4k

LT3420-1

0.1µF

1:10

(3mm TALL)

4

3

632

SW

SEC

1

R

REF

GND

5

6

7

PHOTOFLASH

CAPACITOR

2k

D1

100µF

330V

320V

C3

+

3420 F02

V

BAT

1.8V TO 6V

INPUT CURRENT

≈450mA

V

2.5V TO 6V

CHARGE

DONE

C1, C2: 4.7µF, X5R or X7R, 6.3V

C3: RUBYCON 100µF PHOTOFLASH CAPACITOR

T1: KIJIMA MUSEN SBL-5.6S-2

D1: VISHAY GSD2004S SOT-23

DUAL DIODE. DIODES CONNECTED IN SERIES

C1

4.7µF

V

BATRFB

C2

4.7µF

4

V

9

CHARGE

8

DONE

C

CC

T

10 5

CC

Figure 2. Small Size LT3420-1 Photoflash Circuit

3420fb

1

LT3420/LT3420-1

WW

W

U

ABSOLUTE AXI U RATI GS

(Note 1)

V

Voltage .............................................................. 16V

CC

Voltage ............................................................ 16V

V

BAT

SW Voltage (Note 2)

LT3420 ................................................................ 38V

LT3420-1............................................................ 50V

SEC Current ...................................................... ±200mA

RFB Current ........................................................... ±3mA

R

Voltage ........................................................... 2.5V

REF

CHARGE Voltage...................................................... 16V

CT Voltage .............................................................. 1.5V

U

W

PACKAGE/ORDER INFORMATION

TOP VIEW

R

1

REF

V

2

BAT

3

R

FB

4

V

CC

5

GND

10-LEAD (3mm × 3mm) PLASTIC DFN

T

JMAX

DD PACKAGE

= 125°C, θJA = 43°C/W, θJC = 3°C/W

EXPOSED PAD IS GND (PIN 11)

AND MUST BE SOLDERED TO PCB

10

C

CHARGE

9

11

DONE

8

7

SEC

6

SW

T

ORDER PART

NUMBER

LT3420EDD

LT3420EDD-1

DD PART

MARKING

LBJW

LBJX

DONE Voltage .......................................................... 16V

Current into DONE Pin .......................................... ±1mA

Maximum Junction Temperature .......................... 125°C

Operating Ambient Temperature Range

(Note 3) .............................................. –40°C to 85°C

Storage Temperature Range ................. –40°C to 125°C

Lead Temperature (Soldering, 10 sec)

(For MS Package only) ..................................... 300°C

U

ORDER PART

TOP VIEW

1

R

REF

V

2

BAT

R

3

FB

V

4

CC

GND

5

MS PACKAGE

10-LEAD PLASTIC MSOP

T

= 125°C, θJA = 100°C/W, θJC = 45°C/W

JMAX

(4-LAYER BOARD)

10

9

8

7

6

C

T

CHARGE

DONE

SEC

SW

NUMBER

LT3420EMS

LT3420EMS-1

MS PART MARKING

LTYH

LTAJG

Consult LTC Marketing for parts specified with wider operating temperature ranges.

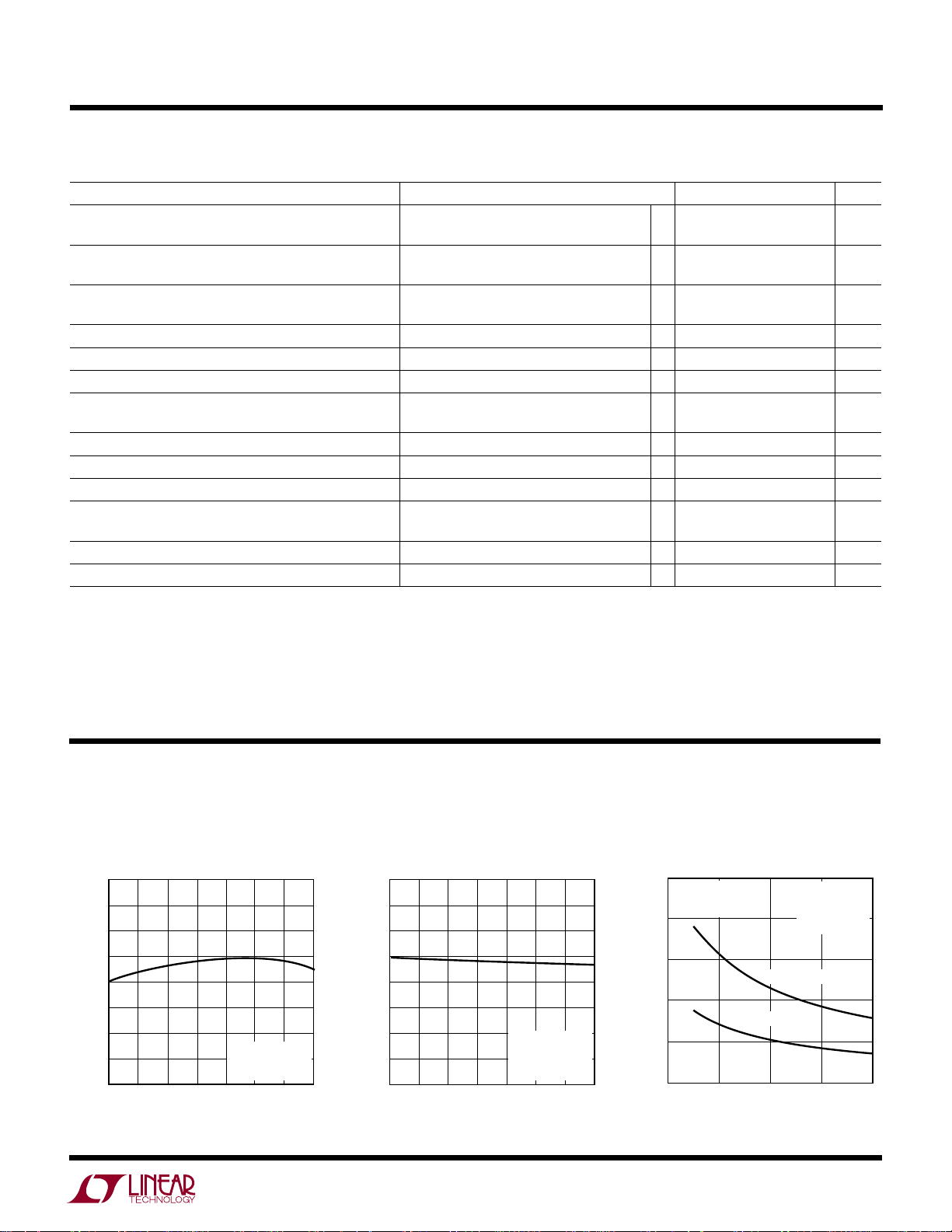

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VCC = V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage, V

Maximum Operating Voltage, V

VCC UVLO Hysteresis 40 mV

Minimum V

Maximum V

V

UVLO Hysteresis 275 mV

BAT

R

Threshold Voltage 0.98 1.00 1.02 V

REF

R

Pin Bias Current V

REF

Quiescent Current V

Quiescent Current in Shutdown V

Voltage 1.6 1.8 V

BAT

Voltage 16 V

BAT

CC

CC

The ● denotes the specifications which apply over the full operating

= 3.3V, V

BAT

= 0V, Switching 2 4 µA

RREF

V

= V

RFB

RREF

CHARGE

– 0.2V (Note 4)

BAT

= 1.1V, Not Switching 90 130 µA

= 0V, VIN = 3.3V 0.01 1 µA

= VCC unless otherwise noted. (Note 3)

CHARGE

● 2.2 2.5 V

● 0.975 1.025 V

16 V

3420fb

2

LT3420/LT3420-1

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● denotes the specifications which apply over the full operating

= 25°C. VCC = V

A

= 3.3V, V

BAT

= VCC unless otherwise noted. (Note 3)

CHARGE

PARAMETER CONDITIONS MIN TYP MAX UNITS

Primary Side Current Limit LT3420 (Note 5) 1.20 1.4 1.60 A

LT3420-1 (Note 5) 0.75 0.9 1.05 A

Secondary Side Current Limit LT3420 (Note 5) 20 40 50 mA

LT3420-1 (Note 5) 5 15 25 mA

Leakage Blanking Pulse Width LT3420 200 ns

LT3420-1 0 ns

Refresh Timer Charge/Discharge Current VCT = 0.75V 1.5 2.5 3.5 µA

Refresh Timer Upper Threshold 0.9 1.0 1.1 V

Refresh Timer Lower Threshold 0.45 0.5 0.55 V

Switch V

CESAT

LT3420, SW = 1A (Note 5) 220 340 mV

LT3420-1, SW = 0.5A (Note 5) 130 230 mV

Switch Leakage Current VSW = 38V (LT3420), VSW = 50V (LT3420-1) 0.01 1 µA

CHARGE Input Voltage High 1.5 V

CHARGE Input Voltage Low 0.2 V

CHARGE Pin Bias Current V

V

= 3V 4.5 15 µA

CHARGE

= 0V 0.01 0.1 µA

CHARGE

DONE Output Signal High 100k from VCC to DONE 3.3 V

DONE Output Signal Low 33µA into DONE Pin 100 200 mV

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Rated breakdown with LT3420 in power delivery mode and power

switch off.

Note 3: The LT3420/LT3420-1 are guaranteed to meet performance

operating temperature range are assured by design, characterization and

correlation with statistical process controls.

Note 4: Bias current flows out of R

Note 5: Current limit and V

to static test for DD package.

specifications from 0°C to 70°C. Specifications over the –40°C to 85°C

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Graphs apply to both the LT3420 and LT3420-1 unless otherwise noted.

Output Voltage in Refresh Mode,

LT3420

335

330

325

320

(V)

315

OUT

V

310

305

300

295

–50

050

–25 25 75 125

TEMPERATURE (°C)

FIGURE 1 CIRCUIT

V

CC

V

BAT

= 3.3V

= 3.3V

100

3420 G01

Output Voltage in Refresh Mode,

LT3420

335

330

325

320

(V)

315

OUT

V

310

305

300

295

2.5

FIGURE 1 CIRCUIT

V

CC

V

BAT

TA = 25°C

4.03.53.0 5.55.04.5 6.0

VIN (V)

= V

= V

pin.

FB

guaranteed by design and/or correlation

CESAT

Charge Time, LT3420

10

FIGURE 1 CIRCUIT

UNLESS OTHERWISE

NOTED.

8

6

TIME (s)

4

C

= 100µF

OUT

IN

IN

3420 G02

2

0

2

V

CHARGED

OUT

FROM

50V TO 320V

= 25°C

T

A

C

= 220µF

OUT

453

V

(V)

BAT

6

3420 G03

3420fb

3

LT3420/LT3420-1

TEMPERATURE (°C)

–50

CURRENT (mA)

100

3420 G09

050

60

55

50

45

40

35

30

25

20

–25 25 75 125

TEMPERATURE (°C)

–50

CURRENT (mA)

100

3420 G12

050

35

30

25

20

15

10

5

–25 25 75 125

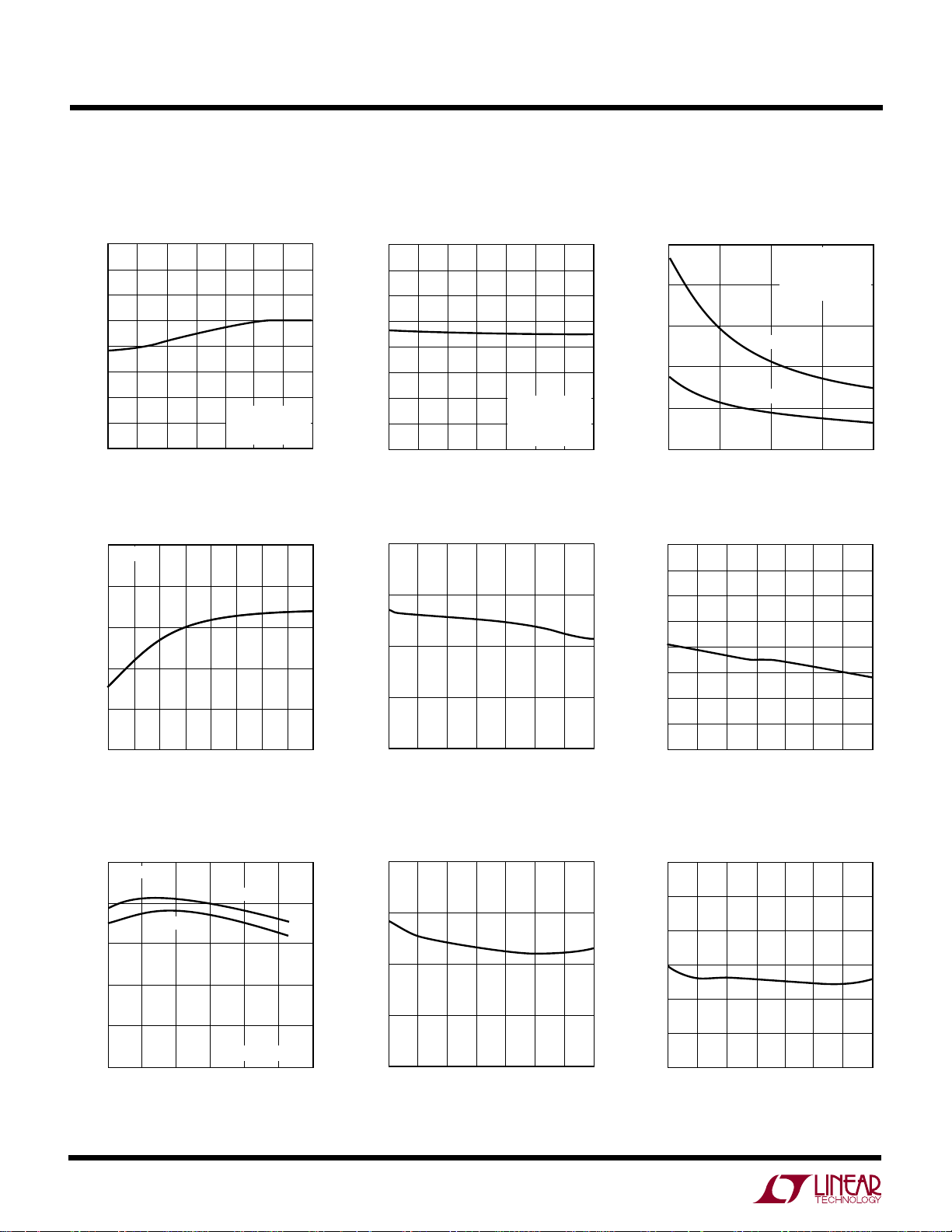

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Graphs apply to both the LT3420 and LT3420-1 unless otherwise noted.

Output Voltage in Refresh Mode,

LT3420-1

335

330

325

320

(V)

315

OUT

V

310

305

300

295

–50

050

–25 25 75 125

TEMPERATURE (°C)

FIGURE 2 CIRCUIT

V

CC

V

BAT

Charge Pin Input Current

10

TA = 25°C

8

6

4

CURRENT (µA)

2

= 3.3V

= 3.3V

100

3420 G04

Output Voltage in Refresh Mode,

LT3420-1

335

330

325

320

(V)

315

OUT

V

310

305

300

295

2.5

FIGURE 2 CIRCUIT

V

V

TA = 25°C

VIN (V)

CC

BAT

Primary Current Limit, LT3420

1.7

1.5

1.3

CURRENT (A)

1.1

= V

IN

= V

IN

5.03.0 4.03.5 4.5 6.0

5.5

3420 G05

Charge Time, LT3420-1

10

8

6

TIME (s)

4

2

0

C

2

3

OUT

C

OUT

= 40µF

V

BAT

FIGURE 2 CIRCUIT

CHARGED

V

OUT

FROM 50V TO 320V

= 25°C

T

A

= 100µF

4

(V)

Secondary Current Limit, LT3420

5

6

3420 G06

4

0

2

34

CHARGE PIN VOLTAGE (V)

6

57 10

Efficiency of Figure 1 Circuit,

LT3420

90

TA = 25°C

V

OUT

VIN = 5V

(V)

80

VIN = 3.3V

70

60

EFFICIENCY (%)

50

40

50 150 350250

100 200 300

VCC = V

89

3420 G07

= V

BAT

IN

3420 G10

0.9

–25 25 75

–50

0

TEMPERATURE (°C)

50

Primary Current Limit, LT3420-1

1.2

1.1

1.0

CURRENT (A)

0.9

0.8

–25 25 75

–50

0

TEMPERATURE (°C)

50

100

100

125

3420 G08

Secondary Current Limit, LT3420-1

125

3420 G11

3420fb

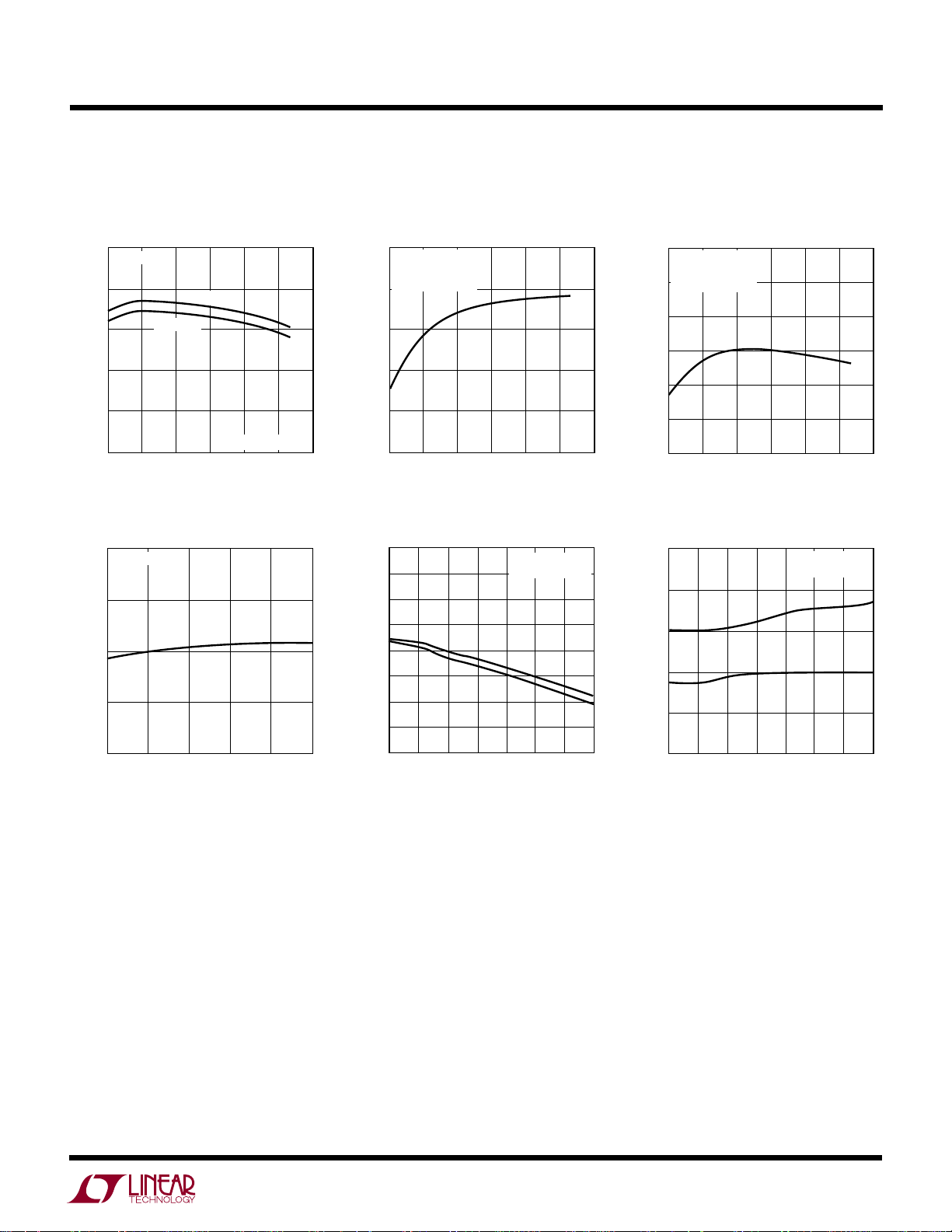

UW

TEMPERATURE (°C)

–50

V

BAT

PIN VOLTAGE (V)

100

3420 G18

050–25 25 75 125

2.0

1.8

1.6

1.4

1.2

1.0

V

+

V

–

ENABLE VOLTAGE

IS HYSTERETIC

TYPICAL PERFOR A CE CHARACTERISTICS

Graphs apply to both the LT3420 and LT3420-1 unless otherwise noted.

Efficiency for Figure 2 Circuit,

LT3420-1 Input Current, LT3420

90

TA = 25°C

80

70

60

EFFICIENCY (%)

50

40

50 150 350250

140

120

100

80

QUIESCENT CURRENT (µA)

60

2.5

VIN = 3.3V

100 200 300

V

TA = 25°C

4.0 7.0

5.5 8.5

VIN = 5V

(V)

OUT

VCC (V)

VCC = V

BAT

= V

IN

3420 G13

10

3420 G16

1000

FIGURE 1 CIRCUIT

= V

V

T

900

800

700

600

AVERAGE INPUT CURRENT (mA)

500

50 150 350250

V

2.6

2.5

2.4

2.3

2.2

2.1

PIN VOLTAGE (V)

CC

V

2.0

1.9

1.8

–50

= 3.3V

CC

BAT

= 25°C

A

100 200 300

V

OUT

Minimum Operating VoltageQuiescent Current in Refresh Mode V

CC

–

V

050

–25 25 75 125

TEMPERATURE (°C)

(V)

ENABLE VOLTAGE

IS HYSTERETIC

+

V

100

3420 G14

3420 G17

LT3420/LT3420-1

Input Current, LT3420-1

600

FIGURE 2 CIRCUIT

= V

V

550

T

500

450

400

AVERAGE INPUT CURRENT (mA)

350

300

50

= 3.3V

CC

BAT

= 25°C

A

150 200 250

100

Minimum Operating Voltage

BAT

V

(V)

OUT

300 350

3420 G15

3420fb

5

LT3420/LT3420-1

U

UU

PI FU CTIO S

R

(Pin 1): Reference Resistor Pin. Place a resistor (R2)

REF

from the R

(Pin 2): Battery Voltage Input. This pin should be

V

BAT

connected to the power supply or battery, which supplies

power to transformer T1. Must be locally bypassed.

RFB (Pin 3): Feedback Resistor Pin. Place a resistor (R1)

from the SW pin to the R

following formula:

R

1

=++

R

1

=++

V

OUT

N: Transformer Turns Ratio

R

SEC

VD: Diode Forward Voltage Drop

pin to GND. 2k is recommended.

REF

pin. Set R1 according to the

FB

R

2

2

N

R

2

2

N

: Desired Output Voltage

: Transformer Secondary Resistance

RNV V

14 2

(. • ) ( )

[]

()( )

[]

SEC OUT D

RNV V

SEC OUT D

2

(LT3420)

(LT3420-1)

GND (Pin 5): Ground. Tie directly to local ground plane.

SW (Pin 6): Switch Pin. This is the collector of the internal

NPN power switch. Minimize the metal trace area connected to this pin to minimize EMI.

SEC (Pin 7): Transformer Secondary Pin. Tie one end of

the transformer secondary to this pin. Take care to use the

correct phasing of the transformer (Refer to Figures 1

and 2).

DONE (Pin 8): Done Output Pin. Open collector NPN

output. DONE is pulled low whenever the chip is delivering

power to the output and goes high when power delivery

stops.

CHARGE (Pin 9): Charge Pin. Drive CHARGE high (1.5V or

more) to commence charging of the output capacitor.

Drive to 0.2V or less to put the part in shutdown mode.

CT (Pin 10): Refresh Timer Capacitor Pin. Place a capacitor

from the CT pin to GND to set the refresh timer sample rate

according to the following formula:

R2: Resistor from the R

Choice

VCC (Pin 4): Input Supply Pin. Must be locally bypassed

with a 4.7µF or larger ceramic capacitor.

Pin to GND. 2k is a Typical

REF

CT = 2.5 • 10–6 • t

t

REFRESH

EXPOSED PAD (Pin 11) (DD Package only): GND. Must be

soldered to local ground plane on PCB.

: Desired Refresh Period in Seconds.

REFRESH

6

3420fb

W

BLOCK DIAGRA S

V

BAT

DONE

8

REFRESH

10

C3

CHARGE

V

CC

C2

CT

TIMER

ENABLE

QQ

MASTER

LATCH

S

ONE-

9

SHOT

CHIP

4

V

ENABLE

CC

Q5 Q3

BLOCK

ENABLE

R

LT3420/LT3420-1

T1

1:12

C1

R1

R2

R

V

BAT

2 3 1 6

D3

R

FB

REF

R

Q

S

DRIVER

PRIMARY

SW

Q1

D1

SECONDARY

PHOTOFLASH

CAPACITOR

+

Q2

+

A3 A2

–

REFERENCE

ONE-

SHOT

1V

POWER DELIVERY BLOCK

A1

–

Q4

–

+

20mV

+

10mV

+

0.014Ω

–

5

GND

0.25Ω

LT3420

7

SEC

3420 F03

–

V

OUT

+

C4

CHARGE

V

Figure 3. Block Diagram, LT3420

T1

V

BAT

C1

R1

R2

DONE

8

REFRESH

10

CT

C3

CC

C2

TIMER

ENABLE

QQ

MASTER

LATCH

S

ONE-

9

SHOT

CHIP

4

V

ENABLE

CC

Q5 Q3

BLOCK

ENABLE

R

A3 A2

R

V

BAT

2 3 1 6

D3

R

FB

REF

R

Q

S

DRIVER

+

Q2

+

–

REFERENCE

ONE-

SHOT

1V

POWER DELIVERY BLOCK

A1

20mV

–

+

–

Q4

–

10mV

+

+

–

PRIMARY

SW

Q1

0.02Ω

0.66Ω

LT3420-1

1:10

5

GND

7

SEC

3420 F04

D1

SECONDARY

PHOTOFLASH

CAPACITOR

V

OUT

+

C4

Figure 4. Block Diagram, LT3420-1

3420fb

7

LT3420/LT3420-1

U

OPERATIO

Overview

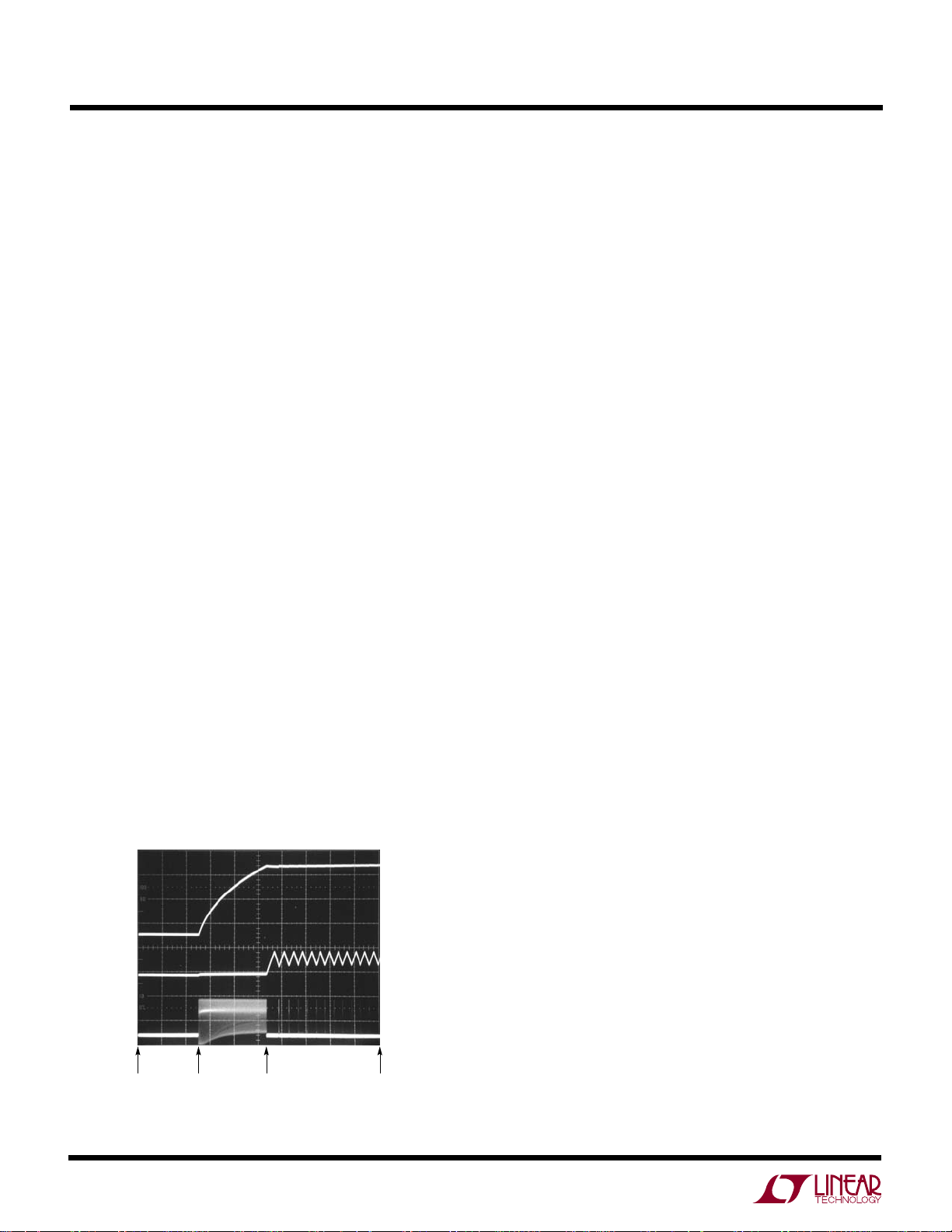

The following text focuses on the operation of the LT3420.

The operation of the LT3420-1 is nearly identical with the

differences discussed at the end of this section.

The LT3420 uses an adaptive on-time/off-time control

scheme to provide excellent efficiency and precise control

of switching currents. Please refer to Figure 3 for the following overview of the part’s operation. At any given instant,

the master latch determines which mode the LT3420 is in:

“charging” or “refresh”. In charging mode, the circuitry

enclosed by the smaller dashed box is enabled, providing

power to charge photoflash capacitor C1. The output voltage is monitored via the flyback pulse on the primary of the

transformer. When the target output voltage is reached, the

charging mode is terminated and the part enters the refresh

mode. In refresh mode, the power delivery block is disabled,

reducing quiescent current, while the refresh timer is enabled. The refresh timer simply generates a user programmable delay, after which the part reenters the charging

mode. Once in the charging mode, the LT3420 will again

provide power to the output until the target voltage is

reached. Figure 5 is an oscillograph photo showing both the

initial charging of the photoflash capacitor and the subsequent refresh action. The upper waveform is the output

voltage. The middle waveform is the voltage on the CT pin.

The lower waveform shows the input current. The mode of

the part is indicated below the photo.

The user can defeat the refresh timer and force the part

into charging mode by toggling the CHARGE pin

V

OUT

100V/DIV

V

CT

1V/DIV

I

IN

1A/DIV

MODE

SHUTDOWN

Shutdown, Charging and Refresh of Photoflash Capacitor

CHARGING

1s/DIV

REFRESH

3420 F05

(high→low→high). The low to high transition on the

CHARGE pin fires a one-shot that sets the master latch,

putting the part in charging mode. Bringing CHARGE low

puts the part in shutdown. The refresh timer can be

programmed to wait indefinitely by simply grounding the

pin. In this configuration, the LT3420 will only reenter

C

T

the charging mode by toggling the CHARGE pin.

Power Delivery Block

The power delivery block consists of all circuitry enclosed

by the smaller dashed box in Figure 3. This circuit block

contains all elements needed for charging and output

voltage detection. To better understand the circuit operation, follow the subsequent description of one cycle of

operation and refer to Figure 6. Assume that initially there

is no current in the primary or secondary of the transformer, so the output of comparator A1 is low, while that

of A2 is high (note the small offset voltages at the inputs

of A1 and A2). The SR latch is thus set and the power NPN

switch, Q1, is turned on. Current increases linearly in the

primary of the transformer at a rate determined by the V

BAT

voltage and the primary inductance of the transformer. As

the current builds up, the voltage across the 14mΩ

resistor increases. When this voltage exceeds the 20mV

offset voltage of A1, the output of A1 goes high, resetting

the SR latch and turning off Q1. The current needed to

reset the latch is approximately 1.4A (~20mV/14mΩ).

When Q1 turns off, the secondary side current quickly

jumps from zero current to the primary side current divided by N (the turns ratio of transformer T1). In this example, the peak secondary current is 116mA (1.4A/12).

Diode D1 now conducts, providing power to the output.

Since a positive voltage exists across the secondary winding of the transformer, the secondary current decreases

linearly at a rate determined by the secondary inductance

and the output voltage (neglecting the diode voltage drop).

When the secondary side current drops below 40mA

(10mV/0.25Ω), the output of A2 goes high, setting the SR

latch and turning on Q1. The initial primary current is simply the minimum secondary current times N, in this case

0.48A (40mA • 12) . Q1 will now remain on until the primary current again reaches 1.4A. This cycle of operation

repeats itself, automatically adjusting the On and Off timesFigure 5. Demonstrating 3 Operating Modes of LT3420:

3420fb

8

OPERATIO

LT3420/LT3420-1

U

I

SW

1A/DIV

I

SEC

200mA/DIV

V

SW

20V/DIV

2µs/DIV

Figure 6a. Switching Waveforms with

V

= 100V, VCC = V

OUT

BAT

= 3.3V

3420 F06a

of Q1 so that the peak current of Q1 is 1.4A and the minimum secondary current is 40mA (typical values).

The previously described charging cycle must be halted

when the output voltage reaches the desired value. The

LT3420 monitors the output voltage via the flyback pulse

on the SW pin. When Q1 turns off, the secondary side

conducts current turning on diode D1. Since the diode is

conducting and the SEC pin is at nearly ground, the voltage

across the secondary is nearly equal to V

across the primary is therefore close to V

proportional to V

pin. The current flows out of the R

/N flows through R1 and into the R

OUT

pin through a resis-

REF

. The voltage

OUT

/N. A current

OUT

FB

tor creating a ground referred voltage. When this voltage

exceeds an internal 1V reference voltage, the output of

comparator A3 goes high which resets the master latch. The

Q output of the master latch goes low, disabling the entire

power delivery block and enabling the refresh timer.

Leakage Spike Blanking

I

SW

1A/DIV

I

SEC

200mA/DIV

V

SW

20V/DIV

2µs/DIV

Figure 6b. Switching Waveforms with

= 300V, VCC = V

V

OUT

BAT

= 3.3V

3420 F06b

C3, from its initial voltage towards 1V. When the voltage

on C3 reaches 1V, the polarity of the current source changes

and 2.5µA discharges C3. When the voltage on C3 reaches

0.5V, the refresh timer sends a set pulse to the master latch,

which puts the LT3420 into the charging mode.

Interface/Control

The CHARGE pin serves two functions. The first is to

enable or shutdown the part depending on the level of the

pin (high = enable, low = shutdown). The second is to

force the part into the charging mode (low→high transition). The LT3420 also has a DONE pin, which signals

whether or not the part is done charging the photoflash

capacitor. The DONE pin is an open collector NPN switch

(Q5) so an external pull-up resistor is needed. Whenever

the part is in charging mode, DONE will be low. DONE will

go high when the charging mode is complete. Both the

CHARGE and DONE pins can be easily interfaced to a

microprocessor in a digital or film camera.

Another function of the LT3420 is leakage spike blanking

when the power switch, Q1, turns off. Right after Q1 turns

off, a one-shot turns on Q2 for 200ns (typ). With Q2 on,

comparator A3 is disabled. This function may prevent A3

from false tripping on the leakage inductance spike on the

SW pin. In practice, the PNP transistor Q3 filters out the

leakage spike.

Refresh Timer

When the refresh timer is enabled, a 2.5µA current source

is switched on, charging up the external timing capacitor,

LT3420-1 Differences

The LT3420-1 has different primary and secondary current limit levels. The primary current limit level of the

LT3420-1 is 1A (typ) and the secondary current limit is

15mA (typ). The LT3420-1 has no leakage spike blanking

which causes no problems since the PNP transistor, Q3,

provides adequate filtering. Finally, the breakdown voltage

of the SW pin of the LT3420-1 is higher at 50V.

3420fb

9

LT3420/LT3420-1

WUUU

APPLICATIO S I FOR ATIO

COMPONENT SELECTION

Choosing the Right Transformer

The flyback transformer plays a key role in any LT3420/

LT3420-1 application. A poorly designed transformer can

result in inefficient operation. Linear Technology Corporation has worked with a number of transformer manufacturers to develop specific transformers for use with the

LT3420/LT3420-1. These predesigned transformers are

sufficient for a large majority of the applications that may

be encountered. In some cases, the reader may choose to

design his own transformer or may simply be curious about

the issues involved in designing the transformer. The following is a brief discussion of the issues relating to transformer design.

Transformer Turns Ratio

The turns ratio for the transformer, N, should be high

enough so that the absolute maximum voltage rating for

the NPN power switch is not exceeded. When the power

switch turns off, the voltage on the collector of the switch

(SW Pin) will “fly” up to the output voltage divided by N

plus the battery voltage (neglecting the voltage drop

across the rectifying diodes). This voltage should not

exceed the 38V (LT3420) or 50V (LT3420-1) breakdown

rating of the power switch.

Choose the minimum N by the following formula.

Transformer Primary Inductance

A flyback transformer needs to store substantial amounts

of energy in the core during each switching cycle. The

transformer, therefore, will generally require an air gap.

The use of an air gap in the core makes the energy storage

ability, or inductance, much more stable with temperature

and variations in the core material. Most core manufacturers will supply standard sizes of air gaps with a given type

of core, resulting in different A

values. AL is the induc-

L

tance of a particular core per square turns of winding. To

get a certain inductance, simply divide the desired inductance by the A

value and take the square root of the result

L

to find the number of turns needed on the primary of the

transformer.

The LT3420/LT3420-1 detect the output voltage via the

flyback pulse on the SW pin. Since this can only occur

while the power switch is off, an important criteria is that

the value of the primary inductance of the transformer be

larger than a certain minimum value. The switch off time

should be 500ns or larger for the LT3420 and 350ns or

larger for the LT3420-1. The minimum inductance can be

calculated with the following formula:

9

–

••

L

L

500 10

≥

PRI

PRI

•( . – . )

NN

14 004

••

350 10

≥−

•(.–. )

NN

10 0015

V

OUT

()

LT

3420

9

–

V

OUT

()

LT

3420 1

V

N

N

MIN

MIN

OUT

≥

≥−

38

50

–

V

–

V

OUT

V

LT

3420

()

BAT

LT

3420 1

()

BAT

For an LT3420 design, a 5V battery voltage and a 330V

output results in a N

of 10 so a turns ratio of 10 or greater

MIN

should be used.

10

V

: Target Output Voltage

OUT

N: Transformer Turns Ratio

Transformer Leakage Inductance

The leakage inductance of the transformer must be carefully minimized for both proper and efficient operation of

the part. The DC voltage rating of the SW pin on the LT3420

is 38V while on the LT3420-1 it is 50V. These ratings are

for DC blocking voltages only and additional precautions

3420fb

WUUU

APPLICATIO S I FOR ATIO

LT3420/LT3420-1

must be taken into account for the dynamic blocking

voltage capabilities of the LT3420/LT3420-1. The dynamic

blocking voltage capability of both parts is 38V.

Table 1 summarizes the various breakdown voltages of the

SW pin for both parts.

Table 1. SW Pin Voltage Ratings

PART SW PIN DC RATING SW PIN DYNAMIC RATING

LT3420 38V 38V

LT3420-1 50V 38V

Figure 7 shows what to examine in a new transformer

design to determine if the specifications for the SW pin are

met.

The first leakage inductance spike labeled “A” must not

exceed the dynamic rating of the SW pin. If it does exceed

the rating, then the transformer leakage inductance must

be lowered. The flyback waveform after the initial spike

labeled “B” must not exceed the DC rating of the SW pin.

If it does exceed the rating, then the turns ratio of the

transformer must be lowered. In measuring the voltage on

the SW pin, care must be taken in minimizing the ground

loop of the voltage probe. Careless probing will result in

inaccurate readings.

Note also the magnitude of the initial current spike in the

primary of the transformer labeled “C” when the power

switch turns on. If the leakage inductance is lowered to a

very low level, the internal capacitances of the transformer

will be high. This will result in the initial spike of current in

the primary becoming excessively high. The level of “C”

should be kept to 4A or less in a typical design for both the

LT3420 and LT3420-1. Please note that by inserting a loop

of wire in the primary to measure the primary current, the

leakage inductance of the primary will be made artificially

high. This may result in erroneous voltage measurements

on the SW pin.

The measurements shown in Figure 7 should be made

with both V

OUT

and V

at the maximum levels for the

BAT

given application. This results in the highest voltage and

current stress on the SW pin.

Transformer Secondary Capacitance

The total capacitance of the secondary should be minimized for both efficient and proper operation of the LT3420/

LT3420-1. Since the secondary of the transformer undergoes large voltage swings (approaching 600V

P-P

), any

capacitance on the secondary can severely affect the

MUST BE LESS THAN 4A

FOR BOTH THE LT3420

AND LT3420-1

“C”

I

PRI

0A

MUST BE LESS THAN 38V

FOR THE LT3420

“B”

“A”

V

SW

0V

Figure 7. New Transformer Design Check (Not to Scale)

MUST BE LESS THAN 50V

FOR THE LT3420-1

MUST BE LESS THAN 38V

FOR BOTH THE LT3420

AND LT3420-1

3420 F07

3420fb

11

LT3420/LT3420-1

U

WUU

APPLICATIO S I FOR ATIO

efficiency of the circuit. In addition, the effective capacitance on the primary is largely dominated by the actual

secondary capacitance. This is simply a result of any

secondary capacitance being multiplied by N2 when reflected to the primary. Since N is generally 10 or higher, a

small capacitance of 10pF on the secondary is 100 times

larger, or 1.0nF, on the primary. This capacitance forms a

resonant circuit with the primary leakage inductance of the

transformer. As such, both the primary leakage inductance and secondary side capacitance should be minimized.

Table 2 shows various predesigned transformers along

with relevant parameters. Contact the individual transformer manufacturer for additional information or

customization.

Table 2a. Predesigned Transformers, LT3420

PART RATIO (µH) LxWxH (mm) VENDOR

SRW10EPC 1:12 24 10.9x10.8x5.2 TDK

-U01H003 (847) 803-6100

6375-T108 1:12 15 10.8x9.5x3.6 Sumida

SBL-6.4 1:12 17.5 10.3x6.4x5.2 Kijima Musen

Table 2b. Predesigned Transformers, LT3420-1

PART RATIO (µH) LxWxH (mm) VENDOR

SBL-5.6S-2 1:10 15 5.6x8.5x3.0 Kijima Musen

LDT565630T 1:10.2 14.5 5.8x5.8x3.0 TDK

-002 (847) 803-6100

TURNS L SIZE

www.components.tdk.com

(847) 956-0666

www.sumida.com

852-2489-8266

kijimahk@netvigator.com

TURNS L SIZE

852-2489-8266

kijimahk@netvigator.com

www.components.tdk.com

DIODE SELECTION

The rectifying diode(s) should be low capacitance type

with sufficient reverse voltage and forward current ratings. The peak reverse voltage that the diode(s) will see is

approximately:

V

≈ +

PK-R

VNV

()

(• )•.165

OUT BAT

The peak current of the diode is simply:

14

.

I

PK-SEC

I

PK-SEC

For the circuit of Figure 1 with V

and I

PK-SEC

A

=

3420

()

LT

N

10

.

A

= −

3420 1

()

LT

N

of 3.3V, V

BAT

PK-R

is 590V

is 116mA. Table 3 shows various diodes that

can work with the LT3420/LT3420-1. These are chosen for

low capacitance and high reverse blocking voltage. Use

the appropriate number of diodes to achieve the necessary

reverse breakdown voltage.

Table 3

PART VOLTAGE (V) (pF) VENDOR

GSD2004S 2x300 5 Vishay

(Dual diode) (402) 563-6866

BAS21 250 1.5 Philips Semiconductor

(Single diode) (800) 234-7381

MMBD3004S 2x300 5 Diodes Inc.

MAX REVERSE CAPACITANCE

www.vishay.com

www.philips.com

(805) 446-4800

www.diodes.com

12

3420fb

WUUU

APPLICATIO S I FOR ATIO

LT3420/LT3420-1

CAPACITOR SELECTION

The V

and VCC decoupling capacitors should be multi-

BAT

layer ceramic type with X5R or X7R dielectric. This insures

adequate decoupling across wide ambient temperature

ranges. A good quality ceramic capacitor is also recommended for the timing capacitor on the CT pin. Avoid Y5V

or Z5U dielectrics.

Selectively Disabling the LT3420/LT3420-1

The LT3420/LT3420-1 can be disabled at any time, even

during the charge phase. This may be useful when a digital

camera enters a sensitive data acquisition phase. Figure 8

illustrates this feature. Midway through the charge cycle,

the CHARGE pin is brought low, which disables the part.

After the sensitive data operation is complete, the CHARGE

pin is brought high and the charging operation continues.

Measuring Efficiency

Measuring the efficiency of a circuit designed to charge

large capacitive loads is a difficult issue, particularly with

photoflash capacitors. The ideal way to measure the

efficiency of a capacitor charging circuit would be to find

the energy delivered to the output capacitor (0.5 • C • V2)

and divide it by the total input energy. This method does

not work well here because photoflash capacitors are far

from ideal. Among other things, they have relatively high

leakage currents, large amounts of dielectric absorption,

and significant voltage coefficients. A much more accurate, and easier, method is to measure the efficiency as a

function of the output voltage. In place of the photoflash

capacitor, use a smaller, high quality capacitor, reducing

errors associated with the non-ideal photoflash capacitor.

Using an adjustable load, the output voltage can be set

anywhere between ground and the maximum output

voltage. The efficiency is measured as the output power

(V

• I

OUT

) divided by the input power (VIN • IIN). This

OUT

method also provides a good means to compare various

charging circuits since it removes the variability of the

photoflash capacitor from the measurement. The total

efficiency of the circuit, charging an ideal capacitor, would

be the time average of the given efficiency curve, over time

as V

changes.

OUT

Adjustable Input Current

With many types of modern batteries, the maximum

allowable current that can be drawn from the battery is

limited. This is generally accomplished by active circuitry

or a polyfuse. Different parts of a digital camera may

require high currents during certain phases of operation

and very little at other times. A photoflash charging circuit

should be able to adapt to these varying currents by

drawing more current when the rest of the camera is

drawing less, and vice-versa. This helps to reduce the

charge time of the photoflash capacitor, while avoiding the

V

CHARGE

V

OUT

50V/DIV

CHARGE

NO

CHARGE

Figure 8. Halting the Charge Cycle at Any Time

0.5s/DIV

3420 F08

5V/

DIV

3420fb

13

LT3420/LT3420-1

WUUU

APPLICATIO S I FOR ATIO

risk of drawing too much current from the battery. The

input current to the LT3420/LT3420-1 circuit can be

adjusted by driving the CHARGE pin with a PWM (pulse

width modulation) signal. The microprocessor can adjust

the duty cycle of the PWM signal to achieve the desired

level of input current. Many schemes exist to achieve this

function. Once the target output voltage is reached, the

PWM signal should be halted to avoid overcharging the

photoflash capacitor, since the signal at the CHARGE pin

overrides the refresh timer.

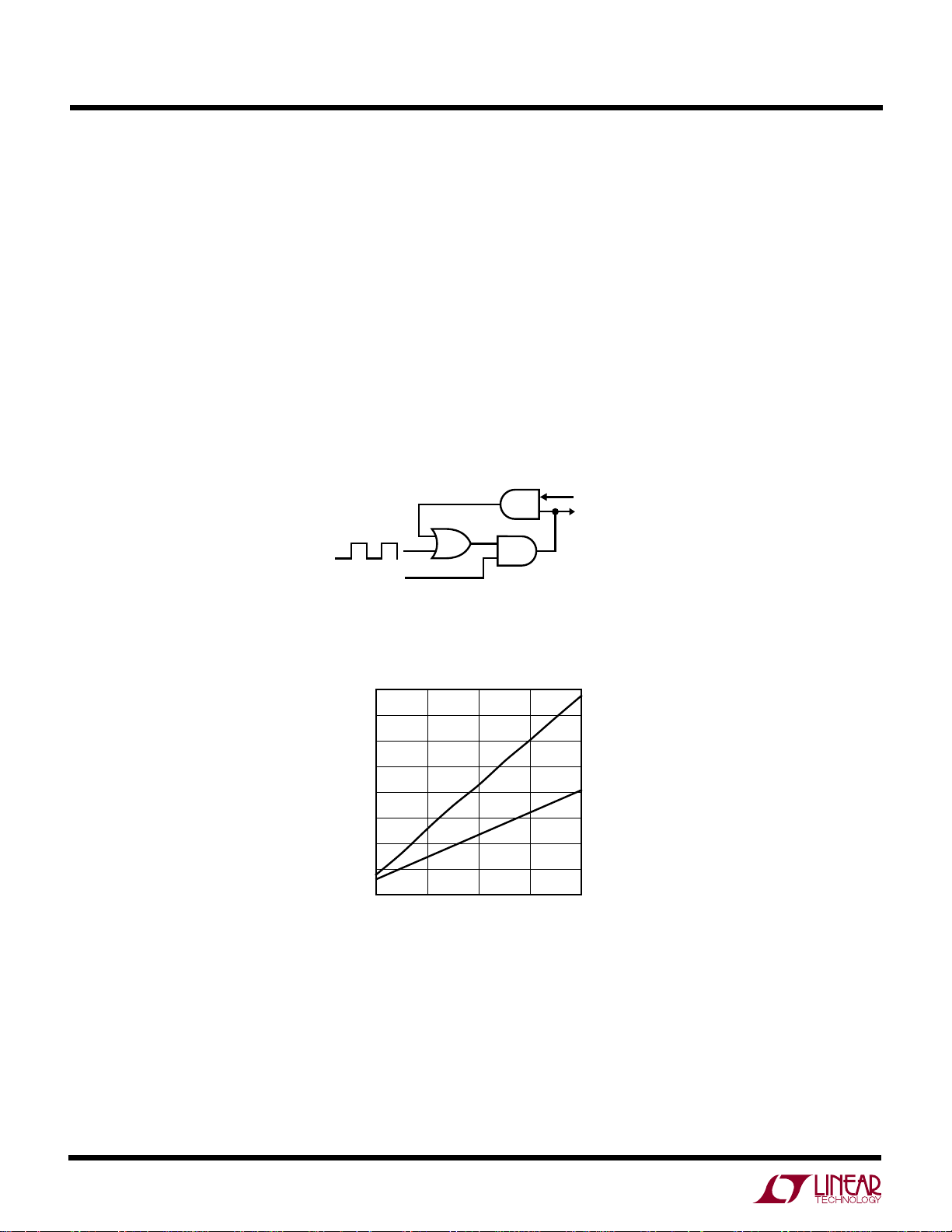

A simple method to achieve adjustable input current is

shown in Figure 9. The PWM signal has a frequency of

1kHz PWM

SIGNAL

ON

Figure 9. Simple Logic for Adjustable Input Current

A2

1kHz. When ON is logic high, the circuit is enabled and the

CHARGE pin is driven by the PWM signal. When the target

output voltage is reached, DONE goes high while CHARGE

is also high. The output of A1 goes high, which forces

CHARGE high regardless of the PWM signal. The part is

now in the Refresh mode. Once the refresh period is over,

the DONE pin goes low, allowing the PWM signal to drive

the CHARGE pin once again. This function can be easily

implemented in a microcontroller. Figure 10 shows the

input current for the LT3420 and LT3420-1 as the duty

cycle of the PWM signal is varied.

A1

A3

DONE

CHARGE

TO

LT3420

CIRCUIT

3420 F09

800

600

400

INPUT CURRENT (mA)

200

0

10

LT3420

LT3420-1

30 50 70

DUTY CYCLE (%)

90

3420 F10

Figure 10. Input Current as Duty Cycle is Varied

14

3420fb

WUUU

APPLICATIO S I FOR ATIO

LT3420/LT3420-1

BOARD LAYOUT

The high voltage operation of the LT3420/LT3420-1

demands careful attention to board layout. You will not

get advertised performance with careless layout. Figures 11 and 12 show the recommended component

placement. Keep the area for the high voltage end of the

secondary as small as possible. Note the larger than

minimum spacing for all high voltage nodes. This is

R2

V

CC

GND

C2

C1

necessary to meet the breakdown specifications for the

circuit board. If the Photoflash capacitor is placed far

from the LT3420/LT3420-1 circuit, place a small (20nF50nF) ceramic capacitor with sufficient voltage rating

close to the part. This insures adequate bypassing.

Remember that LETHAL VOLTAGES ARE PRESENT in

this circuit. Use caution when working with the circuit.

CHARGE DONE

C3

PHOTOFLASH

CAPACITOR

–

+

R1

T1

V

OUT

V

V

GND

V

BAT

BAT

D1B

D1A

3420 F11

Figure 11. Suggested Layout (MS10 Package)

CHARGE DONE

R2

CC

C2

C1

C3

PHOTOFLASH

CAPACITOR

–

+

R1

T1

V

OUT

D1B

D1A

Figure 12. Suggested Layout (DD Package)

3420 F12

3420fb

15

LT3420/LT3420-1

TYPICAL APPLICATIO S

Professional Charger uses Multiple LT3420 Circuits in Parallel to Charge Large Photoflash Capacitors Quickly

U

DANGER HIGH VOLTAGE

OPERATION BY HIGH VOLTAGE

TRAINED PERSONEL ONLY

V

CC

R3

100k

Q1

2N3904

C1, C2, C4, C5, C6, C7: 4.7µF, X5R or X7R, 10V

T1-T3: TDK SRW10EPC-U01H003 FLYBACK TRANSFORMER

D1-D3: VISHAY GSD2004S SOT-23

DUAL DIODE. DIODES CONNECTED IN SERIES

Q1: 2N3904 OR EQUIVALENT

* CAN CHARGE ANY SIZE PHOTOFLASH CAPACITOR

** USE AS MANY SLAVE CHARGERS AS NEEDED.

V

BAT

1.8V TO 6V

V

2.5V TO 10V

CHARGE

V

BAT

R4

100k

V

BAT

V

D1

C1

4.7µF

V

BATRFB

CC

CC

C2

4.7µF

0.1µF

C4

4.7µF

C5

4.7µF

C6

4.7µF

C7

4.7µF

4

9

8

C3

4

9

8

4

9

8

V

CC

CHARGE

DONE

C

V

BATRFB

V

CC

CHARGE

DONE

C

V

BATRFB

V

CC

CHARGE

DONE

C

5, 6 8

3, 4

R1

52.3k

2

36

LT3420

R

T

10 5

2

T

10 5

2

T

10 5

GND

5, 6

3, 4

36

LT3420

R

GND

5, 6

3, 4

36

LT3420

R

GND

SW

SEC

REF

SW

SEC

REF

SW

SEC

REF

T1

1:12

1

7

MASTER

CHARGER

1

R2

2k

8

T2

1:12

1

7

SLAVE**

CHARGER

1

8

T3

1:12

1

1

7

SLAVE**

CHARGER

1

3420 TA01

D2

D3

+

320V

650µF*

350V

PHOTOFLASH

CAPACITOR

16

3420fb

U

TYPICAL APPLICATIO S

LT3420 Photoflash Charging Circuit Uses Small Transformer

DANGER HIGH VOLTAGE

OPERATION BY HIGH VOLTAGE

TRAINED PERSONEL ONLY

1.8V TO 5V

2.5V TO 10V

CHARGE

C1: 4.7µF, X5R or X7R, 6.3V

C2: 4.7µF, X5R or X7R, 10V

C4: RUBYCON 220µF PHOTOFLASH CAPACITOR

D1: VISHAY GSD2004S SOT-23

DUAL DIODE. DIODES CONNECTED IN SERIES

T1: KIJIMA MUSEN SBL-6.4

* MAXIMUM AMBIENT TEMPERATURE OF 60°C DICTATED BY TRANSFORMER

V

BAT

V

DONE

LT3420/LT3420-1

T1*

1:12

3

LT3420

C3

0.1µF

R1

47.5k

2

1

SW

SEC

R

GND

REF

632

1

5

7

PHOTOFLASH

CAPACITOR

R2

2k

D1

220µF

330V

C1

4.7µF

V

BATRFB

CC

C2

4.7µF

9

8

4

V

CC

CHARGE

DONE

C

T

10 5

300V

C4

+

3420 TA02

90

VCC = V

80

70

60

EFFICIENCY (%)

50

40

50

100

Efficiency

= V

BAT

IN

VIN = 3.3V

150 200 250

V

OUT

VIN = 5V

300 350

(V)

3420 TA03

3420fb

17

LT3420/LT3420-1

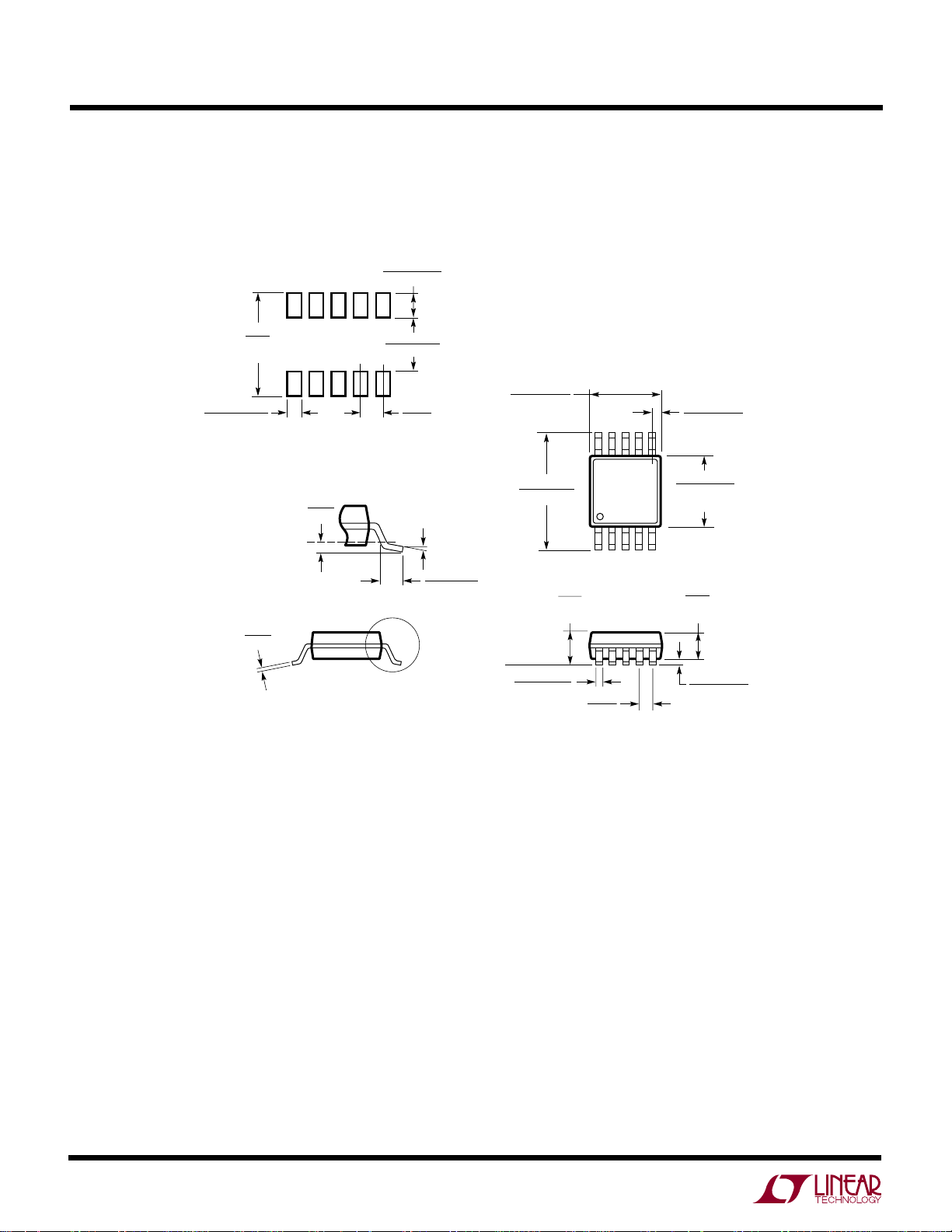

PACKAGE DESCRIPTIO

U

MS Package

10-Lead Plastic MSOP

(Reference LTC DWG # 05-08-1661)

0.889 ± 0.127

± .005)

(.035

5.23

(.206)

MIN

0.305

± 0.038

± .0015)

(.0120

TYP

RECOMMENDED SOLDER PAD LAYOUT

0.254

(.010)

GAUGE PLANE

0.18

(.007)

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

3.20 – 3.45

(.126 – .136)

DETAIL “A”

DETAIL “A”

0.50

(.0197)

BSC

0° – 6° TYP

0.53 ± 0.152

(.021 ± .006)

SEATING

PLANE

3.00 ± 0.102

(.118 ± .004)

(NOTE 3)

4.90 ± 0.152

(.193 ± .006)

(.043)

0.17 – 0.27

(.007 – .011)

TYP

1.10

MAX

12

0.50

(.0197)

BSC

8910

3

7

6

45

0.497 ± 0.076

(.0196 ± .003)

REF

3.00 ± 0.102

(.118 ± .004)

(NOTE 4)

0.86

(.034)

REF

0.127

± 0.076

(.005 ± .003)

MSOP (MS) 0603

18

3420fb

PACKAGE DESCRIPTIO

LT3420/LT3420-1

U

DD Package

10-Lead Plastic DFN (3mm × 3mm)

(Reference LTC DWG # 05-08-1699)

0.675 ±0.05

3.50 ±0.05

1.65 ±0.05

(2 SIDES)2.15 ±0.05

PACKAGE

OUTLINE

0.25 ± 0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

PIN 1

TOP MARK

(SEE NOTE 6)

0.200 REF

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WEED-2).

CHECK THE LTC WEBSITE DATA SHEET FOR CURRENT STATUS OF VARIATION ASSIGNMENT

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE

TOP AND BOTTOM OF PACKAGE

0.50

BSC

2.38 ±0.05

(2 SIDES)

3.00 ±0.10

(4 SIDES)

0.75 ±0.05

1.65 ± 0.10

(2 SIDES)

0.00 – 0.05

R = 0.115

TYP

2.38 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

106

15

0.25 ± 0.05

0.50 BSC

0.38 ± 0.10

(DD10) DFN 1103

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3420fb

19

LT3420/LT3420-1

TYPICAL APPLICATIO

LT3420-1 Photoflash Circuit Uses Tiny (3mm Tall) Transformer

U

60.4k

5

8

SW

SEC

R

GND

REF

T1

1:10.2

632

4

1

7

PHOTOFLASH

CAPACITOR

1

2k

D1

100µF

330V

320V

Charge Time

10

8

C3

+

3420 TA04

6

TIME (s)

4

2

0

C

2

3

OUT

C

OUT

= 40µF

V

BAT

V

CHARGED

OUT

FROM 50V TO 320V

= 100µF

4

(V)

5

6

3420 TA05

V

BAT

1.8V TO 6V

DANGER HIGH VOLTAGE

OPERATION BY HIGH VOLTAGE

TRAINED PERSONEL ONLY

V

CC

2.5V TO 6V

CHARGE

DONE

C1, C2: 4.7µF, X5R or X7R, 6.3V

C3: RUBYCON 100µF PHOTOFLASH CAPACITOR

T1: TDK LDT565630T-002 FLYBACK TRANSFORMER

D1: VISHAY GSD2004S SOT-23

DUAL DIODE. DIODES CONNECTED IN SERIES

C1

4.7µF

C2

4.7µF

9

8

4

V

BATRFB

V

CC

CHARGE

DONE

C

LT3420-1

T

10 5

0.1µF

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC®3400/LTC3400B 600mA (ISW), 1.2MHz, Synchronous Step-Up V

DC/DC Converters I

LTC3401/LTC3402 1A/2A (ISW), 3MHz, Synchronous Step-Up V

DC/DC Converters MS Package

LTC3405/LTC3405A 300mA (I

), 1.5MHz, Synchronous Step-Down 95% Efficiency, V

OUT

DC/DC Converters I

LTC3406/LTC3406B 600mA (I

), 1.5MHz, Synchronous Step-Down 95% Efficiency, V

OUT

DC/DC Converters I

LTC3407 Dual 600mA (I

), 1.5MHz, Synchronous Step-Down 95% Efficiency, V

OUT

DC/DC Converter I

LTC3411 1.25A (I

), 4MHz, Synchronous Step-Down 95% Efficiency, V

OUT

DC/DC Converter I

LTC3425 5A (ISW), 8MHz, Multiphase Synchronous Step-Up 95% Efficiency, V

DC/DC Converter I

LTC3440/LTC3441 600mA/1A (I

), 2MHz/1MHz, Synchronous Buck-Boost 95% Efficiency, V

OUT

DC/DC Converters I

LT3464 85mA (ISW), Constant Off-Time, High Efficiency V

Step-Up DC/DC Converter with Integrated Schottky ThinSOT Package

and Output Disconnect

LTC3467 1.1A (ISW), 1.3MHz, High Efficiency Step-Up V

DC/DC Converter ThinSOT Package

LTC3468/LTC3468-1/ Photoflash Capacitor Charger in ThinSOT Fast Photoflash Charge Times; 4.6sec for LT3468, 5.5sec for

LTC3468-2 LT3468-1, 5.7sec for LT3468-2

ThinsSOT is a trademark of Linear Technology Corporation.

Linear Technology Corporation

20

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

= 0.85V to 5V, V

IN

= <1µA, ThinSOTTM Package

SD

= 0.5V to 5V, V

IN

= <1µA, ThinSOT Package

SD

= <1µA, ThinSOT Package

SD

= <1µA, ThinSOT Package

SD

= <1µA, MS Package

SD

= <1µA, QFN Package

SD

= <1µA, MS Package

SD

= 2.3V to 10V, V

IN

= 2.4V to 16V, V

IN

OUT(MAX)

OUT(MAX)

= 2.7V to 6V, V

IN

= 2.5V to 5.5V, V

IN

= 2.5V to 5.5V, V

IN

= 2.5V to 5.5V, V

IN

= 0.5V to 4.5V, V

IN

= 2.5V to 5.5V, V

IN

OUT(MAX)

OUT(MAX)

= 5V, IQ = 19µA/300µA,

= 6V, IQ = 38µA, ISD = <1µA,

= 0.8V , IQ = 20µA,

OUT(MIN)

= 0.6V, IQ = 20µA,

OUT(MIN)

= 0.6V, IQ = 40µA,

OUT(MIN)

= 0.8V, IQ = 60µA,

OUT(MIN)

= 5.25V, IQ = 12µA,

OUT(MIN)

= 2.5V, IQ = 25µA,

OUT(MIN)

= 34V, IQ = 25µA, ISD = <0.5µA,

= 40V, IQ = 1.2mA, ISD = <1µA,

LT/LT 0305 REV B • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2002

3420fb

Loading...

Loading...