LT1930/LT1930A

1A, 1.2MHz/2.2MHz,

Step-Up DC/DC Converters

FEATURES

■

1.2MHz Switching Frequency (LT1930)

■

2.2MHz Switching Frequency (LT1930A)

■

Low V

■

High Output Voltage: Up to 34V

■

5V at 480mA from 3.3V Input (LT1930)

■

12V at 250mA from 5V Input (LT1930A)

■

Wide Input Range: 2.6V to 16V

■

Uses Small Surface Mount Components

■

Low Shutdown Current: <1µA

■

Low Profile (1mm) ThinSOTTM Package

■

Pin-for-Pin Compatible with the LT1613

Switch: 400mV at 1A

CESAT

U

APPLICATIO S

■

TFT-LCD Bias Supply

■

Digital Cameras

■

Cordless Phones

■

Battery Backup

■

Medical Diagnostic Equipment

■

Local 5V or 12V Supply

■

External Modems

■

PC Cards

■

xDSL Power Supply

, LTC and LT are registered trademarks of Linear Technology Corporation

ThinSOT is a trademark of Linear Technology Corporation.

U

in ThinSOT

DESCRIPTIO

The LT®1930 and LT1930A

power SOT-23 switching regulators. Both include an

internal 1A, 36V switch allowing high current outputs to be

generated in a small footprint. The LT1930 switches at

1.2MHz, allowing the use of tiny, low cost and low height

capacitors and inductors. The faster LT1930A switches at

2.2MHz, enabling further reductions in inductor size.

Complete regulator solutions approaching one tenth of a

square inch in area are achievable with these devices.

Multiple output power supplies can now use a separate

regulator for each output voltage, replacing cumbersome

quasi-regulated approaches using a single regulator and

custom transformers.

A constant frequency internally compensated current mode

PWM architecture results in low, predictable output noise

that is easy to filter. Low ESR ceramic capacitors can be

used at the output, further reducing noise to the millivolt

level. The high voltage switch on the LT1930/LT1930A is

rated at 36V, making the device ideal for boost converters

up to 34V as well as for single-ended primary inductance

converter (SEPIC) and flyback designs. The LT1930 can

generate 5V at up to 480mA from a 3.3V supply or 5V at

300mA from four alkaline cells in a SEPIC design.

The LT1930/LT1930A are available in the 5-lead ThinSOT

package.

are the industry’s highest

U

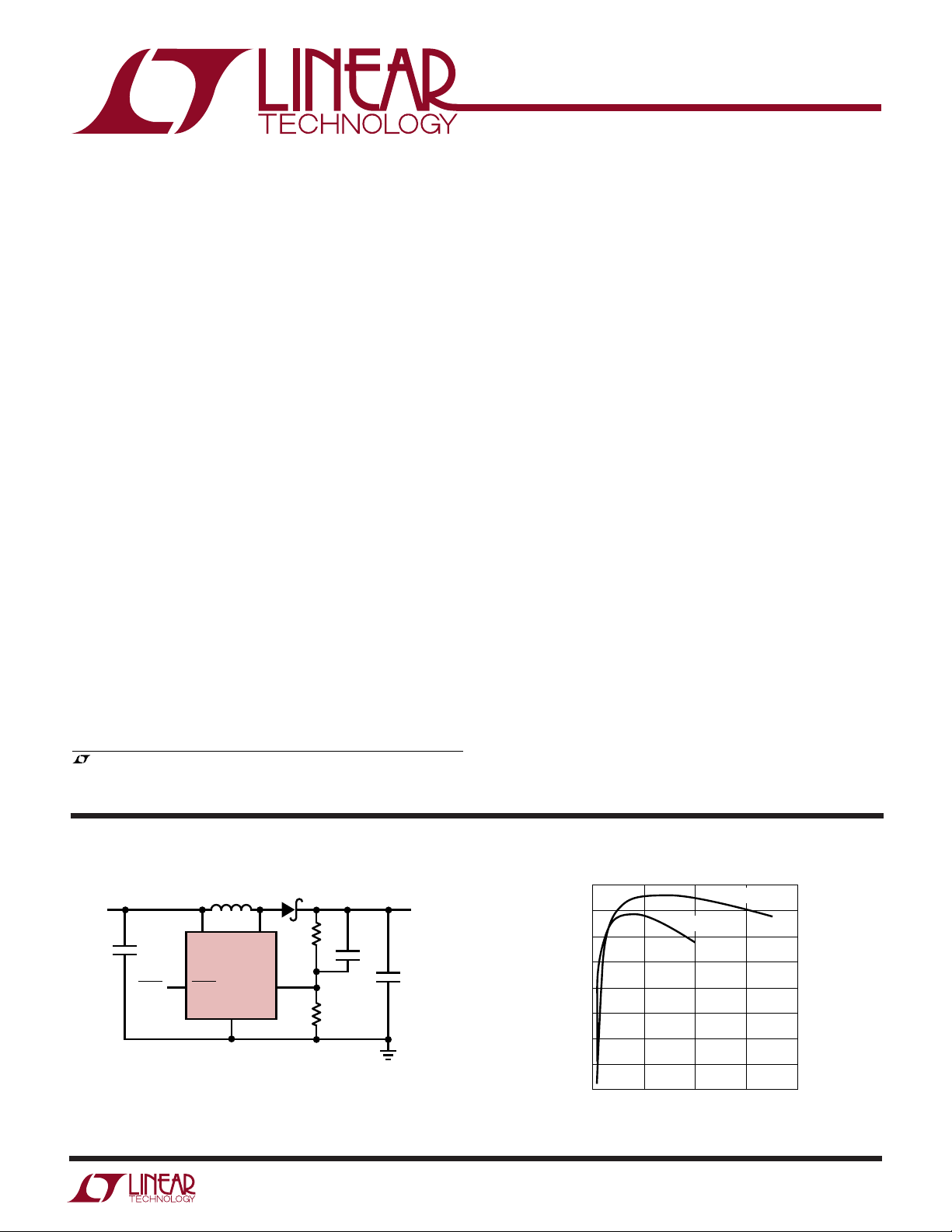

TYPICAL APPLICATIO

L1

V

IN

5V

C1

2.2µF

SHDN

C1: TAIYO-YUDEN X5R LMK212BJ225MG

C2: TAIYO-YUDEN X5R EMK316BJ475ML

D1: ON SEMICONDUCTOR MBR0520

L1: SUMIDA CR43-100

*OPTIONAL

10µH

51

V

IN

LT1930

4

SHDN FB

GND

2

Figure 1. 5V to 12V, 300mA Step-Up DC/DC Converter

SW

D1

R1

113k

3

R2

13.3k

C3*

10pF

V

12V

300mA

C2

4.7µF

1930/A F01

OUT

90

85

80

75

70

65

EFFICIENCY (%)

60

55

50

0

Efficiency

VIN = 3.3V

100

200

LOAD CURRENT (mA)

VIN = 5V

300

400

1930 TA01

1

LT1930/LT1930A

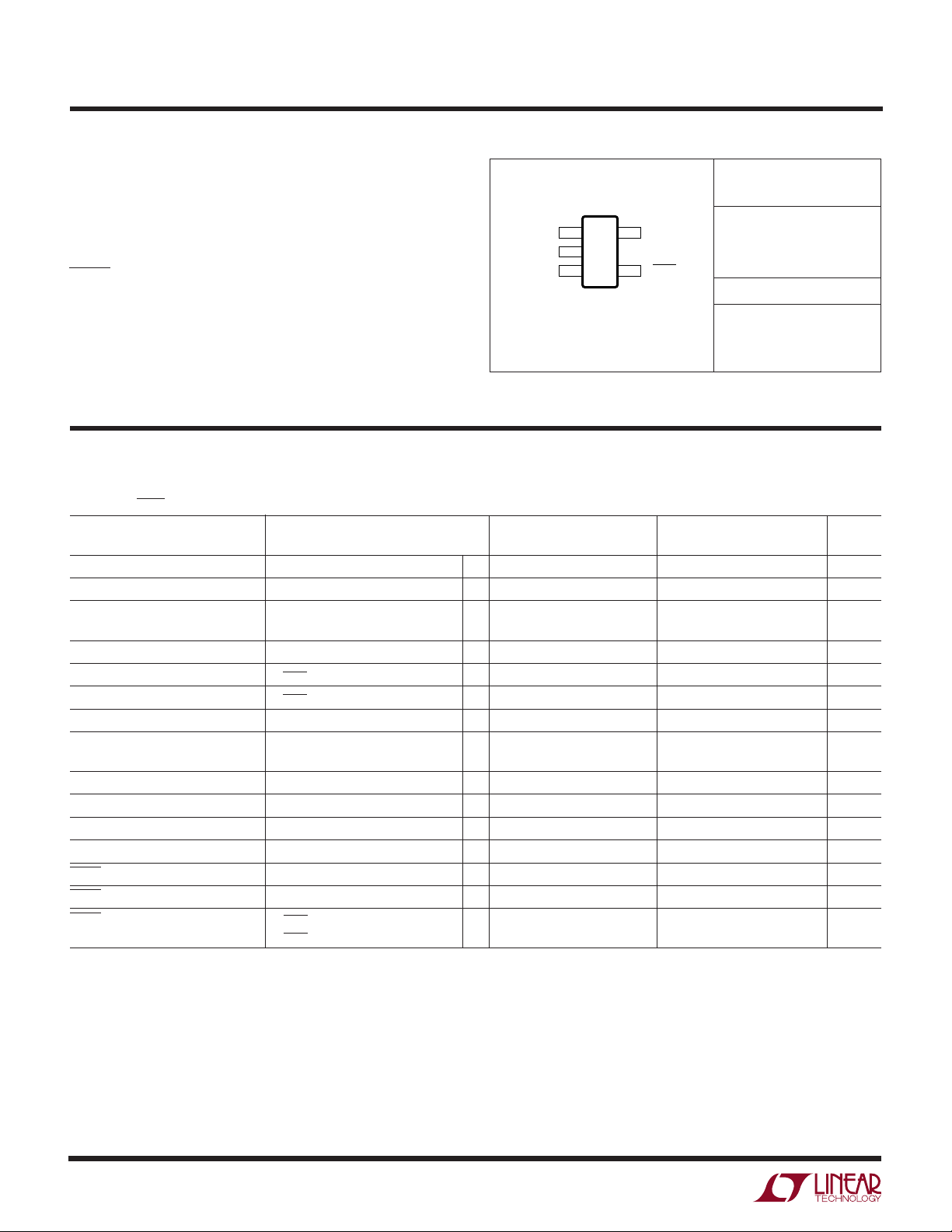

PACKAGE/ORDER I FOR ATIO

UU

W

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

VIN Voltage .............................................................. 16V

SW Voltage ................................................–0.4V to 36V

FB Voltage .............................................................. 2.5V

Current Into FB Pin .............................................. ±1mA

SHDN Voltage ......................................................... 10V

Maximum Junction Temperature ......................... 125°C

Operating Temperature Range (Note 2) .. –40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

TOP VIEW

SW 1

GND 2

FB 3

S5 PACKAGE

5-LEAD PLASTIC SOT-23

T

= 125°C, θJA = 256°C/W

JMAX

Consult LTC Marketing for parts specified with wider operating temperature ranges.

5 V

IN

4 SHDN

ORDER PART

NUMBER

LT1930ES5

LT1930AES5

S5 PART MARKING

LTKS

LTSQ

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VIN = 3V, V

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

Minimum Operating Voltage 2.45 2.6 2.45 2.6 V

Maximum Operating Voltage 16 16 V

Feedback Voltage 1.240 1.255 1.270 1.240 1.255 1.270 V

FB Pin Bias Current VFB = 1.255V ● 120 360 240 720 nA

Quiescent Current V

Quiescent Current in Shutdown V

Reference Line Regulation 2.6V ≤ VIN ≤ 16V 0.01 0.05 0.01 0.05 %/V

Switching Frequency 1 1.2 1.4 1.8 2.2 2.6 MHz

Maximum Duty Cycle ● 84 90 75 90 %

Switch Current Limit (Note 3) 1 1.2 2 1 1.2 2.5 A

Switch V

CESAT

Switch Leakage Current VSW = 5V 0.01 1 0.01 1 µA

SHDN Input Voltage High 2.4 2.4 V

SHDN Input Voltage Low 0.5 0.5 V

SHDN Pin Bias Current V

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LT1930E/LT1930AE are guaranteed to meet performance

specifications from 0°C to 70°C. Specifications over the –40°C to 85°C

= VIN unless otherwise noted. (Note 2)

SHDN

= 2.4V, Not Switching 4.2 6 5.5 8 mA

SHDN

= 0V, VIN = 3V 0.01 1 0.01 1 µA

SHDN

ISW = 1A 400 600 400 600 mV

= 3V 16 32 35 70 µA

SHDN

= 0V 0 0.1 0 0.1 µA

V

SHDN

LT1930 LT1930A

● 1.230 1.280 1.230 1.280 V

● 0.85 1.6 1.6 2.9 MHz

operating temperature range are assured by design, characterization and

correlation with statistical process controls.

Note 3: Current limit guaranteed by design and/or correlation to static test.

2

LT1930/LT1930A

UW

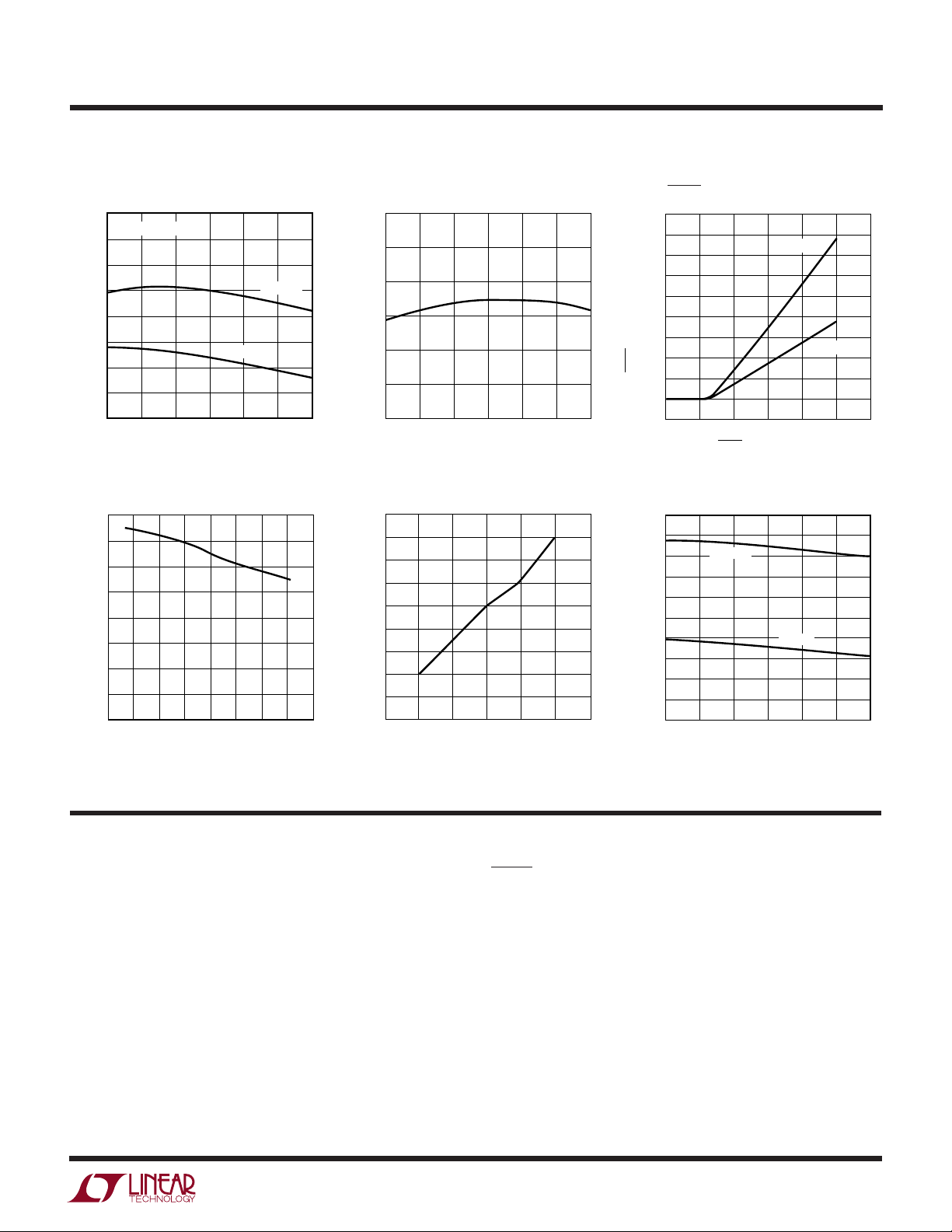

TYPICAL PERFOR A CE CHARACTERISTICS

Quiescent Current FB Pin Voltage SHDN Pin Current

7.0

NOT SWITCHING

6.5

6.0

5.5

5.0

4.5

4.0

QUIESCENT CURRENT (mA)

3.5

3.0

–50 –25

0 25 100

TEMPERATURE (°C)

LT1930A

LT1930

50 75

1930/A G01

1.28

1.27

1.26

1.25

FB VOLTAGE (V)

1.24

1.23

1.22

–50

–25

02550

TEMPERATURE (°C)

75 100

1930/A G02

90

80

70

60

50

40

30

20

SHDN PIN CURRENT (µA)

10

0

–10

0

LT1930A

LT1930

12 4

SHDN PIN VOLTAGE (V)

3

5

1930/A G03

6

Current Limit

1.6

1.4

1.2

1.0

0.8

0.6

CURRENT LI MIT (A)

0.4

0.2

0

10

3020 5040 7060 9080

U

DUTY CYCLE (%)

1930/A G04

UU

Switch Saturation Voltage

0.45

0.40

0.35

0.30

0.25

(V)

0.20

CESAT

V

0.15

0.10

0.05

0

0

0.4 1.2

0.2 1.0

SWITCH CURRENT (A)

PI FU CTIO S

SW (Pin 1): Switch Pin. Connect inductor/diode here.

Minimize trace area at this pin to reduce EMI.

GND (Pin 2): Ground. Tie directly to local ground plane.

Oscillator Frequency

2.5

2.3

LT1930A

LT1930

25 50 75 100

TEMPERATURE (°C)

1930/A G06

0.6

0.8

1930/A G05

2.1

1.9

1.7

1.5

1.3

FREQUENCY (MHz)

1.1

0.9

0.7

0.5

–50 –25 0

SHDN (Pin 4): Shutdown Pin. Tie to 2.4V or more to enable

device. Ground to shut down.

V

(Pin 5): Input Supply Pin. Must be locally bypassed.

IN

FB (Pin 3): Feedback Pin. Reference voltage is 1.255V.

Connect resistive divider tap here. Minimize trace area at

FB. Set V

according to V

OUT

= 1.255V(1 + R1/R2).

OUT

3

LT1930/LT1930A

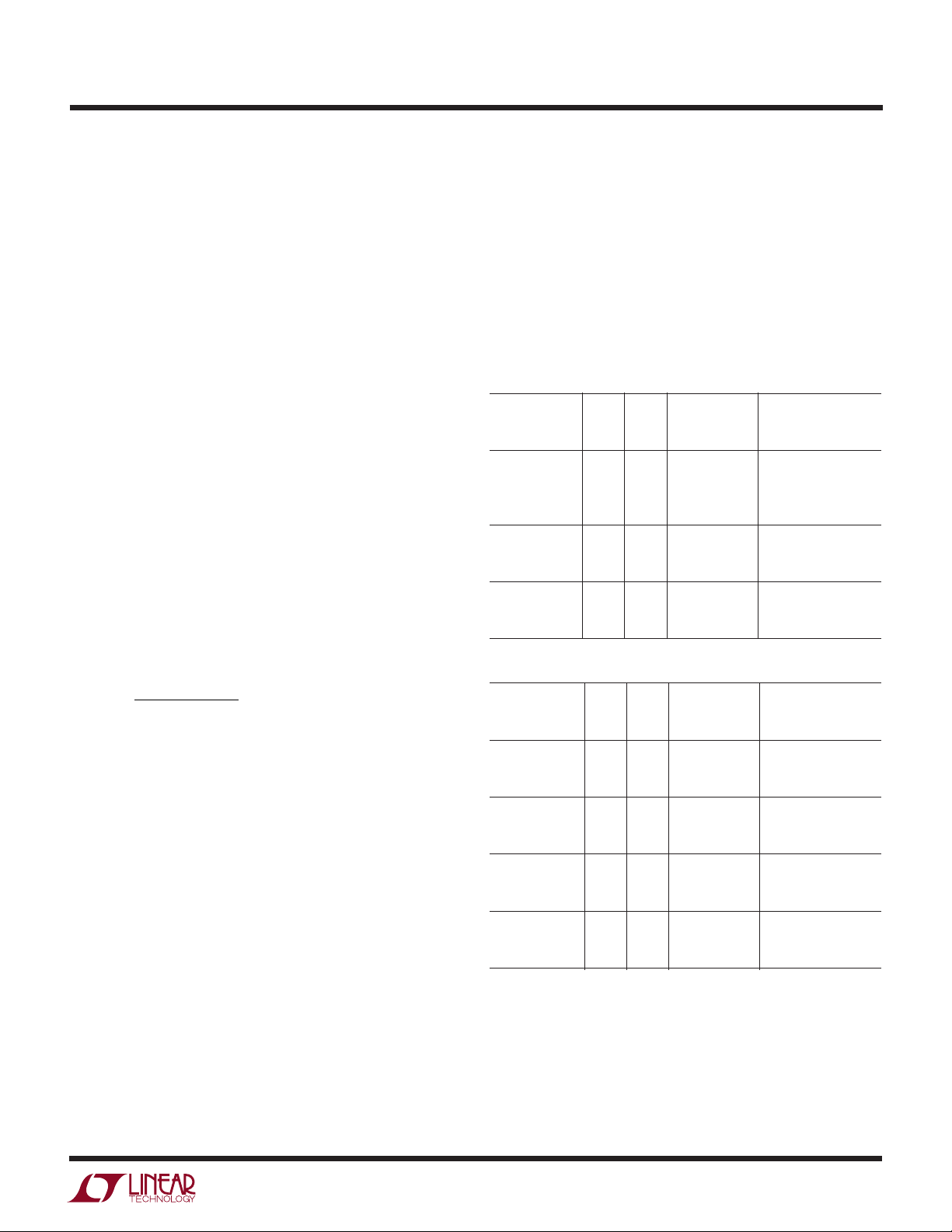

BLOCK DIAGRA

V

IN

5

V

OUT

R1 (EXTERNAL)

FB

R2 (EXTERNAL)

W

1.255V

REFERENCE

1

+

A1

–

R

C

C

C

COMPARATOR

–

A2

+

RQ

S

DRIVER

SW

Q1

+

Σ

0.01Ω

–

RAMP

GENERATOR

SHUTDOWN

SHDN

4

FB

3

Figure 2. Block Diagram

U

OPERATIO

The LT1930 uses a constant frequency, current-mode

control scheme to provide excellent line and load regulation. Operation can be best understood by referring to the

block diagram in Figure 2. At the start of each oscillator

cycle, the SR latch is set, which turns on the power switch

Q1. A voltage proportional to the switch current is added

to a stabilizing ramp and the resulting sum is fed into the

positive terminal of the PWM comparator A2. When this

voltage exceeds the level at the negative input of A2, the SR

latch is reset turning off the power switch. The level at the

negative input of A2 is set by the error amplifier A1, and is

simply an amplified version of the difference between the

feedback voltage and the reference voltage of 1.255V. In

2

GND

1.2MHz

OSCILLATOR*

*2.2MHz FOR LT1930A

1930/A BD

this manner, the error amplifier sets the correct peak

current level to keep the output in regulation. If the error

amplifier’s output increases, more current is delivered to

the output; if it decreases, less current is delivered. The

LT1930 has a current limit circuit not shown in Figure 2.

The switch current is constantly monitored and not allowed to exceed the maximum switch current (typically

1.2A). If the switch current reaches this value, the SR latch

is reset regardless of the state of comparator A2. This

current limit helps protect the power switch as well as the

external components connected to the LT1930.

The block diagram for the LT1930A (not shown) is identical except that the oscillator frequency is 2.2MHz.

4

LT1930/LT1930A

U

WUU

APPLICATIONS INFORMATION

LT1930 AND LT1930A DIFFERENCES

Switching Frequency

The key difference between the LT1930 and LT1930A is

the faster switching frequency of the LT1930A. At 2.2MHz,

the LT1930A switches at nearly twice the rate of the

LT1930. Care must be taken in deciding which part to use.

The high switching frequency of the LT1930A allows

smaller cheaper inductors and capacitors to be used in a

given application, but with a slight decrease in efficiency

and maximum output current when compared to the

LT1930. Generally, if efficiency and maximum output

current are critical, the LT1930 should be used. If application size and cost are more important, the LT1930A will be

the better choice. In many applications, tiny inexpensive

chip inductors can be used with the LT1930A, reducing

solution cost.

Duty Cycle

The maximum duty cycle (DC) of the LT1930A is 75%

compared to 84% for the LT1930. The duty cycle for a

given application using the boost topology is given by:

VV

||–||

DC

For a 5V to 12V application, the DC is 58.3% indicating that

the LT1930A could be used. A 5V to 24V application has

a DC of 79.2% making the LT1930 the right choice. The

LT1930A can still be used in applications where the DC, as

calculated above, is above 75%. However, the part must

be operated in the discontinuous conduction mode so that

the actual duty cycle is reduced.

INDUCTOR SELECTION

Several inductors that work well with the LT1930 are listed

in Table 1 and those for the LT1930A are listed in Table 2.

These tables are not complete, and there are many other

manufacturers and devices that can be used. Consult each

manufacturer for more detailed information and for their

entire selection of related parts, as many different sizes and

shapes are available. Ferrite core inductors should be used

to obtain the best efficiency, as core losses at 1.2MHz are

much lower for ferrite cores than for cheaper powdered-

OUT IN

=

V

||

OUT

iron types. Choose an inductor that can handle at least 1A

without saturating, and ensure that the inductor has a low

DCR (copper-wire resistance) to minimize I2R power losses.

A 4.7µH or 10µH inductor will be the best choice for most

LT1930 designs. For LT1930A designs, a 2.2µH to 4.7µH

inductor will usually suffice. Note that in some applications, the current handling requirements of the inductor

can be lower, such as in the SEPIC topology where each

inductor only carries one-half of the total switch current.

Table 1. Recommended Inductors – LT1930

MAX SIZE

L DCR L × W × H

PART (µH) mΩ (mm) VENDOR

CDRH5D18-4R1 4.1 57 4.5 × 4.7 × 2.0 Sumida

CDRH5D18-100 10 124 (847) 956-0666

CR43-4R7 4.7 109 3.2 × 2.5 × 2.0 www.sumida.com

CR43-100 10 182

DS1608-472 4.7 60 4.5 × 6.6 × 2.9 Coilcraft

DS1608-103 10 75 (847) 639-6400

www.coilcraft.com

ELT5KT4R7M 4.7 240 5.2 × 5.2 × 1.1 Panasonic

ELT5KT6R8M 6.8 360 (408) 945-5660

www.panasonic.com

Table 2. Recommended Inductors – LT1930A

MAX SIZE

L DCR L × W × H

PART (µH) mΩ (mm) VENDOR

LQH3C2R2M24 2.2 126 3.2 × 2.5 × 2.0 Murata

LQH3C4R7M24 4.7 195 (404) 573-4150

www.murata.com

CR43-2R2 2.2 71 4.5 × 4.0 × 3.0 Sumida

CR43-3R3 3.3 86 (847) 956-0666

www.sumida.com

1008PS-272 2.7 100 3.7 × 3.7 × 2.6 Coilcraft

1008PS-332 3.3 110 (800) 322-2645

www.coilcraft.com

ELT5KT3R3M 3.3 204 5.2 × 5.2 × 1.1 Panasonic

(408) 945-5660

www.panasonic.com

The inductors shown in Table 2 for use with the LT1930A

were chosen for small size. For better efficiency, use

similar valued inductors with a larger volume. For

example, the Sumida CR43 series in values ranging from

2.2µH to 4.7µH will give an LT1930A application a few

percentage points increase in efficiency, compared to the

smaller Murata LQH3C Series.

5

LT1930/LT1930A

U

WUU

APPLICATIONS INFORMATION

CAPACITOR SELECTION

Low ESR (equivalent series resistance) capacitors should

be used at the output to minimize the output ripple voltage.

Multi-layer ceramic capacitors are an excellent choice, as

they have extremely low ESR and are available in very

small packages. X5R dielectrics are preferred, followed by

X7R, as these materials retain the capacitance over wide

voltage and temperature ranges. A 4.7µF to 10µF output

capacitor is sufficient for most applications, but systems

with very low output currents may need only a 1µF or 2.2µF

output capacitor. Solid tantalum or OSCON capacitors can

be used, but they will occupy more board area than a

ceramic and will have a higher ESR. Always use a capacitor

with a sufficient voltage rating.

Ceramic capacitors also make a good choice for the input

decoupling capacitor, which should be placed as close as

possible to the LT1930/LT1930A. A 1µF to 4.7µF input

capacitor is sufficient for most applications. Table 3 shows

a list of several ceramic capacitor manufacturers. Consult

the manufacturers for detailed information on their entire

selection of ceramic parts.

Table 3. Ceramic Capacitor Manufacturers

Taiyo Yuden (408) 573-4150 www.t-yuden.com

AVX (803) 448-9411 www.avxcorp.com

Murata (714) 852-2001 www.murata.com

By choosing the appropriate values for the resistor and

capacitor, the zero frequency can be designed to improve

the phase margin of the overall converter. The typical

target value for the zero frequency is between 35kHz to

55kHz. Figure 3 shows the transient response of the stepup converter from Figure 1 without the phase lead capacitor C3. The phase margin is reduced as evidenced by more

ringing in both the output voltage and inductor current. A

10pF capacitor for C3 results in better phase margin,

which is revealed in Figure 4 as a more damped response

and less overshoot. Figure 5 shows the transient response

when a 33µF tantalum capacitor with no phase lead

capacitor is used on the output. The higher output voltage

ripple is revealed in the upper waveform as a set of double

lines. The transient response is not greatly improved

which implies that the ESR zero frequency is too high to

increase the phase margin.

V

OUT

0.2V/DIV

AC COUPLED

I

LI

0.5A/DIV

AC COUPLED

250mA

LOAD

CURRENT

150mA

50µs/DIV

1930 F03

The decision to use either low ESR (ceramic) capacitors or

the higher ESR (tantalum or OSCON) capacitors can affect

the stability of the overall system. The ESR of any capacitor, along with the capacitance itself, contributes a zero to

the system. For the tantalum and OSCON capacitors, this

zero is located at a lower frequency due to the higher value

of the ESR, while the zero of a ceramic capacitor is at a

much higher frequency and can generally be ignored.

A phase lead zero can be intentionally introduced by

placing a capacitor (C3) in parallel with the resistor (R1)

between V

and VFB as shown in Figure 1. The frequency

OUT

of the zero is determined by the following equation.

ƒ=

Z

1

RC

213π••

6

Figure 3. Transient Response of Figure 1's Step-Up

Converter without Phase Lead Capacitor

V

OUT

0.2V/DIV

AC COUPLED

I

LI

0.5A/DIV

AC COUPLED

250mA

LOAD

CURRENT

150mA

50µs/DIV

Figure 4. Transient Response of Figure 1's Step-Up

Converter with 10pF Phase Lead Capacitor

1930 F04

LT1930/LT1930A

U

WUU

APPLICATIONS INFORMATION

V

OUT

0.2V/DIV

AC COUPLED

I

LI

0.5A/DIV

AC COUPLED

LOAD

250mA

CURRENT

Figure 5. Transient Response of Step-Up Converter with 33µF

Tantalum Output Capacitor and No Phase Lead Capacitor

DIODE SELECTION

A Schottky diode is recommended for use with the LT1930/

LT1930A. The Motorola MBR0520 is a very good choice.

Where the switch voltage exceeds 20V, use the MBR0530

(a 30V diode). Where the switch voltage exceeds 30V, use

the MBR0540 (a 40V diode). These diodes are rated to

handle an average forward current of 0.5A. In applications

where the average forward current of the diode exceeds

0.5A, a Microsemi UPS5817 rated at 1A is recommended.

150mA

200µs/DIV

1930 F04

LAYOUT HINTS

The high speed operation of the LT1930/LT1930A

demands careful attention to board layout. You will not get

advertised performance with careless layout. Figure 6

shows the recommended component placement.

D1 C1

V

OUT

+

C2

GND

Figure 6. Suggested Layout

L1

+

V

IN

SHUTDOWN

R2

R1

C3

1930 F06

Driving SHDN Above 10V

SETTING OUTPUT VOLTAGE

To set the output voltage, select the values of R1 and R2

(see Figure 1) according to the following equation.

RR

12

V

OUT

.

1 255

–

1=

V

A good value for R2 is 13.3k which sets the current in the

resistor divider chain to 1.255V/13.3k = 94.7µA.

V

16V

IN

C1

121k

4

Figure 7. Keeping SHDN Below 10V

L1

51

V

IN

LT1930

SHDN FB

GND

The maximum voltage allowed on the SHDN pin is 10V. If

you wish to use a higher voltage, you must place a resistor

in series with SHDN. A good value is 121k. Figure 7 shows

a circuit where VIN = 16V and SHDN is obtained from VIN.

The voltage on the SHDN pin is kept below 10V.

D1

V

OUT

SW

2

R1

3

R2

C2

1930 F07

7

LT1930/LT1930A

TYPICAL APPLICATIO S

U

4-Cell to 5V SEPIC Converter

4V TO 6.5V

C1

4-CELL

BATTERY

C1: TAIYO-YUDEN X5R LMK212BJ225MG

C2: TAIYO-YUDEN X5R JMK316BJ106ML

C3: TAIYO-YUDEN X5R LMK212BJ105MG

2.2µF

SHDN

4

4-Cell to 5V SEPIC Converter with Coupled Inductors

4V TO 6.5V

C1

4-CELL

BATTERY

C1: TAIYO-YUDEN X5R LMK212BJ225MG

C2: TAIYO-YUDEN X5R JMK316BJ106ML

C3: TAIYO-YUDEN X5R LMK212BJ105MG

D1: ON SEMICONDUCTOR MBR0520

L1: SUMIDA CLS62-100

2.2µF

SHDN

4

L1

10µH

51

V

IN

LT1930

SHDN FB

GND

2

D1: ON SEMICONDUCTOR MBR0520

L1, L2: MURATA LQH3C100K24

L1A

10µH

51

V

IN

LT1930

SHDN FB

GND

2

1µF

SW

3

1µF

•

SW

3

C3

C3

243k

82.5k

243k

82.5k

L2

10µH

•

L1B

10µH

Efficiency

80

D1

V

5V

300mA

C2

10µF

1930 TA02a

OUT

75

70

65

60

55

EFFICIENCY (%)

50

45

40

0

200

100

LOAD CURRENT (mA)

VIN = 4V

300

VIN = 6.5V

400 500

1930 TA02b

5V to 24V Boost Converter

D1

V

5V

300mA

C2

10µF

1930/A TA03

OUT

V

IN

5V

C1

4.7µF

4

SHDN

C1: TAIYO-YUDEN X5R EMK316BJ475ML

C2: TAIYO-YUDEN X5R JMK212BJ475MG

D1: ON SEMICONDUCTOR MBR0530

L1: SUMIDA CR43-100

L1

10µH

51

V

IN

SHDN FB

SW

LT1930

GND

2

D1

R1

665k

3

R2

36.5k

V

24V

90mA

C2

2.2µF

1930/A TA04

OUT

8

±15V Dual Output Converter with Output Disconnect

L1

V

IN

5V

C1

2.2µF

OFF ON

C1: TAIYO-YUDEN X5R LMK212BJ225MG

C2, C3: TAIYO-YUDEN X5R EMK316BJ225ML

C4, C5: TAIYO-YUDEN X5R TMK316BJ105ML

(408) 573-4150

D1 TO D4: ON SEMICONDUCTOR MBR0520 (800) 282-9855

L1: SUMIDA CR43-3R3 (874) 956-0666

3.3µH

51

V

IN

LT1930

4

SHDN FB

GND

2

SW

3

1µF

C5

1µF

C4

D1

R1

D2

D3

D4

147k

R2

13.3k

C6

2.2µF

1930/A TA05

15V

70mA

C2

2.2µF

–15V

70mA

TYPICAL APPLICATIO S

M1

V

IN

3V to 6V

U

Boost Converter with Reverse Battery Protection

L1

4.7µH

C1

2.2µF

SHDN

C1: TAIYO-YUDEN X5R LMK432BJ226MM

C2: TAIYO-YUDEN X5R LMK212BJ225MG

D1: ON SEMICONDUCTOR MBR0520

L1: SUMIDA CR43-4R7

M1: SILICONIX Si6433DQ

51

V

IN

LT1930

4

SHDN FB

GND

D1

C3

SW

3

2

R1

60.4k

R2

11.3k

47pF

1930/A TA06

V

OUT

8V

520mA AT V

240mA AT V

C2

22µF

LT1930/LT1930A

= 6V

IN

= 3V

IN

3.3V to 5V Boost Converter

L1

V

IN

3.3V

C1

4.7µF

OFF ON

C1: TAIYO-YUDEN X5R JMK212BJ475MG www.t-yuden.com

C2: TAIYO-YUDEN X5R JMK316BJ106ML

D1: ON SEMICONDUCTOR MBR0520 www.onsemi.com

L1: SUMIDA CR43-5R6 www.sumida.com

5.6µH

51

V

IN

LT1930

4

SHDN FB

GND

2

D1

SW

3

5V to 12V, 250mA Step-Up Converter

L1

V

IN

5V

C1

2.2µF

SHDN

C1: TAIYO-YUDEN X5R LMK212BJ225MG

C2: TAIYO-YUDEN X5R EMK316BJ225ML

D1: ON SEMICONDUCTOR MBR0520

L1: MURATA LQH3C2R2M24

2.2µH

51

V

IN

LT1930A

4

SHDN FB

GND

2

SW

Efficiency

R1

40.2k

R2

13.3k

V

OUT

5V

480mA

C2

10µF

1930/A TA07a

90

85

80

75

70

65

EFFICIENCY (%)

60

55

50

0

100 200 400

LOAD CURRENT (mA)

VIN = 2.6V

300

VIN = 3.3V

500

1930/A TA07b

Efficiency

90

D1

R1

115k

3

R2

13.3k

V

OUT

12V

250mA

C2

2.2µF

1930/A TA08a

VIN = 5V

V

OUT

85

80

75

70

65

EFFICIENCY (%)

60

55

50

0

= 12V

50 100 200

150

LOAD CURRENT (mA)

250

1930/A TA08b

300

9

LT1930/LT1930A

U

TYPICAL APPLICATIO S

9V, 18V, –9V Triple Output TFT-LCD Bias Supply with Soft-Start

D1

D2

C3

0.1µF

V

IN

3.3V

+

C1

2.2µF

V

SS

3.3V

0V

C1: X5R OR X7R, 6.3V

C2,C3, C5: X5R OR X7R, 10V

C4: X5R OR X7R, 25V

D1- D4: BAT54S OR EQUIVALENT

D5: MBR0520 OR EQUIVALENT

L1: PANASONIC ELT5KT4R7M

R

30k

D

1N4148

SS

SS

L1

4.7µH

51

V

IN

LT1930

4

SHDN FB

GND

C

68nF

2

SS

SW

D5

R1

124k

3

R2

20k

C2

0.1µF

D4

D3

C6

1µF

18V

10mA

C4

1µF

9V

200mA

C5

10µF

–9V

10mA

1930/A TA11a

9V OUTPUT

5V/DIV

–9V OUTPUT

5V/DIV

18V OUTPUT

10V/DIV

I

0.5A/DIV

L1

Start-Up Waveforms

2ms/DIV

8V, 23V, –8V Triple Output TFT-LCD Bias Supply with Soft-Start

D1

D2

C3

0.1µFC40.1µFC50.1µF

V

IN

3.3V

+

C1

2.2µF

V

SS

3.3V

0V

C1: X5R OR X7R, 6.3V

C2-C4, C7, C8: X5R OR X7R, 10V

C5: X5R OR X7R, 16V

C6: X5R OR X7R, 25V

D1- D6: BAT54S OR EQUIVALENT

D7: MBR0520 OR EQUIVALENT

L1: PANASONIC ELT5KT4R7M

R

30k

D

1N4148

SS

SS

L1

4.7µH

51

V

IN

LT1930

4

SHDN FB

GND

C

68nF

2

SS

SW

D7

R1

113k

3

R2

21k

C2

0.1µF

D5

D6

D3 D4

C8

1µF

C6

1µF

8V

220mA

C7

10µF

–8V

10mA

23V

10mA

1930/A TA12a

8V OUTPUT

5V/DIV

–8V OUTPUT

5V/DIV

23V OUTPUT

10V/DIV

I

0.5A/DIV

L1

Start-Up Waveforms

2ms/DIV

10

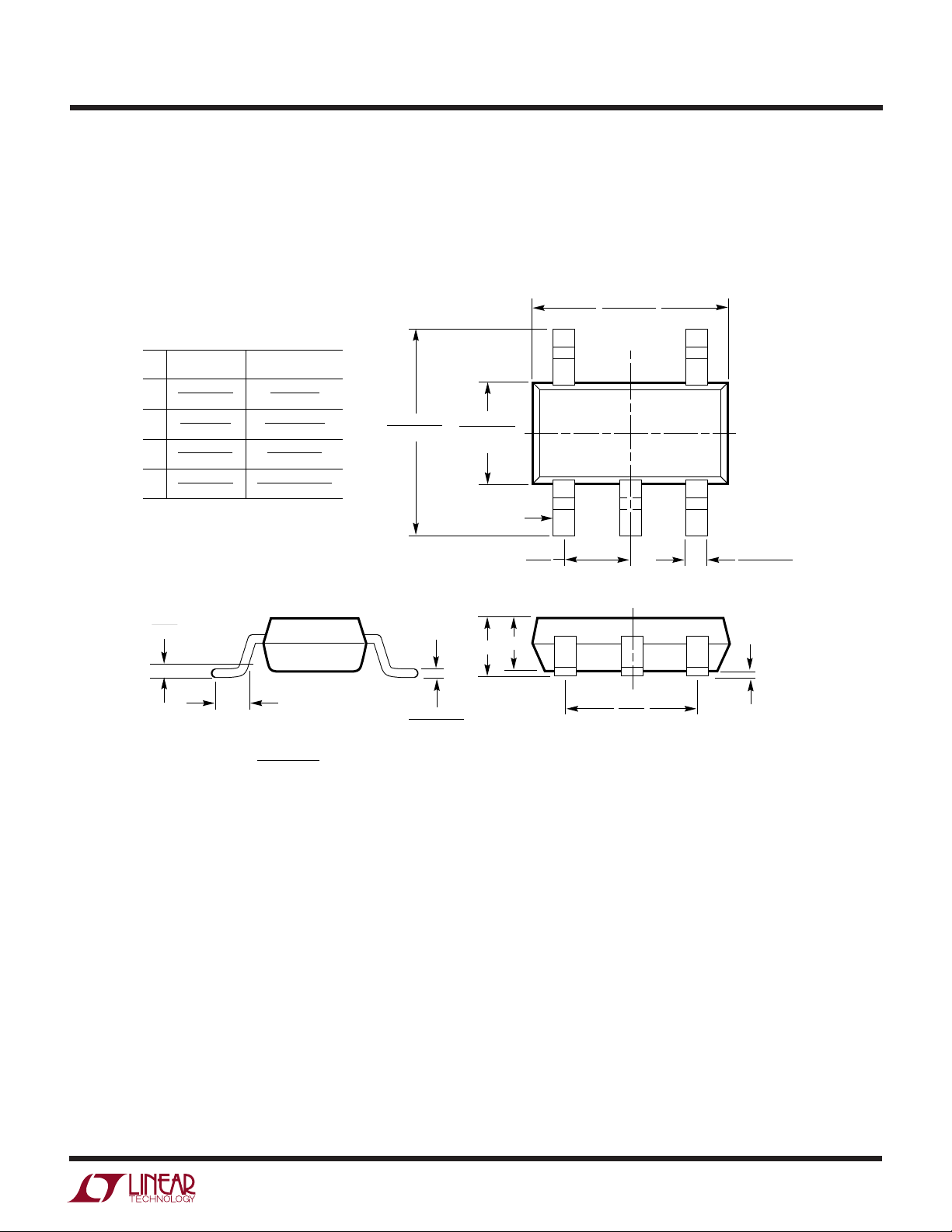

PACKAGE DESCRIPTIO

U

S5 Package

5-Lead Plastic SOT-23

(Reference LTC DWG # 05-08-1633)

(Reference LTC DWG # 05-08-1635)

2.80 – 3.10

(.110 – .118)

(NOTE 3)

LT1930/LT1930A

SOT-23

(Original)

.90 – 1.45

A

(.035 – .057)

.00 – .15

A1

(.00 – .006)

.90 – 1.30

A2

(.035 – .051)

.35 – .55

L

(.014 – .021)

.20

(.008)

DATUM ‘A’

L

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

4. DIMENSIONS ARE INCLUSIVE OF PLATING

5. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

6. MOLD FLASH SHALL NOT EXCEED .254mm

7. PACKAGE EIAJ REFERENCE IS:

SC-74A (EIAJ) FOR ORIGINAL

JEDEL MO-193 FOR THIN

SOT-23

(ThinSOT)

1.00 MAX

(.039 MAX)

.01 – .10

(.0004 – .004)

.80 – .90

(.031 – .035)

.30 – .50 REF

(.012 – .019 REF)

MILLIMETERS

(INCHES)

2.60 – 3.00

(.102 – .118)

.09 – .20

(.004 – .008)

(NOTE 2)

1.50 – 1.75

(.059 – .069)

(NOTE 3)

PIN ONE

A

.95

(.037)

REF

A2

1.90

(.074)

REF

.25 – .50

(.010 – .020)

(5PLCS, NOTE 2)

A1

S5 SOT-23 0401

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

11

LT1930/LT1930A

TYPICAL APPLICATIO

U

3.3V to 5V, 450mA Step-Up Converter

AC COUPLED

AC COUPLED

LOAD

CURRENT

V

OUT

50mV/DIV

0.5A/DIV

300mA

200mA

V

IN

3.3V

C1

2.2µF

SHDN

C1: TAIYO-YUDEN X5R LMK212BJ225MG

C2: TAIYO-YUDEN X5R JMK316B106ML

D1: ON SEMICONDUCTOR MBR0520

L1: MURATA LQH3C2R2M24

51

V

IN

4

SHDN FB

L1

2.2µH

LT1930A

GND

2

SW

D1

R1

30.1k

3

R2

10k

V

OUT

5V

450mA

C2

10µF

1930/A TA09a

Efficiency

3.3V to 5V Transient Response

I

LI

20µs/DIV

1930 F03

90

85

80

75

70

65

EFFICIENCY (%)

60

55

50

0

100 200 400

LOAD CURRENT (mA)

300

VIN = 3.3V

= 5V

V

OUT

1930/A TA09b

500

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1307 Single Cell Micropower 600kHz PWM DC/DC Converter 3.3V at 75mA from Single Cell, MSOP Package

LT1316 Burst ModeTM Operation DC/DC Converter with Programmable Current Limit 1.5V Minimum, Precise Control of Peak Current Limit

LT1317 2-Cell Micropower DC/DC Converter with Low-Battery Detector 3.3V at 200mA from 2 Cells, 600kHz Fixed Frequency

LT1610 Single Cell Micropower DC/DC Converter 3V at 30mA from 1V, 1.7MHz Fixed Frequency

LT1611 Inverting 1.4MHz Switching Regulator in 5-Lead ThinSOT – 5V at 150mA from 5V Input, ThinSOT Package

LT1613 1.4MHz Switching Regulator in 5-Lead ThinSOT 5V at 200mA from 3.3V Input, ThinSOT Package

LT1615 Micropower Constant Off-Time DC/DC Converter in 5-Lead ThinSOT 20V at 12mA from 2.5V, ThinSOT Package

LT1617 Micropower Inverting DC/DC Converter in 5-Lead ThinSOT –15V at 12mA from 2.5V Input, ThinSOT Package

LT1931/LT1931A Inverting 1.2MHz/2.2MHz Switching Regulator in 5-Lead ThinSOT – 5V at 350mA from 5V input, ThinSOT Package

Burst Mode is a trademark of Linear Technology Corporation.

1930af LT/TP 0801 2K • PRINTED IN USA

LINEAR TECHNOLOGY CORP ORATION 2001

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

Loading...

Loading...