Linear Technology LT1777 Datasheet

FEATURES

LT1777

Low Noise Step-Down

Switching Regulator

U

DESCRIPTIO

■

Programmable dI/dt Limit

■

Internally Limited dV/dt

■

High Input Voltage: 48V Max

■

700mA Peak Switch Rating

■

True Current Mode Control

■

100kHz Fixed Operating Frequency

■

Synchronizable to 250kHz

■

Low Supply Current in Shutdown: 30µA

■

Low Thermal Resistance 16-Pin SO Package

U

APPLICATIO S

■

Automotive Cellular and GPS Receivers

■

Telecom Power Supplies

■

Industrial Instrument Power Supplies

U

TYPICAL APPLICATIO

The LT®1777 is a Buck (step-down) regulator designed for

noise sensitive applications. It contains a dI/dt limiting

circuit programmed via a small external inductor in the

switching path. Internal circuitry also generates controlled

dV/dt ramp rates.

The monolithic die includes all oscillator, control and

protection circuitry. The part can accept operating input

voltages as high as 48V, and contains an output switch

rated at 700mA peak current. Current mode control offers

excellent dynamic input supply rejection and short-circuit

protection. The internal control circuitry is normally powered via the VCC pin, thereby minimizing power drawn

directly from the VIN supply (see Applications Information). The fused-lead SO16 package and 100kHz switching frequency allow for minimal PC board area

requirements.

, LTC and LT are registered trademarks of Linear Technology Corporation.

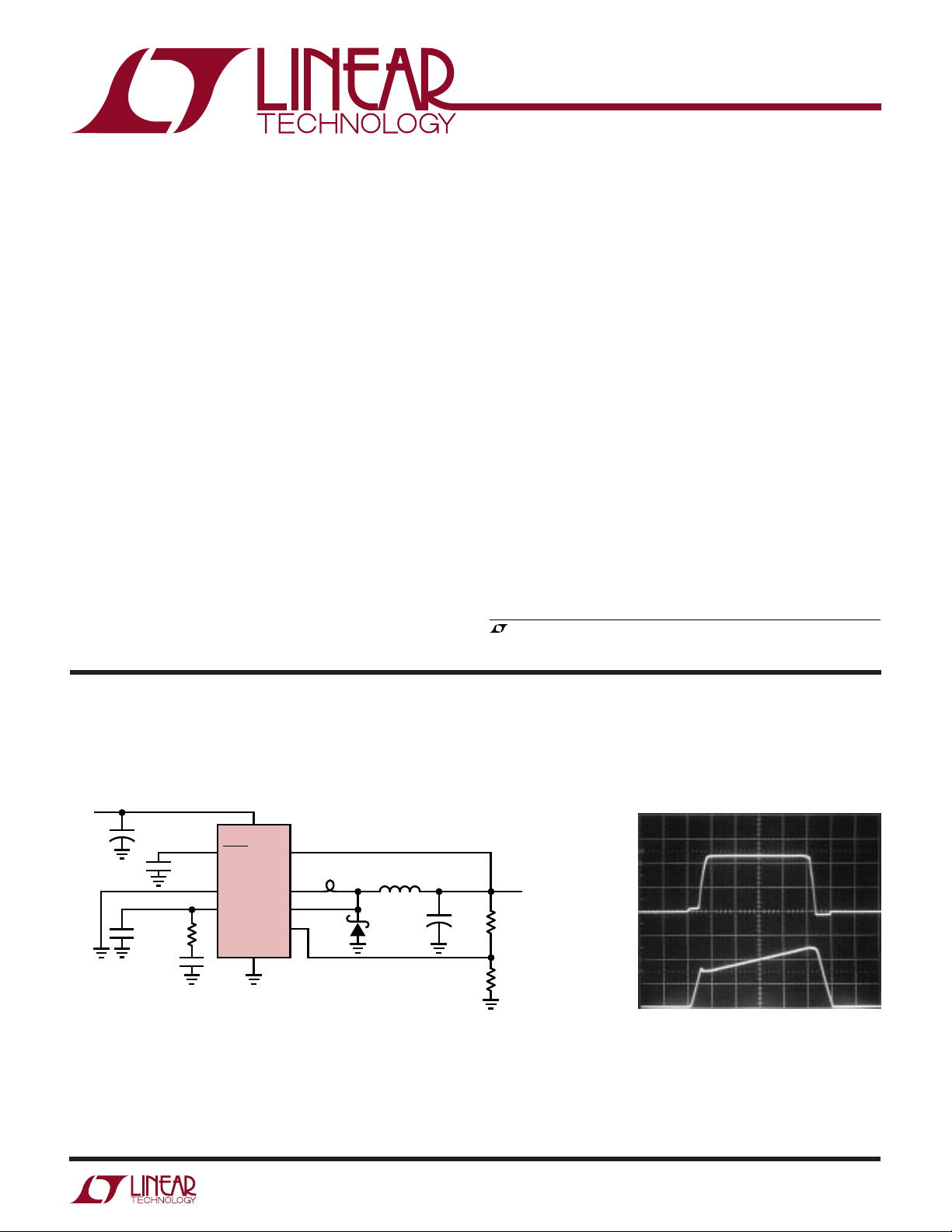

V

IN

24V

+

*PROGRAMS dI/dT

39µF

63V

100pF

2200pF

100pF

12k

VSW Switching WaveformsLow Noise 5V Step-Down Supply

10

V

IN

3

SHDN

LT1777

12

SYNC

14

V

C

SGND

4

V

CC

1µH*

6

V

SW

5

V

D

13

FB

7

220µH

MBRS1100

V

OUT

5V

+

100µF

10V

36.5k

1%

12.1k

1%

1777 TA01

400mA

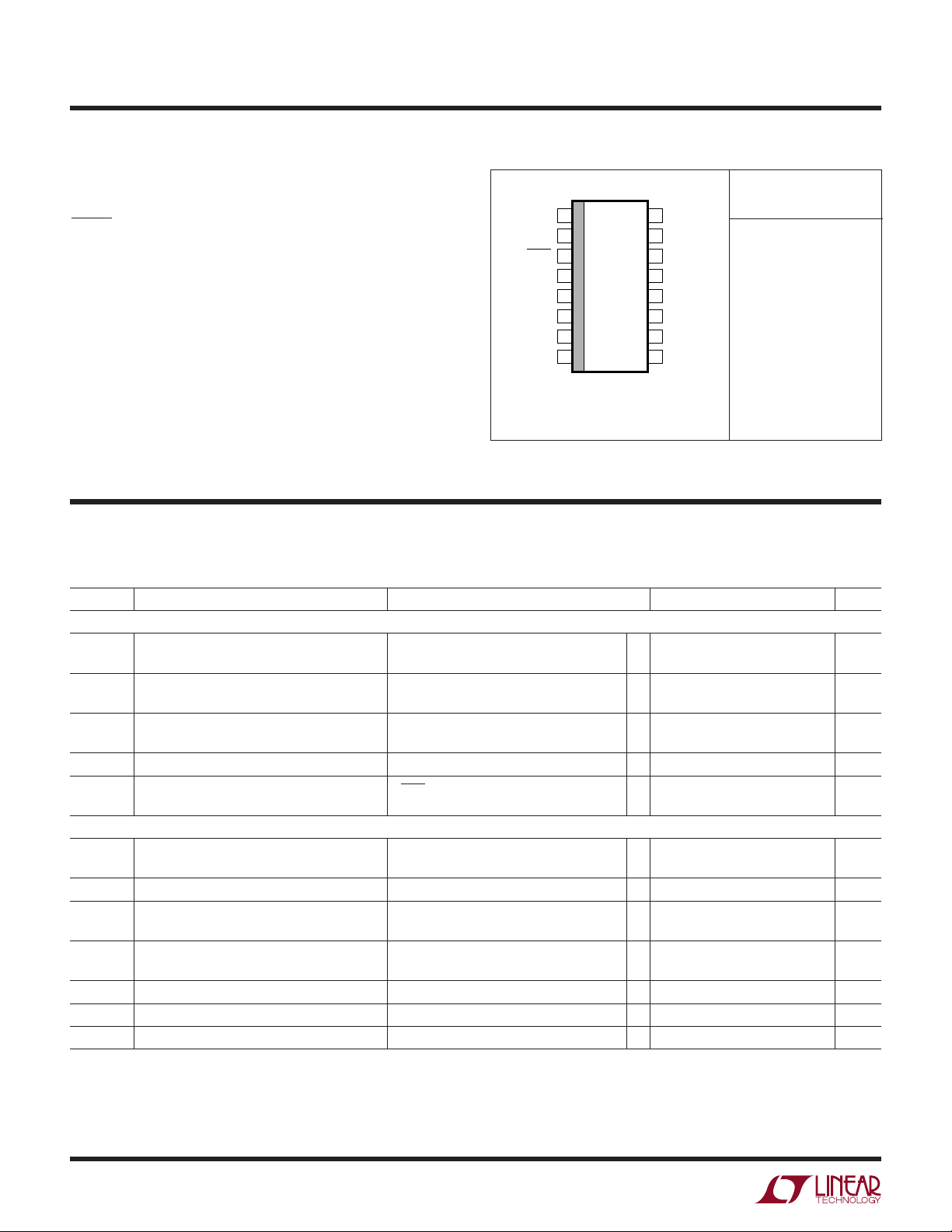

V

SW

VOLTAGE

10V/DIV

V

SW

CURRENT

200mA/DIV

500ns/DIV

1777 TA02

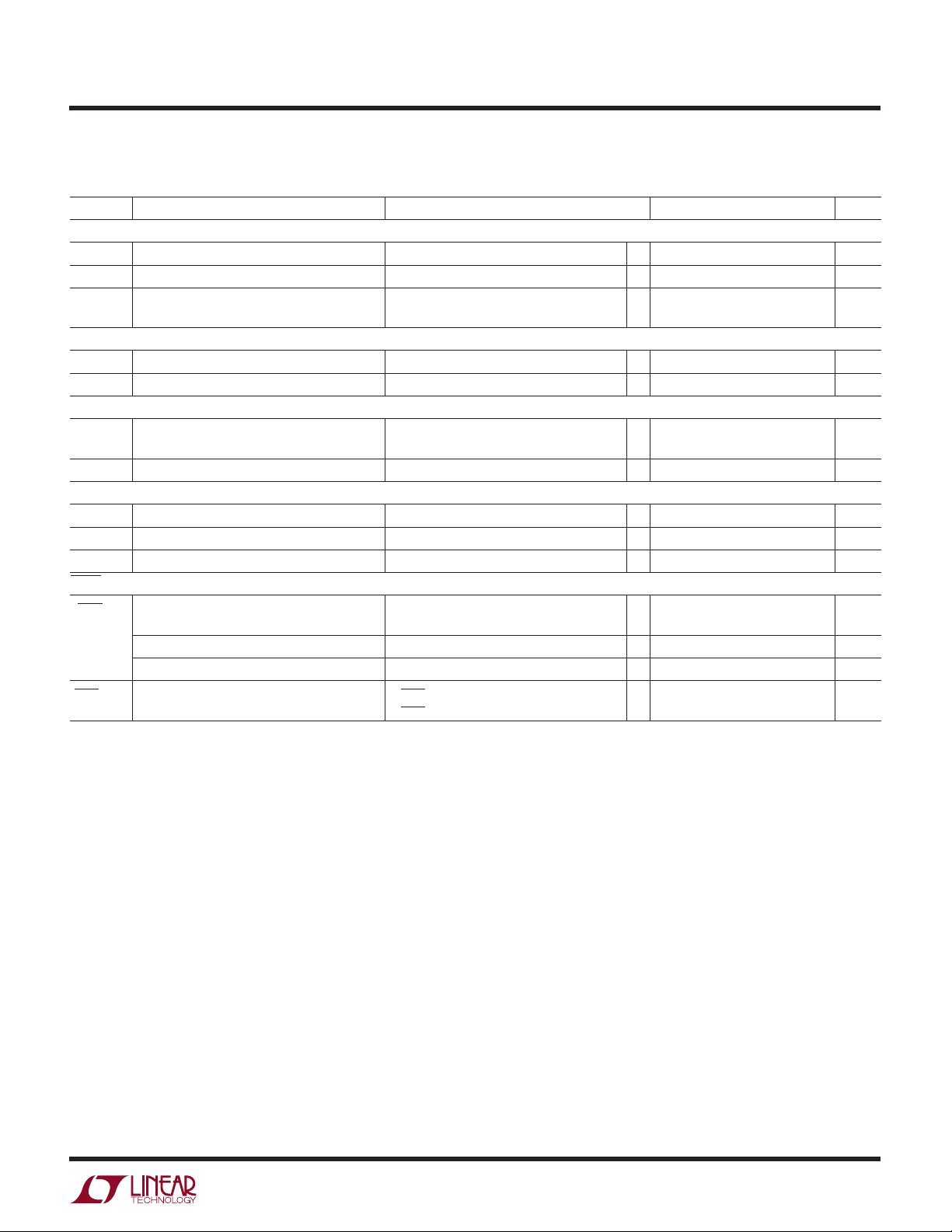

1

LT1777

TOP VIEW

S PACKAGE

16-LEAD PLASTIC SO

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

GND*

NC

SHDN

V

CC

V

D

V

SW

SGND

GND*

GND*

NC

V

C

FB

SYNC

NC

V

IN

GND*

WW

W

ABSOLUTE MAXIMUM RATINGS

U

PACKAGE

/

O

RDER I FOR ATIO

WU

(Note 1)

Supply Voltage ....................................................... 48V

Switch Voltage (VIN – VSW) (Note 4) ...................... 51V

ORDER PART

NUMBER

SHDN, SYNC Pin Voltage.......................................... 7V

VCC Pin Voltage ...................................................... 30V

FB Pin Voltage ........................................................ 3.0V

LT1777CS

LT1777IS

Operating Junction Temperature Range

LT1777C............................................... 0°C to 125°C

LT1777I ........................................... –40°C to 125°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

T

= 125°C, θJA = 50°C/W*

JMAX

Consult factory for Military grade parts.

*FOUR CORNER PINS ARE

FUSED TO INTERNAL DIE

ATTACH PADDLE FOR HEAT

SINKING. CONNECT THESE

FOUR PINS TO EXPANDED PC

LANDS FOR PROPER HEAT

SINKING.

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are at TJ = 25°C.

VIN = 24V, VSW Open, VCC = 5V, VC = 1.4V unless otherwise noted.

U

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Power Supplies

V

IN(MIN)

I

VIN

I

VCC

V

VCC

Feedback Amplifier

V

REF

I

IN

g

m

I

, I

SRC

V

CL

2

Minimum Input Voltage 6.7 7.0 V

● 7.4 V

VIN Supply Current VC = 0V 620 800 µA

● 900 µA

VCC Supply Current VC = 0V 2.5 3.5 mA

● 4.5 mA

VCC Dropout Voltage (Note 2) ● 2.8 3.1 V

Shutdown Mode I

Reference Voltage 1.225 1.240 1.255 V

FB Pin Input Bias Current 600 1500 nA

Feedback Amplifier Transconductance ∆IC = ±10µA 400 650 1000 µmho

Feedback Amplifier Source or Sink Current 60 100 170 µA

SNK

Feedback Amplifier Clamp Voltage 2.0 V

Reference Voltage Line Regulation 12V ≤ VIN ≤ 48V ● 0.01 %/V

Voltage Gain 200 600 V/V

VIN

V

= 0V 30 50 µA

SHDN

● 75 µA

● 1.215 1.265 V

● 200 1500 µmho

● 45 220 µA

LT1777

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are at TJ = 25°C.

VIN = 24V, VSW Open, VCC = 5V, VC = 1.4V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Output Switch

R

ON

I

LIM

Current Amplifier

Timing

f Switching Frequency 90 100 110 kHz

Sync Function

SHDN Pin Function

V

SHDN

I

SHDN

Output Switch On Voltage ISW = 0.5A 1.0 1.5 V

Switch Current Limit (Note 3) ● 0.55 0.70 1.0 A

Output dl/dt Sense Voltage 1.3 V

● 0.6 2.0 V

Control Pin Threshold Duty Cycle = 0% 0.9 1.1 1.25 V

Control Voltage to Switch Transconductance 2 A/V

● 85 115 kHz

Maximum Switch Duty Cycle ● 85 90 %

Minimum Sync Amplitude ● 1.5 2.2 V

Synchronization Range ● 130 250 kHz

SYNC Pin Input R 40 kΩ

Shutdown Mode Threshold 0.5 V

● 0.2 0.8 V

Upper Lockout Threshold Switching Action On 1.260 V

Lower Lockout Threshold Switching Action Off 1.245 V

Shutdown Pin Current V

= 0V 12 20 µA

SHDN

V

= 1.25V 2.5 10 µA

SHDN

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Control circuitry powered from V

Note 3: Switch current limit is DC trimmed and tested in production.

Inductor dI/dt rate will cause a somewhat higher current limit in actual

application.

CC

.

Note 4: During normal operation the V

below ground. However, the LT1777 may not be used in an inverting

DC/DC configuration.

pin may fly as much as 3V

SW

3

LT1777

UW

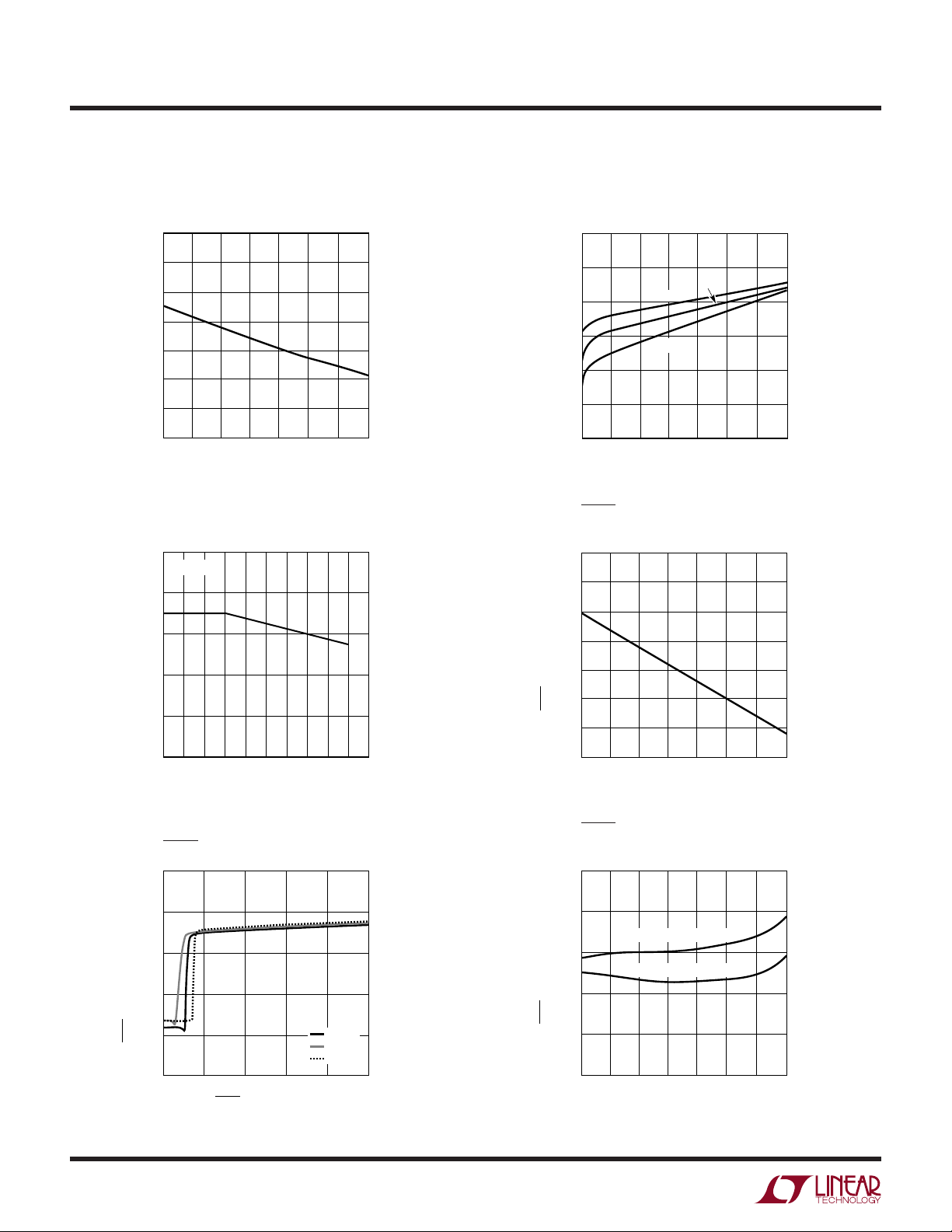

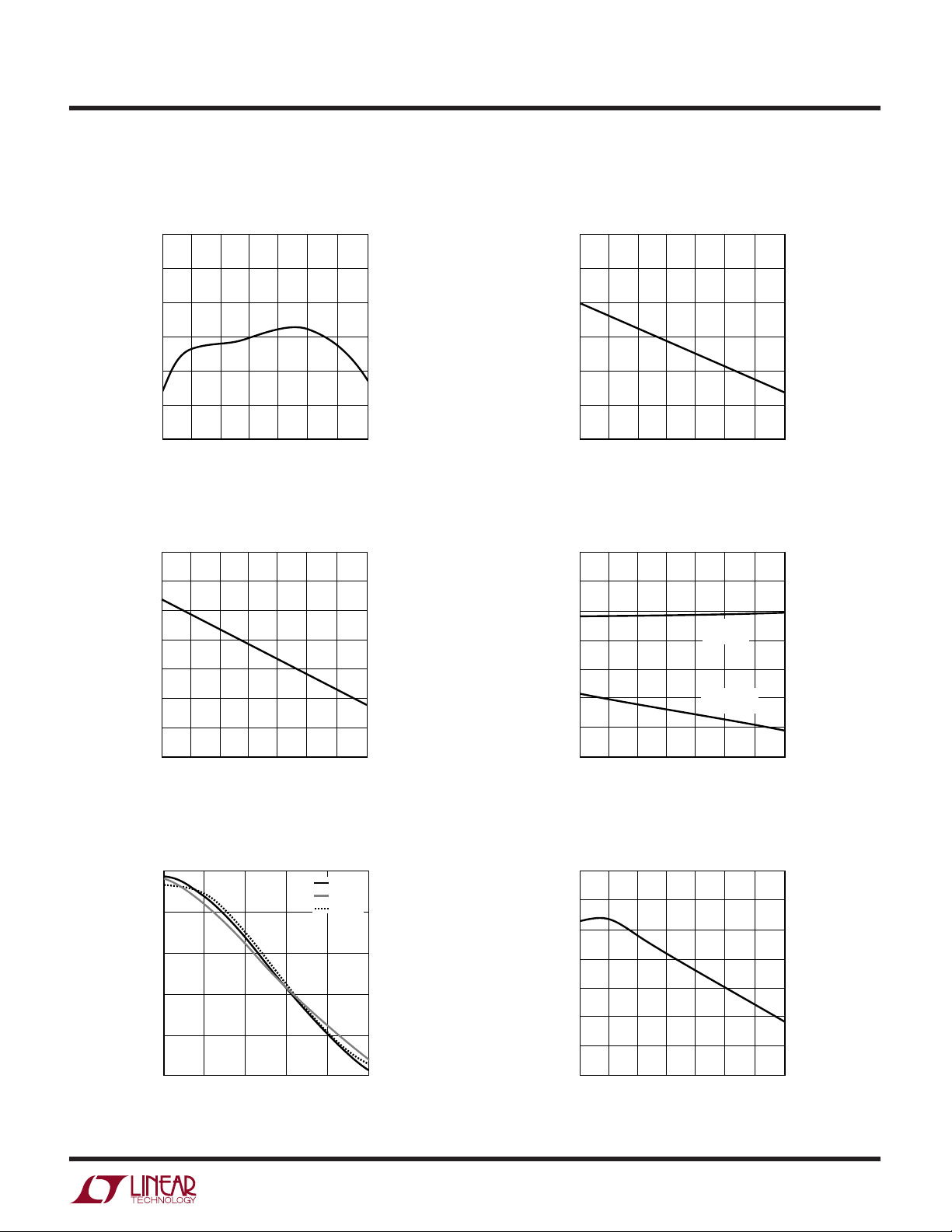

TYPICAL PERFOR A CE CHARACTERISTICS

Minimum Input Voltage

vs Temperature

7.4

7.2

7.0

6.8

6.6

INPUT VOLTAGE (V)

6.4

6.2

6.0

–50

–25 0

TEMPERATURE (°C)

Switch Current Limit

vs Duty Cycle

1000

TA = 25°C

800

600

50 100 125

25 75

1777 G01

Switch On Voltage

vs Switch Current

1.50

1.25

1.00

0.75

0.50

SWITCH VOLTAGE (V)

0.25

0

0

100 200

SWITCH CURRENT (mA)

–55°C

125°C

25°C

400 600 700

300 500

SHDN Pin Shutdown Threshold

vs Temperature

900

800

700

600

1777 G02

400

200

SWITCH CURRENT LIMIT (mA)

0

2010 30 50 70 90

0

40

DUTY CYCLE (%)

SHDN Pin Current vs Voltage

5

0

–5

–10

–15

SHDN PIN INPUT CURRENT (µA)

–20

1

0

2

SHDN PIN VOLTAGE (V)

500

400

SHDN PIN VOLTAGE (mV)

300

60

80

100

1777 G03

200

–50

–25 0

50 100 125

25 75

TEMPERATURE (°C)

1777 G04

SHDN Pin Lockout Thresholds

vs Temperature

1.30

1.28

UPPER THRESHOLD

1.26

LOWER THRESHOLD

1.24

25°C

125°C

–55°C

3

4

5

1777 G05

SHDN PIN VOLTAGE (V)

1.22

1.20

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

1777 G06

4

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LT1777

Switching Frequency

vs Temperature

106

104

102

100

98

SWITCHING FREQUENCY (kHz)

96

94

–50 25 75

–25 0

TEMPERATURE (°C)

Output dI/dt Sense Voltage

vs Temperature

2.0

1.8

1.6

1.4

50 100 125

1777 G07

Minimum Synchronization

Voltage vs Temperature

2.25

2.00

1.75

1.50

1.25

1.00

MINIMUM SYNCHRONIZATION VOLTAGE (V)

0.75

–50 25 75

–25 0

TEMPERATURE (°C)

50 100 125

VC Pin Switching Threshold,

Clamp Voltage vs Temperature

2.2

2.0

1.8

1.6

CLAMP

VOLTAGE

1777 G08

1.2

1.0

dI/dt SENSE VOLTAGE (V)

0.8

0.6

–50 25 75

–25 0

TEMPERATURE (°C)

Feedback Amplifier Output

Current vs FB Pin Voltage

100

50

0

–50

–100

FEEDBACK AMPLIFIER OUTPUT CURRENT (µA)

–150

1.0

1.1

1.2

FB PIN VOLTAGE (V)

50 100 125

1777 G09

25°C

125°C

–55°C

1.3

1.4

1777 G11

1.5

1.4

PIN VOLTAGE (V)

C

V

1.2

1.0

0.8

–50

–25 0

TEMPERATURE (°C)

SWITCHING

THRESHOLD

50 100 125

25 75

Error Amplifier Transconductance

vs Temperature

750

700

650

600

550

500

TRANSCONDUCTANCE (µmho)

450

400

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

1777 G10

1777 G12

5

LT1777

PIN FUNCTIONS

UUU

GND (Pins 1, 8, 9, 16): These corner package pins are

mechanically connected to the die paddle and thus aid in

conducting away internally generated heat. As these are

electrically connected to the die substrate, they must be

held at ground potential. A direct connection to the local

ground plane is recommended.

NC (Pins 2, 11, 15): Package Pins 2, 11 and 15 are

unconnected.

SHDN (Pin 3): When pulled below the shutdown mode

threshold, nominally 0.5V, this pin turns off the regulator

and reduces VIN input current to a few tens of microamperes (shutdown mode).

When this pin is held above the shutdown mode threshold,

but below the lockout threshold, the part will be operational with the exception that output switching action will

be inhibited (lockout mode). A user-adjustable undervoltage lockout can be implemented by driving this pin from

an external resistor divider to VIN. This action is logically

“ANDed” with the internal UVLO, nominally set at 6.7V,

such that minimum VIN can be increased above 6.7V, but

not decreased (see Applications Information).

If unused, this pin should be left open. However, the high

impedance nature of this pin renders it susceptible to

coupling from the VSW node, so a small capacitor to

ground, typically 100pF or so is recommended when the

pin is left open.

VCC: (Pin 4): Pin to power the internal control circuitry

from the switching supply output. Proper use of this pin

enhances overall power supply efficiency. During start-up

conditions, internal control circuitry is powered directly

from VIN. If the output capacitor is located more than an

inch from the VCC pin, a separate 0.1µF bypass capacitor

to ground may be required right at the pin.

VD (Pin 5): This pin is used in conjunction with a small

external sense inductor to limit power path dI/dt. The

sense inductor is placed between the VSW output node and

the cathode of the freewheeling (power) diode, and the V

pin is connected to the diode. As the voltage across the

inductor reaches ±2VBE, drive to the output transistor is

D

removed or supplied accordingly to limit dI/dt (see Applications Information).

VSW (Pin 6): This is the emitter node of the output switch

and has large currents flowing through it. Keep the traces

to the switching components as short as possible to

minimize electromagnetic radiation and voltage spikes.

SGND (Pin 7): This is the device signal ground pin. The

internal reference and feedback amplifier are referred to it.

Keep the ground path connection to the FB divider and the

VC compensation capacitor free of large ground currents.

VIN (Pin 10): This is the high voltage supply pin for the

output switch. It also supplies power to the internal control

circuitry during start-up conditions or if the VCC pin is left

open. A high quality bypass capacitor which meets the

input ripple current requirements is needed here (see

Applications Information).

SYNC (Pin 12): Pin to synchronize internal oscillator to

external frequency reference. It is directly logic compatible and can be driven with any signal between 10% and

90% duty cycle. The sync function is internally disabled if

the FB pin voltage is low enough to cause oscillator

slowdown. If unused, this pin should be grounded.

FB (Pin 13): This is the inverting input to the feedback

amplifier. The noninverting input of this amplifier is internally tied to the 1.24V reference. This pin also slows down

the frequency of the internal oscillator when its voltage is

abnormally low, e.g. 2/3 of normal or less. This feature

helps maintain proper short-circuit protection. Coupling

from high speed noise to this pin can cause irregular

operation. (See Switch Node Considerations section.)

VC (Pin 14): This is the control voltage pin which is the

output of the feedback amplifier and the input of the

current comparator. Frequency compensation of the overall loop is effected by placing a capacitor (or in most cases

a series R/C combination) between this node and ground.

Coupling from high speed noise to this pin can cause

irregular operation. (See Switch Node Considerations

section.)

6

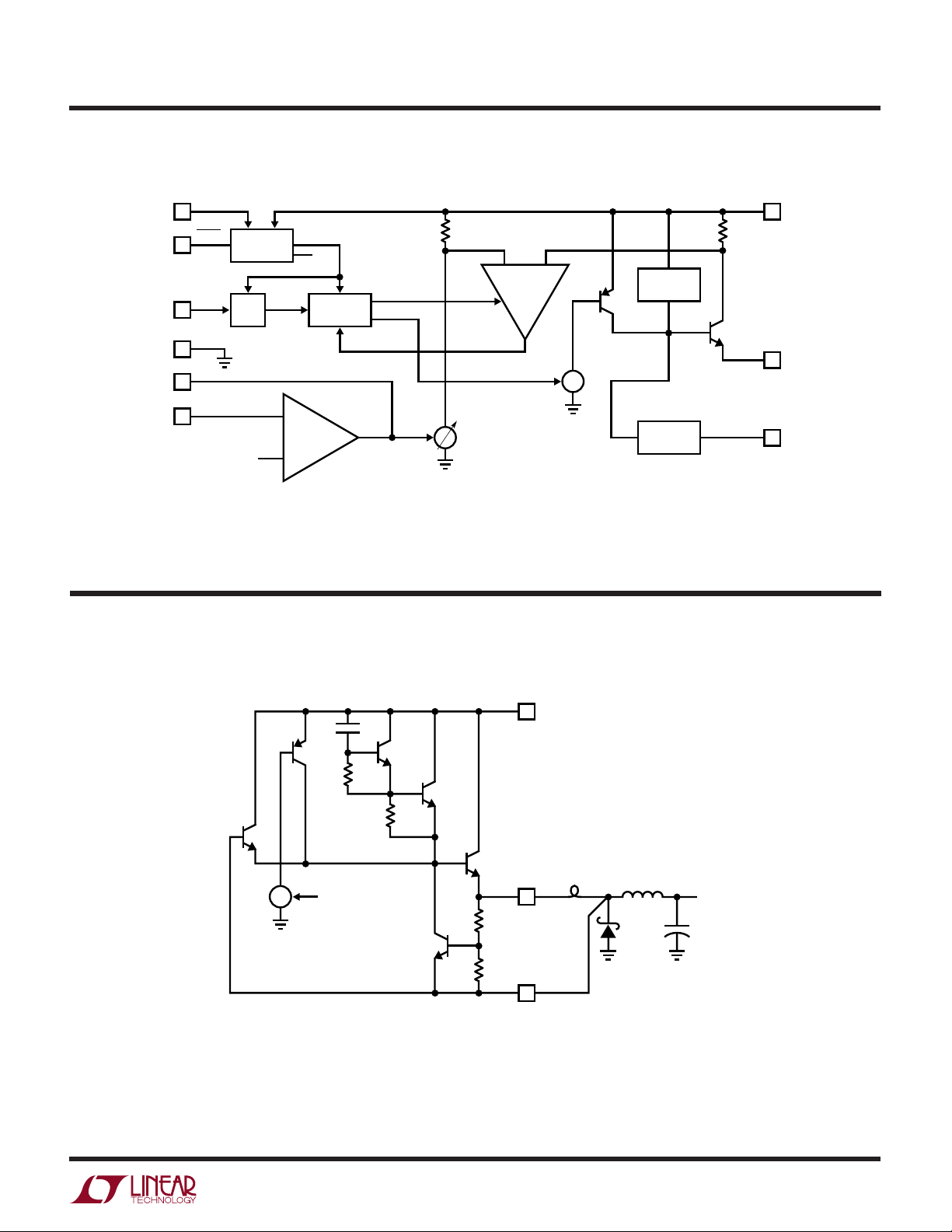

BLOCK DIAGRA

LT1777

W

V

CC

4

V

V

BG

LOGIC

FEEDBACK

AMP

g

m

B

SWDR

SWON

SHDN

3

SYNC

12

SGND

7

V

C

14

FB

13

OSC

V

BG

BIAS

R1

I

I

2

WW

OUTPUT STAGE SI PLIFIED SCHE ATIC

I

COMP

V

IN

10

R

SENSE

–dV/dt

LIMITER

Q2

Q1

V

SW

6

I

1

I

V

±dI/dt

LIMITER

1777 BD

D

5

V

C1

Q3Q2

R1

Q4

R2

Q6

Q1

I

1

SWITCH ON

I

SIGNAL

R3

Q5

R4

IN

L

V

SW

SENSE

L

MAIN

V

OUT

+

V

D

1777 SS

NOTE: R3 = R4

7

LT1777

OPERATIO

U

The LT1777 is a current mode step-down switcher regulator IC designed for low noise operation. The Block

Diagram shows an overall view of the system. The individual blocks are straightforward and similar to those

found in traditional designs, including: Internal Bias Regulator, Oscillator, Logic, and Feedback Amplifier. The novel

portion includes a specialized Output Switch section including circuits to limit the dI/dt and dV/dt switching rates.

The LT1777 operates much the same as traditional current

mode switchers, the major difference being its specialized

output switch section. Due to space constraints, this

discussion will not reiterate the basics of current mode

switcher/controllers and the “buck” topology. A good

source of information on these topics is Application Note

AN19.

A straightforward output stage is provided by current

source I1 driving the base of PNP transistor Q2. The

collector of Q2 in turn drives the base of NPN output device

Q1. The considerable base/collector capacitance of PNP

Q2 acts to limit dV/dt rate during switch turn-on. However,

when the switch is to be turned off, the only natural limit

to voltage slew rate would be the collector/base capacitance of Q1 providing drive for the same device. While

dependent upon output load level and Q1’s β, the turn-off

voltage slew rate would be typically much faster than the

turn-on rate. To limit the voltage slew rate on switch turnoff, an extra function is supplied. This is denoted by the

block labeled “–dV/dt Limiter.”

The details of the – dV/dt Limiter can be seen in the Output

Stage Simplified Schematic. Transistors Q3 and Q4 are

connected in a Darlington configuration whose input is

coupled with small-valued capacitor C1 to the VIN supply

rail. The product of negative voltage slew rate times this

capacitor value equals current, and when this current

through emitter/base resistor R1 exceeds a diode drop, Q3

and then Q4 turn on supplying base drive to output device

Q1 to limit –dV/dt rate.

In addition to voltage rates, the current slew rate also

needs to be controlled for reduced noise behavior. This is

provided by the section in the Block Diagram labeled

“±dI/dt Limiter.” The details of this circuit can be seen in

the Output Stage Simplified Schematic. Note that an extra,

small-valued inductor, termed the “sense inductor” has

been added to the classic buck topology. As this inductor

is external to the LT1777, its value can be chosen by the

user allowing for optimization on a per application basis.

Operation of the current slew limiter is as follows: The

product of the sense inductor times the dI/dt through it

generates a voltage according to the well known formula

V = (L)(dI/dt). The remainder of the circuit is configured

such that when the voltage across the sense inductor

reaches ±2VBE, drive current will be supplied or removed

as necessary to limit current slew rate. The actual sensing

is performed between the output node labeled VSW and a

new node labeled VD.

In the case of switch turn-on, current drive is provided by

PNP Q2. If the voltage at VSW reaches 2VBE above that at

VD, transistor Q5 turns on and removes a portion of Q2’s

drive from Q1’s base. Similarly for turn-off, as the V

node goes 2VBE below VD, transistor Q6 then turns on to

drive Q1’s base as needed. The net effect is that of limiting

the switch node dI/dt in both directions at a rate inversely

proportional to the external sense inductor value.

SW

8

Loading...

Loading...