FEATURES

LT1737

High Power

Isolated Flyback Controller

U

DESCRIPTIO

■

Drives External Power MOSFET

■

Supply Voltage Range: 4.5V to 20V

■

Flyback Voltage Limited Only by

External Components

■

Senses Output Voltage Directly from Primary Side

Winding—No Optoisolator Required

■

Switching Frequency from 50kHz to 250kHz

with External Capacitor

■

Moderate Accuracy Regulation Without User Trims

■

Regulation Maintained Well into Discontinuous Mode

■

External I

■

Optional Load Compensation

■

Optional Undervoltage Lockout

■

Shutdown Feature Reduces IQ to 50µA Typ

■

Available in 16-Pin GN and SO Packages

SENSE

Resistor

U

APPLICATIO S

■

Isolated Flyback Switching Regulators

■

Medical Instruments

■

Instrumentation Power Supplies

The LT®1737 is a monolithic switching regulator controller specifically designed for the isolated flyback topology.

It drives the gate of an external MOSFET and is generally

powered from a DC supply voltage. Output voltage feedback information may be supplied by a variety of methods

including a third transformer winding, the primary winding or even direct DC feedback (see Applications Information). Its gate drive capability, coupled with a suitable

external MOSFET and other power path components, can

deliver load power up to tens of Watts.

The LT1737 has a number of features not found on other

isolated flyback controller ICs. By utilizing current mode

switching techniques, it provides excellent AC and DC line

regulation. Its unique control circuitry can maintain regulation well into discontinuous mode in most applications.

Optional load compensation circuitry allows for improved

load regulation. An optional undervoltage lockout pin

halts operation when the application input voltage is too

low. An optional external capacitor implements a softstart function.

, LTC and LT are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

TYPICAL APPLICATIO

R2

35.7k

1%

D2

R3

3.01k

1%

BAS16

FB

V

1nF

UVLO

C

ON

47pF

Q1

2N3906

U

12V-18V to Isolated 15V Converter

240k

V

CC

OCMP

R

C3

0.1µF

CMPC

33k

LT1737

R

MINENAB

ENDLYOSCAP t

75k 150k 100k 4.7k 0.1µF

22µF

SGND

V

IN

+

C1

GATE

I

SENSE

PGND

T1

COILTRONICS

CTX150-4

•

150µH 150µH

•

M1

IRFL014

R1

0.27Ω

D1

MBRS1100

+

C2

33µF

NOTE: SEE APPLICATIONS

INFORMATION FOR ADDITIONAL

COMPONENT SPECIFICATIONS

R4

7.5k

V

I

OUT

OUT

= 15V

= 300mA

1737 TA01

1737fa

1

LT1737

PACKAGE/ORDER I FOR ATIO

UU

W

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

VCC Supply Voltage................................................. 22V

UVLO Pin Voltage .................................................... V

I

Pin Voltage .................................................... 2V

SENSE

FB Pin Current ..................................................... ± 2mA

Operating Junction

Temperature Range

LT1737C ............................................... 0°C to 100°C

LT1737I ............................................ –40°C to 125°C

Storage Temperature Range ................ – 65°C to 150°C

Lead Temperature (Soldering, 10 sec)................ 300°C

CC

TOP VIEW

1

PGND

2

I

SENSE

3

SFST

4

R

OCMP

5

R

CMPC

6

OSCAP

7

V

C

8

FB

GN PACKAGE

16-LEAD PLASTIC SSOP

T

= 125°C, θJA = 110°C/W (GN)

JMAX

= 125°C, θJA = 110°C/W (SO)

T

JMAX

16

GATE

15

V

CC

14

t

ON

13

ENDLY

12

MINENAB

11

SGND

10

UVLO

9

3V

OUT

S PACKAGE

16-LEAD PLASTIC SO

ORDER PART

NUMBER

LT1737CGN

LT1737CS

LT1737IGN

LT1737IS

GN PART MARKING

1737

1737I

Consult LTC Marketing for parts specified with wider operating temperature ranges.

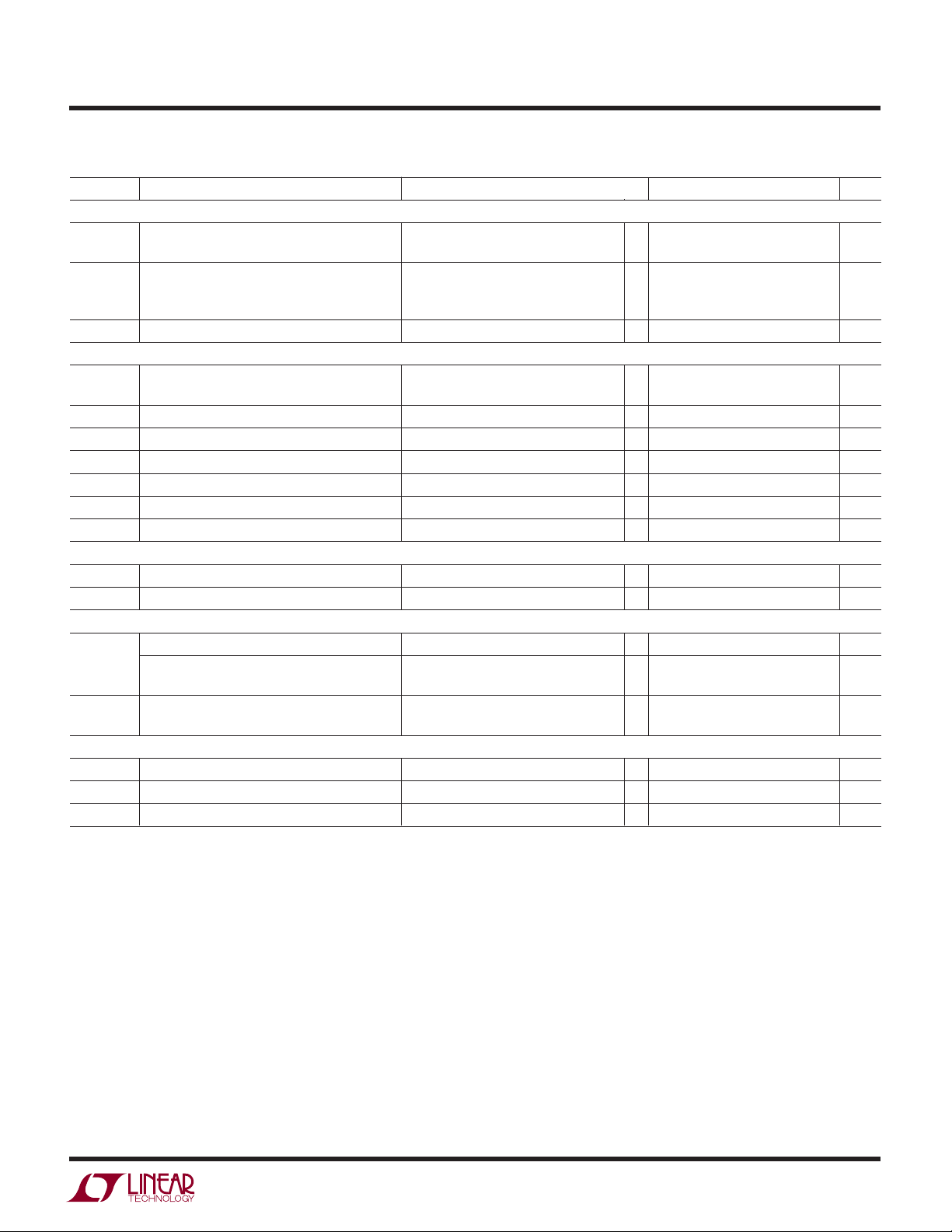

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VCC = 14V, GATE open, VC = 1.4V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Power Supply

V

CC(MIN)

I

CC

Feedback Amplifier

V

FB

I

FB

g

m

I

, I

SRC

V

CL

Gate Output

V

GATE

I

GATE

t

r

t

f

Minimum Input Voltage ● 4.1 4.5 V

Supply Current VC = Open ● 10 15 mA

Shutdown Current V

= 0V, VC = Open ● 50 150 µA

UVLO

Feedback Voltage 1.230 1.245 1.260 V

● 1.220 1.270 V

Feedback Pin Input Current 500 nA

Feedback Amplifier Transconductance ∆lC = ±10µA ● 400 1000 1800 µmho

Feedback Amplifier Source or Sink Current ● 30 50 80 µA

SNK

Feedback Amplifier Clamp Voltage 2.5 V

Reference Voltage/Current Line Regulation 4.75V ≤ VIN ≤ 18V ● 0.01 0.05 %/V

Voltage Gain VC = 1V to 2V 2000 V/V

Soft-Start Charging Current V

Soft-Start Discharge Current V

Output High Level I

Output Low Level I

Output Sink Current in Shutdown, V

UVLO

= 0V V

= 0V 25 40 50 µA

SFST

= 1.5V, V

SFST

= 100mA ● 11.5 12.1 V

GATE

= 500mA ● 11.0 11.8 V

I

GATE

= 100mA ● 0.3 0.45 V

GATE

I

= 500mA ● 0.6 1.0 V

GATE

= 2V ● 1.2 2.5 mA

GATE

= 0V 0.8 1.5 mA

UVLO

Rise Time CL = 1000pF 30 ns

Fall Time CL = 1000pF 30 ns

2

1737fa

LT1737

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● denotes specifications which apply over the full operating

= 25°C. VCC = 14V, GATE open, VC = 1.4V unless otherwise noted.

A

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Current Amplifier

V

C

V

ISENSE

Control Pin Threshold Duty Cycle = Min 0.90 1.12 1.25 V

● 0.80 1.35 V

Switch Current Limit Duty Cycle ≤ 30% 220 250 270 mV

Duty Cycle ≤ 30%

● 200 280 mV

Duty Cycle = 80% 220 mV

∆V

ISENSE

/∆V

C

0.30 mV

Timing

f Switching Frequency C

C

OSCAP

t

ON

t

ED

t

EN

R

t

Oscillator Capacitor Value (Note 2) 33 200 pF

Minimum Switch On Time R

Flyback Enable Delay Time R

Minimum Flyback Enable Time R

Timing Resistor Value (Note 2) 24 240 kΩ

= 100pF 90 100 115 kHz

OSCAP

= 50k 200 ns

tON

= 50k 200 ns

ENDLY

= 50k 200 ns

MENAB

● 80 125 kHz

Maximum Switch Duty Cycle ● 85 90 %

Load Compensation

Sense Offset Voltage 25mV

Current Gain Factor 0.80 0.95 1.05 mV

UVLO Function

V

UVLO

UVLO Pin Lockout Threshold ● 1.21 1.25 1.29 V

UVLO Pin Shutdown Threshold 0.75 V

● 0.4 0.95 V

I

UVLO

UVLO Pin Bias Current V

= 1.2V –0.25 + 0.1 +0.25 µA

UVLO

= 1.3V –4.50 – 3.5 –2.50 µA

V

UVLO

3V Output Function

V

REF

Reference Output Voltage I

= 1mA ● 2.8 3.0 3.2 V

LOAD

Output Impedance 10 Ω

Current Limit ● 815 mA

Note 1: Absolute Maximum Ratings are those values beyond which the life of

a device may be impaired.

Note 2: Component value range guaranteed by design.

1737fa

3

LT1737

UW

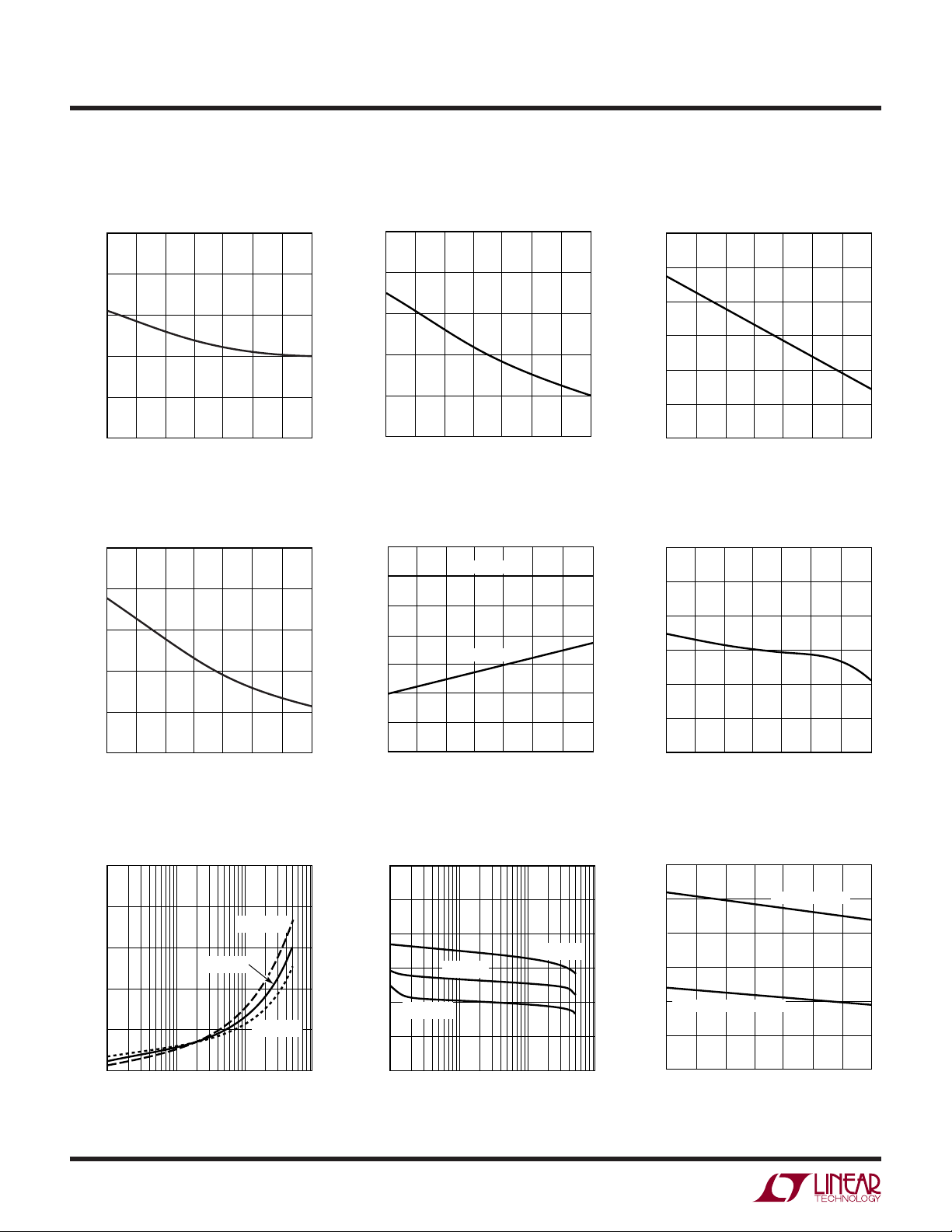

TYPICAL PERFOR A CE CHARACTERISTICS

Minimum Input Voltage vs

Temperature Shutdown I

4.3

4.2

4.1

4.0

3.9

MINIMUM INPUT VOLTAGE (V)

3.8

–50

–25

25

0

TEMPERATURE (°C)

50

75

100

125

1737 G01

125

100

(µA)

75

CC

50

SHUTDOWN I

25

0

–50

UVLO Pin Input Current vs

Supply Current vs Temperature

13

12

11

10

SUPPLY CURRENT (mA)

9

Temperature

1

0

–1

–2

–3

–4

UVLO PIN INPUT CURRENT (µA)

–5

0

–25

TEMPERATURE (°C)

vs Temperature

CC

50

V

UVLO

V

25

UVLO

75

= 1.2V

= 1.3V

100

1737 G02

125

Shutdown Voltage (V

Temperature

1.0

0.9

(V)

UVLO

0.8

0.7

0.6

SHUTDOWN VOLTAGE V

0.5

0.4

–50

–25 0

25 75

TEMPERATURE (°C)

Oscillator Frequency vs

Temperature

115

110

105

100

95

OSCILLATOR FREQUENCY (kHz)

90

) vs

UVLO

50 100 125

1737 G03

(V)

GATE

V

4

1.0

0.8

0.6

0.4

0.2

8

0

–50

V

1

–25

GATE

0

TEMPERATURE (°C)

vs I

SINK

10 100 1000

I

SINK

75

TA = 125°C

TA = 25°C

(mA)

50

25

100

1737 G04

TA = –55°C

1737 G07

125

–0.5

–1.0

(V)

GATE

–1.5

-V

CC

V

–2.0

–2.5

–3.0

–6

–50

0

1

–25 0

VCC-V

TA = –55°C

50 100 125

25 75

TEMPERATURE (°C)

vs I

GATE

SOURCE

TA = 125°C

TA = 25°C

10 100 1000

I

(mA)

SOURCE

1737 G05

1737 G08

85

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

VC Clamp Voltage, Switching

Threshold vs Temperature

3.0

2.5

2.0

1.5

1.0

SWITCHING THRESHOLD

0.5

CLAMP VOLTAGE, SWITCHING THRESHOLD (V)

C

0

V

–50

–25 0

TEMPERATURE (°C)

CLAMP VOLTAGE

50 100 125

25 75

1737 G06

1737 G09

1737fa

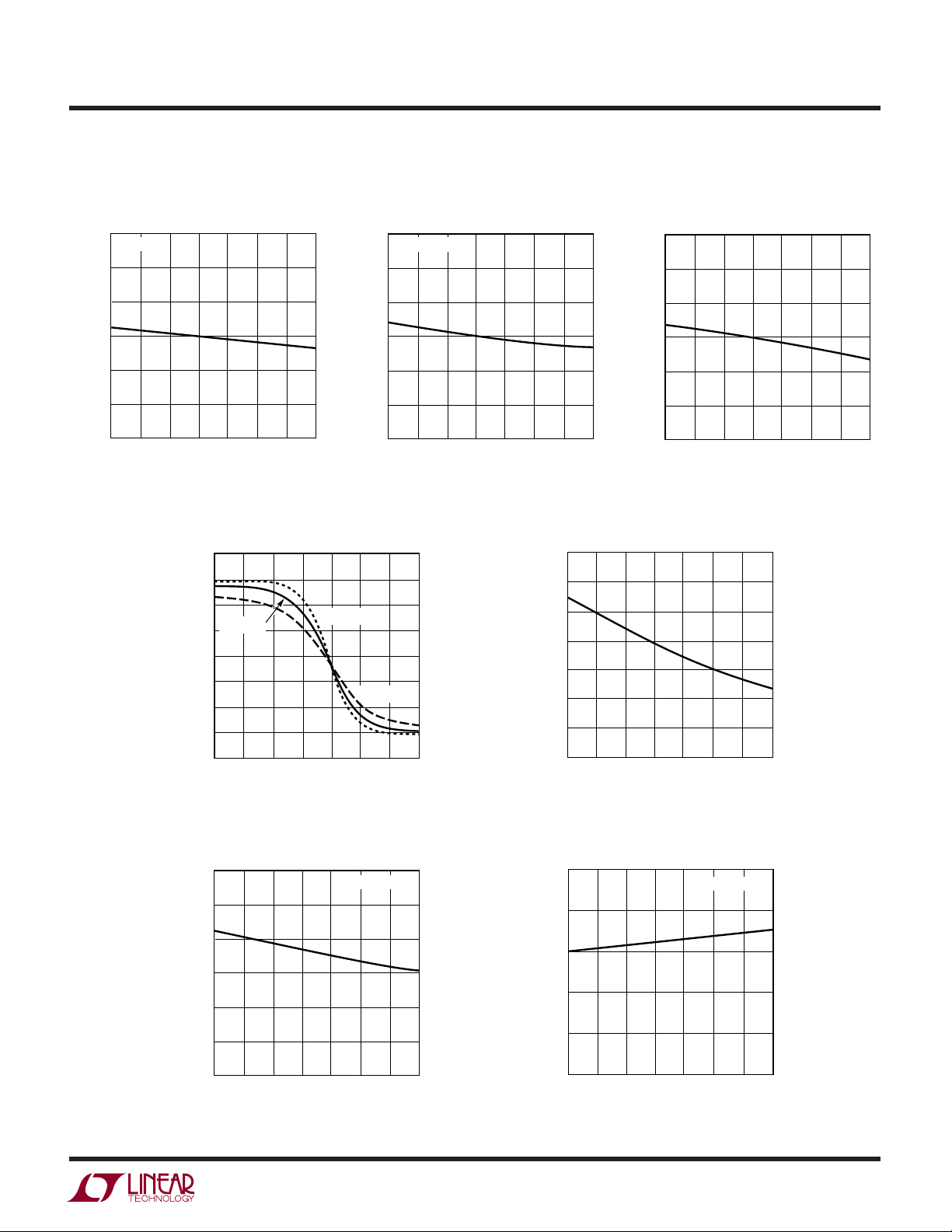

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LT1737

Minimum Switch On Time vs

Temperature

275

R

= 50k

TON

250

225

200

175

MINIMUM SWITCH ON TIME (ns)

150

125

–50

–25 0

25 75

TEMPERATURE (°C)

Feedback Amplifier Output Current

vs FB Pin Voltage

80

60

40

20

0

–20

–40

–60

FEEDBACK AMPLIFIER OUTPUT CURRENT (µA)

–80

1.05

Minimum Enable Time vs

Temperature

275

250

225

200

175

MINIMUM ENABLE TIME (ns)

150

50 100 125

1737 G10

TA = 25°C

1.15 1.25

1.10 1.20 1.30 1.40

TA = –55°C

FB PIN VOLTAGE (V)

125

–50

TA = 125°C

1.35

R

MINENAB

–25 0

1737 G13

= 50k

25 75

TEMPERATURE (°C)

50 100 125

1737 G11

Feedback Amplifier

Transconductance vs Temperature

1600

1400

1200

1000

800

600

400

200

–50

FEEDBACK AMPLIFIER TRANSCONDUCTANCE (µmho)

–25 0

Enable Delay Time vs

Temperature

275

250

225

200

175

ENABLE DELAY TIME (ns)

150

125

–50

–25 0

50 100 125

25 75

TEMPERATURE (°C)

50 100 125

25 75

TEMPERATURE (°C)

1737 G14

1737 G12

Soft-Start Charging Current vs

Temperature

60

50

40

30

20

10

SOFT-START CHARGING CURRENT (µA)

0

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

V(SFST) = 0V

1737 G15

Soft-Start Sink Current vs

Temperature

2.5

2.0

1.5

1.0

0.5

SOFT-START SINK CURRENT (mA)

0

–50

0

–25

TEMPERATURE (°C)

50

25

V(SFST) = 1.5V

75

100

125

1737 G16

1737fa

5

LT1737

U

UU

PI FU CTIO S

PGND (Pin 1): The power ground pin carries the GATE

node discharge current. This is typically a current spike of

several hundred mA with a duration of tens of nanoseconds. It should be connected directly to a good quality

ground plane.

(Pin 2): Pin to measure switch current with external

I

SENSE

sense resistor. The sense resistor should be of a noninductive construction as high speed performance is essential. Proper grounding technique is also required to avoid

distortion of the high speed current waveform. A preset

internal limit of nominally 250mV at this pin effects a

switch current limit.

SFST (Pin 3): Pin for optional external capacitor to effect

soft-start function. See Applications Information for

details.

R

(Pin 4): Input pin for optional external load com-

OCMP

pensation resistor. Use of this pin allows nominal compensation for nonzero output impedance in the power

transformer secondary circuit, including secondary winding impedance, output Schottky diode impedance and

output capacitor ESR. In less demanding applications, this

resistor is not needed. See Applications Information for

more details.

R

(Pin 5): Pin for external filter capacitor for optional

CMPC

load compensation function. A common 0.1µF ceramic

capacitor will suffice for most applications. See Applications Information for further details.

OSCAP (Pin 6): Pin for external timing capacitor to set

oscillator switching frequency. See Applications Information for details.

VC (pin 7):

output of the feedback amplifier and the input of the

current comparator. Frequency compensation of the

overall loop is effected in most cases by placing a

capacitor between this node and ground.

This is the control voltage pin which is the

3V

(Pin 9): Output pin for nominal 3V reference. This

OUT

facilitates various user applications. This node is internally

current limited for protection and is intended to drive

either moderate capacitive loads of several hundred pF or

less, or, very large capacitive loads of 0.1µF or more. See

Applications Information for more details.

UVLO (Pin 10): This is a dual function pin that implements

both undervoltage lockout and shutdown functions. Pulling this pin to near ground effects shutdown and reduces

quiescent current to tens of microamperes.

Additionally, an external resistor divider between VIN and

ground may be connected to this pin to implement an

undervoltage lockout function. The bias current on this pin

is a function of the state of the UVLO comparator; as the

threshold is exceeded, the bias current increases. This

creates a hysteresis band equal to the change in bias

current times the Thevenin impedance of the user’s resistive divider. The user may thereby adjust the impedance of

the UVLO divider to achieve a desired degree of hysteresis.

A 100pF capacitor to ground is recommended on this pin.

See Application Information for details.

SGND (Pin 11): The signal ground pin is a clean ground.

The internal reference, oscillator and feedback amplifier

are referred to it. Keep the ground path connection to the

FB pin, OSCAP capacitor and the VC compensation capacitor free of large ground currents.

MINENAB (Pin 12): Pin for external programming resistor

to set minimum enable time. See Applications Information

for details.

ENDLY (Pin 13): Pin for external programming resistor to

set enable delay time. See Applications Information for

details.

tON (Pin 14): Pin for external programming resistor to set

switch minimum on time. See Applications Information

for details.

FB (Pin 8): Input pin for external “feedback” resistor

divider. The ratio of this divider, times the internal bandgap (VBG) reference, times the effective transformer turns

ratio is the primary determinant of the output voltage. The

Thevenin equivalent resistance of the feedback divider

should be roughly 3k. See Applications Information for

more details.

6

VCC (Pin 15): Supply voltage for the LT1737. Bypass this

pin to ground with 1µF or more.

GATE (Pin 16): This is the gate drive to the external power

MOSFET switch and has large dynamic currents flowing

through it. Keep the trace to the MOSFET as short as

possible to minimize electromagnetic radiation and voltage spikes. A series resistance of 5Ω or more may help to

dampen ringing in less than ideal layouts.

1737fa

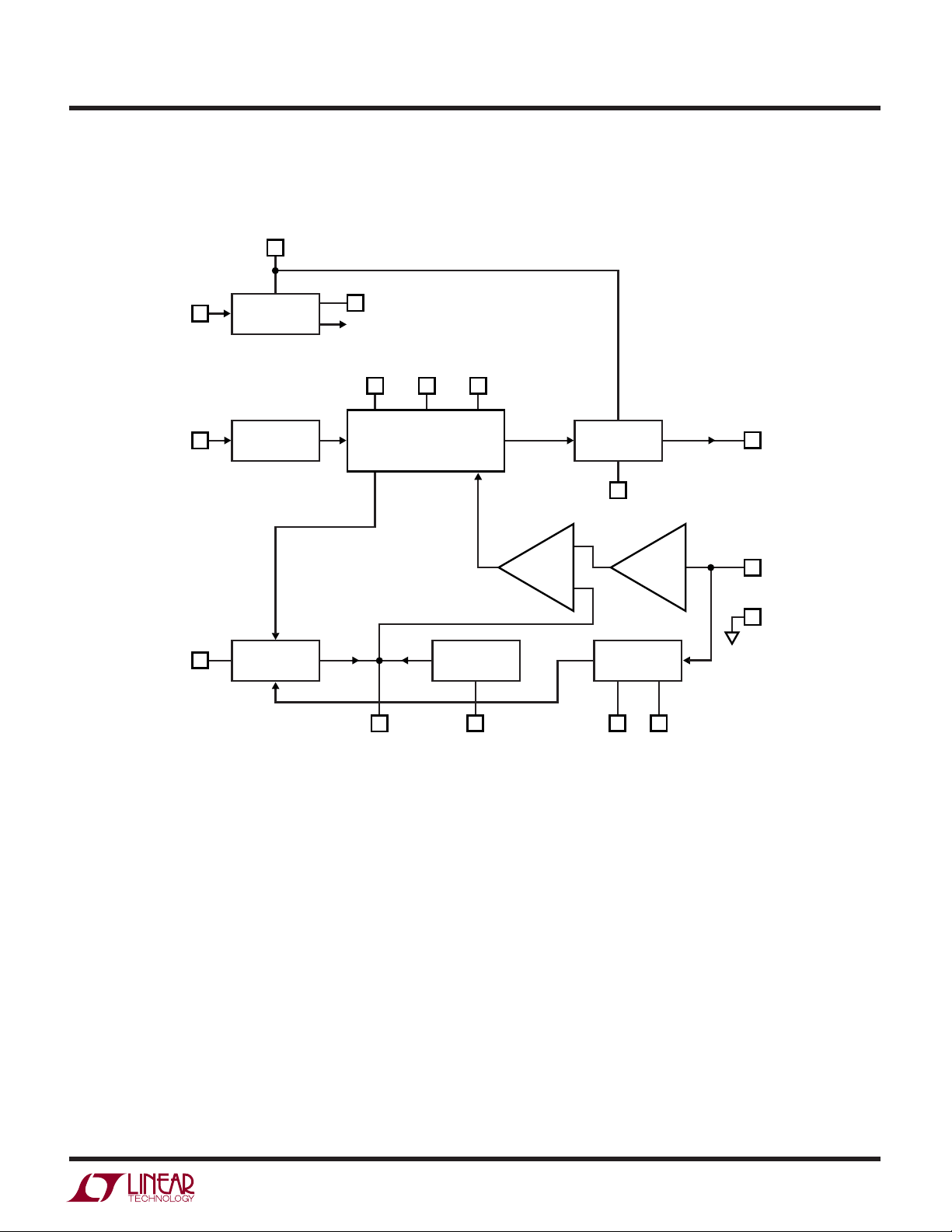

BLOCK DIAGRA

UVLO

BIAS

V

W

CC

3V

OUT

3V REG

(INTERNAL)

LT1737

OSCAP

FB

OSC

FDBK

MINENABt

ON

LOGIC

V

C

ENDLY

MOSFET

DRIVER

PGND

COMP

SOFT-START

SFST R

COMPENSATION

R

OCMP

LOAD

I

AMP

CMPC

1737 BD

GATE

I

SENSE

SGND

1737fa

7

LT1737

UWW

TI I G DIAGRA

V

SW

VOLTAGE

V

IN

GND

SWITCH

STATE

OFF ON

MINIMUM t

ON

FLYBACK AMP

STATE

ENABLE DELAY

MINIMUM ENABLE TIME

V

FLBK

OFF ON

ENABLEDDISABLED DISABLED

0.80×

V

FLBK

COLLAPSE

DETECT

1737 TD

W

FLYBACK ERROR A PLIFIER

V

IN

M1

R1

FB

Q1 Q2

R2

I

T1

•

D1

•

+

C1

+

ISOLATED

V

OUT

–

•

I

M

V

BG

I

FXD

V

C

ENAB

C2

I

M

1737 EA

8

1737fa

OPERATIO

LT1737

U

The LT1737 is a current mode switcher controller IC

designed specifically for the isolated flyback topology. The

Block Diagram shows an overall view of the system. Many

of the blocks are similar to those found in traditional

designs, including: Internal Bias Regulator, Oscillator,

Logic, Current Amplifier and Comparator, Driver and Output Switch. The novel sections include a special Flyback

Error Amplifier and a Load Compensation mechanism.

Also, due to the special dynamic requirements of flyback

control, the Logic system contains additional functionality

not found in conventional designs.

The LT1737 operates much the same as traditional current

mode switchers, the major difference being a different

type of error amplifier that derives its feedback information from the flyback pulse. Due to space constraints, this

discussion will not reiterate the basics of current mode

switcher/controllers and isolated flyback converters. A

good source of information on these topics is Application

Note AN19.

ERROR AMPLIFIER—PSEUDO DC THEORY

Please refer to the simplified diagram of the Flyback Error

Amplifier. Operation is as follows: when MOSFET output

switch M1 turns off, its drain voltage rises above the V

IN

rail. The amplitude of this flyback pulse as seen on the third

winding is given as:

V V I ESR

V

FLBK

=

N

++

()

OUT F SEC

•

ST

The relatively high gain in the overall loop will then cause

the voltage at the FB pin to be nearly equal to the bandgap

reference V

. The relationship between V

BG

FLBK

and V

BG

may then be expressed as:

RR

+

12

V

FLBK BG

()

=

Combination with the previous V

expression for V

V

R

2

expression yields an

FLBK

in terms of the internal reference,

OUT

programming resistors, transformer turns ratio and diode

forward voltage drop:

VV

=

OUT BG

12

()

RN

⎛

⎞

1

V I ESR

–– •

⎟

⎠

F SEC

⎜

2

⎝

ST

RR

+

Additionally, it includes the effect of nonzero secondary

output impedance, which is discussed in further detail, see

Load Compensation Theory. The practical aspects of

applying this equation for V

are found in the Applica-

OUT

tions Information section.

So far, this has been a pseudo-DC treatment of flyback

error amplifier operation. But the flyback signal is a pulse,

not a DC level. Provision must be made to enable the

flyback amplifier only when the flyback pulse is present.

This is accomplished by the dotted line connections to the

block labeled “ENAB”. Timing signals are then required to

enable and disable the flyback amplifier.

ERROR AMPLIFIER—DYNAMIC THEORY

VF = D1 forward voltage

I

= transformer secondary current

SEC

ESR = total impedance of secondary circuit

NST = transformer effective secondary-to-third

winding turns ratio

The flyback voltage is then scaled by external resistor

divider R1/R2 and presented at the FB pin. This is then

compared to the internal bandgap reference by the differential transistor pair Q1/Q2. The collector current from Q1

is mirrored around and subtracted from fixed current

source I

at the VC pin. An external capacitor integrates

FXD

this net current to provide the control voltage to set the

current mode trip point.

There are several timing signals that are required for

proper LT1737 operation. Please refer to the Timing

Diagram.

Minimum Output Switch On Time

The LT1737 effects output voltage regulation via flyback

pulse action. If the output switch is not turned on at all,

there will be no flyback pulse and output voltage information is no longer available. This would cause irregular loop

response and start-up/latchup problems. The solution chosen is to require the output switch to be on for an absolute

minimum time per each oscillator cycle. This in turn establishes a minimum load requirement to maintain regulation. See Applications Information for further details.

1737fa

9

LT1737

OPERATIO

U

Enable Delay

When the output switch shuts off, the flyback pulse

appears. However, it takes a finite time until the transformer primary side voltage waveform approximately represents the output voltage. This is partly due to finite rise

time on the MOSFET drain node, but more importantly,

due to transformer leakage inductance. The latter causes

a voltage spike on the primary side not directly related to

output voltage. (Some time is also required for internal

settling of the feedback amplifier circuitry.)

In order to maintain immunity to these phenomena, a fixed

delay is introduced between the switch turnoff command

and the enabling of the feedback amplifier. This is termed

enable delay. In certain cases where the leakage spike is

not sufficiently settled by the end of the enable delay

period, regulation error may result. See Application Information for further details.

Collapse Detect

Once the feedback amplifier is enabled, some mechanism

is then required to disable it. This is accomplished by a

collapse detect comparator, which compares the flyback

voltage (FB referred) to a fixed reference, nominally 80%

of VBG. When the flyback waveform drops below this

level, the feedback amplifier is disabled. This action

accommodates both continuous and discontinuous mode

operation.

Minimum Enable Time

The feedback amplifier, once enabled, stays enabled for a

fixed minimum time period termed “minimum enable

time.” This prevents lockup, especially when the output

voltage is abnormally low, e.g., during start-up. The minimum enable time period ensures that the V

node is able

C

to “pump up” and increase the current mode trip point to

the level where the collapse detect system exhibits proper

operation. The “minimum enable time” often determines

the low load level at which output voltage regulation is lost.

See Applications Information for details.

Effects of Variable Enable Period

It should now be clear that the flyback amplifier is enabled

during only a portion of the cycle time. This can vary from

the fixed “minimum enable time” described to a maximum

of roughly the “off” switch time minus the enable delay

time. Certain parameters of flyback amp behavior will then

be directly affected by the variable enable period. These

include effective transconductance and V

node slew rate.

C

LOAD COMPENSATION THEORY

The LT1737 uses the flyback pulse to obtain information

about the isolated output voltage. A potential error source

is caused by transformer secondary current flow through

the real life nonzero impedances of the output rectifier,

T1

10

R1

R2

FB

LOAD

COMP I

Q1 Q2

I

M

+

Q3

V

BG

I

M

Figure 1. Load Compensation Diagram

R

OCMP

A1

–

R

R3

50k

CMPC

I

SENSE

V

IN

M1

R

SENSE

1737 F01

1737fa

OPERATIO

LT1737

U

transformer secondary and output capacitor. This has

been represented previously by the expression “I

SEC

•

ESR.” However, it is generally more useful to convert this

expression to an effective output impedance. Because the

secondary current only flows during the off portion of the

duty cycle, the effective output impedance equals the

lumped secondary impedance times the inverse of the OFF

duty cycle. That is:

R ESR

=

OUT

R

= effective supply output impedance

OUT

⎛

⎜

DC

⎝

1

OFF

⎞

where

⎟

⎠

ESR = lumped secondary impedance

DC

= OFF duty cycle

OFF

Expressing this in terms of the ON duty cycle, remembering DC

R ESR

OFF

OUT

= 1 – DC,

⎛

=

⎜

1–

⎝

1

DC

⎞

⎟

⎠

DC = ON duty cycle

In less critical applications, or if output load current

remains relatively constant, this output impedance error

may be judged acceptable and the external FB resistor

divider adjusted to compensate for nominal expected

error. In more demanding applications, output impedance

error may be minimized by the use of the load compensation function.

To implement the load compensation function, a voltage is

developed that is proportional to average output switch

current. This voltage is then impressed across the external

R

resistor, and the resulting current acts to decrease

OCMP

the voltage at the FB pin. As output loading increases,

average switch current increases to maintain rough output

voltage regulation. This causes an increase in R

OCMP

resistor current which effects a corresponding increase in

flyback voltage amplitude.

Assuming a relatively fixed power supply efficiency, Eff,

Power Out = Eff • Power In

V

• I

OUT

= Eff • VIN • I

OUT

IN

Average primary side current may be expressed in terms

of output current as follows:

⎛

I

=

IN

⎜

V Eff

⎝

V

IN

OUT

•

⎞

•

I

OUT

⎟

⎠

combining the efficiency and voltage terms in a single

variable:

= K1 • I

I

IN

K

1=

⎛

⎜

V Eff

⎝

V

IN

OUT

OUT

•

, where

⎞

⎟

⎠

Switch current is converted to voltage by the external

sense resistor and averaged/lowpass filtered by R3 and

the external capacitor on R

impressed across the external R

. This voltage is then

CMPC

resistor by op amp

OCMP

A1 and transistor Q3. This produces a current at the

collector of Q3 which is then mirrored around and then

subtracted from the FB node. This action effectively increases the voltage required at the top of the R1/R2

feedback divider to achieve equilibrium. So the effective

change in V

VKI

∆ = ∆

OUT OUT

∆

V

OUT

∆

I

OUT

target is:

OUT

⎛

112

••(||)

()

⎛

R

=

SENSE

K

112

⎜

R

⎝

OCMP

R

⎜

R

⎝

⎞

•( || )

⎟

⎠

SENSE

OCMP

RR

⎞

RRor

⎟

⎠

Nominal output impedance cancellation is obtained by

equating this expression with R

⎛

R

RK

OUT

RK

OCMP

112

=

⎜

R

⎝

⎛

=

112

⎜

⎝

SENSE

OCMP

R

SENSE

R

OUT

⎞

•( || )

R R and

⎟

⎠

⎞

•( || )

R R where

⎟

⎠

K1 = dimensionless variable related to VIN, V

OUT

:

and

OUT

efficiency as above

R

R

= external sense resistor

SENSE

= uncompensated output impedance

OUT

(R1||R2) = impedance of R1 and R2 in parallel

The practical aspects of applying this equation to determine an appropriate value for the R

resistor are found

OCMP

in the Applications Information section.

1737fa

11

LT1737

WUUU

APPLICATIO S I FOR ATIO

TRANSFORMER DESIGN CONSIDERATIONS

Transformer specification and design is perhaps the most

critical part of applying the LT1737 successfully. In addition to the usual list of caveats dealing with high frequency

isolated power supply transformer design, the following

information should prove useful.

Turns Ratios

Note that due to the use of the external feedback resistor

divider ratio to set output voltage, the user has relative

freedom in selecting transformer turns ratio to suit a given

application. In other words, “screwball” turns ratios like

“1.736:1.0” can scrupulously be avoided! In contrast,

simpler ratios of small integers, e.g., 1:1, 2:1, 3:2, etc. can

be employed which yield more freedom in setting total

turns and mutual inductance. Turns ratio can then be

chosen on the basis of desired duty cycle. However,

remember that the input supply voltage plus the secondary-to-primary referred version of the flyback pulse (including leakage spike) must not exceed the allowed external

MOSFET breakdown rating.

Leakage Inductance

As a rough guide, total leakage inductances of several

percent (of mutual inductance) or less may require a

snubber, but exhibit little to no regulation error due to

leakage spike behavior. Inductances from several percent

up to perhaps ten percent cause increasing regulation

error.

Severe leakage inductances in the double digit percentage

range should be avoided if at all possible as there is a

potential for abrupt loss of control at high load current.

This curious condition potentially occurs when the leakage spike becomes such a large portion of the flyback

waveform that the processing circuitry is fooled into

thinking that the leakage spike itself is the real flyback

signal! It then reverts to a potentially stable state whereby

the top of the leakage spike is the control point, and the

trailing edge of the leakage spike triggers the collapse

detect circuitry. This will typically reduce the output voltage abruptly to a fraction, perhaps between one-third to

two-thirds of its correct value. If load current is reduced

sufficiently, the system will snap back to normal operation. When using transformers with considerable leakage

inductance, it is important to exercise this worst-case

check for potential bistability:

Transformer leakage inductance (on either the primary or

secondary) causes a spike after output switch turnoff. This

is increasingly prominent at higher load currents, where

more stored energy must be dissipated. In many cases a

“snubber” circuit will be required to avoid overvoltage

breakdown at the output switch node. Application Note

AN19 is a good reference on snubber design.

In situations where the flyback pulse extends beyond the

enable delay time, the output voltage regulation will be

affected to some degree. It is important to realize that the

feedback system has a deliberately limited input range,

roughly ± 50mV referred to the FB node, and this works to

the user’s advantage in rejecting large, i.e., higher voltage,

leakage spikes. In other words, once a leakage spike is

several volts in amplitude, a further increase in amplitude

has little effect on the feedback system. So the user is

generally advised to arrange the snubber circuit to clamp

at as high a voltage as comfortably possible, observing

MOSFET breakdown, such that leakage spike duration is

as short as possible.

1. Operate the prototype supply at maximum expected

load current.

2. Temporarily short circuit the output.

3. Observe that normal operation is restored.

If the output voltage is found to hang up at an abnormally

low value, the system has a problem. This will usually be

evident by simultaneously monitoring the VSW waveform

on an oscilloscope to observe leakage spike behavior

firsthand. A final note—the susceptibility of the system to

bistable behavior is somewhat a function of the load I/V

characteristics. A load with resistive, i.e., I = V/R behavior

is the most susceptible to bistability. Loads which exhibit

“CMOSsy”, i.e., I = V2/R behavior are less susceptible.

Secondary Leakage Inductance

In addition to the previously described effects of leakage

inductance in general, leakage inductance on the secondary in particular exhibits an additional phenomenon. It

forms an inductive divider on the transformer secondary,

1737fa

12

WUUU

APPLICATIO S I FOR ATIO

LT1737

which reduces the size of the primary-referred flyback

pulse used for feedback. This will increase the output

voltage target by a similar percentage. Note that unlike

leakage

spike

behavior, this phenomena is load independent. To the extent that the secondary leakage inductance

is a constant percentage of mutual inductance (over

manufacturing variations), this can be accommodated by

adjusting the feedback resistor divider ratio.

Winding Resistance Effects

Resistance in either the primary or secondary will act to

reduce overall efficiency (P

OUT/PIN

). Resistance in the

secondary increases effective output impedance which

degrades load regulation, (at least before load compensation is employed).

Bifilar Winding

A bifilar or similar winding technique is a good way to

minimize troublesome leakage inductances. However, remember that this will increase primary-to-secondary capacitance and limit the primary-to-secondary breakdown

voltage, so bifilar winding is not always practical.

Finally, the LTC Applications group is available to assist

in the choice and/or design of the transformer. Happy

Winding!

two unknowns” is obtained from noting that the Thevenin

impedance of the resistor divider should be roughly 3k for

bias current cancellation and other reasons.

SELECTING R

RESISTOR VALUE

OCMP

The Operation section previously derived the following

expressions for R

R

, the external resistor value required for its nominal

OCMP

, i.e., effective output impedance and

OUT

compensation:

R ESR

OUT

RK

OCMP

⎛

=

⎜

⎝

⎛

=

112

⎜

⎝

While the value for R

1

–

R

SENSE

R

⎞

1

⎟

DC

⎠

⎞

||

RR

()

⎟

⎠

OUT

may therefore be theoretically

OCMP

determined, it is usually better in practice to employ

empirical methods. This is because several of the required

input variables are difficult to estimate precisely. For

instance, the ESR term above includes that of the transformer secondary, but its effective ESR value depends on

high frequency behavior, not simply DC winding resistance. Similarly, K1 appears to be a simple ratio of VIN to

V

times (differential) efficiency, but theoretically esti-

OUT

mating efficiency is not a simple calculation. The suggested empirical method is as follows:

SELECTING FEEDBACK RESISTOR DIVIDER VALUES

The expression for V

developed in the Operation sec-

OUT

tion can be rearranged to yield the following expression for

the R1/R2 ratio:

RR

12

+

()

R

V

OUT

=

2

= desired output voltage

++

V V I ESR

()

OUT F SEC

V

BG

•

N

ST

where:

VF = switching diode forward voltage

I

• ESR = secondary resistive losses

SEC

VBG = data sheet reference voltage value

NST = effective secondary-to-third winding turns ratio

The above equation defines only the ratio of R1 to R2, not

their individual values. However, a “second equation for

Build a prototype of the desired supply using the eventual

secondary components. Temporarily ground the R

CMPC

pin to disable the load compensation function. Operate the

supply over the expected range of output current loading

while measuring the output voltage deviation. Approximate this variation as a single value of R

(straight line

OUT

approximation). Calculate a value for the K1 constant

based on VIN, V

ciency. These are then combined with R

to yield a value for R

and the measured (differential) effi-

OUT

as indicated

SENSE

.

OCMP

Verify this result by connecting a resistor of roughly this

value from the R

ground short to R

pin to ground. (Disconnect the

OCMP

and connect the requisite 0.1µF

CMPC

filter capacitor to ground.) Measure the output impedance

with the new compensation in place. Modify the original

R

value if necessary to increase or decrease the

OCMP

effective compensation.

1737fa

13

LT1737

WUUU

APPLICATIO S I FOR ATIO

SELECTING OSCILLATOR CAPACITOR VALUE

The switching frequency of the LT1737 is set by an

external capacitor connected between the OSCAP pin and

ground. Recommended values are between 200pF and

33pF, yielding switching frequencies between 50kHz and

250kHz. Figure 2 shows the nominal relationship between

external capacitance and switching frequency. To minimize stray capacitance and potential noise pickup, this

capacitor should be placed as close as possible to the IC

and the OSCAP node length/area minimized.

300

(Hz)

OSC

f

100

50

30

Figure 2. f

OSC

100 200

C

(pF)

OSCAP

vs OSCAP Value

1737 F02

1000

500

TIME (ns)

100

20

Figure 3. “One Shot” Times vs Programming Resistor

100 250

RT (kΩ)

1737 F03

indicative of actual current level in the transformer primary, and may cause irregular current mode switching

action, especially at light load.

However, the user must remember that the LT1737 does

not “skip cycles” at light loads. Therefore, minimum on

time will set a limit on minimum delivered power and consequently a minimum load requirement to maintain regulation (see Minimum Load Considerations). Similarly,

minimum on time has a direct effect on short-circuit behavior (see Maximum Load/Short-Circuit Considerations).

SELECTING TIMING RESISTOR VALUES

There are three internal “one-shot” times that are programmed by external application resistors: minimum on

time, enable delay time and minimum enable time. These

are all part of the isolated flyback control technique, and

their functions have been previously outlined in the Operation section. Figure 3 shows nominal observed time versus external resistor value for these functions.

The following information should help in selecting and/or

optimizing these timing values.

Minimum On Time

This time defines a period whereby the normal switch

current limit is ignored. This feature provides immunity to

the leading edge current spike often seen at the source

node of the external power MOSFET, due to rapid charging

of its gate/source capacitance. This current spike is not

The user is normally tempted to set the minimum on time

to be short to minimize these load related consequences.

(After all, a smaller minimum on time approaches the ideal

case of zero, or no minimum.) However, a longer time may

be required in certain applications based on MOSFET

switching current spike considerations.

Enable Delay Time

This function provides a programmed delay between

turnoff of the gate drive node and the subsequent enabling

of the feedback amplifier. At high loads, a primary side

voltage spike after MOSFET turnoff may be observed due

to transformer leakage inductance. This spike is not indicative of actual output voltage (see Figure 4B). Delaying

the enabling of the feedback amplifier allows this system

to effectively ignore most or all of the voltage spike and

maintain proper output voltage regulation. The enable

delay time should therefore be set to the maximum expected duration of the leakage spike. This may have

1737fa

14

WUUU

APPLICATIO S I FOR ATIO

LT1737

implications regarding output voltage regulation at minimum load (see Minimum Load Considerations).

A second benefit of the enable delay time function occurs

at light load. Under such conditions the amount of energy

stored in the transformer is small. The flyback waveform

becomes “lazy” and some time elapses before it indicates

the actual secondary output voltage (see Figure 4C). So

the enable delay time should also be set long enough to

ignore the “irrelevant” portion of the flyback waveform at

light load.

Additionally, there are cases wherein the gate output is

called upon to drive a large geometry MOSFET such that

the turnoff transition is slowed significantly. Under such

circumstances, the enable delay time may be increased to

accommodate for the lengthy transition.

MOSFET GATE DRIVE

A

IDEALIZED FLYBACK

WAVEFORM

Average “start-up” VC current =

MinimumEnable Time

SwitchingFrequency

•

I

SRC

Minimum enable time can also have implications at light

load (see Minimum Load Considerations). The temptation

is to set the minimum enable time to be fairly short, as this

is the least restrictive in terms of minimum load behavior.

However, to provide a “reliable” minimum start-up current

of say, nominally 1µA, the user should set the minimum

enable time at no less that 2% of the switching period

(= 1/switching frequency).

CURRENT SENSE RESISTOR CONSIDERATIONS

The external current sense resistor allows the user to

optimize the current limit behavior for the particular application under consideration. As the current sense resistor

is varied from several ohms down to tens of milliohms,

peak switch current goes from a fraction of an ampere to

tens of amperes. Care must be taken to ensure proper

circuit operation, especially with small current sense

resistor values.

FLYBACK WAVEFORM

B

C

ENABLE

DELAY

TIME

NEEDED

ENABLE DELAY

TIME NEEDED

DISCONTINUOUS

Figure 4

MODE

RINGING

WITH LARGE LEAKAGE

SPIKE AT HEAVY LOAD

“SLOW” FLYBACK

WAVEFORM AT

LIGHT LOAD

1737 F04

Minimum Enable Time

This function sets a minimum duration for the expected

flyback pulse. Its primary purpose is to provide a minimum source current at the VC node to avoid start-up

problems.

For example, a peak switch current of 10A requires a

sense resistor of 0.025Ω. Note that the instantaneous

peak power in the sense resistor is 2.5W, and it must be

rated accordingly. The LT1737 has only a single sense line

to this resistor. Therefore, any parasitic resistance in the

ground side connection of the sense resistor will increase

its apparent value. In the case of a 0.025Ω sense resistor,

one milliohm

of parasitic resistance will cause a 4%

reduction in peak switch current. So resistance of printed

circuit copper traces and vias cannot necessarily be

ignored.

An additional consideration is parasitic inductance. Inductance in series with the current sense resistor will

accentuate the high frequency components of the current

waveform. In particular, the gate switching spike and

multimegahertz ringing at the MOSFET can be

considerably amplified. If severe enough, this can cause

erratic operation. For example, assume 3nH of parasitic

inductance (equivalent to about 0.1 inch of wire in free

space) is in series with an ideal 0.025Ω sense resistor.

A “zero” will be formed at f = R/(2πL), or 1.3MHz. Above

1737fa

15

LT1737

WUUU

APPLICATIO S I FOR ATIO

this frequency the sense resistor will behave like an

inductor.

Several techniques can be used to tame this potential

parasitic inductance problem. First, any resistor used for

current sensing purposes must be of an inherently noninductive construction. Mounting this resistor directly

above an unbroken ground plane and minimizing its

ground side connection will serve to absolutely minimize

parasitic inductance. In the case of low valued sense

resistors, these may be implemented as a parallel combination of several resistors for the thermal considerations

cited above. The parallel combination will help to lower the

parasitic inductance. Finally, it may be necessary to place

a “pole” between the current sense resistor and the

LT1737 I

pin to undo the action of the inductive zero

SENSE

(see Figure 5). A value of 51Ω is suggested for the resistor,

while the capacitor is selected empirically for the particular

application and layout. Using good high frequency measurement techniques, the I

pin waveform may be

SENSE

observed directly with an oscilloscope while the capacitor

value is varied.

SENSE RESISTOR ZERO AT:

R

SENSE

f =

2πL

P

COMPENSATING POLE AT:

FOR CANCELLATION:

f =

2π(51Ω)C

C

COMP

1

COMP

L

P

=

R

(51Ω)

SENSE

PGNDSGND

GATE

I

SENSE

51Ω

C

COMP

PARASITIC

INDUCTANCE

R

SENSE

L

P

1737 F05

Figure 5

SOFT-START FUNCTION

The LT1737 contains an optional soft-start function that is

enabled by connecting an explicit external capacitor between the SFST pin and ground. Internal circuitry prevents

the control voltage at the VC pin from exceeding that on the

SFST pin.

Th

e soft-start function is enagaged whenever VCC power

is removed, or as a result of either undervoltage lockout

or thermal (overtemperature) shutdown. The SFST node

is then discharged rapidly to roughly a VBE above ground.

(Remember that the VC pin control node switching

threshold is deliberately set at a VBE

plus

several hundred

millivolts.) When this condition is removed, a nominal

40µA current acts to charge up the SFST node towards

roughly 3V. So, for example, a 0.1µF soft-start capacitor

will place a 0.4V/ms limit on the ramp rate at the VC node.

UVLO PIN FUNCTION

The UVLO pin effects both undervoltage lockout and

shutdown functions. This is accomplished by using different voltage thresholds for the two functions—the shutdown function is at roughly a V

above ground (0.75V at

BE

25°C, large temperature variation), while the UVLO function is at nearly a bandgap voltage (1.25V, fairly stable with

temperature). An external resistor divider between the

input supply and ground can then be used to achieve a

user-programmable undervoltage lockout (see Figure 6a).

An additional feature of this pin is that there is a change in

the input bias current at this pin as a function of the state

of the internal UVLO comparator. As the pin is brought

above the UVLO threshold, the bias current sourced by the

part increases. This positive feedback effects a hysteresis

band for reliable switching action. Note that the size of the

hysteresis is proportional to the Thevenin impedance of

the external UVLO resistor divider network, which makes

it user programmable. As a rough rule of thumb, each 4k

or so of impedance generates about 1% of hysteresis.

(This is based on roughly 1.25V for the threshold and 3µA

for the bias current shift.)

Even in good quality ground plane layouts, it is common

for the switching node (MOSFET drain) to couple to the

UVLO pin with a stray capacitance of several

thousandths

of a pF. To ensure proper UVLO action, a 100pF capacitor

is recommended from this pin to ground as shown in

Figure 6b. This will typically reduce the coupled noise to

a few millivolts. The UVLO filter capacitor should not be

made much larger than a few hundred pF, however, as the

hysteresis action will become too slow. In cases where

further filtering is required, e.g., to attenuate high speed

supply ripple, the topology in Figure 6c is recommended.

Resistor R1 has been split into two equal parts. This

provides a node for effecting capacitor filtering of high

speed supply ripple, while leaving the UVLO pin node

impedance relatively unchanged at high frequency.

1737fa

16

WUUU

APPLICATIO S I FOR ATIO

LT1737

V

IN

V

IN

R1

UVLO

R2

(6a) “Standard” UVLO

Divider Topology

(6b) Filter Capacitor

Directly on UVLO Note

C1

100pF

V

IN

R1

R2

Figure 6

FREQUENCY COMPENSATION

Loop frequency compensation is performed by connecting a capacitor from the output of the error amplifier (V

C

pin) to ground. An additional series resistor, often required in traditional current mode switcher controllers, is

usually not required and can even prove detrimental. The

phase margin improvement traditionally offered by this

extra resistor will usually be already accomplished by the

nonzero secondary circuit impedance, which adds a “zero”

to the loop response.

In further contrast to traditional current mode switchers,

VC pin ripple is generally not an issue with the LT1737. The

dynamic nature of the clamped feedback amplifier forms

an effective track/hold type response, whereby the V

C

voltage changes during the flyback pulse, but is then “held”

during the subsequent “switch on” portion of the next

cycle. This action naturally holds the VC voltage stable

during the current comparator sense action (current mode

switching).

OUTPUT VOLTAGE ERROR SOURCES

R1/2

C2

R1/2

UVLO

C1

100pF

(6c) Recommended Topology to

Filter High Frequency Ripple

UVLO

R2

1737 F06

Internal Voltage Reference

The internal bandgap voltage reference is, of course,

imperfect. Its error, both at 25°C and over temperature is

already included in the specifications.

User Programming Resistors

Output voltage is controlled by the user-supplied feedback

resistor divider ratio. To the extent that the resistor ratio

differs from the ideal value, the output voltage will be

proportionally affected. Highest accuracy systems will

demand 1% components.

Schottky Diode Drop

The LT1737 senses the output voltage from the transformer primary side during the flyback portion of the

cycle. This sensed voltage therefore includes the forward

drop, VF, of the rectifier (usually a Schottky diode). The

nominal VF of this diode should therefore be included in

feedback resistor divider calculations. Lot to lot and

ambient temperature variations will show up as output

voltage shift/drift.

Conventional nonisolated switching power supply ICs

typically have only two substantial sources of output

voltage error: the internal or external resistor divider

network that connects to V

and the internal IC refer-

OUT

ence. The LT1737, which senses the output voltage in both

a dynamic and an isolated manner, exhibits additional

potential error sources to contend with. Some of these

errors are proportional to output voltage, others are fixed

in an absolute millivolt sense. Here is a list of possible

error sources and their effective contribution.

Secondary Leakage Inductance

Leakage inductance on the transformer secondary reduces the effective secondary-to-third winding turns ratio

(NS/NT) from its ideal value. This will increase the output

voltage target by a similar percentage. To the extent that

secondary leakage inductance is constant from part to

part, this can be accommodated by adjusting the feedback

resistor ratio.

1737fa

17

LT1737

Minimum Power

f

L

Vtt

VI

SEC

OUT EN ED

OUT OUT

=

⎛

⎝

⎜

⎞

⎠

⎟

+

()

[]

=

1

2

2

•

•

WUUU

APPLICATIO S I FOR ATIO

Output Impedance Error

An additional error source is caused by transformer secondary current flow through the real life nonzero impedances of the output rectifier, transformer secondary and

output capacitor. Because the secondary current only

flows during the off portion of the duty cycle, the effective

output impedance equals the “DC” lumped secondary

impedance times the inverse of the off duty cycle. If the

output load current remains relatively constant, or, in less

critical applications, the error may be judged acceptable

and the feedback resistor divider ratio adjusted for nominal expected error. In more demanding applications, output impedance error may be minimized by the use of the

load compensation function (see Load Compensation).

MINIMUM LOAD CONSIDERATIONS

The LT1737 generally provides better low load performance than previous generation switcher/controllers utilizing indirect output voltage sensing techniques.

Specifically, it contains circuitry to detect flyback pulse

“collapse,” thereby supporting operation well into discontinuous mode. Nevertheless, there still remain constraints

to ultimate low load operation. These relate to the minimum switch on time and the minimum enable time.

Discontinuous mode operation will be assumed in the

following theoretical derivations.

As outlined in the Operation section, the LT1737 utilizes a

minimum output switch on time, tON. This value can be

combined with expected VIN and switching frequency to

yield an expression for minimum delivered power.

Minimum Power

f

1

=

⎜

L

2

⎝

PRI

VI

=

OUT OUT

⎞

Vt

()

IN ON

⎟

⎠

•

2

•

⎛

This expression then yields a minimum output current

constraint:

I

OUT MIN

⎛

1

⎜

2

LV

⎝

PRI OUT

•

⎞

f

Vt

()

IN ON()

⎟

⎠

2

•=

where

f = switching frequency

L

= transformer primary side inductance

PRI

VIN = input voltage

V

= output voltage

OUT

tON = output switch minimum on time

An additional constraint has to do with the minimum

enable time. The LT1737 derives its output voltage information from the flyback pulse. If the internal minimum

enable time pulse extends beyond the flyback pulse, loss

of regulation will occur. The onset of this condition can be

determined by setting the width of the flyback pulse equal

to the sum of the flyback enable delay, tED, plus the

minimum enable time, tEN. Minimum power delivered to

the load is then:

Which yields a minimum output constraint:

I

OUT MIN

⎛

•

1

fV

=

⎜

2

L

⎝

⎞

OUT

tt

()

ED EN()

⎟

⎠

SEC

2

+

where

f = switching frequency

L

= transformer secondary side inductance

SEC

V

= output voltage

OUT

tED = enable delay time

tEN = minimum enable time

Note that generally, depending on the particulars of input

and output voltages and transformer inductance, one of

the above constraints will prove more restrictive. In other

words, the minimum load current in a particular application will be either “output switch minimum on time”

constrained, or “minimum flyback pulse time” constrained.

(A final note—L

PRI

and L

refer to transformer induc-

SEC

tance as seen from the primary or secondary side respectively. This general treatment allows these expressions to

be used when the transformer turns ratio is nonunity.)

18

1737fa

WUUU

APPLICATIO S I FOR ATIO

LT1737

MAXIMUM LOAD/SHORT-CIRCUIT CONSIDERATIONS

The LT1737 is a current mode controller. It uses the V

C

node voltage as an input to a current comparator that turns

off the output switch on a cycle-by-cycle basis as this peak

current is reached. The internal clamp on the V

node,

C

nominally 2.5V, then acts as an output switch peak current

limit.

This 2.5V at the VC pin corresponds to a value of 250mV

at the I

pin, when the (ON) switch duty cycle is less

SENSE

than 40%. For a duty cycle above 40%, the internal slope

compensation mechanism lowers the effective I

SENSE

voltage limit. For example, at a duty cycle of 80%, the

nominal I

voltage limit is 220mV. This action be-

SENSE

comes the switch current limit specification. Maximum

available output power is then determined by the switch

current limit, which is somewhat duty cycle dependent

due to internal slope compensation action.

Overcurrent conditions are handled by the same mechanism. The output switch turns on, the peak current is

quickly reached and the switch is turned off. Because the

output switch is only on for a small fraction of the available

period, power dissipation is controlled.

Loss of current limit is possible under certain conditions.

Remember that the LT1737 normally exhibits a minimum

switch on time, irrespective of current trip point. If the duty

cycle exhibited by this minimum on time is greater than the

ratio of secondary winding voltage (referred-to-primary)

divided by input voltage, then peak current will not be

controlled at the nominal value, and will cycle-by-cycle

ratchet up to some higher level. Expressed mathematically, the requirement to maintain short-circuit control is:

+

<

tf

•

ON

VI R

()

F SC SEC

•

VN

•

IN SP

where

tON = output switch minimum on time

f = switching frequency

Trouble is typically only encountered in applications with

a relatively high product of input voltage times secondaryto-primary turns ratio and/or a relatively long minimum

switch on time. (Additionally, several real world effects such

as transformer leakage inductance, AC winding losses, and

output switch voltage drop combine to make this simple

theoretical calculation a conservative estimate.)

THERMAL CONSIDERATIONS

Care should be taken to ensure that the worst-case input

voltage condition does not cause excessive die temperatures. The 16-lead SO package is rated at 100°C/W, and

the 16-lead GN at 110°C/W.

Average supply current is simply the sum of quiescent

current given in the specifications section plus gate drive

current. Gate drive current can be computed as:

IG = f • QG where

QG = total gate charge

f = switching frequency

(Note: Total gate charge is more complicated than CGS • V

G

as it is frequently dominated by Miller effect of the CGD.

Furthermore, both capacitances are nonlinear in practice.

Fortunately, most MOSFET data sheets provide figures

and graphs which yield the total gate charge directly per

operating conditions.) Nearly all gate drive power is dissipated in the IC, except for a small amount in the external

gate series resistor, so total IC dissipation may be computed as:

P

D(TOTAL)

= VCC (IQ + • f • QG ), where

IQ = quiescent current (from specifications)

QG = total gate charge

f = switching frequency

VCC = LT1737 supply voltage

ISC = short-circuit output current

VF = output diode forward voltage at I

R

= resistance of transformer secondary

SEC

SC

VIN = input voltage

NSP = secondary-to-primary turns ratio (N

SEC/NPRI

SWITCH NODE CONSIDERATIONS

For maximum efficiency, gate drive rise and fall times are

made as short as practical. To prevent radiation and high

frequency resonance problems, proper layout of the

components connected to the IC is essential, especially

)

1737fa

19

LT1737

WUUU

APPLICATIO S I FOR ATIO

the power paths (primary

and

secondary). B field (magnetic) radiation is minimized by keeping MOSFET leads,

output diode and output bypass capacitor leads as short

as possible. E field radiation is kept low by minimizing the

length and area of all similar traces. A ground plane

should always be used under the switcher circuitry to

prevent interplane coupling.

The high speed switching current paths are shown schematically in Figure 7. Minimum lead length in these paths

are essential to ensure clean switching and minimal EMI.

The path containing the input capacitor, transformer primary and MOSFET, and the path containing the transformer secondary, output diode and output capacitor

contain “nanosecond” rise and fall times. Keep these

paths as short as possible.

GATE DRIVE RESISTOR CONSIDERATIONS

The gate drive circuitry internal to the LT1737 has been

designed to have as low an output impedance as practically possible—only a few ohms. A strong L/C resonance

is potentially presented by the inductance of the path

leading to the gate of the power MOSFET and its overall

gate capacitance. For this reason the path from the GATE

package pin to the physical MOSFET gate should be kept

as short as possible, and good layout/ground plane practice used to minimize the parasitic inductance.

An explicit series gate drive resistor may be useful in some

applications to damp out this potential L/C resonance

(typically tens of MHz). A minimum value of perhaps

several ohms is suggested, and higher values (typically a

few tens of ohms) will offer increased damping. However,

as this resistor value becomes too large, gate voltage rise

time will increase to unacceptable levels, and efficiency

will suffer due to the sluggish switching action.

V

CC

+

V

PGND

Figure 7. High Speed Current Switching Paths

GATE

CHARGE

PATH

CC

GATE

GATE

DISCHARGE

PATH

V

IN

+

+

SECONDARY

POWER

PATH

PRIMARY

POWER

PATH

1737 F07

20

1737fa

U

TYPICAL APPLICATIO S

LT1737

BASIC APPLICATION WITH

3-WINDING TRANSFORMER

Figure 8 shows a compact, low power application of the

TM

LT1737. Transformer T1 is an off-the-shelf VERSA-PAC

,

#VP1-0190, produced by Coiltronics. As manufactured, it

consists of six ideally identical independent windings. In

this application, two windings are stacked in series on the

primary side and three are placed in parallel on the

secondary side. This arrangement provides a 2:1 primaryto-secondary turns ratio while maximizing overall efficiency. The remaining primary side winding provides a

ground-referred version of the flyback voltage waveform

for the purpose of feedback.

The design accepts an input voltage in the range of 8V to

25V and outputs an isolated 5V. To prevent overvoltage on

V

IN

+

C1

330µF

35V

C3

1µF

25V

Z5U

V

CC

SGND

C7

0.1µF

25V

Z5U

R3

12.7k

1%

R4

3.92k

1%

C5

1nF

25V

X7R

U2

MINENAB

R6

51k

5%

OUT

ADJ

1

2

LT1737

R7

51k

5%

R

R11

24k

5%

R12

20k

5%

OCMP

R8

4.3k

5%

R

CMPC

8

INP

LT1121

3

GND

910 15

UVLO3V

8

7

OUT

FB

V

C

ENDLYSFSTOSCAP t

ON

6

C6

47pF

50V

NPO

14 13 12 4 5 11 1

3

R5

51k

5%

the LT1737 and the gate of MOSFET M1, an LT1121 low

dropout linear regulator is employed (U2). Resistor divider R11/R12 sets the output of U2 at nominally 8.25V. (A

few hundred millivolts of dropout will therefore be seen at

the very bottom of the input supply range.) The positive

going drive potential at the LT1737 GATE pin is typically 2V

or so below its VCC supply pin, so a logic level MOSFET has

been specified for M1.

Capacitor C6 sets the switching frequency at approximately 200kHz. Optimal load compensation for the

trans

former and secondary circuit components is set by

resistor R8. Resistor R10 provides a guaranteed minimum load of about 20mA to maintain rough output voltage

regulation. The soft-start and UVLO features are unused

as shown.

VERSA-PAC is a trademark of Coiltronics, Inc.

6

T1

COILTRONICS

VP1-0190

•

D2

1N5250

D3

MBR0540

GATE

I

SENSE

PGND

1737 F08

3

1 10

R9

68Ω

5%

R2

5.1Ω

5%

16

2

C9

1nF

25V

X7R

C4

470pF

50V

X7R

R13

51Ω

5%

•

•

7

4

2

•

5

M1

IRLL014

R1

0.2Ω

0.5W

IRC TYPE LR 2010

•

11

8

D1

MBRD330

12

+

•

9

1µH

OPTIONAL OUTPUT FILTER

C2

68µF

10V

L1

V

OUT

5V

500mA

R10

240Ω

5%

V

OUT

5V

C8

33µF

10V

500mA

+

C1: SANYO ALUMINUM ELECTROLYTIC (35CV331GX)

C2: SANYO POSCAP (10TPC68M)

C8: SANYO POSCAP (10TPA33M)

D1: MOTOROLA 30V, 3A SCHOTTKY RECTIFIER

D2: 20V, 500mW ZENER DIODE

D3: MOTOROLA 40V, 0.5A SCHOTTKY RECTIFIER

L1: COILCRAFT DO1608C-102 1µH, 0.05Ω INDUCTOR

M1: INT’L RECTIFIER IRLL014 60V, 0.2Ω LOGIC LEVEL N-CH MOSFET

U2: LINEAR TECHNOLOGY MICROPOWER LDO REGULATOR

Figure 8. 8V-25V to Isolated 5V Converter

1737fa

21

LT1737

TYPICAL APPLICATIO S

U

Overall power supply efficiency and output regulation

versus input voltage and load current may be seen in

Figures 9 and 10. Available output current is a function of

input voltage, varying from 650mA with 8V input to

1100mA with 25V input.

In cases when the output switching noise is objectionable,

the optional output L/C filter shown may be added. The

oscilloscope photos in Figure 11 show the dramatic reduction in output voltage ripple with the optional filter.

Note: It is theoretically possible to extend the input voltage

range of this topology higher by raising the breakdown

voltage ratings on Q1, U2 and M1, while adjusting the

transformer windings as necessary. However this approach is generally undesirable as the relatively fixed

90

80

70

60

50

EFFICIENCY (%)

40

VIN = 8V

V

IN

V

= 25V

IN

= 15V

supply current required by the LT1737 generates more

and more wasted heat in linear regulator U2 as input

voltage is increased. The LT1725, a close “cousin” of the

LT1737 is recommended in such instances.

The LT1725 is very similar to the LT1737, but it contains

an integral wide hysteresis undervoltage lockout (UVLO)

circuit that monitors the VCC voltage. When used in

conjunction with a 3-winding transformer to provide both

device power and output voltage feedback information,

this allows for a “trickle charge” start-up from an input

voltage of up to hundreds of volts. The LT1725 is thus well

suited to operate from “telecom” input voltages of 48V to

72V, or even offline inputs up to several hundred volts! See

the LT1725 data sheet for further information.

Without L/C Filter

50mV/DIV

AC COUPLED

30

20

0.01

Figure 9. Efficiency vs I

5.25

V

IN

5.00

OUTPUT VOLTAGE (V)

4.75

250

0

Figure 10. Output Regulation

= 8V

500

I

I

LOAD

0.1

LOAD

(A)

VIN = 15V

750

(mA)

LOAD

VIN = 25V

1000

1737 F09

1737 F10

1250

1

= 15V 1µs/DIV 1737 F11a

V

IN

I

= 900mA

LOAD

20MHz BANDWIDTH LIMITED

With L/C Filter

50mV/DIV

AC COUPLED

= 15V 1µs/DIV 1737 F11b

V

IN

I

= 900mA

LOAD

20MHz BANDWIDTH LIMITED

Figure 11

1737fa

22

U

TYPICAL APPLICATIO S

LT1737

APPLICATION WITH 2-WINDING TRANSFORMER

The previous application example utilized a 3-winding

transformer, the third winding providing only feedback

information. Additional circuitry may be employed to

provide feedback information, thus allowing the transformer to be reduced to a 2-winding topology. (The cost

and size savings associated with the transformer often

R2

35.7k

1%

D2

C3

1nF

25V

X7R

BAS16

8

FB

7

V

R8

240k

5%

R9

33k

5%

910 15

UVLO3V

OUT

C

MINENAB

ENDLYSFSTOSCAP t

ON

6

3

C5

47pF

50V

NPO

14 13 12 4 5 11 1

R5

R4

150k

75k

5%

5%

LT1737

R6

100k

5%

R

V

CC

OCMP

R7

4.7k

5%

C8

0.1µF

25V

Z5U

CMPC

SGNDR

C4

0.1µF

25V

Z5U

Q1

2N3906

R3

3.01k

1%

make this a preferable alternative. Furthermore, a variety

of manufacturers offer off-the-shelf dual wound magnetics which often can be applied as 1:1 transformers.)

Figure 12 shows an LT1737 configured for operation with

a dual wound toroid, the Coiltronics #CTX150-4

OCTA-PACTM. A ground referred version of the flyback

voltage waveform is now provided by components Q1, R2,

OCTA-PAC is a trademark of Coiltronics, Inc.

V

IN

+

D4

1N5252

MBRS1100

GATE

I

SENSE

PGND

22µF

35V

D3

1737 F12

C1

R11

100Ω

5%

C6

470pF

50V

X7R

R10

5.1Ω

5%

16

2

T1

COILTRONICS

CTX150-4

13

•

•

4

2

M1

IRFL014

R1

0.27Ω

0.5W

IRC TYPE LR 2010

MBRS1100

R12

100Ω

5%

C7

470pF

50V

X7R

D1

V

OUT

15V

250mA

C2

33µF

25V

R13

7.5k

5%

+

C1: AVX TPS TANTALUM (TPSE226M035R0300)

C2: AVX TPS TANTALUM (TPSE336M025R0200)

D1, D3: MOTOROLA 100V, 1A SCHOTTKY DIODE

D2: SIGNAL DIODE

D4: 24V, 500mW ZENER DIODE

90

80

70

60

50

EFFICIENCY (%)

40

30

20

1

VIN = 12V

VIN = 15V

10 100 1000

I

LOAD

VIN = 18V

(mA)

Figure 13. Efficiency vs I

M1: INT’L RECTIFIER 60V, 0.2Ω N-CH MOSFET

Figure 12. 12V-18V to Isolated 15V Converter

15.5

15.0

OUTPUT VOLTAGE (V)

14.5

0

1737 F13

LOAD

V

= 12V

IN

VIN = 15V

VIN = 18V

100

I

LOAD

200

(mA)

1737 F14

Figure 14. Load Regulation

300

1737fa

23

LT1737

TYPICAL APPLICATIO S

U

R3 and D2. (Diode D2 prevents reverse emitter/base

breakdown in Q1 when MOSFET M1 is in the “ON” state.)

The raw flyback voltage at the drain of MOSFET M1 minus

the VBE of Q1 is converted to a current by R2 and then back

to a voltage at R3. Or, stated mathematically:

⎛

⎞

R

VV V

=

()

FB FLBK BE

–

3

⎜

⎟

R

2

⎝

⎠

Resistor R13 provides an initial pre-load to the supply

output to improve light load regulation. Resistor divider

R8/R9 sets the undervoltage lockout threshold at nominally 10.4V for turn-on, with turn-off about 600mV lower.

Overall power supply efficiency and output regulation

versus input voltage and load current may be seen in

Figures 13 and 14.

R2

11.0k

2N3906

1%

D2

Q1

BAS16

C8

1µF

25V

Z5U

C1A

220µF

10V

1N5240

MBR0520

APPLICATION

5V

IN

The LT1737 is a bipolar technology IC specified to operate

down to a minimum input supply voltage of 4.5V. Although

its GATE pin drives “low” nearly to ground, its “high”

capability is limited by a headroom requirement of roughly

2V

s. Thus when operating at a worst case 4.5V supply,

BE