查询LT1500供应商

FEATURES

LT1500/LT1501

Adaptive-Frequency

Current Mode Switching Regulators

U

DESCRIPTION

■

Low Noise Adaptive-Frequency Current Mode

Operation Avoids Low Frequency Noise at

Most Load Currents

■

Can Be Externally Synchronized (LT1500)

■

Micropower Quiescent Current: 200µA

■

Shutdown Current: 8µA Typ

■

Internal Loop Compensation

■

Low-Battery Comparator Active in Shutdown

■

Minimum Input Voltage: 1.8V Typ

■

Additional Negative Voltage Feedback Pin (LT1500)

■

Up to 500kHz Switching Frequency

■

Uses Low Profile, Low Cost Surface Mount Inductors

U

APPLICATIONS

■

Portable Instrumentation

■

Battery Operated Systems

■

PDA’s

■

Standby Power

The LT®1500 is an adaptive-frequency current mode stepup switching regulator with an internal power switch that

is rated up to 700mA. In contrast to pulse skipping

switching regulators, the LT1500 uses a current mode

topology that provides lower noise operation and improved efficiency. Only at very light loads is Burst Mode

TM

activated to give high efficiency and micropower operation. High switching frequency (up to 500kHz) allows very

small inductors to be used, along with ceramic capacitors

if desired.

The LT1500 operates with input voltages from 1.8V to 15V

and has only 200µ A operating current dropping to 8µA in

shutdown. A low-battery comparator is included which

stays alive in shutdown. A second output feedback pin

with negative polarity allows negative output voltages to

be regulated when the switcher is connected up as a Cuk

or a flyback converter.

Two package types are available. The LT1500 comes in a

14-pin SO package, with two options available for fixed

output (3.3V or 5V) or adjustable operation. A reduced

feature part, the LT1501, comes in the smaller 8-pin SO

package with internal frequency compensation. It is also

available in adjustable and fixed output voltage versions.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a trademark of Linear Technology Corporation.

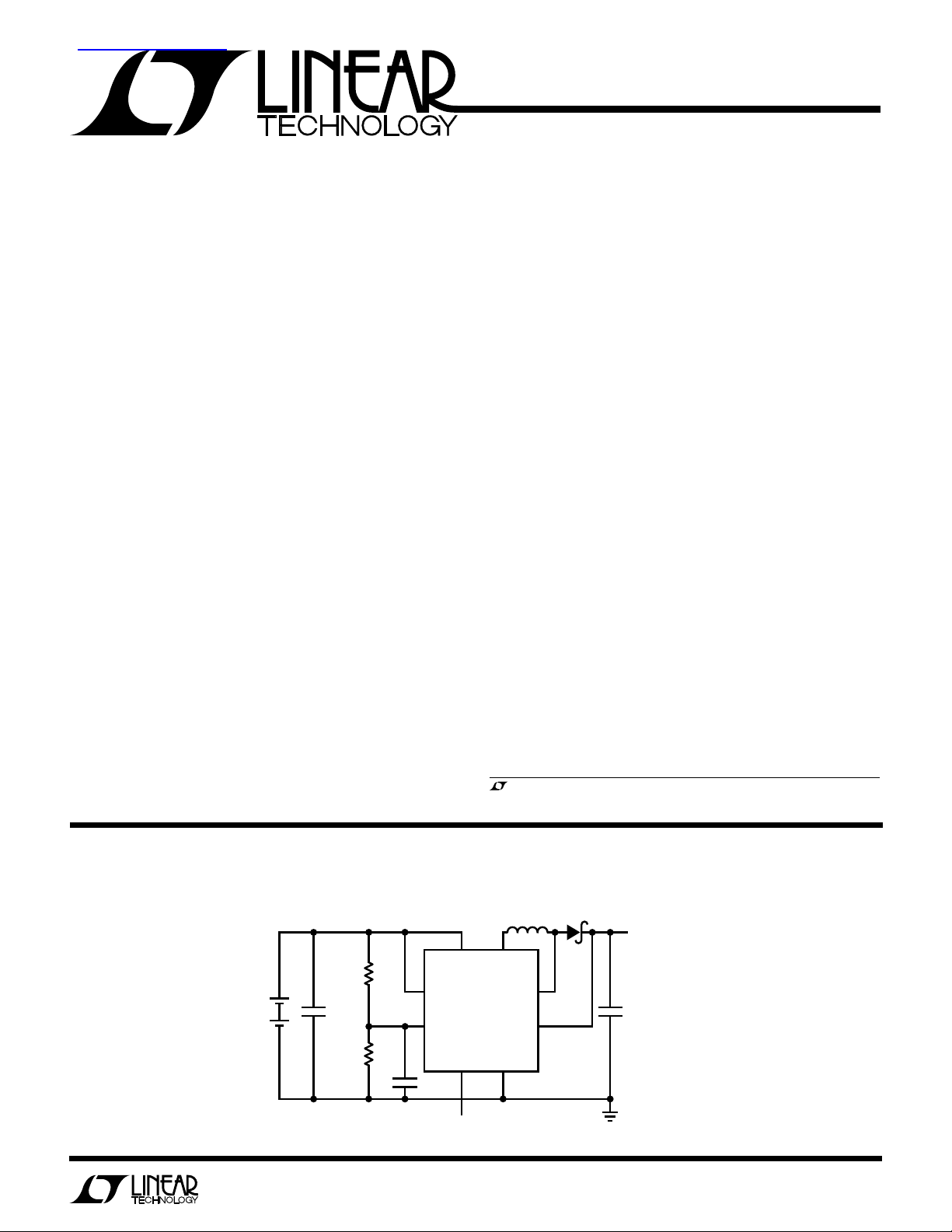

TYPICAL APPLICATION

2 EACH

NiCd OR

ALKALINE

CELLS

+

U

33µF*

6V

2-Cell to 5V Converter

V

301k

1%

301k

1%

(USE EXTERNAL PULL-UP)

IN

SHDN

LT1501-5

LBI

LBO

1nF

LOW-BATTERY FLAG

I

SENSE

GND

22µH

SW

OUT

MBR0520L

†

D1

5V, 200mA

220µF**

+

10V

TANT

AVX, TPSC107M006R0150

*

AVX, TPSD107M010 R0100

**

†

SUMIDA CD73-220, CD54-220

OR CD43-220. SELECT ACCORDING

TO MAXIMUM LOAD CURRENT

LT1500/01 • TA01

1

LT1500/LT1501

1

2

3

4

8

7

6

5

TOP VIEW

FB/OUT

LBI

LBO

SW

SHDN

V

IN

I

SENSE

GND

S8 PACKAGE

8-LEAD PLASTIC SO

WW

W

U

ABSOLUTE MAXIMUM RATINGS

Supply Voltage ........................................................ 20V

Switch Voltage (SW)................................................ 30V

Shutdown Voltage (SHDN) ...................................... 20V

I

Voltage.......................................................... 20V

SENSE

FB Voltage ................................................................. 5V

LBI Voltage................................................................ 5V

LBO Voltage............................................................. 15V

U

W

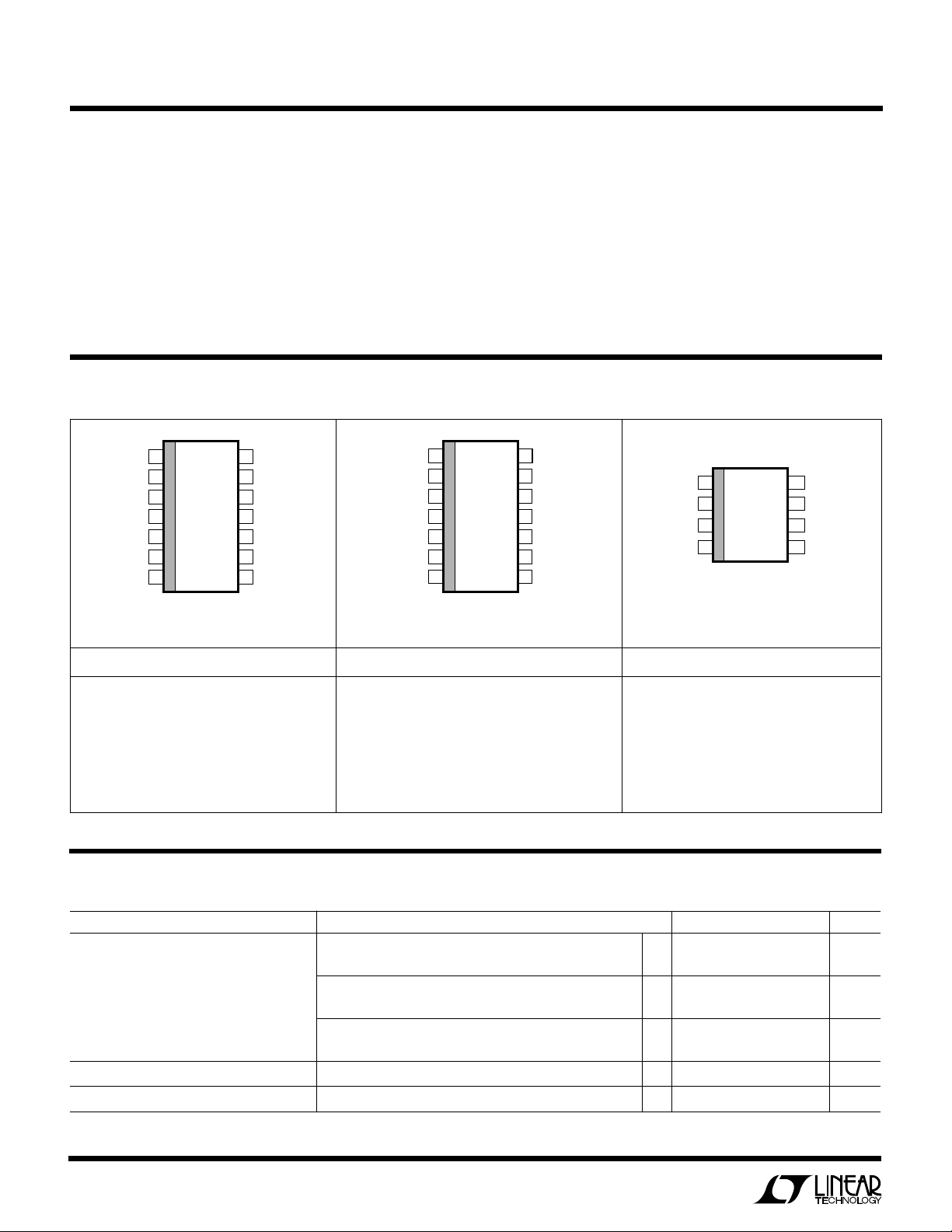

PACKAGE/ORDER INFORMATION

TOP VIEW

1

1

SHDN

2

V

C

3

V

IN

4

I

SENSE

5

NC

6

GND

7

PGND

14-LEAD PLASTIC SO

T

JMAX

14

13

12

11

10

9

8

S PACKAGE

= 100°C, θJA = 100°C/W

FB

NFB

SS

LBI

LBO

SYNC

SW

SHDN

2

V

C

3

V

IN

4

I

SENSE

5

NC

6

GND

7

PGND

14-LEAD PLASTIC SO

T

= 100°C, θJA = 100°C/W

JMAX

Operating Ambient Temperature Range

Commercial .............................................0°C to 70°C

Industrial ............................................ –40°C to 85°C

Operating Junction Temperature Range

Commercial ...........................................0°C to 100°C

Industrial .......................................... –40°C to 100°C

Storage Temperature Range................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

U

TOP VIEW

14

(3.3V/5V)

V

OUT

13

SELECT

12

SS

11

LBI

10

LBO

9

SYNC

8

SW

S PACKAGE

T

= 100°C, θJA = 120°C/W

JMAX

ORDER PART NUMBER ORDER PART NUMBER ORDER PART NUMBER

LT1500CS

LT1500IS

LT1500CS-3/5

LT1500IS-3/5

LT1501CS8

LT1501CS8-3.3

LT1501CS8-5

LT1501IS8

LT1501IS8-3.3

LT1501IS8-5

Consult factory for Military grade parts.

ELECTRICAL CHARACTERISTICS

TJ = 25°C, VIN = 2.3V unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Feedback/Output Pin Reference Voltage LT1500/LT1501, T

= 25°C 1.240 1.265 1.290 V

J

All Conditions (Note 6) ● 1.235 1.295 V

LT1500-3/5, Select Pin Open 3.230 3.300 3.370 V

All Conditions (Note 6) ● 3.200 3.400 V

LT1500-3/5, Select Pin Grounded 4.900 5.000 5.100 V

All Conditions (Note 6) ● 4.85 5.15 V

Reference Voltage Line Regulation VIN = 2.3V to 15V ● 0.02 0.06 %/V

Feedback Pin Bias Current ● 30 100 nA

2

LT1500/LT1501

ELECTRICAL CHARACTERISTICS

PARAMETER CONDITIONS MIN TYP MAX UNITS

Internal Divider Current LT1500-3.3/LT1501-3.3

LT1500-5/LT1501-5 ● 33 45 µA

Operating Quiescent Current V

Supply Current in Shutdown V

Shutdown Pin Threshold ● 0.4 1.1 V

Shutdown Pin Input Current V

Input Start-Up Voltage V

Undervoltage Lockout Light Load 1.8 V

Power Switch

Switch On Resistance ISW = 0.7A (Note 2) ● 0.50 0.72 Ω

Peak Switch Current (Note 3) ● 0.7 0.85 1.3 A

Switch Breakdown Voltage ISW = 100µA ● 30 45 V

Switch Leakage Current V

Switch Turn-On Delay (Note 5) 800 ns

Switch Turn-Off Delay (Note 5) 400 ns

Current Sense Resistor ● 0.28 0.42 Ω

Low-Battery Comparator

Low-Battery Threshold Falling Edge ● 1.20 1.24 1.28 V

Threshold Hysteresis 20 mV

LBI Input Bias Current ● 20 50 nA

LBO Output Low State V

LBO Leakage Current V

LT1500 Functions

SYNC Pin Bias Current V

SYNC Pin Threshold ● 0.4 1.3 V

Error Amplifier Transconductance 600 µmho

VC Pin Source Current 20 µA

VC Pin High Clamp Voltage 1.20 1.26 1.32 V

NFB Reference Voltage FB Pin Open ● 1.230 1.265 1.300 V

NFB Pin Bias Current ● 12 20 µA

NFB to FB Transconductance Note 4 10,000 µmho

Soft Start Bias Current Current Flows Out of Pin ● 247 µA

≤ 5V, V

IN

VIN = 15V ● 320 µA

≤ 0.2V, Fixed Voltages (Note 7)

SHDN

≥ 0°C ● 815 µA

T

J

T

< 0°C20µA

J

= 2.3V ● 310 µA

SHDN

= V

SHDN

Full Load 2.0 2.1 V

SW

VSW = 20V ● 0.3 10 µA

LBI

I

SINK

LBI

SYNC

IN

TJ ≥ 0°C ● 2.0 2.1 V

TJ < 0°C 2.2 V

= 5V ● 0.2 5 µA

= 1.2V, I

= 2mA ● 0.3 0.5 V

= 1.3V, V

= 3.3V ● 15 35 µA

TJ = 25°C, VIN = 2.3V unless otherwise noted.

● 22 30 µA

= 2.3V (Note 1) ● 200 280 µA

SHDN

= 100µA ● 0.1 0.25 V

SINK

≤ 15V ● 2 µA

LBO

3

LT1500/LT1501

LOAD CURRENT (mA)

0255075

FREQUENCY (kHz)

1000

100

10

100 125 150 175 200

LTC1500/01 • TPC22

10µH

50µH

20µH

100µH

BURST REGION

VIN = 5V

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range.

Note 1: Feedback pin or output is held sightly above the regulated value to

force the V

node low and switching to stop.

C

Note 2: See Typical Performance Characteristics for graph of Guaranteed

Switch Voltage vs Saturation Voltage.

Note 3: Peak switch current is the guaranteed minimum value of switch

current available in normal operation. Highest calculated switch current at

full load should not exceed the minimum value shown.

Note 4: Loading on FB pin will affect NFB reference voltage. ∆V

= IFB/gm.

NFB

Do not exceed 10µA loading on FB when NFB is being used.

Note 5: This is the delay between sense pin current reaching its upper or

lower threshold and switch transition. Switch delay times cause peak-to-

W

U

peak inductor current to increase and therefore switching frequency to be

low. This effect will be significant for frequencies above 100kHz. See

Application Information and Typical Performance Characteristics.

Note 6: Reference voltage under all conditions includes V

all loads and full temperature range.

Note 7: As with all boost regulators the output voltage of the LT1500

cannot fall to less than input voltage because of the path through the catch

diode. This means that the output voltage divider on adjustable parts will

still be generating feedback voltage at the FB pin (fixed voltage parts have

an internal switch to disconnect the divider in shutdown). If the voltage on

FB is greater than 0.6V in shutdown, the internal error amplifier will draw

current that adds to shutdown current. See graph of Shutdown Current vs

FB voltage in Typical Performance Characteristics.

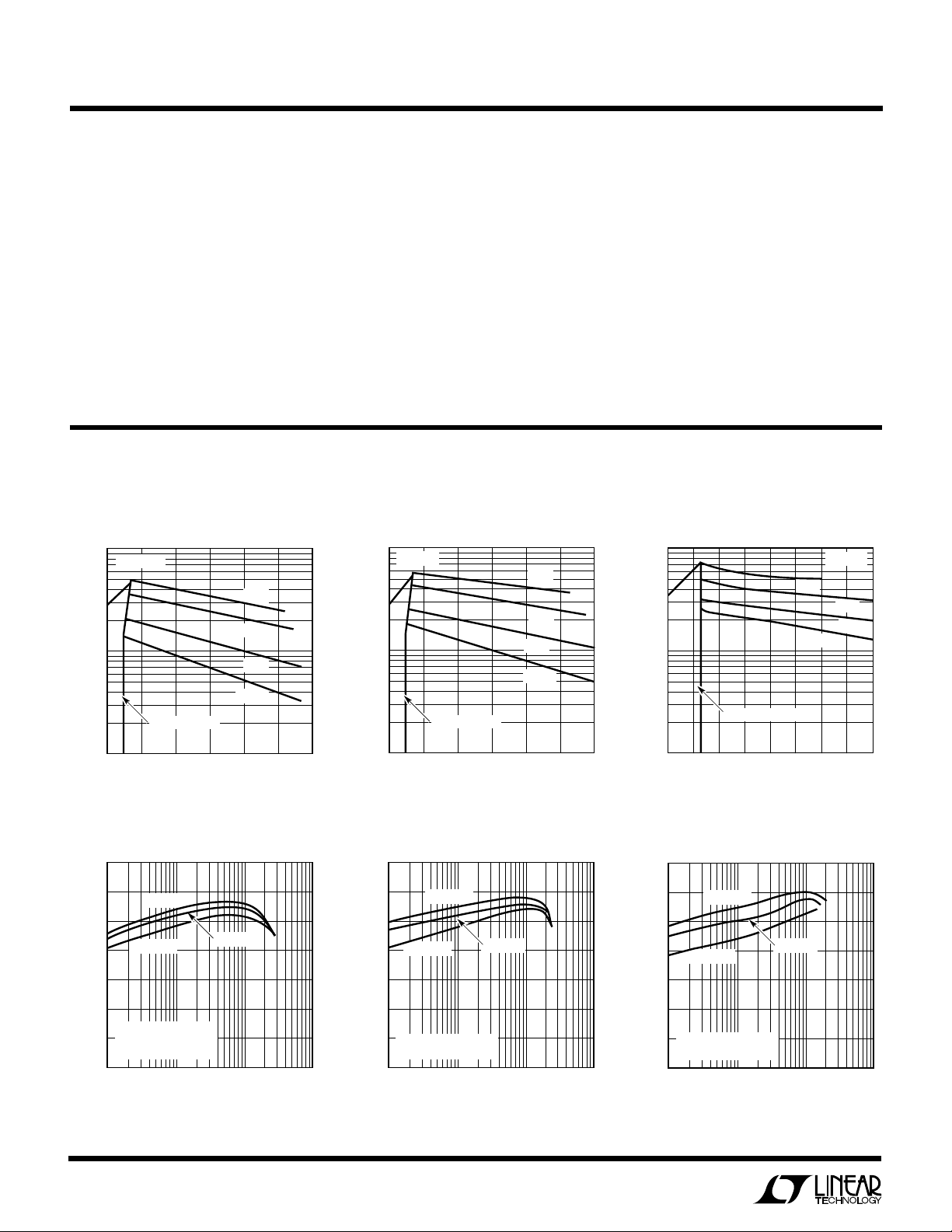

TYPICAL PERFORMANCE CHARACTERISTICS

Switching Frequency

(3.3V Output)

1000

VIN = 2.3V

100

FREQUENCY (kHz)

10µH

20µH

50µH

100µH

Switching Frequency (5V Output)

1000

VIN = 3V

100

FREQUENCY (kHz)

50µH

100µH

10µH

20µH

= 2.1V to 15V,

IN

Switching Frequency (12V Output)

EFFICIENCY (%)

BURST REGION

10

0 50 100

LOAD CURRENT (mA)

Efficiency (3.3V Output)

100

90

80

70

60

50

40

30

L = 100µH

L = 10µH

TJ = 25°C

= 2.3V

V

IN

LOW LOSS INDUCTOR

1

LOAD CURRENT (mA)

10 100 1000

150 200 250 300

LTC1500/01 • TPC20

L = 33µH

LTC1500/01 • TPC17

BURST REGION

10

0 50 100

LOAD CURRENT (mA)

Efficiency (5V Output)

100

90

80

70

60

EFFICIENCY (%)

50

40

30

L = 100µH

L = 10µH

VIN = 3V

LOW LOSS INDUCTOR

1

10 100 1000

LOAD CURRENT (mA)

150 200 250 300

LTC1500/01 • TPC21

L = 33µH

LTC1500/01 • TPC18

Efficiency (12V Output)

100

90

80

70

60

EFFICIENCY (%)

50

40

30

L = 100µH

L = 10µH

VIN = 5V

LOW LOSS INDUCTOR

1

10 100 1000

LOAD CURRENT (mA)

L = 33µH

LTC1500/01 • TPC19

4

W

I

LOAD

= 50mA

I

LOAD

= 10mA

INPUT VOLTAGE (V)

0

EFFICIENCY (%)

100

90

80

70

60

50

40

2

468

LT1500/01 • TPC13

10 12

TJ = 25°C

L = 33µH

LOW LOSS INDUCTOR

U

TYPICAL PERFORMANCE CHARACTERISTICS

LT1500/LT1501

Efficiency (3.3V Output)

100

90

80

70

EFFICIENCY (%)

60

TJ = 25°C

50

L = 33µH

LOW LOSS INDUCTOR

40

1.75

I

LOAD

2.25 2.50 2.75

2.00

INPUT VOLTAGE (V)

= 100mA

Inductor Copper Loss

(3.3V Output)

10

R = 1Ω

1

I

LOAD

R = 0.5Ω

R = 0.2Ω

R = 0.1Ω

= 10mA

3.00 3.25

LT1500/01 • TPC11

Efficiency (5V Output)

100

I

= 10mA

90

80

70

EFFICIENCY (%)

60

50

40

2.0

LOAD

TJ = 25°C

L = 33µH

LOW LOSS INDUCTOR

3.0 3.5 4.0

2.5

INPUT VOLTAGE (V)

I

LOAD

= 100mA

Inductor Copper Loss (5V Output)

10

VIN = 3V

1

R = 1Ω

R = 0.5Ω

4.5 5.0

LT1500/01 • TPC12

R = 0.2Ω

R = 0.1Ω

Efficiency (12V Output)

Inductor Copper Loss

(12V Output)

10

VIN = 5V

1

R = 1Ω

R = 0.5Ω

R = 0.2Ω

EFFICIENCY LOSS (%)

VIN = 2.3V

0.1

0 50 100

LOAD CURRENT (mA)

Maximum Load Current

(3.3V Output)

600

500

400

300

200

OUTPUT CURRENT (mA)

100

0

1.50

2.00 2.25 2.50

1.75

INPUT VOLTAGE (V)

150 200 250 300

LT1500/01 • TPC14

L ≥ 33µH

L = 10µH

2.75 3.00

LT1500/01 • TPC08

EFFICIENCY LOSS (%)

0.1

600

500

400

300

200

OUTPUT CURRENT (mA)

100

0

0 50 100

150 200 250 300

LOAD CURRENT (mA)

Maximum Load Current

(5V Output)

L ≥ 33µH

L = 10µH

2.0

3.0 3.5 4.0

2.5

INPUT VOLTAGE (V)

LT1500/01 • TPC15

4.5 5.0

LT1500/01 • TPC09

EFFICIENCY LOSS (%)

0.1

600

500

400

300

200

OUTPUT CURRENT (mA)

100

0

0255075

100 125 150 175 200

LOAD CURRENT (mA)

Maximum Load Current

(12V Output)

L = 33µH

L = 100µH

L = 10µH

0

468

2

INPUT VOLTAGE (V)

LTC1500/01 • TPC16

10 12

LT1500/01 • TPC10

5

LT1500/LT1501

AVERAGE SWITCH CURRENT

0

220

200

180

160

140

120

100

80

0.3 0.5

LT1500/01 • TPC07

0.1 0.2

0.4 0.6 0.7

PEAK-TO-PEAK INDUCTOR CURRENT

VIN = 3.3V

V

OUT

= 5V

L

= 50µH

NOTE THAT RIPPLE CURRENT

INCREASES WITH SMALLER

INDUCTORS DUE TO

PROPAGATION DELAY

IN THE CURRENT

COMPARATOR

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

Burst Mode Threshold

120

TJ = 25°C

LOAD CURRENT IS

100

REDUCED UNTIL Burst

Mode OPERATION STARTS

80

60

40

LOAD CURRENT (mA)

20

V

= 3.3V

OUT

V

= 5V

OUT

V

= 12V

OUT

Switch Saturation Voltage

1.0

TJ = 25°C

0.8

0.6

0.4

SWITCH VOLTAGE (V)

0.2

Peak-to-Peak Inductor Ripple

Current

0

0

468

2

INPUT VOLTAGE (V)

10 12

LT1500/01 • TPC01

0

0.2

0

SWITCH CURRENT (A)

0.4

0.6

0.8

LT1500/01 • TPC06

1.0

Low-Battery Output Saturation

VoltageQuiescent Input Supply Current

400

TJ = 25°C

OR V

V

350

FB

SO THAT Burst Mode

OPERATION IS ACTIVATED.

300

DOES NOT INCLUDE

OUTPUT DIVIDER CURRENT

250

200

150

SUPPLY CURRENT (µA)

100

50

0

510 20

0

HELD 5% HIGH,

OUT

INPUT VOLTAGE (V)

15

25

LT1500/01 • TPC04

0.6

TJ = 25°C

V

LBI

0.5

0.4

0.3

VOLTAGE (V)

0.2

0.1

0

0

≤ 1.2V

234

1

SINK CURRENT (mA)

56

LT1500/01 • TPC02

Shutdown Input Current vs

Input Current in Shutdown

20

TJ = 25°C

= 0V

V

SHDN

16

12

8

CURRENT (µA)

4

0

5

0

INPUT VOLTAGE (V)

15

20

10

25

LT1500/01 • TPC03

Feedback Pin Voltage

140

TJ = 25°C

= 5V

V

120

IN

ADJUSTABLE PARTS ONLY.

FIXED VOLTAGE PARTS DO

100

NOT SHOW SHUTDOWN

CURRENT INCREASE WITH

80

60

CURRENT (µA)

40

20

0

0

FEEDBACK VOLTAGE

0.2 0.4

FEEDBACK PIN VOLTAGE (V)

0.8 1.2 1.4

0.6 1.0

LT1500/01 • TPC05

6

UUU

PIN FUNCTIONS

LT1500/LT1501

SHDN: Logic Level Shutdown Pin.

high (> 1.1V) for the regulator to run

directly to VIN, even with VIN = 18V. The low-battery

detector remains active in shutdown, but all other circuitry

is turned off.

VIN: This pin supplies power to the regulator and is

connected to one side of the inductor sense resistor. It

should be bypassed close to the chip with a low ESR

capacitor.

I

: This is one end of the internal inductor-current

SENSE

sense resistor. With most applications, only the external

inductor is tied to this pin.

GND: This pin carries only low level current in the LT1500,

but it carries full switch current in the LT1501. The

negative end of the input bypass capacitor should be

connected close to this pin and the pin should go directly

to the ground plane with the LT1501.

PGND (LT1500 Only): This pin is the emitter of the internal

NPN power switch. Connect it directly to the ground plane.

This pin must be held

. SHDN can be tied

NFB/SELECT (LT1500 Only): NFB is a second feedback

node used to regulate a negative output voltage. Negative

output voltages can be generated by using a transformer

flyback circuit, a Cuk converter or a capacitor charge pump

added to a boost converter. The regulating point for NFB

is 1.265V and the internal resistance to ground is 100kΩ.

External divider current should be 300µA or greater to

avoid negative output voltage variations due to production

variations in the internal resistor value. FB should be left

open when using NFB.

On fixed voltage parts, NFB is replaced with Select. The

Select pin is used to set output voltage at either 3.3V or 5V.

VC (LT1500 Only): This is the output of the error amplifier

and the input to the current comparator. The VC pin voltage

is about 700mV at very light loads and about 1.2V at full

load. An internal comparator detects when the VC voltage

drops below about 750mV and shuts down the current

comparator and the power switch biasing to reduce quiescent current. This forces the regulator to operate in Burst

Mode operation.

SW: This is the collector of the internal NPN power switch.

To avoid EMI and overvoltage spikes, keep connections to

this pin very short.

LBI: This is the input to the low-battery detector with a

threshold of 1.24V. Maximum pin voltage is 5V. Bypass

LBI with a small filter capacitor when used. If unused, tie

LBI to ground. The low-battery detector remains active in

shutdown.

LBO : This is the open collector output of the low-battery

detector. It will sink up to 2mA. Leave open if not used.

FB/V

a regulating point of 1.265V and a typical bias current of

30nA. Bias current is reduced with a canceling circuit, so

bias current could flow in either direction. FB is replaced

with V

internal divider that is connected to the internal FB node.

A switch disconnects the divider in shutdown so that the

divider current does not load VIN through the inductor and

catch diode.

: FB is the inverting input to the error amplifier with

OUT

on fixed voltage parts. V

OUT

is the top of an

OUT

SYNC (LT1500 Only): This is a logic level input used to

synchronize switching frequency to an external clock. The

sync signal overrides the internal current comparator and

turns the switch on. Minimum sync pulse width should be

50ns and maximum width should be 300ns. A continuous

high sync signal will force the power switch to stay on

indefinitely and current will increase without limit. Don’t

do this!

SS (LT1500 Only): This is the soft start function using the

base of a PNP transistor whose emitter is tied to the VC pin.

Grounding SS will turn off switching by pulling VC low. A

capacitor tied from SS to ground will force VC to ramp up

slowly during start-up at a rate set by the capacitor value

and the internal 4µ A pull-up current. An external resistor

must be used to reset the capacitor voltage completely to

0V at power down.

7

LT1500/LT1501

BLOCK DIAGRAM

LBI

+

–

1.24V

W

INSYNCLBO

I

SENSE

R

SENSE

Rh

0.28Ω

18mV

–

+

OUTPUT

+

0.75V

–

SHDN

BIAS

COMPARATOR

1.265V

REFERENCE

100k

BURST

+

+

ERROR AMP

–

–

100k

NEGATIVE

ERROR AMP

+

FBNFB GND

U

150pF

WUU

APPLICATIONS INFORMATION

CURRENT

COMPARATOR

SW

FIXED

HYSTERESIS

I

1

VARIABLE

HYSTERESIS

I

2

S1

V

C

Q1

PGND

R1

R2

LTC1500/01 • BD

OPERATION (SEE BLOCK DIAGRAM)

The LT1500 uses a current mode architecture without the

need for an internal oscillator. Switching frequency is

determined by the value of the external inductor used. This

technique allows the selection of an operating frequency

best suited to each application and considerably simplifies

the internal circuitry needed. It also eliminates a

subharmonic oscillation problem common to all fixed

frequency (clocked) current mode switchers. In addition,

it allows for high efficiency micropower operation while

maintaining higher operating frequencies. Because the

power switch (Q1) is grounded, the basic topology used

8

will normally be a boost converter with output voltage

always higher than the input voltage. Special topologies

such as the SEPIC, flyback and Cuk converter can also be

used when the output voltage may not always be higher

than the input or when full shutdown of the output voltage

is needed. Operation as a boost converter is as follows.

Assume that inductor current is continuous, meaning that

it never drops to zero. When the switch is on, inductor

current will increase with voltage across the inductor

equal to VIN. When the switch is off inductor current will

decrease with inductor voltage equal to V

OUT

– VIN.

Switching frequency will be determined by the inductor

LT1500/LT1501

U

WUU

APPLICATIONS INFORMATION

value, the peak-to-peak inductor current (set internally)

and the values for VIN and V

output voltage in continuous mode by adjusting the average value of inductor current while maintaining the peakto-peak value of the current relatively constant, hence, the

name “current mode architecture.”

The LT1500 sets the peak-to-peak value of switch current

internally to establish operating frequency. This peak-topeak value is scaled down somewhat at light load currents

to avoid as long as possible the characteristic of other

micropower converters wherein their switching frequency

drops very low (into the audio range) at less than full load

currents. At extremely light loads, even the LT1500 can no

longer maintain higher frequency operation, and utilizes a

Burst Mode operation to control output voltage.

Details of Continuous Mode Operation

At the start of a switch cycle, inductor current has decreased to the point where the voltage across R

less than the internally generated voltage across Rh. This

causes the current comparator output to go high and turn

on the switch. At the same time, extra current is added to

Rh via S1 to create hysteresis in the trip point of the

comparator. This extra current is composed of a fixed

amount (I1), and an amount proportional to average

inductor current (I2). The presence of a variable I2 increases switching frequency at lighter loads to extend the

load current range where high frequency operation is

maintained and no Burst Mode operation exists.

With the switch turned on, inductor current will increase

until the voltage drop across R

voltage across Rh. Then the comparator output will go

low, the switch will turn off and the current through Rh will

be switched back to its lower value. Inductor current will

decrease until the original condition is reached, completing one switch cycle.

Control of output voltage is maintained by adjusting the

continuous current flowing through Rh. This affects both

upper and lower inductor current trip levels at the same

time. Continuous Rh current is controlled by the error

amplifier which is comparing the voltage on the Feedback

pin to the internal 1.265V reference. An internal frequency

. The LT1500 controls

OUT

SENSE

is equal to the higher

SENSE

is

compensation capacitor filters out most the ripple voltage

at the amplifier output.

Operation at Light Loads

At light load currents the lower trip level (switch turn-on)

for inductor current drops below zero. At first glance, this

would seem to initiate a permanent switch off-state because the inductor current cannot reverse in a boost

topology. In fact, what happens is that output voltage

drops slightly between switch cycles, causing the error

amplifier output to increase and bring the current trip level

back up to zero. The switch then turns back on and

inductor current increases to a value set by I1 (I2 is near

zero at this point). The switch then turns off, and the

inductor energy is delivered to the output, causing it to rise

back up slightly. One or more switch cycles may be needed

to raise the output voltage high enough that the amplifier

output drops enough to force a sustained switch off

period. The output voltage then slowly drops back low

enough to cause the amplifier output to rise high enough

to initiate a switch turn-on. Switching operation now

consists of a series of bursts where the switch runs at

normal frequency for one or more cycles, then turns off for

a number of cycles. This Burst Mode operation is what

allows the LT1500 to have micropower operation and high

efficiency at very light loads.

Saving Current in Burst Mode Operation

Internal current drain for the LT1500 control circuitry is

about 400µA when everything is operating. To achieve

higher efficiency at extremely light loads, a special operating mode is initiated when the error amplifier output is

toward the low end of its range. The adaptive bias circuit

comparator detects that the error amplifier output is below

a predetermined level and turns off the current comparator

and switch driver biasing. This reduces current drain to

about 200µA, and forces a switch off state. Hysteresis in

the comparator forces the device to remain in this

micropower mode until the error amplifier output rises up

beyond the original trip point. The regulated output voltage will fall slightly over a relatively long period of time

(remember that load current is very low) until the error

amplifier output rises enough to turn off the adaptive bias

9

LT1500/LT1501

U

WUU

APPLICATIONS INFORMATION

mode. Normal operation resumes for one or more switch

cycles and the output voltage increases until the error

amplifier output falls below threshold, initiating a new

adaptive bias shutdown.

DESIGN GUIDE

Selecting Inductor Value

Inductor value is chosen as a compromise between size,

switching frequency, efficiency and maximum output current. Larger inductor values become physically larger but

provide higher output current and give better efficiency

(because of the lower switching frequency). Low inductance minimizes size but may limit output current and the

higher switching frequency reduces efficiency.

The simplest way to handle these trade-offs is to study the

graphs in the Typical Performance Characteristics section. A few minutes with these graphs will clearly show the

trade-offs and a value can be quickly chosen that meets the

requirements of frequency, efficiency and output current.

This leaves only physical size as the final consideration.

The concern here is that for a given inductor value, smaller

size usually means higher series resistance. The graphs

showing efficiency loss vs inductor series resistance will

allow a quick estimate of the additional losses associated

with very small inductors.

One final consideration is inductor construction. Many

small inductors are “open frame ferrites” such as rods or

barrels. These geometries do not have a closed magnetic

path, so they radiate significant B fields in the vicinity of the

inductor. This can affect surrounding circuitry that is

sensitive to magnetic fields. Closed geometries such as

toroids or E-cores have very low stray B fields, but they are

larger and more expensive (naturally).

Catch Diode

The catch diode in a boost converter has an average

current equal to output current, but the peak current can

be significantly higher. Maximum reverse voltage is equal

to output voltage. A 0.5A Schottky diode like MBR0520L

works well in nearly all applications.

Input Capacitor

Input capacitors for boost regulators are less critical than

the output capacitor because the input capacitor ripple

current is a simple triwave without the higher frequency

harmonics found in the output capacitor current. Peak-topeak current is less than 200mA and worst-case RMS

ripple current in the input capacitor is less than 70mA.

Input capacitor series resistance (ESR) should be low

enough to keep input ripple voltage to less than 100mV

This assumes that the capacitor is an aluminum or tantalum type where the capacitor reactance at the switching

frequency is small compared to the ESR.

C

≥

A typical input capacitor is a 33µ F, 6V surface mount solid

tantalum type TPS from AVX. It is a “C” case size, with

0.15Ω maximum ESR. Some caution must be used with

solid tantalum input capacitors because they can be damaged with turn-on surge currents that occur when a low

impedance power source is hot-switched to the input of

the regulator. This problem is mitigated by using a capacitor with a voltage rating at least twice the highest expected

input voltage. Consult with the manufacturer for additional

guidelines.

If a ceramic input capacitor is used, different design

criteria are used because these capacitors have extremely

low ESR and are chosen for a minimum number of

microfarads.

C Ceramic

()

f = switching frequency

A typical unit is an AVX or Tokin 3.3µF or 4.7µF.

Output Capacitor

Output ripple voltage is determined by the impedance of

the output capacitor at the switching frequency. Solid

tantalum capacitors rated for switching applications are

recommended. These capacitors are essentially resistive

at frequencies above 50kHz, so ESR is the important factor

in determining ripple voltage. A typical unit is a 220µ F, 10V

2

π

f ESR

()( )

1

=

f

4

P-P

.

10

LT1500/LT1501

U

WUU

APPLICATIONS INFORMATION

type TPS from AVX, or type 595D from Sprague. These

have an ESR of 0.06Ω in a “E” case size. At lower output

current levels, a 100µF unit in a “D” case size may be

sufficient. Output ripple voltage can be calculated from:

V ESR

RIPPLE

=+

0112.

IV

.

()( )

OUT OUT

V

IN

Loop frequency stability is affected by the characteristics

of the output capacitor. The ESR of the capacitor should be

very low, and the capacitance must be large (> 200µ F) to

ensure good loop stability under worst-case conditions of

low input voltage, higher output voltages, and high load

currents. The 14-pin LT1500 can use external frequency

compensation on the VC pin to give good loop stability with

smaller output capacitors. See Loop Stability section for

details.

Precautions regarding solid tantalum capacitors for input

bypassing do not apply to the output capacitor because

turn-on surges are limited by the inductor and discharge

surges do not harm the capacitors.

M

1 1 265

.

R

()

12 1 265

–.

=

k2

118=

Note that there is an internal switch that disconnects the

internal divider for fixed 3.3V and 5V parts in shutdown.

This prevents the divider from adding to shutdown current. Without this switch, shutdown current increases

because of the divider current directly, but even more so

if the FB pin is held above 0.6V by the divider. See graphs

in Typical Performance Characteristics.

= 12V

V

OUT

R1

FB

–

ERROR

AMPLIFIER

Figure 1. External Voltage Divider

+

1.265V

1M

1%

R2

118K

1%

LTC1500/01 • F01

Selectable Output (Fixed Voltage Parts)

Setting Output Voltage

Preset 3.3V and 5V parts are available. For other voltage

applications the adjustable part uses an external resistor

divider to set output voltage. Bias current for the feedback

(FB) pin is typically ±30nA (it is internally compensated).

Thevenin divider resistance should be 100kΩ or less to

keep bias current errors to a minimum. This leads to a

value for R1 and R2 (see Figure 1) of:

kV

100

Ω

()

R

1

=

R

2

=

V

OUT

Example: V

100 12

R

OUT

V

1 265

.

R

1 1 265

.

()

1 265

–.

= xxV

OUT

k

Ω

1 265

.

()

=

949=

k1

) (use 1M

The Select pin (available only on LT1500-3/5) allows the

user to select either a 3.3V or 5V output. Floating the pin

sets output voltage at 3.3V and grounding the pin sets

output voltage at 5V. The equivalent circuit of the Select

pin function is shown in Figure 2.

V

OUT

204k

–

ERROR

AMPLIFIER

Figure 2. Schematic of Select Pin Function

+

1.265V

GND

Note that there is a switch in series with the V

69k

58k

SELECT

LTC1500/01 • F02

pin. This

OUT

switch is turned off in shutdown to eliminate shutdown

current drawn by the voltage divider. For adjustable parts

11

LT1500/LT1501

U

WUU

APPLICATIONS INFORMATION

with an external divider no switch exists and the divider

current remains. There may be additional current drawn

by the adjustable LT1500 in shutdown if the divider

voltage at the feedback node exceeds 0.6V. See Typical

Performance Characteristics.

Loop Stability

The LT1501 is internally compensated since the device

has no spare pin for a compensation point. The LT1500

brings out the VC pin to which an external series R

network is connected. This provides roll-off for the error

amplifier, ensuring overall loop stability. Typical values

when using tantalum output capacitors are 1000pF and

100kΩ.

Transient response of Figure 3’s circuit with a 30mA to

100mA load step is detailed in Figure 4. The maximum

output disturbance is approximately 20mV. The “splitting”

of the V

due to ESR of C

trace when load current increases to 100mA is

OUT

. C

OUT

can be replaced by a ceramic

OUT

unit, which has lower ESR, size and cost. Figure 5 shows

transient response to the same 30mA to 100mA load step,

with C

= 15µ F ceramic, CC = 2200pF and RC = 10k. The

OUT

maximum output disturbance in this case is 100mV.

C

Low-Battery Detector

The low-battery detector is a combined reference and

comparator. It has a threshold of 1.24V with a typical input

bias current of 20nA. In a typical application a resistor

divider is connected across the battery input voltage with

the center tap tied to Low Battery Input (LBI), see Figure

6. The suggested parallel resistance of the divider is 150k

V

COMP

500mV/DIV

V

OUT

20mV/DIV

AC COUPLED

I

LOAD

100mA

30mA

I

L

500mA/DIV

500µs/DIV

Figure 4. Transient Response of LT1500 with RC = 100k,

CC = 1000pF and C

V

COMP

500mV/DIV

= 220µF. V

OUT

Disturbance is 20mV

OUT

VIN

2V

SHDN

*TANTALUM = AVX TPS SERIES

CERAMIC = TOKIN 1E156ZY5U

Figure 3. LT1500 2V to 5V Converter

V

IN

LT1500

GND

I

SENSE

PGND

33µH

CTX33-1

SW

FB

V

C

MBR0520L

RC

100k

CC

1000pF

1M

332k

100pF

V

OUT

5V

+

C

OUT

220µF

LT1500/01 • F03

*

V

OUT

50mV/DIV

AC COUPLED

100mA

I

LOAD

30mA

I

L

500mA/DIV

200µs/DIV

Figure 5. Transient Response of LT1500 with RC = 10k, CC =

2200pF and C

=15µF Ceramic. V

OUT

R3

301k

1%

R4

274k

1%

V

LBI LBO

GND

R5

10M

IN

LT1500

LT1501

LT1500/01 • F06

Disturbance is 100mV

OUT

V

CC

470k

PULL-UP RESISTOR

SHOULD BE AT LEAST

FIVE TIMES SMALLER THAN

R5 TO ENSURE LBO

HIGH STATE

Figure 6. Low Battery Detection

12

LT1500/LT1501

R

kM

Mk

4

301 10 1 24

10 2 5 1 24 301 5 1 24

=

()()()

−

()

+−

()

=

.

.. .

272k (Use 274k 1%)

ff

f

fV

VV

SYNC NATURAL

SYNC

NATURAL OUT

OUT IN

>

<

()

–

(Use Minimum V )

IN

U

WUU

APPLICATIONS INFORMATION

and it should be no more than 300k to keep bias current

errors under 1%, giving:

RV

()

R

R

V

BAT

R

DIV

There is about 20mV of hysteresis at the LBI pin. Hysteresis can be increased by adding a resistor (R5) from the

output (LBO) back to LBI. This resistor can be calculated

from the following equation, but note that the equation for

R4 will have to be changed when R5 is added.

R

VCC = supply voltage for LBO pull-up resistor

DIV BAT

3

=

124

.

R

3124

()

=

4

V

–.

BAT

= low battery voltage

= Thevenin divider resistance = R3 in parallel with R4

5

=

VmVV

() ()

HYST BAT

V

.

124

RV

3

()

CC

17

–

The total divider resistance will be 274k + 301k = 575k, and

this will draw about 7µA from a fully charged battery.

Synchronizing

The SYNC pin on the LT1500 can be used to synchronize

switching frequency to an external clock. The pin should

be driven with a 50ns to 300ns pulse which will trigger the

switch to an on state. There is a fairly restricted range over

which synchronizing will work, because the period between

sync pulses must be greater than the natural on-time of

the regulator when it is running unsynchronized, and the

sync frequency must be greater than the unsynchronized

switching frequency. This puts the following restrictions

on synchronized operation:

V

= desired hysteresis at the battery

HYST

R4 (When R5 is Used)=

124

R3 R5

5 1 24 3 1 24

The LBO pin is open collector. The external pull-up resistor

value is determined by user needs. Generally the resistor

is 100k to 1M to keep current drain low, but the LBO pin

can sink several milliamperes if needed.

Example: low battery voltage = 2.5V, desired hysteresis =

200mV, VCC = 5V.

Use R

R

3

R

5

−

()

BAT CC

DIV

150 2 5

=

=

() ()

..RV RV

= 150k

.

k

()

.

124

301 5

.–. .

02 001725

.

()( )

+−

()

k (use 301k, 1%)

302

=

kV

()

=

9

.56M (Use 10M)

f

NATURAL

quency of the regulator. It is a function of load current, so

a careful check must be done to ensure that the above

conditions are met under all load and input voltage conditions.

Soft Start (SS)

The LT1500 can be soft started by connecting a capacitor

to the SS pin. This pin is the base of a PNP transistor

whose emitter is tied to the VC pin. Soft start action will

occur over the range of 0V to 0.8V on the SS pin and the

pin is clamped at 1.2V with an internal clamp. An internal

4µ A pull-up current and the external capacitor value

determine soft start time. In a typical application a 0.22µ F

capacitor is sufficient to limit input surges and prevent

output overshoot, even with overcompensation on the V

pin. Output voltages greater than 6V with very large output

is the natural unsynchronized switching fre-

C

13

LT1500/LT1501

P

W

TOTAL

=

()()()

−

()

()

+

−

()

+

()

()

=+ + =

015 072 5 5 22220155 22

30

0 42 0 15 5

22

0 47 0 014 0 049 0 11

2

2

2

2

.. .

.

..

..•

.

.. . .

U

WUU

APPLICATIONS INFORMATION

capacitors may require the capacitor to be larger. To

ensure proper reset of the soft start capacitor, an external

resistor must be connected in parallel with the capacitor.

The resistor value should be 470k or more.

Calculating Temperature Rise

For most applications, temperature rise in the IC will be

fairly low and will not be a problem. However, if load

currents are near the maximum allowed and ambient

temperatures are also high, a calculation should be done

to ensure that the maximum junction temperature of

100°C is not exceeded. The calculations must account for

power dissipation in the switch, the drive circuitry and the

sense resistor.

2

P

TOTAL

IRVVV

()()( )

OUT SW OUT OUT IN

=

()

IV V R I V

()

OUT OUT IN SENSE OUT OUT

+

−

()

2

V

IN

+

30

−

•

()

2

()

V

IN

2

P

= total device power dissipation

TOTAL

RSW = switch resistance (0.72Ω max)

R

With VIN = –2.2V, V

= sense resistance (0.42Ω max)

SENSE

= 5V, I

OUT

= 150mA, an 8-pin SO

OUT

package and maximum ambient temperature of 85°C

(industrial range),

The SO package has a thermal resistance of 120°C/W, so

maximum device temperature will be:

T

= 85°C + 0.11W(120°C/W) = 98°C

JMAX

PACKAGE DESCRIPTION

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

14

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0.016 – 0.050

0.406 – 1.270

U

Dimensions in inches (millimeters) unless otherwise noted.

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.189 – 0.197*

(4.801 – 5.004)

0°– 8° TYP

0.228 – 0.244

(5.791 – 6.197)

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

7

8

1

2

5

6

3

4

0.150 – 0.157**

(3.810 – 3.988)

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

SO8 0695

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

S Package

14-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.337 – 0.344*

(8.560 – 8.738)

13

12

14

11 10

9

LT1500/LT1501

8

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0° – 8° TYP

0.016 – 0.050

0.406 – 1.270

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

0.150 – 0.157**

(3.810 – 3.988)

1

3

2

4

5

0.050

(1.270)

TYP

7

6

0.004 – 0.010

(0.101 – 0.254)

S14 0695

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

15

LT1500/LT1501

TYPICAL APPLICATION

Typical LT1500 (14-Pin) Application, 2-Cell to 5V Converter

2 EACH

NiCd OR

ALKALINE

CELLS

+

249k

U

OFF (LO)

5V

470k

TO

SYSTEM

ON(HI)

IN

SHDN

LBI

LT1500-3.3/LT1501-5

LBO

SYNC

SS

GND PGND

I

SENSE

SW

OUT

SELECT

COMP

33µH

MBR0520L

5V

+

220µF

10V

402k

1nF

1M

0.22µF

100k

1000pF

LT1500/01 • TA02

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC®1163 Triple High Side Driver for 2-Cell Inputs 1.8V Minimum Input, Drives N-Channel MOSFETs

LTC1174 Micropower Step-Down DC/DC Converter 94% Efficiency, 130µA IQ, 9V to 5V at 300mA

LT1302 High Output Current Micropower DC/DC Converter 5V/600mA from 2V, 2A Internal Switch, 200µA I

LT1304 2-Cell Micropower DC/DC Converter Low-Battery Detector Active in Shutdown

LTC1440/1/2 Ultralow Power Single/Dual Comparator with Reference 2.8µA IQ, Adjustable Hysteresis

LTC1516 2-Cell to 5V Regulated Charge Pump 12µA IQ, No Inductors, 5V at 50mA from 3V Input

LT1521 Micropower Low Dropout Linear Regulator 500mV Dropout, 300mA Current, 12µA I

Q

Q

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1 900

●

FAX

: (408) 434-0507

●

TELEX

: 499-3977

LT/GP 0896 7K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1996

Loading...

Loading...