Applications of the LT1300 and LT1301

Micropower DC/DC Converters

Dale Eagar and Steve Pietkiewicz

INTRODUCTION

Application Note 59

January 1994

The design of battery-powered equipment can often be

quite challenging. Since few ICs can operate directly from

the end-of-life voltage from a 2-cell battery (about 1.8V),

most systems require a DC/DC converter. The system

designer often has a limited area in which to place the DC/

DC converter; associated inductors and capacitors must be

small. Surface mount components are a must and heat

sinks are out of the question! The LT1300 and LT1301

micropower DC/DC converter ICs provide new possibilities

for more efficient, compact and cost effective designs.

When designing equipment for battery-powered

operation, a number of important design constraints

should be considered. Some of these are detailed in the

check list given here:

• Design for high efficiency. A high efficiency converter

increases battery life, eliminates most heat sinks, reduces

weight and decreases PC board area. The designer

should strive for high efficiency at:

– Full Load

– Light Load

• Plan to utilize all the capacity of the battery. Can the

circuit run down to the “dead cell” voltage? Is there a

micropower shutdown mode?

• Can the DC/DC converter circuitry provide high output

power for short time intervals? Often this is a requirement

on battery-powered equipment.

• Cost. Is the complete circuit cost competitive?

• Does the design meet packaging constraints?

– Height

– PC Board Area

– Weight

The LT1300 family of DC/DC converters allows a maximum

of flexibility in the design of circuits which provide

solutions for battery-operated and other equipment

needing high efficiency, space efficient, micropower

power solutions.

INDEX TO LT1300 CIRCUITS

Figure Description Page

1 LT1300/LT1301 Block Diagram ................................................................................................................ 2

2 2-Cell to 5V DC/DC Converter Delivers >200mA with a 2V Input .............................................................. 3

8 Lower Power Applications Can Use Smaller Components. L1 is Tallest Component at 3.1mm ................ 5

11 4-Cell to 3.3V or 5V Converter Output Goes to Zero When in Shutdown .................................................. 6

13 LT1301 Delivers 12V From 3.3V or 5V Input ............................................................................................ 7

15 Flame Detector.......................................................................................................................................... 8

16, 17 Voltage Buffer ....................................................................................................................................... 8, 9

18 CCFL Driver............................................................................................................................................. 10

19 Electronic Light Stick .............................................................................................................................. 11

20 Backlight LED Driver ............................................................................................................................... 11

21 Efficiency of LED Driver .......................................................................................................................... 12

AN59-1

Application Note 59

NEW LT1300 AND LT1301 MICROPOWER

DC/DC CONVERTERS

by Steve Pietkiewicz

Introduction

The new LT1300 and LT1301 micropower DC/DC converters provide improvements in both electrical and physical

efficiency, two key areas of battery-based power supply

design. Housed in 8-lead DIP or SOIC packages, the

devices feature a 1A on-chip switch with a V

CESAT

of just

170mV. The internal oscillator frequency is set at 155kHz,

allowing the use of tiny, 5mm diameter surface mount

inductors along with standard D-case size tantalum capacitors. A complete 2-cell to 12V, 5V, or 3.3V converter

can fit in less than 0.4 square inches of PC board area.

The devices use Burst ModeTM operation to maintain high

efficiency across the full load range. The fully operating

quiescent current is only 120µ A. It can be further reduced

to 10µA by taking the SHUTDOWN pin high, which also

disables the device. The output voltage of the LT1300 can

be set at either 5V or 3.3V via the logic-controlled SELECT

pin, and the LT1301 output can be set at either 5V or 12V

using the same pin. The I

pin allows the reduction of

LIM

peak switch current and allows the use of even smaller

components. The switch current is nominally set at 1A and

can be reduced via the I

pin to approximately 400mA,

LIM

further improving efficiency in systems requiring lower

peak powers.

Theory of Operation

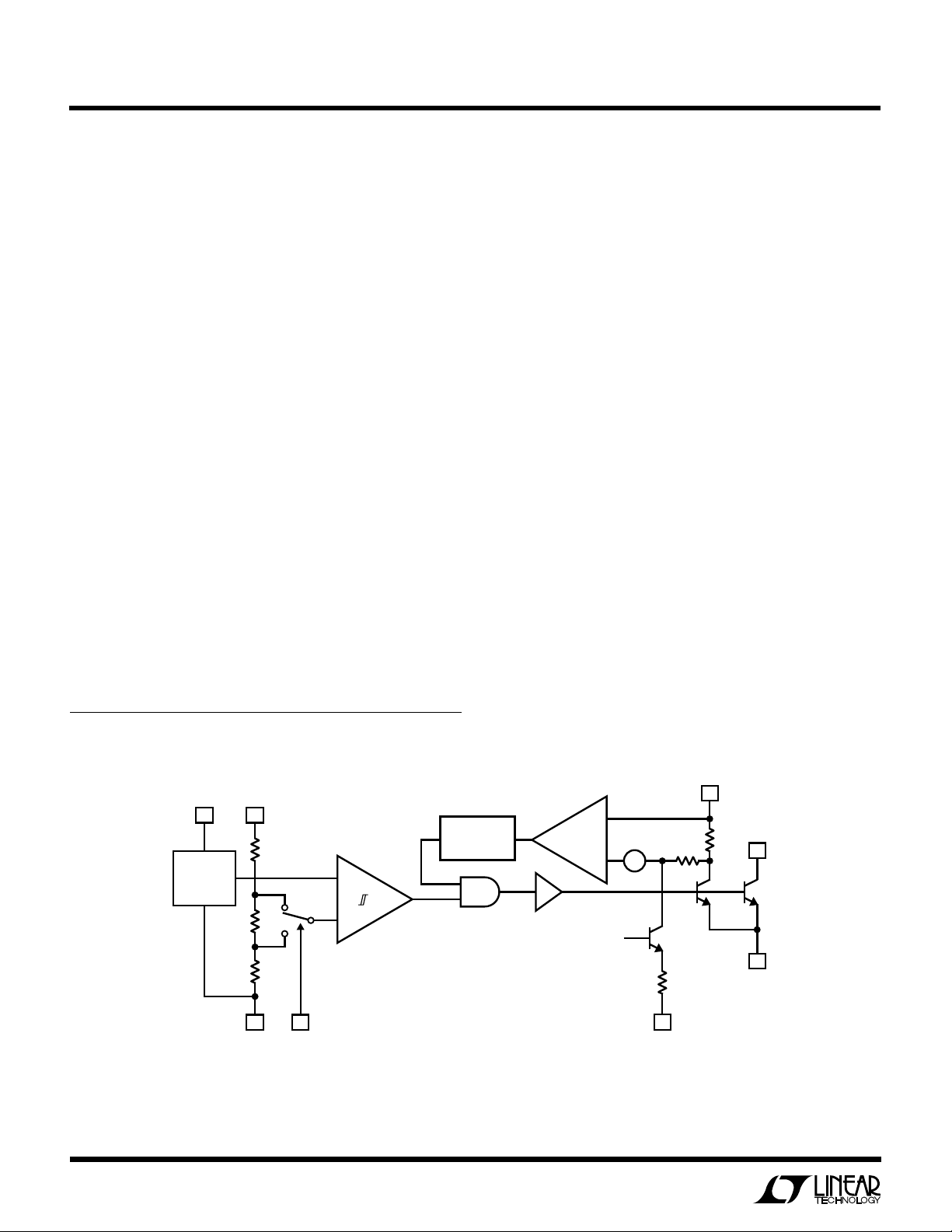

Figure 1 is a block diagram of the LT1300/LT1301. Refer

also to Figure 2 for associated component hookup. When

A1’s negative input, related to the SENSE pin voltage by the

appropriate resistor-divider ratio, is higher than the 1.25V

reference voltage, A1’s output is low. A2, A3 and the

oscillator are turned off, drawing no current. Only the

reference and A1 consume current, typically 120µ A. When

the voltage at A1’s negative input decreases below 1.25V,

overcoming A1’s 6mV hysteresis, A1’s output goes high,

enabling the oscillator, current comparator A2, and driver

A3. Quiescent current increases to 2mA as the device

prepares for high current switching. Q1 then turns on in a

controlled saturation for (nominally) 5.3µ s or until current

comparator A2 trips, whichever comes first. After a fixed

off-time of (nominally) 1.2µ s, Q1 turns on again. Refering

to Figure 2, the LT1300’s switching causes current to

alternately build up in L1 and dump into output capacitor

C1via D1, increasing the output voltage. When the output

is high enough to cause A1’s output to go low (Figure 1),

switching action ceases. C1 is left to supply current to the

Burst ModeTM is a trademark of Linear Technology Corporation

SENSESHUTDOWN

500k

1.25V

REFERENCE

144k

161k

GND SELECT

CURRENT

COMPARATOR

OSCILLATOR

5.3µs ON

1.2µs OFF

+

A3

DRIVER

–

A1

SLOW

COMPARATOR

ENABLE

Figure 1. LT1300/LT1301 Block Diagram

A2

V

IN

+

R1

SW

3Ω

Q2

3×

PGND

AN59 • F01

Q1

500×

–

BIAS

+

–

18mV

R2

700Ω

Q3

8.5k

I

LIM

AN59-2

Application Note 59

load until V

decreases enough to force A1’s output

OUT

high, and the entire cycle repeats. If switch current reaches

1A, causing A2 to trip, switch on-time is reduced and offtime increases slightly. This allows continuous mode

operation during bursts. Current comparator A2 monitors

the voltage across 3Ω resistor R1 which is

directly related

to inductor L1’s current. Q2’s collector current is set by

the emitter-area ratio to 0.6% of Q1’s collector current.

When R1’s voltage drop exceeds 18mV, corresponding to

1A inductor current, A2’s output goes high, truncating the

on-time portion of the oscillator cycle and increasing offtime to about 2µs as shown in Figure 3, trace A. This

programmed peak current can be reduced by tying the

I

pin to ground, causing 15µA to flow through R2 into

LIM

Q3’s collector. Q3’s current causes a 10.4mV drop in R2,

so that only an additional 7.6mV is required across R1 to

turn off the switch. This corresponds to a 400mA switch

current, as shown in Figure 3, trace B. The reduced peak

L1*

10µH

Burst ModeTM Operation

Burst ModeTM operation, a technique used by many LTC

switching regulator products, extends high efficiency

over widely varying loads.

At light load, switching regulators employing traditional

PWM regulation techniques suffer from low efficiency.

This is primarily due to relatively high quiescent (or

housekeeping) supply current and AC switching losses

resulting from constant frequency operation.

100

Burst ModeTM

SWITCHER

75

NON-Burst Mode

50

EFFICIENCY (%)

25

TM

2×

AA

CELL

SHUTDOWN

+

100µF

*SUMIDA CD54-100LC

COILCRAFT D03316-103

NC

SELECT

SHDN

I

LIM

V

IN

LT1300

SENSE

GND PGND

SW

D1

1N5817

+

Figure 2. Two-Cell to 5V DC/DC Converter Delivers >200mA

with a 2V Input

TRACE A

500mA/DIV

I

PIN

LIM

OPEN

TRACE B

500mA/DIV

I

PIN

LIM

GROUNDED

5µs/DIV

Figure 3. Switch Pin Current with I

Floating or Grounded

LIM

AN59 • F03

C1

100µF

AN59 • F02

5V OUTPUT

200mA

0

1255075

POWER (%)

100

AN59 • F1a

Figure 1a. Characteristics of Burst and Non-Burst Switchers

As seen in Figure 1a, the switching regulator not using

Burst ModeTM operation does not reach peak efficiency

until load power approaches 100%. Relatively high

fixed power drain inside the regulator accounts for the

efficiency fall-off as load is decreased. The regulator

utilizing Burst ModeTM operation, on the other hand,

maintains its high efficiency at light loads. It does this

by delivering energy to the output in discrete peak

efficiency packets. The energy packets result in a small

amount of ripple voltage (typically 50mV) on the output.

When not delivering these packets of energy to the

output, the regulator puts itself in a “sleep” mode with

only a voltage reference and a comparator powered up.

These two functions can be accomplished with very low

power drain. As the load is decreased to zero, even the

small amount of power consumed in sleep mode becomes significant compared to the load, resulting ultimately in decreasing efficiency.

AN59-3

Application Note 59

BATTERY

TIME (HOURS)

0

0

OUTPUT/BATTERY VOLTAGE (V)

5.0

11

AN59 • F06

9651

1.0

2.0

4.5

4.0

3.5

3.0

2.5

1.5

0.5

234 78 10

2× L91

LITHIUM

2× E91

ALKALINE

OUTPUT

switch current reduces I2R losses in Q1, L1, C1, and D1.

You can increase efficiency by doing this provided that the

accompaning reduction in full load output current is acceptable. Lower peak currents also extend alkaline battery

life due to the alkaline cells’ high internal impedance.

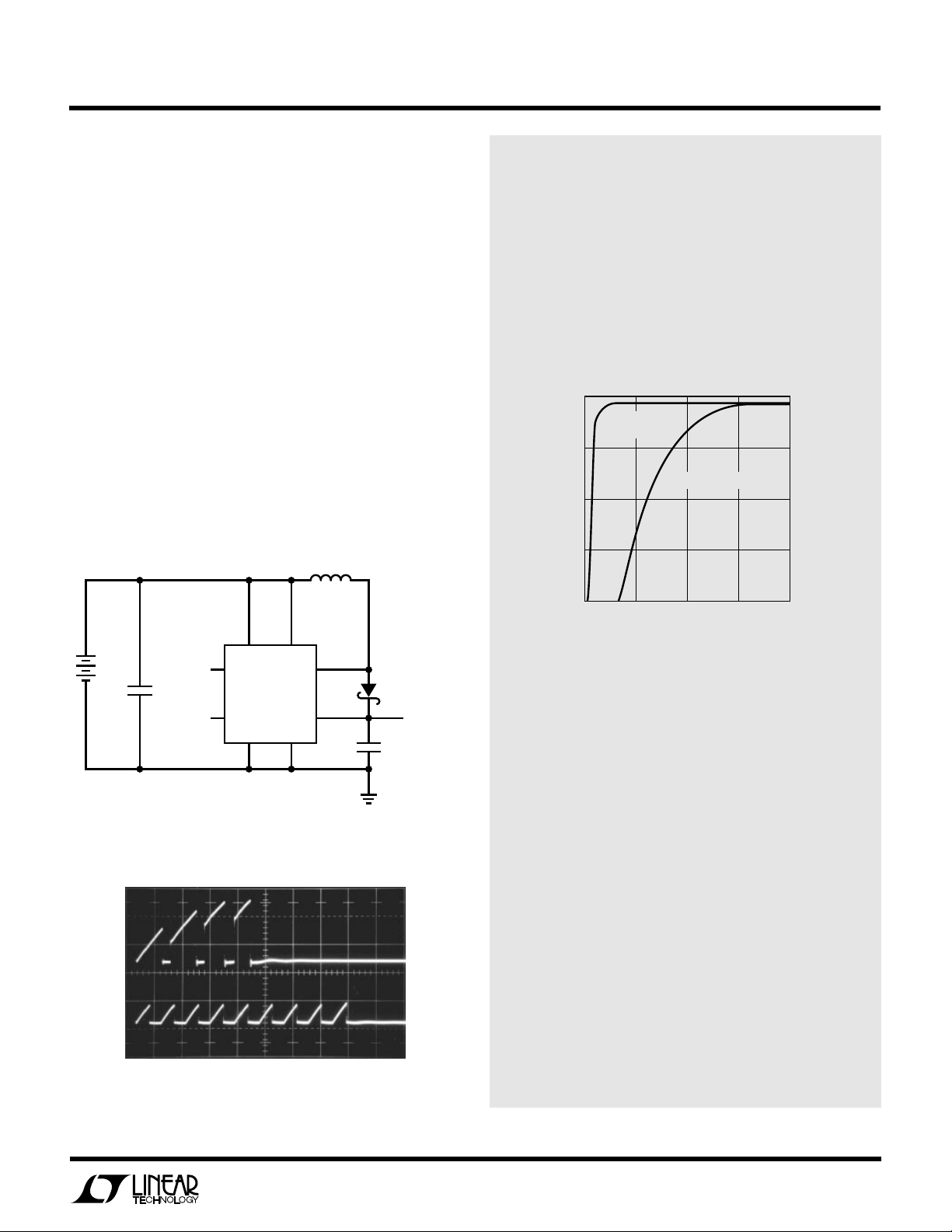

5V from 2 Cells

Figure 2’s circuit provides 5V from a 2-cell input. Shutdown is effected by taking the SHUTDOWN pin high. V

IN

current drops to 10µ A in this condition. This simple boost

topology does not provide output isolation and in shutdown the load is still connected to the battery via L1 and

D1. Figure 4 shows the efficiency of the circuit with a range

of input voltages, including a fresh battery (3V) and an

“almost dead” battery (2V). At load currents below a few

milliamperes, the 120µA quiescent current of the device

becomes significant, causing the fall-off in efficiency de-

90

88

86

84

82

80

EFFICIENCY (%)

78

76

74

1

10 500

LOAD CURRENT (mA)

VIN = 4.0V

VIN = 3.0V

VIN = 2.5V

VIN = 2.0V

100

AN59 • F04

tailed in Figure 4. At load currents in the 20mA to 200mA

range, efficiency flattens out in the 80% to 88% range,

depending on the input. Figure 5 details circuit operation.

V

is shown in trace A. The burst repetition pattern is

OUT

clearly shown as V

decays, then steps back up due to

OUT

switching action. Trace B shows the voltage at the switch

node. The damped, high frequency waveform at the end of

each burst is due to the inductor “ringing off,” forming an

LC tank with the switch and diode capacitance. It is not

harmful and contains far less energy than the high speed

edge which occurs when the switch turns off. Switch

current is shown in trace C. The current comparator inside

the LT1300 controls peak switch current, turning off the

switch when the current reaches approximately 1A.

Although efficiency curves present useful information, a

more important measure of battery-powered DC/DC converter performance is operating life. Figures 6 and 7 detail

battery life tests with Figure 2’s circuit at load currents of

100mA and 200mA respectively. Operating life curves are

shown using both Eveready E91 alkaline cells and new L91

“Hi-Energy” lithium cells. These lithium cells, new to the

market, are specifically designed for high drain applications. The performance advantage of lithium is about 2:1

at 100mA load current (Figure 6), increasing to 2.5:1 at

200mA load (Figure 7). Alkaline cells perform poorly at

high drain rates because their internal impedance ranges

V

OUT

A = 20mV/DIV

AC COUPLED

V

SW

B = 5V/DIV

AN59-4

I

SW

C = 1A/DIV

Figure 4. Efficiency of Figure 2’s Circuit

20µs/DIV

Figure 5. Burst ModeTM Operation in Action

AN59 • F05

Figure 6. Two Eveready L91 Lithium AA Cells Provide

Approximately Twice the Life of E91 AA Alkaline Cells at a

100mA Load Current

Application Note 59

TIME (HOURS)

0

0

OUTPUT/BATTERY VOLTAGE (V)

5.0

22

AN59 • F10

1812102

1.0

2.0

4.5

4.0

3.5

3.0

2.5

1.5

0.5

468 1416 20

2× L91

LITHIUM

2× E91

ALKALINE

OUTPUT

BATTERY

24

5.0

OUTPUT

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

OUTPUT/BATTERY VOLTAGE (V)

0.5

0

0

1.0 1.5 2.0 3.5 4.0 5.0

2× E91

ALKALINE

2× L91

LITHIUM

BATTERY

TIME (HOURS)

5.5

4.53.02.50.5

AN59 • F07

Figure 7. Doubling Load Current to 200mA Causes E91 Alkaline

Battery Life to Drop by 2/3; L91 Lithium Battery Shows 2.5:1

Difference in Operating Life

from 0.20Ω to 0.50Ω, causing a large voltage drop within

the cell. The alkaline cells feel quite warm at 200mA load

current, the result of I2R losses inside the cells.

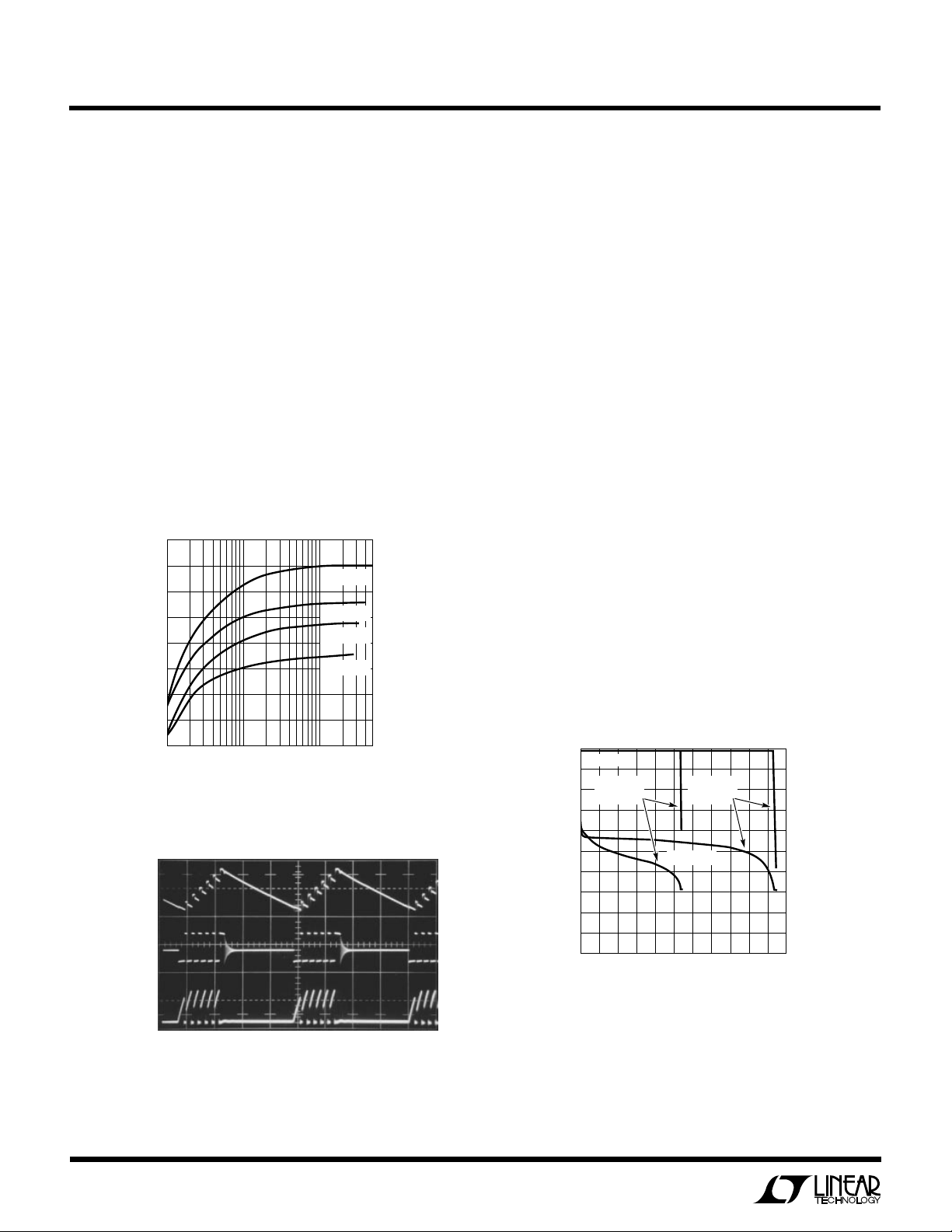

The reduced power circuit shown in Figure 8 can generate 5V at currents up to 50mA. Here the I

LIM

pin is

grounded, reducing peak switch current to 400mA.

Lower profile components can be used in this circuit.

The capacitors are C-case size solid tantalum and inductor L1 is the tallest component at 3.2mm. The reduced

peak current also extends battery life since the I2R loss

due to internal battery impedance is reduced. Figure 9

L1*

22µH

90

88

86

84

82

80

EFFICIENCY (%)

78

76

74

1

10 100

LOAD CURRENT (mA)

VIN = 3V

VIN = 2.5V

VIN = 2V

AN59 • F09

Figure 9. Efficiency of Figure 8’s Circuit

Figure 10. 50mA Load and Reduced Switch Current Are

Kind to E91 AA Alkaline Battery; the Advantages of L91

Lithium Are Not as Evident

2×

AA

CELL

+

*COILCRAFT 1608-223

Figure 8. Lower Power Applications Can Use Smaller

Components. L1 is Tallest Component at 3.1mm

SHUTDOWN

47µF

SELECT

SHDN

LT1300

I

LIM

GND PGND

V

IN

SW

SENSE

details efficiency versus load current for several input

voltages and Figure 10 shows battery life at a 50mA load.

Note that the L91 lithium battery lasts only about 40%

longer than the alkaline. The higher cost of the lithium

cells makes the alkaline cells more cost effective in this

application. A pair of Eveready AAA alkaline cells (type

E92) lasts 96.6 hours with 5mA load, very close to the

+

D1

MBRS140T3

5V OUTPUT

50mA

33µF

rated capacity of the battery.

AN59 • F08

AN59-5

Application Note 59

A 4-Cell Application

A 4-cell pack is a convenient, popular battery size. Alkaline

cells are sold in 4-packs at retail stores and four cells

usually provide sufficient energy to keep battery replacement frequency reasonable. Generating 5V from four

cells, however, is a bit tricky. A fresh 4-cell pack has a

terminal voltage of 6.4V but at the end of its life, the pack’s

terminal voltage is around 3.2V; hence, the DC/DC converter must step the voltage either up or down, depending

on the state of the batteries.

A flyback topology with a costly, custom designed transformer could be employed, but Figure 11’s circuit gets

around these problems by using a flying capacitor scheme

along with a second inductor. The circuit also isolates the

input from the output, allowing the output to go to 0V

during shutdown. The circuit can be divided conceptually

into boost and buck sections. L1 and the LT1300 switch

comprise the boost or step-up section, and L2, D1, and C3

comprise the buck or step-down section. C2 is charged to

VIN and acts as a level shift between the two sections. The

switch node toggles between ground and VIN + V

the L2-C2 diode node toggles between –VIN and V

OUT

, and

OUT

+

VD. Figure 12 shows efficiency versus load current for the

circuit. All four energy storage elements must handle

power, which accounts for the lower efficiency of this

circuit compared to the simpler boost circuit in Figure 2.

84

82

80

78

76

74

72

EFFICIENCY (%)

70

68

66

64

1

VIN = 3V

VIN = 4V

VIN = 5V

VIN = 6V

10

LOAD CURRENT (mA)

100

AN59 • F12

Figure 12. Efficiency of Up-Down Converter in Figure 11

Efficiency is directly related to the ESR and DCR of the

capacitors and inductors used. Better capacitors cost

more money. Better inductors do not necessarily cost

more, but they do take up more space. Worst case RMS

current through C2 occurs at minimum input voltage and

measures 0.4A at full load with a 3V input. C2’s specified

maximum RMS current must be greater than this worst

case current. The Sanyo capacitors noted specify a maximum ESR of 0.045Ω with a maximum ripple current rating

of 2.1A. The Gowanda inductors specify a maximum DCR

of 0.058Ω.

AN59-6

C2**

100µF

+

L2*

27µH

C3**

100µF

1N5817

5V OR

3.3V

220mA

+

AN59 • F11

NC

4×

AA

+

CELLS

*L1, L2 = GOWANDA GA20-272K (716) 532-2234

**C1, C2, C3 = SANYO OS-CON 16SA100M (619) 661-6835

5V/3.3V

C1**

100µF

SHUTDOWN

I

LIM

SELECT

GND PGND

LT1300

V

IN

SW

SENSESHDN

L1*

27µH

Figure 11. 4-Cell to 3.3V or 5V Converter Output Goes to Zero When in Shutdown.

Inductors May Have, But Do Not Require Coupling; a Transformer or Two Separate

Units Can Be Used

Application Note 59

LT1301 Outputs 5V or 12V

The LT1301 is identical to the LT1300 in every way except

output voltage. The LT1301 can be set to a 5V or 12V

output via its SELECT pin. Figure 13 shows a simple 3.3V

or 5V to 12V step-up converter. It can generate 120mA at

12V from either 3.3V or 5V inputs, enabling the circuit to

provide VPP on a PCMCIA card socket. Figure 14 shows

the circuit’s efficiency. Switch voltage drop is a smaller

percentage of input voltage at 5V than 3.3V, resulting in a

high efficiency at 5V input.

L1*

3.3V

OR 5V

INPUT

SELECT

SHUTDOWN

+

*L1 =

100µF

SUMIDA

CD75-220K

(708) 956-0666

SHDN

LT1301

I

LIM

GND PGND

SENSE

Figure 13. LT1301 Delivers 12V from 3.3V or 5V Input

90

88

86

84

82

80

EFFICIENCY (%)

78

76

74

VIN = 5V

VIN = 3.3V

1

10 100

LOAD CURRENT (mA)

Figure 14. Efficiency of Figure 13’s Circuit

22µH

V

IN

SW

1N5817

12V

OUTPUT

+

47µF0.1µF

AN59 • F13

AN59 • F14

THE LT1300: TWO CELLS TO REAL WORLD INTERFACE

By Dale Eagar

Introduction

The LT1300 micropower, high speed, step-up DC/DC

converter opens up many new applications to the user,

such as those requiring high efficiency in battery-operated

equipment. The LT1300 can be used to produce high

voltages for many specialized tasks with high efficiency.

Here are three such applications. In the first application, a

flame detector, the LT1300 is used to produce 325V

DC

while drawing a mere 200µA from two C-size cells.

Flame Sensor

An interesting characteristic of flame is that it emits short

wavelength ultraviolet light (<260nm). This short wavelength light falls into a window of the light spectrum that

is relatively empty. Tungsten light, fluorescent light and

sunlight below the atmosphere are almost totally devoid of

spectral energy in this window. The circuit shown in

Figure 15 uses a photoelectric sensor with a sufficiently

high cathode work function to make it blind to anything

with a wavelength longer than 260nm (such as normal UV,

visible light or infrared). Cathode work function is a

measure of how hard it is to free an electron from an atom;

when related to light illuminating a cathode, it specifies the

minimum energy of a photon that can liberate an electron.

UV photons have higher energy than visible light.

Theory of Operation (see Figure 15)

The LT1300 and transformer T1 form a flyback converter

to step up the voltage from 3V to 325V. The secondary

winding of T1 connects through D1 (a MUR1100) to C1, a

holding capacitor for the 325VDC, which in turn is applied

to the anode of the photoelectric sensor tube V1. The

LT1300 SENSE pin senses the voltage on C1, as scaled by

the turns ratio, through T1. The voltage on the primary

winding is programmed to be 10.6V, translating to 325V

on C1. When C1 has charged to 325V the feedback loop

comprised of D3, R2 and Q1 kicks in and charges C4

through D4. When the voltage at C4 exceeds 3.3V the

LT1300 goes into its wait mode. In wait mode the LT1300

AN59-7

Application Note 59

D1

MUR1100

T1

C1

V1

R2868

1N4148

PULSE

R1

100k

V1 =

HAMAMATSU R2868

FLAME SENSOR

HAMAMATSU (408) 261-2022

=

T1

COILTRONICS CTX02-12186

COILTRONICS (407) 241-7876

=

Q1

ZETEX ZTX788

ZETEX (516) 543-7100

=

C1

47pF > 500V

D2

47pF

3V

3V

V

3

SHUTDOWN

C2

0.01µF

54

NC

U1

LT1300

I

LIM

SEL GND

218

Figure 15. Flame Detector

consumes only 120µA of current. The LT1300 stays in

wait mode until the voltage on C4 falls below 3.3V at which

time the LT1300 turns on to burst recharge both C1 and

C4. Burst Mode operation ensures 30Hz oscillation in this

system. This rate is determined by the value of C4, the

internal sense resistance to ground in the LT1300 (approximately 1MΩ), and the amount of overcharge C4 gets

when charging. D5 is a Schottky catch diode to keep

reverse current out of U1.

When illuminated with a photon of sufficient energy the

photoelectric tube’s cathode liberates an electron. The

tube V1 has 325V across its terminals to get sufficient

energy into a liberated photo-electron to ionize the gas

that fills the tube. Once the gas in the tube ionizes there are

more electrons available; they cause a chain reaction in

the tube that causes the tube to avalanche. When the tube

avalanches most of the charge on C1 is transferred to C2

and the voltage across C1 drops to a fraction of its original

325V. When C2 has charged to 3.6V all the excess charge

residing in C1 gets bypassed through D2 back into the

battery. The voltage across C2 is the output signal called

PULSE. PULSE asserts the shutdown pin of the LT1300,

allowing the plasma in the photoelectric tube to quench.

IN

6

D5

1N5718

C3

+

100µF

6.3V

7

SW

SENSE

PGND

ZTX788

Q1

D4

1N5718

C4

0.47µF

R2

1k

D3

1N758A

3V

AN59 • F15

For you analog purists, page 8 of the October 1993 issue

of

Linear Technology

magazine shows a discriminator

circuit with low-battery detect for a complete 3V flame

alarm. The discriminator is needed because the photo

detector occasionally detects a cosmic ray or some rare

room light photon.

Infinite Input Impedance Voltage Buffer

In the flame detector circuit (Figure 15), it is difficult to

measure the voltage across C1 because almost any load

invalidates the meter reading. This next application for the

LT1300 is a voltage buffer that overcomes this measurement problem. This is a four-terminal, unity-gain buffer as

shown functionally in Figure 16. The input impedance is

+OUT

–

ISOLATION

+IN

–IN

+

Figure 16. Voltage Buffer Block Diagram

+

E

AN59 • F16

–OUT

AN59-8

Application Note 59

+OUT

+IN

SW1

1.5V

1.5V

R1, R10 =

3V

LT1097

R3

1M

C1

1000pF

R1

100M

T1 =

R2

1M

COILTRONICS CTX02-12179

COILTRONICS (407) 241-7876

VICTOREEN SLIM-MOX100

VICTOREEN (216) 248-9300

R10

0.01µF

2

3

–OUT

C8

0.1

C2

–

LT1097

+

100M

+

R4

100k

U1

–IN

3V

R11

20Ω

7

U1

4

C7

1000pF

C6

100µF

6.3V

57

NC

I

4

SENSE

10k

6

6

V

IN

LIM

U2

LT1300

218

R5

R6

10k

D3

MUR1110

R9

5.1Ω

SW

3

SHUT-

DOWN

R7

1k

Q1

2N3904

3V

100µF

6.3V

C5

Z1

15V

C3

0.01µF

D1

1N4148

R8

1M

T1

+

C4

220pF

D2

1N4148

3V

AN59 • F17

Figure 17. Voltage Buffer Schematic

essentially infinite, the input bias current is negligible and

the input offset voltage is less than 0.05V. The output

voltage tracks the input voltage from 0V to 520V. For

safety (and to isolate the input capacitance) a 100M

resistor is placed in series with the input, but with the

± 570pA of input bias current (over temperature) for the

LT1097, this translates into only ±57mV of additional

offset. The input impedance of this buffer measures four

trillion ohms when measured with a 100V to 400V input.

The detailed circuit is shown in Figure 17.

Theory of Operation

U1 monitors the voltage difference between the circuit’s

noninverting input and output and attempts to make it

zero. If the voltage on the noninverting input is less than

the voltage on the noninverting output, U1’s output goes

positive, turning Q1 on slightly. Q1 acts as a current sink

discharging C3. When the voltage on C3 falls below

approximately 0.6V, U2 is enabled. When it is enabled U2

turns its switch on (U2’s pin 7 pulls low, to near 0V). This

causes approximately 3V to be imposed across the primary winding of T1. The magnetizing inductance of the

primary winding of T1, across which a voltage is applied,

requires a steadily increasing current. At the same time,

C4 is charged through D2. When the current flowing

through the switch of the LT1300 reaches 1A, the LT1300

switches off. The magnetizing inductance of the primary

winding of T1, seeing that the LT1300 is attempting to

discontinue current flow, takes over by swinging positive

in voltage until it finds something that will take the 1A of

magnetizing current. While the primary winding is finding

somewhere to put the magnetizing current, the secondary

winding takes it upon itself to do the same, but due to its

turns ratio with the primary winding, it moves 100 times

faster and 100 times as far as the primary winding. T1’s

secondary dumps a significant portion of the magnetizing

energy into C7 via D3, thus forming a flyback inverter.

AN59-9

Application Note 59

AN59 •F18

V

IN

SHUTDOWN

SW

I

LIM

SENSE

SEL GND

PGND

U1

LT1300

218

54

7

NC

3

6

PWM

IN

C1

100µF

6.3V

3V

CCFL LAMP =

T1

=

C2

=

JKL BF650-20B

JKL (800) 897-3056

COILTRONICS CTX02-12189

COILTRONICS (407) 241-7876

15pF, 500V

T1

+

D1

1N5718

C2

15pF

CCFL

Z1 dissipates the energy stored in T1’s leakage inductance. During the flyback time, C4 charges C3 through D1.

This causes the voltage across C3 to exceed 0.6V, shutting

down U2. U2 stays shut down until Q1 discharges C3 to

restart the sequence.

When the +output voltage is more positive than the + input

voltage the output of U1 goes low, Q1 stays off, R8 keeps

C3 charged to more than 0.6V, and U2 stays shut down.

The parallel combination of R10 and the load resistance

(e.g., 10M in a handheld voltmeter) discharges C7 and the

+output and the +input voltages are again equal. The

current output of this circuit is limited to a safe value (1mA

at 50V, 0.1mA at 500V) even when the +input is attached

to 500V. We do not recommend increasing the value of C7

because at higher voltages it may become a shock hazard.

Battery life is 40 hours for a pair of AA alkaline batteries

driving 10MΩ at 500V.

Cold Cathode Florescent Lamp Driver

CCFLs seem to be the latest craze; they offer high brightness, long life, small size and produce white light. Figure

18 shows a CCFL driver circuit.

Electronic Light Stick

Camping in November with my kids has its own unique

problems, even if we aren’t camping in six feet of snow.

Although we had the usual light sources something was

missing, namely a light that simulates the natural sunset

at bedtime to wind the kids down for the night. The circuit

in Figures 18 and 19 (see explantation below) details a

high efficiency fluorescent lantern with a built-in sunset

feature.

The function of the circuit is as follows:

• To turn on: switch SW1 into the ON position.

• To turn off fast: switch SW1 into the OFF position.

• To simulate sunset:

1. Turn light ON.

2. Switch SW1 into the SUNSET position.

This application uses the circuitry of both Figure 18 and

Figure 19. The pulse-width output of Figure 19 drives the

pulse-width input of Figure 18.

Theory of Operation

This is a forward/flyback inverter optimized for minimum

parts count. When enabled, U1 charges the primary winding of T1 to 1A, and lets go. T1 then flies back exciting

many hundreds of volts across its secondary winding,

which in turn ionizes the CCFL. Because the initial current

through the CCFL is only in one direction, C2 takes on a DC

potential. As the circuit runs, the voltage across C2 stabilizes at about 100VDC. Additionally, C2 removes the DC

current component from the tube, extending tube life. The

nonlinear V/I characteristic of the CCFL, in conjunction

with C2, forces the converter to run in both forward and

flyback modes simultaneously. The light intensity can be

pulse-width modulated by modulating the shutdown pin.

When the shutdown pin is pulled high the LT1300 goes

into its shutdown mode where it draws only 10µ A of input

current.

Figure 18. CCFL Driver

AN59-10

Application Note 59

1N4148

SUNSET

10Ω

LT1178

D1

OFF

ON

R7

3V

3V

C4

0.1µF

LIGHT LEVEL

PROGRAM

R7

100M

R5

1k

C2

470µF

0.022µF

D2

2N3904

R1

300k

R6

1M

PULSE-

7

WIDTH

OUT

C3

0.01µF

6

–

+

C1

LT1178

5

+

SAWTOOTH

U1B

lated. When the voltage on C2 is at or below 1V the light is

off. D1 and R5 charge and hold C2 when SW1 is in the ON

position. R5 and SW1 discharge and hold C2 when SW1

is in the OFF position. The combination of D2, R6 and U1B

discharge C2 when SW1 is in the SUNSET position. The

discharging of C2 when in the SUNSET mode is doubly

exponential causing the tail end of the simulated sunset to

go very slowly (a good idea because kids have a logarithmic response to light). The first exponential aspect of the

SUNSET decay is implemented by R6 and C2 which form

an exponential RC time constant. The second exponential

aspect of the SUNSET decay is implemented because R6

8

4

270k

3V

2

–

U1A

LT1178

3

+

R3

R4

200k

270k

1

R2

AN59 • F19

is driven by U1B pin 7, whose duty factor is changing,

causing the off-time to decrease exponentially as the light

level fades. The output of U1B is a pulse-width modulated

level gating the light driver on and off. The lamp is

illuminated when U1B’s output is low. C3 is a trash

compactor and R7 and C4 form a trash compactor to

decouple U1 from the high frequency ripple generated by

the switcher.

Figure 19. Electronic Light Stick Controller for the CCFL Driver

Circuit Shown in Figure 18. This Controller, When Controlling the

CCFL, Causes the Light Output Level to Fade from Full Brightness

to Off, Thus Simulating a Natural Sunset.

U1A, R1 to R4 and C1 form a sawtooth oscillator for pulsewidth modulating the light (implementing light levels less

than 100%). U1B acts as a comparator, comparing the

sawtooth output of the oscillator with the programmed

light level (as seen on the +terminal of C2). C2 is the

holding capacitor that programs the light level; when it is

charged to 2.5V the light is on 100% of the time. As the

voltage on C2 drops below 2.5V, the overall light level

decreases because the light is being pulse-width modu-

1.8V TO 10V

C1

+

H = LEDs OFF

L = LEDs ON

PWM = ADJUSTABLE

LIGHT LEVEL

47µF

16V

5

3

6

V

CC

I

LIM

SHDN

182

LT1300

DGND

SW

SELGND

22µH

7

4

FB

Constant Current Source

The LT1300 can be configured as a constant current

source, a current source that not only possesses good

power conversion efficiency, but can be shut down to a

state of practically no current draw. These benefits coupled

with the LT1300’s ability to operate over a wide input

voltage range, make the LT1300 an ideal candidate for

many current operated devices. Popular uses include

solenoid drivers, relay drivers, small motor drives and LED

drivers.

Here is an example of a high efficiency LED driver. The LED

light source (shown in Figure 20) is used in applications

1N5817

+

C2

I

LED

10µF

0.8

=

R2

R1

100k

LT1004-2.5

AN59 • F20

8 ×

•

•

1.6V LEDs

C3

1µF

R2

39Ω

Figure 20. Backlight LED Driver

Information furnished by Linear Technology Corporation is believed to be accurate and reliable. However,

no responsibility is assumed for its use. Linear Technology Corporation makes no representation that

the interconnection of its circuits as described herein will not infringe on existing patent rights.

AN59-11

Application Note 59

89

88

87

86

85

84

EFFICIENCY (%)

83

82

81

80

123

4

610

5

INPUT VOLTAGE (V)

789

AN59 • F21

Figure 21. Efficiency of LED Driver

ranging from LCD backlights to special flashlights that

preserve full night vision. This circuit sports an impressive

list of features:

• Logic input to strobe LED’s on/off

• Low current draw when off (10µA)

• Constant LED drive current when on (20mA)

Theory of Operation

When enabled the LT1300 runs in Burst ModeTM, regulating the voltage on the FB pin to 3.3V. Subtracting 2.5V

(corresponding to the knee voltage of the LT1004-2.5)

from the 3.3V voltage at the FB pin yields 0.8V, which is

seen across R2. This 0.8V and the value of R2 sets the

output current level through the LEDs. For proper functionality the voltage across the LED stack should be:

1. Greater than the maximum input voltage less one

Schottky drop.

2. Less than 14V.

The LT1300 is optimized for battery operation and lends

itself to these and many more applications.

• LED current unaffected by temperature

• LED current constant with input voltage range

(1.8V to 10V)

• High overall efficiency (87%)

• Small size

AN59-12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7487

(408) 432-1900

●

FAX

: (408) 434-0507

●

TELEX

: 499-3977

LT/GP 0294 10K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1994

Loading...

Loading...