Datasheet LT1008S8, LT1008MH, LT1008IN8, LT1008CN8, LT1008CJ8 Datasheet (Linear Technology)

...

FEATURES

LT1008

Picoamp Input Current,

Microvolt Offset,

Low Noise Op Amp

U

DESCRIPTIO

■

Guaranteed Bias Current

TA = 25°C: 100pA Max

TA = –55°C to 125°C: 600pA Max

■

Guaranteed Offset Voltage: 120µV Max

■

Guaranteed Drift: 1.5µV/°C Max

■

Low Noise, 0.1Hz to 10Hz: 0.5µV

■

Guaranteed Low Supply Current: 600µA Max

■

Guaranteed CMRR: 114dB Min

■

Guaranteed PSRR: 114dB Min

■

Guaranteed Voltage Gain with 5mA Load Current

P-P

U

APPLICATIO S

■

Precision Instrumentation

■

Charge Integrators

■

Wide Dynamic Range Logarithmic Amplifiers

■

Light Meters

■

Low Frequency Active Filters

■

Standard Cell Buffers

■

Thermocouple Amplifiers

The LT®1008 is a universal precision operational amplifier

that can be used in practically all precision applications.

The LT1008 combines for the first time, picoampere bias

currents (which are maintained over the full –55°C to

125°C temperature range), microvolt offset voltage (and

low drift with time and temperature), low voltage and

current noise, and low power dissipation. Extremely high

common mode and power supply rejection ratios, and the

ability to deliver 5mA load current with high voltage gain

round out the LT1008’s superb precision specifications.

The all around excellence of the LT1008 eliminates the

necessity of the time consuming error analysis procedure

of precision system design in many applications; the

LT1008 can be stocked as the universal precision op amp.

The LT1008 is externally compensated with a single capacitor for additional flexibility in shaping the frequency

response of the amplifier. It plugs into and upgrades all

standard LM108A/LM308A applications. For an internally

compensated version with even lower offset voltage but

otherwise similar performance see the LT1012.

, LTC and LT are registered trademarks of Linear Technology Corporation.

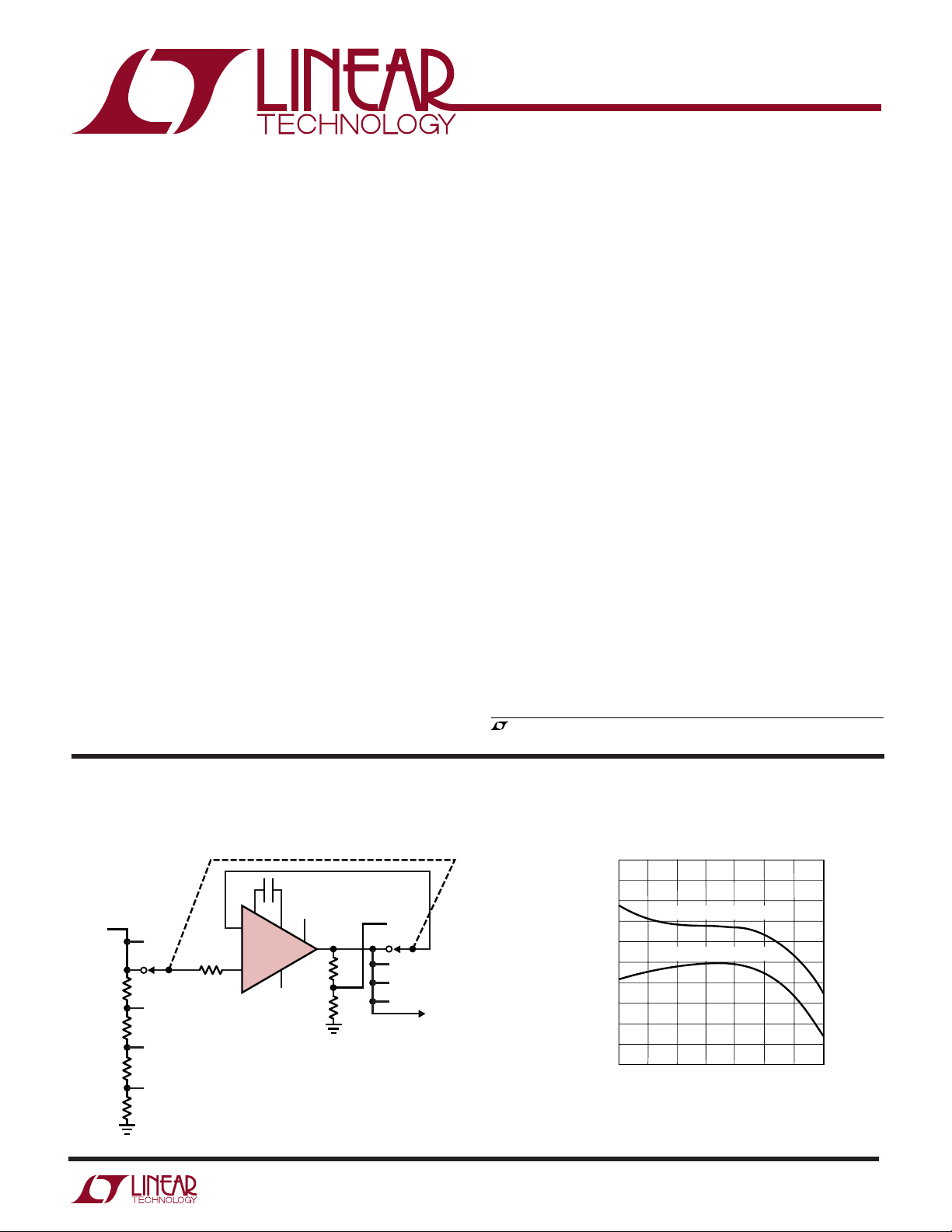

TYPICAL APPLICATIO

Input Amplifier for 4.5 Digit Voltmeter

1000pF

1

–

INPUT

1V

9M

900k

90k

10k

0.1V

10V

100V

1000V

100k

5%

FN507

ALLEN BRADLEY

DECADE VOLTAGE DIVIDER

2

3

8

LT1008

+

4

–15V

U

15V

7

6

9k*

1k*

*RATIO MATCH ±0.01%

THIS APPLICATION REQUIRES LOW

BIAS CURRENT AND OFFSET VOLTAGE,

LOW NOISE AND LOW DRIFT WITH

TIME AND TEMPERATURE

0.1V

1V

10V

100V

1000V

TO 1V FULL-SCALE

ANALOG-TO-DIGITAL

CONVERTER

1008 TA01

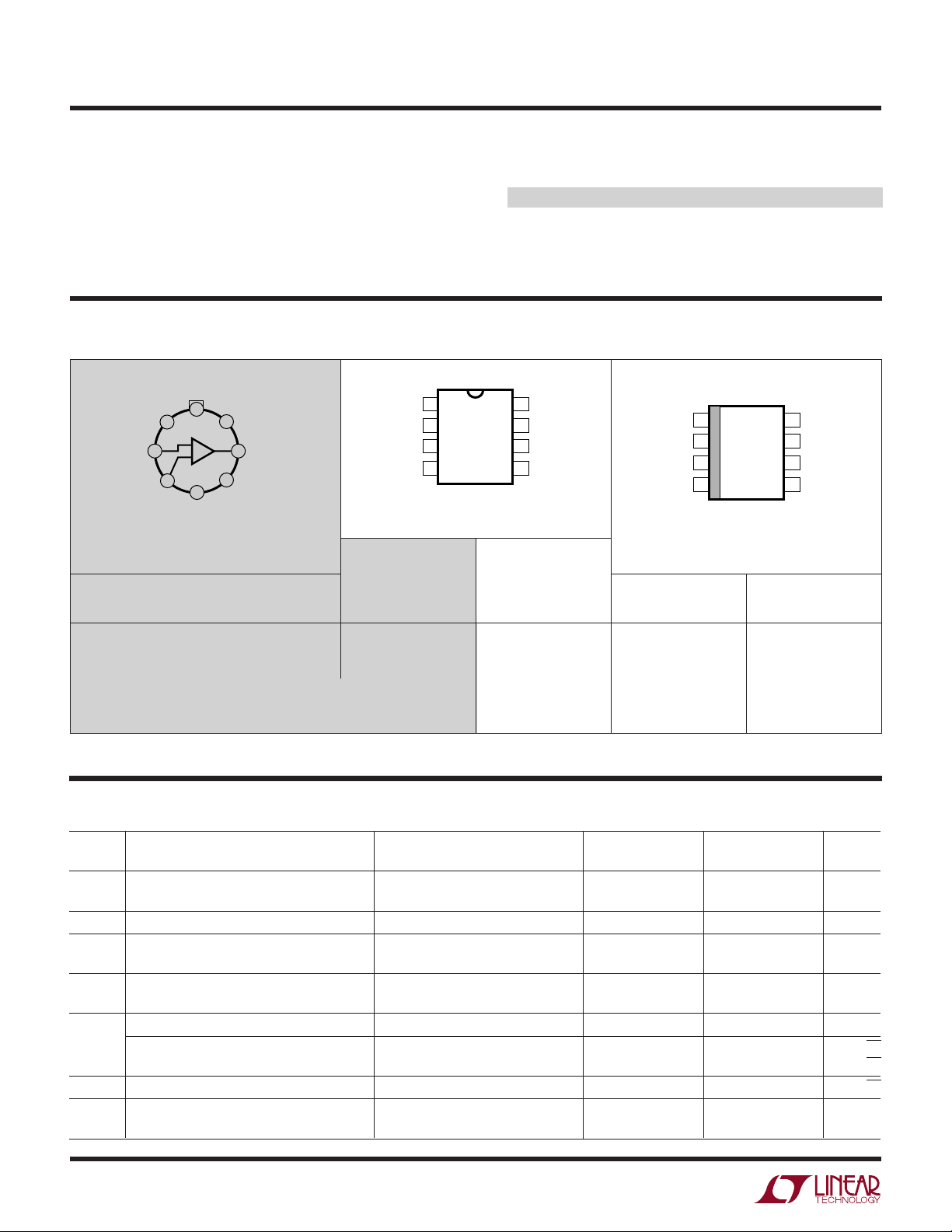

Input Bias Current vs Temperature

100

50

0

–50

INPUT BIAS CURRENT (pA)

–100

–150

–50

UNDERCANCELLED UNIT

OVERCANCELLED UNIT

25

0

–25

TEMPERATURE (°C)

50

75

100

125

1008 TA02

1

LT1008

1

2

3

4

8

7

6

5

TOP VIEW

COMP2

V

+

OUT

NC

COMP1

–IN

+IN

V

–

S8 PACKAGE

8-LEAD PLASTIC SO

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Supply Voltage ...................................................... ±20V

Differential Input Current (Note 2) ..................... ±10mA

Input Voltage ........................................................ ±20V

Output Short-Circuit Duration......................... Indefinite

Storage Temperature Range ................. –65°C to 150°C

UU

W

PACKAGE/ORDER I FOR ATIO

TOP VIEW

COMP2

8

–

(CASE)

7

–

+

5

4

1

COMP1

2

–IN

+IN

3

V

H PACKAGE

8-LEAD TO-5 METAL CAN

T

= 150°C, θJA = 150°C/W, θJC = 45°C/W

JMAX

ORDER PART

NUMBER

+

V

6

OUT

NC

COMP1

1

–IN

2

+IN

3

–

V

4

N8 PACKAGE

8-LEAD PDIP

T

= 150°C, θJA = 130°C/W

JMAX

J8 PACKAGE 8-LEAD CERDIP

= 150°C, θJA = 100°C/W

T

JMAX

ORDER PART

NUMBER

Operating Temperature Range

LT1008M (OBSOLETE) ............... –55°C to 125°C

LT1008C................................................. 0°C to 70°C

LT1008I ............................................. –40°C to 85°C

Lead Temperature (Soldering, 10 sec)..................300°C

TOP VIEW

COMP2

8

+

V

7

OUT

6

NC

5

T

= 150°C, θJA = 190°C/W

JMAX

ORDER PART

NUMBER

ORDER PART

NUMBER

S8 PART

MARKING

LT1008MH

LT1008CH

OBSOLETE PACKAGES

Consider N8 or S8 Package for Alternate Source

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

I

OS

I

B

e

i

n

A

2

OS

n

VOL

Input Offset Voltage 30 120 30 120 µV

Long-Term Input Offset Voltage Stability 0.3 0.3 µV/Month

Input Offset Current 30 100 30 100 pA

Input Bias Current ±30 ±100 ±30 ±100 pA

Input Noise Voltage 0.1Hz to 10Hz 0.5 0.5 µV

Input Noise Voltage Density fO = 10Hz (Note 4) 17 30 17 30 nV√Hz

Input Noise Current Density fO = 10Hz 20 20 fA/√Hz

Large-Signal Voltage Gain V

LT1008MJ8

LT1008CJ8

LT1008CN8

LT1008IN8

LT1008S8

1008

VS = ±15V, VCM = 0V, TA = 25°C, unless otherwise noted.

LT1008M/I LT1008C

(Note 3) 40 180 40 180 µV

(Note 4) 40 150 40 150 pA

(Note 5) ±40 ±150 ±40 ±150 pA

= 1000Hz (Note 5) 14 22 14 22 nV/√Hz

f

O

= ±12V, RL ≥ 10k 200 2000 200 2000 V/mV

OUT

V

= ±10V, RL ≥ 2k 120 600 120 600 V/mV

OUT

P-P

LT1008

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

CMRR Common Mode Rejection Ratio VCM = ±13.5V 114 132 114 132 dB

PSRR Power Supply Rejection Ratio VS = ±2V to ±20V 114 132 114 132 dB

Input Voltage Range ±13.5 ±14 ±13.5 ±14 V

V

I

OUT

S

Output Voltage Swing RL = 10k ±13 ±14 ±13 ±14 V

Slew Rate CF = 30pF 0.1 0.2 0.1 0.2 V/µs

Supply Current (Note 3) 380 600 380 600 µA

VS = ±15V, VCM = 0V, TA = 25°C, unless otherwise noted.

LT1008M/I LT1008C

The ● indicates specifications which apply over the full operating temperature range of –55°C ≤ TA ≤ 125°C for the LT1008M, –40°C

≤ TA ≤ 85°C for the LT1008I and 0°C ≤ TA ≤ 70°C for the LT1008C. VS = ±15V, VCM = 0V, unless otherwise noted.

LT1008M/I LT1008C

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

OS

I

OS

I

B

A

VOL

CMRR Common Mode Rejection Ratio VCM = ±13.5V ● 108 128 110 130 dB

PSRR Power Supply Rejection Ratio VS = ±2.5V to ±20V ● 108 126 110 128 dB

V

OUT

I

S

Input Offset Voltage ● 50 250 40 180 µV

(Note 3)

Average Temperature Coefficient of

Input Offset Voltage

Input Offset Current ● 60 250 40 180 pA

(Note 3)

Average Temperature Coefficient of

Input Offset Current

Input Bias Current ● ±80 ±600 ±40 ±180 pA

(Note 3)

Average Temperature Coefficient of

Input Bias Current

Large-Signal Voltage Gain V

Input Voltage Range ● ±13.5 ±13.5 V

Output Voltage Swing RL = 10k ● ±13 ±14 ±13 ±14 V

Supply Current ● 400 800 400 800 µA

= ±12V, RL ≥ 10k ● 100 1000 150 1500 V/mV

OUT

● 60 320 50 250 µV

● 0.2 1.5 0.2 1.5 µV/°C

● 80 350 50 250 pA

● 0.4 2.5 0.4 2.5 pA/°C

● ±150 ±800 ±50 ±250 pA

● 0.6 6 0.4 2.5 pA/°C

(LT1008S8 only) VS = ±15V, VCM = 0V, TA = 25°C, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

OS

I

OS

I

B

e

n

Input Offset Voltage 30 200 µV

(Note 3) 40 250 µV

Long-Term Input Offset Voltage Stability 0.3 µV/Month

Input Offset Current 100 280 pA

(Note 3) 120 380 pA

Input Bias Current ±100 ±300 pA

(Note 3) ±120 ±400 pA

Input Noise Voltage 0.1Hz to 10Hz 0.5 µV

Input Noise Voltage Density fO = 10Hz (Note 5) 17 30 nV/√Hz

= 1000Hz (Note 5) 14 22 nV/√Hz

f

O

P-P

3

LT1008

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

i

n

A

VOL

CMRR Common Mode Rejection Ratio VCM = ±13.5V 110 132 dB

PSRR Power Supply Rejection Ratio VS = ±2V to ±20V 110 132 dB

V

OUT

I

S

Input Noise Current Density fO = 10Hz 20 fA/√Hz

Large-Signal Voltage Gain V

Input Voltage Range ±13.5 ±14 V

Output Voltage Swing RL = 10k ±13 ±14 V

Slew Rate CF = 30pF 0.1 0.2 V/µs

Supply Current (Note 3) 380 600 µA

(LT1008S8 only) VS = ±15V, VCM = 0V, TA = 25°C, unless otherwise noted.

= ±12V, RL ≥ 10k 200 2000 V/mV

OUT

= ±10V, RL ≥ 2k 120 600 V/mV

V

OUT

(LT1008S8 only) The ● indicates specifications which apply over the full operating temperature range of 0°C ≤ TA ≤ 70°C.

VS = ±15V, VCM = 0V, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

OS

I

OS

I

B

A

VOL

CMRR Common Mode Rejection Ratio VCM = ±13.5V ● 108 130 dB

PSRR Power Supply Rejection Ratio VS = ±2.5V to ±20V ● 108 128 dB

V

OUT

I

S

Input Offset Voltage ● 40 280 µV

(Note 3)

Average Temperature Coefficient of ● 0.2 1.8 µV/°C

Input Offset Voltage

Input Offset Current ● 120 380 pA

(Note 3)

Average Temperature Coefficient of ● 0.4 4 pA/°C

Input Offset Current

Input Bias Current ● ±120 ±420 pA

(Note 3)

Average Temperature Coefficient of ● 0.4 5 pA/°C

Input Bias Current

Large-Signal Voltage Gain V

Input Voltage Range ● ±13.5 V

Output Voltage Swing RL = 10k ● ±13 ±14 V

Supply Current ● 400 800 µA

= ±12V, RL ≥ 10k ● 150 1500 V/mV

OUT

● 50 340 µV

● 140 500 pA

● ±140 ±550 pA

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Differential input voltages greater than 1V will cause excessive

current to flow through the input protection diodes unless current limiting

resistors are used.

4

Note 3: These specifications apply for ±2V ≤ V

(±2.5V ≤ V

–13.5V ≤ V

Note 4: 10Hz noise voltage density is sample tested on every lot. Devices

100% tested at 10Hz are available on request.

Note 5: This parameter is tested on a sample basis only.

≤ ±20V over the temperature range) and

S

≤ 13.5V (for VS = ±15V).

CM

≤ ±20V

S

LT1008

COMMON MODE INPUT VOLTAGE (V)

–15

–60

INPUT BIAS CURRENT (pA)

–40

–20

0

20

60

–10

–5 0 5

1008 G03

10 15

40

+

–

I

B

V

CM

DEVICE WITH POSITIVE INPUT CURRENT

DEVICE WITH NEGATIVE INPUT CURRENT

V

S

= ±15V

T

A

= 25°C

R

INCM

= 2 × 1012Ω

U

W

UU

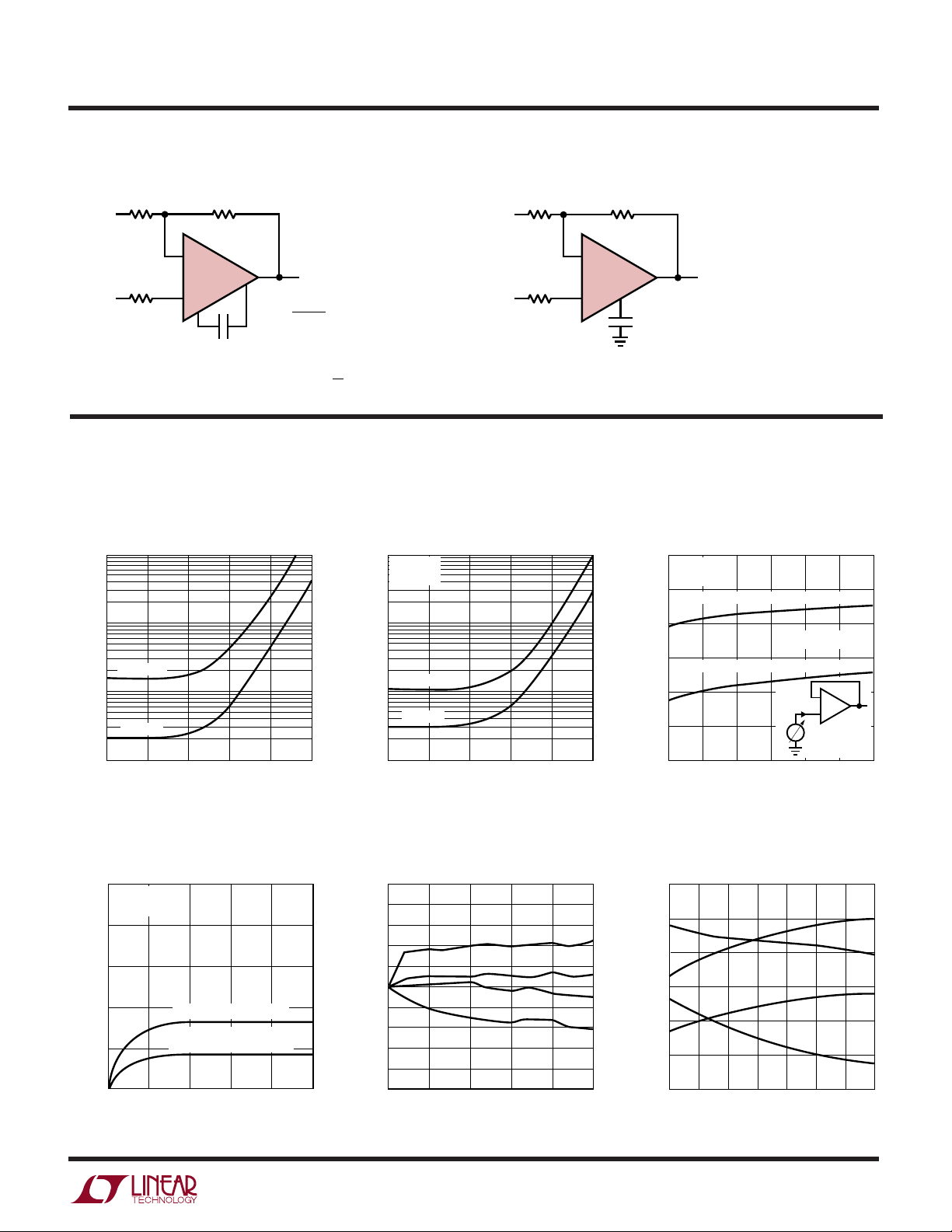

FREQUE CY CO PE SATIO CIRCUITS

Standard Compensation Circuit Alternate* Frequency Compensation

–V

IN

+V

IN

R1 R2

–

2

R3

LT1008

3

+

1

C

**BANDWIDTH AND SLEW RATE

ARE PROPORTIONAL TO 1/C

6

V

8

**

F

OUT

R1C

O

C

≥

F

R1 + R2

C

= 30pF

O

1008 FCC01

R2

FOR > 200, NO EXTERNAL FREQUENCY COMPENSATION IS NECESSARY

R1

F

–V

IN

+V

IN

R1 R2

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Offset Voltage Drift vs Source

Resistance (Balanced or

Unbalanced)

100

Offset Voltage vs Source

Resistance (Balanced or

Unbalanced)

10

VS = ±15V

T

= 25°C

A

*IMPROVES REJECTION OF POWER

SUPPLY NOISE BY A FACTOR OF 5

–

2

8

**

C

S

100pF

6

LT1008

3

+

**BANDWIDTH AND SLEW RATE ARE

PROPORTIONAL TO 1/C

V

OUT

1008 FCC02

S

Input Bias Current vs

Common Mode Range

10

MAXIMUM

1

TYPICAL

0.1

1k 10k

OFFSET VOLTAGE DRIFT WITH TEMPERATURE (µV/°C)

Warm-Up Drift

5

= ±15V

V

S

= 25°C

T

A

4

3

2

1

CHANGE IN OFFSET VOLTAGE (µV)

0

0

TIME AFTER POWER ON (MINUTES)

100k 1M 10M 100M

SOURCE RESISTANCE (Ω)

METAL CAN (H) PACKAGE

DUAL-IN-LINE PACKAGE

PLASTIC (N) OR CERDIP (J)

1

3

2

4

1008 G01

1008 G04

1

MAXIMUM

0.1

TYPICAL

INPUT OFFSET VOLTAGE (mV)

0.01

1k 10k

100k 1M 10M 100M

SOURCE RESISTANCE (Ω)

1008 G02

Offset Voltage Drift with

Long-Term Stability of Four

Representative Units

10

8

6

4

2

0

–2

–4

–6

CHANGE IN OFFSET VOLTAGE (µV)

–8

5

–10

1

0

TIME (MONTHS)

3

4

2

5

1008 G05

Temperature of Four

Representative Units

60

40

20

0

–20

OFFSET VOLTAGE (µV)

–40

–60

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

1008 G06

5

LT1008

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Supply Current vs Supply Voltage

500

450

400

SUPPLY CURRENT (µA)

350

300

0

0.1Hz to 10Hz Noise

TA = 25°C

= ±2V TO ±20V

V

S

NOISE VOLTAGE (400nV/DIV)

2

0

4

TIME (SECONDS)

25°C

125°C

–55°C

5

SUPPLY VOLTAGE (±V)

6

8

1008 G09

Output Short-Circuit Current vs Time

15

12

9

6

SOURCING

3

0

–3

–6

–9

SINKING

SHORT-CIRCUIT CURRENT (mA)

–12

–15

0

10

15

20

1008 G07

0.5

TIME FROM OUTPUT SHORT (MINUTES)

1.0

25°C

1.5

Noise Spectrum

1000

TA = 25°C

V

= ±2V TO ±20V

S

100

CURRENT NOISE

VOLTAGE NOISE

10

1/f CORNER

2.5Hz

CURRENT NOISE DENSITY (fA/√Hz)

VOLTAGE NOISE DENSITY (nV/√Hz)

1

10

1

10 100 1000

FREQUENCY (Hz)

1/f CORNER

120Hz

1008 G10

0.1

TOTAL NOISE DENSITY (µV/√Hz)

0.01

–55°C

125°C

125°C

25°C

–55°C

2.0

2.5

3.0

3.5

1008 G08

Total Noise vs Source Resistance

10

TA = 25°C

V

= ±2V TO ±20V

S

AT 10Hz

1

R

–

R

+

= 2R

R

S

AT 1Hz

AT 10Hz

2103104105106107108

10

RESISTOR NOISE ONLY

SOURCE RESISTANCE (Ω)

AT 1Hz

1008 G11

Voltage Gain vs Frequency

140

120

100

80

60

40

VOLTAGE GAIN (dB)

20

–20

0

0.01 0.1

CS = 100pF

C

1

10

FREQUENCY (Hz)

= 30pF

F

6

100

CF = 3pF

CS = 10pF

1k

10k

100k

1M

1008 G12

10M

Gain, Phase Shift vs Frequency

with Alternate Compensation

40

30

20

GAIN (dB)

10

PHASE MARGIN

0

WITH C

T

A

V

S

–10

0.01

= 10pF

C

S

C

= 25°C

= ±15V

GAIN

CS = 10pF

φ

GAIN

= 100pF

S

= 100pF = 56°

S

0.1 1 10

FREQUENCY (MHz)

φ

= 100pF

C

S

1008 G13

100

120

140

160

180

200

40

30

PHASE SHIFT (DEG)

20

GAIN (dB)

10

–10

Gain, Phase Shift vs Frequency

with Standard (Feedback)

Compensation

φ

= 30pF

C

F

φ

C

C

GAIN

= 30pF

C

F

PHASE MARGIN

0

WITH C

= 25°C

T

A

= ±15V

V

S

0.01

GAIN

= 3pF

F

= 30pF = 60°

F

0.1 1 10

FREQUENCY (MHz)

= 3pF

F

100

120

PHASE SHIFT (DEG)

140

160

180

200

1008 G14

UW

FREQUENCY (Hz)

0.1

POWER SUPPLY REJECTION RATIO (dB)

100

120

140

100 10k

1008 G17

80

60

110

1k 100k 1M

40

20

NEGATIVE

SUPPLY

VS = ±15V

T

A

= 25°C

POSITIVE

SUPPLY

C

F

= 30pF

POSITIVE

SUPPLY

C

S

= 100pF

TYPICAL PERFOR A CE CHARACTERISTICS

LT1008

Voltage Gain vs Load Resistance

10M

VS = ±15V

= ±10V

V

O

3M

1M

VOLTAGE GAIN

300k

100k

12 5

LOAD RESISTANCE (kΩ)

10 20

Large-Signal Transient Response

2V/DIV

AV = 1 20µs/DIV 1008 G18

CS = 100pF

–55°C

25°C

125°C

1008 G15

Common Mode Rejection

vs Frequency

140

120

100

80

60

40

20

COMMON MODE REJECTION RATIO (dB)

0

1

10 100

CF = 30pF

= 100pF

C

S

FREQUENCY (Hz)

10k 1M

1k 100k

Slew Rate

vs Compensation Capacitance

10

VS = ±15V

T

= 25°C

A

1

SLEW RATE (V/µs)

0.1

0

C

F

20 100806040

COMPENSATION CAPACITOR (pF)

Power Supply Rejection

vs Frequency

V

= ±15V

S

= 25°C

T

A

1008 G16

Large-Signal Transient Response

2V/DIV

C

S

AV = 1 20µs/DIV 1008 G20

CF = 30pF

108 G19

Small-Signal Transient Response

20mV/DIV

AV = 1 5µs/DIV 1008 G21

CS = 100pF

C

LOAD

= 100pF

Small-Signal Transient Response

20mV/DIV

AV = 1 5µs/DIV 1008 G22

CS = 100pF

= 600pF

C

LOAD

Small-Signal Transient Response

20mV/DIV

AV = 1 5µs/DIV 1008 G23

CF = 30pF

= 100pF

C

LOAD

7

LT1008

–

+

LT1008

6

V

O

2

3

*RESISTORS MUST HAVE LOW

THERMOELECTRIC POTENTIAL

THIS CIRCUIT IS ALSO USED AS

THE BURN-IN CONFIGURATION

FOR THE LT1008 WITH SUPPLY

VOLTAGES INCREASED TO ±20V

V

O

= 1000V

OS

100Ω*

50k*

50k*

7

4

15V

–15V

1008 AI02

i

enV

M

n

no

=

()

Ω×

2

2

12

820

40 100

–

/

WUUU

APPLICATIO S I FOR ATIO

Achieving Picoampere/Microvolt Performance

In order to realize the picoampere—microvolt level accuracy of the LT1008, proper care must be exercised. For

example, leakage currents in circuitry external to the op

amp can significantly degrade performance. High quality

insulation should be used (e.g., TeflonTM, Kel-F); cleaning

of all insulating surfaces to remove fluxes and other

residues will probably be required. Surface coating may be

necessary to provide a moisture barrier in high humidity

environments.

Board leakage can be minimized by encircling the input

circuitry with a guard ring operated at a potential close to

that of the inputs: in inverting configurations the guard

ring should be tied to ground, in noninverting connections

to the inverting input at Pin 2. Guarding both sides of the

printed circuit board is required. Bulk leakage reduction

depends on the guard ring width. Nanoampere level leakage into the compensation terminals can affect offset

voltage and drift with temperature.

COMPENSATION

+

V

8

OUTPUT

7

6

5

4

1

2

3

The LT1008 is specified over a wide range of power supply

voltages from ±2V to ±18V. Operation with lower supplies

is possible down to ±1.2V (two Ni-Cad batteries).

Test Circuit for Offset Voltage and Its Drift with Temperature

Noise Testing

The 0.1Hz to 10Hz peak-to-peak noise of the LT1008 is

measured in the test circuit shown. The frequency response of this noise tester indicates that the 0.1Hz corner

is defined by only one zero. The test time to measure 0.1Hz

to 10Hz noise should not exceed 10 seconds, as this time

limit acts as an additional zero to eliminate noise contributions from the frequency band below 0.1Hz.

A noise voltage density test is recommended when measuring noise on a large number of units. A 10Hz noise

voltage density measurement will correlate well with a

0.1Hz to 10Hz peak-to-peak noise reading since both

results are determined by the white noise and the location

of the 1/f corner frequency.

REFERENCE ONLY—OBSOLETE PACKAGE

Microvolt level error voltages can also be generated in the

external circuitry. Thermocouple effects caused by temperature gradients across dissimilar metals at the contacts to the input terminals can exceed the inherent drift of

the amplifier. Air currents over device leads should be

minimized, package leads should be short, and the two

input leads should be as close together as possible and

maintained at the same temperature.

Teflon is a trademark of Dupont Company

8

Current noise is measured in the circuit shown and calcu-

INPUTS

1008 AI01

lated by the following formula where the noise of the

source resistors is subtracted.

10k

10M*

10M*

2

100Ω

10M*

10M*

*METAL FILM

–

LT1008

3

+

6

e

no

1008 AI04

–

V

GUARD

WUUU

APPLICATIO S I FOR ATIO

0.1µF

100k

LT1008

0.1Hz to 10Hz Noise Test Circuit

10Ω

*DEVICE UNDER TEST

NOTE: ALL CAPACITOR VALUES ARE FOR

NONPOLARIZED CAPACITORS ONLY

–

LT1008*

+

VOLTAGE

GAIN: 50,000

2k

+

4.7µF

–

24.3k

Frequency Compensation

The LT1008 is externally frequency compensated with a

single capacitor. The two standard compensation circuits

shown earlier are identical to the LM108A/LM308A frequency compensation schemes. Therefore, the LT1008

operational amplifiers can be inserted directly into

LM108A/LM308A sockets, with similar AC and upgraded

DC performance.

External frequency compensation provides the user with

additional flexibility in shaping the frequency response of

the amplifier. For example, for a voltage gain of ten and

CF = 3pF, a gain bandwidth product of 5MHz and slew rate

of 1.2V/µs can be realized. For closed-loop gains in excess

of 200, no external compensation is necessary, and slew

rate increases to 4V/µs. The LT1008 can also be overcom-

pensated (i.e., CF > 30pF or CS > 100pF) to improve capacitive load handling capability or to narrow noise bandwidth.

In many applications, the feedback loop around the amplifier has gain (e.g., logarithmic amplifiers); overcompensation can stabilize these circuits with a single capacitor.

The availability of the compensation terminals permits the

use of feedforward frequency compensation to enhance

slew rate in low closed-loop gain configurations. The

inverter slew rate is increased to 1.4V/µs. The voltage

follower feedforward scheme bypasses the amplifier’s

gain stages and slews at nearly 10V/µs.

The inputs of the LT1008 are protected with back-to-back

diodes. Current limiting resistors are not used, because the

leakage of these resistors would prevent the realization of

picoampere level bias currents at elevated temperatures.

LT1001

100k

0.1µF

4.3k

2.2µF

22µF

110k

SCOPE

×1

= 1M

R

IN

1008 AI03

In the voltage follower configuration, when the input is

driven by a fast, large-signal pulse (>1V), the input protection diodes effectively short the output to the input during

slewing, and a current, limited only by the output shortcircuit protection, will flow through the diodes.

The use of a feedback resistor, as shown in the voltage

follower feedforward diagram, is recommended because

this resistor keeps the current below the short-circuit

limit, resulting in faster recovery and settling of the output.

Inverter Feedforward Compensation

C2

5pF

INPUT

2V/DIV

R1

10k

2

–

3

+

C1

500pF

5µs/DIV 1008 AI07

LT1008

1

R2

10k

8

R3

3k

1008 AI05

6

C3

10pF

V

OUT

9

LT1008

WUUU

APPLICATIO S I FOR ATIO

Follower Feedforward Compensation

30pF

10k

2

INPUT*

10k

–

LT1008

3

+

6

OUTPUT

8

5V/DIV

1000pF

*SOURCE RESISTANCE ≤15k FOR STABILITY

TYPICAL APPLICATIO S

10k*

INPUT

Amplifier for Bridge Transducers Saturated Standard Cell Amplifier

2

–

LT1008

3

+

1

30pF

U

15V

7

8

1008 AI06

330pF

6

4

–15V OUTPUT

Logarithmic Amplifier

Q1A

2N2979

15.7k

*1% FILM RESISTOR

LOW BIAS CURRENT AND OFFSET VOLTAGE OF THE LT1008

ALLOW 4.5 DECADES OF VOLTAGE INPUT LOGGING

Q1B

2N2979

1k

TEL. LABS

TYPE Q81

124k* 5.1k

–

100pF2k

6

LM107

2

3

+

5µs/DIV 1008 AI07

15V

LT1004C

1.2V

10

100k

100k

S2

LT1008

1

15V

7

6

4

8

–15V

R2

OUTPUT

R5

+

V

S1

T

100k

R1

T

100k

R3

510k

R4

510k

R2

R6

56M

56M

C1

30pF

1

2

–

LT1008

3

+

VOLTAGE GAIN ≈ 100

3

2

R1

1008 TA05

+

–

1000pF

2N3609

1.018235V

SATURATED

+

8

6

OUTPUT

1008 TA04

STANDARD

CELL #101

EPPLEY LABS

NEWPORT, R.I.

THE TYPICAL 30pA BIAS CURRENT OF THE LT1008 WILL

DEGRADE THE STANDARD CELL BY ONLY 1ppm/YEAR.

NOISE IS A FRACTION OF A ppm. UNPROTECTED GATE

MOSFET ISOLATES STANDARD CELL ON POWER DOWN

TYPICAL APPLICATIO S

Amplifier for Photodiode Sensor Five Decade Kelvin-Varley Divider Buffered by the LT1008

LT1008

U

R1

5M

1%

2

–

λ

S1

R2

5M

1%

LT1008

3

+

8

C1

100pF

6

V

OUT

OUTPUT

= 10V/µA

1008 TA06

The LT1008 integrator extends low frequency range. Total

dynamic range is 0.01Hz to 10kHz (or 120dB) with 0.01%

linearity.

Extended Range Charge Pump Voltage to Frequency Converter

15V

–15V

50k

OPTIONAL 0.01Hz TRIM

22M

15V

1.8k

15V

10V

KELVIN-VARLEY

00000 – 99999 + 1

(POLYSTYRENE)

100k

DIVIDER

ESI #DP311

APPROXIMATE ERROR DUE TO NOISE, BIAS CURRENT,

COMMON MODE REJECTION. VOLTAGE GAIN OF THE

AMPLIFIER IS 1/5 OF A LEAST SIGNIFICANT BIT

1000pF

2

3

–

LT1008

+

1

1000pF

7

4

8

–15V

6

OUTPUT

1008 TA07

V

0V TO 10V

1µF

IN

63.4k*

10k*

2

–

LT1008

3

+

8

100pF

22k

2

+

7

LT311A

–

1

*1% METAL FILM RESISTOR

ALL DIODES 1N4148

3

4

–15V

10k*

6

100k

750k

5pF

3

10k*

2

10k

LT1004C

1.2V

+

LM301A

–

15V

6

10k

1008 TA08

1k

LM329

FREQUENCY OUPUT

0.01Hz TO 10kHz

10k

15V–15V

11

LT1008

TYPICAL APPLICATIO S

U

Precision, Fast Settling, Lowpass Filter

INPUT

*OPTO-MOS SWITCH

TYPE OFM1A

THETA-J CORP

2k

15V

This circuit is useful where fast signal acquisition and high

10k

2

7

7

–15V

100Ω

–15V

4

8

4

–

3

+

15V

8

LT311A

LT311A

LT1008

#1

#2

1

1000pF

+

–

1

5

–

+

1

2

3

10k

3

2

6

8

FILTER CUT

IN ADJUST

1008 TA09

OUTPUT

1.5M

1µF

OPTO-MOS*

1k

15V

precision are required, as in electronic scales.

The filter’s time constant is set by the 2k resistor and the

1µF capacitor until comparator 1 switches. The time

constant is then set by the 1.5M resistor and the 1µF

capacitor. Comparator 2 provides a quick reset.

The circuit settles to a final value three times as fast as a

simple 1.5M-1µF filter with almost no DC error.

INPUT

10k*

15k

10k

2pF TO 8pF

10k*

2N4393

×2

10k

2

3

–15V

2

3

1

–

LT318A

+

1N4148 (4)

300pF

15V

–

LT1008

+

1

30pF

Fast Precision Inverters

INPUT

15V

5

7

6

OUTPUT

4

7

6

4

8

SLEW RATE = 100V/µs

–15V

SETTLING (10V STEP) = 5µs TO 0.01%

OFFSET VOLTAGE = 30µV

BIAS CURRENT DC = 30pA

*1% METAL FILM

10k*

10k

10k

2

3

1N4148 ×2

300pF

15V

–

LT1008

+

1

30pF

7

8

–15V

1000pF

6

4

10k

10k*

10pF

15V

2

3

FULL POWER BANDWIDTH = 2MHz

SLEW RATE AT 50V/µs

SETTLING (10V STEP) = 12µs TO 0.01%

BIAS CURRENT DC = 30pA

OFFSET DRIFT = 0.3µV/°C

OFFSET VOLTAGE = 30µV

*1% METAL FILM

–

LT318A

+

–15V

7

6

OUTPUT

4

1008 TA10

12

WW

SCHE ATIC DIAGRA

LT1008

–INPUT

2

+INPUT

3

–

V

4

Q7 Q8

Q5

Q9

Q10

Q22

Q24

COMP2

8

Q20

3k

J1

Q32

Q33

16k

Q35

3.3k 320Ω

20k

Q29

Q25

Q30

Q27

Q28

1.5k

Q40

3k

40Ω

Q26

Q37

Q38

Q41

330Ω

Q43

Q42

60Ω

70Ω

+

V

7

OUTPUT

6

COMP1

1

1.3k 4.2k

22k

22k

Q6

Q16

Q13

Q2

Q1

Q39

Q17

Q14

Q4

Q3

SSS

Q15

Q18 Q19

3.3k

4.8k4.3k

3.3k

Q11

50kS1.5k

Q12

Q21

3k

Q23

Q31

Q34

13

LT1008

PACKAGE DESCRIPTIO

0.335 – 0.370

(8.509 – 9.398)

DIA

0.305 – 0.335

(7.747 – 8.509)

0.016 – 0.021**

(0.406 – 0.533)

SEATING

PLANE

0.040

(1.016)

MAX

0.010 – 0.045*

(0.254 – 1.143)

*

LEAD DIAMETER IS UNCONTROLLED BETWEEN THE REFERENCE PLANE

AND 0.045" BELOW THE REFERENCE PLANE

**

FOR SOLDER DIP LEAD FINISH, LEAD DIAMETER IS

U

H Package

8-Lead TO-5 Metal Can (.200 Inch PCD)

(Reference LTC DWG # 05-08-1320)

0.050

(1.270)

MAX

(4.191 – 4.699)

GAUGE

PLANE

(12.700 – 19.050)

0.016 – 0.024

(0.406 – 0.610)

0.165 – 0.185

0.500 – 0.750

REFERENCE

PLANE

45°TYP

0.028 – 0.034

(0.711 – 0.864)

0.110 – 0.160

(2.794 – 4.064)

INSULATING

STANDOFF

0.027 – 0.045

(0.686 – 1.143)

PIN 1

H8(TO-5) 0.200 PCD 1197

0.200

(5.080)

TYP

8-Lead CERDIP (Narrow .300 Inch, Hermetic)

(Reference LTC DWG # 05-08-1110)

CORNER LEADS OPTION

(4 PLCS)

0.023 – 0.045

(0.584 – 1.143)

HALF LEAD

0.045 – 0.068

(1.143 – 1.727)

FULL LEAD

OPTION

0.300 BSC

(0.762 BSC)

0.008 – 0.018

(0.203 – 0.457)

NOTE: LEAD DIMENSIONS APPLY TO SOLDER DIP/PLATE

OR TIN PLATE LEADS

0° – 15°

OPTION

J8 Package

0.005

(0.127)

MIN

0.025

(0.635)

RAD TYP

0.045 – 0.065

(1.143 – 1.651)

0.014 – 0.026

(0.360 – 0.660)

0.405

(10.287)

MAX

87

12

65

3

4

0.220 – 0.310

(5.588 – 7.874)

0.015 – 0.060

(0.381 – 1.524)

0.100

(2.54)

BSC

0.200

(5.080)

MAX

0.125

3.175

MIN

J8 1298

14

OBSOLETE PACKAGES

PACKAGE DESCRIPTIO

U

N8 Package

8-Lead PDIP (Narrow .300 Inch)

(Reference LTC DWG # 05-08-1510)

0.255 ± 0.015*

(6.477 ± 0.381)

0.400*

(10.160)

MAX

876

LT1008

5

12

0.300 – 0.325

(7.620 – 8.255)

0.065

(1.651)

0.009 – 0.015

(0.229 – 0.381)

+0.035

0.325

–0.015

+0.889

8.255

()

–0.381

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm)

TYP

0.045 – 0.065

(1.143 – 1.651)

0.100

(2.54)

BSC

S8 Package

8-Lead Plastic Small Outline (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1610)

8

3

0.189 – 0.197*

(4.801 – 5.004)

7

6

4

0.130 ± 0.005

(3.302 ± 0.127)

0.125

(3.175)

MIN

0.018 ± 0.003

(0.457 ± 0.076)

5

0.020

(0.508)

MIN

N8 1098

0.228 – 0.244

(5.791 – 6.197)

1

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

× 45°

0.016 – 0.050

(0.406 – 1.270)

0.053 – 0.069

(1.346 – 1.752)

0°– 8° TYP

0.014 – 0.019

(0.355 – 0.483)

TYP

3

2

0.150 – 0.157**

(3.810 – 3.988)

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

SO8 1298

15

LT1008

TYPICAL APPLICATIO

U

Ammeter measures currents from 100pA to 100µA with-

out the use of expensive high value resistors. Accuracy at

Ammeter with Six Decade Range

CURRENT

INPUT

Q1 TO Q4: RCA CA3146 TRANSISTOR ARRAY

CALIBRATION: ADJUST R1 FOR FULL SCALE

DEFLECTION WITH 1µA INPUT CURRENT

10k

15V

2

3

–

LT1008

+

1

0.01µF

7

8

–15V

4

6

PIN 13

CA3146

33k

100µA is limited by the offset voltage between Q1 and Q2

and at 100pA by the inverting bias current of the LT1008.

10k

15V

10nA

1µA

10µA

Q3

R1

2k

1.2k

549Ω

549Ω

549Ω

549Ω

549Ω

549Ω

LT1004C-1.2

1008 TA11

100µA

METER

Q1

Q4

100pA

RANGE 1nA

Q2

100nA

100µA

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1012 Picoamp Input Current, Microvolt Offset, Low Noise Op Amp Internally Compensated LT1008

LT1112 Dual Low Power, Precision, Picoamp Input Op Amp Dual LT1012

LT1880 SOT-23, Rail-to-Rail Output, Picoamp Input Current Precision Op Amp Single SOT-23 Version of LT1884

LT1881/LT1882 Dual and Quad Rail-to-Rail Output, Picoamp Input Precision Op Amps Dual/Quad C

LT1884/LT1885 Dual and Quad Rail-to-Rail Output, Picoamp Input Precision Op Amps Dual/Quad Faster LT1881/LT1882

1008fa LT/TP 0701 1.5K REV A • PRINTED IN THE USA

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

Stable

LOAD

LINEAR TECHNOLOGY CORPORATION 1991

Loading...

Loading...