FEATURES

■

1µA to 10mA Operation

■

0.02%/V Regulation

■

0.8V to 40V Operating Voltage

■

Can be Used as Linear Temperature Sensor

■

Draws No Reverse Current

■

Supplied in Standard Transistor Packages

U

APPLICATIO S

■

Current Mode Temperature Sensing

■

Constant Current Source for Shunt References

■

Cold Junction Compensation

■

Constant-Gain Bias for Bipolar Differential Stage

■

Micropower Bias Networks

■

Buffer for Photoconductive Cell

■

Current Limiter

LM134 Series

Constant Current Source

and Temperature Sensor

U

DESCRIPTIO

The LM134 is a three-terminal current source designed to

operate at current levels from 1µA to 10mA, as set by an

external resistor. The device operates as a true twoterminal current source, requiring no extra power connections or input signals. Regulation is typically 0.02%/V and

terminal-to-terminal voltage can range from 800mV to

40V.

Because the operating current is

absolute temperature

in degrees Kelvin, the device will

also find wide applications as a temperature sensor. The

temperature dependence of the operating current is

0.336%/°C at room temperature. For example, a device

operating at 298µA will have a temperature coefficient of

1µA/°C. The temperature dependence is extremely accu-

rate and repeatable. Devices specified as temperature

sensors in the 100µA to 1mA range are the LM134-3,

LM234-3 and the LM134-6, LM234-6, with the dash

numbers indicating ±3°C and ±6°C accuracies, respectively.

directly proportional to

, LTC and LT are registered trademarks of Linear Technology Corporation.

U

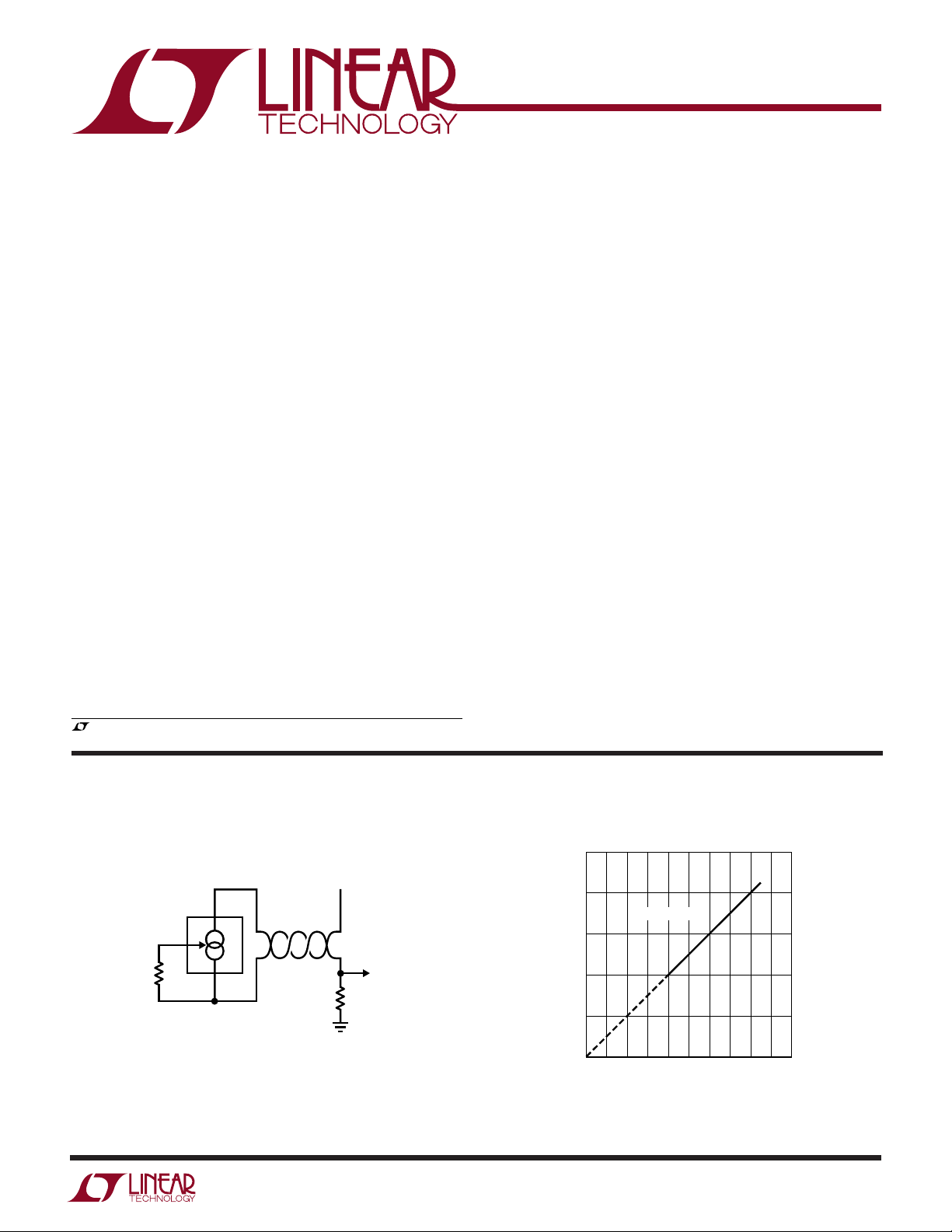

TYPICAL APPLICATIO

Remote Temperature Sensor with Voltage Output

≥ 5V

V

IN

+

V

R

R

SET

226Ω

LM234-3

–

V

R1

10k

10mV/°K

TA01a

If a zero temperature coefficient current source is required, this is easily achieved by adding a diode and a

resistor.

Operating Current vs Temperature

TA01b

500

225

125

TEMPERATURE (°C)

25

–75

–175

–275

500

400

R

= 226Ω

SET

300

200

TEMPERATURE (°K)

100

0

100

0

OPERATING CURRENT (µA)

200

300

400

1

LM134 Series

WW

W

ABSOLUTE AXI U RATI GS

U

(Note 1)

V+ to V– Forward Voltage

LM134 ................................................................. 40V

LM134-3/LM134-6/LM234-3/

LM234-6/LM334 ................................................. 30V

V+ to V– Reverse Voltage ........................................ 20V

R Pin to V– Voltage.................................................... 5V

Set Current ........................................................... 10mA

UUW

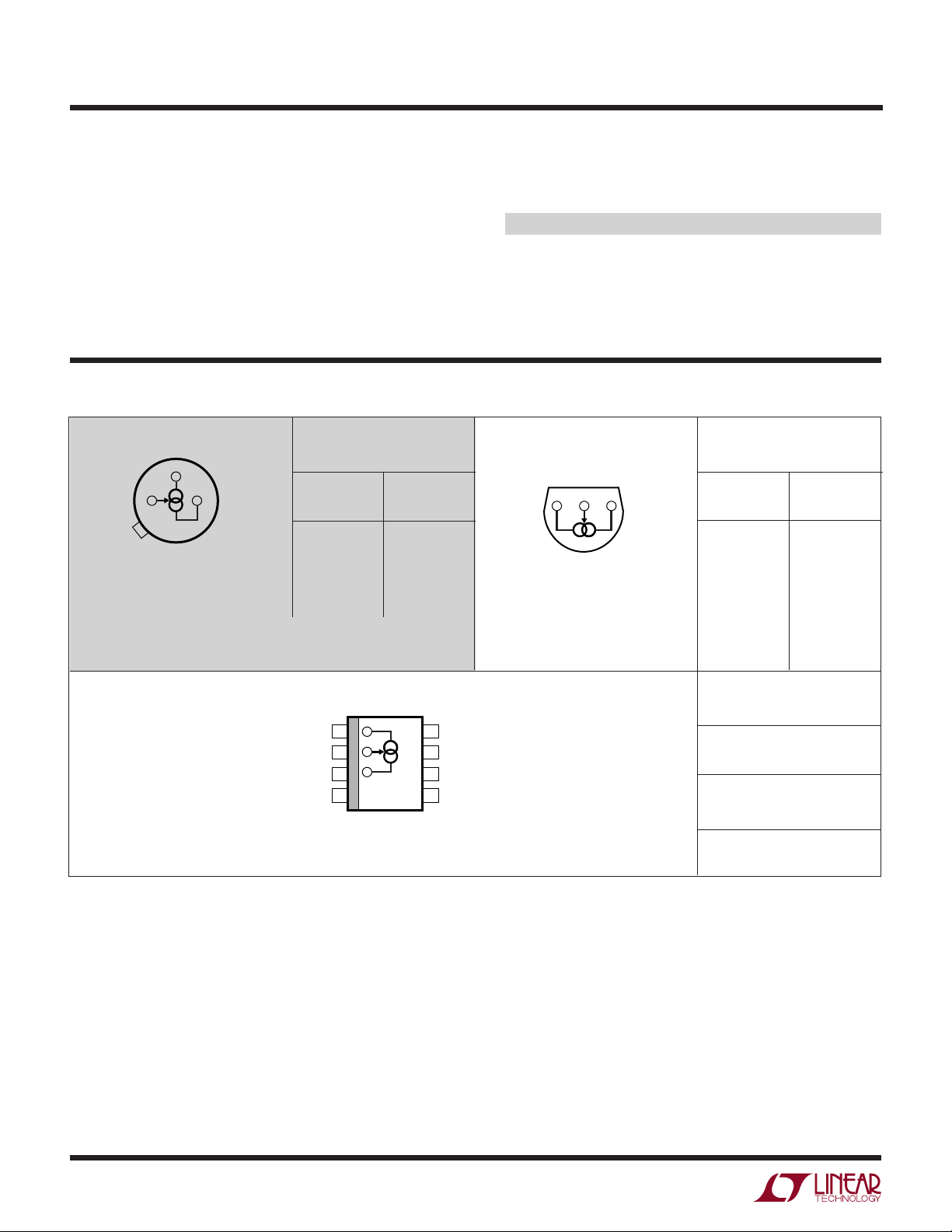

PACKAGE/ORDER I FOR ATIO

BOTTOM VIEW

+

V

–

V

R

H PACKAGE

3-LEAD TO-46 METAL CAN

T

= 150°C, θJA = 440°C/W, θJA = 80°C/W

JMAX

ORDER PART

NUMBER

CURRENT

SOURCE

LM134H

LM334H

TEMP

SENSOR

LM134H-3

LM234H-3

LM134H-6

LM234H-6

Power Dissipation.............................................. 200mW

Operating Temperature Range

LM134 (OBSOLETE) ................... –55°C to 125°C

LM234-3/LM234-6 ............................–25°C to 100°C

LM334 ..................................................... 0°C to 70°C

Storage Temperature Range ................. – 65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ORDER PART

BOTTOM VIEW

+

V

Z PACKAGE

3-LEAD PLASTIC TO-92

T

= 100°C, θJA = 160°C/W

JMAX

V

R

–

CURRENT

LM334Z

NUMBER

SOURCE

TEMP

SENSOR

LM234Z-3

LM234Z-6

OBSOLETE PACKAGE

Consider the S8 or Z Packages for Alternate Source

–

V

1

R

2

+

V

3

NC

4

S8 PACKAGE

8-LEAD PLASTIC SO

= 100°C, θJA = 180°C/W

T

JMAX

Consult LTC Marketing for availability of LM234Z-3 and LM234Z-6

ORDER PART

NUMBER

NC

8

NC

7

NC

6

NC

5

LM334S8

S8 PART

MARKING

334

2

LM134 Series

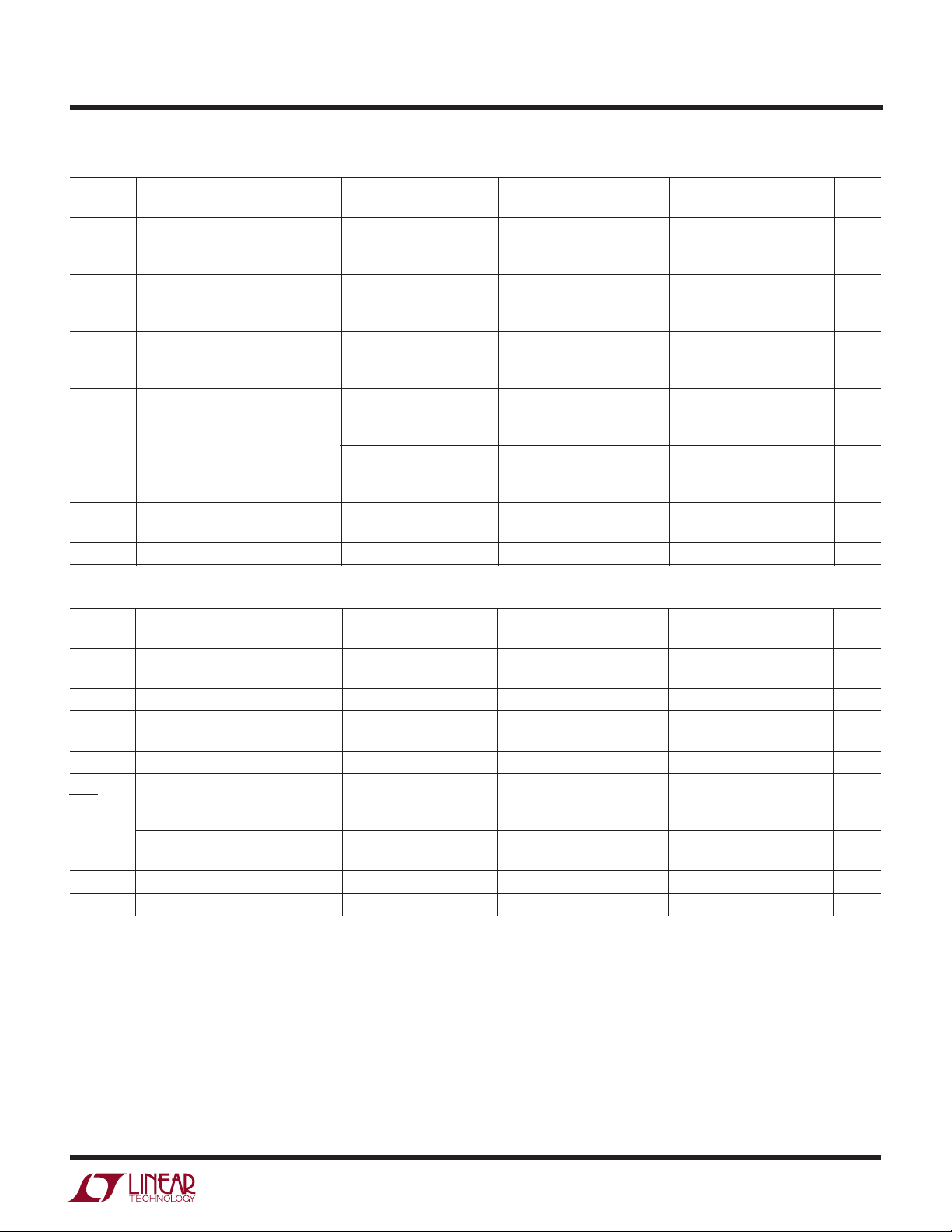

ELECTRICAL CHARACTERISTICS

CURRENT SOURCE (Note 2)

LM134 LM334

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

∆I

V

∆I

∆V

C

SET

MIN

SET

IN

S

Set Current Error, V+ = 2.5V 10µA ≤ I

(Note 3) 1mA < I

2µA ≤ I

Ratio of Set Current to 10µA ≤ I

–

Current 1mA ≤ I

V

2µA ≤ I

Minimum Operating Voltage 2µA ≤ I

100µA < I

1mA < I

≤ 1mA 3 6 %

SET

≤ 5mA 5 8 %

SET

< 10µA812%

SET

≤ 1mA 141823141826

SET

≤ 5mA 14 14

SET

≤ 10µA 1823 1826

SET

≤ 100µA 0.8 0.8 V

SET

≤ 1mA 0.9 0.9 V

SET

≤ 5mA 1.0 1.0 V

SET

Average Change in Set Current 1.5V ≤ V+ ≤ 5V 0.02 0.05 0.02 0.1 %/V

with Input Voltage 2µA ≤ I

5V ≤ V

+

SET

≤ V

≤ 1mA

(Note 5) 0.01 0.03 0.01 0.05 %/V

MAX

1.5V ≤ V ≤ 5V 0.03 0.03 %/V

1mA < I

5V ≤ V ≤ V

Temperature Dependence of 25µA ≤ I

≤ 5mA

SET

(Note 5) 0.02 0.02 %/V

MAX

≤ 1mA 0.96 1.04 0.96 1.04

SET

Set Current (Note 4)

Effective Shunt Capacitance 15 15 pF

TEMPERATURE SENSOR (Note 2)

LM134-3,LM234-3 LM134-6, LM234-6

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

∆I

SET

V

MIN

∆I

SET

∆V

IN

C

S

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Unless otherwise specified, tests are performed at T

pulse testing so that junction temperature does not change during test.

Note 3: Set current is the current flowing into the V

by the following formula: I

Set Current Error, V+ = 2.5V 100µA ≤ I

(Note 3) T

= 25°C

j

≤ 1mA ±1 ±2%

SET

Equivalent Temperature Error ±3 ±6 °C

Ratio of Set Current to 100µA ≤ I

–

Current

V

Minimum Operating Voltage 100µA ≤ I

≤ 1mA 141826141826

SET

≤ 1mA 0.9 0.9 V

SET

Average Change in Set Current 1.5V ≤ V+ ≤ 5V 0.02 0.05 0.02 0.1 %/V

with Input Voltage 100µA ≤ I

5V ≤ V

Temperature Dependence of 100µA ≤ I

≤ 1mA

SET

+

≤ 30V 0.01 0.03 0.01 0.05 %/V

≤ 1mA 0.98 1.02 0.97 1.03

SET

Set Current (Note 4)

Equivalent Slope Error ±2 ±3%

Effective Shunt Capacitance 15 15 pF

= 67.7mV/R

SET

= 25°C with

j

+

pin. It is determined

(at 25°C). Set current error

SET

is expressed as a percent deviation from this amount. I

0.336%/°C at T

Note 4: I

(°K). I

SET

where I

Note 5: V

= 25°C.

j

is nominally directly proportional to absolute temperature

SET

at any temperature can be calculated from: I

is I

measured at TO (°K).

O

SET

= 40V for LM134 and 30V for other grades.

MAX

increases at

SET

= IO (T/TO)

SET

3

LM134 Series

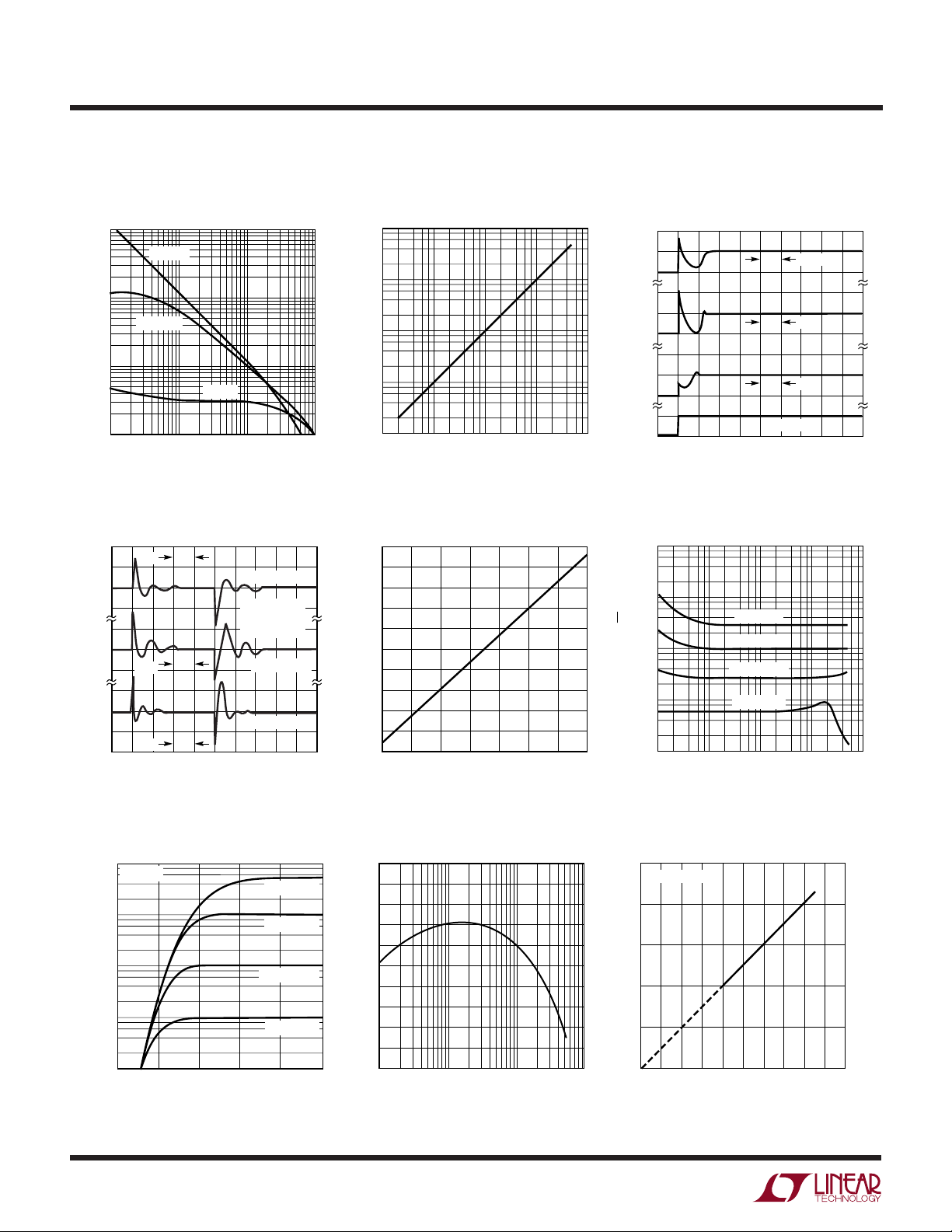

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Maximum Slew Rate for

Output Impedance

9

10

I = 10µA

8

10

I = 100µA

7

IMPEDANCE (Ω)

10

6

10

10

I = 1mA

100 1k 10k

FREQUENCY (Hz)

134 G01

Linear Operation

10

1.0

0.1

SLEW RATE (V/µs)

0.01

0.001

1 100 1000

10

I

SET

(µA)

134 G02

10000

Start-Up

10µA

0µA

100µA

0µA

SET

I

1mA

0mA

5V

0V

(*NOTE SCALE CHANGES FOR EACH CURRENT LEVEL)

TIME

200µs

50µs

5µs

INPUT

134 G03

Transient Response

2

2µs

1

0

–1

5

(%)

0

SET

∆I

10µs

–5

10

0

–10

50µs

–20

(*NOTE SCALE CHANGES FOR EACH CURRENT LEVEL)

TIME

I

= 1mA

SET

V+ TO V– = 5V

∆V = 0.4V

t

= 500ns

r, f

I

= 100µA

SET

I

= 10µA

SET

Turn-On Voltage

10mA

Tj = 25°C

1mA

100µA

SET

I

10µA

1µA

0.6

0.4 0.8 1.21.0

V+ TO V– VOLTAGE

R

R

R

R

SET

SET

SET

SET

= 680Ω

134 G04

= 14Ω

= 68Ω

= 6.8k

134 G02

1.4

Voltage Across R

86

82

78

74

70

66

62

VOLTAGE (mV)

58

54

50

46

–50

–25

Ratio of I

21

20

19

18

17

16

RATIO

15

14

13

12

11

10µA

SET

0

TEMPERATURE (°C)

to V– Current

SET

100µA 1mA 10mA

I

SET

75

50

25

100

1314/15 G01

134 G08

125

Current Noise

10k

1k

100

CURRENT (pA/√Hz)

10

1

10 1k 10k

100

FREQUENCY (Hz)

Operating Current vs

Temperature

500

R

= 226Ω

SET

400

300

200

TEMPERATURE (°K)

100

0

100

0

200

OPERATING CURRENT (µA)

I

SET

I

SET

I

SET

I

SET

= 5mA

= 1mA

= 100µA

= 10µA

300

400

134 G09

134 G06

500

100k

225

125

TEMPERATURE (°C)

25

–75

–175

–275

4

LM134 Series

U

WUU

APPLICATIO S I FOR ATIO

Basic Theory of Operation

The equivalent circuit of the LM134 is shown in Figure 1.

A reference voltage of 64mV is applied to the minus input

of A1 with respect to the V– pin. A1 serves the drive to Q2

to keep the R pin at 64mV, independent of the value of

R

. Transistor Q1 is matched to Q2 at a 17:1 ratio so that

SET

the current flowing out of the V– pin is always 1/18 of the

total current into the V+ pin. This total current is called I

and is equal to:

64 181767 7mV

R

SET SET

=

mV

.

R

A1

Figure 1.

+

–

64mV

+

V

I

SET

Q2Q1

R

R

+

SET

–

–

V

134 F01

The 67.7mV equivalent reference voltage is directly proportional to absolute temperature in degrees Kelvin (see

curve, “Operating Current vs Temperature”). This means

that the reference voltage can be plotted as a straight line

going from 0mV at absolute zero temperature to 67.7mV

at 298°K (25°C). The slope of this line is 67.7mV/298 =

227µV/°C.

The accuracy of the device is specified as a percent error

at room temperature, or in the case of the -3 and -6

devices, as both a percent error and an equivalent temperature error. The LM134 operating current changes at a

percent rate equal to (100)(227µV/°C)/(67.7mV) = 0.336%/

°C at 25°C, so each 1% operating current error is equivalent to ≈3°C temperature error when the device is used as

a temperature sensor. The slope accuracy (temperature

coefficient) of the LM134 is expressed as a ratio compared to unity. The LM134-3, for instance, is specified at

0.98 to 1.02, indicating that the maximum slope error of

SET

the device is ±2% when the room temperature current is

set to the exact desired value.

Supply Voltage Slew Rate

At slew rates above a given threshold (see curve), the

LM134 may exhibit nonlinear current shifts. The slewing

rate at which this occurs is directly proportional to I

I

= 10µA, maximum dv/dt is 0.01V/µs; at I

SET

SET

. At

SET

= 1mA,

the limits is 1V/µs. Slew rates above the limit do not harm

the LM134, or cause large currents to flow.

Thermal Effects

Internal heating can have a significant effect on current

regulation for I

1V increase across the LM134 at I

greater than 100µA. For example, each

SET

= 1mA will increase

SET

junction temperature by ≈0.4°C in still air. Output current

(I

) has a temperature coefficient of ≈0.33%/°C, so the

SET

change in current due to temperature rise will be (0.4)(0.33)

= 0.132%. This is a 10:1 degradation in regulation compared to true electrical effects. Thermal effects, therefore,

must be taken into account when DC regulation is critical

and I

exceeds 100µA. Heat sinking of the TO-46 pack-

SET

age or the TO-92 leads can reduce this effect by more than

3:1.

Shunt Capacitance

In certain applications, the 15pF shunt capacitance of the

LM134 may have to be reduced, either because of loading

problems or because it limits the AC output impedance of

the current source. This can be easily accomplished by

buffering the LM134 with a FET, as shown in the applications. This can reduce capacitance to less than 3pF and

improve regulation by at least an order of magnitude. DC

characteristics (with the exception of minimum input

voltage) are not affected.

Noise

Current noise generated by the LM134 is approximately 4

times the shot noise of a transistor. If the LM134 is used

as an active load for a transistor amplifier, input referred

noise will be increased by about 12dB. In many cases, this

is acceptable and a single stage amplifier can be built with

a voltage gain exceeding 2000.

5

LM134 Series

U

WUU

APPLICATIO S I FOR ATIO

Lead Resistance

The sense voltage which determines the operating current

of the LM134 is less than 100mV. At this level, thermocouple or lead resistance effects should be minimized by

locating the current setting resistor physically close to the

device. Sockets should be avoided if possible. It takes only

0.7Ω contact resistance to reduce output current by 1% at

the 1mA level.

Start-Up Time

The LM134 is designed to operate at currents as low as

1µA. This requires that internal biasing current be well

below that level because the device achieves its wide

operating current range by using part of the operating

current as bias current for the internal circuitry. To ensure

start-up, however, a fixed trickle current must be provided

internally. This is typically in the range of 20nA to 200nA

and is provided by the special ultralow I

the Schematic Diagrams as Q7 and Q8. The start-up time

of the LM134 is determined by the I

DSS

the capacitor C1. This capacitor must charge to approximately 500mV before Q3 turns on to start normal circuit

operation. This takes as long as (500mV)(50pF)/(20nA) =

1.25ms for very low I

DSS

values.

Using the LM134 as a Temperature Sensor

Because it has a highly linear output characteristic, the

LM134 makes a good temperature sensor. It is particularly

useful in remote sensing applications because it is a

current output device and is therefore not affected by long

wire runs. It is easy to calibrate, has good long term

stability and can be interfaced directly with most data

acquisition systems, eliminating the expensive preamplifiers required for thermocouples and platinum sensors.

A typical temperature sensor application is shown in

Figure␣ 2. The LM134 operating current at 25°C is set at

298µA by the 226Ω resistor, giving an output of 1µA/°K.

The current flows through the twisted pair sensor leads to

the 10k termination resistor, which converts the current

output to a voltage of 10mV/°K referred to ground. The

FETs shown in

DDS

of these FETs and

voltage across the 10k resistor will be 2.98V at 25°C, with

a slope of 10mV/°C. The simplest way to convert this

signal to a Centigrade scale is to subtract a constant 2.73V

in software. Alternately, a hardware conversion can be

used, as shown in Figure 3, using an LT1009 as a level

shifter to offset the output to a Centigrade scale.

The resistor (R

) used to set the operating current of the

SET

LM134 in temperature sensing applications should have

low temperature coefficient and good long term stability.

A 30ppm/°C drift in the resistor will change the slope of the

temperature sensor by 1%, assuming that the resistor is

at the same temperature as the sensor, which is usually the

case since the resistor should be located physically close

to the LM134 to prevent errors due to wire resistance. A

long term shift of 0.3% in the resistor will create a 1°C

temperature error. The long term drift of the LM134 is

typically much better than this, so stable resistors must be

used for best long term performance.

Calibration of the LM134 as a temperature sensor is

extremely easy. Referring to Figure 2, calibration is achieved

by trimming the termination resistor.

This theoretically

trims both zero and slope simultaneously for Centigrade

and Fahrenheit applications.

The initial errors in the LM134

are directly proportional to absolute temperature, just like

the actual output. This allows the sensor to be trimmed at

any temperature and have the slope error be corrected at

the same time. Residual slope error is typically less than

1% after this single trim is completed.

VS ≥ 5V

+

V

LM234-3

R

TO DATA

ACQUISITION

SYSTEM

10mV/°K

CALIBRATE

–

V

9.53k

Figure 2 Kelvin Temperature Sensor

I = 1µA/°K

1k

R

SET

226Ω

134 F02

6

LM134 Series

U

WUU

APPLICATIO S I FOR ATIO

The two trims shown in Figure 3 are still intended to be a

“one point” temperature calibration, where the zero and

the slope are trimmed at a single temperature. The LT1009

reference is adjusted to give 2.700V at node “a” at T

= 25°C. The 1k trimmer then adjusts the output for 0.25V,

completing the calibration. If the calibration is to be done

at a temperature other than 25°C , trim the LT1009 for

2.7025—(1µA)[T

SENSOR

(°C)](100Ω) at node “a”, then

adjust the 1k trimmer for proper output.

≥ 4V

V

S

+

V

LM134-3

R

OUTPUT

10mV/°C

“a”

–15V

9.53k

1%

1k

SLOPE

ADJ

100Ω

10k

LT1009

10k

ZERO

ADJ

–

V

R

SET

226Ω

134 F03

SENSOR

If higher accuracy is required, a two point calibration

technique can be used. In Figure 4, separate zero and slope

trims are provided. Residual nonlinearity is now the limitation on accuracy. Nonlinearity of the LM134 in a 100°C

span is typically less than 0.5°C. This particular method of

trimming has the advantage that the slope trim does not

interact with the zero trim. Trim procedure is to adjust for

zero output with T

SENSOR

= 0°C, then trim slope for proper

output at some convenient second temperature. No further trimming is required.

+

≥ 5V

V

+

LM134-3

226Ω*

*LOW TC, STABLE RESISTOR

V

R

1%

OUTPUT

10mV/°C

ZERO

TRIM

10k

134 F04

–

V

SLOPE

TRIM

500k

50k

–15V

332k1%11k*

15k

LT1009

Figure 3. Centigrade Temperature Sensor

TYPICAL APPLICATIO S

Basic 2-Terminal

Current Source

V

IN

+

V

I

SET

LM334

R

R

–

V

–V

IN

SET

134 TA02

Figure 4. Centigrade Temperature Sensor with 2 Point Trim

U

Low Output Impedance

Thermometer (Kelvin Output)

V

≥ 4.8V

IN

+

V

LM334

0.1µF

*OUTPUT IMPEDANCE OF THE LM134 AT THE “R” PIN IS

APPROXIMATELY Ω, WHERE R

EXTERNAL RESISTANCE CONNECTED TO THE V

NEGATIVE RESISTANCE CAN BE REDUCED BY A FACTOR OF

5 OR MORE BY INSERTING AN EQUIVALENT RESISTOR IN

SERIES WITH THE OUTPUT.

–

V

C1

–R

O

16

R3*

600Ω

R

R1

230Ω

1%

R2

10k

1%

O

V

OUT

Z

OUT

IS THE EQUIVALENT

= 10mV/°K

≤ 100Ω

134 TA03

–

PIN. THIS

Zero Temperature

Coefficient Current Source

V

IN

+

I

+

V

R

LM334

1N457

*SELECT RATIO OF R1 TO R

OBTAIN ZERO DRIFT. I

–

V

R

SET

D1

–V

IN

R1*

≈10 R

134 TA04

+

≈2 I

SET

SET

SET

TO

.

7

LM134 Series

TYPICAL APPLICATIO S

U

Higher Output Current

V

IN

R1*

+

V

LM334

*SELECT R1 AND C1 FOR OPTIMUM STABILITY

–

V

2N2905

C1*

R

R

SET

–V

TA05

IN

Micropower Bias

V

IN

LM4250

1µA

+

LM334

V

–

V

R

SET

68k

R

–V

IN

TA08

Low Output Impedance Thermometer

V

IN

C1

0.0022

LM334

R1

15k

V

V

+

–

R2

300Ω

2N4250

V

= 10mV/°K

OUT

≤ 2Ω

R

Z

R3

100Ω

R4

4.5k

OUT

1.2V Regulator with 1.8V Minimum Input

100k

C1

0.001

+

V

LM134**

*

SELECT RATIO OF R1 TO R2 FOR ZERO TEMPERATURE DRIFT

**

LM134 AND DIODE SHOULD BE ISOTHERMAL

R

–

V

2N4250

R1

33k

TA06

VIN ≥ 1.8V

V

OUT

I

OUT

1N457**

R1*

≈6k

1%

R2*

680Ω

1%

V

≥ V

IN

= 1.2V

≤ 200µA

TA09

Low Input Voltage Reference Driver

+ 200mV

REF

R1

1.5k

C1

LM334

0.1

+

V

–

V

Q1

2N4250

V

= VZ + 64mV AT 25°C

OUT

≤ 3mA

I

+

V

Z

–

R

LT1009

R2

120Ω

OUT

Zener Biasing

V

IN

+

V

LM334

R

–

V

V

Z

TA10

TA07

R

SET

V

OUT

Alternate Trimming Technique

V

IN

+

V

R

–

R1*

V

–V

IN

LM334

*FOR ±10% ADJUSTMENT, SELECT R

10% HIGH AND MAKE R1 ≈ 3R

8

Buffer for Photoconductive Cell

+

V

LM334

R

SET

TA11

1.5V

R

–

V

TA12

High Precision Low TC Current Source

+

I

≥ 50µA

SET

+

V

LM334

V

LT1004-1.2

(1.235V)

R

–

R1

6.8k

R2*

TA13

–

SET

SET

1.37V

*I

= + 10µA

SET

R2

TC = 0.016%/°C + 33nA/°C

I

SET

REGULATION ≈ 0.001%/V

TYPICAL APPLICATIO S

LM134 Series

U

Precision 10nA Current Source

15V

+

V

–

V

LT1004-1.2

2

–

3

+

–15V

R

R1

2.7k

15V

LT1008

4

7

LM134

R2

226k

R3

1M

R4

100MΩ

I

O

= 10nA

I

O

Z

≥ 1012Ω

O

COMPLIANCE = –14V TO 12.5V

8

6

200pF

LM334

LT1004-1.2

(1.235V)

BUFFERED

VOLTAGE

OUTPUT

TA14

FET Cascoding for Low Capacitance

and/or Ultrahigh Output Impedance

V

IN

I

SET

Q1*

+

V

LM334

R

V

IN

+

V

–

V

LM334

R

Micropower 5V Reference

V

R

5.6k

+

LM4250

–

4

7

22M

3

2

1M

1%

R

SET

= 6.5V TO 15V

IN

6

8

150pF

V

OUT

3.01M

1%

= 5V

TA15

W

SCHE ATIC DIAGRA

R

SET

–

V

–V

*SELECT Q1 OR Q2 TO ENSURE AT LEAST 1V

IN

ACROSS THE LM134. V

(1 – I

P

W

Q7 Q8

Q3

Q2

C1

50pF

SET/IDSS

Q5Q4

–V

Q2*

I

SET

IN

) ≥ 1.2V.

Q1

+

V

Q6

134 SD

TA16

R

–

V

9

LM134 Series

PACKAGE DESCRIPTIO

U

H Package

2-Lead and 3-Lead TO-46 Metal Can

(Reference LTC DWG # 05-08-1340)

REFERENCE

PLANE

0.209 – 0.219

(5.309 – 5.537)

0.178 – 0.195

(4.521 – 4.953)

0.500

(12.700)

0.016 – 0.021**

(0.406 – 0.533)

DIA

± 0.005

0.060

(1.524± 0.127)

DIA

0.180 ± 0.005

(4.572 ± 0.127)

MIN

0.085 – 0.105

(2.159 – 2.667)

*

0.025

(0.635)

MAX

0.050

(1.270)

0.036 – 0.046

(0.914 – 1.168)

*

LEAD DIAMETER IS UNCONTROLLED BETWEEN THE REFERENCE PLANE

AND 0.045" BELOW THE REFERENCE PLANE

**

FOR SOLDER DIP LEAD FINISH, LEAD DIAMETER IS

TYP

0.100

(2.540)

TYP

PIN 1

45°

OBSOLETE PACKAGE

Z Package

3-Lead Plastic TO-92 (Similar to TO-226)

(Reference LTC DWG # 05-08-1410)

0.180 ± 0.005

(4.572 ± 0.127)

0.90

(2.286)

NOM

0.050

(1.270)

TYP

FOR 3-LEAD PACKAGE ONLY

0.028 – 0.048

(0.711 – 1.219)

H02/03(TO-46) 1098

0.016 – 0.024

(0.406 – 0.610)

10

0.500

(12.70)

MIN

0.050

(1.27)

BSC

10° NOM

0.050

UNCONTROLLED

LEAD DIMENSION

(1.270)

MAX

0.016 ± 0.003

(0.406 ± 0.076)

0.060 ± 0.010

(1.524 ± 0.254)

0.140 ± 0.010

(3.556 ± 0.127)

5°

NOM

0.015 ± 0.002

(0.381 ± 0.051)

0.098 +016/–0.04

(2.5 +0.4/–0.1)

2 PLCS

TO-92 TAPE AND REEL

REFER TO TAPE AND REEL SECTION OF

LTC DATA BOOK FOR ADDITIONAL INFORMATION

Z3 (TO-92) 0401

PACKAGE DESCRIPTIO

U

S8 Package

8-Lead Plastic Small Outline (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1610)

0.189 – 0.197*

(4.801 – 5.004)

7

8

6

LM134 Series

5

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0°– 8° TYP

0.016 – 0.050

(0.406 – 1.270)

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.150 – 0.157**

(3.810 – 3.988)

SO8 1298

1

3

2

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

11

LM134 Series

TYPICAL APPLICATIO S

In-Line Current Limiter Generating Negative Output Impedance

R

SET

R

+

V

V

IN

LM334

–

V

OP AMP

U

C1*

LM334

V

IN

+

V

–

V

R1*

R

R

SET

*USE MINIMUM VALUE REQUIRED TO

ENSURE STABILITY OF PROTECTED

DEVICE. THIS MINIMIZES INRUSH

CURRENT TO A DIRECT SHORT.

TA17

*Z

OUT

Ground Referred Fahrenheit Thermometer

V

≥ 3V

IN

R4

56k

2N4250

LM334

*SELECT R3 = V

**SELECT FOR 1.2mA

C1

0.01

+

V

–

V

R1

8.25k

1%

R

R2

100Ω

1%

REF

R3*

/583µA

V

= 10mV/°F

OUT

10°F ≤ T ≤ 250°F

V

IN

R5**

LT1009

2.5V*

TA19

–V

IN

≈ –16 • R1(R1/VIN MUST NOT EXCEED I

TA18

SET

).

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

134sc LT/CP 1001 1.5K REV C • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1991

Loading...

Loading...