Page 1

DEMO MANUAL DC1996A

LTC2323/LTC2321

Dual 16-Bit/14-Bit/12-Bit,

DESCRIPTION

Demonstration circuit 1996A features the LTC®2323 family.

With up to 5Msps, these differential, dual channel, 16-bit,

serial, high speed successive approximation register

(SAR) ADCs are available in a 28-lead QFN package. The

LTC2323 family has an internal 20ppm/°C reference and

an SPI-compatible serial interface that supports CMOS

and LVDS logic. Note the demo board is configured for

CMOS operation by default; see the note under JP3 for

LVDS operation. The following text refers to the LTC2323,

but applies to all members of the family, the only differ

ence being the sample rate and the number of bits. The

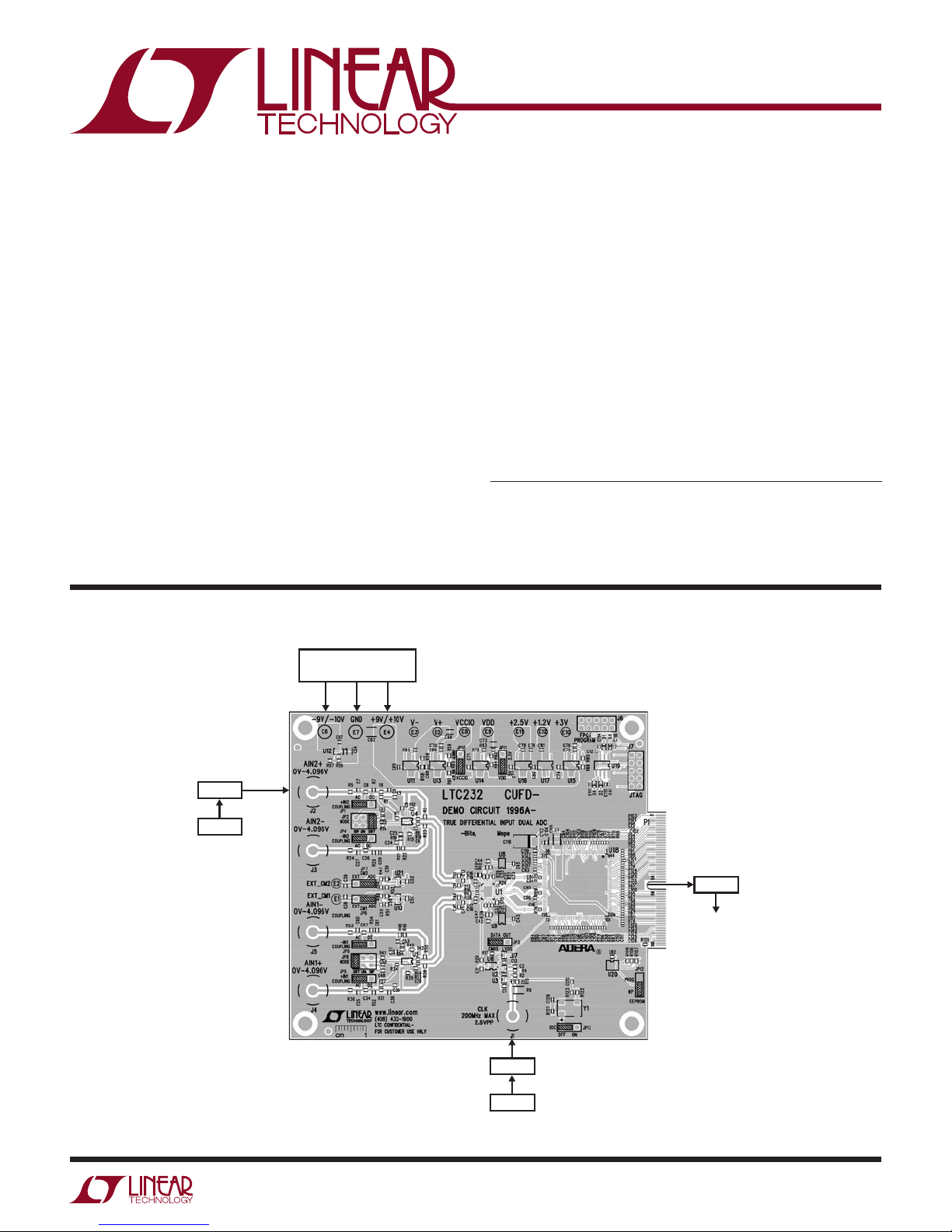

BOARD PHOTO

5Msps/2Msps, Serial,

High Speed SAR ADCs

DC1996A demonstrates the DC and AC performance of

the LTC2323 in conjunction with the DC890 PScope™

data collection board. Alternatively, by connecting the

DC1996A into a customer application, the performance

of the LTC2323 can be evaluated directly in that circuit.

Design files for this circuit board are available at

http://www.linear.com/demo

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks and PScope

is a trademark of Linear Technology Corporation. All other trademarks are the property of their

respective owners.

-

BPF

HP8642B

DC POWER SUPPLY

–9.5V

GND 9.5V

DC

DC

DC890

TO PC USB PORT

dc1996a F02

BPF

HP8642B

Figure 1. DC1996A Connection Diagram

dc1996afb

1

Page 2

DEMO MANUAL DC1996A

ASSEMBLY OPTIONS

Table 1. DC1996A Assembly Options

VERSION U1 PART NUMBER MAX CONVERSION RATE # OF BITS MAX CLOCK FREQUENCY

DC1996A-A LTC2323CUFD-16#PBF 5Msps 16 110MHz

DC1996A-B LTC2321CUFD-16#PBF 2Msps 16 64MHz

DC1996A-C LTC2323CUFD-14#PBF 5Msps 14 110MHz

DC1996A-D LTC2321CUFD-14#PBF 2Msps 14 62MHz

DC1996A-E LTC2323CUFD-12 #PBF 5Msps 12 95MHz

DC1996A-F LTC2321CUFD-12#PBF 2Msps 12 58MHz

QUICK START PROCEDURE

Demonstration circuit 1996A is easy to set up and evaluate

for performance. Refer to Figure 1 and follow the proce

dure below.

n

Connect the DC1996A to a DC890 USB high speed data

collection board using edge connector P1.

n

Connect the DC890 to a host PC with a standard USB

A/B cable.

n

Apply a low jitter signal source to J2 to test channel

2, or to J4 to test channel 1. Note that the DC1996A

is capable of accepting a differential input signal as

well as a single-ended signal. See the Hardware Setup

section for the jumper positions that correspond to

these configurations.

n

As a clock source, apply a low jitter 10dBm sine wave or

square wave to connector J1. See Table 1 for maximum

clock frequencies. Note that J1 has a 50Ω termination

resistor to ground.

n

Run the PScope software (Pscope.exe version K73,

or later) supplied with the DC890 or download it from

www.linear.com/software. Complete software doc-

umentation is available from the Help menu. Updates

can be downloaded from the Tools menu. Check for

updates periodically, as new features may be added.

The PScope software should recognize

-

and configure itself automatically.

n

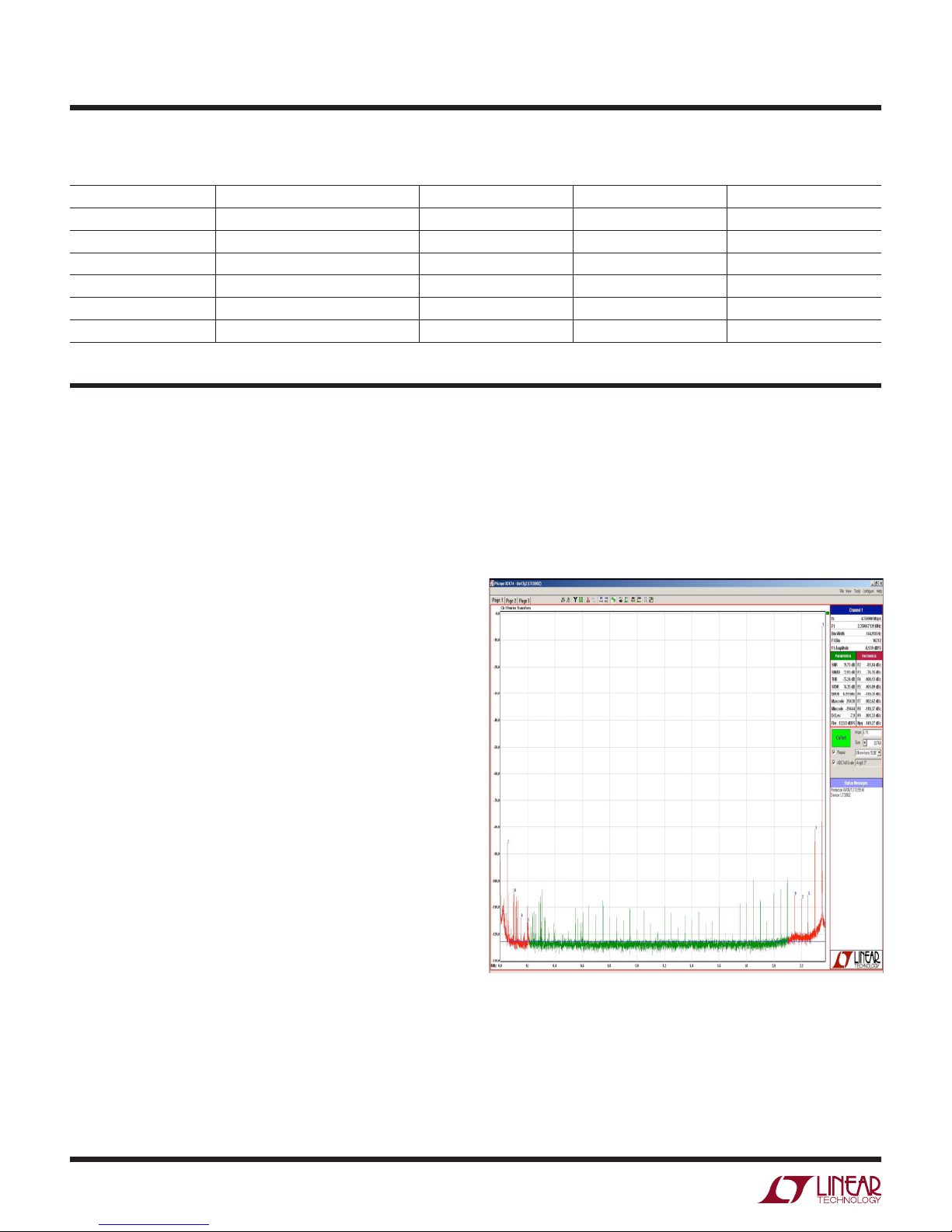

Click the Collect button (Figure 2) to begin acquiring

the DC1996A

data. The Collect button then changes to Pause, which

can be used to stop data acquisition.

Figure 2. DC1996A PScope Screenshot

2

dc1996afb

Page 3

HARDWARE SETUP

DEMO MANUAL DC1996A

SIGNAL CONNECTIONS

J1 CLK IN: This input has a 50Ω termination resistor,

and is intended to be driven by a low jitter 10dBm sine or

square wave. To achieve the full AC performance of this

part, the clock jitter should be kept under 2ps. This input

is capacitively coupled so that the input clock can be either

0V to 3.3V or ±1.65V. This eliminates the need for level

shifting. To run at the maximum conversion rate, apply

the frequency specified in the Table 1.

J2 Ch2+ Input: In the single-ended configuration, this is

the channel 2 signal input. For differential operation, this

serves as the positive channel 2 signal input.

J3 Ch2– Input: This input is used only for differential

operation. It serves as the negative channel 2 signal input.

J4 Ch1+ Input: In the single-ended configuration, this is

the channel 1 signal input. For differential operation, this

serves as the positive channel 1 signal input.

J5 Ch1– Input: This input is used only for differential

operation. It serves as the negative channel 1 signal input.

J6 FPGA Program: Factory use only.

J7 JTAG: Factory use only.

JP1 +IN2 Coupling: Use this jumper to select AC- or DC-

coupling of the signal applied to J2.

is DC. At very low input frequencies, using AC-coupling

may degrade the distortion performance.

JP2 Mode: Use this jumper to select the signal input mode

for the channel 2 input of the LTC2323. The default setting

is Diff. The Diff setting accepts a single-ended signal from

J2 and applies it as a differential signal to channel 2 of the

LTC2323. The Bip setting accepts a single-ended signal

from J2 and applies it as a single-ended bipolar signal to

channel 2 of the LTC2323. The Uni setting also accepts a

single-ended signal from J2, but applies it as a unipolar

signal to channel 2 of the LTC2323.

The default setting

JP3 Data Out: Use this jumper to select the data output

format from the LTC2323. The default setting is CMOS.

The output data will not be valid if the jumper is moved

to the LVDS position unless the following changes have

been made:

Install 100Ω S0402 resistors at R26, 75, 76, 99

Reprogram the CPLD through J6 using the program

ming file LTC2323.pof found at:

http://www.linear.com/demo/DC1996A

Move JP3 to the LVDS position.

JP4 –IN2 Coupling: Use this jumper to select AC- or DCcoupling of the signal applied to J3. The default setting

is DC. At very low input frequencies, using AC-coupling

may degrade the distortion performance.

JP5 +IN1 Coupling: Use this jumper to select AC- or DCcoupling of the signal applied to J4. The default setting

is DC. At very low input frequencies, using AC-coupling

may degrade the distortion performance.

JP6 CM1: Use this jumper to set the DC bias point for the

signal applied to J4 when JP5 (+IN1 coupling) is in the

AC position. The default setting is ADC. The EXT setting

allows the use of an externally applied common mode

voltage applied at E1 (EXT_CM1).

JP7 CM2: Use this jumper to set the DC bias point for the

signal applied to J2 when JP1 (+IN2 coupling) is in the

AC position. The default setting is ADC. The EXT setting

allows the use of an externally applied common mode

voltage applied at E2 (EXT_CM2).

JP8 Mode: Use this jumper to select the signal input mode

for the channel 1 input of the LTC2323. The default setting

is Diff. The Diff setting accepts a single-ended signal from

J4 and applies it as a differential

LTC2323. The Bip setting accepts a single-ended signal

from J4 and applies it as a single-ended bipolar signal to

channel 1 of the LTC2323. The Uni setting also accepts a

single-ended signal from J4, but applies it as a unipolar

signal to channel 1 of the LTC2323.

signal to channel 1 of the

-

dc1996afb

3

Page 4

DEMO MANUAL DC1996A

HARDWARE SETUP

JP9 –IN1 Coupling: Use this jumper to select AC- or DCcoupling of the signal applied to J5. The default setting

is DC. At very low input frequencies, using AC-coupling

may degrade the distortion performance.

JP10 VCCIO: Use this jumper to select the VCCIO sup

ply voltage. The default setting is 2.5V. The 1.8V setting

selects a 1.8V supply voltage.

JP11 VDD: Use this jumper to select the VDD supply voltage. The default setting is 5V. The 3.3V setting selects a

3.3V supply voltage.

JP12 EEPROM: Factory use only.

-

JP13 OSC: Use this jumper to enable the onboard encode

clock source. The default setting

is OFF. The ON setting

energizes this source. Refer to the DC1996A schematic for

additional passive elements required to use the onboard

source.

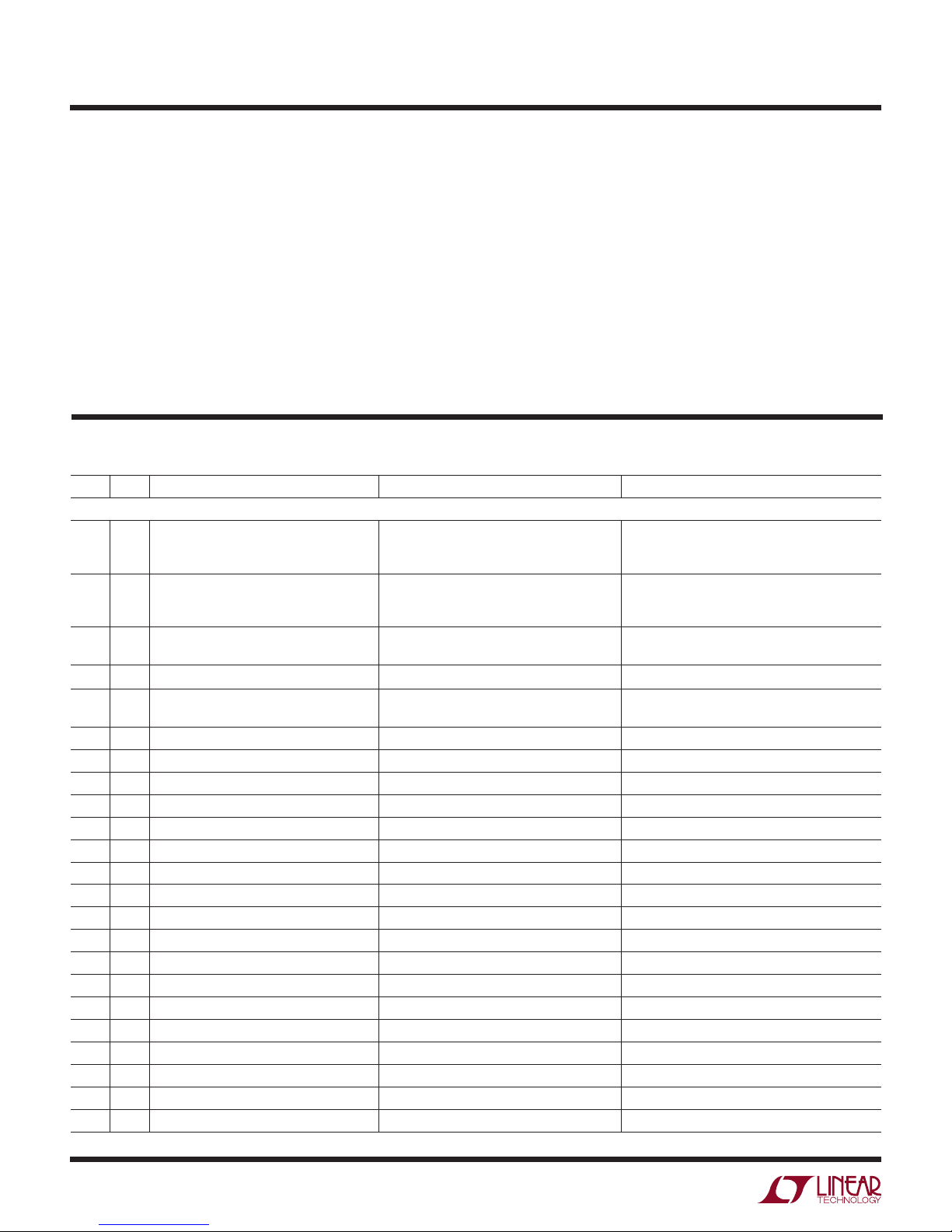

PARTS LIST

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

Required Circuit Components

1 20 C1, C2, C4, C5, C9, C11, C13, C18, C19,

C22, C23, C29, C37, C51, C52, C58, C59,

C82, C129, C130

2 24 C3, C6, C16, C17, C20, C21, C24-C26,

C28, C30, C34, C47-C50, C53, C54, C57,

C61, C70, C76, C79, C81

3 0 C7, C8, C10, C14, C27, C35, C36, C40,

C41, C60

4 2 C12, C41 CAP., NPO, 200pF, 16V, 5%, 0603 MURAA, GRM1885C1H201JA01D

5 12 C15, C32, C38, C39, C43, C45, C65, C67,

C68, C71, C74, C77

6 6 C31, C33, C55, C56, C106, C119 CAP., X5R, 4.7µF, 6.3V, 10%, 0603 AVX, 06036D475K AT2A

7 2 C42, C44 CAP., X5R, 2.2µF, 10V, 10%, 0603 MURATA, GRM188R61A225KE34D

8 1 C62 CAP., X7R, 47µF, 10V, 10%, 1210 MURATA, GRM32ER71A476KE15L

9 5 C63, C69, C72, C75, C78 CAP., X7R, 0.01µF, 6.3V, 10%, 0603 MURATA, GRM188R70J103KA01D

10 3 C64, C66, C73 CAP., X7R, 10µF, 10V, 10%, 0805 MURATA, GRM21BR71A106KE51L

11 1 C80 CAP., X5R, 3.3µF

12 28 C83-C104, C108, C122-C126 CAP., X7R, 0.1µF, 16V, 10%, 0402 NIC, NMC0402X7R104K16TRPF

13 1 C105 CAP., X5R, 47µF, 6.3V, 20%, 0805 TAIYO YUDEN, JMK212BJ476MG-T

14 3 C107, C120, C121 CAP., X7R, 0.01µF, 16V, 10%, 0402 NIC, NMC0402X7R103K16TRPF

15 1 C109 CAP., X7R, 1nF, 16V, 10%, 0402 AVX, 0402YC102K AT2A

16 3 C110, C111, C112 CAP., X7R, 22nF, 16V, 10%, 0402 AVX, 0402YC223K AT2A

17 2 C113, C128 CAP., X7R, 4.7nF, 16V, 10%, 0402 AVX, 0402YC472KAT2A

18 4 C114, C115, C116, C117 CAP., NP0, 10pF, 16V, 10%, 0402 AVX, 0402YA100KAT2A

19 1 C118 CAP., TANT, 470µF 10V, 20%, 7343 AVX, TPSE477M010R0050

20 1 C127 CAP., X7R, 2.2nF, 16V, 10%, 0402 AVX, 0402YC222KAT2A

21 4 D1, D2, D3, D4 DIODE, SCHOTTKY, 30V, 200mW SOD-323 DIODE INC., BAT54WS-7-F

22 9 E1-E3, E5, E8-E12 TEST POINT, TURRET, 0.064" MILL-MAX, 2308-2-00-80-00-00-07-0

23 3 E4, E6, E7 TEST POINT, TURRET, 0.094" MILL-MAX, 2501-2-00-80-00-00-07-0

CAP., X7R, 0.1µF, 16V, 10%, 0603 NIC, NMC0603X7R104K16TRPF

CAP., X5R, 10µF, 6.3V, 20%, 0603 NIC, NMC0603X5R106M6.3TRPF4KF

CAP., 0603 OPT

CAP., X7R, 1µF, 25V, 10%, 0603 TDK, C1608X7R1E105K

, 6.3V, 10%, 0603 AVX, 06036D335K AT2A

dc1996afb

4

Page 5

DEMO MANUAL DC1996A

PARTS LIST

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

24 11 JP1, JP3-JP7, JP9-JP11, JP13, JP15 HEADER, 1×3, 0.100" SAMTEC, TSW-103-07-L-S

25 2 JP2, JP8 HEADER, 2×3, 0.100" SAMTEC, TSW-103-07-L-D

26 2 J6, J7 HEADER, 2×5, 0.100" SAMTEC, TSW-105-07-L-D

27 5 J1, J2, J3, J4, J5 CONN BNC FEM JACK PC MNT STRGHT AMPHENOL CONNEX, 112404

28 1 L1 IND, FERRITE CHIP, 390Ω, 2000mA, 1206 MURATA, BLM31PG391SN1L

29 15 R1, R2, R10, R21, R27, R46-R48, R51,

R52, R57, R58, R60, R64, R66

30 0 R3, R7, R11, R22, R23, R25, R28, R29,

R32, R34, R36, R37, R49, R50, R54,

R123

31 2 R4, R17 RES., CHIP, 33Ω, 1/10W, 5%, 0603 PANASONIC, ERJ-3GEYJ330V

RES., CHIP, 1k, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF1001V

RES., CHIP, 0603 OPT

32 11 R5, R6, R12, R20, R24, R30, R31, R35,

R39, R40, R53

33 4 R8, R18, R33, R44 RES., CHIP, 49.9Ω, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF49R9V

34 1 R9 RES., CHIP, 49.9Ω, 1/4W, 1%, 1206 PANASONIC, ERJ-8ENF49R9V,

35 4 R13, R16, R38, R43 RES., CHIP, 0Ω, 1/16W, 0402 PANASONIC, ERJ-2GE0R00X

36 4 R14, R15, R41, R42 RES., CHIP, 301, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF3010V

37 2 R19, R45 RES., CHIP, 150, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF1500V

38 0 R26, R75, R76, R99 RES., CHIP, 0402

39 2 R55, R56 RES., CHIP

40 1 R59 RES., CHIP, 499Ω, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF4990V

41 1 R61 RES., CHIP, 866Ω, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF8660V

42 1 R62 RES., CHIP, 3.09k, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF3091V

43 1 R63 RES., CHIP, 4.02k, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF4021V

44 1 R65 RES., CHIP, 1.43k, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF1431V

45 33 R69-R72, R77-R98, R100-R104, R119,

R120

46 1 R118 RES., CHIP, 1k, 1/16W, 1%, 0402 PANASONIC, ERJ-2EKF1001V

47 4 R105, R106, R107, R108 RES., CHIP, 4.99k, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF4991V

48 9 R109-R117 RES., CHIP, 10k, 1/16W, 5%, 0402 PANASONIC, ERJ-2GEYJ103V

49 1 R121 RES., CHIP, 10k, 1/16W, 5%, 0603 PANASONIC, ERJ-3GEYJ103V

50 1 R122 RES., CHIP, 100Ω, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF1000V

51 3 U2, U3, U7 IC, INVERTER, UHS, SINGLE, SC70-5 FAIRCHILD, NC7SZ04P5X

52 2 U4, U5 IC, 400MHz, AMPLIFIER, MS8 LINEAR TECHNOLOGY, LT1819CMS8#PBF

53 1 U6 IC, FLIP FLOP, D-TYPE LOG, US8 ON SEMI., NL17SZ74USG

54 2 U8, U9 IC, VOLTAGE REFERENCE, MSOP8 LINEAR TECHNOLOGY, LTC6655BHMS8-

55 2 U10, U21 IC, OP-AMP, MS8 LINEAR TECHNOLOGY, LT6202CS5#PBF

56 4 U11, U13, U14, U15 IC, MICROPOWER REGULATOR, SO8 LINEAR TECHNOLOGY, LT1763CS8#PBF

57 1 U12 IC, MICROPOWER NEG. REGULATOR,

58 1 U16 IC, MICROPOWER REGULATOR, SO8 LINEAR TECHNOLOGY, LT1763CS8-2.5#PBF

59 1 U17 IC, LINEAR REGULATOR, SO8 LINEAR TECHNOLOGY, LT3021ES8-1.2#PBF

RES., CHIP, 0Ω, 1/10W, 0603 PANASONIC, ERJ-3GEY0R00V

, 3.92k, 1/10W, 1%, 0603 PANASONIC, ERJ-3EKF3921V

RES., CHIP, 33Ω, 1/16W, 5%, 0402 PANASONIC, ERJ-2GEJ330X

4.096#PBF

LINEAR TECHNOLOGY, LT1964ES5-SD#PBF

SOT-23

dc1996afb

5

Page 6

DEMO MANUAL DC1996A

PARTS LIST

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

60 1 U18 IC, EQFP, CYCLONE3, WIRE BOND,

61 1 U19 IC, 4-BIT, FLASH MEMORY, SO8 ALTERA, EPCS4SI8

62 1 U20 IC, EEPROM, 2kBIT, 400kHz, 8TSSOP MICROCHIP, 24LC024-I/ST

63 1 Y1 OSCILLATOR, 106.2500MHz, 3.3V, SMD CTS-FREQUENCY CONTROLS, CB3LV -3I-

64 12 SHOWN ON ASSY DWG SHUNT, 0.100", 2POS SAMTEC, SNT-100-BK-G

65 4 MH1-MH4 STANDOFF, NYLON, 0.25" KEYSTONE, 8831 (SNAP-ON)

DC1996A-A Required Circuit Components

1 1 DC1996A GENERAL BOM

2 2 R67, R73 RES., CHIP, 1k, 1/16W, 5%, 0402 PANASONIC, ERJ-2EKF1001V

3 1 U1 I.C., DUAL SAR ADC, QFN28UFD-4X5 LINEAR TECHNOLOGY, LTC2323CUFD-16#PBF

DC1996A-B Required Circuit Components

1 1 DC1996A GENERAL BOM

2 2 R67, R73 RES., CHIP, 1k, 1/16W, 5%, 0402 PANASONIC, ERJ-2EKF1001V

3 1 U1 I.C., DUAL SAR ADC, QFN28UFD-4X5 LINEAR TECHNOLOGY, LTC2321CUFD-16#PBF

DC1996A-C Required Circuit Components

1 1 DC1996A GENERAL BOM

2 2 R68, R73 RES., CHIP, 1k, 1/16W, 5%, 0402 PANASONIC, ERJ-2EKF1001V

3 1 U1 I.C., DUAL SAR ADC, QFN28UFD-4X5 LINEAR TECHNOLOGY, LTC2323CUFD-14#PBF

DC1996A-D Required Circuit Components

1 1 DC1996A GENERAL BOM

2 2 R68, R73 RES., CHIP, 1k, 1/16W, 5%, 0402 PANASONIC, ERJ-2EKF1001V

3 1 U1 I.C., DUAL SAR

DC1996A-E Required Circuit Components

1 1 DC1996A GENERAL BOM

2 2 R67, R74 RES., CHIP, 1k, 1/16W, 5%, 0402 PANASONIC, ERJ-2EKF1001V

3 1 U1 I.C., DUAL SAR ADC, QFN28UFD-4X5 LINEAR TECHNOLOGY, LTC2323CUFD-12#PBF

DC1996A-F Required Circuit Components

1 1 DC1996A GENERAL BOM

2 2 R67, R74 RES., CHIP, 1k, 1/16W, 5%, 0402 PANASONIC, ERJ-2EKF1001V

3 1 U1 I.C., DUAL SAR ADC, QFN28UFD-4X5 LINEAR TECHNOLOGY, LTC2321CUFD-12#PBF

EQFP144

ADC, QFN28UFD-4X5 LINEAR TECHNOLOGY, LTC2321CUFD-14#PBF

ALTERA, EP3C5E144C7

106M2500

6

dc1996afb

Page 7

SCHEMATIC DIAGRAMS

5

4

3

2

1

D

C

B

A

04-01-14

04-01-14

04-01-14

R123

OPT

R123

OPT

R122

100

R122

C130

C130

NC7SZ04P5XU2NC7SZ04P5X

NC7SZ04P5XU3NC7SZ04P5X

R101kR10

1k

R9

49.9

1206R949.9

1206

0.1uF

0.1uF

100

2

3

OUT

GND

Y1

CB3LVY1CB3LV

EOH1VCC

4

+3V

C129

0.1uF

C129

0.1uF

+3V

C13

0.1uF

C13

0.1uF

53

VCCIOVCCIO VDD

C11

0.1uF

C11

0.1uF

VCCIO

2

1

C18

C18

C17

C17

C19

C19

C16

C16

C15

C15

DOUG S.PRODUCTION

DOUG S.PRODUCTION

DOUG S.PRODUCTION

1

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

2

3

VCCIO VCCIO VCCIO

2

2

2

C2

0.1uFC20.1uF

53

C1

0.1uFC10.1uF

53

R21kR2

33

R433R4

1k

C5

0.1uFC50.1uF

J1J1

CLK

CLKIN

4

U2

2

4

U3

2

2.5VPP

200MHz MAX

R121

R121

0.1uF

0.1uF

10uF

10uF

0.1uF

0.1uF

10uF

10uF

1uF

1uF

DEMO MANUAL DC1996A

3

3

3

2

2

2

1

1

C45

1uF

C45

1uF

+9V/+10V+9V/+10V

1

2

4

VIN

GND3GND

E2

EXT_CM2E2EXT_CM2

E1

EXT_CM1E1EXT_CM1

U8

U8

C39

1uF

C39

1uF

U9

U9

C38

1uF

C38

1uF

SHDN

LTC6655BHMS8-4.096

LTC6655BHMS8-4.096

8

0

R400R40

R37

OPT

R37

OPT

132

CM2

CM2

JP7

JP7

EXT

EXT

ADC

ADC

C43

1uF

C43

1uF

1

2

VIN

GND3GND

SHDN

LTC6655BHMS8-4.096

LTC6655BHMS8-4.096

8

0

R390R39

R36

OPT

R36

OPT

132

CM1

CM1

JP6

JP6

EXT

EXT

ADC

ADC

VREF_2

4

VREF_1

GND5VOUT_S6VOUT_F7GND

C44

2.2uF

C44

2.2uF

C56

4.7uF

C56

0.1uF

0.1uF

0.1uF

0.1uF

R471kR47

1k

3

52

U21

U21

LT6202CS5

LT6202CS5

R461kR46

1k

3

52

U10

U10

LT6202CS5

LT6202CS5

4

+

+

1

VCM_BIAS_2VCM_BIAS_1

4

+

+

1

4.7uF

R521kR52

1k

-

-

C55

4.7uF

C55

4.7uF

R511kR51

1k

-

-

C49

10uF

6.3V

C49

10uF

6.3V

V+

C52

C52

GND5VOUT_S6VOUT_F7GND

C42

2.2uF

C42

2.2uF

C47

10uF

6.3V

C47

10uF

6.3V

V+

C51

C51

ON

OFF

ON

OFF

OSC

OSC

JP13

JP13

132

10k

10k

CSB

U7

NC7SZ04P5XU7NC7SZ04P5X

2

4

33

R1733R17

U6

7

8

NL17SZ74U6NL17SZ74

PR

D

Q

VCC

5

CP

Q

3

CLR

GND

6

4

6.3V

6.3V

C23

0.1uF

C23

0.1uF

C22

0.1uF

C22

0.1uF

6.3V

6.3V

132

JP3

JP3

DATA OUT

DATA OUT

LVDS

LVDS

CMOS

CMOS

R2033R20

33

REFOUT1

REFOUT2

ADD 20 MIL SQUARE

SDO1+

SDO1-

15

16

SDO1-

SDO1+

26

12

24

13

VDD2

8

VDD1

1

14

LVDS

25

AIN2+2AIN2-

AIN2+

PAD OPENING ON

TOP SOLDER MASK

LAYER ON THESE

CLKOUT+

SCK+

SCK-

9

21

22

17

18

SCK-

SCK+

CNVL

CLKOUT+

REFOUT2

VBYP2

VBYP1

*

*

QFN28UFD-4X5

QFN28UFD-4X5

U1

U1

OVDD

7

3

AIN2-

AIN1+

CONNETIONS.

CLKOUT-

SDO2+

SDO2-

20

19

SDO2-

SDO2+

CLKOUT-

REFRTN2

REFRTN111REFOUT1

GND

GND

GND

GND

GND

REFBG

AIN1-6AIN1+

AIN1-

C31 4.7uFC31 4.7uF

C33 4.7uFC33 4.7uF

27

29

23

10

5

4

C32

1uF

C32

1uF

28

R29

OPT

R29

OPT

www.linear.com

www.linear.com

www.linear.com

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

V-

KIM T.

KIM T.

C59

0.1uF

C59

0.1uF

V-

C58

0.1uF

C58

0.1uF

KIM T.

APPROVALS

APPROVALS

APPROVALS

PCB DES.

PCB DES.

PCB DES.

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

R73 R74

R68

1k OPT

R67

225

5A

Msps

161414

16

BITS

1

SHEET OF

SHEET OF

SHEET OF

LTC232XCUFD FAMILY

LTC232XCUFD FAMILY

LTC232XCUFD FAMILY

DEMO CIRCUIT 1996A

DEMO CIRCUIT 1996A

DEMO CIRCUIT 1996A

04/01/2014, 12:58 PM

04/01/2014, 12:58 PM

04/01/2014, 12:58 PM

IC NO. REV.

IC NO. REV.

IC NO. REV.

SCHEMATIC

SCHEMATIC

SCHEMATIC

TRUE DIFFERENTIAL INPUT DUAL ADC

TRUE DIFFERENTIAL INPUT DUAL ADC

TRUE DIFFERENTIAL INPUT DUAL ADC

B

B

B

SIZE

DATE:

SIZE

DATE:

SIZE

DATE:

TITLE:

TITLE:

TITLE:

DOUG S.

DOUG S.

DOUG S.

SCALE = NONE

SCALE = NONE

SCALE = NONE

APP ENG.

APP ENG.

APP ENG.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

1k OPT

1k OPT OPT 1k

OPT 1k

5

2

12

R13

0 0402

R13

0 0402

C10

OPT

C10

OPT

R3

C4 0.1uFC4 0.1uF

V+

VCM_BIAS_2

R60R6

C3

10uF

R11kR1

1k

C6

C6

R50R5

OPTR3OPT

R8

49.9R849.9

1

U4A

U4A

LT1819CMS8

LT1819CMS8

84

+

-

+

-

3

2

C8

0

6.3VC310uF

6.3V

R7

6.3V

6.3V

10uF

10uF

C7

0

J2J2

AIN2+

0V - 4.096V

D

C9 0.1uFC9 0.1uF

OPTC8OPT

OPTR7OPT

OPTC7OPT

C12

C12

NP0

NP0

200pF

200pF

R15

301

R15

301

R12 0R12 0

V-

R14

301

R14

301

R11 OPTR11 OPT

2

MODE

135 6

DIFF

JP1

JP1

1

2

3

AC DC

AC DC

+IN2

+IN2

VREF_2

COUPLING

4

5

R16

R16

C14

C14

4

UNI

BIP

VCM_BIAS_2

0 0402

0 0402

OPT

OPT

JP2

HD2X3-100

JP2

HD2X3-100

C21

10uF

C21

10uF

C20

10uF

C20

10uF

R43

0 0402

R43

R38

R38

C40

C40

R28

OPT

R28

C29 0.1uFC29 0.1uF

V+

VCM_BIAS_1

R310R31

C30

10uF

C30

10uF

R271kR27

1k

C34

C34

R300R30

OPT

R33

R33

49.9

49.9

7

U5B

U5B

LT1819CMS8

LT1819CMS8

84

+

+

5

0

6.3V

6.3V

6.3V

6.3V

10uF

10uF

0

J4J4

AIN1+

0V - 4.096V

R35 0R35 0

C37 0.1uFC37 0.1uF

V-

-

-

6

C36

OPT

C36

OPT

R34 OPTR34 OPT

R32

OPT

R32

OPT

JP5

JP5

1

2

3

C35

OPT

C35

OPT

+IN1

+IN1

COUPLING

R23

OPT

R23

OPT

R18

49.9

R18

49.9

7

U4B

U4B

LT1819CMS8

LT1819CMS8

+

-

+

-

8 4

5

6

C25

10uF

C25

10uF

R22

OPT

R22

OPT

R19

150

R19

150

C28

10uF

6.3V

C28

10uF

6.3V

C24

10uF

6.3V

C24

10uF

6.3V

6.3V

6.3V

6.3V

6.3V

R211kR21

VCM_BIAS_2

R25

OPT

R25

OPT

1k

C26

C26

R240R24

10uF

10uF

6.3V

6.3V

0

J3J3

AIN2-

C27

OPT

C27

OPT

0V - 4.096V

C

JP4

JP4

1

2

3

AC DC

AC DC

-IN2

-IN2

COUPLING

0 0402

0 0402

0 0402

OPT

OPT

C46

OPT

C46

OPT

R50

OPT

R50

OPT

C41

C41

NP0

NP0

R44

49.9

R44

200pF

200pF

R42

R42

R41

R41

AC DC

AC DC

B

49.9

1

U5A

JP8

JP8

C50

C50

BIP

C48

C48

VCM_BIAS_1

-

-

2

HD2X3-100

HD2X3-100

10uF

6.3V

10uF

6.3V

10uF

6.3V

10uF

6.3V

R45

150

R45

150

U5A

LT1819CMS8

LT1819CMS8

+

+

8 4

3

C54

C54

R49

R49

C53

C53

R481kR48

VCM_BIAS_1

10uF

10uF

OPT

OPT

10uF

6.3V

10uF

6.3V

1k

C57

C57

6.3V

6.3V

10uF

10uF

0

R530R53

J5J5

AIN1-

0V - 4.096V

301

301

301

301

4

2

MODE

135 6

DIFF

UNI

VREF_1

U1

LTC2323CUFD-12 12

LTC2323CUFD-16

LTC2321CUFD-16

LTC2321CUFD-14D

LTC2323CUFD-14

E

F LTC2321CUFD-12

B

C

ASSY

*

C61

10uF

6.3V

C61

10uF

6.3V

R54

OPT

R54

OPT

JP9

JP9

1

2

3

AC DC

AC DC

C60

OPT

C60

OPT

-IN1

-IN1

COUPLING

1. ALL RESISTORS ARE IN OHMS, 0603.

ALL CAPACITORS ARE IN MICROFARADS, 0603

NOTES: UNLESS OTHERWISE SPECIFIED

A

dc1996afb

7

Page 8

DEMO MANUAL DC1996A

5

4

3

2

1

D

C

B

A

SCHEMATIC DIAGRAMS

D

C

B

A

www.linear.com

www.linear.com

www.linear.com

3

3

3

2

2

2

2

2

2

SHEET OF

SHEET OF

SHEET OF

1

2

E3E3

5

U12

LT1964ES5-SD

U12

LT1964ES5-SD

-9V/-10V

V-

V-

C64

10uF

10V

C64

10uF

10V

R55

3.92k

R55

3.92k

4

ADJ

OUT

GND1IN2SHDN

3

C67

C67

E6E6

0805

0805

R571kR57

1k

1uF

16V

1uF

16V

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

LTC232XCUFD-16/-14 FAMILY

LTC232XCUFD-16/-14 FAMILY

LTC232XCUFD-16/-14 FAMILY

DEMO CIRCUIT 1996A

DEMO CIRCUIT 1996A

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

APPROVALS

APPROVALS

APPROVALS

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

DEMO CIRCUIT 1996A

04/01/2014, 01:00 PM

04/01/2014, 01:00 PM

04/01/2014, 01:00 PM

IC NO. REV.

IC NO. REV.

IC NO. REV.

SCHEMATIC

SCHEMATIC

SCHEMATIC

TRUE DIFFERENTIAL INPUT DUAL ADC

TRUE DIFFERENTIAL INPUT DUAL ADC

TRUE DIFFERENTIAL INPUT DUAL ADC

B

B

B

SIZE

DATE:

SIZE

DATE:

SIZE

DATE:

TITLE:

TITLE:

TITLE:

KIM T.

KIM T.

KIM T.

DOUG S.

DOUG S.

DOUG S.

SCALE = NONE

SCALE = NONE

PCB DES.

PCB DES.

PCB DES.

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

SCALE = NONE

APP ENG.

APP ENG.

APP ENG.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

-9V/-10V

3

V+

E5E5

C66

10uF

10V

0805

C66

10uF

10V

0805

V+

R56

3.92k

R56

3.92k

R581kR58

1k

C63

0.01uF

C63

0.01uF

1

2

U11

U11

LT1763CS8

LT1763CS8

4

SEN

BYP

OUT

GND

7

GND

6

GND

3

SHDN

IN

5

8

C65

1uF

16V

C65

1uF

16V

4

VCCIO

U13

U13

LT1763CS8

LT1763CS8

E8E8

VCCIO

1

OUT

IN

8

C70

10uF

6.3V

C70

10uF

6.3V

2.5V

1.8V

JP10JP10

VCCIO

132

R59

499

R59

499

C69

0.01uF

C69

0.01uF

2

4

SEN

BYP

GND

7

GND

6

GND

3

SHDN

5

C68

1uF

16V

C68

1uF

16V

VDD

E9E9

C73

10uF

10V

0805

C73

10uF

10V

0805

VDD

3.3V

VDD

R61

866

R61

866

R601kR60

1k

U14

U14

LT1763CS8

LT1763CS8

132

R63

4.02k

R63

4.02k

R62

3.09k

R62

3.09k

C72

0.01uF

C72

0.01uF

1

2

4

SEN

BYP

OUT

GND

7

GND

6

GND

3

SHDN

IN

5

8

C71

1uF

16V

C71

1uF

16V

+3V

E10E10

C76

10uF

6.3V

C76

10uF

6.3V

+3V

5V

JP11JP11

R661kR66

R65

1.43k

R65

R641kR64

1.43k

1k

C75

C75

0.01uF

0.01uF

1

2

4

SEN

BYP

OUT

GND

7

GND

6

GND

3

SHDN

IN

U15

U15

LT1763CS8

LT1763CS8

5

8

C74

1uF

16V

C74

1uF

16V

+2.5V

E11E11

C79

10uF

6.3V

C79

10uF

6.3V

+2.5V

1k

C78

0.01uF

C78

0.01uF

1

2

4

SEN

BYP

OUT

GND

7

GND

6

GND

3

SHDN

IN

U16

U16

LT1763CS8-2.5

LT1763CS8-2.5

5

8

C77

1uF

16V

C77

1uF

16V

E12E12

+1.2V

U17

LT3021ES8-1.2

U17

LT3021ES8-1.2

2

8

+1.2V

C81

C81

VCCINT

OUT

IN

C80

C80

10uF

6.3V

10uF

6.3V

3

SEN

AGND

4

GND

6

SHDN

5

3.3uF

16V

3.3uF

16V

C62

47uF

1210

16V

C62

47uF

1210

16V

+9V/+10V

E4E4

5

E7E7

GND

+9V/+10V

8

dc1996afb

Page 9

SCHEMATIC DIAGRAMS

5

4

3

2

1

D

C

B

A

D

1

135791113151719212325272931333537394143454749515355575961636567697173757779818385878991939597

P1

P1

246

8

101214161820222426283032343638404244464850525456586062646668707274767880828486889092949698

CNVCLK

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB8

DB9

DB10

DB11

DB12

DB13

DB14

DB15

2

SDO1-

SDO1+

CLKOUT+

CLKOUT-

R76

OPT

R76

OPT

R99

OPT

R99

OPT

54

55

58

59

60

64

65

66

67

69

70

72

71

IO3

IO6

IO1068IO11

IO8_RUP2

IO7_VREF4

IO5_DIFFIOB16N

SDO2-

R75

OPT

R75

OPT

44

46

49

50

51

IO6_VREF3

IO7_DIFFIOB9P

IO8_DIFFIOB9N

31

32

33

34

IO6

IO4_RUP1

IO5_RDN1

IO3_VREF2

SCK+

DB15

R26

OPT

R26

OPT

33R119 33R119

7

10

11

23

CLK022CLK1

IO5_VREF1

IO6_DIFFL4P

IO7_DIFFL4N

IO9_RDN2

IO12_DIFFIOB21P

IO13_DIFFIOB21N

SDO2+

52

53

IO9

IO10_DIFFIOB11P

IO11_DIFFIOB11N

SCK-

IO14

CLKIN

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

BANK4

BANK4

IO1_DIFFIOB12P

IO4_DIFFIOB16P

IO2_DIFFIOB12N

U18E

U18E

3

38

39

IO342IO443IO5

BANK3

BANK3

IO1_DIFFIOB1P

IO2_DIFFIOB1N

U18D

U18D

4

25

30

IO128IO2

CLK224CLK3

BANK2

BANK2

U18C

U18C

DB12

DB13

DB14

CNVCLK

33R69 33R69

33R70 33R70

33R71 33R71

33R72 33R72

5

U18B

U18B

BANK1

BANK1

4

IO11IO22IO33IO4

DA15

U18I

U18I

U18H

U18H

U18G

U18G

U18F

U18F

DA12

DA13

DA14

DB1

DB2

DB3

DB4

33R91 33R91

33R88 33R88

33R81 33R81

33R79 33R79

128

129

132

133

BANK8

BANK8

IO2_DIFFIOT11P

IO1_DIFFIOT11N

IO3_DIFFIOT10N

DA6

DA7

DA8

DA9

33R90 33R90

33R87 33R87

33R78 33R78

33R80 33R80

110

111

112

113

IO1

IO2

IO3

BANK7

BANK7

DA4

33R89 33R89

33R86 33R86

90

91

100

104

IO1

BANK6

BANK6

CLK4_DIFFCLK2P

CLK5_DIFFCLK2N

DA0

DA1

DA2 DA3

33R85 33R85

33R84 33R84

33R77 33R77

75

76

IO173IO274IO3

BANK5

BANK5

DA8

DA9

DA10

DA11

DB5

DB6

DB7

DB8

33R96 33R96

33R94 33R94

33R92 33R92

33R82 33R82

135

136

137

138

141

IO5

IO7

IO8

IO9

IO6_VREF8

IO4_DIFFIOT10P

DA12

DA10

DA11

33R97 33R97

33R95 33R95

33R93 33R93

114

115

119

120

121

IO4

IO5_RUP4

IO6_RDN4

IO7_VREF7

IO9_DIFFIOT16P

IO8_DIFFIOT16N

DA5

33R83 33R83

105

106

IO2

IO4

IO3_VREF6

CSB

VCCIO

*

R73*R73

77

79

80

84

83

IO5

IO7

IO4_RUP3

IO4_RDN3

IO6_VREF5

IO8_DIFFIOR8N

C

DA5

DA6

DA7

DB9

DB10

DB11

33R103 33R103

33R101 33R101

33R98 33R98

142

143

144

IO10

IO12_DIFFIOT01P

IO11_DIFFIOT01N

DA13

DA14

DB0

DA15

33R104 33R104

33R102 33R102

33R120 33R120

33R100 33R100

124

125

126

127

IO10

IO11

IO13_DIFFIOT12P

IO12_DIFFIOT12N

*

R74*R74

85

88

89

IO9_DIFFIOR8P

CLK6_DIFFCLK3P

CLK7_DIFFCLK3N

DA4

R67*R67

VCCIO

VCCIO

DA2

DA3

*

R105

4.99k

R105

4.99k

99

100

DA0

DA1

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

R68*R68

*

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

DEMO MANUAL DC1996A

0603

0603

EDGE-CON-100

EDGE-CON-100

1356

FPGA

PROGRAM

2

+3V

B

PROG

WP

PROG

WP

JP12

JP12

EEPROM

EEPROM

5

3

7

6

WP

SCL

SDA

U20

U20

24LC024-I /ST

24LC024-I /ST

VCC

8

C92

0.1uF

0402

C92

0.1uF

0402

C91

0.1uF

0402

C91

0.1uF

0402

+3V +3V

5

8

7

6

VCC

VCC

ASDI

DCLK

NCS1DATA2VCC3GND

U19

U19

4

+3V

10k

10k

10k

10k

10k

10k

10k

10k

10k

10k

10k

10k

6

8

9

12

13

14

DCLK

CONFIG

CONFIG

N_STATUS

IO1_DATA1

IO3_DATA0

IO2_FLASH_NCE

C90

C90

0.1uF

0.1uF

C89

C89

0.1uF

0.1uF

C88

C88

0.1uF

0.1uF

C87

C87

0.1uF

0.1uF

C86

C86

0.1uF

0.1uF

C85

C85

0.1uF

0.1uF

C84

C84

0.1uF

0.1uF

C83

C83

VCCIO

0.1uF

0.1uF

102

116

134

VCCINT5VCCINT29VCCINT45VCCINT61VCCINT78VCCINT

VCCINT

PWR

PWR

GND19GND27GNDA136GND41GND48GND57GND63GND82GND95GNDA2

132

A01A12A2

ARRAY

ARRAY

EEPROM

EEPROM

GND

4

EPCS4SI8

EPCS4SI8

TDI

TMS

TCK

TDO

NCE

15

16

21

86

87

92

TDI

TCK

TMS18TDO20NCE

NCONFIG

IO4_DEV_OE

IO5_DEV_CLRN

C104

C104

0.1uF

0.1uF

C103

C103

0.1uF

0.1uF

C102

C102

0.1uF

0.1uF

C101

C101

0.1uF

0.1uF

C100

C100

0.1uF

0.1uF

C99

C99

0.1uF

0.1uF

C98

C98

0.1uF

0.1uF

C97

C97

0.1uF

0.1uF

C96

C96

0.1uF

0.1uF

C95

C95

0.1uF

0.1uF

C94

C94

0.1uF

0.1uF

C93

C93

0.1uF

0.1uF

VCCINT

VCCIO117VCCIO226VCCIO340VCCIO347VCCIO456VCCIO462VCCIO581VCCIO693VCCIO7

GND

GND

GND

108

118

123

131

140

+3V +3V +3V +3V

+2.5V

97

98

MSEL094MSEL196MSEL2

CONF_DONE

+2.5V

117

122

130

139

VCCIO7

VCCIO8

GND

GND

145

D4

12

D3

12

D2

12

D1

12

R1181kR118

1k

R117

10k

R117

10k

R116

10k

R116

10k

R115

10k

R115

10k

99

101

103

IO8_NCEO

IO9_CLKUSR

IO6_INIT_DONE

IO7_CRC_ERROR

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

C113

C113

4.7nF

4.7nF

C112

C112

22nF

22nF

C111

C111

22nF

22nF

C110

C110

22nF

22nF

C109

C109

1nF

1nF

C108

C108

0.1uF

0.1uF

C107

C107

0.01uF

0.01uF

C106

C106

4.7uF

4.7uF

C105

C105

47uF

47uF

107

109

VCCA135VCCA2

VCCIO8

VCCD_PLL137VCCD_PLL2

BAT54WSD4BAT54WS

BAT54WSD3BAT54WS

BAT54WSD2BAT54WS

BAT54WSD1BAT54WS

0603

0603

0805

0805

CYCLONE3-EP3C5E144

CYCLONE3-EP3C5E144

R108

4.99k

0603

R108

4.99k

0603

R107

4.99k

0603

R107

4.99k

0603

R106

4.99k

0603

R106

4.99k

0603

C82

0.1uF

0603

C82

0.1uF

0603

7

9

J6

HD2X5-100J6HD2X5-100

4

8

10

R114

R114

R113

R113

R112

R112

R111

R111

R110

R110

R109

R109

VCCIO

U18J

U18J

+1.2V

U18A

U18A

A

www.linear.com

www.linear.com

www.linear.com

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

SCHEMATIC

SCHEMATIC

SCHEMATIC

TITLE:

TITLE:

TITLE:

KIM T.

KIM T.

KIM T.

DOUG S.

DOUG S.

DOUG S.

APPROVALS

APPROVALS

APPROVALS

PCB DES.

PCB DES.

PCB DES.

APP ENG.

APP ENG.

C117

10pF

C117

10pF

C116

10pF

C116

10pF

C115

10pF

C115

10pF

C114

10pF

C114

10pF

JTAG

VCCIO

+1.2V

L1

L1

BLM31PG391SN1L

BLM31PG391SN1L

VCCD_PLL

APP ENG.

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

TDI

TCK

TDO

TMS

1356

7

9

J7

HD2X5-100J7HD2X5-100

4

2

8

10

C128

C128

4.7nF

4.7nF

C127

C127

2.2nF

2.2nF

C126

C126

0.1uF

0.1uF

C125

C125

0.1uF

0.1uF

C124

C124

0.1uF

0.1uF

C123

C123

0.1uF

0.1uF

C122

C122

0.1uF

0.1uF

C121

C121

0.01uF

0.01uF

C120

C120

0.01uF

0.01uF

C119

0603

C119

0603

4.7uF

4.7uF

C118

7343+C118

7343

470uF

470uF

+

3

3

3

2

2

2

3

3

3

SHEET OF

SHEET OF

SHEET OF

LTC232XCUFD-16/-14 FAMILY

LTC232XCUFD-16/-14 FAMILY

LTC232XCUFD-16/-14 FAMILY

DEMO CIRCUIT 1996A

DEMO CIRCUIT 1996A

DEMO CIRCUIT 1996A

04/01/2014, 12:59 PM

04/01/2014, 12:59 PM

04/01/2014, 12:59 PM

IC NO. REV.

IC NO. REV.

IC NO. REV.

TRUE DIFFERENTIAL INPUT DUAL ADC

TRUE DIFFERENTIAL INPUT DUAL ADC

TRUE DIFFERENTIAL INPUT DUAL ADC

B

B

B

SIZE

DATE:

SIZE

DATE:

SIZE

DATE:

SCALE = NONE

SCALE = NONE

SCALE = NONE

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

1. ALL RESISTORS AND CAPACITORS ON THIS PAGE ARE 0402.

NOTES: UNLESS OTHERWISE SPECIFIED

2. SEE ASSEMBLY TABLE ON PAGE 1 FOR R67, R68, R73, AND R74 VALUES.

dc1996afb

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

9

Page 10

DEMO MANUAL DC1996A

DEMONSTRATION BOARD IMPORTANT NOTICE

Linear Technology Corporation (LT C ) provides the enclosed product(s) under the following AS IS conditions:

This demonstration board (DEMO BOARD) kit being sold or provided by Linear Technology is intended for use for ENGINEERING DEVELOPMENT

OR EVALUATION PURPOSES ONLY and is not provided by LT C for commercial use. As such, the DEMO BOARD herein may not be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including but not limited to product safety

measures typically found in finished commercial goods. As a prototype, this product does not fall within the scope of the European Union

directive on electromagnetic compatibility and therefore may or may not meet the technical requirements of the directive, or other regulations.

If this evaluation kit does not meet the specifications recited in the DEMO BOARD manual the kit may be returned within 30 days from the date

of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY THE SELLER TO BUYER AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THIS INDEMNITY, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user releases LTC from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. Also be aware that the products herein may not be regulatory compliant or

agency certified (FCC, UL, CE, etc.).

No License is granted under any patent right or other intellectual property whatsoever. LTC assumes no liability for applications assistance,

customer product design, software performance, or infringement of patents or any other intellectual property rights of any kind.

LT C currently services a variety of customers for products around the world, and therefore this transaction is not exclusive.

Please read the DEMO BOARD manual prior to handling the product. Persons handling this product must have electronics training and

observe good laboratory practice standards. Common sense is encouraged.

This notice contains important safety information about temperatures and voltages. For further safety concerns, please contact a LTC application engineer.

Mailing Address:

Linear Technology

1630 McCarthy Blvd.

Milpitas, CA 95035

Copyright © 2004, Linear Technology Corporation

Linear Technology Corporation

10

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

dc1996afb

LT 0414 REV B • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2014

Page 11

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Analog Devices Inc.:

DC1996A-C DC1996A-E DC1996A-F DC1996A-A DC1996A-B DC1996A-D

Loading...

Loading...