Page 1

Description

+

–

DEMO MANUAL

DC1977A-A/DC1977A-B

LTC4121EUD/LTC4121EUD-4.2

400mA Synchronous Buck

Battery Charger

DC1977A-A LTC4120EUD-4.2 (Fixed Output)

DC1977A-B LTC4121EUD (Adjustable Output)

The LTC4121 and LTC4121-4.2 feature constant-current–

constant-voltage charging capability suitable for lithiumion or lead-acid cells. The LTC4121-4.2 supports charging

Demonstration Board DC1977A showcases the

LTC4121-4.2 and LTC4121 40V, 400mA synchronous-

buck battery charger integrated circuit. The DC1977A

a single lithium-ion cell with a cell voltage of 4.2V. The

LTC4121 may be programmed to charge battery voltages

up to 18V with a resistive divider.

supports the maximum-power-point tracking (MPPT)

feature of the LTC4121EUD to optimize power delivery

from photovotalic cells or highly resistive sources.

performance summary

SYMBOL PARAMETER CONDITIONS

IN DC1977A Input Voltage I(IN) < 800mA 4.4 40 V

PV

IN

DC1977A PV Cell Input I(IN) < 800mA 5 40.5 V

V(BAT) DC1977A BAT Pin Voltage R11 = 1.40MΩ, R12 = 1.05MΩ 2.5 4.25 V

I(BAT) DC1977A BAT Pin Current V(BAT) = 3.7V; DC1977A; (R7) = 3.01kΩ; JP1 (“MPPT”) = ‘OFF’ 383 402 421 mA

Note: Reference designators refer to Schematic on p. 7.

Specifications are at TA = 25°C

Design files for this circuit board are available at

http://www.linear.com/demo/DC1977

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Analog

Devices, Inc. All other trademarks are the property of their respective owners.

MIN TYP MAX

UNITS

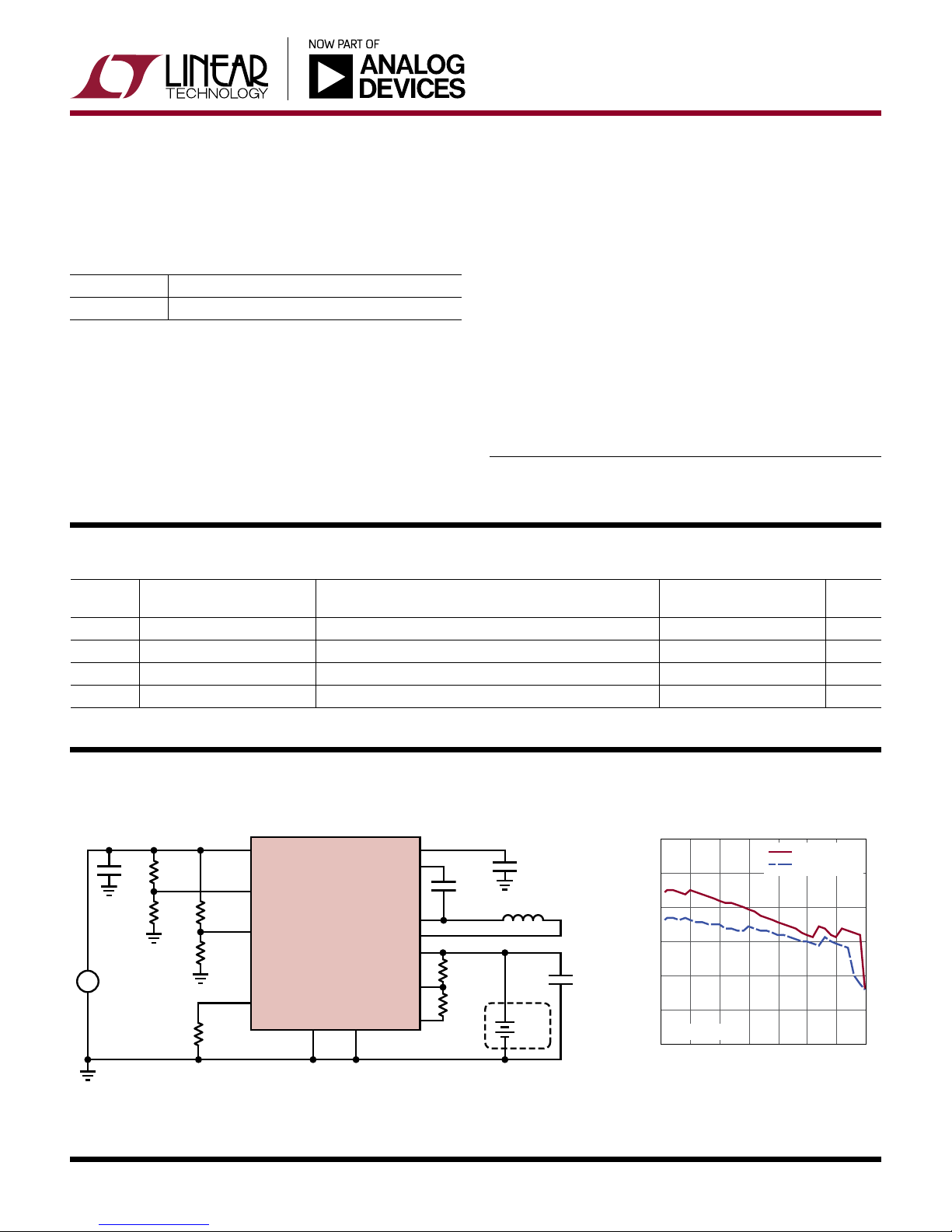

Demo BoarD application

High Efficiency, Wide Input Voltage Range Charging with LTC4121

MPPT1

MPPT2

PROG

IN

RUN

LTC4121

MPPT

PROG

FREQ

C

IN

R

RUN1

10µF

261k

R

R

RUN2

787k

324k

R

V

IN

V

+ 200mV

BAT

TO 40V

121k

R

3.01k

GND

INTV

BOOST

SW

CHGSNS

BAT

FBG

LTC4121 Efficiency vs V

CC

C

BOOST

22nF

R

FB1

1.05M

FB

R

FB2

1.40M

C

INTVCC

2.2µF

LPS4018-333ML

+

Li-Ion

dc1977a F01

C

BAT

47µF

100

95

90

85

EFFICIENCY (%)

80

75

V

BAT

70

5

= 4.1V

10 15 20 25 30 35 40

VIN (V)

R

R

PROG

PROG

IN

= 6.04k

= 3.01k

DC1977A F02

dc1977afb

1

Page 2

DEMO MANUAL

DC1977A-A/DC1977A-B

assemBly test proceDure

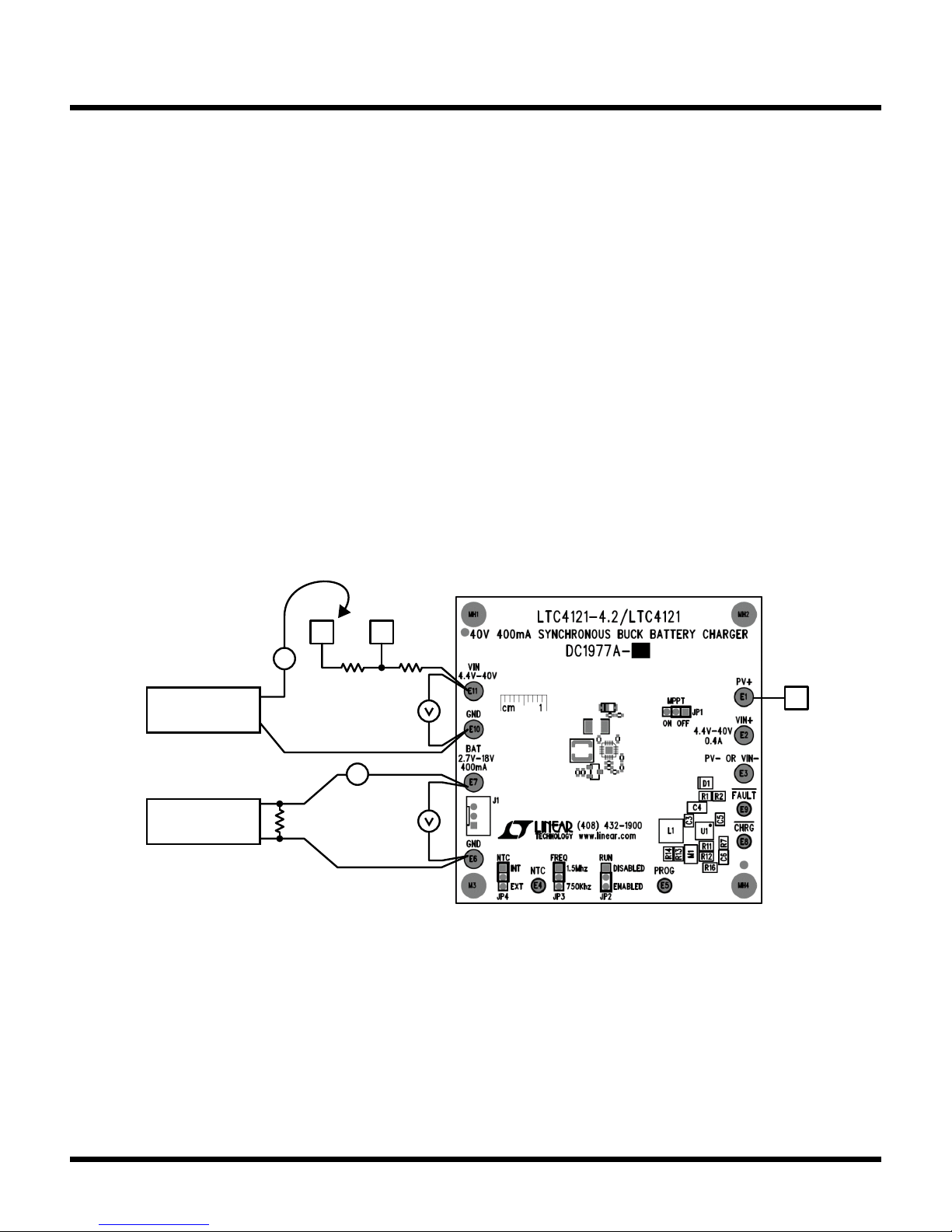

Refer to Figure 1 for the proper measurement equipment

setup and jumper settings and follow the procedure below.

1. Set JP1 (“MPPT”) to ‘ON’, set PS1 to 3.6V and turn

on.

2. Connect PS2 to point A, set to 15V and turn on.

3. Verify that VM1 indicates 3.3V to 3.9V, and then verify

that AM1 indicates 387mA to 417mA. Verify that VM2

shows 14.5V to 15.1V. There is only a series diode

between PV+ and the VIN pin of the LTC4121. The

purpose of this diode is prevent backfeeding a PV

cell, if connected. A single diode Vf is insufficient to

activate the MPPT feature, and the LTC4121 delivers

full charge current to the battery.

4. Turn PS2 off, move connection to point B, and turn

PS2 on.

5. Verify that VM1 indicates 3.3V to 3.9V, and then verify

that AM1 indicates 387mA to 417mA. Verify that VM2

shows 12.6V to 13.2. The source impedance of the

power supply is now ≈ 16Ω. But this impedance still

allows delivering full charge current without engaging

the MPPT feature.

6. Turn PS2 off, move connection to Point C, and turn

PS2 on.

7. Verify that VM1 indicates 3.3V to 3.9V, and then Verify

that AM1 indicates 105mA to 115mA. Verify that VM2

shows 10.6V to 11.3V. The source impedance of the

power supply is now 98Ω. The MPPT feature has

engaged and the charge delivered to the battery has

been reduced to allow V

to stay at the programmed

IN

MPPT point.

8. Set JP1 (“MPPT”) to ‘OFF’, test is finished.

PS2

15V POWER SUPPLY

0.25A

PS1

3.6V BIPOLAR SUPPLY

1A

AM2

+

–

+

–

– +

–

3.6Ω

BC

82.4Ω

2W

AM1

15.8Ω

2W

+

VM2

–

+–

–

+

VM1

–

Figure1. DC1977A Equipment Setup

Note: All connections from equipment should be kelvin-connected directly to the board pins

which they are connected on this diagram. All input or output leads should be twisted pair.

A

DC1977a F03

2

dc1977afb

Page 3

theory of operation

V

1.227V

DEMO MANUAL

DC1977A-A/DC1977A-B

The LTC4121EUD-4.2/LTC4121EUD is a 4.4V ~ 40V input

buck topology battery charger with maximum power point

tracking (MPPT) for use with PV cells or highly resistive

power supplies. The buck-topology charger uses current

mode control for stable operation.

LTC4121EUD ENABLE

The LTC4121 can be enabled or disabled via the RUN pin,

and this functionality can be accessed via JP2, the RUN

jumper. When JP2 is in the “ENABLE” position, R3 and

R4 ensure that the LTC4121 is not enabled until Vin is

greater than 4.4V.

Note: Do not float the LTC4121 RUN pin. Operate

the demo board with JP2 in either the DISABLED or

ENABLED position.

Buck Charger

The heart of the LTC4121EUD is the buck-topology bat

tery charger. The buck-topology charger is a synchronous,

current-mode-control regulator with N-channel FETs. The

use of N-channel FETs minimizes conduction losses, and

requires only a single external 0.022µF capacitor to generate the high-side gate drive.

The LTC4121EUD can charge up to four Li-Ion cells in

series, and supports a maximum battery voltage of 18V.

The LTC4121EUD-4.2 is optimized for charging a single

Li-Ion cell to a fixed cell voltage of 4.2V.

The current in the buck inductor passes through a small

on-die resistor for current measurement, and then goes

back out to the BAT pin. The battery is connected to the

BAT pin; this allows the LTC4121EUD to measure not only

the cycle-by-cycle current, but also the average current.

The cycle-by-cycle current is used by the current-mode

buck regulator, and the average current is the battery

charge current as programmed by R

= 3.01kΩ, so I(BAT) = 402mA provided that the

R

PROG

MPPT function does not reduce the current.

. On DC1977A,

PROG

-

The buck regulator acts as a current source when the

battery is in the constant-current charging region and as

a classic voltage output buck regulator when the battery

is in the constant-voltage charging region.

The battery charge current is programmed by

R

=3.01kΩ. The equation for R

PROG

R

The LTC4121EUD provides a switching frequency select

pin, FREQ, to select between 750kHz and 1.5MHz; this

function is accessed by JP4, the “FREQ” jumper.

Note: Do not float the LTC4121 FREQ pin. Operate the

demo board with JP3 in either the 750kHz or 1.5MHz

position.

Figure2 shows various nodes of interest with V

and the switching frequency at 750kHz (T = 1.333µs), The

duty cycle is 86% for V(BAT) = 3.6V, not the 72% duty

expected from a buck regulator. When the battery voltage

is 3.6V, the charger is in constant-current mode, so the

control loop is forcing the output of the buck regulator

to the voltage necessary to push 400mA into the battery.

This “effective” voltage, 5 • 0.86 = 4.3V, is the voltage

necessary to ensure that a 400mA average current is flowing through the on-die sense resistor.

Figure3 shows the same nodes as Figure2, but with

VIN = 40V. The switching frequency is still 750kHz. The

duty cycle is ≈ 200ns/1.333µs, or 15%, but the period is

2.7µs. This is because the LTC4121 minimum on time was

greater than that needed to achieve 4.3V, and the LTC4121

starts to pulse skip to get the necessary average duty

cycle. The average duty cycle is 300ns/2.667µs=11%.

This produces an output voltage of 4.3V, so the battery

still charges at 400mA.

Maximum Power Point Tracking (MPPT)

The LTC4121EUD provides a maximum-power-point

tracking (MPPT) function for use with PV cells or highly

PROG

= h

PROG

•

PROG

I

CHG

= 986 •

PROG

0.4

is:

= 3.01kΩ

= 5V,

IN

dc1977afb

3

Page 4

DEMO MANUAL

DC1977A-A/DC1977A-B

theory of operation

Figure2. Normal Operation, Zoom, VIN = 5.1V, DK. Blue = VIN,

Grn = I

, LT. Blue = VSW, Pk. = INTVCC, 750kHz

CHARGE

resistive power supplies. The MPPT pin allows programming of the MPPT point as a percentage of the opencircuit VIN (VOC). To access this functionality the demo

board provides JP1, the “MPPT” jumper, and R1 and R2.

It is important to note that the disabled position for MPPT

is the MPPT pin at VIN. To enable MPPT, set the MPPT

point as a fraction of VOC. See the discussion in Maximum

Power Point Tracking section of the LTC4121 data sheet.

When MPPT is enabled (not equal to VIN), the LTC4121EUD

periodically disconnects the load from the power source,

and measures V

the load on V

with no load = VOC. It then increases

IN

to meet charger demand until the V

IN

MPPT

threshold is reached, after which it no longer increases

the load. This allows the MPPT voltage divider to set the

desired MPPT point as a percentage of V

with no load.

IN

Figure4 shows the LTC4121EUD operating from a source

impedance of 98Ω. The MPPT pin of the LTC4121EUD

sets the MPPT point to 0.75 of the open-circuit voltage.

First, V

V

IN

until the voltage at V

is determined by removing all load and letting

OC

rise to VOC. The power drawn from VIN is increased

falls to the MPPT point, 0.75 • VOC

IN

= 0.75•15V = 11.25V. The resolution of the MPPT DAC

is 330mV, thus this example has the MPPT point at

11V. The LTC4121 stops drawing power at this point, and

the charge current (green) never exceeds 200mA, even

though the Rprog value was chosen for 400mA.

Figure3. Normal Operation, Zoom, VIN = 40V, DK. Blue = VIN,

Grn = I

, LT. Blue = VSW, Pk. = V

CHARGE

BOOST

4

, 750kHz

Figure5 shows the same system, but the source imped

ance was lowered to 16Ω. Consequently, the full power

needed to meet the requirements of the programmed

charge current is available before VIN falls to the MPPT

voltage.

dc1977afb

Page 5

theory of operation

Battery capacitors C1 and C2

The maximum battery voltage for the LTC4121EUD is

18V, and for the LTC4121EUD-4.2, it is 4.2V. Analog

Devices recommends 47µF of capacitance on the BAT

pin, if the battery is not present. For the LTC4121EUD

the voltage rating of the capacitor will need to be 25V, so

two 22µF, 25V, MLCC capacitors are used. In the case of

the LTC4121EUD-4.2, a 6.3V capacitor will suffice, and

a single 47µF, 6.3V, MLCC capacitor is used for C1, with

C2 not placed.

Reverse-Blocking Circuit

Components Q1, R16 and C6 comprise a reverse-blocking

circuit. The circuit performs two functions. First, the circuit prevents the battery from back-charging the power

source when the power sour

cell in the absence of illumination). Note that this func

tionality can also be provided through D1. Second, when a

charged battery is connected to the circuit in the absence

of input voltage, current will flow from the battery into the

BAT pin and out the IN pin, charging C4. With battery voltages in excess of ~10V, this current surge can destroy the

device. Note that this is not a problem when only one or

two series Li-Ion cells are employed. Thus, this reverseblocking circuit may not be necessary depending on the

application. If reverse-blocking is not required, C6 and

R16 also become unnecessary. These two components

provide a path to the BAT pin from which the LTC4121

derives bias for internal circuits which would be provided

by the battery directly in the absence of Q1. See, for example, the application on the first page of this manual.

ce is dormant (e.g., a solar

-

DEMO MANUAL

DC1977A-A/DC1977A-B

Figure4. MPPT Test, DK. Blue = VIN (Through 98Ω), Green = IL,

LT. Blue = V(SW), k = 0.15, V

Figure5. MPPT Test, DK. Blue = VIN (Through 16Ω), Green = IL,

LT. Blue = V(SW), k = 0.15, V

MPPT/VOC

MPPT/VOC

= 0.75

= 0.75

dc1977afb

5

Page 6

DEMO MANUAL

DC1977A-A/DC1977A-B

parts list

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

DC1977A General Bill of Materials

Required Circuit Components

1 1 C3 CAP, CHIP, X7R, 0.022µF, ±10%, 50V, 0402 TDK, C1005X7R1E223K

2 1 C4 CAP, CHIP, X5R, 10µF, ±10%, 50V, 1210 TAIYO-YUDEN, UMK325BJ106KM-T

3 1 C5 CAP, CHIP, X5R, 2.2µF, ±20%, 6.3V, 0402 MURATA, GRM155R60J225ME15D

4 1 L1 IND, SMT, 33µH, 420mΩ, ±20%, 0.80A, 4mm × 4mm COILCRAFT, LPS4018-333ML

5 1 R1 RES, CHIP, 787kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW0402787KFKED

6 1 R2 RES, CHIP, 121kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW0402121KFKED

7 1 R3 RES, CHIP, 261kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW0402261KFKED

8 1 R4 RES, CHIP, 324kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW0402324KFKED

9 1 R7 RES, CHIP, 3.01kΩ, ±1, 1/16W, 0402 VISHAY, CRCW04023K01FKED

Additional Demo Board Circuit Components

1 1 C6 CAP, CHIP, X5R, 4.7µF, ±20%, 6.3V, 0603 MURATA, GRM188R60J475KE19D

2 1 D1 DIODE, SCHOTTKY, 40V, 2A, PowerDI123 DIODES, DFLS240L

3 1 M1 MOSFET, P-Channel, –30V, –5.9A, 45mΩ, SOT-23 VISHAY, Si2343CDS

4 2 R5, R9 RES, CHIP, 10kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW040210K0FKED

5 1 R6 RES, CHIP, 2kΩ, ±5%, 1/16W, 0402 VISHAY, CRCW04022K00JNED

6 2 R8, R10 RES, CHIP, 0Ω jumper, 1/16W, 0402 VISHAY, CRCW04020000Z0ED

7 1 R13 RES, CHIP, 47kΩ, ±5%, 1/16W, 0402 VISHAY, CRCW040247K0JNED

8 1 R14 RES, CHIP, 5.1kΩ, ±1%, 1/16W, 0402 VISHAY, CRCW04025K10JNED

9 1 R15 RES, CHIP, 100kΩ, ±5%, 1/16W, 0402 VISHAY, CRCW0402100KJNED

10 1 R16 RES, CHIP, 464kΩ, ±1%, 1/10W, 0603 YAGEO, RC0603FR-07464KL

Hardware: For Demo Board Only

1 7 E1, E2, E3, E6, E7, E10, E11 TURRET, 0.09 DIA MILL-MAX, 2501-2-00-80-00-00-07-0

2 4 E4, E5, E8, E9 TURRET, 0.061" MILL-MAX, 2308-2-00-80-00-00-07-0

3 0 J1-OPT CONN, 3 Pin Polarized HIROSE, DF3-3P-2DSA

4 4 JP1-JP4 HEADER, 3 Pin, SMT, 2mm SULLIN, NRPN031PAEN-RC

5 4 JP1-JP4 SHUNT, 2mm SAMTEC, 2SN-BK-G

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

DC1977A-A Bill of Materials

Required Circuit Components

1 0 R11 DO NOT INSTALL

2 1 R12 RES, CHIP, 0Ω jumper, 1/16W, 0402 VISHAY, CRCW04020000Z0E

3 1 U1 40V 400mA SYNCHRONOUS STEP-DOWN BATTERY

1 1 C1 CAP, CHIP, X5R, 47µF, ±10%, 16V, 1210 MURATA, GRM32ER61C476KE15L

2 0 C2 CAP, CHIP, X5R, 47µF, ±10%, 16V, 1210 MURATA, GRM32ER61C476KE15L

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

DC1977A-B Bill of Materials

Required Circuit Components

1 1 R11 RES, CHIP, 1.40MΩ, ±1%, 1/16W, 0402 VISHAY, CRCW04021M40FKE

2 1 R12 RES, CHIP, 1.05MΩ, ±1%, 1/16W, 0402 VISHAY, CRCW04021M05FKED

3 1 U1 40V, 400mA SYNCHRONOUS STEP-DOWN BATTERY

1 2 C1, C2 CAP, CHIP, X5R, 47µF, ±10%, 16V, 1210 MURATA, GRM32ER61C476KE15L

6

CHARGER, 3mm × 3mmQFN16

LINEAR TECH., LTC4121EUD-4.2#PBF

LINEAR TECH., LTC4121EUD#PB

CHARGER, 3mm × 3mmQFN16

dc1977afb

Page 7

schematic Diagram

1

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

-

-

-

2

VIN

4.4V - 40V

E11

C4

10uF

GND

E10

E9

5%

R15

100k

50V

1210

U1

LTC4121EUD-4.2 / LTC4121EUD

3

FAULT

IN

JP2

DEMO MANUAL

DC1977A-A/DC1977A-B

1

1

1

1

1

1

CHRG

E8

R14

5.1k

5%

6.3V

20%

C5

2.2uF

INTVCC

C3

0.022µF

25V

1

2

INTVcc

BOOST

4

sw

FREQ

7

14

15

CHRG

FAULT

RUN

16

BAT

2.7V - 18V

E7

R12 TO BE CONNECTED TO C2 & C3

R13

47k

5%

Q1

Si2343DS

L1

33.0uH

8

9

BAT

CHGSNS

MPPT

6

JP3

R16

12

400mA

E6

464k

C6

NTC

6.3V

GND

0603

*

*

C2

C1

4.7uF

0603

BATSNS/FB

10

OPT

J1

DF3-3P-2DSA

BAT1GND2ENTC

3

www.linear.com

www.linear.com

0 Ohm

JUMPER

R10

www.linear.com

1

1

1

SHEET OF

SHEET OF

SHEET OF

OPEN47µF/16V

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

C1 C2

22µF/25V 22µF/25V

R12

0 OhmOPEN

R11

1.40M 1.05M

*

R12

*

R11

11

NC/FBG

17

EPAD

5

GND

PROG

13

R7

3.01k

U1

LTC4121EUD

LTC4121EUD - 4.2

-B

-A

ASSY

*

UNLESS NOTED:

RESISTORS: OHMS, 0402, 1%, 1/16W

CAPACITORS: uF, 0402, 10%, 50V

LTC Confidential-For Customer Use Only

BATTERY CHARGER

40V 400mA SYNCHRONOUS STEP-DOWN

40V 400mA SYNCHRONOUS STEP-DOWN

40V 400mA SYNCHRONOUS STEP-DOWN

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

SCHEMATIC

SCHEMATIC

SCHEMATIC

TITLE:

TITLE:

TITLE:

NC

WAT

NC

WAT

NC

WAT

APPROVALS

APPROVALS

APPROVALS

PCB DES.

PCB DES.

PCB DES.

APP ENG.

APP ENG.

APP ENG.

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

1

DEMO CIRCUIT 1977A - A / B

DEMO CIRCUIT 1977A - A / B

DEMO CIRCUIT 1977A - A / B

LTC4121EUD - 4.2 / LTC4121EUD

LTC4121EUD - 4.2 / LTC4121EUD

LTC4121EUD - 4.2 / LTC4121EUD

2017-02-22

2017-02-22

2017-02-22

IC NO. REV.

IC NO. REV.

IC NO. REV.

N/A

N/A

N/A

SIZE

DATE:

SIZE

DATE:

SIZE

DATE:

SCALE = NONE

SCALE = NONE

SCALE = NONE

2

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

3

R3

261k

R1

787k

D1

DFLS240L

4

E1

E2

PV+

VIN +

4.4V - 40V

4 4

0.4A

RUN

E3

PV- or Vin-

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

ENABLED

DISABLED

R4

324k

R2

121k

INTVCC

JP1

MPPT

FREQ

750 kHz

1.5 MHz

R5

10.0k

ON

OFF

5%

R6

2.0k

E4

3 3

NTC

E5

PROG

2 2

JP4

NTC

EXT

INT

R8

0 Ohm

JUMPER

R9

10.0k

1 1

3

4

dc1977afb

7

Page 8

DEMO MANUAL

DC1977A-A/DC1977A-B

DEMONSTRATION BOARD IMPORTANT NOTICE

Linear Technology Corporation (LTC) provides the enclosed product(s) under the following AS IS conditions:

This demonstration board (DEMO BOARD) kit being sold or provided by Linear Technology is intended for use for ENGINEERING DEVELOPMENT

OR EVALUATION PURPOSES ONLY and is not provided by LTC for commercial use. As such, the DEMO BOARD herein may not be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including but not limited to product safety

measures typically found in finished commercial goods. As a prototype, this product does not fall within the scope of the European Union

directive on electromagnetic compatibility and therefore may or may not meet the technical requirements of the directive, or other regulations.

If this evaluation kit does not meet the specifications recited in the DEMO BOARD manual the kit may be returned within 30 days from the date

of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY THE SELLER TO BUYER AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THIS INDEMNITY, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user releases LTC from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. Also be aware that the products herein may not be regulatory compliant or

agency certified (FCC, UL, CE, etc.).

No License is granted under any patent right or other intellectual property whatsoever. LTC assumes no liability for applications assistance,

customer product design, software performance, or infringement of patents or any other intellectual property rights of any kind.

LTC currently services a variety of customers for products around the world, and therefore this transaction is not exclusive.

Please read the DEMO BOARD manual prior to handling the product. Persons handling this product must have electronics training and

observe good laboratory practice standards. Common sense is encouraged.

This notice contains important safety information about temperatures and voltages. For further safety concerns, please contact a LTC application

engineer.

Mailing Address:

Linear Technology

1630 McCarthy Blvd.

Milpitas, CA 95035

Copyright © 2004, Linear Technology Corporation

8

dc1977afb

LT 0817 REV B • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2014

Loading...

Loading...