Page 1

Description

DEMO MANUAL DC2378A-A

LTM4650

High Efficiency, Single 50A or Dual 25A

Step-Down Power µModule Regulator

Demonstration circuit DC2378A-A features the LT M®4650EY,

the high efficiency, high density, dual 25A, single 50A,

switch mode step-down power module regulator. The

input voltage is from 4.5V to 15V. The output voltage is

programmable from 0.6V to 1.8V. DC2378A-A can deliver

25A maximum current from each channel. As explained

in the data sheet, output current derating is necessary

, V

for certain V

operates in continuous conduction mode in heavy load

conditions. For high efficiency at low load currents, the

MODE jumper (JP1) selects pulse-skipping mode for noise

sensitive applications or Burst Mode

noise sensitive applications. Tw o outputs can be connected

in parallel for a single 50A output solution with optional

jumper resistors. The board allows the user to program

IN

, and thermal conditions. The board

OUT

®

operation in less

how its output ramps up and down through the TRACK/

SS pin. The output can be set up to either coincidentally or

ratiometrically track with another supply’s output. Remote

output voltage sensing is available for improved output

voltage regulation at the load point. These features and

the availability of the LTM4650EY in a compact 15mm ×

15mm × 5.01mm BGA package make it ideal for use in

many high density point-of-load regulation applications.

The LTM4650 data sheet must be read in conjunction with

this demo manual for working on or modifying the demo

circuit DC2378A-A.

Design files for this circuit board are available at

http://www.linear.com/demo/DC2378A-A

L, LT, LTC, LTM, Linear Technology, the Linear logo and Burst Mode are registered trademarks

of Linear Technology Corporation. All other trademarks are the property of their respective

owners.

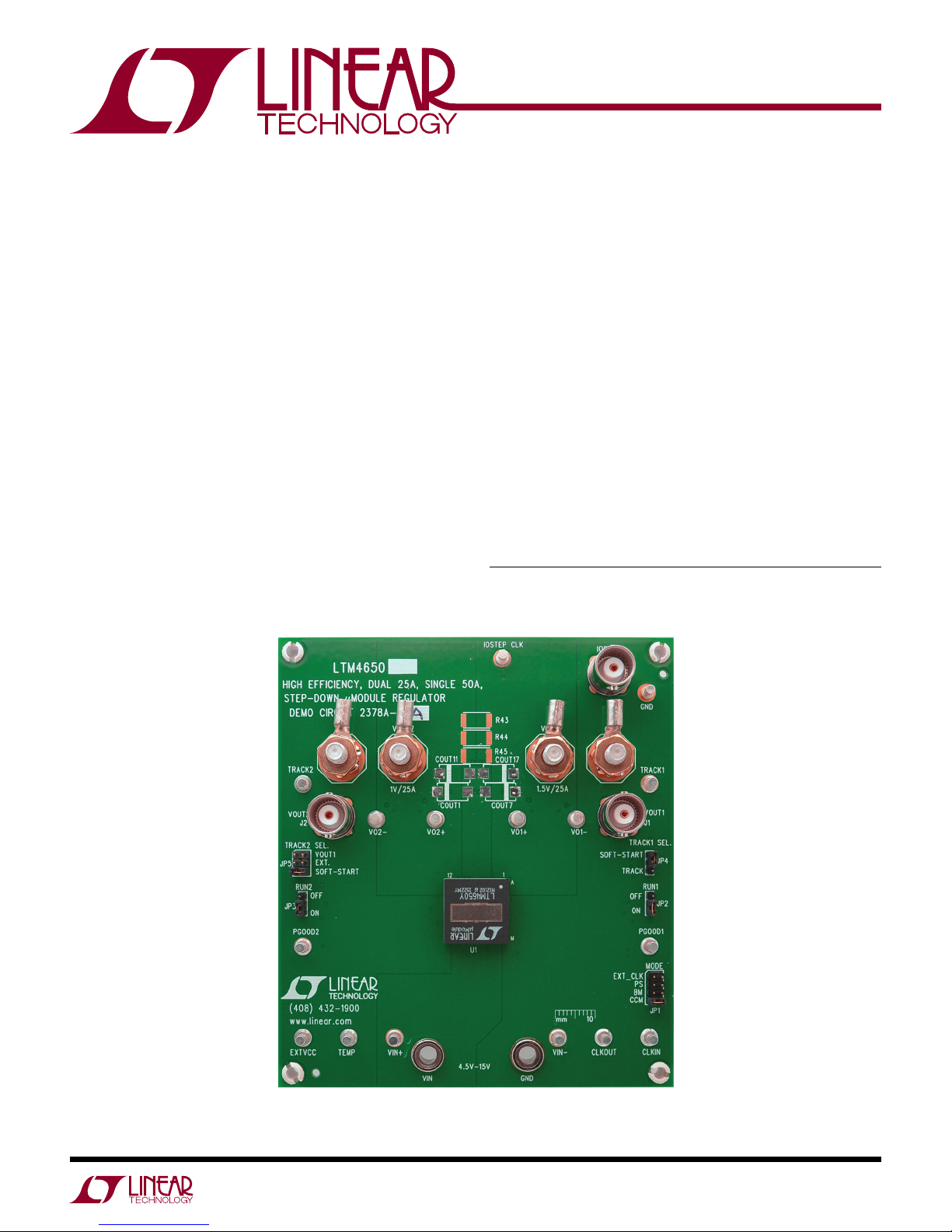

Figure 1. LTM4650/DC2378A-A Demo Board

dc2378aaf

1

Page 2

DEMO MANUAL DC2378A-A

performance summary

PARAMETER CONDITIONS MIN TYP MAX UNITS

Input Voltage Range 4.5 15 V

Output Voltage V

Output Voltage V

Per-Channel Maximum Continuous Output

Current

Default Operating Frequency 500 kHz

Resistor Programmable Frequency Range 250 780 kHz

External Clock Sync. Frequency Range 400 780 kHz

Efficiency of Channel 1 V

Efficiency of Channel 2 V

Load Transient of Channel1 V

Load Transient of Channel2 V

VIN = 4.5V ~ 15V, I

OUT1

VIN = 4.5V ~ 15V, I

OUT2

Derating Is Necessary for Certain V

Thermal Conditions, See Data Sheet for Detail.

= 12V, V

IN

= 12V, V

IN

= 12V, V

IN

= 12V, V

IN

Specifications are at TA = 25°C

= 0A ~ 25A, JP1: CCM 1.5 ±1.5% V

OUT1

= 0A ~ 25A, JP1: CCM 1 ±1.5% V

OUT2

, V

and

IN

OUT

OUT1

OUT2

OUT1

OUT2

= 1.5V, I

= 1V, I

= 1.5V, I

= 1V, I

= 25A, fSW = 500kHz 88.8

OUT1

= 25A, fSW = 500kHz 86.5

OUT2

= 12.5A ~ 18.75A See Figure 6

STEP

= 12.5A ~ 18.75A See Figure 7

STEP

25

(Per-Channel)

%

See Figure 4

%

See Figure 5

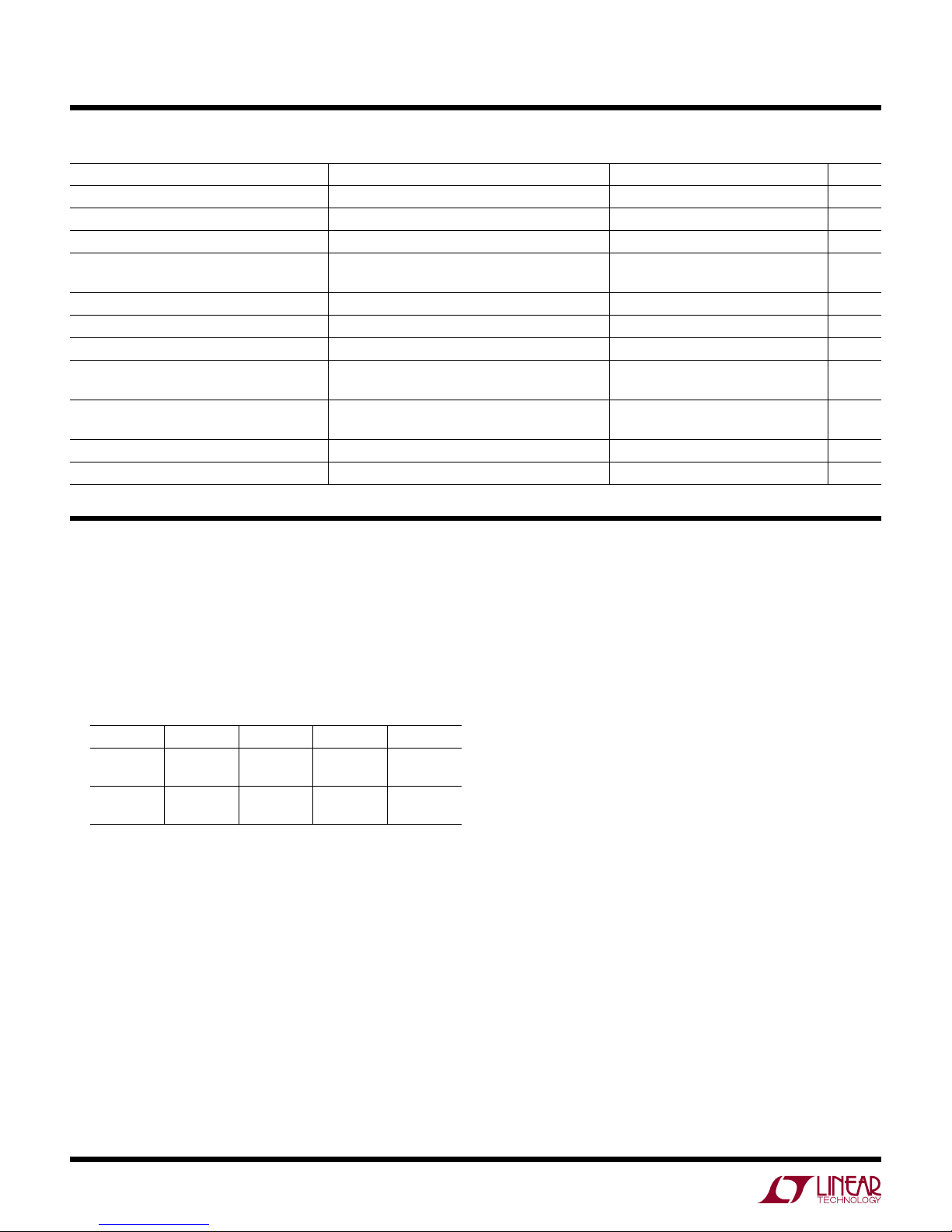

Quick start proceDure

Demonstration circuit DC2378A-A is easy to set up to

evaluate the performance of the LTM4650EY. Please refer

to Figure 2 for proper measurement setup and follow the

procedure below:

1. Place jumpers in the following positions for a typical

application:

JP1 JP2 JP3 JP4 JP5

MODE RUN1 RUN2 TRACK1

CCM

ON ON SOFT-

SEL.

START

TRACK2

SEL.

SOFT-

START

2. With power off, connect the input power supply, load

and meters as shown in Figure 2. Preset the load to 0A

and V

supply to 12V.

IN

3. Turn on the power supply at the input. The output

voltage in channel 1 should be 1.5V ±1.5% (1.4775V

~ 1.5225V) and the output voltage in channel 2 should

be 1V ±1.5% (0.985V ~ 1.015V).

4. Once the proper output voltage is established, adjust the

load within the operating range and observe the output

voltage regulation, output voltage ripple, efficiency and

other parameters. Output ripple should be measured

at J1 and J2 with BNC cables. 50Ω termination should

be set on the oscilloscope or BNC cables.

5. (Optional) For optional load transient test, apply an

adjustable pulse signal between IOSTEP CLK and GND

test point. Pulse amplitude (3V ~ 3.5V) sets the load

step current amplitude. The output transient current

can be monitored at the BNC connector J3 (10mV/A).

The pulse signal should have very small duty cycle (<

1%) to limit the thermal stress on the transient load

circuit. Switch the jumper resistors R34 or R35 (on the

backside of boards) to apply load transient

on channel

1 or channel 2 correspondingly.

6.

(Optional) LTM4650 can be synchronized to an external

clock signal. Place the JP1 jumper on EXT_CLK and

apply a clock signal (0V ~ 5V, square wave) on the

CLKIN test point.

7. (Optional) The outputs of LTM4650 can track another

supply. The jumpers JP4 and JP5 allow choosing softstart or output tracking. If tracking external voltage is

selected, the corresponding test points, TRACK1 and

TRACK2, need to be connected to a valid voltage signal.

8. (Optional) LTM4650 can be configured for a 2-phase

single output at up to 50A on DC2378A-A. Install 0Ω

resistors on R14, R17, R28, R39, R43, R44, R45 and

remove R7, R19. Output voltage is set by R25 based

on equation V

= 0.6V(1 + 60.4k/R25).

OUT

dc2378aaf

A

2

Page 3

Quick start proceDure

OUT

DEMO MANUAL DC2378A-A

Figure 2. Test Setup of DC2378A-A

+ –

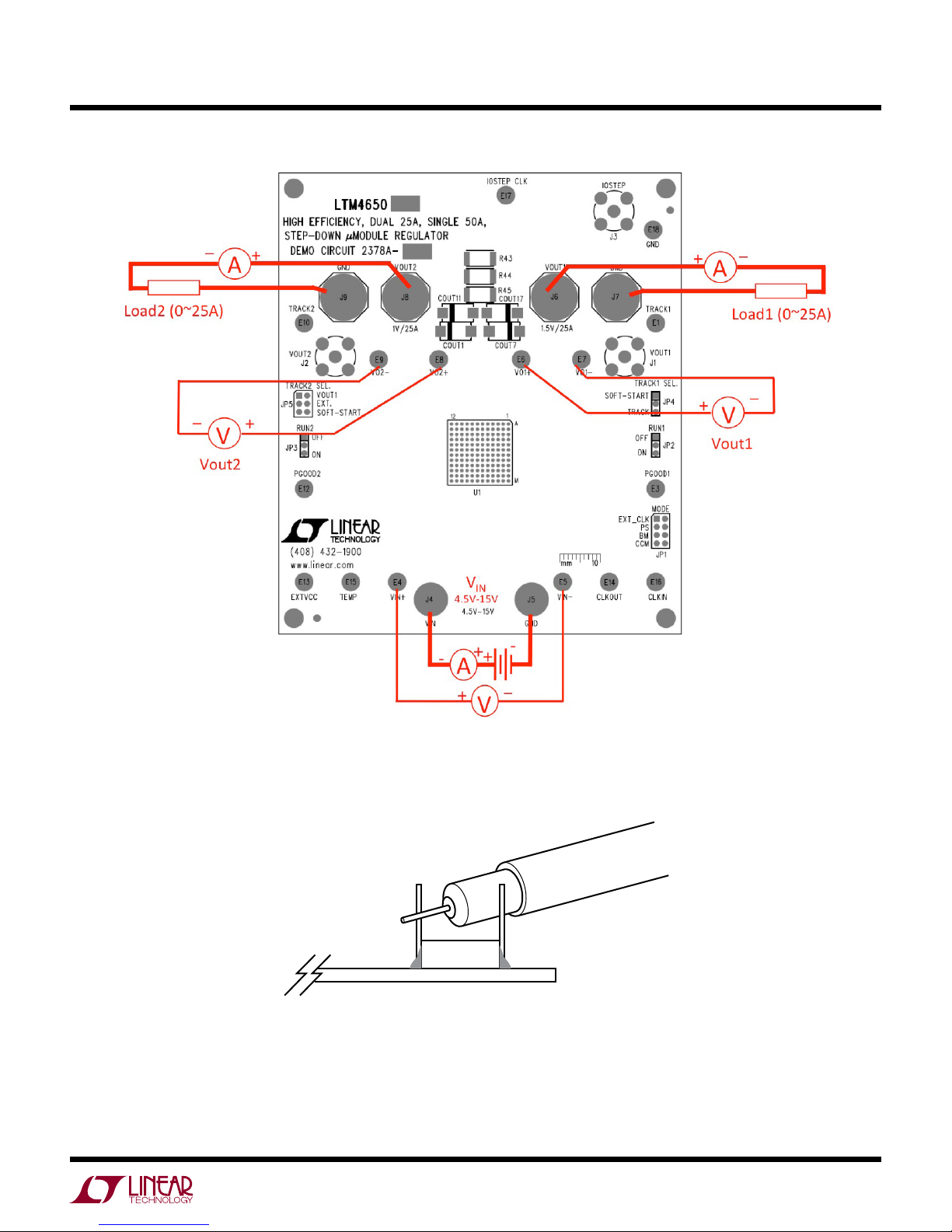

Figure 3. Measuring Output Voltage Ripple

C

OUT

V

GND

dc2378aaf

3

Page 4

DEMO MANUAL DC2378A-A

dc2378aa F06

dc2378aa F07

EFFICIENCY (%)

95

dc2378aa F04

25

EFFICIENCY (%)

95

dc2378aa F05

25

Quick start proceDure

5VIN, 1.5V

O

90

12VIN, 1.5V

85

O

5VIN, 1V

O

90

12VIN, 1V

85

O

80

75

70

0

OUTPUT LOAD CURRENT (A)

20105

15

Figure 4. Measured Efficiency on Channel 1

(V

= 1.5V, fSW = 500kHz, Channel 2 Disabled)

OUT1

1.5V OUTPUT (20MHz BW) [20mV/DIV]

80

75

70

0

OUTPUT LOAD CURRENT (A)

20105

15

Figure 5. Measured Efficiency on Channel 2

= 1V, fSW = 500kHz, Channel 1 Disabled)

(V

OUT2

1V OUTPUT (20MHz BW) [20mV/DIV]

12.5V TO 18.75A

Figure 6. Measured Channel 1 12.5A to 18.75A Load Transient

(V

= 12V, V

IN

4

OUT1

= 1.5V)

12.5V TO 18.75A

Figure 7. Measured Channel 2 12.5A to 18.75A Load Transient

(V

= 12V, V

IN

OUT2

= 1V)

dc2378aaf

Page 5

Quick start proceDure

dc2378aa F08

dc2378aa F09

DEMO MANUAL DC2378A-A

1.5V OUTPUT (20MHz BW) [20mV/DIV]

Figure 8. Measured Output Voltage Ripple at 12V Input,

1.5V/25A with Standard Demo Circuit Default Setup

1V OUTPUT (20MHz BW) [20mV/DIV]

Figure 9. Measured Output Voltage Ripple at 12V Input,

1V/25A with Standard Demo Circuit Default Setup

Figure 10. Thermal Capture at 12VIN, 1.5V

(Ambient Temperature = 23°C, 200 LFM Airflow and No Heat Sink)

at 25A and 1V

OUT

OUT

at 25A

dc2378aaf

5

Page 6

DEMO MANUAL DC2378A-A

parts List

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

Required Circuit Components

1 1 CIN1 CAP., ALUM. ELECT., 330µF, 25V, 20% PANASONIC, 25SVPF330M

2 4 CIN2, CIN3, CIN4, CIN5 CAP., 22µF, X5R, 25V, 10%, 1210 MURATA, GRM32ER61E226KE15L

3 8 COUT9, COUT10, COUT12, COUT18 CAP., POSCAP, 470µF, 2.5V, 0.005Ω, 7343 PANASONIC, ETPF470M5H

4 10 COUT2, COUT3, COUT4, COUT5, COUT6,

COUT8, COUT13, COUT14, COUT15, COUT16

5 1 C1 CAP., 4.7µF, X5R, 16V, 20%, 0805 KEMET, C0805C475M4PACTU

6 1 C2 CAP., 1µF, X7R, 25V, 10%, 0805 AVX, 08053C105KAT2A

7 2 C5, C7 CAP., 0.1µF, X5R, 25V, 10%, 0603 AVX, 06033D104K AT2A

8 4 C13, C14, C15, C16 CAP., 1µF, X7R, 10V, 10%, 0603 AVX, 0603ZC105KAT2A

9 1 Q1 XSTR., N-CH, 40V, DPAK-2, TO-252 VISHAY, SUD50N04-8M8P-4GE3

10 4 R1, R3, R22, R26 RES., 10Ω, 1/10W, 1%, 0603 NIC, NRC06F10R0TRF

11 1 R5 RES., 100k, 1/10W, 1%, 0603 VISHAY, CRCW0603100KFKEA

12 4 R9, R12, R15, R18 RES., 60.4k, 1/10W, 1%, 0603 VISHAY, CRCW060360K4FKEA

13 2 R10, R13 RES., 6.04k, 1/10W, 1%, 0603 VISHAY, CRCW06036K04FKEA

14 1 R19 RES., 90.9k, 1/10W, 1%, 0603 VISHAY, CRCW060390K9FKEA

15 3 R24, R27, R36 RES., 10k, 1/10W, 1%, 0603 YAGEO, RC0603FR-0710KL

16 1 R25 RES., 40.2k, 1/10W, 1%, 0603 VISHAY, CRCW060340K2FKEDA

17 1 R30 RES., 121k, 1/10W, 1%, 0603 VISHAY, CRCW

18 1 R37 RES., HIGH POWER, 0.01Ω, 2W, 1%, 2512

19 1 U1 I.C., 16×16×5.01 BGA LINEAR TECH., LTM4650EY#PBF

Additional Demo Board Circuit Components

1 0 COUT1, COUT7, COUT11, COUT17 CAP., OPT, 7343 OPT

2 0 C3, C4, C6, C8, C9, C10, C11, C12, C17, C18 CAP., OPTION, 0603 OPT

3 0 R2, R4, R6, R8, R11, R14, R16, R17, R20,

R23, R28, R31, R33, R39, R40, R41, R42,

R46, R47, R48

4 4 R7, R21, R29, R32 RES., 0Ω, 1/10W, 0603 VISHAY, CRCW06030000Z0EA

5 1 R34 RES., 0Ω, 1/2W, 2010 VISHAY, CRCW20100000Z0EF

6 0 R35 RES., OPTION, 2010 OPT

7 0 R38, R43, R44, R45 RES., OPTION, 2512 OPT

CAP., 100µF, X5R, 6.3V, 20%, 1210 AVX, 12106D107M AT2A

0603121KFKEA

VISHAY, WSL2512R0100FEA18

RES., OPTION, 0603 OPT

6

dc2378aaf

Page 7

DEMO MANUAL DC2378A-A

parts List

Hardware: For Demo Board Only

1 16 E1, E3, E4, E5, E6, E7, E8, E9, E10, E12, E13,

E14, E15, E16, E17, E18

2 1 JP1 CONN., HEADER, 2×4, 2mm WURTH ELEKTRONIK, 62000821121

3 3 JP2, JP3, JP4 CONN., HEADER, 1×3, 2mm WURTH ELEKTRONIK, 62000311121

4 1 JP5 CONN., HEADER, 2×3, 2mm WURTH ELEKTRONIK, 62000621121

5 5 XJP1, XJP2, XJP3, XJP4, XJP5 SHUNT, 2mm WURTH ELEKTRONIK, 60800213421

6 3 J1, J2, J3 CONN., BNC STR PCB JK, THRU- HOLE, 5PINS CONNEX 112404

7 2 J4, J5 CONN., JACK, BANANA, NON-INSULATED, 0.218" KEYSTONE, 575-4

8 4 J6, J7, J8, J9 STUD, TESTPIN PEM KFH-032-10

9 8 J6, J7, J8, J9 (x2) NUT, BRASS 10-32 ANY #10-32

10 4 J6, J7, J8, J9 RING, LUG #10 KEYSTONE, 8205, #10

11 4 J6, J7, J8, J9 WASHER, TIN PLATED BRASS ANY #10, #10EXT BZ TN

12 4 (STAND-OFF) STANDOFF, NYLON, SNAP-ON, 0.500" KEYSTONE, 8833

TEST POINT, TURRET, 0.094" MTG. HOLE MILL-MAX, 2501-2-00-80-00-00-07-0

dc2378aaf

7

Page 8

DEMO MANUAL DC2378A-A

5

4

3

2

1

12

12

12

schematic Diagram

1

1

1

VOUT2

GND

1V / 25A

VO2+

JL

JL

JL

E8

R1

VO2+

PRODUCTION

PRODUCTION

PRODUCTION

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

REVISION HISTORY

DESCRIPTION DATEAPPROVEDECO REV

__

__

__

1 8-12-15

1 8-12-15

1 8-12-15

VO2+

VOUT2

J9

J8

10

6.3V

COUT14

100uF

6.3V

6.3V

COUT13

100uF

COUT4

100uF

COUT2

100uF

6.3V

COUT3

100uF

6.3V

COUT10

COUT12

470uF

2.5V

470uF

2.5V

+

+

COUT1

COUT11

OPT

OPT

+

+

E13

EXTVCC

C1

4.7uF

INTVCC

E14

CLKOUT

CLKIN

2465

MODE

1

3

7 8

BM

PS

EXT_CLK

CCM

E16

INTVCC

TEMP

E15

VIN

25V

CIN5

22uF

1210

1210

25V

CIN4

22uF

25V

CIN3

22uF

1210

25V

CIN2

22uF

1210

R2

OPT

330uF

25V

CIN1

+

J4

E4

VIN+

VIN

GND

4.5V-15V

D D

1210

1210

1210

2.5V

2.5V

INTVCCTEMP

J5

7343

7343

VIN-

VO2-

RUN2

C2

JP1

RUN1

E5

VO2-

E9

R3

10

R10

6.04K

VOUT1

VO2-

13

C4

R8

OPT

OPT

2

JP3

100K

OPT

VOUT2S

R7

0

C12

C11

C10

C9

B12

B11

B10

B9

B8

A12

A11

A10

A9

A8

J7

H8

G5

F4

TEMP

J6

VIN

J2

VIN

J3

VIN

J4

VIN

J9

VIN

J10

VIN

J11

VIN

K2

VIN

K3

VIN

K4

VIN

K9

VIN

K10

VIN

K11

VIN

L2

VIN

L3

VIN

L4

VIN

L5

VIN

L6

VIN

L7

VIN

L8

VIN

L9

VIN

L10

OFF

ON

R4

VIN

1uF

R5

RUN1

R6

OPT

OPT

C3

2

1 3

ON

OFF

JP2

TRACK1 SEL.

R9

R13

6.04K

TRACK2 SEL.

VOUT1

RUN2

F9

C8

VOUT2

VOUT2

RUN2

VOUT2

VOUT2S

VOUT2

VOUT2

VOUT2

VOUT2

VOUT2

VOUT2

VOUT2

VOUT2

VOUT2

VOUT2

VOUT2

EXTVCC

INTVCC

CLKOUT

MODE-PLLIN

VINM2VINM3VINM4VINM5VINM6VINM7VINM8VINM9VIN

VIN

L11

TRACK

SOFT-START

2

3

R12

60.4K

TRACK2

E10

R15

60.4K

R18

2

4

C7

1

3

5 6

JP5

EXT.

SOFT-START

C8

TRACK2

C6

OPT

OPT

R16

D8

TRACK2

VIN

RUN1F5TRACK1E5VOUT1SC5VOUT1A1VOUT1A2VOUT1A3VOUT1A4VOUT1

M10

M11

TRACK1

C5

0.1uF

JP4

1

60.4K

E1

TRACK1

C C

60.4K

0.1uF

OPT

D7

VFB2

U1

VOUT1S

VO1+

SW2

INTVCC

R19

90.9K

VFB2

G8

G11

SW2

PGOOD2

LTM4650EY

DIFFOUT

F8

0

R21

DIFFOUT

R20

OPT

C9

OPT

VOUT1

VOUT1

R22

10

E6

J6

VO1+

VOUT1

1.5V / 25A

PGOOD2

R24

10K

E7

G7

COMP2

VOUT1B1VOUT1B2VOUT1B3VOUT1B4VOUT1B5VOUT1C1VOUT1C2VOUT1C3VOUT1

A5

2.5V

2.5V

COUT18

470uF

COUT9

470uF

+

+

OPT

7343

OPT

7343

COUT7

COUT17

+

+

6.3V

6.3V

100uF

100uF

COUT16

COUT15

6.3V

6.3V

100uF

100uF

COUT6

COUT8

6.3V

COUT5

100uF

J7

E12

7343

7343

1210

1210

COMP2

VFB1

1210

GND

C18

R47

OPT

C10

OPT

L12

M12

GNDL1GND

GNDM1GND

SGNDC7SGNDD6SGNDF6SGNDF7SGNDG6SGND

VFB1D5SW1G2PGOOD1G9COMP1

C4

OPT

C11

R25

40.2K

VO1-

10

R26

E7

VO1-

B B

OPT

K12

SW1

GNDK1GNDK5GNDK6GNDK7GNDK8GND

R27

INTVCC

www.linear.com

www.linear.com

www.linear.com

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

TECHNOLOGY

TECHNOLOGY

U1

LTM4650‐1‐B

‐A LTM4650

ASSY

H10

H11

H12

J12

GNDH3GNDH4GNDH5GNDH6GNDH7GNDH9GND

GND

GND

GNDJ1GNDJ5GNDJ8GND

E6

10K

GND

H2

GND

H1

GND

G12

GND

G10

GND

G3

GND

G1

GND

F12

GND

F11

GND

F10

GND

F3

GND

F2

GND

F1

GND

E12

GND

E11

GND

E10

GND

E4

GND

E3

GND

E2

GND

E1

GND

D12

GND

D11

GND

D10

GND

D9

GND

D4

GND

D3

GND

D2

GND

D1

GND

B7

GND

B6

GND

A7

GND

A6

PHASMD

G4

R30

121K

FSET

C6

DIFFP

E8

DIFFN

E9

0

R29

VO1-

C12

OPT

R46

OPT

C17

OPT

VO1+

TECHNOLOGY

SCHEMATIC

SCHEMATIC

SCHEMATIC

TITLE:

TITLE:

TITLE:

LT

LT

LT

APPROVALS

APPROVALS

APPROVALS

PCB DES.

PCB DES.

PCB DES.

APP ENG.

APP ENG.

APP ENG.

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

R42

R41

OPT

INTVCC

DIFFP

DIFFN

0

R32

SHEET OF

SHEET OF

SHEET OF

1

m

LTM4650EY

LTM4650EY

LTM4650EY

STEP-DOWN MODULE REGULATOR

STEP-DOWN MODULE REGULATOR

STEP-DOWN MODULE REGULATOR

DEMO CIRCUIT 2378A-A

DEMO CIRCUIT 2378A-A

DEMO CIRCUIT 2378A-A

HIGH EFFICIENCY, DUAL 25A, SINGLE 50A,

HIGH EFFICIENCY, DUAL 25A, SINGLE 50A,

HIGH EFFICIENCY, DUAL 25A, SINGLE 50A,

Monday, August 17, 2015

Monday, August 17, 2015

Monday, August 17, 2015

IC NO. REV.

IC NO. REV.

IC NO. REV.

N/A

N/A

N/A

DATE:

SIZE

DATE:

SIZE

DATE:

SIZE

JL

JL

JL

SCALE = NONE

SCALE = NONE

SCALE = NONE

2

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

OPT

3

4

5

E3

PGOOD1

COMP1

NOTE: UNLESS OTHERWISE SPECIFIED

1. ALL RESISTORS AND CAPACITORS ARE 0603.

A A

dc2378aaf

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

8

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

Page 9

schematic Diagram

5

4

3

2

1

22

22

22

DEMO MANUAL DC2378A-A

1

1

1

www.linear.com

www.linear.com

www.linear.com

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

IOSTEP CLK

GND

m

SHEET OF

SHEET OF

SHEET OF

1

VOUT2

J2

VOUT2

1uF

C14

1

Q1

E17

R35

OPT

2010

R31

R33

OPT

OPT

R23

OPT

R11

OPT

DIFF SENSING SELECTION

VO2- DIFFN

VO2+ DIFFP

VOUT1S VOUT1

VOUT2S DIFFOUT

Load Transient Circuit

R34

0.5W

2010

0 OHm

C13

1uF

VOUT1

SUD50N04-8M8P-4GE3

2

4

C16

1uF

C15

1uF

R36

3

10K

R38

R37

J3

IOSTEP

E18

2512

OPT

0.0102W2512

LTM4650EY

LTM4650EY

LTM4650EY

STEP-DOWN MODULE REGULATOR

STEP-DOWN MODULE REGULATOR

STEP-DOWN MODULE REGULATOR

DEMO CIRCUIT 2378A-A

DEMO CIRCUIT 2378A-A

DEMO CIRCUIT 2378A-A

HIGH EFFICIENCY, DUAL 25A, SINGLE 50A,

HIGH EFFICIENCY, DUAL 25A, SINGLE 50A,

HIGH EFFICIENCY, DUAL 25A, SINGLE 50A,

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

Monday, August 17, 2015

Monday, August 17, 2015

Monday, August 17, 2015

IC NO. REV.

IC NO. REV.

IC NO. REV.

SCHEMATIC

SCHEMATIC

SCHEMATIC

N/A

N/A

N/A

SIZE

DATE:

SIZE

DATE:

SIZE

TITLE:

TITLE:

TITLE:

JL

JL

JL

LT

LT

LT

APPROVALS

APPROVALS

APPROVALS

PCB DES.

PCB DES.

PCB DES.

APP ENG.

APP ENG.

APP ENG.

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

DATE:

2

SCALE = NONE

SCALE = NONE

SCALE = NONE

3

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

J1

INTVCC

R48

OPT

OPT

R40

VIN

TEMP INTVCC

D D

VOUT1

R14

TRACK1 TRACK2

OPT

R17

OPT

VFB1 VFB2

R28

OPT

COMP1 COMP2

R43

OPT

2512

VOUT1 VOUT2

R44

R39

OPT

RUN1 RUN2

OPTIONAL JUMPER FOR SINGLE OUTPUT CONFIGURATION

C C

B B

OPT 2512

R45

OPT

4

2512

5

A A

dc2378aaf

9

Page 10

DEMO MANUAL DC2378A-A

DEMONSTRATION BOARD IMPORTANT NOTICE

Linear Technology Corporation (LTC) provides the enclosed product(s) under the following AS IS conditions:

This demonstration board (DEMO BOARD) kit being sold or provided by Linear Technology is intended for use for ENGINEERING DEVELOPMENT

OR EVALUATION PURPOSES ONLY and is not provided by LTC for commercial use. As such, the DEMO BOARD herein may not be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including but not limited to product safety

measures typically found in finished commercial goods. As a prototype, this product does not fall within the scope of the European Union

directive on electromagnetic compatibility and therefore may or may not meet the technical requirements of the directive, or other regulations.

If this evaluation kit does not meet the specifications recited in the DEMO BOARD manual the kit may be returned within 30 days from the date

of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY THE SELLER TO BUYER AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THIS INDEMNITY, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user releases LTC from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. Also be aware that the products herein may not be regulatory compliant or

agency certified (FCC, UL, CE, etc.).

No License is granted under any patent right or other intellectual property whatsoever. LTC assumes no liability for applications assistance,

customer product design, software performance, or infringement of patents or any other intellectual property rights of any kind.

LTC currently services a variety of customers for products around the world, and therefore this transaction is not exclusive.

Please read the DEMO BOARD manual prior to handling the product. Persons handling this product must have electronics training and

observe good laboratory practice standards. Common sense is encouraged.

This notice contains important safety information about temperatures and voltages. For further safety concerns, please contact a LTC application

engineer.

Mailing Address:

Linear Technology

1630 McCarthy Blvd.

Milpitas, CA 95035

Copyright © 2004, Linear Technology Corporation

Linear Technology Corporation

10

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

dc2378aaf

LT 1015 REV A • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2015

Loading...

Loading...