Page 1

Description

DEMO MANUAL DC2392A

LTC7860

High Voltage Switching

Surge Stopper

Demonstration circuit 2392A is a high efficiency switching

®

surge stopper featuring the LT C

7860. The board operates

from an input range of 7V to 100V, and provides a 7V to

34V output at 0A to 10A. Its output is current limited. A

soft-start feature controls output voltage slew rate at startup, reducing current surge and voltage overshoot. The

demonstration board includes an optional reverse polarity

protection MOSFET and has options for an input filter and

diode to attenuate spikes. For a lower output voltage limit

of less than 12V, there is an optional feedback circuit.

The LTC7860 high efficiency surge stopper protects loads

from high voltage transients. High efficiency compared to

linear circuits permits higher currents and smaller solution

sizes. During an input overvoltage event, such as a load

dump in vehicles, the LTC7860 controls the gate of an

external MOSFET to act as a switching DC/DC regulator

(PROTECTIVE PWM mode). This operation regulates the

output voltage to a safe level, allowing the loads to oper

ate through the input overvoltage event. During normal

operation (SWITCHON mode), the

LTC7860

turns on the

external MOSFET continuously, passing the input voltage

through to the output. An internal comparator limits the

voltage across the current sense resistor and regulates the

maximum output current to protect against overcurrent

faults. An adjustable timer limits the time that the LTC7860

can spend in overvoltage or overcurrent regulation. When

the timer expires, the external MOSFET is turned off until

the LTC7860 restarts after a cool down period. By strictly

limiting the time in PROTECTIVE PWM mode when the

power loss is higher, the components and thermal design

can be optimized for normal operation and safely oper

ate through high voltage input surges and/or overcurrent

faults. This demo board takes advantage of the LTC7860’s

-centric PMOS architecture to float the control ground

V

IN

allowing operation beyond the controller’s 60V rating.

This board is suitable for a wide range of automotive,

military, telecom, industrial, and other applications. The

LTC7860 is available in a small 12-pin thermally enhanced

MSOP package. For other output requirements, see the

LTC7860 data sheet or contact the LTC factory.

Design files for this circuit board are available at

http://www.linear.com/demo/DC2392A

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Linear

Technology Corporation. All other trademarks are the property of their respective owners.

performance summary

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN

V

OUT

I

OUT

I

LIMIT

I

LIMIT

V

IN-VOUT

F

SW

T

PWM

V

OUT P-P

Input Supply Range Normal Operation 7 32 V

Output Voltage 7 28 35 V

Output Current Range, continuous Free Air 0 10 A

Current Limit VIN = 28V 13 A

Current Limit VIN = 40V 10.5 A

Insertion Loss VIN = 28V, I

Switching (Clock) Frequency 350 kHz

PROTECTIVE PWM Mode Time Limit VIN > 35V 0.85 1.06 1.24 s

Output Ripple VIN = 40V, V

Approximate Size Component Area x Top Component Height 35 × 42 × 10 mm

Specifications are at TA = 25°C

500ms Ride-Through 7 100 V

DC Survival 0 100 V

= 10A 400 mV

OUT

= 17.2V, I

OUT

= 5A (20MHz BW) 100 mV

OUT

P–P

dc2392af

1

Page 2

DEMO MANUAL DC2392A

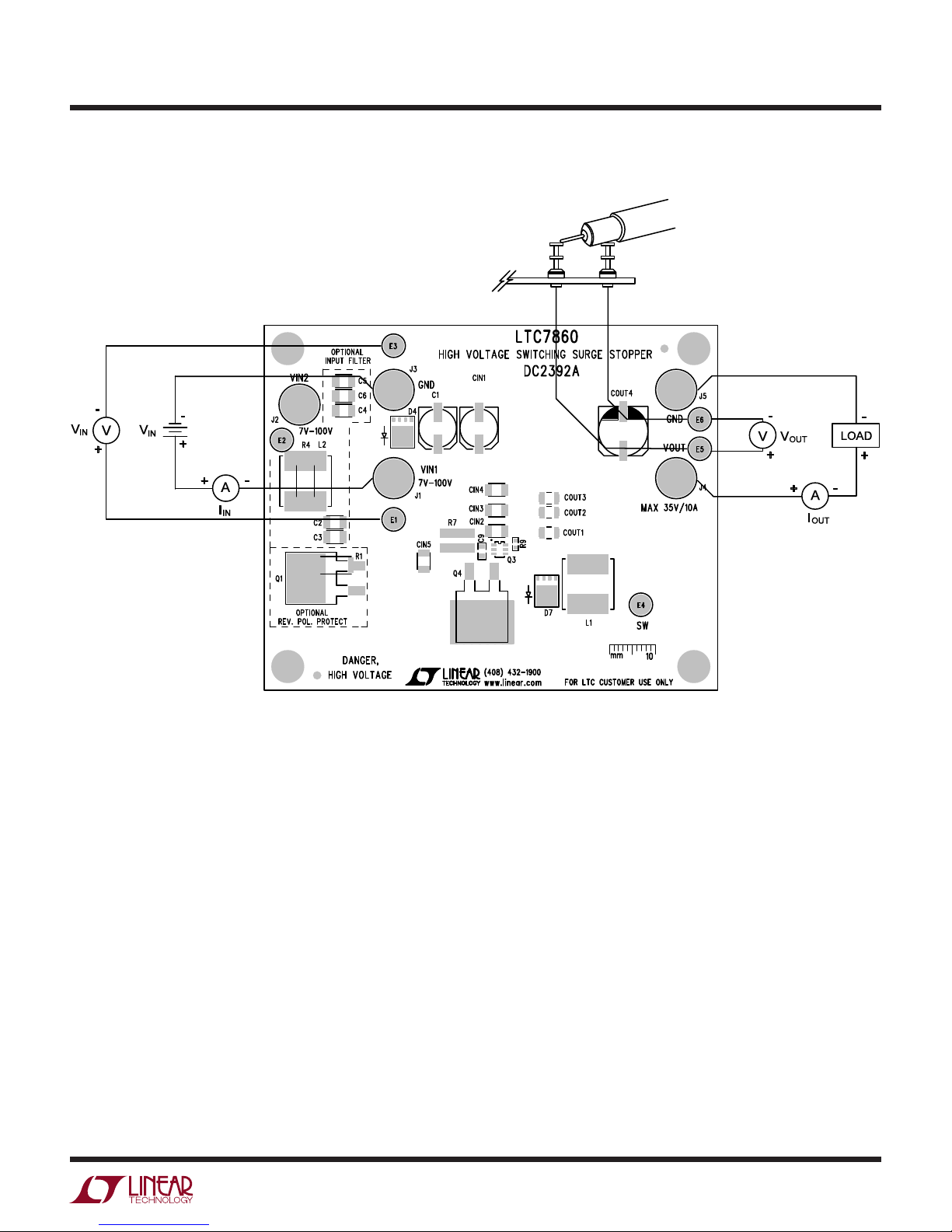

Quick start proceDure

Demonstration circuit 2392 is easy to set up to evaluate

the performance of the LTC7860. Refer to Figure 1 for

proper measurement equipment setup and follow the

procedure below:

NOTE: When measuring the output voltage ripple, care must

be taken to avoid a long ground lead on the oscilloscope

probe. Measure the output voltage ripple by touching the

probe tip and ground ring directly across the last output

capacitor as shown in Figure 1.

1. Set an input power supply that is capable of 7V to

100V to 10V. Then turn off the supply.

2. With power off, connect the supply to the input termi

nals +VIN and –VIN.

a. Input Voltages lower than 7V can keep the converter

from turning on due to the undervoltage lockout feature

of the LTC7860.

b. A voltmeter with a capability of measuring at least 100V

can be placed across the input terminals in order to

get an accurate input voltage measurement.

3. Turn on the power at the input.

-

5. Once the proper output voltage is established, connect

a variable load capable of sinking 10A at 34V to the

output terminals +V

0A.

a. A Voltmeter with a capability of measuring at least 36V

can be placed across the output terminals in order to

get an accurate output voltage measurement.

6. Turn on the power at the input.

NOTE: If there is no output, temporarily disconnect the

load to make sure that the load is not set too high.

7. Once the proper output voltage is again established,

adjust the load and/or input within the operating range

up to 33V

desired parameters.

8. Now apply an input between 35V and 100V and observe the output voltage and fault timer operation.

9. If desired, you may apply input transient profiles in

the range of 0V

to illustrate operation of the circuit to prevent input

surges from reaching the output.

and observe the output voltage and other

IN

IN

and –V

OUT

to 100VIN and observe the output

. Set the current for

OUT

NOTE: Make sure that the input voltage never exceeds

100V.

4. Check for the proper output voltage of 10V. Turn off

the power at the input.

10. The output limit voltage can be set in accordance

with the feedback notes on the schematic. The first

line shows the complete formula. The second line is

simplified for the use of a 2:1 divider as shown on the

schematic.

2

dc2392af

Page 3

Quick start proceDure

DEMO MANUAL DC2392A

Figure 1. Proper Measurement Equipment Setup

dc2392af

3

Page 4

DEMO MANUAL DC2392A

DC2392A F03

Quick start proceDure

V

100V

IN

V

OUT

0V

TIME

DC2392A F02

Figure 2. Output Response Waveform with 28V to 100V

to 28V Input Surge, (10A

100

98

96

94

92

5A

90

EFFICIENCY (%)

88

86

84

6

OUT

10A

OUT

10A

OUT-PD

10 100

) (20V, 20V, 10ms/DIV)

OUT

V

IN

40

35

POWER DISSIPATION (W)

30

25

20

15

10

5

0

Figure 3. Efficiency and Power Dissipation

4

dc2392af

Page 5

DEMO MANUAL DC2392A

parts List

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

Required Circuit Components

1 1 CIN1 CAP., ALUM, 15µF, 100V 8X12 PANASONIC, 100SXV15M

2 4 CIN2, CIN3, CIN4, CIN5 CAP., X7R, 2.2µF, 100V, 10%, 1210 MURATA, GCJ32DR72A225KA01L

3 3 COUT1, COUT2, COUT3 CAP., X7S, 10µF, 50V, 10%, 1210 MURATA, GCM32EC71H106KA01L

4 1 COUT4 CAP., ALUM 150µF 50V 10x10 SUN ELECTRONIC INDUSTRIES CORP., 50CE150AX

5 1 C9 CAP., X7R, 1µF, 50V, 10%, 0805 MURATA, GCM21BR71H105KA01L

6 1 C10 CAP., X7R, 22µF, 10V, 10%, 1206 MURATA, GCM31CR71A226KE01L

7 1 C11 CAP., NPO, 100pF, 50V, 10%, 0603 AVX, 06035A101KAT2A

8 1 C12 CAP., X7R, 0.1µF, 50V, 10%, 0603 MURATA, GCM188R71H104KA57D

9 1 C13 CAP., X7R, 0.47µF, 16V, 10%, 0603 MURATA, GCM188R71C474KA55L

10 1 C14 CAP., X7R, 0.1µF, 50V, 10%, 0805 MURATA, GCM21BR71H104KA37L

11 1 C15 CAP., COG, 47pF, 50V, 5%, 0603 MURATA, GCM1885C1H470JA16D

12 1 C17 CAP., COG, 3300pF, 50V, 5%, 0603 MURATA, GCM1885C1H332JA16D

13 1 C18 CAP, 1.5nF, X7R, 50V,10%,0603 AVX, 06035C152KAT2A

14 1 D1 ZENER DIODE, 500mW, SOD123 ON SEMI, SZMMSZ5242BT1G/T3G

15 1 D7 SCHOTTKY DIODE, 100V, 10A, DFN5-SO-8FL ON SEMI, NRVTS10100MFST1G

16 1 D8 SWITCH DIODE, SOD323 ON SEMI., SMMDL914T1G

17 1 L1 INDUCTOR, 10µH COILCRAFT, XAL1010-103ME

18 2 Q1, Q4 FET, P-CHAN.,100V, TO-263 VISHAY, SUM90P10-19L-E3

19 1 Q2 FET, P-CHAN., POWER, TO-252 ON SEMI, SFT1345-TL-H

20 1 Q3 DIODE, IGBT MOSFET 10A, SOT23-6 DIODES INC., ZXGD3005E6TA

21 1 Q6 FET, NPN, SOT23 ON SEMI, SMMBTA42LT1G

22 2 R3, R13 RES., 100k, 1/8W, 1%, 0805 VISHAY, CRCW0805100KFKEA

23 1 R5 RES., 35.7k, 1/10W, 1%, 0603 VISHAY, CRCW060335K7FKEA

24 2 R6, R8 RES., 100Ω, 1/10W, 1%, 0603 VISHAY, CRCW0603100RFKEA

25 1 R7 RES., 6m, 3W, 1%, 1225 SUSUMU, KRL6432E-M-R006-F-T1

26 1 R9 RES., 1.0k, 1/10W, 1%, 0603 VISHAY, CRCW06031K00FKEA

27 1 R16 RES., 10Ω, 1/10W, 5%, 0805 VISHAY, CRCW080510R0JNEA

28 2 R17, R19 RES., 10k, 1/16W, 1%, 0603 VISHAY, CRCW060310K0FKEA

29 2 R24, R26 RES., 31.6k, 1/10W, 1%, 0603 VISHAY, CRCW060331K6FKEA

30 1 R25 RES., 205k, 1/16W, 1%, 0603 VISHAY, CRCW0603205KFKEA

31 1 U1 IC, LTC7860EMSE MSE12 LINEAR TECH.CORP. LTC7860EMSE#PBF

Additional Demo Board Circuit Components

1 0 C1 CAP., OPT 8×12 OPT

2 0 C2, C3, C4, C5, C6, C8 CAP., OPT 1210 OPT

3 0 C7, C16 CAP., OPT 0603 OPT

4 0 D2, D3, D5 ZENER DIODE, OPT SOD123 OPT

5 0 D4

6

7 0 L2 INDUCTOR, 1µH OPT

8 0 L3 INDUCTOR, 0.6µH OPT

0 D6 ZENER DIODE, OPT, SOD323 OPT

DIODE, OPT, DFN5-SO-8FL OPT

dc2392af

5

Page 6

DEMO MANUAL DC2392A

parts List

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

9 0 Q4 HEATSINK, OPT, 573100D00010G OPT

10 0 Q5 OPT, SOT363 OPT

11 0 R1, R2, R29 RES., OPT, 2512 OPT

12 3 R11, R14, R21 RES., 0Ω, 1/16W, 0603 VISHAY, CRCW06030000Z0EA

13 1 R4 RES., 1mΩ, 1%, 1W, 2512 PANASONIC, ERJ-M1WTF1M0U

14 0 R12 RES., OPT, 0805 OPT

15 0 R10, R15, R18, R20,

R22, R23, R27, R28

Hardware: For Demo Board Only

1 6 E1, E2, E3, E4, E5, E6 TESTPOINT, TURRET, .094" MILL MAX, 2501-2-00-80-00-00-07-0

2 5 J1, J2, J3, J4, J5 CONN, BANANA JACK, KEYSTONE 575-4

3 4 MTGS AT 4 CORNERS STAND-OFF, SNAP ON NYLON 0.50" TALL KEYSTONE, 8833(SNAP ON)

RES., OPT, 0603 O PT

6

dc2392af

Page 7

DEMO MANUAL DC2392A

5

4

3

2

1

12

12

12

schematic Diagram

2

2

DATE

DATE

DATE

DBPRODUCTION2 09-29-15

DBPRODUCTION2 09-29-15

DBPRODUCTION2 09-29-15

APPROVED

APPROVED

APPROVED

REVISION HISTORY

DESCRIPTION

REVISION HISTORY

DESCRIPTION

REVISION HISTORY

DESCRIPTION

REV

REV

REV

__

__

__

ECO

ECO

ECO

3W

R76m1225

R8

100

R9

C9

Q3

1K

SW

E4

Q4

SUM90P10-19L

1uF

0805

50V

4

2

ZXGD3005E6TA

VOUT

VOUT

J4

E5

VOUT

L1

10uH

316

5

COUT3

COUT2

XAL1010-103

10Aout,

COUT4

+

COUT1

D7

R15

Limited at 34V

150uF

GND

E6

J5

10X10

50V

50CE150AX

1210

10uF

50V

100V

10A

NRVTS10100MFST

R16100805

VIN-10V

OPT

GND

CAP

28V

100V

7.0V-32.0V

100V, 500ms

NOMINAL INPUT

INPUT DC SURVIVAL

SURGE RIDE-THROUGH

OUTPUT VOLTAGE LIMIT 34.0V

INPUT OPERATING RANGE

www.linear.com

www.linear.com

www.linear.com

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

LT

LT

LT

APPROVALS

APPROVALS

APPROVALS

PCB DES.

PCB DES.

PCB DES.

2

SHEET OF

SHEET OF

SHEET OF

1

DC2392A

LTC7860EMSE

LTC7860EMSE

LTC7860EMSE

Tuesday, November 17, 2015

Tuesday, November 17, 2015

Tuesday, November 17, 2015

IC NO. REV.

IC NO. REV.

IC NO. REV.

SCHEMATIC

HIGH VOLTAGE SWITCHING SURGE STOPPER

SCHEMATIC

HIGH VOLTAGE SWITCHING SURGE STOPPER

SCHEMATIC

HIGH VOLTAGE SWITCHING SURGE STOPPER

N/A

N/A

N/A

SIZE

DATE:

SIZE

DATE:

SIZE

TITLE:

TITLE:

TITLE:

DB

DB

DB

APP ENG.

APP ENG.

APP ENG.

DATE:

2

SCALE = NONE

SCALE = NONE

SCALE = NONE

R6

100

R28

OPT

C11

12

U1

LTC7860EMSE

1

R10 OPT

C10 22uF

VIN-10V

Q2

C C

11

GATE

FREQ

1206

D5

R12

SFT1345

100pF

VIN

FREQ2TMR

OPT

OPT

R13

R11 0

0805

100K

10

3

0805

CAP

9

SENSE

C12 0.1uF

CAP

C14

C13

8

RUN

VFB5SS4SGND

VIN-10V

D6

0.1uF

50V

0.47uF

7

6

OPT

R14

0805

16V

VFBN

ITH

0

PGND

VIN-10V

13

R17

10K

VIN

C16

C15

VIN-10V

OPT

C17

47pF

R19

10K

R18

3.3nF

OPT

VFB

VIN-10V

R20

FREQ

SMMDL914

OPT

D8

VIN-10V

R21

0

B B

Q6C

C18

1.5nF

R24

31.6K

Q6

SMMBTA42L

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

CAUTION, SHOCK HAZARD: CONTACT WITH HIGH VOLTAGE

CAN RESULT IN A DANGEROUS ELECTRIC SHOCK.

R26

31.6K

R25

205K

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

Feedback Notes

V-limit = ( R24 + R26 ) / R26 * ( 0.8V / R19 * R25 + Q6Vbe )

= 2 * ( 0.8 / 10K * 205K + 0.6 ) = 34.0Vnominal

NOTE: UNLESS OTHERWISE SPECIFIED:

ALL RESISTORS ARE 0603.

ALL CAPACITORS ARE 0603 50V.

150uF 50V Suncon 50CE150AX (10x10mm)

15uF 100V Panasonic 100SXV15M (8x12mm)

2.2uF 100V Murata GCJ32DR72A225KA01L

A A

10uF 50V Murata GCM32EC71H106KA01L

22uF 10V Murata GCM31CR71A226KE01L

10uH Coilcraft XAL1010-103ME

0.006 Susumu KRL6432E-M-R006-F-T1

3

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

4

5

D3

OPT

D2

OPT

C7

R3

CIN4

2.2uF

CIN5

2.2uF

CIN3

2.2uF

CIN2

2.2uF

C1

OPT

+

CIN1

15uF

+

7V - 100V

100K

100V

0805

100V

100V

8X12

8x12

J3

R5

1210

1210

1210

1210

100SXV15M

GND

OPT

35.7K

E3

GND

VIN-10V

C8

OPT

1210

D1

SZMMSZ5242B

VIN

J1

E1

VIN1

VIN1

D D

dc2392af

7

Page 8

DEMO MANUAL DC2392A

5

4

3

2

1

22

22

22

schematic Diagram

2

2

2

C4

OPT

C2

7V - 100V

C6

C5

OPT

C3

OPT

D4

VIN2

E2

OPT

1210

100V

OPT

1210

100V

OPT

1210

100V

R41m2512

1210

1210

100V

CAP

OPT

www.linear.com

www.linear.com

www.linear.com

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

1630 McCarthy Blvd.

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

LTC Confidential-For Customer Use Only

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

LT

LT

LT

APPROVALS

APPROVALS

APPROVALS

PCB DES.

PCB DES.

PCB DES.

1

SHEET OF

SHEET OF

SHEET OF

DC2392A

DC2392A

DC2392A

LTC7860EMSE

LTC7860EMSE

LTC7860EMSE

2

Monday, November 16, 2015

Monday, November 16, 2015

Monday, November 16, 2015

IC NO. REV.

IC NO. REV.

SCHEMATIC

SCHEMATIC

SCHEMATIC

TITLE:

TITLE:

TITLE:

DB

DB

DB

APP ENG.

APP ENG.

APP ENG.

IC NO. REV.

HIGH VOLTAGE SWITCHING SURGE STOPPER

HIGH VOLTAGE SWITCHING SURGE STOPPER

HIGH VOLTAGE SWITCHING SURGE STOPPER

N/A

N/A

N/A

SIZE

DATE:

SIZE

DATE:

SIZE

DATE:

3

SCALE = NONE

SCALE = NONE

SCALE = NONE

VIN2

J2

PROTECTED )

( REVERSE POLARITY

R29

OPT

2512

R2

OPT

2512

OPT

0.6uH

OPT

2512

L2

1uH

Q1

SUM90P10-19L

L3

OPTIONAL INPUT FILTER

R1

OPTIONAL

VIN

REV. POL. PROTECT

OPTIONAL

INPUT FILTER

R23

OPT

4

VIN

D D

R22

Q5

OPT

BC857BS

16

8

4

R27

OPT

3

5

2

VIN-10V

FOR VOUT < 12V

OPTIONAL FEEDBACK CIRCUIT

VFB

Q6C

C C

B B

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

A A

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

5

dc2392af

Page 9

DEMO MANUAL DC2392A

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

GND

CAUTION, SHOCK HAZARD: CONTACT WITH HIGH VOLTAGE

OPTIONAL REVERSE POLARITY PROTECTION

0805

3W

CAN RESULT IN A DANGEROUS ELECTRIC SHOCK.

DC2392 - Simplified

7V - 100Vin

VIN1

16V

100V

100SXV15M

7V - 100V

GND

10Aout

Limited at 34V

100V

VIN2

100V

50V

50V

10A

VOUT

8x12

50V

50V

0805

12V

0805

FLOATING

GROUND

(INPUT DC SURVIVAL = -100V to +100V)

7.0V-32.0V

100V

100V, 500ms

NOMINAL INPUT

INPUT DC SURVIVAL

INPUT OPERATING RANGE

28V

SURGE RIDE-THROUGH

OUTPUT VOLTAGE LIMIT

34.0V

Feedback Notes

V-limit = ( R24 + R26 ) / R26 * ( 0.8V / R19 * R25 + Q6Vbe )

= 2 * ( 0.8 / 10K * 205K + 0.6 ) = 34.0Vnominal

NOTE: UNLESS OTHERWISE SPECIFIED:

ALL RESISTORS ARE 0603.

ALL CAPACITORS ARE 0603 50V.

150uF 50V Suncon 50CE150AX (10x10mm)

15uF 100V Panasonic 100SXV15M (8x12mm)

2.2uF 100V Murata GCJ32DR72A225KA01L

10uF 50V Murata GCM32EC71H106KA01L

22uF 10V Murata GCM31CR71A226KE01L

10uH Coilcraft XAL1010-103ME

0.006 Susumu KRL6432E-M-R006-F-T1

+VIN

+VIN

CAP

CAP

+VOUT

+VOUT

VIN-10V

REVISION HISTORY

DESCRIPTION

DATE

APPROVED

ECO

REV

DAVID B.PROTOTYPE2 09-29-15

__

REVISION HISTORY

DESCRIPTION

DATE

APPROVED

ECO

REV

DAVID B.PROTOTYPE2 09-29-15

__

REVISION HISTORY

DESCRIPTION

DATE

APPROVED

ECO

REV

DAVID B.PROTOTYPE2 09-29-15

__

SIZE

DATE:

IC NO. REV.

SHEET OF

TITLE:

APPROVALS

PCB DES.

APP ENG.

TECHNOLOGY

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SCHEMATIC

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

SCALE = NONE

www.linear.com

2

Tuesday, November 17, 2015

11

HIGH VOLTAGE SWITCHING SURGE STOPPER

LT

DAVID B.

N/A

LTC7860EMSE

SIZE

DATE:

IC NO. REV.

SHEET OF

TITLE:

APPROVALS

PCB DES.

APP ENG.

TECHNOLOGY

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SCHEMATIC

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

SCALE = NONE

www.linear.com

2

Tuesday, November 17, 2015

11

HIGH VOLTAGE SWITCHING SURGE STOPPER

LT

DAVID B.

N/A

LTC7860EMSE

SIZE

DATE:

IC NO. REV.

SHEET OF

TITLE:

APPROVALS

PCB DES.

APP ENG.

TECHNOLOGY

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SCHEMATIC

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

SCALE = NONE

www.linear.com

2

Tuesday, November 17, 2015

11

HIGH VOLTAGE SWITCHING SURGE STOPPER

LT

DAVID B.

N/A

LTC7860EMSE

Q3

ZXGD3005E6TA

+

CIN1

15uF

R3

100K

R26

31.6K

D8

SMMDL914

C13

0.47uF

CIN2,3,4,5

4x2.2uF

1210

C17

3.3nF

R24

31.6K

C18 1.5nF

Q4

SUM90P10-19L

D7

NRVTS10100MFST

C9

1uF

0805

R16

10

U1

LTC7860EMSE

VFB

5SS4

SGND

3

FREQ

2

TMR

1

PGND

13

SENSE

10

CAP

9

RUN

8

VFBN

7

ITH

6

VIN

11

GATE

12

R9

1K

R8

100

R13

100K

R6

100

Q6

SMMBTA42L

C15

47pF

C12 0.1uF

R25

205K

COUT1,2,3

3x10uF

1210

R17

10K

C14

0.1uF

0805

+

COUT4

150uF

Q1

SUM90P10-19L

R19

10K

L1

10uH

R7

0.006

1225

J4

Q2

SFT1345

R5

35.7K

D1

SZMMSZ5242B

C11

100pF

C10 22uF

10V

schematic Diagram

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

dc2392af

9

Page 10

DEMO MANUAL DC2392A

DEMONSTRATION BOARD IMPORTANT NOTICE

Linear Technology Corporation (LTC) provides the enclosed product(s) under the following AS IS conditions:

This demonstration board (DEMO BOARD) kit being sold or provided by Linear Technology is intended for use for ENGINEERING DEVELOPMENT

OR EVALUATION PURPOSES ONLY and is not provided by LTC for commercial use. As such, the DEMO BOARD herein may not be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including but not limited to product safety

measures typically found in finished commercial goods. As a prototype, this product does not fall within the scope of the European Union

directive on electromagnetic compatibility and therefore may or may not meet the technical requirements of the directive, or other regulations.

If this evaluation kit does not meet the specifications recited in the DEMO BOARD manual the kit may be returned within 30 days from the date

of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY THE SELLER TO BUYER AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THIS INDEMNITY, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user releases LTC from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. Also be aware that the products herein may not be regulatory compliant or

agency certified (FCC, UL, CE, etc.).

No License is granted under any patent right or other intellectual property whatsoever. LTC assumes no liability for applications assistance,

customer product design, software performance, or infringement of patents or any other intellectual property rights of any kind.

LTC currently services a variety of customers for products around the world, and therefore this transaction is not exclusive.

Please read the DEMO BOARD manual prior to handling the product. Persons handling this product must have electronics training and

observe good laboratory practice standards. Common sense is encouraged.

This notice contains important safety information about temperatures and voltages. For further safety concerns, please contact a LTC application

engineer.

Mailing Address:

Linear Technology

1630 McCarthy Blvd.

Milpitas, CA 95035

Copyright © 2004, Linear Technology Corporation

Linear Technology Corporation

10

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

dc2392af

LT 1215 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2015

Loading...

Loading...