Page 1

QUICK START GUIDE FOR DEMONSTRATION CIRCUIT 802

DESCRIPTION

LTC3828 DUAL 2-PHASE STEP DOWN CONVERTER WITH TRACKING

LTC3828EUH

Demonstration circuit 802 features the dual-output,

2-phase synchronous buck regulator LTC3828EUH.

The input voltage range of the demo board is 7V to

21V. The outputs are 5V/5A

and 3.3V/5A

MAX

MAX

. Depending on the setting of the optional resistors and

jumpers, each output can track an external ramp

voltage during start up or one output can track another output on the same board during start up. At

light load, the supplies can operate in high efficiency

mode or low output ripple mode depending on

jumper selection.

The switching frequency is a jumper-selectable

250kHz or 550kHz, or one resistor can set the frequency anywhere in between. The supply can also be

synchronized by an external clock signal. A

CLOCKOUT pin provides an output clock signal to

synchronize other supplies if needed. The

LTC3828EUH regulator IC is in a small 5 mm x 5 mm

package with exposed thermal pad for low thermal

impedance.

Design files for this circuit board are available.

Call the LTC factory.

, LTC and LT are registered trademarks of Linear Technology Corporation.

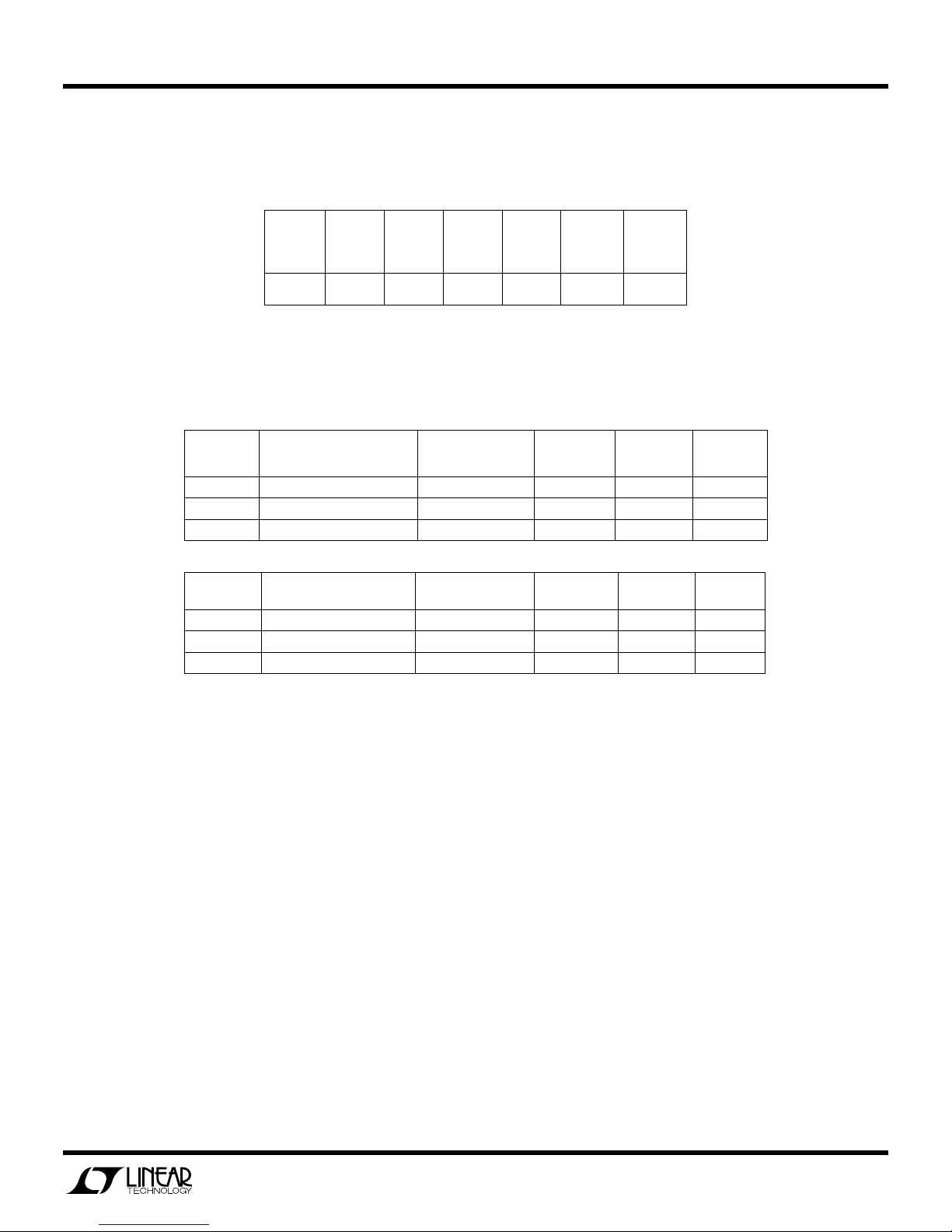

Table 1. Performance Summary (TA = 25°C)

PARAMETER CONDITION VALUE

Input Voltage 7V-21V

Output Voltage V

Output Voltage V

Maximum Output Current VIN = 7V-21V 5A Each Output

Switching frequency FCB = CCM

Full Load Efficiency VIN = 12V, V

VIN = 12V, V

I

OUT1

I

OUT2

= 0A to 5A 5V ± 2%

OUT1

= 0A to 5A 3.3V ± 2%

OUT2

OUT1

OUT2

= 5V, I

= 3.3V, I

= 5A, fsw=550kHz 93% Typical

OUT1

= 5A, fsw=550kHz 91% Typical

OUT2

Jumper selectable

250kHz or 550kHz

QUICK START PROCEDURE

Demonstration circuit 802 is easy to set up to evaluate the performance of the LTC3828EUH. Refer to

Figure 1 for proper measurement equipment setup

and follow the procedure below:

NOTE:

When measuring the input or output voltage

ripple, care must be taken to avoid a long ground lead

on the oscilloscope probe. Measure the input or output voltage ripple by touching the probe tip directly

1

Page 2

QUICK START GUIDE FOR DEMONSTRATION CIRCUIT 802

LTC3828 DUAL 2-PHASE STEP DOWN CONVERTER WITH TRACKING

across the Vin or Vout and GND terminals. See Figure 2 for proper scope probe technique.

1.

Following table should be the default jumper settings of the DC802A demo board:

JP1

PHSMD

0 550kHz CCM ON ON VOUT1 EXT1

JP2

FSET

JP3

FCB

JP4

RUN1

JP5

RUN2

JP6

TRACK2

JP7

TRACK1

With the above default setting, the supply runs at 550kHz forced continuous current mode.

Following tables show the assembly options for the tracking circuits for VOUT1 and VOUT2:

VOUT1 TRACKING

*

1

2 Track EXT1 EXT1 105K 20K DNP

3 Track VOUT2 VOUT2 105K 20K DNP

OPTIONS TRACK2 JP6 R23 R25 C21

Softstart W/O tracking N/A DNP DNP 0.01uF

VOUT2 TRACKING

1 Softstart W/O tracking N/A DNP DNP 0.01uF

2 Track EXT2 EXT2 95.3K 30.1K DNP

*

3

OPTIONS TRACK1 JP7 R24 R26 C22

Track VOUT1 VOUT1 95.3K 30.1K DNP

*With existing tracking circuit assembly, VOUT1 starts independently (option1). VOUT2 tracks VOUT1 during start

up (option3). Figure 3 shows a typical start-up waveform with tracking.

2.

With power off, connect the input power supply to

VIN and GND. Connect the load between VOUT1

and GND, VOUT2 and GND. Preset the load current

at 0A (minimum). Refer to Figure 1 for correct test

set up.

3.

Turn on the input power.

NOTE:

Make sure that the input voltage does not ex-

ceed 21V.

4.

Check for the proper output voltages. Vout1 =

4.90V-5.10V. Vout2 = 3.23V- 3.36V

NOTE:

If there is no output, temporarily disconnect

the load to make sure that the load is not set too

high.

5.

Once the proper output voltages are established,

adjust the loads within the operating range and observe the output voltage regulation, ripple voltage,

efficiency and other parameters.

2

Page 3

QUICK START GUIDE FOR DEMONSTRATION CIRCUIT 802

VIN

GND

LTC3828 DUAL 2-PHASE STEP DOWN CONVERTER WITH TRACKING

Figure 1. Proper Measurement Equipment Setup

Figure 2. Measuring Input or Output Ripple

3

Page 4

QUICK START GUIDE FOR DEMONSTRATION CIRCUIT 802

LTC3828 DUAL 2-PHASE STEP DOWN CONVERTER WITH TRACKING

Vo1

Vo2

Figure 3. Typical Output Voltage Tracking Waveform during Start-Up

4

Page 5

QUICK START GUIDE FOR DEMONSTRATION CIRCUIT 802

LTC3828 DUAL 2-PHASE STEP DOWN CONVERTER WITH TRACKING

5

Loading...

Loading...