Page 1

Description

DEMO MANUAL DC2064A

LTC3300-1/LTC6803-2

Bidirectional Cell Balancer

Demonstration Circuit DC2064A is a bidirectional cell

®

balancer using two LT C

3300-1 ICs to achieve active cell

balancing of up to 12 Li-Ion batteries. The board uses the

LTC6803-2 multi-cell addressable battery stack monitor to

measure cell voltages and two LTC3300-1 ICs to provide

active cell balancing. The demonstration circuit uses a two

window GUI developed for the DC2064A. One window is

a modified version of the GUI for the LTC6803-2 and also

contains a tab to control the LTC3300-1 ICs through the

DC590B USB Serial controller and the second window

performance summary

Battery Voltage Range 3.2V to 4.5V (2.5V to 4.5V)*

Stack Voltage 60V Max

Average Battery Balancing Charge Current (12 Cell) 2.6A (Typ) (4A)*

Average Battery Balancing Discharge Current (12 Cell) 2.4A (Typ) (3.6A)*

Average Battery Balancing Charge Current (6 Cell) 2.2A (Typ) (3.3A)*

Average Battery Balancing Discharge Current (6 Cell) 2.4A (Typ) (3.6A)*

Balancing Efficiency 92% (Typ)

*The battery voltage range may be expanded to 2.5V-4.5V by changing resistor R

The demo board’s average balancing current is adjustable up to 4A by scaling and installing new values of RS1A and RS1B through RS12A and RS12B.

Specifications are at TA = 25°C

reports the status of the LTC3300-1 devices. All the

functions of the LTC6803-2 GUI are supported except

that cell balancing is achieved through the LTC3300-1

ICs by transferring charge from one to six batteries per

LTC3300-1 to the stack or from the stack to one to six

batteries per LTC3300-1.

Design files for this circuit board are available at

http://www.linear.com/demo/DC2064A

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Linear

Technology Corporation. All other trademarks are the property of their respective owners.

to 19.1k and resistor R

TONS

TONP

to 29.4k.

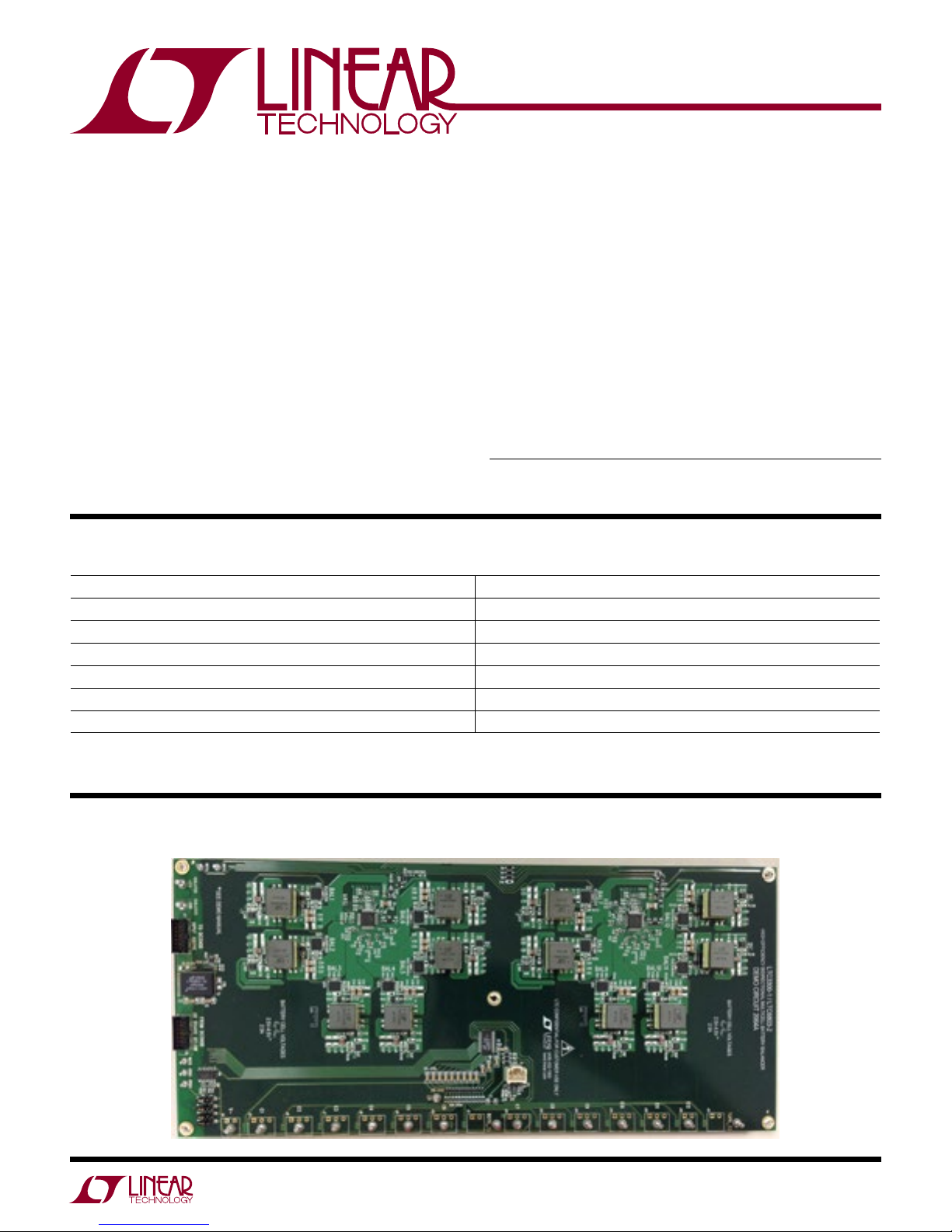

BoarD photo

dc2064afa

1

Page 2

DEMO MANUAL DC2064A

Description

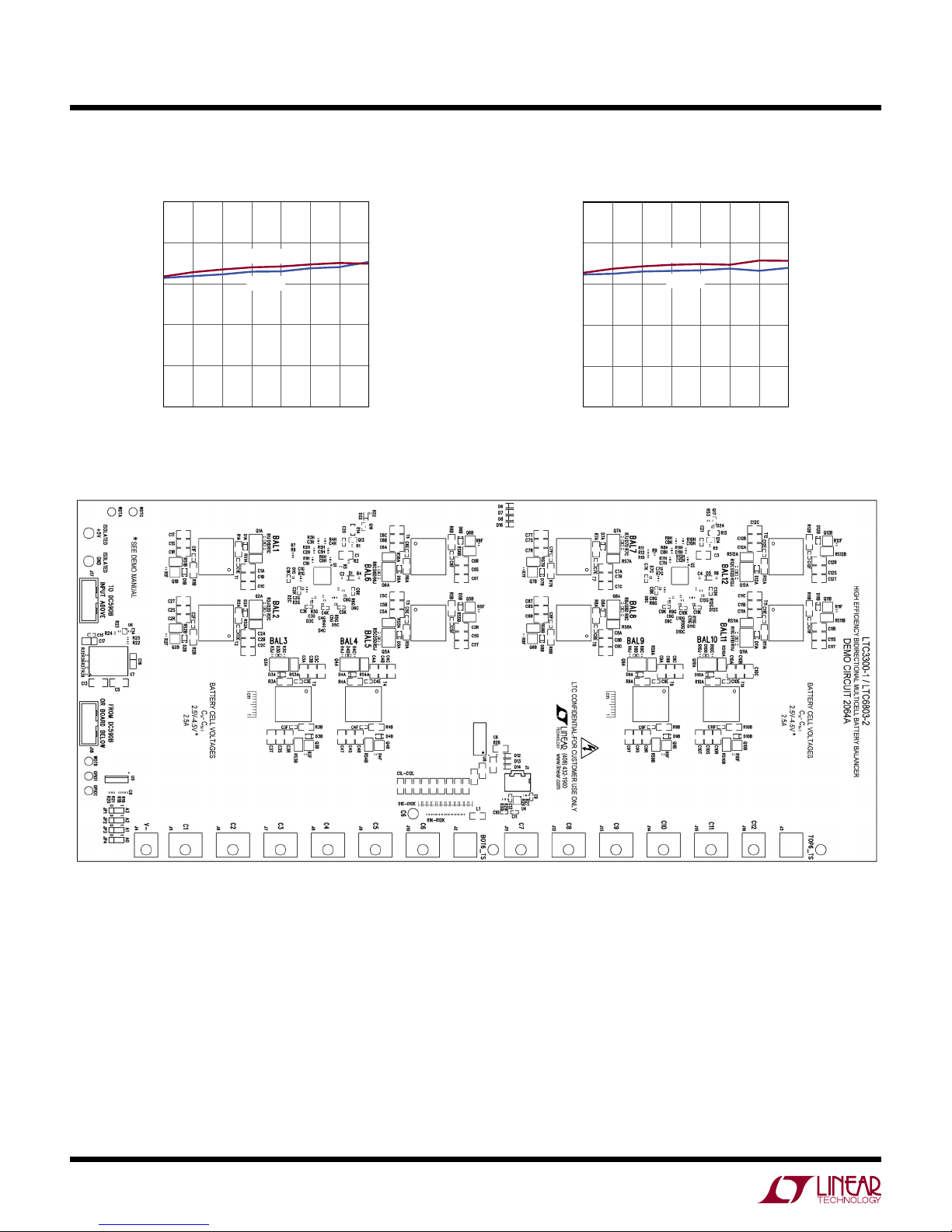

Power Stage Discharge Efficiency Power Stage Charge Efficiency

100

100

95

90

85

EFFICIENCY (%)

80

75

2.6 2.8

6-CELL

12-CELL

3.4

3.2

3.0

CELL VOLTAGE (V)

3.6

3.8

4.0

95

90

85

EFFICIENCY (%)

80

75

2.6 2.8

6-CELL

12-CELL

3.4

3.2

3.0

CELL VOLTAGE (V)

3.6

3.8

4.0

2

Figure 1. DC2064A Size 5.5" × 12.2"

dc2064afa

Page 3

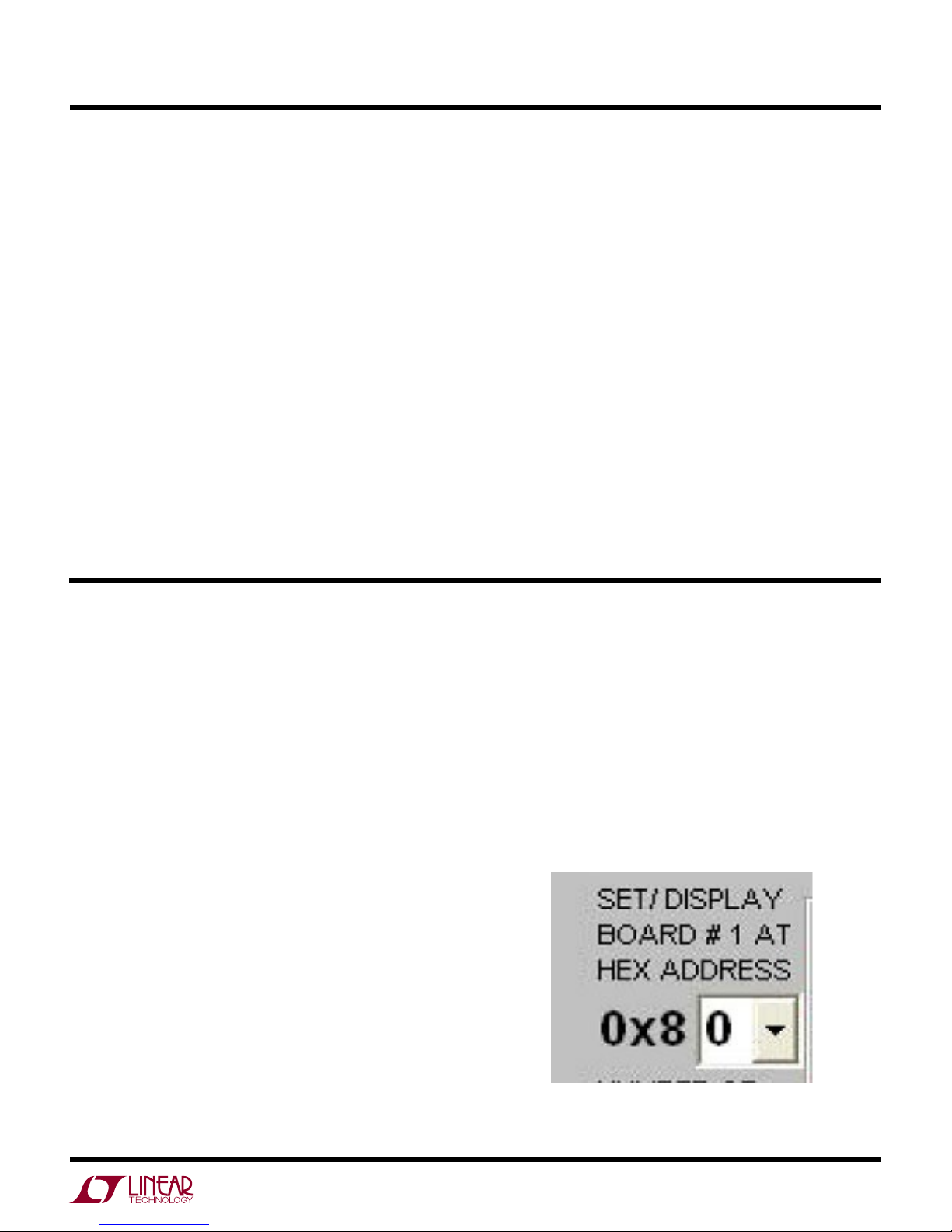

operating principle

DEMO MANUAL DC2064A

Operation of the LTC6803-2 is detailed in the LTC6803-2

data sheet and the operation of the DC2064A GUI is similar

to the DC1652A GUI except additional functionality was

added to control the LTC3300-1 balancing devices. Refer

to the Quick Start Guide for the DC1652B for operation

of the LTC6803-2 GUI. The DC2064A has a two window

GUI, one window based on the DC1652A GUI to control

the LTC6803-2 with a tab to control the LTC3300-1 for

battery balancing and the second window to display the

status of the LTC3300-1 based on the command and status

registers read from the LTC3300-1.

The LTC3300-1 active balancer is a power stage control

IC. The LTC3300-1 does not have a balancer algorithm

built into it. The determination of the balancing times and

directions are performed at a system level and conveyed to

the LTC3300-1 through its SPI interface. The LTC3300-1

only accepts battery charge or discharge commands.

Quick start proceDure

Charge is transferred to/from a cell (battery) from/to the

stack, a series connection of adjacent cells, through a

flyback converter that is operating in boundary mode.

During discharge of a cell, the current in the primary of

a coupled inductor transformer with a turns ratio of 1:2,

ramps up to 6.25A at which point the primary switch turns

off. The charge in the primary inductor is transferred to

the secondary inductor which is connected across the

12-cell pack. This pack current then passes through the

series connected cells thus distributing the charge equally

across each cell. When charging a cell, the current, in the

secondary of the coupled inductor transformer, ramps up

to 3.125A at which point the secondary switch turns off.

The charge in the secondary inductor is transferred to the

primary inductor which is connected across the cell. The

secondary current is drawn from the series connected

cells thus removing charge equally across each cell. The

efficiency through the flyback converter is ≈92%.

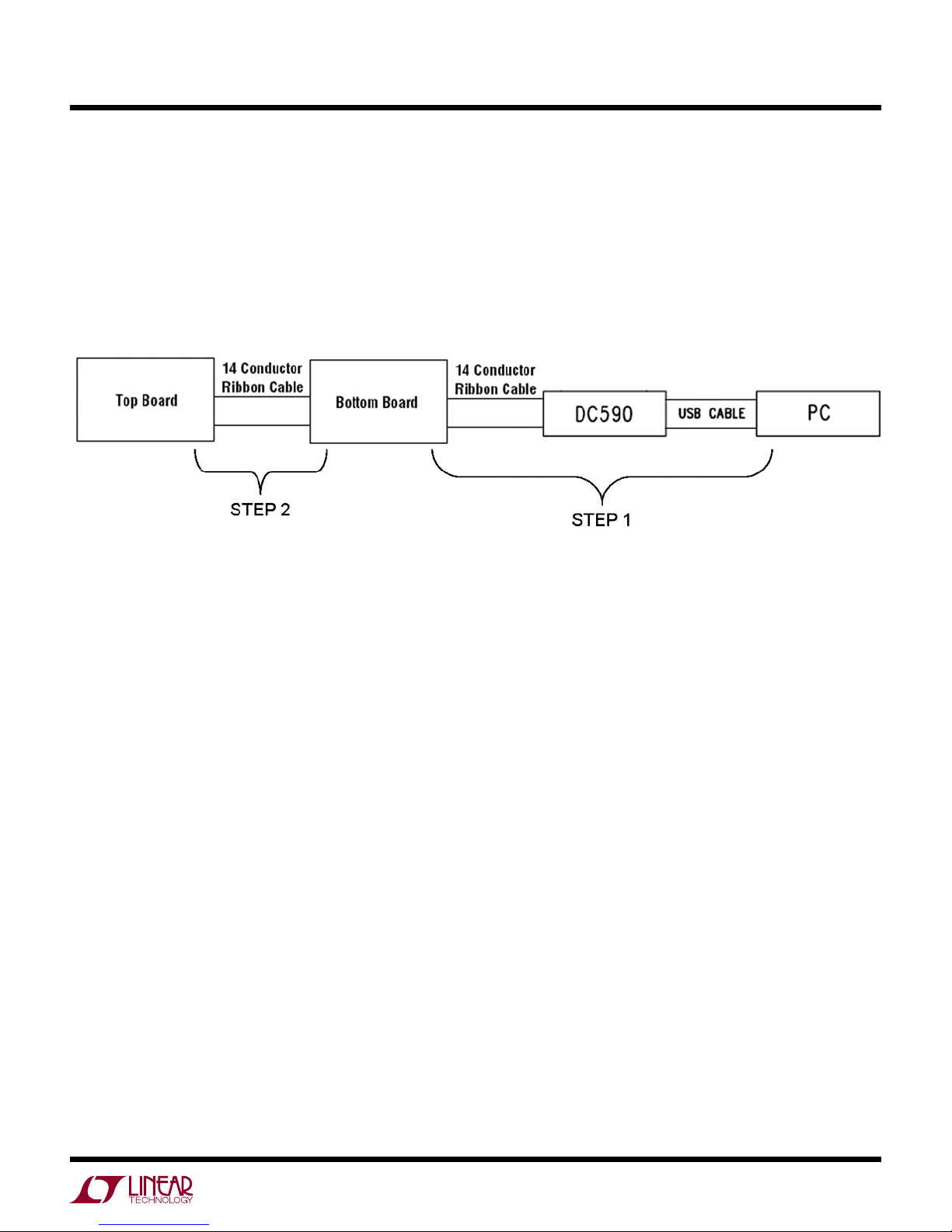

The demonstration circuit is set up per Figure 29 to evaluate

the performance of the DC2064A bidirectional cell balancer

using the LTC3300-1.

Caution: BOT6_TS and TOP6_TS turrets must not be allowed to float and must be connected to their respective

top of stack-battery terminal.

Using short twisted-pair leads for any power connections, refer to Figure 29 for the proper measurement and

equipment setup. The DC2064A will support a system of

4 to 12 batteries.

Recommended Cell Connection Sequence

The recommended cell connection sequence is to connect

the V– connection first followed by connecting cells 1

through cell 12. Disconnection of the cells should follow

this sequence in the reverse order with the V– connection

being removed last. Connecting the V– connection first and

removing last is recommended because the V

is the ground reference for the circuitry within the demo

board. After connecting the V

sequence is less critical as long as the cell circuit

capacitances are matched as they are in the demo board.

–

, all other cell connection

–

connection

Following the recommended cell connection removes the

possibility of excessive voltage on any of the lower cells

due to an imbalance in cell circuit capacitance.

Follow the procedure outlined in the DC1835A Quick

Start Guide for general use of the modified LTC6803-2

GUI window. The 4-bit board ID code that is set by the

A0 through A3 jumpers on the DC2064A must match the

board Address box in the LTC6803-2 GUI window shown

in Figure 2 for each board in the system.

Figure 2. Board Address Box

dc2064afa

3

Page 4

DEMO MANUAL DC2064A

Quick start proceDure

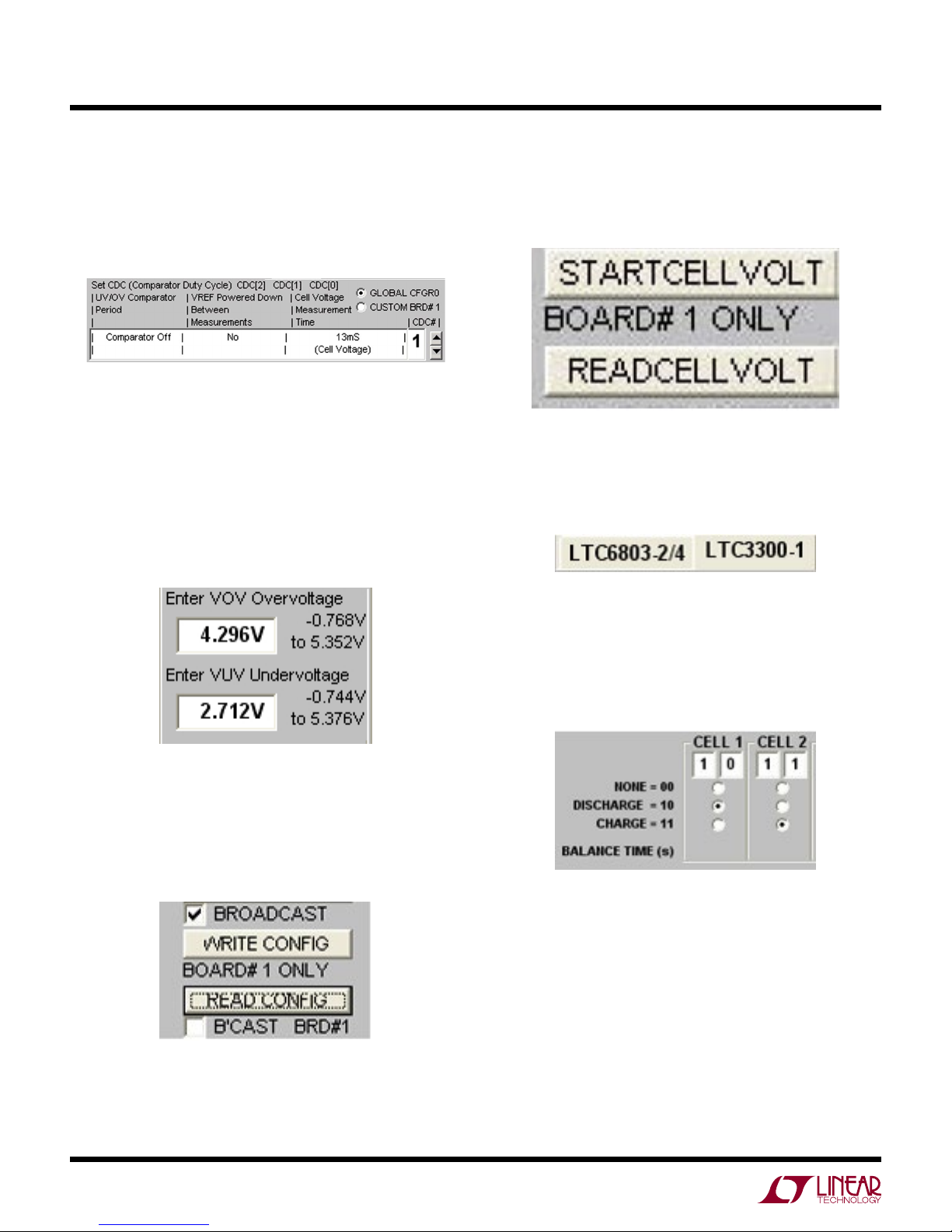

The Voltage Comparator box must be turned off and the

VREF must remain on during balancing. Set window by

using the Up/Down arrows to the right of the box. See

Figure 3.

Figure 3. Voltage Comparator Box

The DC2064A GUI periodically checks for OV and UV

measured on the cells when balancing. To avoid the

program from suspending balancing from an OV or UV

measurement during normal operation, the OV and UV

values must be entered in the VOV and VUV text boxes

on the LTC6803-2 tab shown in Figure 4.

Click the START CELL VOLT button followed by the READ

CELL VOLT to verify that the batteries are connected and

that the LTC6803-2 can read the battery voltages.

Figure 6. Start Cell Voltage Read Box

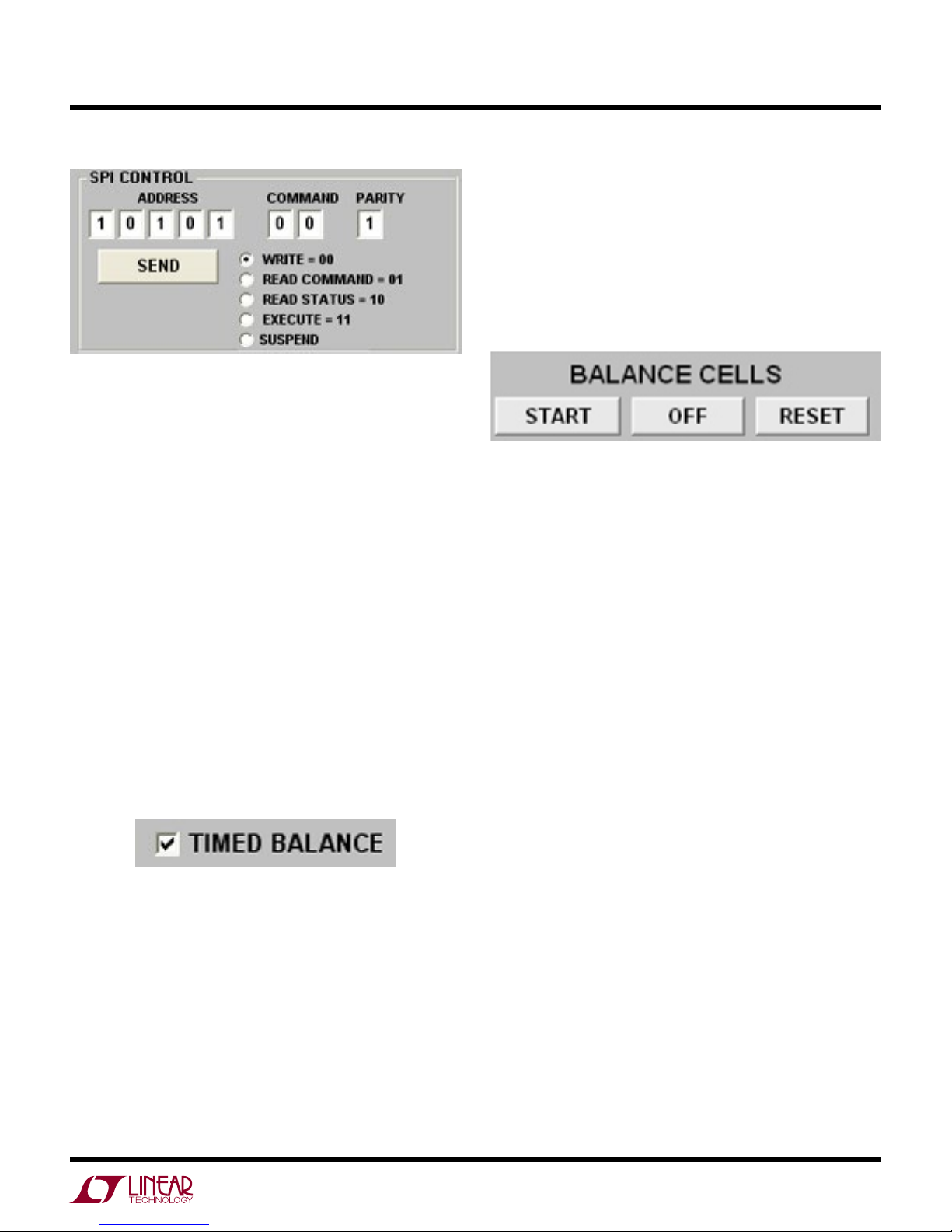

To access the LTC3300-1 screen, click on the LTC3300-1

tab in the upper left of the LTC6803-2 GUI window.

Figure 7. LTC3300-1 Screen Select Box

Figure 4. VOV and VUV text boxes

Once this is done, Click the WRITE CONFIG button and

verify that the configuration was set correctly by clicking

the READ CONFIG.

Figure 5. Write Configuration Box

Within this window you can manually select which cells

are to be discharged by clicking the cell’s DISCHARGE

button and which cells are to be charged by clicking the

cell’s CHARGE button.

Figure 8. Balance Mode Select Boxes

To write this configuration, the WRITE button followed by

the SEND button must be clicked. To enable the balancers,

the EXECUTE button followed by the SEND button must be

clicked. To pause the cell balancers, the SUSPEND button

is clicked followed by clicking the SEND button. This will

turn off all balancers until the EXECUTE button is clicked

followed by clicking the SEND button. This will resume

the previous settings of the cell charge/discharge settings.

4

dc2064afa

Page 5

Quick start proceDure

Figure 9. Write/Execute Command Box

To change any of the settings “on the fly”, a new charge/

discharge setting is entered using the respective CHARGE

and DISCHARGE buttons followed by clicking the WRITE

button followed by the SEND button and then the EXECUTE

button followed by the SEND button. To disable any cell

from operating, the cell’s NONE button must be clicked

in the balance mode box followed by clicking the WRITE

button followed by the SEND button and then the EXECUTE

button followed by the SEND button.

The LTC3300-1 GUI allows the user to program the balancer

to charge or discharge each cell for a specific amount of

time. The LTC3300-1 is a power stage control IC. The

determination of the balancing times and directions are

done at the System level and conveyed to the LTC3300-1

through its SPI communications port. In order to perform

a timed balance, the TIMED BALANCE check shown in

Figure 10 must be selected to have access to the timed

balance controls as shown in Figure 27.

DEMO MANUAL DC2064A

To do this, select the DISCHARGE or CHARGE button for

the desired cell, then enter the time in seconds into the

cells “BALANCE TIME” text box. Press the enter key on

the key board or select another button in the GUI to load

the time. When all the desired balance actions and times

have been entered, select the “Balance Cells” START but

ton to start the balancing sequence.

Figure 11. Balance Cells Start Box

The START button will display PAUSE. The balancing

algorithm will first turn off all cells, then set all cells to

be balanced. The cells will run until the first cell(s) have

elapsed their balance time. At this time all cell balancing is

suspended, the completed cell’s balancing action is set to

“None”, the remaining times to balance are recalculated,

then the remaining cells continue to balance until the next

cell(s) have completed. This sequence continues until all

of the balance times have elapsed.

Selecting the PAUSE button while the balancer is running,

will shut off the active cell and pause the timer. The START

button now displays CONTINUE. Selecting the CONTINUE

button again will start the active cell balancing and continue

the timer. After the last cell has completed balancing, all

the cells are turned off. The START button will again display

START. Selecting the RESET button will reset all the cell

actions and times to the previous entered settings.

-

Figure 10. TIMED BALANCE Check Box

The LTC3300 STATUS window displays the status of all

LTC3300-1 ICs in the system. This GUI is updated every

time the LTC3300-1 status or command registers are read.

When the balancer

is read after each execute command is sent.

timer is running, the command register

dc2064afa

5

Page 6

DEMO MANUAL DC2064A

Vm1• Vm2• 10

Vm3• Vm

Vm5• Vm6• 10

Vm7• Vm

Quick start proceDure

Cell Balancer Efficiency Measurements:

Figure 30 shows the proper connections for measuring

the efficiency of a cell balancer. The secondary of the cell

balancer connects to the top of stack. This connection

needs to be to an isolated power source through a current

sensing resistor (0.10Ω). Cells 1 through 6 are connected

to the BOT6_TS turret with its return path the V– turret

while Cells 7 through 12 are connected to the TOP6_TS

turret with its return path the C6 turret. The primary side

connections of the cell balancers are connected to a string

of batteries that simulate the battery stack. Cell 1 is a 2-wire

connection that connects the positive node, through a

current sensing resistor (0.01Ω), to the C1 turret, and the

negative node to the V– turret. Remote sense connections

for power sources with remote sensing capabilities should

be connected to the C1 and V– respectively. All other

connections of the simulated string of batteries connect

their positive node, through a current sensing resistor

(0.01Ω), to respective turrets. Cell voltage measurements

should be made across the C(x) and C(x – 1) turrets of

the respective cells. Stack voltage measurements should

be made at the BOT6_TS and TOP6_TS turrets and

return path turret.

their

Cells 7-12

Charge Mode

Efficiency11=

Discharge Mode

Efficiency11=

Cell Balancer Performance Measurements:

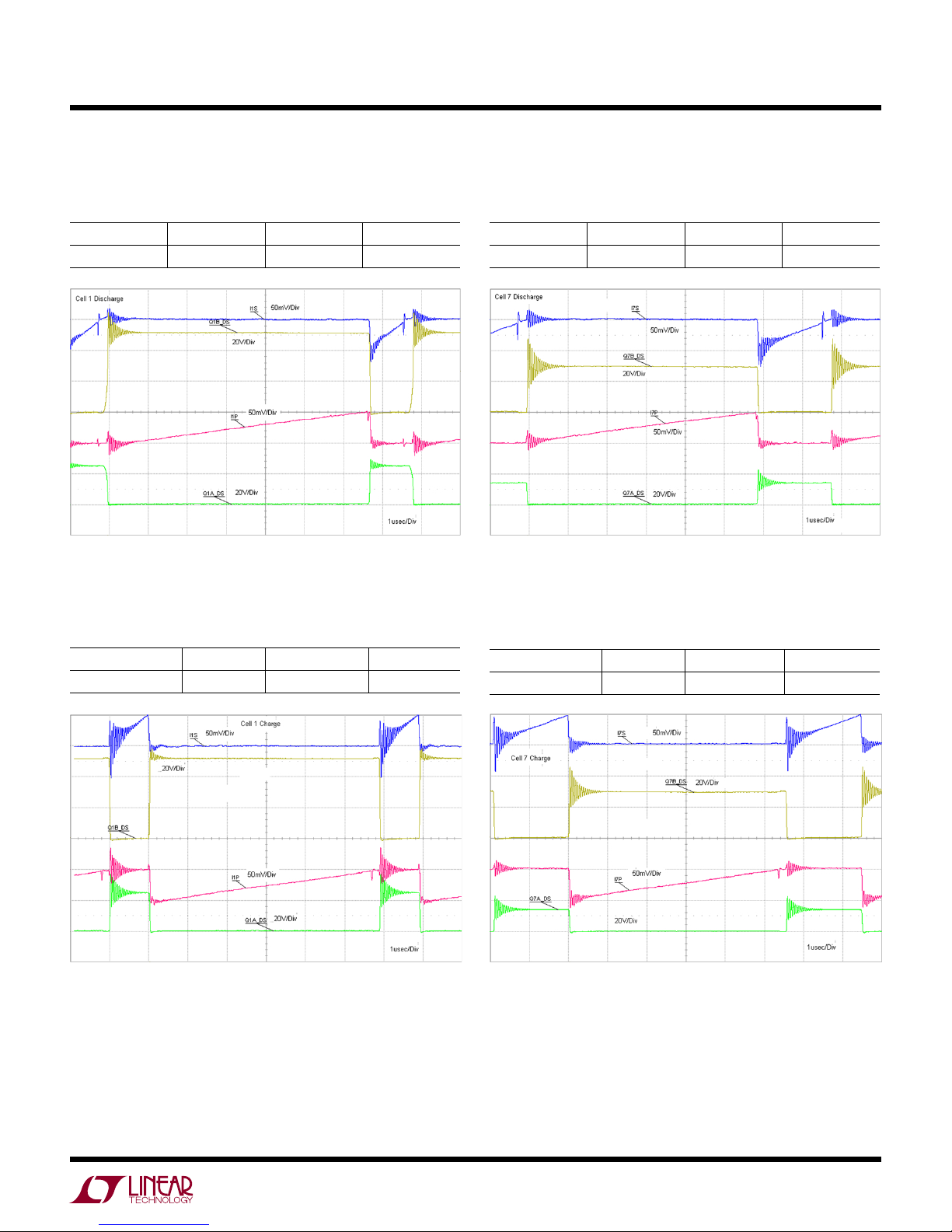

Table 2 through Table 5 present the typical operational data

for a 12-cell and 6-cell balancer in both Discharge and

Charge modes. The cell voltages were 3.6V and measure

ments of Cell Current, Stack Current, Operating Frequency

were taken and

the data. Figure 12 through Figure 15 are actual in circuit

waveforms taken on Cell 1 and Cell 7 while operating in

both modes. The waveforms present voltage on the pri

mary side

voltage and the

sense inputs to the LTC3300-1.

and secondary side MOSFET’s drain to source

Vm7• Vm

Vm5• Vm6• 10

transfer Efficiency was calculated from

primary side and secondary side current

8

8

• 100%

• 100%

-

-

To calculate cell balancer efficiency use the expressions

below:

Cells 1-6

Charge Mode

Efficiency1=

Discharge Mode

Efficiency1=

Vm3• Vm

Vm1• Vm2• 10

4

4

• 100%

• 100%

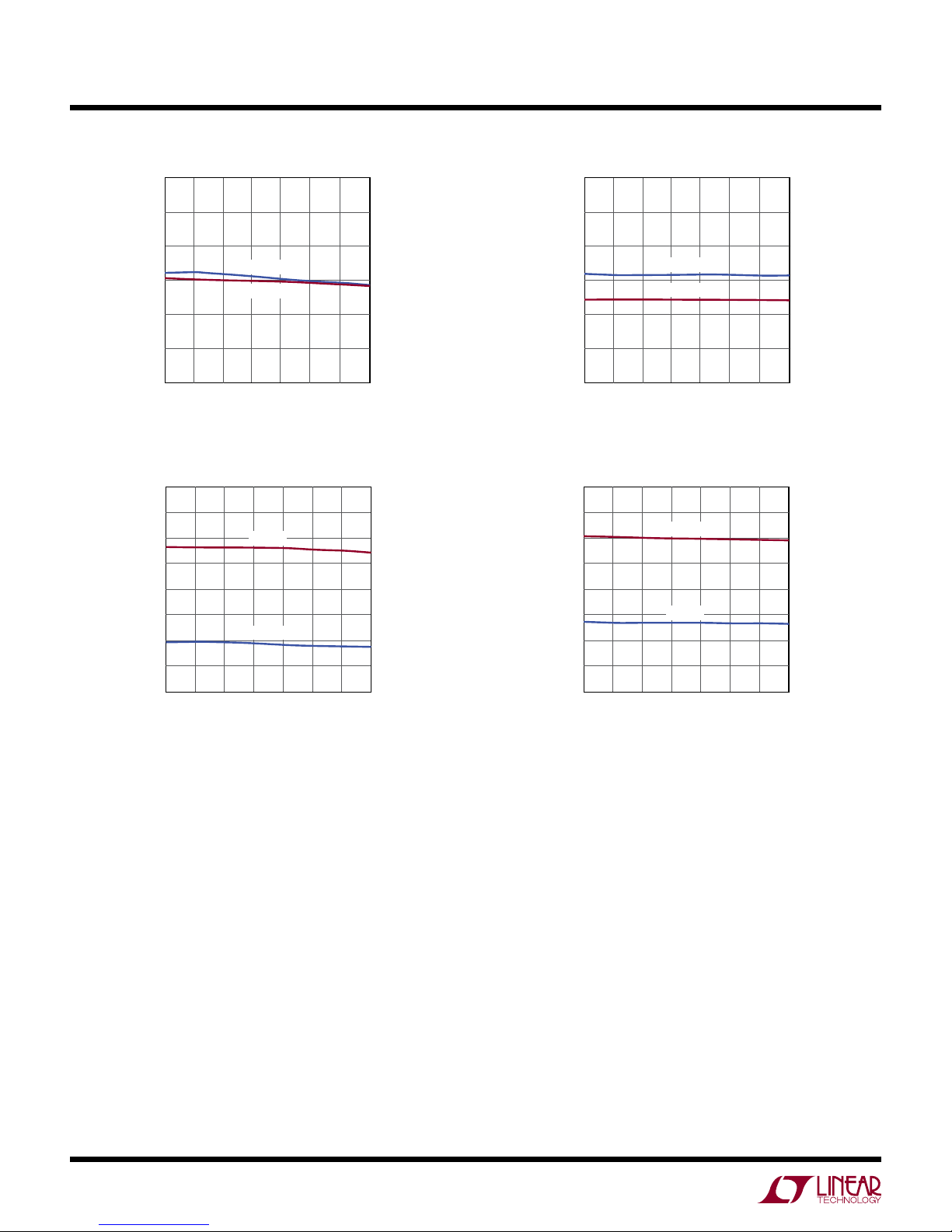

Figures 16 through 19 are cell and stack currents taken

over a range of cell voltages from 2.6V to 4.0V. The RTONP

and RTONS resistors for these graphs were set for 2.6V

cell voltage operation. All cells were set to the cell voltage

under test. The slight negative slope in current at higher

voltages is due to the increased operating frequency

and the circuit delays and dead time becoming a higher

percent-age of the operating period.

6

dc2064afa

Page 7

Quick start proceDure

DEMO MANUAL DC2064A

12 Cell Discharge

Table 2. Typical 12 Cell Discharge Data

Cell I (A) Stack I (A) Frequency (kHz) Efficiency

2.444 0.188 127.7 92.21%

Figure 12. 12 Cell Discharge Waveforms

12 Cell Charge

6 Cell Discharge

Table 4. Typical 6 Cell Discharge Data

Cell I (A) Stack I (A) Frequency (kHz) Efficiency

2.448 0.277 126.1 92.33%

Figure 14. 6 Cell Discharge Waveforms

6 Cell Charge

Table 3. Typical 12 Cell Charge Data

Cell I (A) Stack I (A) Frequency (kHz) Efficiency

2.601 0.237 149.1 91.71%

Figure 13. 12 Cell Charge Waveforms

Table 5. Typical 6 Cell Charge Data

Cell I (A) Stack I (A) Frequency (KHz) Efficiency

2.219 0.399 133.1 92.72%

Figure 15. 6 Cell Charge Waveforms

dc2064afa

7

Page 8

DEMO MANUAL DC2064A

Quick start proceDure

4.0

3.5

3.0

2.5

2.0

CELL DISCHARGE CURRENT (A)

1.5

1.0

2.6

2.8 3.0

12-CELL

6-CELL

3.4 3.8 4.0

3.2 3.6

CELL VOLTAGE (V)

Figure 16. Cell Discharge Current

0.50

0.45

0.40

0.35

0.30

0.25

0.20

STACK DISCHARGE CURRENT (A)

0.15

6-CELL

12-CELL

4.0

3.5

3.0

2.5

2.0

CELL CHARGE CURRENT (A)

1.5

1.0

2.6

2.8 3.0

CELL VOLTAGE (V)

Figure 18. Cell Charge Current

0.50

0.45

0.40

0.35

0.30

0.25

0.20

STACK CHARGE CURRENT (A)

0.15

12-CELL

6-CELL

3.4 3.8 4.0

3.2 3.6

6-CELL

12-CELL

0.10

2.8 3.0 3.4

2.6

3.2

CELL VOLTAGE (V)

3.6 3.8 4.0

Figure 17. Stack Discharge Current

0.10

2.8 3.0 3.4

2.6

3.2

CELL VOLTAGE (V)

Figure 19. Stack Charge Current

3.6 3.8 4.0

8

dc2064afa

Page 9

Quick start proceDure

DEMO MANUAL DC2064A

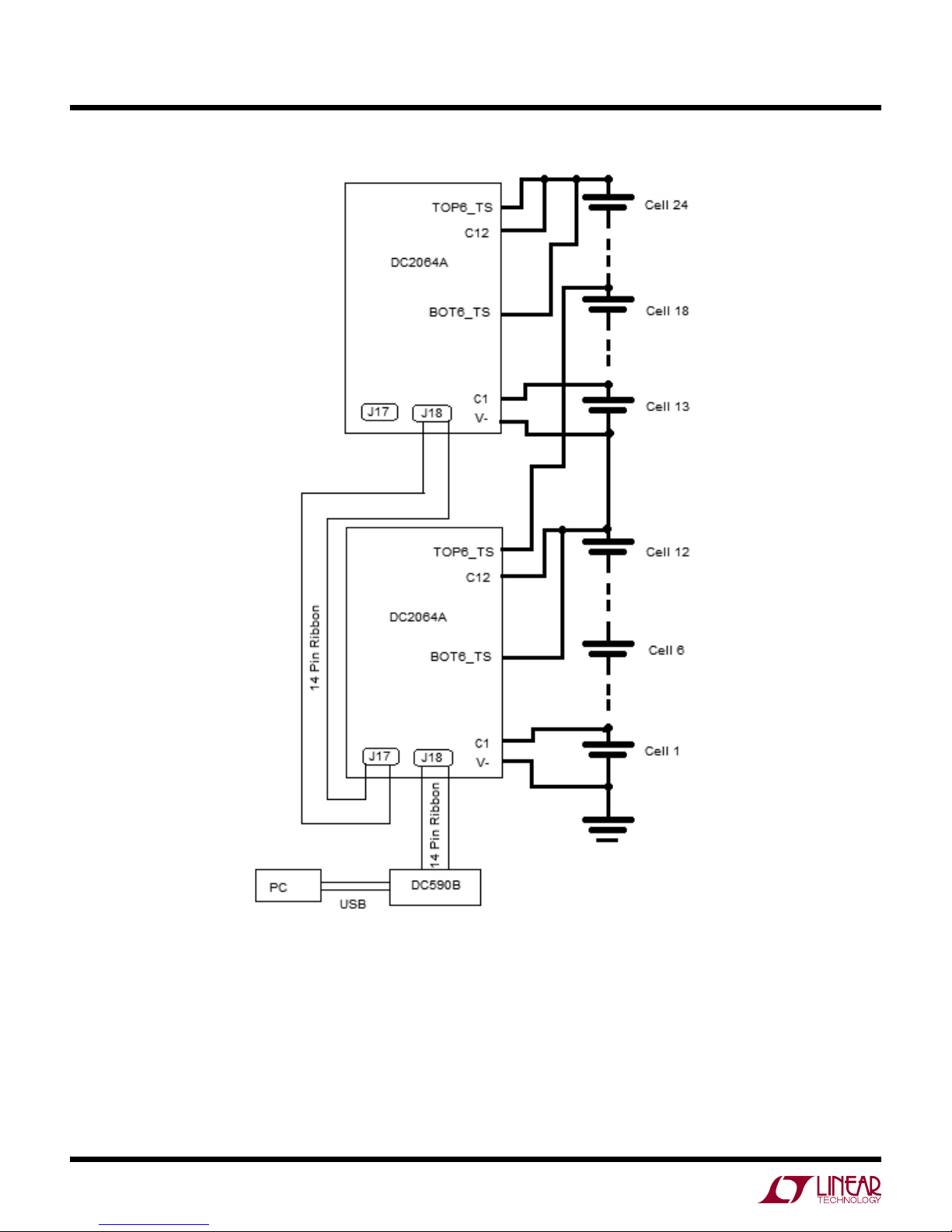

Tw o Board Setup and Operation:

As a result of communication latency to the PC, the system

only supports two series DC2064A boards

When connecting two DC2064A boards together, the in

terface cables must be

in Figure 20 to avoid large inrush currents. The DC590B

DC2064A DC2064A

connected in sequence as shown

Figure 20. Tw o DC2064A SPI Connection Sequence

-

must be connected to the PC USB port and the bottom

DC2064A board first and then the top DC2064A board

may be connected.

The 24 cells should be interconnected to allow balancing

between the two 12-cell stacks, as shown in Figure 21.

dc2064afa

9

Page 10

DEMO MANUAL DC2064A

Quick start proceDure

10

Figure 21. 24 Cell Interconnected Stacks

dc2064afa

Page 11

Quick start proceDure

DEMO MANUAL DC2064A

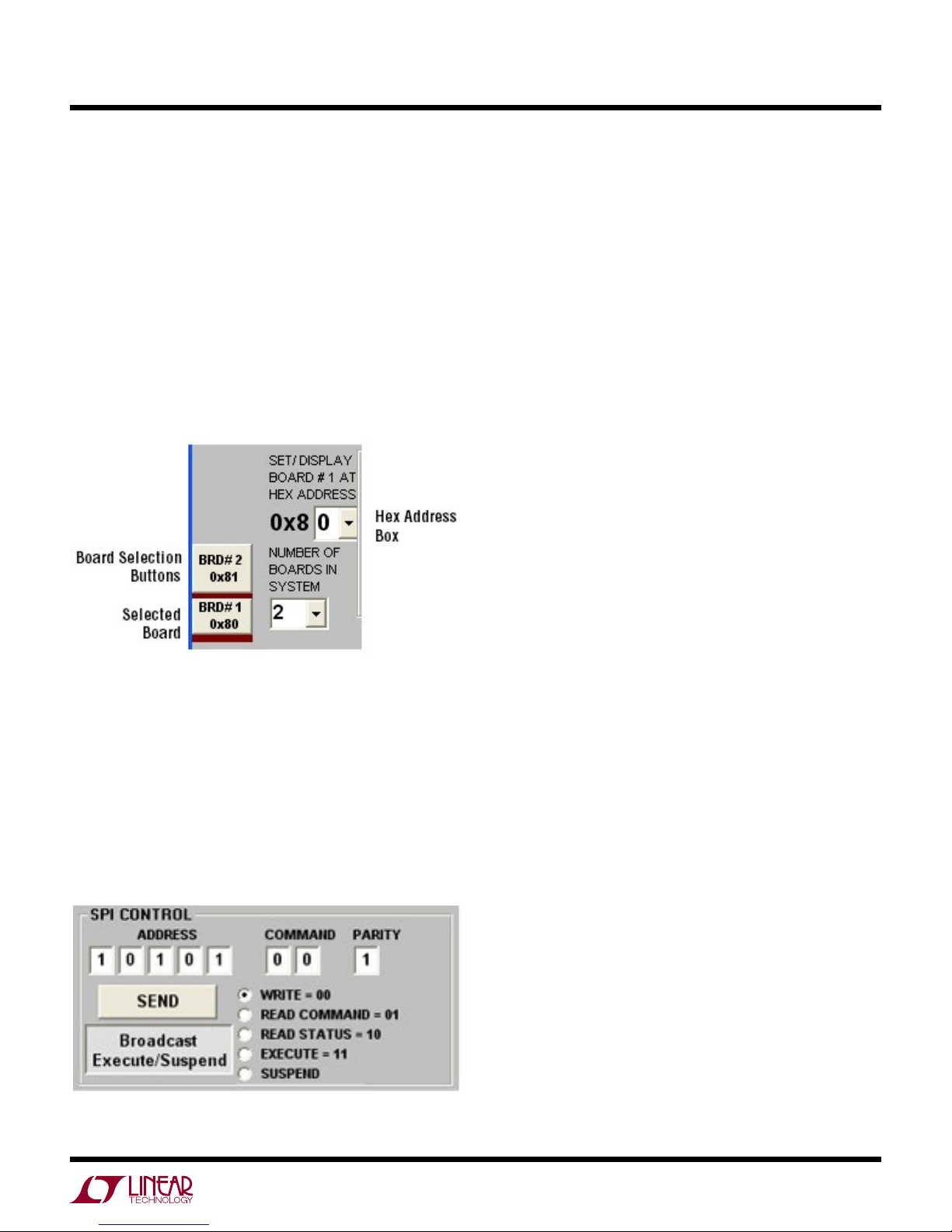

On the LTC6803-2 tab on the DC2064A GUI, the Number

of Boards in the System drop down box will need to be

changed to 2. Make sure the address for each board in

the Hex Address box matches the address set by the A0

to A3 jumpers on the respective DC2064A board. The

board selection buttons on the bottom left side of the GUI

highlight which board is selected in maroon, as shown

and the set hexadecimal address is displayed under each

board. To change the hexadecimal address on the GUI,

select the board to change by clicking on the appropriate

board selection number and then select the correct ad

dress in the Hex Address Box.

Figure 22. DC2064A GUI Board Selection Controls

To set up the charge and discharge actions for each

LTC3300, the appropriate board must be selected first and

then the commands for each LTC3300-1 can be selected

and written to the LTC3300-1 tab. When all the desired

actions are selected and written to the four LTC3300-1

ICs, then a single execute command will send an execute

command to both boards simultaneously provided the

Broadcast Execute/Suspend button is selected as shown

in Figure 23.

-

Additional Circuitry

Additional circuitry has been added to increase the robustness of the design for fault insertions.

6 Wire Disconnection

Cell

A 10A

200V Schottky diode has been added for a high

current path when the connection between battery cells

is broken when a battery stack load is present. The 200V

reverse voltage rating of the diode was selected to mini-mize

the reverse leakage current at a battery voltage of 4.2V.

The 10A current rating was selected for its low forward

voltage drop which will minimize the current in the parallel

diode within the LTC3300-1 as well as surviving the fusing

current of the 7A fuses on the DC2064A.

Tw o overvoltage detection circuits have been added to the

design that will sense an overvoltage condition on Cell 6

and Cell 7 when a disconnection of the Cell 6 wire con

nection between

battery stack occurs. When Cell 6 is being discharged and

other cells controlled by the U1, the lower LTC3300-1, and

U2, the upper LTC3300-1 are operational, an overvoltage

can occur on Cell 7. The overvoltage on Cell 7 will shut

down the operation of Cell 7-Cell 12 but Cell 1-Cell 6 will

continue to operate. The overvoltage sensing circuit Q15,

D21, D23 and R51 will turn off the operations of Cell 1-Cell6

through the internal overvoltage protection circuit within

the LTC3300-1 of U1.

A similar event occurs when Cell 6 is operating in the

Charge Mode and the Cell 6 connection from the board

to the battery is lost. The overvoltage on Cell 6 will shut

down the operation of Cell 1-Cell 6 but Cell7- Cell 12 will

continue to operate. The overvoltage sensing circuit Q16,

D22, D24 and R52 will turn off the operations of Cell 7-Cell

12 through the internal overvoltage protection circuit within

the LTC3300-1 of U2.

battery

Cell 6+ and battery Cell 7– of the

-

Figure 23. Broadcast Execute/Suspend Tab

dc2064afa

11

Page 12

DEMO MANUAL DC2064A

Quick start proceDure

Cell Bypass Capacitors

The DC2064A contains bypass capacitors from the cell

connections and the stack connections. These capacitors

have a dual function of smoothing the high triangular

current wave before the current travels down the inter

connecting wires

the voltage between cells when hot-plugging cells in a

random order. The RMS current rating of these capaci

tors is a critical parameter for these bypass capacitors as

well as their physical size. These high triangular current

waveforms produce an RMS current that passes through

the capacitors which result in an internal heat rise. Larger

physical size MLCC capacitors have higher RMS current

rating due to their greater surface area to dissipate the

heat rise. The capacitance of MLCC capacitors decreases

with applied voltage and this must be taken into account

when selecting the capacitance value. If a connection is

lost during balancing, the differential voltage seen by the

LTC3300-1 power circuit on each side of the break may

increase or decrease in depending on whether the power

stage is charging or discharging and where the break

occurred. The worst-case scenario is when the balanc

each side of the break are active and balancing

ers on

in opposite directions.

increase rapidly on one side and decrease rapidly on the

to the

cells and they also help balance

Here the differential voltage will

-

-

-

other. The LTC3300-1 contains an overvoltage protection

comparator which monitors the cell voltage and will shut

down all balancers before the differential voltage on any

cell input reaches the maximum absolute voltage rating.

Each cell node must have an equivalent capacitance across

it to prevent an overvoltage condition when randomly con

necting cells to the LTC3300-1 battery balancer circuit. In

addition to the

power circuit, there are capacitors across the Cx pins of the

LTC3300-1 to reduce high frequency noise on these pins

and capacitors across adjacent cells to act as a reservoir

of charge for the cell’s MOSFET gate driver circuits. These

reservoir capacitors must also be of equal value to maintain

the balancing of voltage and a capacitor of 2x the value

of the reservoir capacitor must be connected between C1

–

of the lowest LTC3300-1 and from the top cell to

and V

the cell below it to insure an equal voltage across all cells

when the battery stack is initially connected. Figures 25

and 26

The reservoir capacitors must be large compared to the

capacitors across the Cx pins to force the MOSFET gate

charging current to flow through the reservoir capacitors.

An effective 10:1 ratio between these cell capacitors was

selected when considering that a capacitor across two

cells would result in a 5:1 ratio.

detail these capacitor connections and their values.

smoothing capacitors across each balancer

-

12

dc2064afa

Page 13

Quick start proceDure

DEMO MANUAL DC2064A

Figure 24. DC2064A LTC6803-2 Setup Screen

dc2064afa

13

Page 14

DEMO MANUAL DC2064A

G1PI1PWDTA

CMMSH2-40

DC2064a F26

C5

Quick start proceDure

D1

1

C4

CMMSH2-40

0.22µF

BOOST

16V

G6P

I6P

36

35

34

33

32

31

30

29

28

27

26

25

C1K

1µF

16V

0603

G5P

I5P

G4P

I4P

G3P

I3P

G2P

I2P

0603

C23

10µF

10V

0805

C3

0.1µF

16V

0402

42

BOOST

SDO

+

–

–

V

2019 21 22 23 24

3738394041

C6 G6P I6PBOOST

C5

G5P

I5P

C4

G4P

I4P

C3

G3P

I3P

C2

G2P

I2P

C1G1PI1PWDT

C6K

1µF

16V

0603

C5K

1µF

16V

0603

C4K

1µF

16V

0603

C3K

1µF

16V

0603

C2K

1µF

16V

0603

R5

0 OPT

Figure 25. Bypass Capacitors on Lowest LTC3300-1

2

C9

4.7µF

16V

0805

C11

4.7µF

16V

0805

C14

4.7µF

16V

0805

1

2

R6

6.81

C10

4.7µF

16V

0805

C12

4.7µF

16V

0805

DC2064a F25

D2

C6

C5

C4

C3

C2

C1

BOOST

42

BOOST

SDO

C7

0.1µF

16V

0402

+

–

C6 G6P I6PBOOST

–

V

2019 21 22 23 24

WDTC

C6

G7PI7P

G12P

I12P

3738394041

36

C5

35

G5P

34

I5P

33

C4

32

G4P

31

I4P

30

C3

29

G3P

28

I3P

27

C2

26

G2P

25

I2P

C1G1PI1PWDT

G11P

I11P

G10P

I10P

G9P

I9P

G8P

I8P

C7K

1µF

16V

0603

C8

0.22µF

16V

0603

D3

1

CMMSH2-40

R9

0 OPT

C12K

1µF

16V

0603

C11K

1µF

16V

0603

C10K

1µF

16V

0603

C9K

1µF

16V

0603

C8K

1µF

16V

0603

1

D4

2

CMMSH2-40

2

R10

6.81

C12

C24

10µF

10V

0805

C13

4.7µF

16V

0805

C11

C10

C9

C8

C7

C15

4.7µF

16V

0805

C17

4.7µF

16V

0805

C18

4.7µF

16V

0805

C16

4.7µF

16V

0805

C20

4.7µF

16V

0805

14

Figure 26. Bypass Capacitors on the Top LTC3300-1

dc2064afa

Page 15

Quick start proceDure

DEMO MANUAL DC2064A

Figure 27. DC2064A LTC3300-1 Setup Screen with Timed Balance Controls

Figure 28. DC2064A LTC3300-1 Status GUI Screen

dc2064afa

15

Page 16

DEMO MANUAL DC2064A

Quick start proceDure

Figure 29. Proper Measurement Equipment Setup for Bidirectional Cell Balancer

Note: All connections from equipment should be Kelvin connected directly to the Board Pins which they are connected

to on this diagram and any input, or output, leads should be twisted pair, where possible.

16

System Setup Requirements:

LFP or Li-Ion Battery ≥ 10AHr

Internal Resistance < 30mΩ

Recommended Battery Simulator:

Power Supply 2V to 5.0 V ±10A

Interconnect Resistance < 25mΩ

dc2064afa

Page 17

Quick start proceDure

DEMO MANUAL DC2064A

Figure 30. Proper Equipment Setup for Cell Balancer Efficiency Measurements

System Setup Requirements:

LFP or Li-Ion Battery ≥ 10AHr

Internal Resistance < 30mΩ

Recommended Battery Simulator:

Power Supply 2V to 5.0 V ±10A

Interconnect Resistance < 25mΩ

dc2064afa

17

Page 18

DEMO MANUAL DC2064A

Quick start proceDure

Figure 31. Proper Equipment Setup for Minimum Number of Cell Efficiency Measurements

18

System Setup Requirements:

LFP or Li-Ion Battery ≥ 10AHr

Internal Resistance < 30mΩ

Recommended Battery Simulator:

Power Supply 2V to 5.0 V ±10A

Interconnect Resistance < 25mΩ

dc2064afa

Page 19

Quick start proceDure

DEMO MANUAL DC2064A

Figure 32. Configuring the Board for Six Batteries

System Setup Requirements:

LFP or Li-Ion Battery ≥ 10AHr

Internal Resistance < 30mΩ

Recommended Battery Simulator:

Power Supply 2V to 5.0 V ±10A

Interconnect Resistance < 25mΩ

dc2064afa

19

Page 20

DEMO MANUAL DC2064A

Quick start proceDure

Figure 33. Configuring the Board for Seven Batteries

System Setup Requirements:

LFP or Li-Ion Battery ≥ 10AHr

Internal Resistance < 30mΩ

Recommended Battery Simulator:

Power Supply 2V to 5.0 V ±10A

Interconnect Resistance < 25mΩ

dc2064afa

20

Page 21

Quick start proceDure

DEMO MANUAL DC2064A

Figure 34. Configuring the Board for Eight Batteries

System Setup Requirements:

LFP or Li-Ion Battery ≥ 10AHr

Internal Resistance < 30mΩ

Recommended Battery Simulator:

Power Supply 2V to 5.0 V ±10A

Interconnect Resistance < 25mΩ

dc2064afa

21

Page 22

DEMO MANUAL DC2064A

Quick start proceDure

22

System Setup Requirements:

LFP or Li-Ion Battery ≥ 10AHr

Internal Resistance < 30mΩ

Recommended Battery Simulator:

Power Supply 2V to 5.0 V ±10A

Interconnect Resistance < 25mΩ

Figure 35. Configuring the Board for Nine Batteries

dc2064afa

Page 23

Quick start proceDure

DEMO MANUAL DC2064A

System Setup Requirements:

LFP or Li-Ion Battery ≥ 10AHr

Internal Resistance < 30mΩ

Recommended Battery Simulator:

Power Supply 2V to 5.0 V ±10A

Interconnect Resistance < 25mΩ

Figure 36. Configuring the Board for Ten Batteries

dc2064afa

23

Page 24

DEMO MANUAL DC2064A

Quick start proceDure

Figure 37. Configuring the Board for Eleven Batteries

24

System Setup Requirements:

LFP or Li-Ion Battery ≥ 10AHr

Internal Resistance < 30mΩ

Recommended Battery Simulator:

Power Supply 2V to 5.0 V ±10A

Interconnect Resistance < 25mΩ

dc2064afa

Page 25

1

A

A

REVISION HISTORY

REVISION HISTORY

REVISION HISTORY

15

15

15

schematic Diagrams

1 - 11 - 13

1 - 11 - 13

1 - 11 - 13

J.DREWPRODUCTION FAB

J.DREWPRODUCTION FAB

J.DREWPRODUCTION FAB

DESCRIPTION DATEAPPROVEDECO REV

DESCRIPTION DATEAPPROVEDECO REV

DESCRIPTION DATEAPPROVEDECO REV

1

1

1

-

-

-

BOT6_TS

BOT6_TS

OPT

OPT

OPT

OPT

T6

T6

OPT

F13

7A

F13

7A

2.2uF

1210

2.2uF

1210

C6R

C6R

C6S

C6S

1210

1210

2.2uF

2.2uF

1210

1210

C6T

2.2uF

C6T

2.2uF

C6F

C6F

470pF

470pF

R6B181206

R6B181206

674

129

C6E

C6E

R6A201206

R6A201206

C6C

C6C

100uF

100uF

1210

1210

C6B

C6B

1210

1210

100uF

100uF

1210

1210

C6A

C6A

100uF

100uF

1210

1210

470pF

470pF

6.3V

6.3V

100V

100V

100V

100V

100V

100V

0603

0603

100V

100V

100V

100V

6.3V

6.3V

6.3V

6.3V

E8

Q6B

Q6B

SiS892DN

SiS892DN

8

7

642

5

5

WURTH-750312504

WURTH-750312504

10

0603

0603

5

642

7

8

D6F

D6F

BOT6_TSE8BOT6_TS

G6S

R6F

5.1

R6F

5.1

1

3

2 1

D6B

D6B

OPT

DFLS1100

DFLS1100

OPT

D6A

D6A

DFLS260

DFLS260

2 1

3

1

Q6A

Q6A

SiR882DP

SiR882DP

R6C

R6C

5.1

5.1

G6P

SBR10U200P5

SBR10U200P5

3

2 1

J2

J2

OPT

BOT6_TS1BOT6_TS

2

R6H20R6H

3

3

R6G20R6G

CMOSH-4E

CMOSH-4E

2 1

D6C

D6C

179313000_SC

179313000_SC

I6S

RS6A

RS6A

I6P

V-

V-

C6H

C6H

470pF

470pF

20

PLACE RC CLOSE TO LTC3300

4

2 1

BOT6_TS

RS6B

0.016

RS6B

0.016

0.008

0.008

2 1

4

20

C6G

C6G

2.2nF

2.2nF

PLACE RC CLOSE TO LTC3300

C5R

C5R

OPT

C5S

C5S

OPT

C5T

C5T

C5F

C5F

OPT

OPT

674

T5

T5

129

OPT

C5C

C5C

C5B

C5B

C5A

C5A

100V

100V

1210

1210

2.2uF

2.2uF

1210

1210

2.2uF

2.2uF

1210

1210

2.2uF

2.2uF

470pF

470pF

R5B181206

R5B181206

C5E

C5E

20

20

R5A

R5A

1210

1210

100uF

100uF

1210

1210

100uF

100uF

1210

1210

100uF

100uF

100V

100V

100V

100V

100V

100V

470pF

470pF

6.3V

6.3V

6.3V

6.3V

6.3V

6.3V

0603

0603

100V

0603

100V

0603

1206

1206

R5F

R5F

Q5B

SiS892DN

Q5B

SiS892DN

8

7

642

5

OPT

5

WURTH-750312504

WURTH-750312504

10

OPT

5

642

7

8

R5C

R5C

D5F

D5F

SBR10U200P5

SBR10U200P5

G5S

D5A

D5A

G5P

3

2 1

D5B

D5B

Q5A

Q5A

5.1

5.1

DEMO MANUAL DC2064A

www.linear.com

www.linear.com

www.linear.com

V-

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

470pF

470pF

2 1

2 1

LTC Confidential-For Customer Use Only

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

PLACE RC CLOSE TO LTC3300

SCHEMATIC

SCHEMATIC

SCHEMATIC

TITLE:

TITLE:

TITLE:

NC

NC

NC

J. DREW

J. DREW

J. DREW

APPROVALS

APPROVALS

APPROVALS

PCB DES.

PCB DES.

PCB DES.

APP ENG.

APP ENG.

APP ENG.

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

PLACE RC CLOSE TO LTC3300

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

HIGH EFFICIENCY BIDIRECTIONAL

HIGH EFFICIENCY BIDIRECTIONAL

HIGH EFFICIENCY BIDIRECTIONAL

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

5.1

5.1

1

3

2 1

DFLS1100

DFLS1100

DFLS260

DFLS260

2 1

3

1

SiR882DP

SiR882DP

OPT

D5C

D5C

R5H20R5H

3

3

R5G20R5G

CMOSH-4E

CMOSH-4E

2 1

V-

I5S

C5H

C5H

470pF

470pF

20

4

2 1

0.016

0.016

RS5B

RS5B

RS5A

RS5A

0.008

0.008

2 1

4

20

C5G

C5G

2.2nF

2.2nF

I5P

C4R

2.2uF

C4R

2.2uF

1210

1210

100V

100V

100V

100V

1210

1210

C4S

2.2uF

C4S

2.2uF

OPTOPT

100V

100V

1210

1210

C4T

2.2uF

C4T

2.2uF

PLACE RC CLOSE TO LTC3300

OPT

C4F

C4F

0603

0603

470pF

100V

470pF

100V

OPT

R4B181206

R4B181206

BOT6_TS

674

5

T4

T4

129

10

C4E

470pF

0603

C4E

470pF

0603

100V

100V

20

20

R4A

R4A

1206

1206

6.3V

6.3V

1210

1210

OPT

C4C

C4C

100uF

100uF

6.3V

6.3V

1210

1210

C4B

C4B

100uF

100uF

PLACE RC CLOSE TO LTC3300

C4A

C4A

100uF

6.3V

100uF

6.3V

1210

1210

G4S

5.1

5.1

R4F

R4F

4

Q4B

SiS892DN

Q4B

SiS892DN

8

7

6

5

D4B

D4B

OPT

WURTH-750312504

WURTH-750312504

D4A

D4A

OPT

5

642

7

8

Q4A

Q4A

R4C

R4C

5.1

5.1

G4P

D4F

D4F

SBR10U200P5

SBR10U200P5

3

2 1

1

2

3

2 1

DFLS1100

DFLS1100

DFLS260

DFLS260

2 1

3

1

SiR882DP

SiR882DP

CMOSH-4E

CMOSH-4E

D4C

D4C

OPT

I4S

C4H

C4H

20

R4H20R4H

4

3

0.016

0.016

RS4B

RS4B

0.008

0.008

RS4A

RS4A

4

3

20

R4G20R4G

2 1

2.2nF

2.2nF

C4G

C4G

I4P

1

1

1

SHEET OF

SHEET OF

SHEET OF

MULTICELL BATTERY BALANCER

MULTICELL BATTERY BALANCER

MULTICELL BATTERY BALANCER

DEMO CIRCUIT 2064A

LTC3300ILXE-1 / LTC6803IG-2

DEMO CIRCUIT 2064A

LTC3300ILXE-1 / LTC6803IG-2

DEMO CIRCUIT 2064A

LTC3300ILXE-1 / LTC6803IG-2

1 - 11 - 13

1 - 11 - 13

1 - 11 - 13

IC NO. REV.

IC NO. REV.

IC NO. REV.

N/A

N/A

N/A

SIZE

DATE:

SIZE

DATE:

SIZE

DATE:

SCALE = NONE

SCALE = NONE

SCALE = NONE

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

C6

C6

C5

C5

C5

C4

C4

C4

C3

N-1

-

N

C - C

2.5A

2.5V - 4.5V

1

BATTERY CELL VOLTAGES

2.2uF

2.2uF

C3R

1210

100V

C3R

1210

100V

1210

1210

OPTOPT

C3S

100V

C3S

100V

2.2uF

BOT6_TS

C3T

C3T

C3F

C3F

OPT

OPT

T3

T3

C3E

C3E

OPT

C3C

C3C

C3B

C3B

C3A

C3A

2.2uF

2.2uF

2.2uF

18

18

R3B

R3B

674

129

470pF

470pF

R3A

R3A

1210

1210

100uF

100uF

1210

1210

100uF

100uF

100uF

100uF

1210

1210

100V

100V

470pF

470pF

20

20

1210

1210

100V

100V

1206

1206

100V

100V

1206

1206

6.3V

6.3V

6.3V

6.3V

6.3V

6.3V

Q3B

Q3B

8

0603

0603

7

642

5

5

10

0603

0603

5

642

7

8

D3F

D3F

G3S

R3F

5.1

R3F

5.1

SiS892DN

SiS892DN

1

3

2 1

D3B

D3B

OPT

DFLS1100

DFLS1100

WURTH-750312504

WURTH-750312504

OPT

D3A

DFLS260

D3A

DFLS260

2 1

3

1

Q3A

Q3A

SiR882DP

SiR882DP

R3C

5.1

R3C

5.1

G3P

SBR10U200P5

SBR10U200P5

3

2 1

C3

C3

OPT

R3H20R3H

3

3

R3G20R3G

CMOSH-4E

CMOSH-4E

2 1

D3C

D3C

I3S

RS3A

RS3A

I3P

RS3B

RS3B

V-

C3H

470pF

C3H

470pF

20

4

2 1

0.016

0.016

0.008

0.008

2 1

4

20

2.2nF

2.2nF

C3G

C3G

C2

C2R

2.2uF

C2R

2.2uF

1210

1210

OPT

C2S

2.2uF

1210

C2S

2.2uF

1210

OPT

C2T

C2T

1210

1210

2.2uF

2.2uF

C2F

C2F

OPT

470pF

BOT6_TS

OPT

R2B

R2B

674

T2

T2

129

C2E

C2E

470pF

470pF

OPT

C2C

C2C

C2B

C2B

C2A

C2A

R2A

R2A

100uF

100uF

100uF

100uF

100uF

100uF

470pF

18

18

1210

1210

1210

1210

1210

1210

PLACE RC CLOSE TO LTC3300PLACE RC CLOSE TO LTC3300

C2

C2

100V

100V

100V

100V

100V

100V

100V

100V

1206

1206

100V

100V

20

20

6.3V

6.3V

6.3V

6.3V

6.3V

6.3V

0603

0603

5

10

0603

0603

1206

1206

D2F

D2F

8

7

6

5

5

6

7

8

SBR10U200P5

SBR10U200P5

G2S

5.1

5.1

R2F

R2F

4

Q2B

Q2B

SiS892DN

SiS892DN

D2B

DFLS1100

D2B

DFLS1100

WURTH-750312504

WURTH-750312504

OPT OPT

D2A

D2A

DFLS260

DFLS260

Q2A

Q2A

4

5.1

5.1

R2C

R2C

G2P

3

2 1

1

2

3

2 1

2 1

3

2

1

SiR882DP

SiR882DP

CMOSH-4E

CMOSH-4E

D2C

D2C

OPT

I2S

20

R2H20R2H

4

3

RS2B

RS2B

0.008

0.008

RS2A

RS2A

4

3

20

R2G20R2G

2 1

C2G

C2G

I2P

V-

C2H

C2H

470pF

470pF

PLACE RC CLOSE TO LTC3300PLACE RC CLOSE TO LTC3300

2 1

0.016

0.016

2 1

2.2nF

2.2nF

C1

BOT6_TS

C1

C1

OPT

OPT

C1T

C1T

OPT

OPT

T1

T1

OPT

C1R

C1R

2.2uF

2.2uF

2.2uF

2.2uF

C1S

C1S

2.2uF

2.2uF

C1F

C1F

R1B

R1B

674

129

C1E

C1E

R1A

R1A

C1C

C1C

100uF

100uF

C1B

C1B

100uF

100uF

C1A

C1A

100uF

100uF

1210

1210

1210

1210

1210

1210

18

18

470pF

470pF

1210

1210

1210

1210

1210

1210

100V

100V

100V

100V

100V

100V

100V

100V

1206

1206

470pF

470pF

20

20

6.3V

6.3V

0603

0603

5

10

0603

0603

100V

100V

1206

1206

6.3V

6.3V

6.3V

6.3V

G1S

R1F

5.1

R1F

5.1

4

Q1B

Q1B

SiS892DN

SiS892DN

8

7

6

5

OPT

D1B

D1B

WURTH-750312504

WURTH-750312504

OPT

D1A

D1A

DFLS260

DFLS260

5

6

7

8

Q1A

Q1A

4

5.1

5.1

R1C

R1C

G1P

D1F

D1F

SBR10U200P5

SBR10U200P5

3

2 1

1

2

3

2 1

DFLS1100

DFLS1100

2 1

3

2

1

SiR882DP

SiR882DP

OPT

R1H20R1H

R1G20R1G

CMOSH-4E

CMOSH-4E

2 1

D1C

D1C

I1S

C1H

C1H

470pF

470pF

20

4

3

RS1B

0.016

RS1B

0.016

RS1A

0.008

RS1A

0.008

4

3

20

C1G

C1G

2.2nF

2.2nF

I1P

PLACE RC CLOSE TO LTC3300

2 1

V-

2 1

PLACE RC CLOSE TO LTC3300

Figure 38. Schematic Diagram Page 1

dc2064afa

25

Page 26

DEMO MANUAL DC2064A

1

A

A

OPT

25

25

25

schematic Diagrams

1

1

1

E15

E15

TOP6_TS

TOP6_TS

TOP6_TS1TOP6_TS

J3

Q12B

Q12B

SiS892DN

SiS892DN

8

7

6

5

5

WURTH-750312504

WURTH-750312504

10

0603

0603

5

6

7

8

D12F

D12F

Q9B

Q9B

SiS892DN

SiS892DN

8

0603

0603

7

6

5

5

10

WURTH-750312504

WURTH-750312504

0603

0603

5

6

7

8

G12S

5.1

5.1

R12F

R12F

4

1

2

3

2 1

OPT

D12B

D12B

DFLS1100

DFLS1100

OPT

D12A

D12A

DFLS260

DFLS260

2 1

3

2

1

4

Q12A

Q12A

SiR882DP

SiR882DP

5.1

5.1

R12C

R12C

OPT

G12P

SBR10U200P5

SBR10U200P5

3

2 1

G9S

5.1

5.1

R9F

R9F

4

D9B

D9B

OPT

OPT

D9A

D9A

4

Q9A

Q9A

5.1

5.1

R9C

R9C

G9P

D9F

D9F

SBR10U200P5

SBR10U200P5

3

2 1

J3

2 1

D12C CMOSH-4ED12C CMOSH-4E

1

2

3

2 1

DFLS1100

DFLS1100

DFLS260

DFLS260

2 1

3

2

1

SiR882DP

SiR882DP

CMOSH-4E

CMOSH-4E

D9C

D9C

OPT

2

R12H20R12H

3

3

R12G20R12G

R9H20R9H

R9G20R9G

2 1

179313000_SC

179313000_SC

I12S

C12H

C12H

20

4

RS12B

RS12B

RS12A

0.008

RS12A

0.008

4

20

C12G

C12G

I12P

I9S

20

3

RS9B

RS9B

RS9A

RS9A

3

20

I9P

C6

C11R

C11R

C6

OPT

C11S

C11S

470pF

470pF

OPT

C11T

C11T

OPT

PLACE RC CLOSE TO LTC3300

2 1

OPT

TOP6_TS

0.016

0.016

T11

T11

2 1

OPT

C11C

C11C

2.2nF

2.2nF

C11B

C11B

PLACE RC CLOSE TO LTC3300

C11

C11

C11

C6

C9H

470pF

C9H

470pF

4

2 1

0.016

0.016

0.008

0.008

2 1

4

C9G

C9G

2.2nF

2.2nF

PLACE RC CLOSE TO LTC3300 PLACE RC CLOSE TO LTC3300

C8

1210

1210

2.2uF

2.2uF

1210

1210

2.2uF

2.2uF

1210

1210

2.2uF

2.2uF

C11F

C11F

470pF

470pF

18

18

R11B

R11B

674

129

C11E

C11E

R11A

R11A

1210

1210

100uF

100uF

1210

1210

100uF

100uF

1210

1210

C11A

C11A

100uF

100uF

OPT

OPT

OPT

OPT

TOP6_TS

T8

T8

OPT

C8

C8

100V

100V

100V

100V

100V

100V

0603

0603

100V

100V

1206

1206

5

10

0603

0603

470pF

100V

470pF

100V

20

20

1206

1206

6.3V

6.3V

6.3V

6.3V

6.3V

6.3V

C8R

2.2uF

C8R

2.2uF

C8S

2.2uF

C8S

2.2uF

C8T

C8T

2.2uF

2.2uF

C8F

C8F

R8B

R8B

674

129

C8E

C8E

470pF

470pF

R8A201206

R8A201206

C8C

C8C

100uF

100uF

C8B

C8B

100uF

100uF

C8A

C8A

100uF

100uF

G11S

R11F

R11F

4

Q11B

SiS892DN

Q11B

SiS892DN

8

7

6

5

OPT

D11B

D11B

WURTH-750312504

WURTH-750312504

D11A

D11A

OPT

5

6

7

8

Q11A

Q11A

4

5.1

5.1

R11C

R11C

G11P

D11F

D11F

SBR10U200P5

SBR10U200P5

3

2 1

100V

100V

1210

1210

1210

1210

100V

100V

1210

1210

100V

100V

Q8B

Q8B

8

0603

0603

100V

100V

470pF

470pF

7

6

5

18

18

1206

1206

5

10

0603

0603

100V

100V

5

6

7

8

6.3V

6.3V

1210

1210

6.3V

6.3V

1210

1210

6.3V

6.3V

1210

1210

D8F

D8F

5.1

5.1

R11H20R11H

3

1

2

3

2 1

DFLS1100

DFLS1100

DFLS260

DFLS260

2 1

3

2

1

3

SiR882DP

SiR882DP

R11G20R11G

CMOSH-4E

CMOSH-4E

2 1

D11C

D11C

OPT

G8S

5.1

5.1

R8F

R8F

4

SiS892DN

SiS892DN

1

2

3

2 1

D8B

D8B

OPT

DFLS1100

DFLS1100

WURTH-750312504

WURTH-750312504

OPT

D8A

DFLS260

D8A

DFLS260

2 1

3

2

1

4

Q8A

Q8A

SiR882DP

SiR882DP

5.1

5.1

R8C

R8C

OPT

G8P

SBR10U200P5

SBR10U200P5

3

2 1

C6

I11S

C11H

C11H

470pF

470pF

20

PLACE RC CLOSE TO LTC3300

4

2 1

0.016

0.016

RS11B

RS11B

RS11A

RS11A

0.008

0.008

2 1

4

20

C11G

C11G

2.2nF

2.2nF

I11P

PLACE RC CLOSE TO LTC3300

C10

I8S

20

R8H20R8H

3

RS8B

RS8B

RS8A

RS8A

3

20

R8G20R8G

CMOSH-4E

CMOSH-4E

2 1

D8C

D8C

C8G

C8G

I8P

C10R

2.2uF

C10R

2.2uF

1210

1210

1210

1210

C10S

2.2uF

C10S

2.2uF

1210

1210

OPTOPT OPT

C10T

2.2uF

C10T

2.2uF

C10F

C10F

470pF

470pF

R10B181206

R10B181206

OPT

TOP6_TS

674

T10

T10

129

C10E

C10E

R10A

R10A

OPT

C10C

C10C

100uF

100uF

C10B

C10B

100uF

100uF

1210

1210

C10A

C10A

100uF

100uF

C10

C10

C6

C8H

C8H

470pF

470pF

4

2 1

0.016

0.016

0.008

0.008

2 1

4

2.2nF

2.2nF

PLACE RC CLOSE TO LTC3300 PLACE RC CLOSE TO LTC3300

C7

470pF

470pF

20

20

1210

1210

1210

1210

6.3V

6.3V

100V

100V

100V

100V

100V

100V

100V

100V

6.3V

6.3V

6.3V

6.3V

0603

0603

0603

0603

100V

100V

1206

1206

TOP6_TS

C7

C7

R10F

R10F

Q10B

SiS892DN

Q10B

SiS892DN

8

7

642

5

5

WURTH-750312504

WURTH-750312504

10

5

642

7

8

R10C

R10C

D10F

D10F

SBR10U200P5

SBR10U200P5

C7R

C7R

2.2uF

2.2uF

C7S

C7S

OPT

2.2uF

2.2uF

C7T

C7T

OPT

2.2uF

2.2uF

C7F

C7F

OPT

R7B

R7B

OPT

674

T7

T7

129

C7E

C7E

C7C

C7C

OPT

C7B

C7B

C7A

C7A

G10S

5.1

5.1

OPT

D10B

D10B

DFLS1100

DFLS1100

OPT

D10A

DFLS260

D10A

DFLS260

Q10A

Q10A

5.1

5.1

G10P

3

2 1

1210

1210

1210

1210

1210

1210

470pF

470pF

18

18

20

20

R7A

R7A

1210

1210

100uF

100uF

1210

1210

100uF

100uF

1210

1210

100uF

100uF

1

3

2 1

2 1

3

1

SiR882DP

SiR882DP

CMOSH-4E

CMOSH-4E

OPT

D10C

D10C

100V

100V

100V

100V

100V

100V

0603

0603

100V

100V

1206

1206

5

10

470pF

100V

0603

470pF

100V

0603

1206

1206

6.3V

6.3V

6.3V

6.3V

6.3V

6.3V

I10S

C10H

C10H

20

R10H20R10H

4

3

RS10B

RS10B

0.008

0.008

RS10A

RS10A

4

3

20

R10G20R10G

2 1

C10G

C10G

I10P

R7F

R7F

Q7B

Q7B

SiS892DN

SiS892DN

8

7

642

5

OPT

WURTH-750312504

WURTH-750312504

OPT

5

642

7

8

R7C

R7C

D7F

D7F

SBR10U200P5

SBR10U200P5

3

2 1

C6

Milpitas, CA 95035

1630 McCarthy Blvd.

Milpitas, CA 95035

1630 McCarthy Blvd.

Milpitas, CA 95035

1630 McCarthy Blvd.

470pF

470pF

PLACE RC CLOSE TO LTC3300

2 1

0.016

0.016

APPROVALS

APPROVALS

APPROVALS

2 1

2.2nF

2.2nF

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

PLACE RC CLOSE TO LTC3300

C9

G7S

I7S

5.1

5.1

20

R7H20R7H

3

1

3

RS7B

RS7B

2 1

D7B

D7B

DFLS1100

DFLS1100

D7A

DFLS260

D7A

DFLS260

2 1

RS7A

RS7A

3

1

3

Q7A

Q7A

20

R7G20R7G

SiR882DP

SiR882DP

5.1

5.1

CMOSH-4E

CMOSH-4E

2 1

D7C

D7C

OPT

I7P

G7P

www.linear.com

www.linear.com

www.linear.com

Fax: (408)434-0507

Phone: (408)432-1900

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Phone: (408)432-1900

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Phone: (408)432-1900

LTC Confidential-For Customer Use Only

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

NC

NC

NC

PCB DES.

PCB DES.

PCB DES.

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

C - C

SHEET OF

SHEET OF

SHEET OF

DEMO CIRCUIT 2064A

DEMO CIRCUIT 2064A

DEMO CIRCUIT 2064A

LTC3300ILXE-1 / LTC6803IG-2

LTC3300ILXE-1 / LTC6803IG-2

LTC3300ILXE-1 / LTC6803IG-2

HIGH EFFICIENCY BIDIRECTIONAL

HIGH EFFICIENCY BIDIRECTIONAL

HIGH EFFICIENCY BIDIRECTIONAL

MULTICELL BATTERY BALANCER

MULTICELL BATTERY BALANCER

MULTICELL BATTERY BALANCER

1 - 11 - 13

1 - 11 - 13

1 - 11 - 13

IC NO. REV.

IC NO. REV.

IC NO. REV.

SCHEMATIC

SCHEMATIC

SCHEMATIC

N/A

N/A

N/A

SIZE

DATE:

SIZE

DATE:

SIZE

DATE:

TITLE:

TITLE:

TITLE:

J. DREW

J. DREW

J. DREW

SCALE = NONE

SCALE = NONE

SCALE = NONE

APP ENG.

APP ENG.

APP ENG.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

N-1

-

N

2.5A

2.5V - 4.5V

1

BATTERY CELL VOLTAGES

C7H

470pF

C7H

470pF

4

2 1

PLACE RC CLOSE TO LTC3300

0.016

0.016

C6

0.008

0.008

2 1

4

C7G

C7G

2.2nF

2.2nF

PLACE RC CLOSE TO LTC3300

Figure 39. Schematic Diagram Page 2

F147A1210

F147A1210

100V

100V

2.2uF

1210

2.2uF

1210

C12R

C12R

OPT

2.2uF

2.2uF

100V

100V

C12S

1210

C12S

1210

OPTOPT

100V

100V

1210

1210

C12T

C12T

2.2uF

2.2uF

C12F

C12F

0603

0603

100V

100V

470pF

470pF

OPT

R12B181206

R12B181206

TOP6_TS

674

T12

T12

129

TOP6_TS

470pF

100V

470pF

100V

C12E

C12E

20

20

1206

1206

R12A

R12A

OPT

6.3V

6.3V

C12C

100uF

C12C

100uF

1210

1210

6.3V

6.3V

C12B

100uF

C12B

100uF

1210

1210

C12A

C12A

1210

6.3V

1210

6.3V

100uF

100uF

C12

C12

C9R

C9R

2.2uF

1210

2.2uF

1210

100V

100V

1210

1210

100V

100V

C9S

2.2uF

C9S

2.2uF

OPT

C9T

1210

C9T

1210

OPT

2.2uF

2.2uF

100V

C9F

C9F

OPT

OPT

674

T9

T9

129

C9E

C9E

OPT

C9C

C9C

C9B

C9B

C9A

C9A

470pF

470pF

R9B181206

R9B181206

470pF

470pF

20

20

R9A

R9A

1210

1210

100uF

100uF

1210

1210

100uF

100uF

1210

1210

100uF

100uF

100V

100V

100V

100V

100V

1206

1206

6.3V

6.3V

6.3V

6.3V

6.3V

6.3V

TOP6_TS

C9

C9

26

dc2064afa

Page 27

schematic Diagrams

1

A

A

35

35

35

D5

CMMSH2-40

R6

6.8

2 1

21

OPT

0

R42

D20

CMMSH2-40

C18

10V

0603

0.22uF

C4

0402

0.1uF

10V

TOP6_TS

R13

845k

0805

1

R5

BSS123W

1M

2

WDTC

E20

WDTC

3

Q14

D24

CMOSH-4E

2 1

VREG2

C6

C3

4.7uF

16V

1210

0603

C21

16V

1.0uF

C11

C12

*

C34

10uF

10V

0805

0

R46

C27

2512

4.7uF

16V

0603

C12K

1.0uF

C11K

1.0uF

G11P

G12P

I12P

36

35

C5

I6P

G5P

37

G6P

38

C6

39

BOOST+

40

BOOST-

41

BOOST

42

SDOI

43

SCKO

44

CSBO

45

VMODE

46

TOS

47

VREG

48

G6S1I6S2G5S3I5S4G4S5I4S6G3S7I3S8G2S9I2S10G1S11I1S

GND

49

C6

G12S

I12S

DEMO MANUAL DC2064A

1

1

C8

C9

C10

C28

16V

1210

4.7uF

0

2512

I5P

G11S

R44

1210

0

R50

C29

4.7uF

1210

2512

16V

0603

I11P

33

C4

I11S

C10K

16V

C9K

0603

1.0uF

16V

0603

1.0uF

I9P

I10P

G10P

G9P

27

30

29

32

28

31

C3

I3P

I4P

G3P

G4P

G8S

I9S

G10S

I10S

G9S

16V

16V

34

C7

*

www.linear.com

www.linear.com

C5

1210

4.7uF

16V

4.7uF

C31

1210

C7K

1.0uF

24

23

22

C6

21

WDTC

20

19

18

17

16

15

14

13

LTC3300ILXE-1

C32

1210

16V

16V

0603

G7P

I7P

D16

R10

20.5k

R11

15.4k

R9

15.4k

Note: These capacitors are not installed on demo board

*

OPT

RS07J

1 2

12

R12

D8

RS07J

D7

RS07J

12

12

D6

RS07J

0

OPT

C6

0

R43

2512

C30

16V

4.7uF

16V

C8K

0603

1.0uF

G8P

I8P

26

25

C2

I2P

C1

G2P

G1P

I1P

V-

WDT

SDO

SDI

SCKI

CSBI

CTRL

RTONP

RTONS

12

U2

G7S

I8S

I7S

www.linear.com

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

APPROVALS

APPROVALS

APPROVALS

CUSTOMER NOTICE

CUSTOMER NOTICE

CUSTOMER NOTICE

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A

CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS;

C6

1

SHEET OF

SHEET OF

SHEET OF

LTC Confidential-For Customer Use Only

LTC Confidential-For Customer Use Only

LTC Confidential-For Customer Use Only

DEMO CIRCUIT 2064A

DEMO CIRCUIT 2064A

DEMO CIRCUIT 2064A

LTC3300ILXE-1 / LTC6803IG-2

LTC3300ILXE-1 / LTC6803IG-2

LTC3300ILXE-1 / LTC6803IG-2

HIGH EFFICIENCY BIDIRECTIONAL

HIGH EFFICIENCY BIDIRECTIONAL

HIGH EFFICIENCY BIDIRECTIONAL

MULTICELL BATTERY BALANCER

MULTICELL BATTERY BALANCER

MULTICELL BATTERY BALANCER

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

1 - 11 - 13

1 - 11 - 13

1 - 11 - 13

IC NO. REV.

IC NO. REV.

IC NO. REV.

SCHEMATIC

SCHEMATIC

SCHEMATIC

N/A

N/A

N/A

SIZE

DATE:

SIZE

DATE:

SIZE

DATE:

TITLE:

TITLE:

TITLE:

NC

NC

NC

J. DREW

J. DREW

J. DREW

SCALE = NONE

SCALE = NONE

PCB DES.

PCB DES.

PCB DES.

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO

VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL

SCALE = NONE

APP ENG.

APP ENG.

APP ENG.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

APPLICATION. COMPONENT SUBSTITUTION AND PRINTED

CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT

PERFORMANCE OR RELIABILITY. CONTACT LINEAR

TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE.

THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND

SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS.

Q17

CMPDM8002A

2

3

1

R53

100k

C7

R54

R51

D22

CMHZ4689

Q16

CMPT3904E

2 3

2 1

R52

20

D25

0603

PDZ5.6B

2 1

2 1

C6

1

Q15

2.0k

D26

PDZ5.6B

2 1

3 2

CMPT3906E

C5

21

D23

R14

CMOSH-4E

845k

BOT6_TS

0805

3

Q13

1

BSS123W

C2

D1

C6

CMMSH2-40

2 1

R4

6.8

0

R45

21

R41

D19

CMMSH2-40

C19

10V

0.22uF

C2

10V

0.1uF

1M

R1

R3

WDTA

WDTA

VREG1

0

C1

4.7uF

C20

1.0uF

2

E19

2512

OPT

0

C6K

16V

1.0uF

0603

G6P

I6P

37

38

39

40

41

42

0402

43

44

45

46

47

48

OPT

R2

0

V-

16V

1210

16V

0603

C4

C5

C22

4.7uF

0603

C5K

1.0uF

G5P

36

35

C5

I6P

G5P

G6P

C6

BOOST+

BOOST-

BOOST

SDOI

SCKO

CSBO

VMODE

TOS

VREG

G6S1I6S2G5S3I5S4G4S5I4S6G3S7I3S8G2S9I2S10G1S11I1S

GND

49

G6S

I6S

C3

0

R48

C23

16V

1210

4.7uF

0

1210

16V

R47

2512

C24

16V

4.7uF

16V

C4K

0603

1.0uF

16V

0603

I5P

33

34

I5P

G5S

16V

C3K

1.0uF

G3P

I4P

G4P

30

29

32

28

31

C3

C4

I4P

G3P

G4P

I5S

I3S

G4S

I4S

G3S

2512

1210

0603

I3P

27

I3P

G2S

C1

C25

16V

1210

4.7uF

0

R49

2512

C26

16V

1210

4.7uF

*

C2K

16V

0603

1.0uF

I2P

G2P

26

25

C2

I2P

G2P

12

I1S

G1S

I2S

C1

24

G1P

23

I1P

22

V-

21

WDT

20

SDO

19

SDI

18

SCKI

17

CSBI

16

CTRL

15

RTONP

14

RTONS

13

U1

LTC3300ILXE-1

0805

10uF

10V

C33

C1K

16V

0603

1.0uF

G1P

V-

WDTA

SDII

CSBI

R8

20.5k

R7

15.4k

V-

V-

1

R55

C6

20

0603

D21

CMHZ4689

2.0k

1

Figure 40. Schematic Diagram Page 3

I1P

SDO

SCKI

dc2064afa

27

Page 28

DEMO MANUAL DC2064A

1

A

A

45

45

45

schematic Diagrams

C4S+1C4+2C5S-

J8

J8

179314000_SC

179314000_SC

3

C4

E5C4E5

J12

J12

C8S+1C8+2C9S-

3

E10C8E10

179314000_SC

179314000_SC

1

1

1

www.linear.com

www.linear.com

www.linear.com

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

Fax: (408)434-0507

Milpitas, CA 95035

Phone: (408)432-1900

1630 McCarthy Blvd.

LTC Confidential-For Customer Use Only

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

NC

NC

NC

APPROVALS

APPROVALS

APPROVALS

PCB DES.

PCB DES.

PCB DES.

C12

179313000_SC

179313000_SC

C12

E14

E14

C12_CLAMPED

C8

C12S+1C12+

J16

J16

2

SHEET OF

SHEET OF

SHEET OF

DEMO CIRCUIT 2064A

DEMO CIRCUIT 2064A

DEMO CIRCUIT 2064A

LTC3300ILXE-1 / LTC6803IG-2

LTC3300ILXE-1 / LTC6803IG-2

LTC3300ILXE-1 / LTC6803IG-2

HIGH EFFICIENCY BIDIRECTIONAL

HIGH EFFICIENCY BIDIRECTIONAL

HIGH EFFICIENCY BIDIRECTIONAL

MULTICELL BATTERY BALANCER

MULTICELL BATTERY BALANCER

MULTICELL BATTERY BALANCER

1 - 11 - 13

1 - 11 - 13

1 - 11 - 13

IC NO. REV.

IC NO. REV.

IC NO. REV.

SCHEMATIC

SCHEMATIC

SCHEMATIC

N/A

N/A

N/A

SIZE

DATE:

SIZE

DATE:

SIZE

DATE:

TITLE:

TITLE:

TITLE:

J. DREW

J. DREW

J. DREW

SCALE = NONE

SCALE = NONE

SCALE = NONE

APP ENG.

APP ENG.

APP ENG.

1210

J11

J11

1210

1210

F5

F5

C7S+1C7+2C8S-

C6S+1C6+2C7S-

3

C5S+1C5+2C6S-

3

C5

D6E

D6E

3

179314000_SC

179314000_SC

179314000_SC

179314000_SC

7A

7A

PDZ7.5B

PDZ7.5B

2 1

1210

F8

F8

179314000_SC

179314000_SC

1210

1210

F7

F7

1210

1210

F6

F6

C5_FILTER

D5E

D5E

C7 C8

C6

PDZ7.5B

PDZ7.5B

2 1

7A

7A

7A

7A

7A

7A

C4_Filter

E13

E13

E12

E12

E11C9E11

D4E

D4E

C11

C11

C10

C10

C9

PDZ7.5B

PDZ7.5B

2 1

C3_FILTER

D3E

D3E

J15

J15

J14

J14

J13

J13

PDZ7.5B

PDZ7.5B

C11S+1C11+2C12S-

3

C10S+1C10+2C11S-

3

C9S+1C9+2C10S-

3

1210

1210

F9

F9

C9

C2_FILTER

2 1

179314000_SC

179314000_SC

179314000_SC

179314000_SC

179314000_SC

179314000_SC

7A

7A

C1_FILTER

D2E

PDZ7.5B

D2E

PDZ7.5B

2 1

1210

1210

7A

7A

F4

C3S+1C3+2C4S-

J7

J7

3

C2S+1C2+2C3S-

J6

J6

3

C1S+1C1+2C2S-

3

F1

F1

1210

1210

C1

C10_FILTER

D10E

D10E

179314000_SC

179314000_SC

179314000_SC

179314000_SC

179314000_SC

179314000_SC

7A

7A

C9_FILTER

PDZ7.5B

PDZ7.5B

2 1

F4

E9C7E9

C7

1210

1210

7A

7A

F3

F3

E18C6E18

E7C6E7

C6

1210

1210

7A

7A

F2

F2

C2 C3 C4

C8_FILTER

PDZ7.5B

PDZ7.5B

D8E

D8E

D9E

PDZ7.5B

D9E

PDZ7.5B

2 1

E6C5E6

C7_FILTER

2 1

J10

J10

C6

C5

J9

J9

C6_FILTER

D7E

PDZ7.5B

D7E

PDZ7.5B

2 1

E4C3E4

C3

E3C2E3

C2

E2C1E2

C1S-1C1-

J4

J4

2

E1V-E1

V-

C12_FILTER

D12E

D12E

179313000_SC

179313000_SC

1210

1210

F15

F15

V-