Page 1

Description

DEMO MANUAL DC2313A

Programmable

Six Channel Sequencer and

Voltage Supervisor with EEPROM

Demonstration circuit 2313A showcases the LTC2937, a

programmable six channel power supply sequencer and

voltage supervisor.

The LTC2937 provides flexible sequence control for up

to six power supplies. It enables and disables the sup

plies with

monitors

configurable sequence order and time delays,

the supplies for power-up and power-down time,

-

and for overvoltage and undervoltage. It cooperates with

other LTC2937 parts in the system to coordinate power

sequencing activities. It provides flexible fault response to

autonomously supervise the power supplies, and powerful

debug tools to diagnose any problem that causes a powersupply fault. It holds configuration in non-volatile EEPROM

for completely automatic power system supervision.

The DC2313A board demonstrates the powerful features

of the LTC2937 using six onboard LDO voltage regula

tors, or

by controlling an optional, externally-powered

-

performance summary

DC1361 board (an 8-channel power supply board). Multiple

DC2313A boards can also share timing and sequencing

signals to supervise more than six regulated supplies in

a coordinated manner.

The DC2313A connects to a PC through the DC1613 USB-

2

C/SMBus/PMBus Controller. This connection enables

to-I

the LTpowerPlay™ software, to have complete control over

the LTC2937 through the convenient LTpowerPlay GUI.

The GUI allows control over all of the LTC2937 registers,

and visibility into the status of the part in real time, and

it works with Linear Technology demo boards as well as

2

custom boards with an I

C interface.

Design files for this circuit board are available at

http://www.

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks and

LTpowerPlay is a trademark of Linear Technology Corporation. All other trademarks are the

property of their respective owners.

linear.com/demo/DC2313A

PARAMETER CONDITIONS MIN TYP MAX UNITS

Voltage Range All 6 12 14 V

V

IN

Current to the Board Sequenced-Down 3.8 mA

I

IN

Current Sequenced-Up, No Loads 17.5 mA

I

IN

V1-V6 Voltage Range Volts at the Turret 0 6 V

EN1-EN6 Voltage Range Volts at the Turret

Regulated LDO Voltage Tolerance Load Current < 20mA –1 1 %

Rated Output Current *V_OUT pins Load Current Per Channel 20 mA

Board Operating Temperature Powered 0 60 °C

Serial Clock Frequency I

†

NOTE: Analog switches U7, U8, and U9 (LTC222) are powered by 5V, and limit the maximum voltage range allowed at their S and D pins. The LTC2937

can tolerate up to 16.5V on its ENn pins.

†

2

C Bus Operating 10 400 kHz

0 6 V

dc2313af

1

Page 2

DEMO MANUAL DC2313A

Ltc2937 features

• Time and Event-Based Supply Sequencing

• 12Programmable Undervoltage and Overvoltage Com-

parators (0.75% Accuracy)

• Stalled

• Single

sion to 50 Devices (300 Power Supplies)

• Configuration and Fault Logging in EEPROM

• EEPROM Rated to 85°C, 10k Writes, 20 Year Retention

Power-Supply Detection

Wire Synchronization Allows Controller Expan

-

how to use this Document

This demonstration manual introduces the LTC2937

through a series of simple exercises using the DC2313A

demo board and the LTpowerPlay software. Each exercise

introduces one or two key features of the part, as well as

• Supported by LTpowerPlay GUI

• Fault and System Status Registers

• Reset Output with Programmable Delay

2

C/SMBus Interface

• I

• Wide Input Supply Voltage Range: 2.9V to 16.5V

• 28-Pin QFN (5mm × 6mm) Package

recommended methods for interfacing to it. The LTC2937

has more useful features than can be covered here. The

user is referred to the LTC2937 data sheet, and to additional

exercises in the DC2313A Advanced User Guide document.

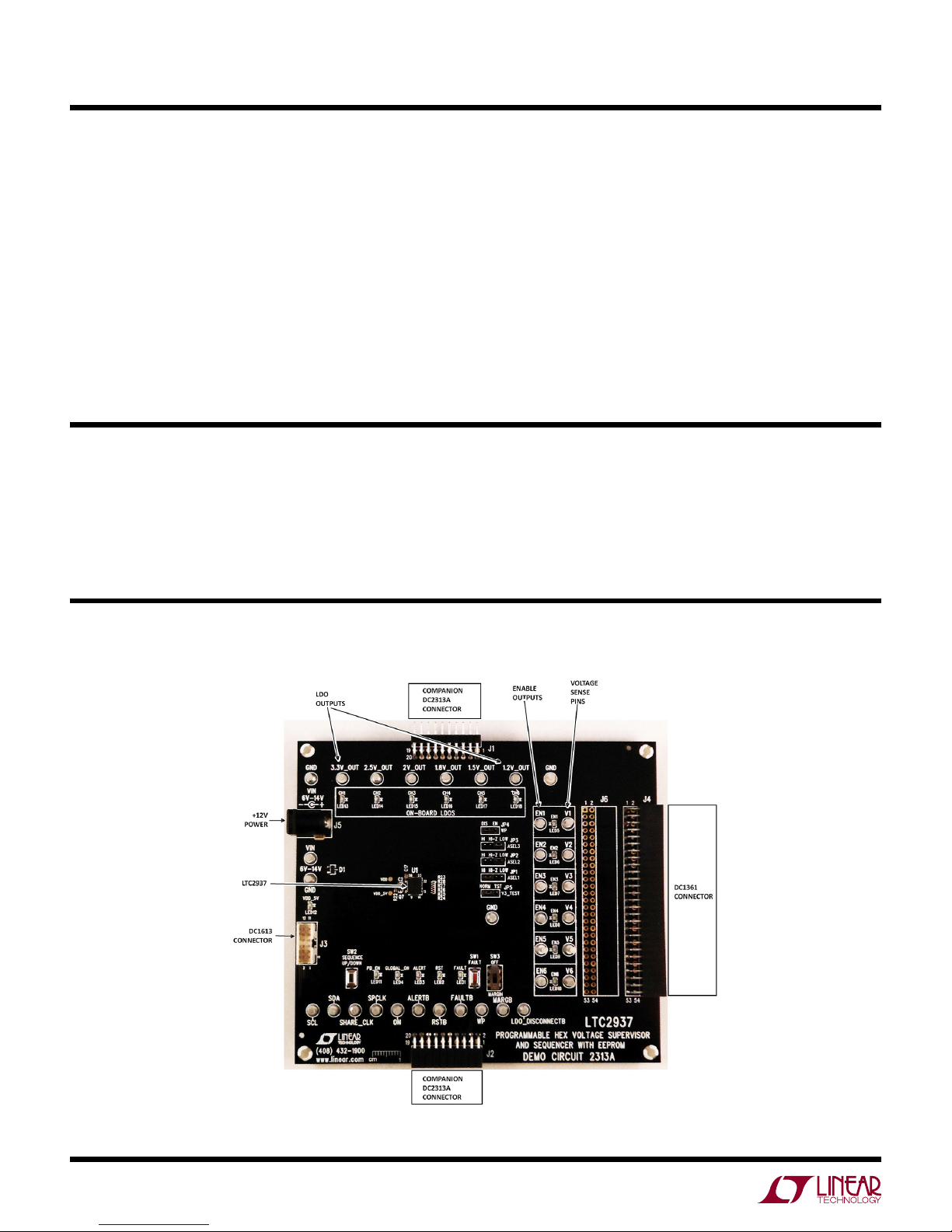

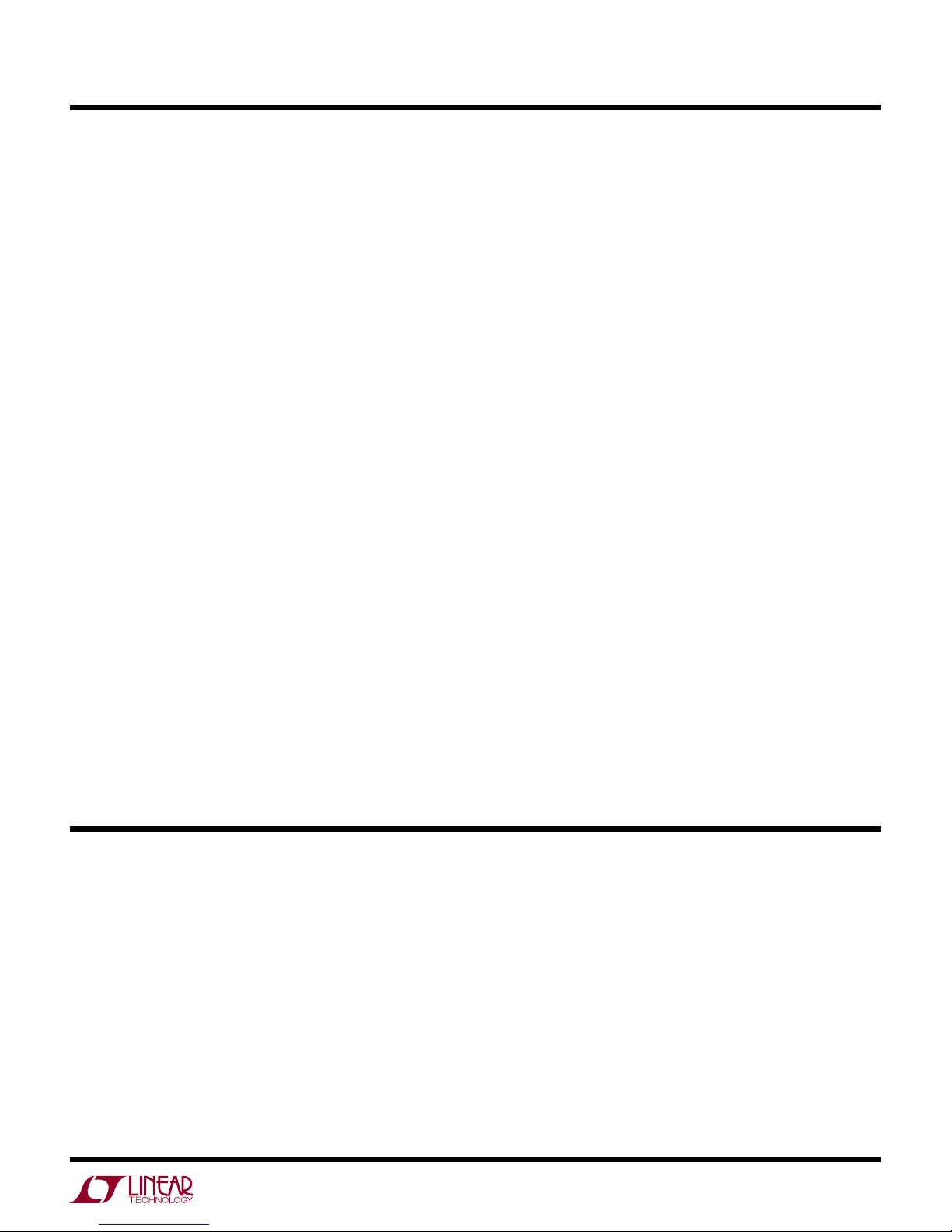

the Dc2313a BoarD

2

Figure 1. DC2313A Board

dc2313af

Page 3

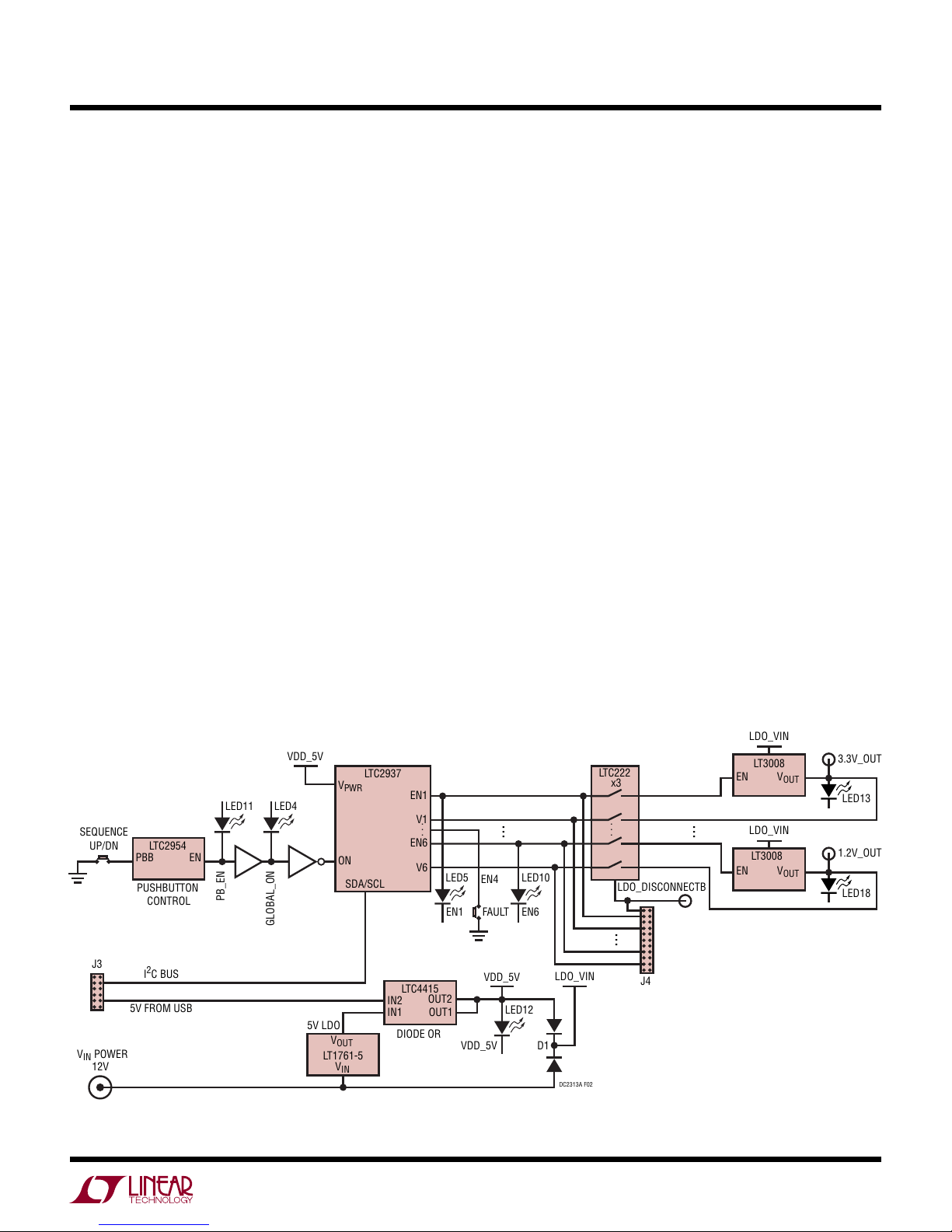

Dc2313 operating principLes

VDD_5V

V

PWR

ON

EN1

EN6

V1

V6

SDA/SCL

. . .

LTC2937

PBB

EN

LTC2954

IN1

OUT1

IN2

OUT2

LTC4415

LED4

LED11

D1

V

OUT

V

IN

LT1761-5

V

OUT

EN

LT3008

V

OUT

EN

LT3008

LTC222

x3

LED12

LED5

LED10J3SEQUENCE

UP/DN

VIN POWER

12V

J4

LDO_DISCONNECTB

LDO_VIN

3.3V_OUT

VDD_5V

LDO_VIN

I2C BUS

5V FROM USB

DC2313A F02

VDD_5V

EN1

FAULT

EN6

EN4

5V LDO

DIODE OR

...

...

PUSHBUTTON

CONTROL

LDO_VIN

LED13

1.2V_OUT

LED18

DEMO MANUAL DC2313A

The DC2313A board is fully functional as a stand-alone

evaluation platform for the LTC2937, and does not require

any external connections, other than power. It provides

convenient access to all of the LTC2937 pins through

turrets on the board, and basic control over the part by

jumpers and pushbuttons. Connectors can attach to ex

ternal devices for system prototyping. The board has six

LDO regulators that respond to control from the LTC2937,

and demonstrate its capabilities.

Additional functionality is accessible using the DC1613

2

USB-to-I

C “dongle” and LTpowerPlay software running on

a PC. The software provides a detailed view of the functions

of the LTC2937, including powerful fault management and

debug capabilities.

POWERING

The DC2313 can draw power from one of two sources.

Either 5V from the DC1613 ribbon cable connected to J3, or

from the V

connector to 12V. The DC1613 can only supply

IN

100mA, so when the board draws power from 5V do not

load any of the LDO outputs, as this may overload the 5V

supply. 12V must be used when loading the LDO outputs.

Multiple DC2313A boards connected together

J2 share power through the connectors, so attach 12V

and

through J1

and the ribbon cable to one of multiple DC2313A boards.

Only connect power to one of the boards. When the external

DC1361 board is attached to connector J4, use 12V power.

CONFIGURATION

A key feature of the LTC2937 is its non-volatile memory (EE

PROM), and its

ability to power-up in the correct configuration

-

to autonomously sequence and supervise the power system.

The DC2313A comes pre-programmed with default settings

to demonstrate the sequencing and supervision capabilities

of the LTC2937. The board functions with no intervention

from LTpowerPlay or other software. The pre-programmed

settings on the board are not the factory default settings

for the LTC2937, but are intended to provide a useful dem

,

onstration platform

The LTC2937 communicates through the I

with observable timing relationships.

2

C bus on the J3

-

connector. Select a bus address by changing the jumpers

ASEL1, ASEL2, and ASEL3. Each jumper can select either

HI, Hi-Z, or LOW, and the three jumpers together select

one of 27 addresses for the device. Select a unique address

2

for each device on the I

C bus. If multiple DC2313 boards

are connected together, each must have its own unique

ASEL jumper setting. Each LTC2937 will always respond

to its global 7-bit address 0x36. See the addressing section

in the LTC2937 data sheet for a complete address table.

Figure 2. DC2313A Simplified Diagram

dc2313af

3

Page 4

DEMO MANUAL DC2313A

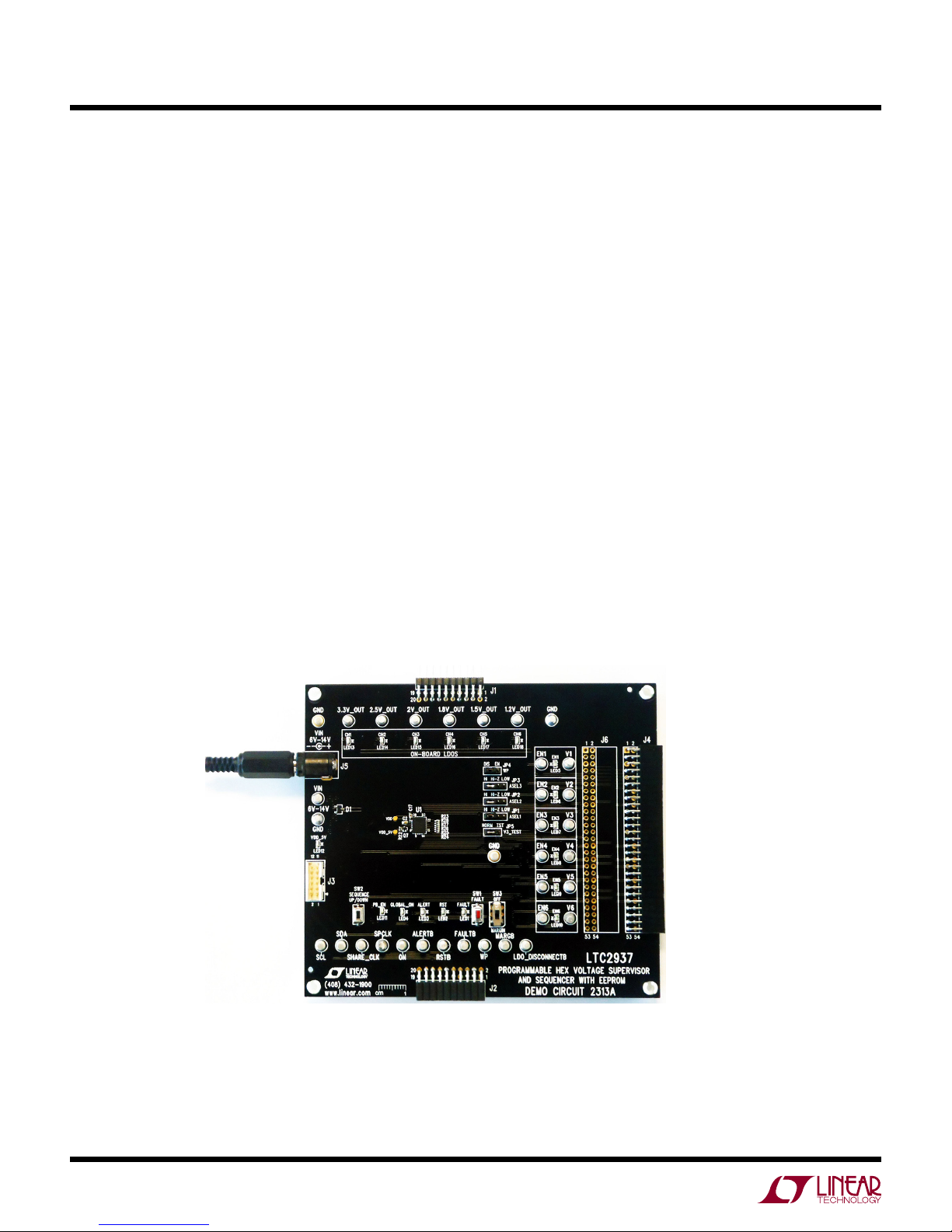

Quick start proceDure (without software)

Begin exploring the basic features of the LTC2937 with

several exercises that do not require software. The following procedures

DC1613 connected, and no LTpowerPlay running. The board

will function autonomously without external software,

which is one of the important capabilities of the LTC2937.

SEQUENCING UP

Sequence up the supplies in an orderly fashion.

1) Apply power to the DC2313A by connecting 12V to the

J5 power connector.

The V

LEDs will be off.

2) Ensure that the SW3 switch is OFF, not in the MARGIN

position.

3) Press the “SEQUENCE UP/DOWN” pushbutton on the

DC2313.

assume a single DC2313A board with no

and RSTB LEDs will illuminate; all other

DD

The pushbutton is de-bounced by an LTC2954, which

requires sufficient time to register the button press

and activate the LTC2937 through the PB_ENB signal.

The PB_EN and GLOBAL_ON LEDs will illuminate.

The ENn LEDs will illuminate in sequence: 1-6.

The CHn LEDs will illuminate in sequence with the

ENn LEDs.

The RST LED will turn off when all supplies are within

their OV/UV limits (after the last CHn LED illuminates).

The FAULT

The ALERT LED will remain off.

The default voltage (UV and OV) limits and timing

parameters should not detect faults.

The DC2313A is programmed to provide human eye

observable sequence-up timing so that the time between

supplies powering-up is easily observable via LEDs. The

actual LTC2937 in-system sequence of events, and the

delays between events are all configurable.

LED will remain off.

4

Figure 3. DC2313A Standalone

dc2313af

Page 5

DEMO MANUAL DC2313A

Quick start proceDure (without software)

SEQUENCING DOWN

Bring down the supplies in an orderly fashion.

1) Begin with the system sequenced-up. The LDOs are on.

2) Press the “SEQUENCE UP/DOWN” pushbutton on the

DC2313.

The PB_EN and GLOBAL_ON LEDs will turn off.

The ENn LEDs will turn off in sequence: 6-1.

The CHn LEDs will turn off in sequence with the ENn

LEDs.

The RST LED will illuminate as soon as the CH6 LED

goes off.

The FAULT LED will remain off.

The ALERT LED will remain off.

The default voltage (UV and OV) limits and timing

parameters should not detect faults.

Notice that the sequence-down order of events is the reverse

of the sequence-up order. Channels can be reconfigured

easily via register programming to sequence-up and

sequence-down in any order, and sequence-down order

is independent of sequence-up order. As with sequencingup, the human-friendly, eye-observable sequence timing

is easily changed through register configuration.

AUTONOMOUS FAULT HANDLING

A fault is any condition that should not exist in the

system. The flexible LTC2937 is capable of autonomously

recognizing and handling faults without software

intervention. The LTC2937

SUPERVISOR fault, SEQUENCE fault, CONTROL fault,

EXTERNAL fault, and SHARE_CLK fault. We address

SUPERVISOR and SEQUENCE faults here. For more in

formation refer

examples, do not use software, or user/external interven-

recover from the fault condition. The LTC2937 is

tion to

programmed to recover on its own.

Note

that the LTC2937 ALERT pin requires a bus response

to de-assert once it asserts low. When using the LTC2937

in fully autonomous mode, we ignore the ALERT pin, and

to the LTC2937 data sheet. The following

recognizes 5 types

of faults:

-

the ALERT LED on the board. Once it is asserted, ALERTB

will remain asserted, and the ALERT LED illuminated. This

is harmless.

Supervisor Fault

A SUPERVISOR fault is caused by overvoltage (OV) detec

tion during sequence-up, or by OV or undervoltage (UV)

detection during normal operation (after a successful

sequence-up). In this demo configuration the LTC2937

automatically detects the fault and re-starts all of the

regulators.

Create this type of fault on the DC2313A board by pressing

the FAULT pushbutton, which momentarily pulls down the

EN4 line to GND, while in the sequenced-up state. This

will briefly disable and bring down the

create a UV condition. The LTC2937 will recognize the low

voltage and signal a SUPERVISOR fault.

1) Start with the system sequenced-up. The LDOs are on.

2) Press and release the FAULT pushbutton. This shorts

EN4 to GND, disabling the 1.8V LDO.

3) Observe the fault response:

All ENn pins pull low immediately. All ENn LEDs turn

off.

All of the LDO regulated supplies turn off immediately.

All CHn LEDs turn off.

The LTC2937 is configured to automatically re-try

after the fault, so it will attempt to sequence-up the

supplies. Since the fault was momentary, the resequence will succeed.

Pin FAULTB will assert low until the fault retry interval

is complete and the re-sequencing begins. The FAULT

LED will illuminate during this interval.

Pin RSTB will assert low until the LDOs come-up

after re-sequencing. The RST LED will illuminate

during this interval.

Pin ALERTB will assert low. The ALERT LED will

illuminate. The alert state will remain until an alert

response or a read from the CLEAR_ALERTB (0x28)

comes from the I

release the ALERTB pin.

2

C bus. Only a bus operation can

associated LDO

and

dc2313af

-

5

Page 6

DEMO MANUAL DC2313A

Quick start proceDure (without software)

The LTC2937 monitors each channel for individuallyprogrammed overvoltage and undervoltage thresholds.

The voltage monitoring is active while the supplies are

up or sequencing-up.

The LTC2937 is configured to re-try after the fault; it will

attempt to sequence-up again. There is a rich suite of fault

response capabilities in the part, including turning off and

staying off, turning-off then re-sequencing, continuing

operation without turning off, or entering a debug mode.

More details are available later in this manual, and in the

LTC2937 data sheet.

The FAULT indicators are self-clearing upon a re-sequence

initiation. The only fault indications after a successful

re-sequence-up are the asserted ALERTB pin, and the

EEPROM record of the first fault condition after the most

recent power-up that produced the fault. The ALERTB

pin will remain asserted low until the ALERT condition is

cleared with an I

Sequence Fault

A SEQUENCE fault is caused by supplies failing to meet

programmed voltage thresholds within programmed time

allowances during sequencing (for example, not ramping

fast enough).

Create this type of fault on the DC2313A board by pulling

and holding down one of the ENn

sequencing-up

sociated LDO

LTC2937 will recognize the unresponsive LDO and signal

a fault.

1) Start with the system sequenced-down. The LDOs are

off.

2) Short turret EN4 to GND and hold it there (press and

hold the FAULT pushbutton).

3) Press the “SEQUENCE UP/DOWN” button to initiate a

sequence-up operation.

EN1 - EN3 go high in sequence

CH1 - CH3 start in response to EN1-EN3

CH4 fails to start. LEDs EN4-6, CH4-6 remain off.

4) Observe the repeated fault retry response (see the table)

2

C bus operation.

turrets to GND while

the supplies. This will hold down the as-

and create a permanent UV condition. The

Pins EN1 - EN3 pull low immediately. All illuminated

ENn LEDs turn off.

All of the LDO regulated supplies turn off. Illuminated

CHn LEDs turn off.

The LTC2937 is configured to automatically re-try

after a delay, so it will attempt to sequence-up the

supplies after detecting the fault. Since the LDO is

shorted, the fault persists, and re-sequencing will

repeatedly fail. The cycle will repeat until the fault is

removed (by releasing the FAULT pushbutton).

Pin FAULTB will assert low for the retry interval,

re-sequence begins. LED FAULT will illuminate

the

during the interval.

The FAULTB pin clears as soon as a re-sequence

begins. The FAULT LED illuminates briefly, then goes

off.

Pin RSTB will remain low. The RST LED will remain

illuminated because not all of the supplies ever come

up.

Pin ALERTB will assert low. The ALERT LED will

illuminate. The alert state will persist until an alert

response or a read from the CLEAR_ALERTB (0x28)

comes from the I

release the ALERTB pin.

5) Remove the EN4 fault by releasing the FAULT pushbut

ton.

6) Observe that the part completes the re-sequence autonomously, and

The RST LED goes off after all supplies are up.

Each channel has an independently-configurable time limit

for starting-up and rising above its UV threshold voltage.

Each channel also has independently-programmable

sequence-down time parameters.

The LTC2937 is configured by default in the FAULT_RE

SPONSE (0x23) register

after all of the supplies are disabled and the voltages fall

below their discharge thresholds. While the EN4 pin is held

the fault persists, and the LTC2937 is programmed

low,

to automatically try to re-sequence the supplies forever,

so the behavior will repeat indefinitely.

2

C bus. Only a bus operation can

the

fault response clears automatically.

to automatically re-sequence-up

until

dc2313af

-

-

6

Page 7

DEMO MANUAL DC2313A

Quick start proceDure (without software)

After the fault goes away the next automatic re-sequence

will succeed. The FAULTB pin will de-assert. The FAULT

LED will go off. Initiation of the next sequence-up operation

will clear the fault information in registers. The ALERTB

pin will remain asserted low until the ALERT condition is

cleared with an I

Margining The Supplies

Margin testing stresses the system by moving voltages

beyond their normal OV and UV limits without generating

a fault. The MARGIN switch on the DC2313A board pulls

down the MARGB pin on the LTC2937, causing it to ignore

OV and UV faults while in the sequenced-up state. Note

that the LTC2937 does not control the voltages. Margining

the supplies involves pulling the regulators to out-of-spec

voltages, which is done outside of the LTC2937. The LDO

regulators on the DC2313A board do not change voltage,

but we can demonstrate MARGIN capability while disabling

one of the LDOs.

1) Begin with the system sequenced-down (all supplies

OFF)

While the supplies are down, the RST LED is illumi

nated.

Switch SW3 to the MARGIN position (MARGIN active).

2)

Observe the RST LED goes

LTC2937 is ignoring the UV conditions.

2

C bus operation.

-

off, indicating that the

3)

Press the “SEQUENCE UP/DOWN” pushbutton to

sequence-up normally.

The PB_EN and GLOBAL_ON LEDs will illuminate.

The ENn LEDs will illuminate in sequence: 1-6.

The CHn LEDs will illuminate in sequence with the

ENn LEDs.

The RST LED will remain off because the MARGIN

function is active.

The FAULT LED will remain off.

The ALERT LED will remain off.

No voltage (UV and OV) limits are measured. The

default timing parameters should not detect faults.

4) While the MARGIN switch is active, short the EN4 turret

to GND by pressing the FAULT pushbutton.

The corresponding CH4 will go down and the LED

will go off.

No faults are detected due to the MARGIN function.

Note that the MARGIN function is only useful while the

supplies are sequenced-up, not while they are in the process

of sequencing. Holding the MARGB pin asserted low does

not mask SEQUENCE (timing) faults during sequencingup operations. If a supply fails to meet its programmed

sequence-up voltage/timing requirements then the normal

fault response prevails, regardless of MARGB state.

software controL with LtpowerpLay

LTpowerPlay is a convenient PC

complete

other Linear Technology Power System Management parts.

Use it in off-line mode to build a system configuration file,

even with no hardware plugged-in, and use it with hard

ware connected

LTpowerPlay communicates using the I

system (covered in this manual), or in your real-world

product environment. It provides unprecedented control

over the Linear Technology chips on the I

access to the registers of the LTC2937, and many

to configure and debug your application.

software GUI that gives

2

C bus in the demo

2

C bus. Use it

during board bring-up to tune and optimize the power

system parameters. Use it during system debug to view

critical system information and troubleshoot board design

or manufacturing issues. LTpowerPlay includes extensive

-

help and documentation under the Help menu. On-line

help includes quick-start videos and tutorials, and detailed

technical documentation from the Linear Technology web

site. Getting started with LTpowerPlay is easy. Simply

download and install the PC software from here:

http://www.linear.com/ltpowerplay

dc2313af

7

Page 8

DEMO MANUAL DC2313A

software controL with LtpowerpLay

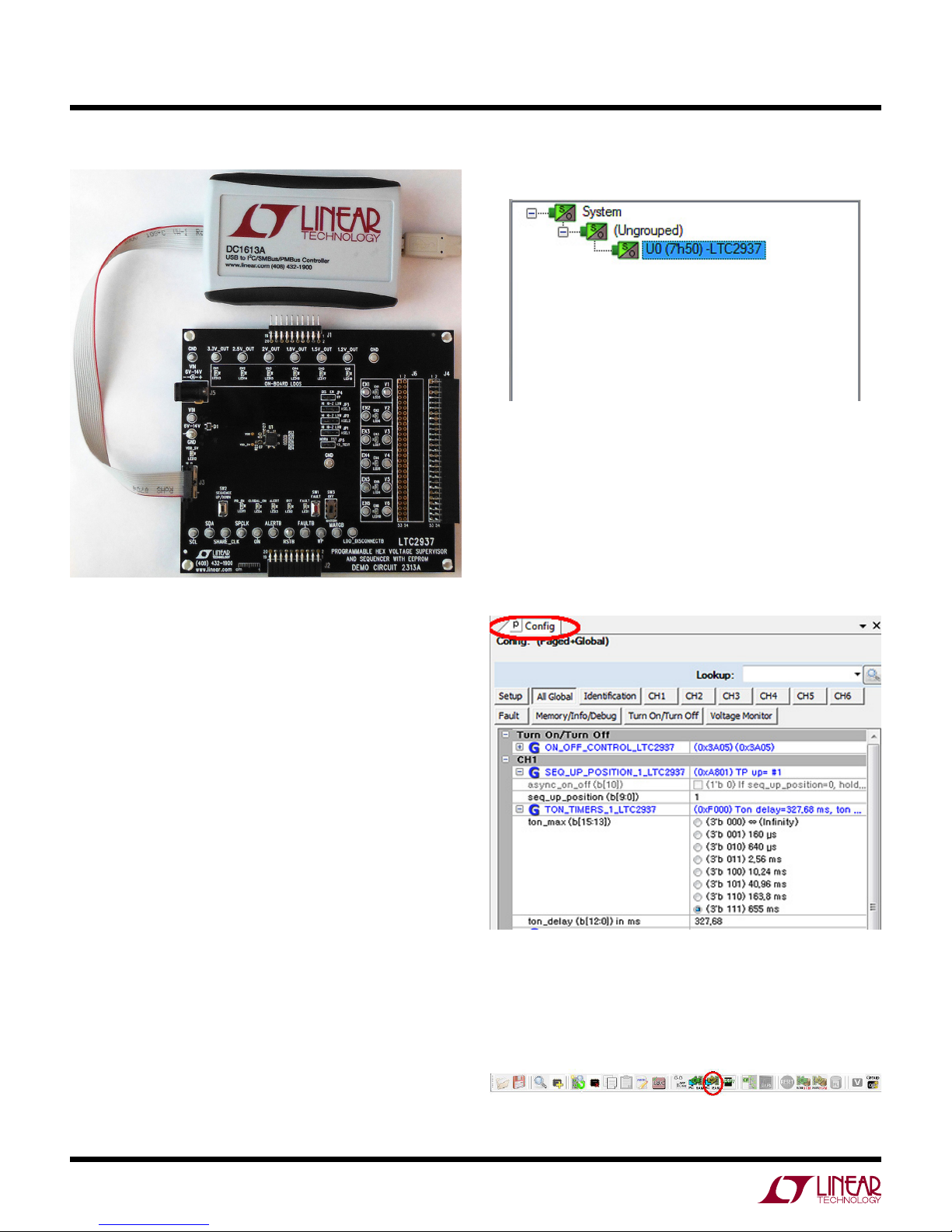

To the right of the system tree is the Configuration Register

pane, displaying all of the configuration registers available on

writable

offers clickable buttons and fields to edit the information

in these registers.

the selected device. This view shows all of the

LTpowerPlay System Tree

user-configurable RAM registers, and the GUI

Figure 4. DC2313A Demo Board Connected

to DC1613A I2C-to-USB Converter

The DC1613 USB-to-I2C adapter interfaces the PC running

LTpowerPlay to the DC2313A board (or any board with an

2

C bus). Connect the DC1613 adapter to the PC through a

I

USB cable, and connect it to the DC2313A board through

the ribbon cable to connector J3.

Launch the LTpowerPlay GUI on the PC. The software

identifies the DC1613 controller, then the DC2313A board,

and begins communicating through the I

LTC2937. Once this communication has been established,

the GUI displays its main window (Figure 5).

The LTpowerPlay GUI divides information into separate

panes in the window. On the left is the System Tree pane,

displaying a list of all Linear Technology devices identified

on the I

small, but if other supported devices are present on the

2

I

this list to selectively access it. Information in other panes

pertains to the selected device.

2

C bus. For a single LTC2937 device, the tree is

C bus, LTpowerPlay will add them. Click on a device in

2

C bus with the

LTpowerPlay Configuration Registers

Update register contents by clicking or typing to change

the desired registers, then selecting the “Write All” but-

the top toolbar. LTpowerPlay writes changes to the

ton in

updated registers.

8

dc2313af

Page 9

DEMO MANUAL DC2313A

software controL with LtpowerpLay

Figure 5. LTpowerPlay GUI Window

Note that programming the registers in the LTC2937 should

generally be done while the part is in the sequenced-down

state. Most of the registers have immediate control over

their respective chip functions, and changing them while

the part is sequenced-up will have unpredictable and ad

. It is

verse effects

updating configuration register settings. LTpowerPlay

implements limits to writing some registers, based upon

the device state, and will pop-up warnings when necessary.

Right of center in LTpowerPlay is the Telemetry pane,

displaying read-only information contained in the status

registers of the selected part. The GUI periodically polls

2

C bus and updates the Telemetry contents in real

the I

time, along with a user-friendly interpretation of the bits.

recommended to sequence-down before

-

LTpowerPlay Telemetry

dc2313af

9

Page 10

DEMO MANUAL DC2313A

software controL with LtpowerpLay

In the upper right corner of LTpowerPlay is the Chip

Dashboard pane, displaying a graphical representation of

the part status in a friendly, easy-to-understand format.

The live channel voltage comparator OV and UV states are

shown in the “Comparator Status”. The sequencing state

is represented in the “Sequencing” block. Fault status is

summarized in the “Fault Summary” block. Other status

bits are represented by light-up red-yellow-green indica

tors on

the part status at-a-glance.

the right-hand side. These intuitive indicators give

LTpowerPlay Chip Dashboard

-

The LTC2937 features an EEPROM non-volatile memory

that holds device configuration information and a snapshot

of past fault information. When the part receives power

it executes a power-on reset, and restores the contents

of the EEPROM to its operating RAM memory. Following

this power-on restore, operating RAM memory can be

modified with I

behavior. This modified state can be stored to the EEPROM

with a STORE (0x2C) command, making it available as the

future default power-up state. The STORE command will

copy the entire contents of the configuration RAM into

EEPROM. The data sheet recommends storing EEPROM

contents only while the part is sequenced-down.

In addition to power-on reset, the EEPROM contents can

also be retrieved to RAM operating memory with a RE

STORE (0x2D) command. RESTORE wipes-out the content

of the RAM and replaces it with the EEPROM contents.

Only perform a RESTORE when the LTC2937 is in the

sequenced-down state, as the RAM operating memory

immediately affects the chip, and changing its contents

while sequenced-up can result in unpredictable behavior.

2

C bus commands that modify the part

-

LTC2937 REGISTERS

LTC2937 RAM and Non-Volatile Memory

The LTC2937 is highly configurable through its register

set. Refer to the LTC2937 data sheet for a complete

discussion of the registers and functions available. Get

immediate access to detailed help for the selected register

in LTpowerPlay by pressing the F1 key on your keyboard.

Both RAM and EEPROM respect write-protection on the

LTC2937. Both the

(0x00) register provide write protection. Configure both the

pin and the register to allow writing to memory. To enable

writing, pull the hardware WP pin to ground by setting

jumper JP4 to DIS. Write the command 0x00 with bit 0 = 0,

and the same key that is in WRITE_PROTECTION[15:2]. The

demo board default for the WRITE_PROTECTION register

and the WP pin allow writing to memory.

The following exercises approach the registers in a task-

oriented manner, demonstrating register functions through

examples.

Default Configuration

If the LTC2937 EEPROM contains non-default contents,

then returning it to the demo-board default settings can

be accomplished with the LTpowerPlay “Demo” menu

selection.

WP pin and the WRITE_PROTECTION

10

dc2313af

Page 11

DEMO MANUAL DC2313A

software controL with LtpowerpLay

Clicking the “Demoboard Defaults” menu item stores

default register settings in RAM, issues a CLEAR command, then

contents

into its default setting for the demo board. Note that this

procedure only works if the ASEL jumpers are configured

in their default settings:

ASEL1 = HI

ASEL2 = HI

ASEL3 = HI

ON/OFF CONTROL

The LTC2937 provides control over all of its functions

through the register interface. This includes ON/OFF con

trol. The

to

a register ON/OFF bit, or to both. In this exercise, we

will sequence the system up and down using the I

command, ignoring the hardware ON/OFF pin. To program

the part to turn on and off through the I

executes a STORE command to store the RAM

into EEPROM. This places the LTC2937 back

part can respond to the hardware ON/OFF pin, or

2

C bus

2

C bus:

-

The supplies sequence-up normally

4)

The ENn LEDs will illuminate in sequence: 1-6.

The CHn LEDs will illuminate in sequence with the

ENn LEDs.

The RST LED will turn off after the last CHn LED

illuminates.

The LTC2937 Chip Dashboard in LTpowerPlay

tracks the internal register status in real time as it

sequences-up.

1) Start with the part sequenced-down (PB_EN LED is off,

LDOs are off).

2) Program register ON_OFF_CONTROL (0x02) by clicking

the checkboxes for each bit to sequence-up via the I

bus:

b[2] = 0 (ignore the ON input pin)

b[3] = 1 (honor the software ON/OFF bit)

b[4] = 1 (software ON

3) Send the register updates from LTpowerPlay to the

LTC2937 by pressing the Write All Button:

/OFF state is ON)

2

C

In the LTC2937 internal registers:

The ON_OFF_CONTROL[7] bit becomes set, indicat

ing that the part is commanded to sequence-up.

The STATUS_INFORMATION[11:10] bits cycle

through the sequence-up states:

00b : sequence-down complete

01b : sequence-up in-progress

11b : sequence-up complete

The SEQ_POSITION_COUNT[9:0] bits count through

the sequence-up states (1 – 7).

The FAULT LED will remain off.

The ALERT LED will remain off.

The PB_EN and GLOBAL_ON LEDs will remain off.

The ON pin is low.

The default voltage (UV and OV) limits and timing

parameters should not detect faults.

-

dc2313af

11

Page 12

DEMO MANUAL DC2313A

software controL with LtpowerpLay

5) Setting register bit ON_OFF_CONTROL[4] = 0

commands the part to sequence-down. All sequence

timing and voltage limits apply. Click the i2c_on_off

(b[4]) checkbox and hit ‘F12’ on the keyboard to update

the register in the LTC2937.

The ENn LEDs will turn off in sequence: 6-1.

The CHn LEDs will turn off in sequence with the ENn

LEDs.

The RST LED will illuminate after the first CH6 LED

turns off.

The ON_OFF_CONTROL[7] bit becomes low, indicating

that the part is commanded to sequence-down.

Restore the EEPROM default register settings by execut

ing a RESTORE (0x2D) command. In LTpowerPlay this

command

followed by the read RAM registers button:

SUPPLY SEQUENCE ORDER

The LTC2937 provides complete sequence order and timing

control over enabling and disabling

supplies

to go down in any (different) order. The LTC2937 provides

up to 1023 ordered sequence positions in which events

can be scheduled during sequence-up and sequence-down.

Each supply has its own SEQ_UP_POSITION_n register

(0x16 – 0x1B) and SEQ_DOWN_POSITION_n register

(0x1C – 0x21). In the demo-board default settings, the

supplies sequence-up in the order 1-6, and sequencedown in the order 6-1. We can change this ordering by

writing to the registers:

is issued by pressing the RESTORE button,

the supplies. Sequenced

can be commanded to come-up in any order, and

-

The STATUS_INFORMATION[11:10] bits cycle through

the sequence-down states:

11b : sequence-up complete

10b : sequence-down in-progress

00b : sequence-down complete

The SEQ_POSITION_COUNT[9:0] bits count through

the sequence-down states (1 – 7).

The FAULT LED will remain off.

The ALERT LED will remain off.

The PB_EN and GLOBAL_ON LEDs will remain off. The

ON pin is low.

The default voltage (UV and OV) limits and timing

parameters should not detect faults.

This procedure is equivalent to pressing the “SEQUENCE

UP/DOWN” pushbutton on the board to command a

sequence-up and sequence-down.

1) Begin with the LTC2937 in the sequenced-down state

(all supplies off).

2) Write each of the 6 SEQ_UP_POSITION_n registers to

change their sequence positions:

SEQ_UP_POSITION_1 = 0x0005 : place channel 1 in

sequence position 5

Do this by clicking on the “SEQ_UP_POSITION_1_

LT C2937” text, and typing 0x0805 then ENTER. This

updates the register value in the GUI.

You may also click on “seq_up_position (b[9:0])” and

typing “5” ENTER. Notice that the hex value updates

as a result.

12

dc2313af

Page 13

DEMO MANUAL DC2313A

software controL with LtpowerpLay

4) If you have not already written the GUI configuration

to RAM (using F12), then update all registers with the

Write All button

5) Initiate a sequence-up by writing ON_OFF_CONTROL[4:2] = 110.

After modifying a register hit F12 on the keyboard to

update that register in the LTC2937 RAM.

Continue with the other channels:

SEQ_UP_POSITION_2 = 0x0007 : place channel 2 in

sequence position 7

SEQ_UP_POSITION_3 = 0x0003 : place channel 3 in

sequence position 3

SEQ_UP_POSITION_4 = 0x0001 : place channel 4 in

sequence position 1

SEQ_UP_POSITION_5 = 0x0002 : place channel 5 in

sequence position 2

SEQ_UP_POSITION_6 = 0x0004 : place channel 6 in

sequence position 4

3) Write each of the 6 SEQUENCE_DOWN_POSITION_n

registers to change their sequence positions:

SEQ_DOWN_POSITION_1 = 0x0001 : place channel 1

in sequence position 1

SEQ_DOWN_POSITION_2 = 0x0001 : place channel 2

in sequence position 1

SEQ_DOWN_POSITION_3 = 0x0007 : place channel 3

in sequence position 7

SEQ_DOWN_POSITION_4 = 0x0003 : place channel 4

in sequence position 3

Remember that we are programmed to ignore the

SEQUENCE UP/DOWN pushbutton.

6) Observe the modified sequence-up order as the sup

plies come up.

The ON_OFF_CONTROL[7] bit becomes set

The STATUS_INFORMATION[11:10] bits cycle

through the sequence-up states

The SEQ_POSITION_COUNT[9:0] bits count through

the sequence-up states (1-8).

7) Initiate a sequence-down by writing ON_OFF_CON

TROL[4:2] = 010.

The SEQ_POSITION_COUNT[9:0] bits count through

the sequence-down states (1-1023-0).

Notice that channel 5 is in the last sequence-down

position (1023). During sequence-down operation

the SEQUENCE POSITION COUNT will count up to

1023 before de-activating EN5, then roll-over to count

0 before stopping.

Restore the EEPROM default register settings by

executing a RESTORE (0x2D) command. In LT

powerPlay this

RESTORE button, followed by the read RAM registers

button:

command is issued by pressing the

-

-

-

SEQ_DOWN_POSITION_5 = 0x03FF : place channel 5

in sequence position 1023

SEQ_DOWN_POSITION_6 = 0x0004 : place channel 6

in sequence position 4

dc2313af

13

Page 14

DEMO MANUAL DC2313A

software controL with LtpowerpLay

Each supply can occupy any one of the 1023 available

sequence positions. Multiple supplies can occupy the same

sequence position – for example, they could all occupy

sequence position 3. Unused sequence positions take a

minimal amount of time (80µs) to complete, but do not

trigger any enable or disable events. The part continues

counting until the last used sequence position, plus one.

Within each sequence position, additional flexibility is

available for enable and disable timing of each supply

using the ton_delay and toff_delay settings. Each supply

can delay up to 655ms from the start of its sequence

position before enabling (TON_TIMERS[12:0]) or disabling

(TOFF_TIMERS[12:0]). This provides deterministic timing

relationships between supplies within a sequence position.

The sequence position clock waits for all scheduled sup

plies in that position. These behaviors are best observed

with a scope, since the time resolution is microseconds

– much faster than the eye can observe the LEDs on the

board sequencing.

Further flexibility is available if multiple LTC2937s

sequence many supplies. The LTC2937 parts communicate

through the SPCLK and SHARE_CLK signals so that

they maintain a common sequence count and timebase,

and a large number of supplies

autonomously

SEQ_UP_POSITION, SEQ_DOWN_POSTION, ton_delay,

and toff_delay registers to freely interleave supplies across

multiple LTC2937s.

coordinated, deterministic manner. Use the

can be sequenced in an

-

Try Count

Re-

In the DC2313 demo board the LTC2937 is configured

to re-try an unlimited number of times when it detects

a SUPERVISOR or SEQUENCE fault. It can instead be

configured to respond in a limited way to a fault, and

give-up if the problem persists. The number of re-try

attempts can be set with the FAULT_RESPONSE[2:0]

register bits (retry_number). Any number of attempts can

be specified, from 0 to 6, or unlimited. The

to a SUPERVISOR or SEQUENCE fault by turning-off the

supplies, then trying to sequence-up. It will register the

number of attempts in the FAULT_RESPONSE[13:11] bits,

and stay off after failing the specified number of times.

Fault Debug

In this exercise set the fault response to zero automatic

re-tries, which will enable debugging. Create a fault on the

DC2313A board with the FAULT pushbutton.

1) Start with the system sequenced-down. The LDOs are

off.

2) Set FAULT_RESPONSE[2:0] = 0x0. This sets zero re-try

attempts after a fault.

part will

respond

FAULT RESPONSE

To this point, the demonstrations have shown the LTC2937

responding to faults by autonomously re-starting the

supplies without software. This important behavior is

only one of the possible choices, however. The LTC2937

provides a rich and configurable set of fault response

capabilities allowing either an autonomous recovery, an

2

C bus mediated response, or a completely interactive

I

software debugging experience.

The LTC2937 data sheet details all of the fault-response

registers, and the various programming options for han

dling faults, and debugging behaviors. Below are several

examples.

14

-

dc2313af

Page 15

DEMO MANUAL DC2313A

software controL with LtpowerpLay

3) Press the “SEQUENCE UP/DOWN” pushbutton and

wait for sequence-up to complete.

4) Press and release the FAULT pushbutton, momentarily

shorting EN4 to GND and bringing down the 1.8V LDO.

The LTC2937 immediately recognizes the low V4 voltage.

5) Observe the fault response

All ENn pins pull low immediately. All ENn LEDs

turn off.

All of the LDO regulated supplies turn off immediately.

All Chn LEDs turn off.

The fault response setting allows no re-try attempts,

so the supplies remain off.

Pin FAULTB will assert and remain low. LED FAULT

will illuminate.

Pin RSTB will assert low. LED RST will illuminate.

Pin ALERTB will assert low. LED ALERT will illuminate.

The alert state will remain until an alert response or

a read from the CLEAR_ALERTB (0x28) comes from

2

C bus.

the I

Register MONITOR_STATUS (0x30) will briefly report

the real time UV comparator assertion until the fault

goes away when the FAULT button is released.

Register MONITOR_STATUS_HISTORY (0x26) will

report the latched SUPERVISOR UV fault condition.

This information remains because the LTC2937 does

not re-sequence.

The LTpowerPlay Chip Dashboard shows the summary

of fault information. This conveniently indicates that the

part has detected a SUPERVISOR UV fault, and that fault

information is stored in the EEPROM MONITOR_BACKUP

register.

Note that the V4 dial has a double red arc, indicating that

the V4 channel caused the UV fault that brought-down

the system.

Notice that ALL status information is retained in the

state it was in when the fault occurred. This includes the

sequencer state (SP=7, Syst=UP, Chip=UP). The STATUS_

INFORMATION[11:10] and STATUS_INFORMATION[9:8]

were in the “sequence-up complete” state when the fault

occurred, so these states are retained. The state machine

still thinks it is in the same state.

Register STATUS_INFORMATION (0x29) will report

the latched SUPERVISOR UV fault condition.

Register MONITOR

MONITOR_STATUS_HISTORY register contents, but

only if this is the first fault since power applied. If this

is not the first fault, MONITOR_BACKUP will contain

older fault information. Execute a RESTORE command

to view the MONITOR_BACKUP register contents.

The LTC2937 does not attempt to recover from the fault.

Instead, it turns-off all of the supplies and retains all of

its status register contents. This enables a thorough postfault examination of status registers in the state they were

when the fault occurred.

_BACKUP in

EEPROM will mirror

dc2313af

15

Page 16

DEMO MANUAL DC2313A

software controL with LtpowerpLay

Status register contents are cleared when the LTC2937

begins a new sequence-up operation, so allowing auto-

-try

matic re

that might exist in the registers.

The only fault information that will persist beyond a

successful re-sequence initiation is in the EEPROM

MONITOR_BACKUP register, which stores the contents

of the MONITOR_STATUS_HISTORY register when the

first fault after power-up is detected.

The ALERTB pin will remain asserted low until the ALERT

condition is cleared with an I

Recovering from and Clearing Faults

The FAULTB pin and status registers respond to a fault

condition, but can be cleared when the LTC2937 resequences the power supplies. Along with the status

information registers, the FAULTB pin is cleared when the

sequence starts. In the case where fault information and

the FAULTB pin need to be cleared manually, the CLEAR

(0x2E) command is available.

after a fault eliminates the debug information

2

C bus (ARA) operation.

Clearing the ALERTB Pin

The ALERTB pin conforms to the SMBus protocol for

the SMBALERT fault response. It is designed to act as

an interrupt for a controller on the I

ALERTB pin asserts when a fault event occurs, and it can

only be cleared by an appropriate bus response from the

controller.

When the ALERTB pin asserts, a controller may either

execute an alert response through the Alert Response

Address (0x0C), which is a defined as the ARA in the

SMBus protocol, or the controller may read from register

CLEAR_ALERTB (0x28) to immediately de-activate the

ALERTB pin.

LTpowerPlay will include the CLEAR_ALERTB command

when sending a CLEAR_FAULTS command if the behavior

is selected in the Preferences menu. Pull-down View→

Preferences…, then select “Issue CLEAR_ALERTB on

CLEAR” = TRUE. When you click the CLEAR_FAULTS

button in the GUI it will also clear ALERTB.

2

C bus. The LTC2937

LTpowerPlay allows the user to issue the CLEAR command

(0x2E) that clears the fault and status registers. Issue the

CLEAR command by pressing the “CLEAR” button in the

toolbar:

Warning: avoid issuing a CLEAR command while the

LTC2937 is in the sequenced-up state. The registers and

state-machines that get cleared have an immediate ef

fect on the part, and will cause the supplies to fault and

re-sequence, which is usually an undesired behavior.

Sequence-down before issuing a CLEAR command.

If the LTC2937 is waiting, not re-trying, after a fault, turn

it off (press the “SEQUENCE UP/DOWN” button to turnoff the PB_EN and GLOBAL_ON LEDs). The LTC2937 will

retain state, but will be ready to sequence-up. Press the

“SEQUENCE UP/DOWN” button again to sequence-up

normally and clear the latched fault status and the FAULTB

pin. The ALERT pin will remain asserted until cleared.

-

16

dc2313af

Page 17

DEMO MANUAL DC2313A

software controL with LtpowerpLay

EEPROM Fault Backup

The LTC2937 stores information about the “first” fault that it

detects into the EEPROM MONITOR_BACKUP register. The

information is a copy of the MONITOR_STATUS_HISTORY

register at the time of the fault. Subsequent power-cycling

has no effect on this stored information, which can be

read with the MONITOR_BACKUP command (0x2F)

after a RESTORE, or a after a power-cycle. This debug

information survives subsequent sequencing operations,

and power cycling. Only the first fault information is stored

in EEPROM. The indicator bit, STATUS_INFORMATION[12]

holds a persistent 1 if the MONITOR_BACKUP register

contains a fault record.

Re-arm the MONITOR_BACKUP register to accept a new

“first” fault by clearing it according to this recipe:

1) Begin in the sequenced-down state. The supplies are

off. The register STATUS_INFORMATION[11:8] = 0x0.

2) Issue a CLEAR command (0x2E) by pressing the “CF”

button in LTpowerPlay. This clears any fault information,

including MONITOR_STATUS_HISTORY.

4) Issue a RESTORE command (0x2D). This restores

the clean MONITOR_BACKUP register contents from

EEPROM. It clears the STATUS_INFORMATION[12]

indicator bit. It also restores all configuration registers

from EEPROM.

Note that it is important to perform the CLEAR and RE

(

STORE operations

sequencing-down. The internal sequencing state machine

receives a reset when the CLEAR command is issued. If the

LTC2937 is sequenced-up, or in the process of sequenc

ing, this reset will generate a fault, possibly turn off the

supplies, and re-sequence-up.

be aware that the STORE command affects the entire

Also

EEPROM, not only the MONITOR_STATUS_HISTORY

word. This means that any changes that have been made to

the RAM configuration registers will be stored in EEPROM.

Also, if there is newer fault information in RAM than in

the first fault MONITOR_BACKUP register, it will be stored

into EEPROM with a STORE command.

in that order) while the part is finished

-

-

3) Issue a STORE command (0x2C). This stores the clean

MONITOR_STATUS_HISTORY register contents to

EEPROM. It also stores all configuration registers to

EEPROM.

dc2313af

17

Page 18

DEMO MANUAL DC2313A

Dc2313a BoarD Description

18

Figure 6. DC2313A Demo Board Layout

dc2313af

Page 19

DEMO MANUAL DC2313A

parts List

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

Required Circuit Components

1 4 C1, C7, C10, C17 CAP., 0.1µF, X5R, 16V, 10%, 0603 MURATA, GRM188R61C104KA01D

2 7 C2, C11-C16 CAP., 2.2µF, X5R, 10V, 10%, 0603 MURATA, GRM188R61A225KE34D

3 2 C3, C4 CAP., 0.01µF, X7R, 10V, 10%, 0603 AVX, 0603ZC103K AT2A

4 2 C5, C9 CAP., 10µF, X5R, 16V, 10%, 0805 MURATA, GRM21BR61C106KE15L

5 1 C6 CAP., 22µF, X5R, 25V, 20%, 0805 MURATA, GRM21BR61E226ME44K

6 1 C8 CAP., 1µF, X5R, 16V, 10%, 0603 MURATA, GRM188R61C105KA93D

7 1 D1 DIODE, Schottky, SOT23 VISHAY, BAS70-05-E3-08

8 34 E1-E34 TEST POINT, TURRET, .094" MTG. HOLE MILL-MAX, 2501-2-00-80-00-00-07-0

9 3 JP1, JP2, JP3

10 2 JP4, JP5

11 1 J1

12 1 J2

13 1 J3

14 1 J4

15 1 J5 CONN., POWER JACK, 2.1mm CUI INC., PJ-002AH

16 0 J6

17 2 LED1, LED3 LED, RED, 0603 PANASONIC, LNJ237W82RA

18 1 LED2 LED, AMBER, 0603 PANASONIC, LNJ426W83RA

19 15 LED4-LED18 LED

20

21 6 Q8-Q13 XSTR., NPN, SOT23 FAIRCHILD, MMBT3904

22 19 R1-R4, R6, R8, R10,

23 20 R5, R7, R9, R11, R13,

24 1 R20 RES., 374k, 1/16W, 1%, 0402 VISHAY, CRCW0402374KFKED

25 11 R27, R28, R32, R37,

26 1 R31 RES., 46.4k, 1/16W, 1%, 0402 VISHAY, CRCW040246K4FKED

27 1 R33 RES., 9.31k, 1/16W, 1%, 0402 VISHAY, CRCW04029K31FKED

28 1 R34 RES., 249, 1/16W, 1%, 0402 VISHAY, CRCW0402249RFKED

29 1 R35 RES., 1k, 1/16W, 1%, 0402 VISHAY, CRCW04021K00FKED

30 6 R43, R44, R50,

31 1 R49 RES., 1.37M, 1/16W, 1%, 0402 VISHAY, CRCW04021M37FKED

32 1 R51 RES., 590k, 1/16W, 1%, 0402 VISHAY, CRCW0402590KFKED

33 1 SW1 SWITCH, Push Button, SW-PTS635-25 C&K Components, PTS635SK25SMTR LFS

7 Q1-Q7 XSTR., MOSFET, N-CH, SOT523 DIODES INC., DMG1012T-7

R12, R14, R16, R18,

R23, R29, R39, R40,

R45, R46, R53, R54

R15, R17, R19, R21,

R22, R24-R26, R30,

R59-R64

R38, R41, R42, R47,

R48, R55, R56

R52, R57, R58

CONN., HEADER, 1×4, 2mm

CONN., HEADER, 1×3, 2mm

CONN., HEADER, 2×10, .100", R/A

CONN., SOCKET, 2×10, .100", R/A

CONN., HEADER, 2×6, 2mm, STR DL PCB

CONN., SOCKET, 2×27, .100", R/A

CONN., SOCKET, 2×27, .100", R/A

, GREEN, 0603 PANASONIC, LNJ326W83RA

RES., 3.01k, 1/10W, 1%, 0402 VISHAY, CRCW04023K01FKED

RES., 100k, 1/16W, 1%, 0402 VISHAY, CRCW0402100KFKED

RES., 10k, 1/16W, 1%, 0402 VISHAY, CRCW040210K0FKED

RES., 200k, 1/16W, 1%, 0402 VISHAY, CRCW0402200KFKED

SULLINS, NRPN041PAEN-RC

SULLINS, NRPN031PAEN-RC

MILL-MAX, 802-40-020-20-001000

MILL-MAX, 803-93-020-20-001000

FCI, 98414-G06-12ULF

SULLINS, PPTC272LJBN-RC

OPT

dc2313af

19

Page 20

DEMO MANUAL DC2313A

parts List

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

34 1 SW2 SWITCH, Push Button, SW-PTS635-25 C&K Components, PTS635SL25SMTR LFS

35 1 SW3 CONN, SUB MINIATURE SLIDE SWITCHES C&K.,JS202011CQN

36 1 U1

37 2 U2, U3 I.C., DUAL BUFFERS, TSOP-6 NXP, 74LVC 2G07GV,125

38 1 U4

39 1 U5 I.C., LINEAR REG - 5V, TSOT23-5 LINEAR TECH., LT1761ES5-5

40 1 U6 I.C., DIODE OR, MSE16 LINEAR TECH., LTC4415IMSE

41 3 U7, U8, U9 I.C ANALOG SWITCH, SO16 LINEAR TECH, LTC222CS

42 1 U10 I.C SERIAL EEPROM, TSSOP8 MICROCHIP, 24AA02-I /ST

43 1 U11

44 1 U12

45 1 U13

46 1 U14

47 1 U15

48 1 U16

49 5 SHUNTS ON JP1-JP5

PINS 1&2

50 4 MH1-MH4 ST

I.C, LTC2937IUHE, QFN28UHE-5×6

I.C., PUSH BUTTON, DFN8DDB-3×2

I.C, LINEAR REG., DFN6DC-2×2

I.C, LINEAR REG., DFN6DC-2×2

I.C, LINEAR REG., DFN6DC-2×2

I.C, LINEAR REG., DFN6DC-2×2

I.C, LINEAR REG., DFN6DC-2×2

I.C, LINEAR REG., DFN6DC-2×2

SHUNT, .079" CENTER SAMTEC, 2SN-BK-

ANDOFF, SNAP ON, 1/4" KEYSTONE, 8831

LINEAR TECH., LTC2937IUHE

LINEAR TECH., LTC2954IDDB-2

LINEAR TECH., LT3008IDC-3.3

LINEAR TECH., LT3008IDC-2.5

LINEAR TECH., LT3008IDC

LINEAR TECH., LT3008IDC-1.8

LINEAR TECH., LT3008IDC-1.5

LINEAR TECH., LT3008IDC-1.2

G

20

dc2313af

Page 21

schematic Diagram

DEMO MANUAL DC2313A

dc2313af

21

Page 22

DEMO MANUAL DC2313A

schematic Diagram

22

dc2313af

Page 23

schematic Diagram

DEMO MANUAL DC2313A

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

dc2313af

23

Page 24

DEMO MANUAL DC2313A

DEMONSTRATION BOARD IMPORTANT NOTICE

Linear Technology Corporation (LT C) provides the enclosed product(s) under the following AS IS conditions:

This demonstration board (DEMO BOARD) kit being sold or provided by Linear Technology is intended for use for ENGINEERING DEVELOPMENT

OR EVALUATION PURPOSES ONLY and is not provided by LT C for commercial use. As such, the DEMO BOARD herein may not be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including but not limited to product safety

measures typically found in finished commercial goods. As a prototype, this product does not fall within the scope of the European Union

directive on electromagnetic compatibility and therefore may or may not meet the technical requirements of the directive, or other regulations.

If this evaluation kit does not meet the specifications recited in the DEMO BOARD manual the kit may be returned within 30 days from the date

of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY THE SELLER TO BUYER AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THIS INDEMNITY, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user releases LT C from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. Also be aware that the products herein may not be regulatory compliant or

agency certified (FCC, UL, CE, etc.).

No License is granted under any patent right or other intellectual property whatsoever. LTC assumes no liability for applications assistance,

customer product design, software performance, or infringement of patents or any other intellectual property rights of any kind.

LT C currently services a variety of customers for products around the world, and therefore this transaction is not exclusive.

Please read the DEMO BOARD manual prior to handling the product. Persons handling this product must have electronics training and

observe good laboratory practice standards. Common sense is encouraged.

This notice contains important safety information about temperatures and voltages. For further safety concerns, please contact a LTC application engineer.

Mailing Address:

Linear Technology

1630 McCarthy Blvd.

Milpitas, CA 95035

Copyright © 2004, Linear Technology Corporation

Linear Technology Corporation

24

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

dc2313af

LT 0615 • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2015

Loading...

Loading...