Page 1

Flat Washer

M3 Nut

Camera Bracket

Axis (pem stud)

Left

Right

Up

Down

34

12

12

6

Viewing window

for camera

Viewing window

for camera

304.8

152.4

304.8

Pen Stud

for Side-mounted

Camera

Push here to

adust the

camera’s viewing

angle

Camera Bracket

Counter Sinks

HeIgHt strIp camera

Hc serIes

I n s t a l l a t I o n a n d o p e r a t I n g I n s t r u c t I o n s

w w w . l I n e a r c o r p . c o m

Page 2

IMPORTANT SAFEGUARDS

1. Read Instructions - All the safety and operating instructions

should be read before the unit is operated.

2. Retain Instructions - The safety and operating instructions

should be retained for future reference.

3. Heed Warnings - All warnings on the unit and in the

operating instructions should be adhered to.

4. Follow Instructions - All operating and use instructions

should be followed.

5. Cleaning - Unplug the unit from the outlet before cleaning.

Do not use liquid cleaners or aerosol cleaners. Use a damp

cloth for cleaning.

6. Attachments - Do not use attachments not recommended by

the product manufacturer as they may cause hazards.

7. Accessories - Do not place this unit on an unstable stand,

tripod, bracket, or mount. The unit may fall, causing serious

injury to a person and serious damage to the unit. Use only

with a stand, tripod, bracket, or mount recommended by

the manufacturer or sold with the product. Any mounting

of the unit should follow the manufacturer’s instructions

and should use a mounting accessory recommended by the

manufacturer.

An appliance and cart combination should be moved with

care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to overturn.

8. Ventilation - Openings in the enclosure, if any, are provided

for ventilation, to ensure reliable operation of the unit, and

to protect it from overheating. These openings must not be

blocked or covered. This unit should not be placed in a builtin installation unless proper ventilation is provided or the

manufacturer’s instructions have been adhered to.

9. Power Sources - This unit should be operated only from

the type of power source indicated on the marking label. If

you are not sure of the type of power supply you plan to

use, consult your dealer or local power company. For units

intended to operate from battery power or other sources,

refer to the operating instructions. This equipment is to be

isolated from the mains supply by a limited power source as

specified in EN60950:1992 Clause 2.11.

10. Grounding or Polarization - This unit may be equipped with

a polarized alternating-current line plug (a plug having one

blade wider than the other). This plug will fit into the power

outlet only one way. This is a safety feature. If you are unable

to insert the plug fully into the outlet, try reversing the plug.

If the plug should still fail to fit, contact your electrician

to replace your obsolete outlet. Do not defeat the safety

purpose of the polarized plug.

Alternately, this unit may be equipped with a 3-wire

grounding-type plug, a plug having a third (grounding) pin.

This plug will only fit into a grounding-type power outlet.

This is a safety feature. If you are unable to insert the plug

into the outlet, contact your electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the

grounding-type plug.

11. Power Cord Protection - Power supply cords should be

routed so that they are not likely to be walked on or

pinched by items placed upon or against them, paying

particular attention to cords and plugs, convenience

receptacles, and the point where they exit from the

appliance.

12. Power Lines - An outdoor system should not be located in

the vicinity of overhead power lines or other electric light

or power circuits or where it can fall into such power lines

or circuits. When installing an outdoor system, extreme care

should be taken to keep from touching such power lines or

circuits as contact with them might be fatal. U.S.A. models only

- refer to the National Electrical Code Article 820 regarding

installation of CATV systems.

13. Overloading - Do not overload outlets and extension cords

as this can result in a risk of fire or electric shock.

14. Object and Liquid Entry - Never push objects of any kind

into this unit through openings, as they may touch dangerous

voltage points or short out parts that could result in a fire or

electric shock. Never spill liquid of any kind on the unit.

15. Servicing - Do not attempt to service this unit yourself as

opening or removing covers may expose you to dangerous

voltage or other hazards. Refer all servicing to qualified

service personnel.

16. Damage Requiring Service - Unplug the unit from the outlet

and refer servicing to qualified service personnel under the

following conditions:

a. When the power supply cord or plug is damaged.

b. If liquid has been spilled or objects have fallen into the

unit.

c. If the unit has been exposed to water and/or inclement

weather (rain, snow, etc.).

d. If the unit does not operate normally by following the

operating instructions. Adjust only those controls that

are covered by the operating instructions, as an improper

adjustment of other controls may result in damage and

will often require extensive work by a qualified technician

to restore the unit to its normal operation.

e. If the unit has been dropped or the cabinet has been

damaged.

f. When the unit exhibits a distinct change in performance--

this indicates a need for service.

17. Replacement Parts - When replacement parts are required,

be sure the service technician has used replacement

parts specified by the manufacturer or have the same

characteristics as the original part. Unauthorized substitutions

may result in fire, electric shock, or other hazards.

18. Safety Check - Upon completion of any service or repairs to

this unit, ask the service technician to perform safety checks

to determine that the unit is in proper operating condition.

19. Coax Grounding - If an outside cable system is connected

to the unit, be sure the cable system is grounded. U.S.A.

models only--Section 810 of the National Electrical Code,

ANSI/NFPA No.70-1981, provides information with respect

to proper grounding of the mount and supporting structure,

grounding of the coax to a discharge unit, size of grounding

conductors, location of discharge unit, connection to

grounding electrodes, and requirements for the grounding

electrode.

20. Lightning - For added protection of this unit during a lightning

storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet and disconnect

the cable system. This will prevent damage to the unit due to

lightning and power line surges.

2

Page 3

SAFETY PRECAUTIONS

CAUTION: TO REDUCE THE RISK

OF ELECTRIC SHOCK, DO NOT

REMOVE COVER (OR BACK). NO USER

SERVICEABLE PARTS INSIDE. REFER

SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol indicates the presence of

uninsulated “dangerous voltage” within the product’s enclosure. This may

constitute a risk of electric shock.

The user should consult the operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

Attention: Installation should be performed

by qualified service personnel only in accordance with the National Electrical Code or

applicable local codes.

Power Disconnect. Units with or without

ON-OFF switches have power supplied to the

unit whenever the power cord is inserted into

the power source; however, the unit is operational only when the ON-OFF switch is in the ON position. The power cord is the main power disconnect for

all units.

1 UNPACKING

Unpack carefully. This is electromechanical equipment and

should be handled with care.

Check for the following items:

• Verify the unit model number.

• Verify that parts listed below have been included.

HC1CH30-6xx - Height Strip w/ one 650TVL color camera

and 3.0mm lens.

Hardware Kit

5 x Cable Ties

5 x Cable Tie Mounts

3 x Plastic Wall Anchor

3 x No. 8 cross recessed self-tapping screw, 1-1/2” length

1 x Barrel Plug Connector, 2.1mm pin, 36” length,

stripped leads

1 x 12VDC 0.5 Amp Power Adapter, 6-foot cord

CAM-HC1CH30-6 - Accessory 650TVL color camera w/

3.0mm fixed lens

Hardware Kit

1 x 12VDC 0.5 Amp Power Adapter, 6-foot cord

1 x M3 Nylon Lock Nut

1 x Flat Washer

MT-HC – Accessory Wall Bracket to turn the Height Strip

90° Left or Right

3 x M4 Screw, Pan Head Cross Recessed

3 x M4 Lock Nut

Equipment Required

5.5mm or 7/32-inch Nut Driver (or Socket)

7.0mm or 9/32-inch Nut Driver (or Socket)

#2 Cross Recessed Screwdriver

Wire Cutters / Scissors

Level

Drill with 3/8” bit

Optional: Step drill bit or 1/8”, 3/32”, 3/16”, 1/4”, 3/8”

bits

Optional: De-burr tool

Note: Optional items listed above are for use with sidemounted cameras. See Installation section.

If an item appears to have been damaged in shipment,

replace it properly in its carton and notify the shipper.

If any items are missing, notify Aigis Mechtronics Sales

Representative or Customer Service. The shipping carton is

the safest container in which the unit may be transported.

Save it for possible future use. Verify that the parts listed as

follows have been included.

3

Page 4

2 SERVICE

4 DESCRIPTION

If the unit ever needs repair service, the customer should

contact Aigis Mechtronics for return authorization and

shipping instructions.

3 CARE AND MAINTENANCE

Clean the viewing window(s) as needed with a mild, nonabrasive detergent in water and a soft cloth. DO NOT use

alcohol based cleaners to clean the viewing window.

An accessory L-bracket (p/n MT-HC)

can be installed to turn the entire

Height Strip 90° in either direction

to orient the viewing windows parallel

to the wall. This provides a profile

shot of customers entering and

exiting a store.

The camera(s) can be adjusted up to 22°

left or right of center to adjust the view

slightly into or out of the store.

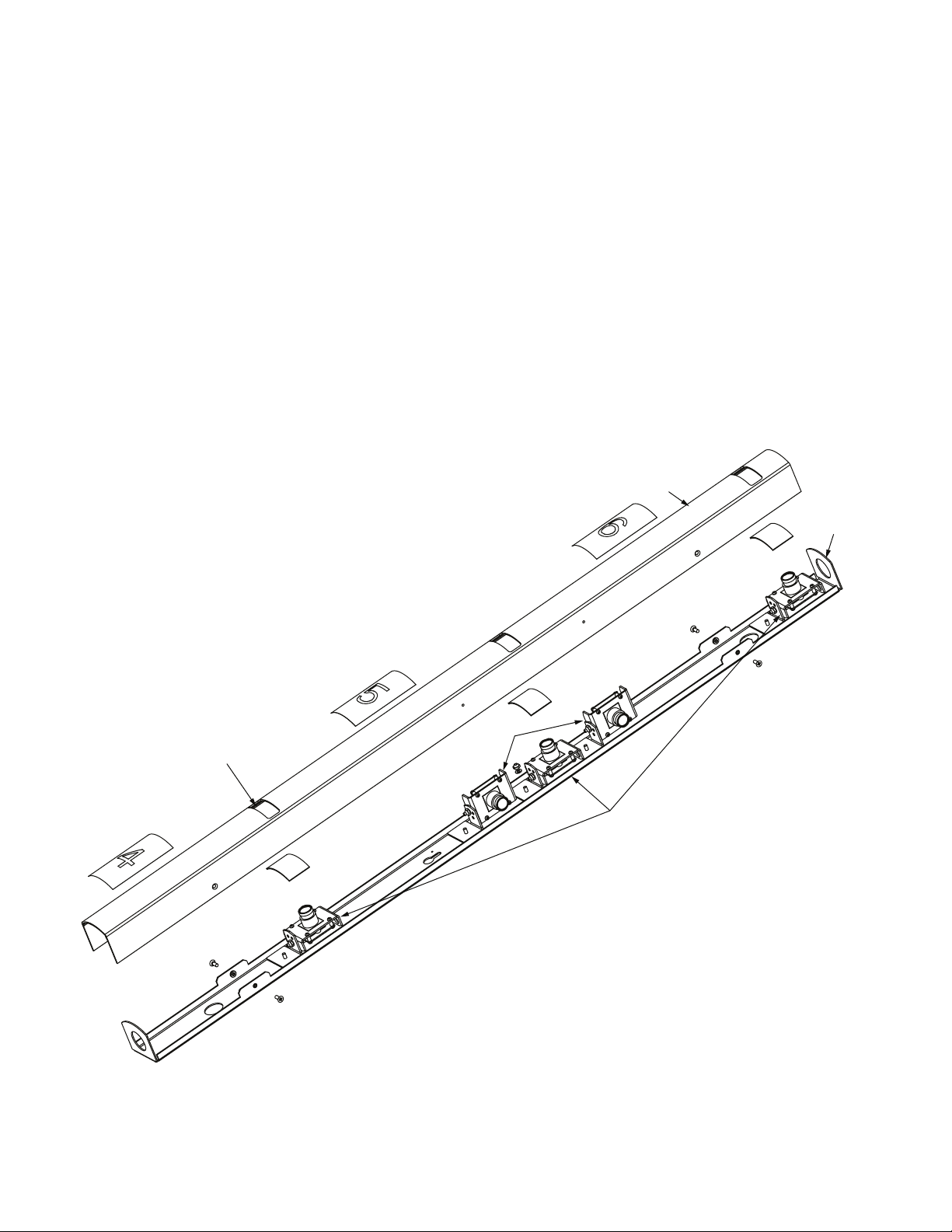

The HC Series of Height Strip camera housings are intended

to improve in-store security in two ways. First, when

installed next to the main entrance of a store, cameras

within the store will capture a subject’s height when exiting

as he or she passes the brightly colored labels. Second, the

Height Strip’s on-board camera will provide a facial shot of

the subject as he or she exits. Each Height Strip unit can

support up to five (5) Color Hi-Resolution cameras. Up to

three (3) cameras can be oriented to look forward through

the curved viewing windows and can be adjusted left or right

of center. Up to an additional two (2) cameras can be turned

90° perpendicular to look directly across the doorway and

provide a profile shot of the subject. Any cameras looking

through the viewing windows can be adjusted 22° left and

right of center. Side-viewing cameras cannot be adjusted,

and require the installer to drill a small hole in the side of the

Height Strip.

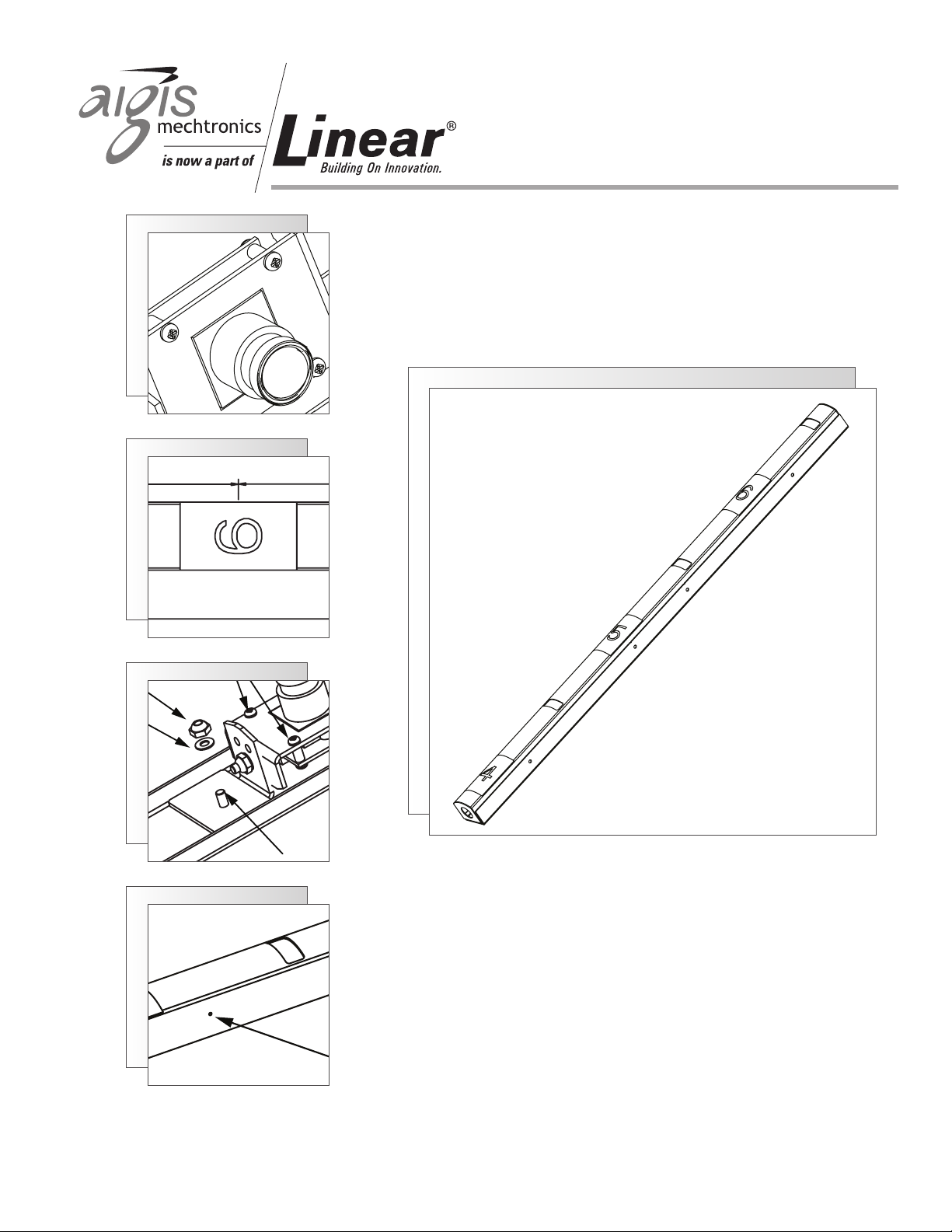

Cover

Base

Viewing Window (x3)

Side-Mounted

Cameras

Front-Mounted Cameras

Figure 1 Height Strip Camera

4

Page 5

5 VOlTAGE & MAx WATTAGE

Color Camera 95mA (Max) @ 12VDC

6.2 Camera Removal/Relocation, and

Installing Accessory Camera

Warning: All cameras are powered by DC voltage.

If you are running DC voltage over a pair of wires,

be careful of polarity. A barrel plug connector

with flying leads is provided. The white/black wire

corresponds to the core of the connector, and should be

supplied with +12VDC voltage. The black wire corresponds

to the shell of the connector, and should be used as DC

ground.

6 DISASSEMbly

6.1 Cover Removal

1. Remove the unit from its packaging. Cut open one end of

the plastic tubing covering the Height Strip. Leave the

window masks in place.

2. Using a No. 2 Cross Recessed screwdriver, remove all four

screws that secure the cover (see Figure 2). Remove

cover.

Height Indicator labels not included

with part numbers ending in "N"

1. Each Height Strip ships from the factory with a single

camera installed that looks through the viewing window

located at the 5-1/2 foot mark. Two other viewing

windows are provided at the 4-1/2 foot mark and 6-1/2

foot.

2. To relocate the existing camera, use a 5.5mm (or 7/32”)

nut driver to remove the M3 nut that attaches the

camera bracket to the base (see Figure 4). Remove the

camera and bracket from the base.

3. When installing a new camera or relocating the existing

camera, always refer to the keyhole to ensure the camera

is not installed upside down. The circular part of the

keyhole should face the ground and the slot should face

the ceiling. Always install the camera above the desired

pem stud in the base.

4. Accessory cameras require the own power supply. Do not

double terminate the supplied power adapter.

5. Install all front-facing cameras before proceeding to the

next section.

6. To install a side-mounted camera, refer to the

“Installation – Side-Mounted Cameras” section.

Use a 5.5mm or

7/32” nut driver

to remove or

install cameras.

Front-Mounted

Camera Position

Remove Screws (x4)

Camera

Bracket

Keyhole

Side-mounted

camera position

Figure 2 Assembled Height Strip Camera

Cover

Side-mounted

camera position

Front-Mounted

Camera Position

Front-Mounted

Camera Position

Base

Counter Sinks

Pen stud

for side-mounted

camera

Keyhole

M3 Nut

Flat Washer

Push here to

adust the

camera’s viewing

angle

Pen Stud for

Front-mounted

Camera

Camera Bracket

Pen Stud

for Side-mounted

Camera

Figure 3 Internal View Camera Postions

Figure 4 Close up View Camera Position

5

Page 6

7 INSTAllATION

7.1 Side-mounted cameras

Note: If NOT using the side-mounted camera feature of the

Height Strip, proceed to the next applicable section.

1. Refer to Figure 5 when side-mounting a camera.

2. Two positions are available for side-mounted cameras,

one directly below and one directly above the center

mounting location (5.5-foot mark). Select which mounting

location you prefer.

3. Determine which direction the camera should face once

installed. Remember to use the keyhole as a guide. The

round part of the keyhole faces the ground.

4. Change the camera bracket’s pivot point. Remove the

M3 nut, flat washer, and nylon washer from the camera

bracket using a 5.5mm (7/32”) nut driver or socket.

Note: the nylon washer is located between the camera

bracket and the “L” bracket. Be careful not to lose it.

5. Place the nylon washer over the pem stud of the camera

bracket (a.k.a. camera bracket axis), then insert the pem

stud into the side of the “L” bracket OPPOSITE the

direction of the camera. Replace the flat washer and M3

nut and tighten (see “Note” in Figure 5).

6. Before drilling, remove the camera bracket and “L” bracket

from the base. Hold the cover next to the base. Locate

the two small indentations (countersinks) on each side

of the cover. Mark the countersink that corresponds to

your mounting location.

7. Fit the cover back over the base and tighten down the

four (4) M3 screws to secure.

8. Locate the marked countersink in the cover.

9. Drill out an appropriate sized hole in the Height Strip

cover using the following guidelines:

Color Camera

a. If using a step drill bit (recommended), drill the

hole to 3/8-inch diameter.

b. If using standard drill bits, first use a 1/8-inch bit,

then 1/4-inch bit, then a 3/8-inch bit. This will

minimize chatter and help ensure a round hole is

drilled.

10. Remove the four M3 screws to remove the cover.

Remove any burrs from the inside of the cover.

11. Install the camera in the side-mounting location using a

flat washer and M3 nut. Proceed to the next applicable

section to complete the installation.

Flat Washer

M3 Nut

Nylon washer

(in between)

Flat Washer

Original Location

of Axis

M3 Nut

Left

Down

Note:

This camera bracket

has been adjusted

to look 90º RIGHT.

Note that the camera bracket axis

was moved to the LEFT Side of the “L” bracket.

Up

Right

Camera Bracket

Axis (pem stud)

“L” bracket

Figure 5 Side Mounted Cameras

6

Page 7

7.2 Installing the Unit onto a Mullion or

Metal Doorframe

1. Measure from the floor to the 5-foot mark on the mounting surface. Make a mark at 5 feet.

2. Drill a 3/16” hole in the center of the mullion at the

5-foot mark.

3. Remove a #8 self tapping screw and a wall anchor from

the hardware kit.

4. Insert the wall anchor into the hole and tighten the self

tapping screw until only a 1/8” gap remains under the

screw head.

5. Hang the base of the Height Strip onto the screw using

the keyhole. Refer to Figure 6. The two small holes

near the top of the keyhole indicate the 5-foot mark.

Align these holes with the screw and hand-tighten the

screw to hold the base.

6. Use a level to ensure the Height Strip base is held vertically.

7. Use the base as a template to mark the hole location

of the other two mounting holes, as well as mark the

desired through-hole(s) for the power and video cables.

8. Refer to Figure 7 regarding cable entry into the unit.

9. If running cables from the top of the mullion down to the

unit, use the cable through-hole near the 6-foot mark.

If running cables up to the unit from the floor, use the

cable through-hole below the 4-foot mark. Note: If

running cables through the knockouts on the top or

bottom of the unit, disregard this step.

10. Unscrew the base and set aside. Drill out the remaining

two mounting holes (3/16” drill bit) and insert the

remaining wall anchors.

11. At the desired through-hole location(s), drill a hole in the

mullion wide enough to accept the customer-provided

power and video cables.

12. Feed the cables down into the mullion and fish them out

of the through-hole.

13. Hang the Height Strip back on the mounting screw in the

mullion and feed the power and video cables into the

unit.

14. Align the base with the 5-foot mark as in Step 5 of this

section and tighten the screw.

15. Insert the remaining two self tapping screws into the

remaining mounting holes and tighten to secure the base

to the mullion.

16. Terminate the ends of the customer-supplied cables as

required, and connect power and video cables to the

camera(s). Be sure to supply 12VDC with the correct

polarity to the camera. The center pin (black/white

wire) should be connected to +12VDC, and the shell of

the connector (black wire) should be connected to DC

Ground.

17. Use the cable ties and tie wrap mounts provided in the

hardware kit to provide strain relief for the customersupplied cables inside the Height Strip.

18. Orient the camera(s) left or right as desired. Turn the

cameras by pushing on the lower part of the camera

bracket (closest to the camera bracket axis).

19. Check the insides of the viewing windows (see Figure 4)

for any dust or debris. Clean with a Kimwipe™ tissue, if

necessary.

20. Replace the cover and secure with the four M3 flathead

screws.

These holes

indicate the

5-foot mark.

Ceiling

Floor

Figure 6 Keyhole

Note that the top

of the keyhole is NOT

the 5-foot mark.

Extra slot provided

for fine adjustments

during installation.

Knockouts provided at

top and bottom of

Height Strip base

7

Knockouts

Cable-entry through holes

Figure 7 Cable Entry

Page 8

7.3 Installing the Unit onto a Solid Wall

1. Refer to steps 1 to 6 above. Replace fasteners and wall

anchors from the hardware kit with customer-supplied

components as desired. The through-hole size for the

wall mounts is sized for a #8 screw (approximately

0.175” diameter).

2. Use the base as a template to mark the hole location of

the other two mounting holes. Remove the base from

the wall and drill the remaining two mounting holes

(3/16” drill bit).

3. Insert wall anchors into the holes in the wall, then place

the Height Strip base back onto the mounting screw

in the wall. Align the base with the 5-foot mark as in

Step 5 of the previous section. Tighten the remaining

mounting screws to secure the Height Strip base to the

wall.

4. Knockouts are provided at the top and bottom of the unit

for cable entry and conduit fittings.

5. Remove the desired knockout by pushing it into the base

with a screw driver, then bending it back and forth until

it snaps off.

6. Insert an appropriate conduit fitting into the hole, then

run the customer-supplied power and video cables into

the conduit fitting.

7. Refer to Step 14 of the previous section when connecting

video and power cables to the camera.

8. Follow steps 15 – 18 of the previous section to complete

the installation.

7.4 Installing the Unit using the Accessory

Wall Bracket (MT-HC)

Note: cable entry can only be accomplished via the

knockouts at the top or bottom of the Height Strip

when using the MT-HC wall bracket.

1. Refer to Figure 8 and Figure 9 when installing this

accessory.

2. Measure from the floor to the 5-foot mark on the

mounting surface. Make a mark at 5 feet.

3. The side of the MT-HC with the rubber pads and notches,

see Figure 9, near the center through-holes is the side

that gets screwed to the wall. Always use the lower

of the two center through-holes as your 5-foot mark

reference. The Height Strip can be mounted facing

either left or right of the accessory bracket by spinning

the bracket 180°.

4. Orient the bracket as appropriate for your installation.

Line up the notch of the lower through hole with the

5-foot mark.

5. Use the MT-HC bracket as a template to mark the

mounting hole locations.

6. Drill 3/16” holes in the mounting surface if using the

anchors and screws from the Height Strip’s hardware kit.

Drill an appropriate size hole if using other fasteners.

7. Insert wall anchors into the holes and secure the MT-HC

to the mounting location using the screws.

Ensure the M4

screw head is

on THIS side

of the Bracket

once the cover

is secured.

Figure 8 Accessory Wall Bracket (MT-HC)

8

Page 9

Notches designate 5-foot mark.

The mounting holes in the Height Strip

base are not symmetrical.

Ta ke care to select the correct

hole for your particular application.

Figure 9

8. Remove the cover from the Height Strip by removing the

four (4) cross-recessed screws.

9. Orient the Height Strip base as desired. Secure the base

to the MT-HC accessory bracket using three (3) M4

screws and three (3) M4 nuts from the hardware kit

sent with the MT-HC.

10. Ensure that the heads of the screws will be outside the

unit and the nuts will be inside the unit once the cover

is replaced.

11. Tighten the screws using a cross recessed screwdriver

and a 7mm (9/32”) socket or nut driver.

12. Knockouts are provided at the top and bottom of the

unit for cable entry and conduit fittings.

13. Remove the desired knockout by pushing it into the base

with a screw driver, then bending it back and forth until

it snaps off.

14. Insert an appropriate conduit fitting into the hole, then

run the customer-supplied power and video cables into

the conduit fitting.

15. Terminate the ends of the customer-supplied cables as

required, and connect power and video cables to the

camera(s). Be sure to supply 12VDC with the correct

polarity to the camera. The center pin (black/white

wire) should be connected to +12VDC, and the shell of

the connector (black wire) should be connected to DC

Ground.

16. Use the cable ties and tie wrap mounts provided in the

hardware kit to provide strain relief for the customersupplied cables inside the Height Strip.

17. Orient the camera(s) left or right as desired. Turn the

cameras by pushing on the lower part of the camera

bracket (closest to the camera bracket axis).

18. Check the insides of the viewing windows for any dust or

debris. Clean with a Kimwipe™ tissue, if necessary.

19. Replace the cover and secure with the four M3 flathead

screws to complete the installation.

9

Page 10

DIMENSIONAl OUTlINES

Back View

Back View

Side View

To p Down

1.7

43.2

1.6

40.6

Viewing window

for camera

in

mm

7.5

190.5

(ø.19 X3) MOUNTING HOLES

14.7

374.7 247.7

12

304.8

Viewing window

for camera

34

863.6

6

152.4

9.7

12

304.8

Viewing window

for camera

Bottom Up

2.5

63.5

3

76.2

10

Page 11

11

Page 12

Now Part of

www.aigismech.com • www.linearcorp.com

1950 Camino Vida Roble, Suite 150

Carlsbad, CA 92008

Tel: 760.438.7000 800.421.1587

100 0266 002 AIG 02/12

Data subject to change without notice.

Copyright © 2012 Linear LLC

Loading...

Loading...