Page 1

CC3008

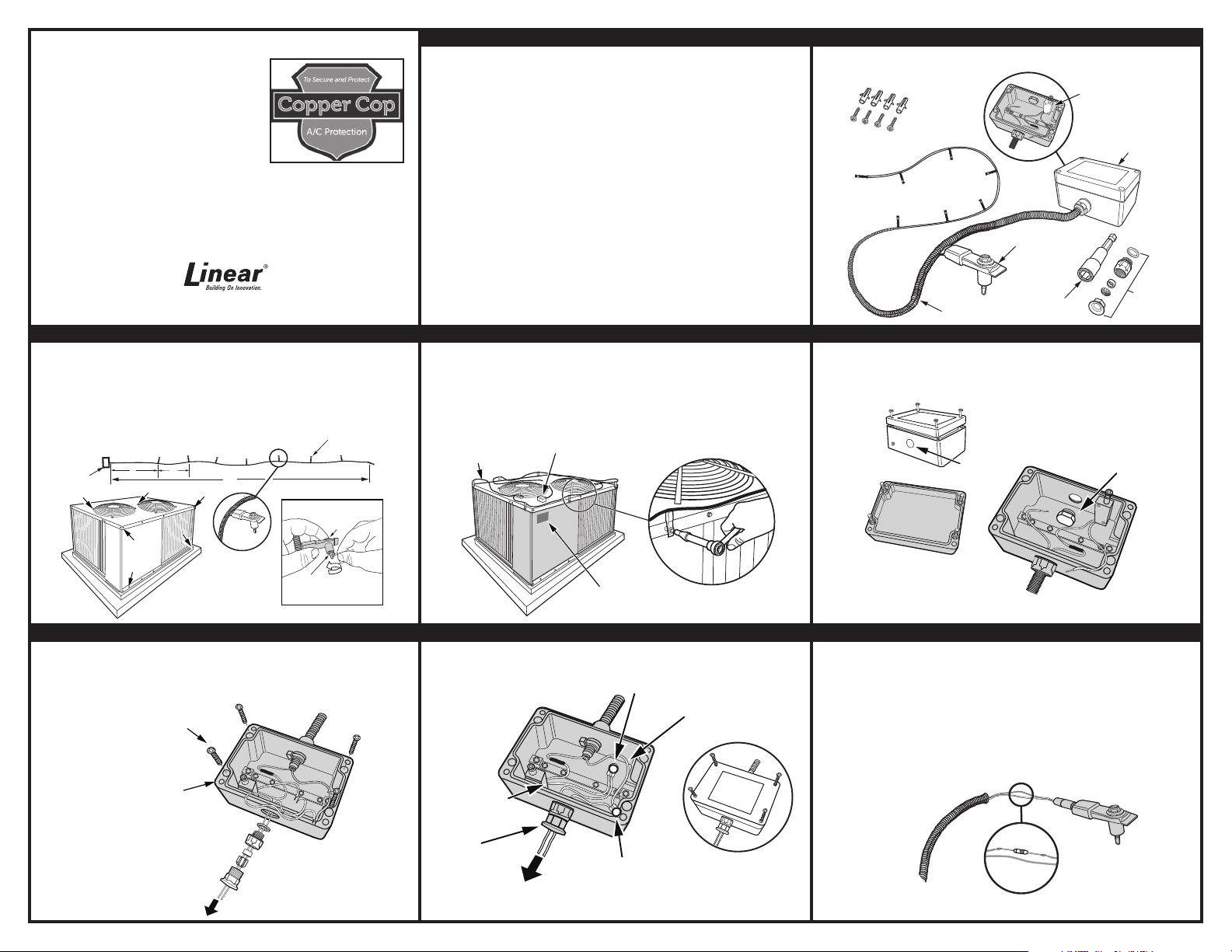

Air Conditioning

Protection System

Installation Instructions

For use with All

Air Conditioning Systems

USA & Canada (800) 421-1587 & (800) 392-0123

(760) 438-7000 - Toll Free FAX (800) 468-1340

www.linearcorp.com

3. SENSOR CLIP LOCATIONS

Begin by stringing out the 27’ cable strand. Place the cable strand and Control Box on

top of air conditioning unit and determine possible screw points where Sensor Clips

can be installed. The diagram below shows suggested clip locations. Air conditioner

units will vary so select a pattern of placement that best suits the installation. To

prepare for installation, REMOVE the tie wrap from each Sensor Clip used as shown.

27´ CABLE STRAND WITH 8 SENSOR CLIPS SPACED

AT 3´ INTERVALS

6´

CONTROL

BOX

3´

SUGGESTED SENSOR CLIP

LOCATION POINTS

27´

SENSOR

CLIP CLOSE UP

UNSCREW TIE WRAP FROM

SENSOR, COUNTER CLOCKWISE

BEFORE INSTALLING

SENSOR

CLIPS (8)

HOLD HEAD OF

SCREW WITH

FINGER

1. PRODUCT DESCRIPTION

Copper Cop Air Conditioning Protection System is designed to detect theft of copper

components typically found in high-end commercial air conditioning units. The product

is a normally closed alarm loop. Unscrewing a Sensor Clip, cutting the cable, or

opening with the Control Box will violate the loop. The system can either be hardwired

to an alarm control panel or connected to a wireless transmitter (not included) placed

inside of the Control Box.

Components of the Copper Cop detector include a Control Box and 27 feet of wire

covered in 3/8” diameter yellow corrugated plastic split wire loom. Each Copper Cop

detector includes 8 Sensor Clips. The fi rst Sensor Clip is positioned six feet from the

Control Box. From that point, additional Sensor Clips are placed at three foot intervals.

Each Sensor Clip has a #10 self tapping screw for mounting. The Sensor Clips can

be installed in pre-existing holes on the air conditioning unit frame structure using the

5/16” socket tool provided. If new holes are required, use a 1/8” diameter drill. The

Control Box is installed on the desired surface using 4 screws and anchors (provided).

IMPORTANT: Drilling holes is advisable only when necessary and if it is known

what is behind the panel being drilled. Linear is not responsible for any damage

to air conditioning systems.

4. SENSOR CLIP INSTALL ATION

Remove screws from the chosen locations of the air conditioning unit and then install

the Sensor Clips at each of these points using the 5/16” socket tool (provided). If

additional holes are needed to position Sensor Clips in more convenient locations,

drill them now with a 1/8” drill bit. Finish mounting the remaining Sensor Clips. It is

recommended that ALL clips be installed for maximum protection. Install the warning

sign in a high visibility location on air conditioner as an added deterrent.

8 SENSOR CLIP

STRAND INSTALLED

CONTROL

BOX

COPPER COP

WARNING SIGN

2. COMPONENTS KIT

The Copper Cop product includes the following components:

CONTROL

BOX SCREWS

AND ANCHORS

8 SENSOR CLIPS PER STRAND AT

3’ INTERVALS

27’ CABLE STRAND

SENSOR CLIP

5/16” HEX

SOCKET

TAMPER SWITCH

INSIDE CONTROL

BOX

CONTROL

BOX

STRAIN

RELIEF

ASSEMBLY

5. CONTROL BOX PREPARATION

When hard wire connecting to an alarm control panel, a strain relief is included for the

wires exiting the Control Box. To prepare for the strain relief, unscrew and remove the

hole plug from inside the Control Box.

REMOVE TOP OF

CONTROL BOX

TOP REMOVED

CONTROL BOX

PLUG

REMOVE

PLUG FROM

INSIDE BOX

6. CONTROL BOX INSTALLATION

FIRST run alarm panel wires through strain relief assembly and screw all parts

together. This will trap wires. THEN feed wires through hole in Control Box and thread

strain relief into hole. Use screws (provided) to mount Control Box to desired surface.

CONTROL BOX

MOUNTING

SCREWS (4)

CONTROL

BOX

FIRST RUN WIRES

THROUGH

STRAIN RELIEF

ASSEMBLY

TO ALARM

PANEL

THEN SCREW

STRAIN RELIEF INTO

CONTROL BOX

7. WIRE CONNECTIONS

Use appropriate type of wire connectors to connect the detector as shown in diagram

below. Reinstall the Control Box top and tighten screws.

CONTROL

BOX

WHITE

WIRE

STRAIN

RELIEF

TO ALARM

PANEL

CONNECTOR

CONNECTOR

YELLOW

WIRE

RE-ATTACH

CONTROL

BOX TOP

8. END OF LINE RESISTOR INSTALLATION

When connecting the detector to an alarm panel, an end-of-line resistor may be

required. It can be soldered into the line at the Sensor Clip farthest from the Control

Box. Pull wires out of loom. Separate coated wires from each other, then strip wire

jacket and solder in the correct value resistor. Complete installation by slipping wires

and resistor back into wire loom and loom into end of the Sensor Clip. NOTE: Refer

to alarm panel for resistor value.

STRIP WIRE AND

CONNECT RESISTOR

PULL BACK WIRE

LOOM TO EXPOSE

WIRES

INTO ONE WIRE

RESISTOR

SENSOR CLIP AT END

OF STRAND

Page 2

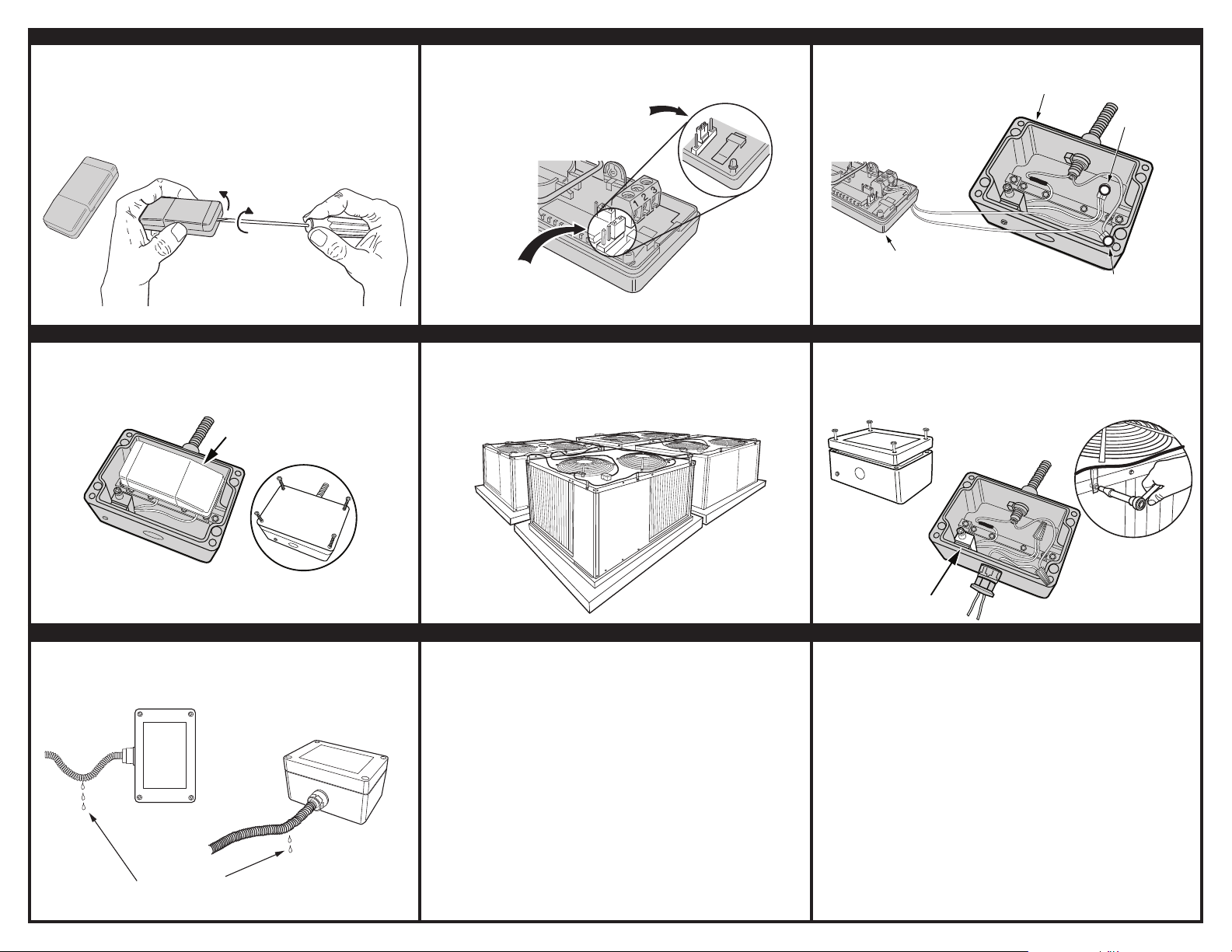

9. WIRELESS TRANSMITTER OPTION

Copper Cop can also be used with a stationary transmitter such as the Linear

DXS-31. Other transmitters that support an external contact input may also be used.

The DXS-31 will fi t inside the Copper Cop Control Box (inside free space dimension

of 3-1/4”x 2” x 1”).

DXS-31 TRANSMITTER

REMOVE THE CASE TOP BY TWISTING A

SMALL FLAT BLADE SCREWDRIVER IN THE

TOP CASE SLOT (ON THE THICK END OF THE

TRANSMITTER)

LIFT

10. TRANSMITTER JUMPER CONFIGURATION

Before wiring the DXS-31 transmitter to the Copper Cop Control Box, confi gure

jumper as shown to accommodate an external contact.

PUT JUMPER ON THE

MIDDLE PINS TO USE

AN EXTERNAL SWITCH

11. TRANSMITTER/CONTROL BOX HOOK-UP

Wire Copper Cop Control Box to DXS-31 transmitter to create a normally closed

circuit.

CONTROL

WIRE EXTERNAL

NORMALY CLOSED

CONTACTS TO

TERMINALS 1 & 2

BOX

CONNECTOR

TWIST

12. MOUNTING TRANSMITTER IN CONTROL BOX

After hooking up the wiring between the DXS-31 transmitter and the Copper Cop

Control Box, place the transmitter inside the Control Box. Re-assemble the Control

Box top and tighten the cover screws.

CONTROL

BOX

LOCATE DXS-31

TRANSMITTER IN

CONTROL BOX

RE-ASSEMBLE CONTROL

BOX TOP

15. CONTROL BOX MOUNTING TIPS

To prevent water wicking into Control Box, a drip loop can be created in the cable

before vertical mounting. When possible, it is recommended that the Control Box be

vertically mounted. If Control Box is horizontally mounted, allow for cable slack prior

to box for water drainage.

VERTICAL MOUNTING

OF CONTROL BOX WITH

DRIP LOOP IN CABLE.

WHEN HORIZONTALLY

MOUNTING CONTROL

MOISTURE WILL DRIP

OFF WIRE LOOM

BOX, ALLOW SOME

CABLE SLACK FOR

DRAINAGE PRIOR TO

ENTERING BOX

THIS IS THE FACTORY SET

JUMPER POSITION, IT

SELECTS THE INTERNAL

CONTACTS

13. MULTIPLE AIR CONDITIONER UNITS

If there are a number of air conditioning units in close proximity to each other, it will

require more than a single Copper Cop Kit. Plan on having ample kits for the project.

It is also recommended that all 8 Sensor Clips be used on a single air conditioning

unit for maximum protection.

NOTE: Each Copper Cop Kit will require an individual connection to the alarm panel.

NOTES

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

__________________________________________________________________

__________________________________________________________________

___________________________________________________________________

___________________________________________________________________

__________________________________________________________________

__________________________________________________________________

DXS-31

TRANSMITTER

CONNECTOR

14. TESTING SYSTEM

After installing and wiring the Copper Cop, to test the system REMOVE the Control

Box top. The tamper switch will open the circuit and alarm should sound. If it does

not, re-check all wire connections for shorts. Make appropriate corrections, then test

again. A second system test is to remove any one of the Sensor Clips. This should

open the circuit and activate the alarm.

CONTROL

BOX

REMOVING

CONTROL BOX

TOP WILL ACTIVATE

TAMPER SWITCH,

SETTING OFF ALARM

TAMPER

SWITCH

REMOVING

ANY SENSOR

CLIP WILL ACTIVATE

AN ALARM

LINEAR LIMITED WARRANTY

This Linear product is warranted against defects in material and workmanship for twenty-four (24) months. This

warranty extends only to wholesale customers who buy direct from Linear or through Linear’s normal distribution

channels. Linear does not warrant this product to consumers. Consumers should inquire from their selling dealer

as to the nature of the dealer’s warranty, if any. There are no obligations or liabilities on the part of Linear LLC for

consequential damages arising out of or in connection with use or performance of this product or other indirect

damages with respect to loss of property, revenue, or profi t, or cost of removal, installation, or reinstallation. All

implied warranties, including implied warranties for merchantability and implied warranties for fi tness, are valid only

until the warranty expires. This Linear LLC Warranty is in lieu of all other warranties express or implied.

All products returned for warranty service require a Return Product Authorization Number (RPA#). Contact Linear

Technical Services at 1-800-421-1587 for an RPA# and other impor tant details.

• Linear radio controls provide a reliable communications link and fi ll an important need in portable wireless

signaling. However, there are some limitations which must be observed.

• For U.S. installations only: The radios are required to comply with FCC Rules and Regulations as Part 15 devices.

As such, they have limited transmitter power and therefore limited range.

• A receiver cannot respond to more than one transmitted signal at a time and may be blocked by radio signals

that occur on or near their operating frequencies, regardless of code settings.

• Changes or modifi cations to the device may void FCC compliance.

• Infrequently used radio links should be tested regularly to protect against undetected interference or fault.

• A general knowledge of radio and its vagaries should be gained prior to acting as a wholesale distributor or

dealer, and these facts should be communicated to the ultimate users.

Copyright © 2012 Linear Corporation 233768 A

IMPORTANT !!!

Loading...

Loading...