Page 1

BIASI B/40

LINEAR

PAGE 1

6-12 SECTION

Please Read Instructions Carefully

Save for Future Reference

WARNING

If the information in this manual is not followed

exactly, a fire explosion may result causing property

damage, personal injury or loss of life.

DANGER

Boiler Manual And Installation

Instructions for Atmospheric Venting

LINEAR

BOILER

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electric switch; do not use any

phone in your building

• Immediately call your gas supplier from another

location. Follow the gas supplier’s instructions.

• If you can not reach your gas supplier call the

fire department

Manufactured by:

Manufactured by:

Manufactured by:Manufactured by:

Biasi S.p.A.

Biasi S.p.A.

Biasi S.p.A.Biasi S.p.A.

Verona, Italy

Verona, Italy

Verona, ItalyVerona, Italy

Distributed By:

Distributed By:

Distributed By:Distributed By:

QHT

QHT

QHTQHT

QUINCY HYDRONIC TECH

QUINCY HYDRONIC TECHNOLOGY

QUINCY HYDRONIC TECHQUINCY HYDRONIC TECH

3560 LAFAYETTE RD

3560 LAFAYETTE RD

3560 LAFAYETTE RD3560 LAFAYETTE RD

PORTSMOUTH, NH 0380

PORTSMOUTH, NH 03801111

PORTSMOUTH, NH 0380PORTSMOUTH, NH 0380

PHONE: 603

PHONE: 603----334

PHONE: 603PHONE: 603

FAX: 603

FAX: 603----334

FAX: 603FAX: 603

334----6401

334334

NOLOGY, INC.

NOLOGYNOLOGY

334----6400

6400

334334

64006400

6401

64016401

, INC.

, INC., INC.

REV. H

Page 2

PAGE 2

BIASI B/40

Dear Customer:

Thank you for buying a Linear commercial boiler.

The Linear is a cast iron, oil or gas fired hot water boiler, using the famous 3-pass design. The

boiler is simple, rugged and engineered for maximum heating efficiency.

We realize that it is not possible to answer all questions about the Linear series boiler in this

manual. Reading this installation manual does not make the reader an expert in all aspects of

installation and operation, and does not replace the need for a qualified, licensed heating

contractor. We urge you to contact your installing contractor or distributor if you are in question

about any aspect of your boiler's performance. Our main concern is that you are satisfied with

your boiler and its performance. We require that your contractor complete efficiency tests

using instruments.

The controls and accessories listed in this manual are intended to serve as guidelines rather than

specific recommendations. We realize that other makes and models of such devices are

available and can be used as successfully as those we specify. The installing contractor is the

best judge of a system's specific requirements, as well as the local availability of certain makes

and models of controls and accessories. The preceding does not apply, however, to the

equipment that comes with every boiler, such as the overheat control (L4006E) and pressure

relief valve. The installation of the specific devices supplied with every boiler is absolutely

necessary to the safe operation of the boiler and protection of the heating system.

This Linear boiler has a limited warranty, a copy of which is provided with the boiler. Please

be sure to return the warranty registration card as the warranty will be void without your boiler's

serial numbers, date of installation and the name of your installer being on record in our files.

Thank you for purchasing our B-40 Linear series boiler. If you have questions or comments,

please don't hesitate to contact us immediately. Our goal is 100% customer satisfaction.

Page 3

BIASI B/40

TABLE OF CONTENTS

BIASI B-40 Linear Series Section Page

Important Information 1 4

General Information 2 6

Codes and Regulations 3 6

Combustion Air Supply 4 7

Boiler Location 5 7

Boiler Block Assembly 6 8

Boiler Trim Kit Installation 7 8

Boiler Tapping Diagram - 9

Burner Set-up 8 10

Gas Piping 9 12

Breeching and Chimney 10 14

Piping 11 15

Boiler Jacket Assembly 12 17

Boiler Jacket Explosion Diagram - 18

Wiring 13 19

B-40 Control Panel Wiring 20-23

Commissioning 14 24

Maintenance 15 24

Installer Notes 16 25

PAGE 3

Page 4

PAGE 4

BIASI B/40

IMPORTANT INFORMATION

Please read this page carefully.

ALL BOILERS MUST BE INSTALLED IN ACCORDANCE WITH NATIONAL, STATE AND

LOCAL PLUMBING, HEATING AND ELECTRICAL CODES AND ORDINANCES, AS WELL AS

THE REGULATIONS OF THE SERVING ELECTRICAL, WATER AND GAS UTILITIES.

All systems should be designed by competent contractors, and only persons knowledgeable in the

layout and installation of heating systems should attempt the installation of any boiler.

It is the responsibility of the installing contractor to see that all controls are correctly installed and

operating properly when the installation is completed.

Do not burn volatile garbage, gasoline, naphtha or other flammable liquids other than No. 2 fuel

oil. All flammable liquids (especially gasoline), chemicals, rags, paper, wood scraps, debris, etc.,

should be kept away from the boiler at all times. Keep the boiler area clean and free of all fire

hazards.

Please read the literature and warranties supplied by the manufacturers of the various accessory

equipment. This equipment is warranted by the respective manufacturers, not by Quincy Hydronic

Technologies, Inc. Each piece of equipment must be installed and used according to the

recommendations of the manufacturer.

This Linear boiler has a limited lifetime warranty, a copy of which is printed on the back page of this

manual.

Page 5

BIASI B/40

PAGE 5

WARNING

Any appliance that burns natural gas, propane gas, fuel oil, wood or coal is capable of producing

carbon monoxide (CO). Carbon Monoxide (CO) is a gas which is odorless, colorless and tasteless but

is very toxic.

If your BIASI B-40 boiler is not working properly, or is not vented properly, dangerous levels of CO

may accumulate. CO is lighter than air and thus may travel throughout the building. BRIEF

EXPOSURE TO HIGH CONCENTRATIONS OF CO, OR PROLONGED EXPOSURE TO

LESSER AMOUNTS OF CO MAY RESULT IN CARBON MONOXIDE POISONING.

EXPOSURE CAN BE FATAL AND EXPOSURE TO HIGH CONCENTRATIONS MAY

RESULT IN THE SUDDEN ONSET OF SYMPTOMS INCLUDING UNCONSCIOUSNESS.

Symptoms of CO poisoning include the following:

Dizziness Vision problems Shortness of breath

Headache Loss of muscle control Unclear thinking

Nausea Weakness Unconsciousness

The symptoms of CO poisoning are often confused with those of influenza, and the highest incidence

of poisoning occurs at the onset of cold weather or during flu season. A victim may not experience

any symptoms , only one symptom, or a few symptoms. Suspect the presence of carbon monoxide if

symptoms tend to disappear when you leave your home.

The following signs may indicate the presence of carbon monoxide:

* Hot gasses from appliance, venting system, pipes or chimney,

escaping into the living space.

* Flames coming out around the appliance.

* Yellow colored flames in the appliance.

* Stale or smelly air.

* The presence of soot or carbon in or around the appliance.

* Very high unexplained humidity inside the building.

If any of the symptoms of CO occur, or if any of the signs of carbon monoxide are present, VACATE

THE PREMISES IMMEDIATELY AND CONTACT A QUALIFIED HEATING SERVICE

COMPANY OR THE GAS COMPANY AND THE FIRE DEPARTMENT.

To reduce the risk of CO poisoning, have your heating system "tuned up" by a licensed heating

contractor or the gas company - preferably before each heating season. Also have the service

company check your chimney or vent pipes for blockage.

The building should be adequately ventilated, particularly if you have tightly insulated your home.

ONLY QUALIFIED, LICENSED SERVICE CONTRACTORS SHOULD PERFORM WORK

ON YOUR BIASI B-40 BOILER.

Page 6

PAGE 6

Net Output

Length

Weight

BIASI B/40

2. General Information:

The Linear series are wet base design, sectional, cast-iron boilers for forced hot water heating

systems. The Linear boilers are designed for firing with oil and deliver high efficiencies through

unique design and construction.

The Linear series boilers are shipped from the factory in assembled blocks and each boiler can

range from 6 to 12 sections. The sections can then be disassembled before delivery to the jobsite by

QHT and then field assembled. The boiler jacket, burner and controls are packed separately for

shipping.

Note: All equipment should be inspected upon delivery, and any damage or shortage should

be reported immediately.

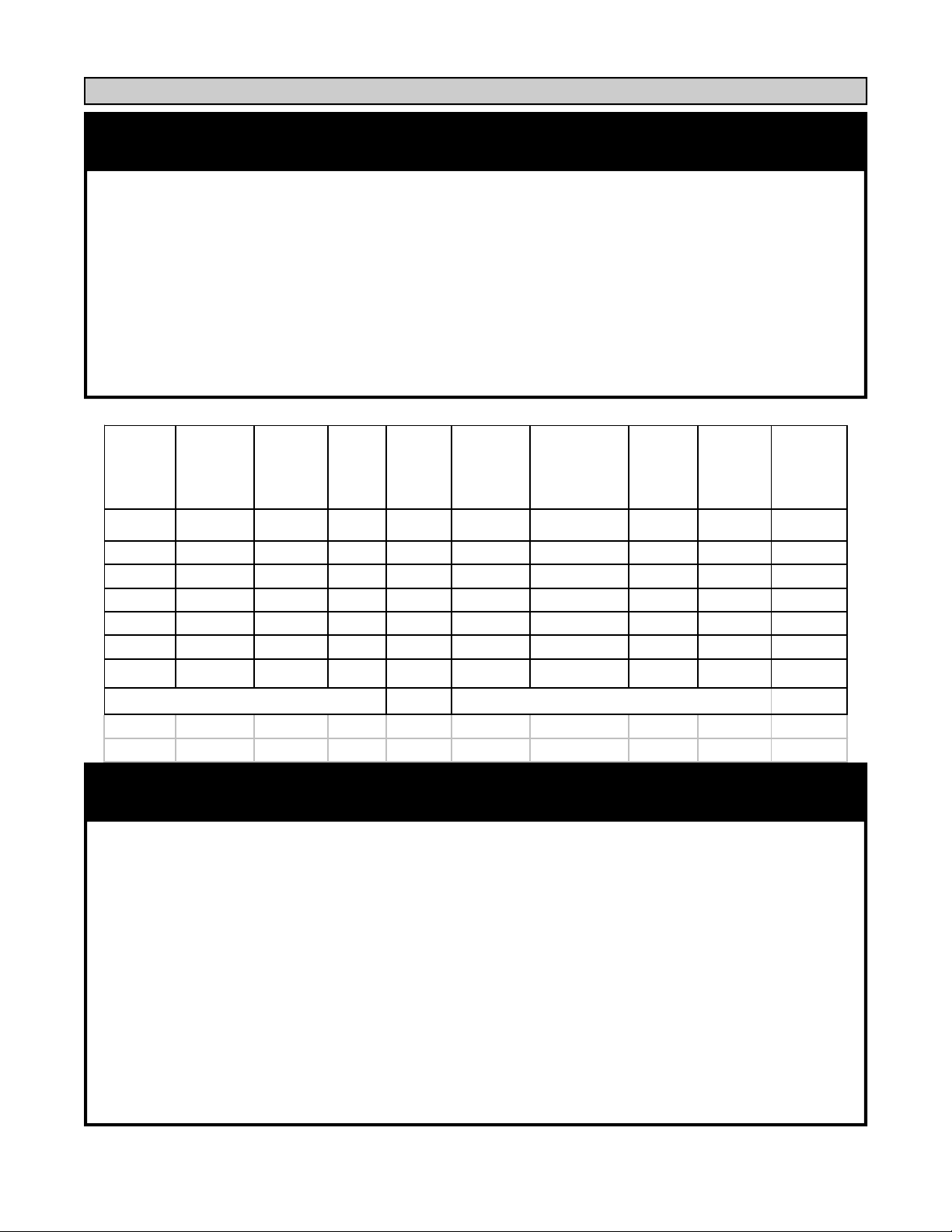

Boiler

Model

Number

B40/6 6 265 2.20 308 230 86.0 17 34.8 902

B40/7 7 352 2.90 406 305 86.7 20 39.5 1023

B40/8 8 437 3.60 504 380 86.8 23 44.4 1144

B40/9 9 524 4.30 602 456 87.0 26 49.2 1265

B40/10 10 610 5.00 700 532 87.2 28 53.9 1386

B40/11 11 696 5.70 798 607 87.2 31 58.8 1507

B40/12 12

Maximum Water Working Pressure 72 psi Maximum Relief Valve is 50 psi @ 900 MBH

Number of

Sections

Heating

Capacity

783

Input

Oil

G.P.H.

6.40

Input

Gas

MBH

896 684

MBH Efficiency %

Water

Content

Gals.

87.4 34 63.8 1628

(L) inches

(LBS)

3. Conforming to Codes and Regulations:

Installation of the boiler, burner, oil tank and related equipment must conform to national,

state and local regulating agencies and codes applicable to the installation of the equipment. In the

absence of local requirements, the following codes apply:

••••

ANSI/NFPA - #31 Installation of Oil Burning Equipment

••••

ANSI/NFPA - #70 National Electric Code

••••

ANSI/NFPA - #211 Chimneys and Vents

The above codes are available from:

National Fire Protection Association (NFPA)

Battery March Park

Quincy, Massachusetts, 02269

Page 7

BIASI B/40

PAGE 7

4. Combustion Air Supply:

The boiler location must provide air for proper combustion and ventilation of the surrounding

area. To burn efficiently, oil requires 30 CFM/GAL. In general, boiler rooms should incorporate two

(2) permanent air supply openings, one commencing within 12 inches of the ceiling, and one

commencing within 12 inches of the floor. These openings should freely communicate with the

outdoors.

OUTSIDE AIR: When combustion air is supplied directly through an outside door or wall,

each opening shall have a free area of one square inch per 4,000 BTUH input for the total input of all

the appliances in the enclosure.

INSIDE AIR: When combustion air is supplied from inside the building, each opening shall

have a free area of one square inch per 1,000 BTUH input for the total of all appliances in the

enclosure. In no case shall the openings be less than 105 square inches each.

In both cases, check manufacturers ratings for louver net free area, and correct for screen

resistance to net free area.

If the boiler is to be installed where the operation of exhaust fans, attic fans, kitchen

ventilation systems, clothes dryers or fireplaces may create severe negative vent pressures causing

unsatisfactory combustion and venting, special provisions should be made for additional make-up air

to supply the other air requirements. If building is of tight construction, combustion air requirements

may not be met and combustion air ducts from outside may be necessary. Please refer to NFPA No.

31.

Do not install the boiler until the proper combustion air has been arranged

5. Boiler Location:

Locate the boiler to provide sufficient clearance for inspection, servicing and maintenance.

Minimum clearance to construction or combustible materials shouldn't be less than six (6) inches from

the top, sides and rear of unit, and eighteen (18) inches from the flue pipe in any direction. Front

clearance should be at least twenty four (24) inches. When choosing a location for the boiler, take

into consideration the 12” supply manifold on the back of the boiler. Adequate space must be given to

pipe the manifold in and for the smoke pipe to clear the manifold. Greater distances for ease of access

should supersede fire protection clearances. The boiler must be located on a non-combustible floor. A

smooth, level concrete floor is recommended. Locate the boiler as close as possible to the chimney. If

boiler is installed on combustible flooring, consult local authorities for proper method of covering

floor. The boiler must not be installed on carpeting.

Caution: Do not store or use flammable materials, chemicals or flammable liquids,

especially gasoline, in the vicinity of this heating appliance.

Page 8

PAGE 8

BIASI B/40

6. Boiler Block Assembly:

All Linear series boilers are shipped either as an assembled boiler block or a knock-down

boiler block. If the block came unassembled, or if the assembled block needs to be split for installation purposes, please read the following:

To assemble split blocks, move the sections into a line facing each other. Sections may be slid

along boards placed underneath the sections. Inspect nipple ports for damage or burrs. Remove any

burrs by brushing the port very lightly. Wipe the push nipples and nipple ports with a clean cloth.

Apply a film of nipple compound to both the nipple and port. Install the nipple in the port and then

seal it by hitting it with a rubber mallet. Apply section sealant to one section only and slide sections

together. If the boiler came in sections, you will want to draw the sections together 2 or three at a time

to insure that the blocks are coming together properly. Install the four draw rods and draw the sections

together evenly (measure with yardstick). The longer draw rods should be installed on the top of the

boiler. The shorter draw rods are installed on the bottom of the boiler. The bottom draw rods should

not extend past the front section. Draw the sections together until sections make iron-to-iron contact

at a point around the top and bottom ports of each section. Check to insure that the combustion chamber is sealed using a flash light or other lighting device. Place the flashlight into the combustion

chamber and look for light on the floor or surrounding walls (this is best done in a dark room). If light

appears out of the boiler use a high temperature caulk to fill in the gaps between the block sections.

DO NOT OVER TIGHTEN DRAW RODS

7. Installation of Boiler Trim Components:

The BIASI B-40 Boiler Trim Kit includes the following components.

1— Honeywell L4006 E Aquastat

1— 3/4” X 3” Nipple

1— 3/4” Elbow

1— 50 PSI Pressure Relief Valve

1— Immersion Well

1— Four Wire Molex Wire Harness

The above mechanical components should be installed following the diagram of the boiler

tappings on the following page. The installation of the above wiring components (wiring harness) will

be described in the wiring portion of this installation manual.

1— Pressure/Temperature Gauge

1— 3/4” Boiler Drain

1— 1/4”X3/4” Bushing

1— 2 1/2” MPT Supply Manifold

1— 2 1/2” MPT Return Manifold

Page 9

BIASI B/40

PAGE 9

Control Panel with

operating aquastats

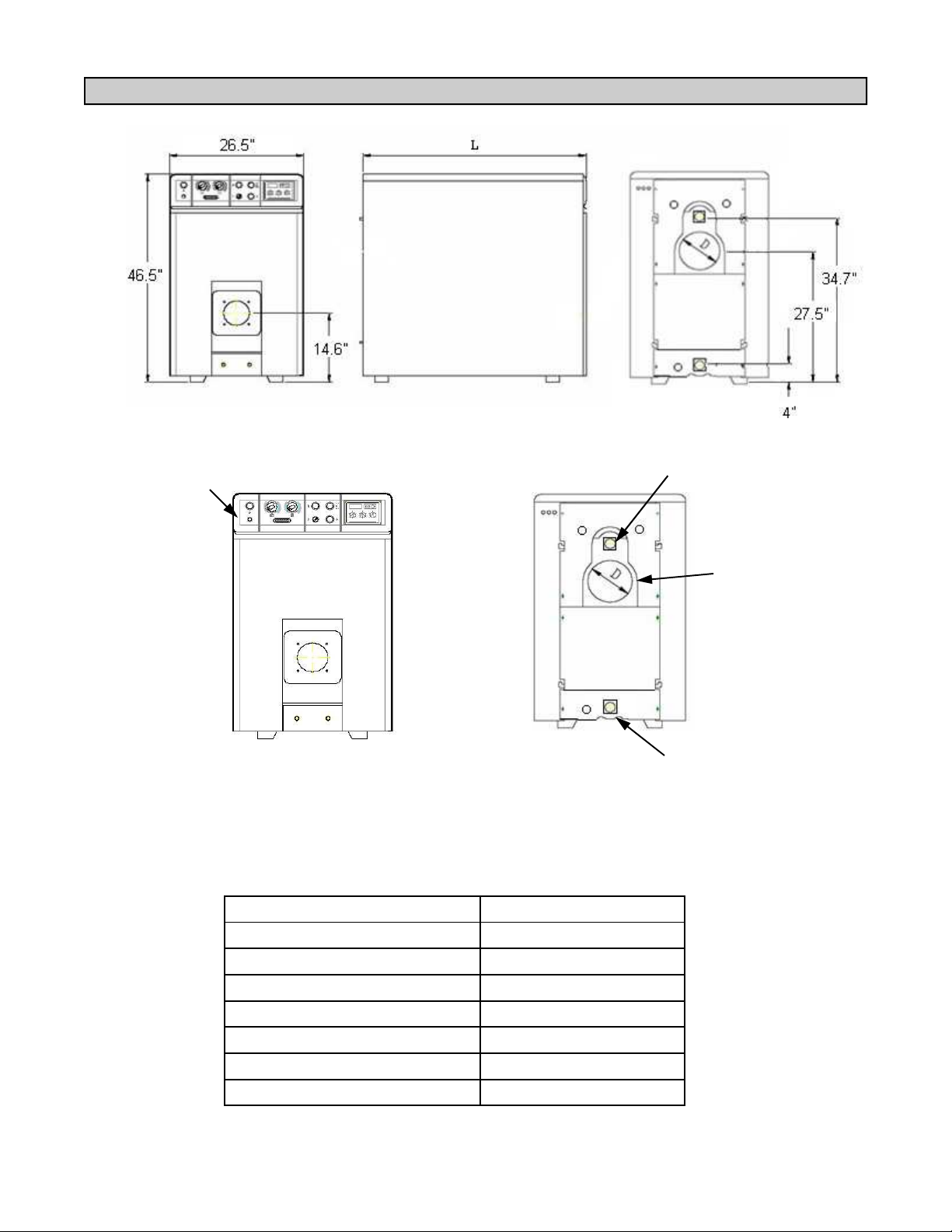

Figure 1:Diagram illustrating the location and function of the front and rear boiler tappings.

2.5” MPT Supply

8” Breech

2.5” MPT Return

Boiler Model Length (L)

B-40/6 34.8”

B-40/7 39.5”

B-40/8 44.5"

B-40/9 49.2"

B-4/10 53.9"

B-4/11 58.8"

B-4/12 63.9"

Page 10

PAGE 10

BIASI B/40

8. Burner Setup:

The following information applies only to the BIASI B-40 series boilers at a maximum output

for power venters or lined chimneys only.

BURNER MANUFACTURER Heatwise

Boiler Mode l B-406 B-407 B-408 B-409 B-410 B-411 B-412

Burner Model

Firing Rate

Insertion Depth

Nozzle

Spray Pattern

Pump Pressure

Head Position

Air Setting

BURNER MANUFACTURER Riello

Boiler Mode l B-406 B-407 B-408 B-409 B-410 B-411 B-412

Burner Model

Firing Rate

Insertion Depth

Nozzle

Spray Pattern

Pump Pressure

Turbulator

Air Gate

P2-KA P2-K P2-K DE-10 DE-10 DE-10 DE-10

2.2 GPH 2.8 GPH 3.5 GPH 4.25 GPH 5.0 GPH 5.7 GPH 6.4 GPH

FULL FULL FULL FULL FULL FULL FULL

2.00 X 45 2.25 X 60 2.75 X 60 3.25 X 60 3.75 X 60 4.5 X 45 5.50 X 45

solid solid solid solid solid solid solid

140 psi 170 psi 175 psi 175 psi 175 psi 160 psi 140 psi

12 16 18 1 1.5 2 2.5

11.50 15.00 18.00 3.5 4.5 5.5 6.75

F-10 F-10 F-15 F-15 F-15 F-20 F-20

2.4 GPH 2.6 GPH 3.3 GPH 4.0 GPH 4.6 GPH 5.3 GPH 5.9 GPH

4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5"

2.00X60 2.00X60 2.50X60 3.00X60 3.50X60 4.0X60 4.5X60

B B B B B B B

145 PSI 175 PSI 175 PSI 175 PSI 175 PSI 175 PSI 175 PSI

3.75 4.5 1.8 2.1 2.8 3.1 5

5 6 3 4 5.5 4 6

BURNER MANUFACTURER Beckett

Boiler Mode l B-407 B-407 B-408 B-409 B-410 B-411 B-412

Burner Model CF 375

Firing Rate

Insertion Depth

Nozzle

Spray Pattern

Pump Pressure

Head Type

Head Position

Air Setting

Good, reliable operation with a minimum of service starts with attention to the small details:

1. Setting the nozzle position and electrodes "by the book" using the manufacturer's gauges.

2. Installing a quality micron filter at the burner.

3. Making careful/tight flare connections without couplings on oil suction line.

4. Checking fuel pump pressure.

5. Checking draft at the breeching to insure it is adequate to overcome flue gas resistance.

6. Setting the air band properly with well maintained instruments. A good target is 11% to 12.5% of (CO2) or 6.5%

to 3.8% of (O2).

Note: Oil and Gas burners on B40-series boilers cannot be properly commissioned

2.1 GPH 2.7 GPH 3.2 GPH 3.7 GPH 4.3 GPH 4.8 GPH 5.3 GPH

4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5"

1.75X60 2.00X45 2.75X45 2.75X45 3.25X45 4.0X30 4.0X30

ES hollow solid solid solid solid solid

140 psi 180 psi 140 psi 180 psi 175 psi 145 psi 180 psi

0 2 3 4.5 3 3 4.5

9/0 3/1 7/0 10/0 7/0 8/0 10/2

CF 375 CF 500 CF 500 CF 800 CF 800 CF 800

without instruments and gauges.

Page 11

BIASI B/40

PAGE 11

8. Burner Setup:

The following information applies only to the BIASI B-40 series boilers at a maximum output

for power venters or lined chimneys only.

BURNER MANUFACTURER Heat Wise

Boiler Model B-406 B-407 B-408 B-409 B-410 B-411 B-412

Burner Model

Fuel

Input

Min. Gas Inlet Size

Manifold in w.c.

Air

Head

BURNER MANUFACTURER Heat Wise

Boiler Model B-406 B-407 B-408 B-409 B-410 B-411 B-412

Burner Model

Fuel

Input

Min. Gas Inlet Size

Manifold in w.c.

Air

Head

SU-3 SU-3 SU-4 SU-5 SU-5 SU-6 SU-6

Natural Natural Natural Natural Natural Natural Natural

315 420 499 577 672 847 954

1" 1" 1" 1" 1" 1" 1-1/4"

1.95" 3" 3.5" 2" 2.8" 1.16" 1.4"

9.5 14 21 7.5 9 4.25 5

6 11 20 2" 2" 2-5/8" 2-5/8"

SU-3 SU-3 SU-4 SU-5 SU-5 SU-6 SU-6

Propane Propane Propane Propane Propane Propane Propane

315 420 527 634 740 847 954

3/4" 3/4" 1" 1" 1" 1" 1"

1.65" 2.4" 2.75" 1" 1.27"

7.25 15 21.5 5.2 5.8

6 10 18 2" 2" 2-5/8" 2-5/8"

Good, reliable operation with a minimum of service starts with attention to the small details:

1. Setting the electrode and flame rod settings against manufacturer's specs to insure proper operation.

2. Installing properly sized gas piping according to BTU input required and length of gas line run.

3. Making sure there is proper manifold pressure before and after the gas valve using a calibrated manometer.

4. Checking draft at the breeching to insure it is adequate to overcome flue gas resistance.

5. Setting the air band properly with well maintained instruments. A good target is 9.5% to 10.5% of (CO2) or 5%

to 2.5% of (O2) for natural gas, or 10% to 12% of (CO2) or 5% to 2.5% of (O2) for lp gas

Note: Oil and Gas burners on B40-series boilers cannot be properly commissioned

To determine how much gas is coming into the

burner, or to set the gas meter correctly, the follow-

Seconds per

Revolution

ing formula can be used.

Ft3/hr = [3600/(sec. Per rev.)]*(Size of gas meter)

The chart to the right can be used to determine the

flow rate depending upon the time per revolution and

the size of the gas meter dial.

without instruments and gauges.

Size of Gas Meter Dial

(Cubic Foot)

0.5 1 2

20 90 180 360

25 72 144 288

30 60 120 240

35 51 103 206

40 45 90 180

45 40 80 160

50 36 72 144

55 33 65 131

60 30 60 120

Page 12

PAGE 12

BIASI B/40

9. Gas Line Piping

Gas supply piping is to be sized and installed properly in order to provide a supply of gas sufficient

to meet the maximum demand without undue loss of pressure between the meter and the boiler. It is

advisable to run a separate gas line from the meter to the gas burner to avoid pressure drops. Consult

with the National Fuel Gas Code ANSI Z223.1 for proper sizing of gas piping for various lengths and

diameters.

Locate a drop pipe adjacent to, but not in front of the boiler. Locate a tee in the drop pipe at the

same elevation as the gas inlet connection to the boiler. Extend the drop line with a nipple towards the

floor and cap to form a sediment trap. Install a tee handle shut off valve before the tee with sediment

trap and a union after the tee before the combination gas valve.

When installing the boiler, Use black steel pipe and malleable fittings (do not use cast iron parts) with

a suitable pipe dope which is resistant to liquefied petroleum gases.

Check piping for leaks. Always check leaks with a water and soap solution. DO NOT USE A

FLAME FOR CHECKING GAS LEAKS

The boiler and its individual shut-off valve must be disconnected from the gas supply piping

during any pressure testing of that piping at test pressures in excess of 1/2 psi.

INSTALLATION OF SEDIMENT TRAP AND BURNER SUPPLY

Direction of

To check for

gas leaks, use

a gas detector

or apply a

soap solution

to the joints.

DO NOT USE AN

Minimum

1” X 1” X 1” Tee

flow

Manual Shutoff Valve

Height of shutoff valve

above ground level to

conform to local codes,

Pressure Gauge

Port

(1/8” NPT plugged)

Male Union 1” NPT

Burner Gas

3” MINIMUM

Pipe Cap

Page 13

BIASI B/40

INSTALLATION OF SEDIMENT TRAP AND BURNER SUPPLY

Piping should consist of:

1. A shut off valve approximately 6’ away from the unit.

2. A 1/8” plugged NPT tapping for gas pressure measurement preferably on the manual

shut-off valve (as shown or anywhere between the gas valve and the shut off value).

Note: The manual shut off valve and tapping are NOT part of the SU-4 Gas Burner.

Please make sure you conform to local and state codes.

3. A gas union.

4. A drip pipe.

Caution: The gas valve should not be subjected to more than ½” PSIG. Therefore, the

burner should be isolated during high-pressure gas leak tests. The appliance and its

individual shut off valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of ½ psig. The

appliance must be isolated from the gas supply piping by closing its individual manual shut off valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ½ psig.

PAGE 13

Page 14

PAGE 14

BIASI B/40

10. Breeching and Venting:

The B-40 Linear boiler is a high efficiency unit that requires proper venting. The boiler must

be vented to the outdoors by means of a tile lined masonry or an approved pre-fabricated chimney of

the size and height recommended by the manufacturer or by a listed "power venting" unit which

provides draft by mechanical venting .

The chimney discharge opening must be located at least 24 inches above any part of the

building structure within 10 feet of the chimney. Be sure the chimney and smoke pipe don't become

obstructed by squirrels, bird nests, soot buildup, chimney liner deterioration, etc. The "power ventor"

system should be installed on the leeward side of the building. Very specific requirements must be

met concerning clearances from combustibles and distances from doors and windows. Please consult

with manufacturer of "power ventor" for this information. In any case, the "ventor" must be installed

by a licensed burner mechanic and done in accordance with local codes. The B-40 boiler is a very low

stack temperature boiler (between 320 and 400F gross stack temp.) so caution should be used when

connecting to an outside built chimney. Should you have concern that the flue gases could condense,

then you should consider using a listed, "power venting" unit. If "power venting" is used to discharge

flue gases, then the power vent unit should be equipped with a postpurge control as well as delay-off,

timing control to prevent problems with fogging and nozzle post drip.

Note: 88% steady state efficiency is achieved when flue gas contains over 12.5% CO2 and the gross

stack temp. is below 350F.

The smoke-pipe connection from the boiler to the chimney should be as short as possible, with

a minimum number of elbows. The vent pipe must have a vertical rise of at least 1/4 inch per foot of

horizontal run. The vent pipe must be of the same diameter as the flue outlet on the boiler. The

chimney connector should have a minimum thickness of 24 gauge, corrosion resistant (galvanized)

steel, assembled with a minimum of three (3) sheet-metal screws, and sealed with high temperature

silicon at each joint. In most cases a barometric draft control isn't recommended as the B-40 is

designed to be pressure-fired. However, one may be needed if the boiler is being used in a high draft

situation.

Page 15

BIASI B/40

PAGE 15

10. Blocked Flue Switch:

1. Pierce a 5/8” hole into the vent pipe near the appliance outlet. Remove one of the securing nuts

from the pipe of the safety switch. Tighten the other securing nut onto the pipe as far as possible.

2. Insert the threaded pipe end into the pierced hole, then install the securing nut, then install the securing nut, which was removed in step 1, and tighten securely.

3. Please consult the wiring section of this manual for the wiring of the blocked flue switch.

11. Piping:

All piping must conform to state and local codes.

The supply and return manifolds for B-40 Linear boilers are 2 1/2” male NPT. Be sure to

provide unions and gate valves at the manifold inlet and outlet of the boiler, so the boiler may be

readily isolated for service.

Install the provided pressure relief valve so the discharge is piped directly to a drain, if

possible. If not, the discharge should be piped to the floor. In either case, the discharge pipe should be

of the same diameter as the outlet of the relief valve, with no valves or obstructions to impede

overflow from the boiler. The installation locations on the manifold for the Pressure Relief Valve, the

Temperature/Pressure Gauge as well the Honeywell L4006E Aquastat can be seen on the following

page.

Install manual and/or automatic air venting devices at the high points in the system to eliminate

trapped air.

The weight of all piping should be supported by suitable hangars and floor stands, not by the

boiler.

It is recommended that the make-up water line have a backflow preventer and a pressurereducing valve to reduce line pressure to 10 to 15 psi installed adjacent to the boiler.

NOTE: If the heating system is to be filled with antifreeze, use only formulations expressly made for

hydronic heating systems (such as propylene glycol). Do not use automotive types of antifreeze

(ethylene glycol). Use of antifreeze will alter system output and characteristics. Consult factory rep's

for details or assistance.

Clearance for hot water pipes are 1 inch to combustibles.

Page 16

PAGE 16

BIASI B/40

Page 17

BIASI B/40

PAGE 17

12. Boiler Jacket Assembly:

NOTE: All piping, boiler controls, gauges and valves must be installed before the jacket has been

assembled on the boiler. Refer to the following page to clarify these boiler jacket assembly

instructions.

Insert the separate piece of insulation (# 92) on top of boiler so the entire top and sides of boiler

are covered. Use plastic strapping to secure the insulation in place. Mount the panel installation

bracket (#82) onto the draw-rods on the upper front of the boiler. Install the six spacers (#86) onto the

draw-rods. Two on the upper draw rods in the front and the remaining spacers onto the draw-rods in

the back of the boiler. Install the rear insulation (#101) onto the boiler. Place the side panels (#66,52)

onto the boiler making sure the draw rod spacers are between the side panels and the boiler casting.

Tighten the sides of the casing to the panel installation bracket (#82) using sheet metal screws. Screw

two studs (#90) into the bottom front of the boiler and screw on the threaded hex spacers (#87) onto

the studs. Attach the lower mounting bracket (#83) to the boiler by using two bolts (#89) and screwing them into the threaded hex spacers. Then using sheet metal screws, attach the lower mounting

bracket to the sides of the casing. Slide the control panel (#110) onto the casing from the top and secure it to the control panel support (#82) using sheet metal screws. Attach the rear panels (#84,85)

using sheet metal screws. Place the top panel (#76) onto the sides of the casing and assure that the

pins on the sides are aligned with the retaining holes on the top casing panel. Finally attach the front

panel (#81) onto the casing by aligning the retaining pins with the retaining holes. Push to insure a

positive connection.

Boiler Components &

Parts Vega B40 - Series

Boiler Jacket Assembly:

Part# Description

84,85 — Rear Jacket Panels*1

92,101— Insulation

52 — Right Jacket Panel

66 — Left Jacket Panel

83 — Front Jacket Supports

110 — Control Panel

82 — Control Panel Support

76 — Top Jacket Panel

81 — Front Jacket Panel*2

*1

Rear insulation not attached, but

included with the casing

*2

Front insulation attached to the

casing

76

101

Page 18

PAGE 18

BIASI B/40

13. Wiring:

The electricity to the boiler shall come from a dedicated breaker in the electric service box. A

service switch should be mounted on the side of the boiler so the burner man can service the burner

and controls. The electrical wiring should be routed so as not to interfere with normal servicing of the

boiler. Wiring done in the field between devices not attached to boiler shall conform with the

temperature limitations for type T wire (63F/35C) or other specified wire as applicable when installed

in accordance to manufacturer's

instructions and wiring diagrams.

Please refer to the wiring section of this manual for instructions on wiring the supplied control

panel.

1

6

1 On/Off Switch

2 Min. Boiler Temp. Thermostat

3 Max Boiler Temp. Thermostat

4 Thermostat By-Pass Button

2

7

3

8

4

5

9

5 Circulator Switch

6 Boiler On/Off Signal Lamp

7 Temperature Gauge

8 Manual Reset High Limit

9 Burner Lock Out Signal Lamp

* NOTE: If the thermostat test button is closed, the thermostats will be bypassed and the burner

will not shutoff until the boiler reaches the manual high limit.

Page 19

BIASI B/40

PAGE 19

CONTROL PANEL DESCRIPTION

1. On/Off Switch — Turns power to control panel on and off and will disable power to the burner

assuming the panel is wired correctly.

2. Minimum Boiler Temperature Thermostat — Maintains a minimum boiler temperature be-

tween 50 degrees F and 170 degrees F.

3. Maximum Boiler Temperature Thermostat — High limit temperature setting for boiler be-

tween 50 degrees F and 205 degrees F.

4. Thermostat Test Button — This button jumps out both thermostats allowing a technician to eas-

ily start the burner for testing if there is no call for heat. Warning, with both thermostats disabled

the only high limit left will be the manual high limit.

5. Circulator Switch - Supplies power to boiler circulator or relay panel. It is not suggested to use

this switch and it is not utilized in any of the suggested wiring diagrams in this manual.

6. Boiler On/Off Signal Lamp — Signal lamp to indicate whether main power switch is turned on

or off.

7. Temperature Gauge - Temperature gauge which takes temperature reading from top front of

boiler.

8. Manual Reset High Limit - Safety high limit that is set to 214 degrees F. If the manual high

limit is tripped, use a flat head screw driver to protective cap on reset button. Then depress reset

button making sure that it stays depressed once you have removed your finger. Once the switch is

reset replace the protective cover.

9. Burner Lock Out Signal Lamp - Lamp to indicate if the burner has gone out on lockout.

1

6

2

7

3

8

4

5

9

Page 20

PAGE 20

BIASI B/40

BURNER CONTROL

B-40 Control Panel Wiring Diagram for Beckett/Heat Wise Oil Burner 24V

CIRCULATOR RELAY

Page 21

BIASI B/40

PAGE 21

CIRCULATOR RELAY

BURNER CONTROL

B-40 Control Panel Wiring Diagram for Beckett/Heat Wise Oil Burner Line Voltage

Page 22

PAGE 22

BIASI B/40

B-40 Control Panel Wiring Diagram for Riello Oil Burner

Page 23

BIASI B/40

PAGE 23

CIRCULATOR RELAY

B-40 Control Panel Wiring Diagram for Heat Wise Gas Burners

Burner Primary Control

Page 24

PAGE 24

BIASI B/40

14. Commissioning:

After installation of oil/gas-fired boiler, operation and performance tests shall be conducted to

make certain that the burner is operating in an acceptable manner and that all safety controls and

devices function properly. It is critical that the high limit, low water

cutoff and burner "cad cell" relay be checked for normal operation before leaving the job. Refer to the

back page of this manual to write down the System Checkout information.

15. Maintenance:

Check for fouling or soot buildup in the combustion chamber at least every twelve (12)

months.

Caution: Black carbon soot in the combustion chamber can, under certain conditions, be

ignited by a spark or open flame. To prevent this unlikely occurrence, dampen the soot deposits with a

wet brush or a fine water spray before servicing or cleaning the combustion chamber. Fouling or

carbon soot buildup on the surfaces in the combustion chamber is caused by incomplete combustion,

and is a sign of combustion air and/or venting problems. As soon as any fouling is observed, the cause

of the fouling should be corrected and the combustion chamber should be cleaned as follows:

Disconnect the electrical power supply to the boiler, burner and controls. Close Fire-O-Matic thermal

shutoff valve at burner prior to servicing. Remove the front jacket panel (#9) and the loosen the two

(2) front boiler door nuts. Swing the boiler door open. Be careful not to damage the door stud threads

or the flexible oil line. Brush and vacuum combustion chamber and flue passages until all deposits are

removed. Reassemble components in reverse order, making sure any damaged gaskets are repaired or

replaced.

Other maintenance requirements are as follows: Inspect wiring and controls for damage. Insure

controls are operating correctly. Inspect oil or gas supply lines for damage, corrosion or leaks. Repair

any leaks immediately. Inspect, clean or replace oil filter as specified by manufacturer. Inspect vent

and fill pipes for any obstruction, damage or corrosion. Clean or replace as necessary. Lubricate the

burner motor if necessary during service. Finally, consult burner manual for specific burner

maintenance instructions.

Page 25

BIASI B/40

16. Installer Notes

System Checkout:

Boiler Model No._________________ Serial No.__________

Original Purchaser: Installer:

_________________________ ______________________

_________________________ ______________________

_________________________ ______________________

Burner Manufacturer----------- Type of Oil Burner-------------

Burner Model No.-------------- Burner Serial No.--------------

Nozzle Manufacturer------------- Nozzle Spray Angle------------

G.P.H. -------------------- Type -----------------------

Burner Performance Tests:

GROSS STACK TEMPERATURE --------------------

ROOM TEMPERATURE (AMBIENT) -------------------

NET STACK TEMPERATURE ---------------------

CO2 -----------------

O2----------------

SMOKE READING ----------------

COMBUSTION EFFICIENCY----------------------

COMMENTS

PAGE 25

Page 26

PAGE 26

BIASI B/40

Page 27

BIASI B/40

PAGE 27

Page 28

PAGE 28

BIASI B/40

Warranty

For BIASI B40 Series Commercial

Cast-Iron Water Boilers

FIRST YEAR through TENTH YEAR-WARRANTY FOR B40 SERIES COMMERCIAL HOT WATER BOILERS: QHT warrants that

its cast-iron boiler and casing are free from defects in material and workmanship for ten years from the date of installation at the

original installation site to the original owner. If the boiler is found to be defective within this period, QHT will replace the

boiler block or casing.

ELEVENTH YEAR and BEYOND -WARRANTY FOR THE CAST IRON BOILER SECTIONS OF THE B40 SERIES COMMER-

CIAL BOILERS: Biasi warrants that the cast-iron sections of the BIASI B40 boilers are free from defects in material and

workmanship for the life of the original installation to the original owner. If the B40 boiler section is then found to be defective,

QHT and Biasi will replace the defective section of the cast iron boiler block.

This warranty is subject to the condition that a heating contractor whose principal occupation is the sale and installation of

heating equipment must have installed the boiler. In addition, the boiler must be installed in accordance with the boiler manual supplied by

QHT Inc with every boiler. PARTS, WHICH ARE COVERED, consists of all materials supplied by Biasi. Other parts supplied in the trim

kit or in the burner pack carry their own warranty and each manufacturer has responsibility for its own products.

NOTE: ANY PART, WHICH IS REPLACED UNDER WARRANTY, CARRIES ONLY THE UNEXPIRED PORTION OF THE

ORIGINAL WARRANTY.

OWNER RESPONSIBILITIES:

1. Provide for proper installation, which includes pressure relief and pressure reducing valves and high limit safety controls on closed

systems.

2. Provide qualified periodic service to prolong proper operation and service.

3. Insure that boiler is installed with approved burner and that installation conforms to all codes and ordinances.

4. This warranty does not apply to boilers, which are subject to misuse, abuse, neglect, alteration, accident, excessive temperature,

excessive pressure, or corrosive water or atmosphere.

5. Owner will be responsible for return of faulty components to Portsmouth, NH, freight pre-paid.

QHT AND BIASI WILL NOT BE RESPONSIBLE FOR:

1. Components that are part of the heating system, but were not manufactured by Biasi or QHT as part of the commercial boiler system.

2. The workmanship of the installers of Biasi B40 Linear boilers. Furthermore, this warranty does not assume any liability for

unsatisfactory performance caused by improper installation.

3. Any costs for labor to remove or replace the faulty component.

4. Improper burner application or adjustments, control settings, care or maintenance.

5. Any damage associated with corrosion or leakage due to the use of "non-barrier", plastic pipe in the heating system.

*THIS WARRANTY DOES NOT EXTEND TO ANYONE EXCEPT THE FIRST PURCHASER AT RETAIL AND ONLY WHEN THE

BOILER IS IN THE ORIGINAL INSTALLATION SITE.

*IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE AND MERCHANTABILITY SHALL BE LIMITED TO

THE DURATION OF THE EXPRESSED WARRANTY. BIASI AND QHT EXPRESSLY DISCLAIM AND EXCLUDE ANY

LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR BREACH OF ANY EXPRESSED OR IMPLIED

WARRANTY.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY HAVE

OTHER RIGHTS THAT VARY FROM STATE TO STATE.

For prompt warranty service, notify the installer, who, in turn, will notify the distributor from whom he purchased the boiler. If this does

not result in corrective action, contact Biasi through Quincy Hydronic Technology (Address Below) with details in support of the warranty

claim. All claims must be processed through proper trade channels. Contact with Biasi directly is not recommended for rapid claim

settlement.

Quincy Hydronic Technology,

3560 Lafayette Rd

Portsmouth, NH, 03801

Tel. (603) 334-6400

ITEM #: B40

REV. H

Loading...

Loading...