Page 1

CENTRAL VACUUM MODELS

IF PROPERLY

BALANCED, THE

DOOR WILL STAY AT A

HALFWAY POSITION

IF PROPERLY

BALANCED, THE

DOOR WILL STAY AT A

HALFWAY POSITION

IF PROPERLY

BALANCED, THE

DOOR WILL STAY AT A

HALFWAY POSITION

AVP3000, AVP7500, AVP12000, AVP24000

AVR3000, AVR7500, AVR12000, AVR24000

INSTALLATION INSTRUCTIONS

For Platinum and Red Series AirVac Units

(for Household Use Only)

IMPORTANT SAFETY NOTES

Please read the instructions carefully! Through many years of continuous use ‑‑ and through quality tests that are

ongoing at our factory ‑‑ AirVac central vacuums, attachments and accessories have built a remarkable record

for cleaning effectiveness and safety. However, there are potential hazards that could occur if the system is not

installed and operated correctly and safely. READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE.

THE FOLLOWING FORMATS ARE USED FOR SAFETY NOTES IN THESE INSTRUCTIONS.

CAUTION

This type of warning note is used to indicate

the possibility of damage to the vacuum power

unit or vacuum duct system.

WARNING

This type of warning note is used to indicate

possible fire or electrical shock hazards that

may cause serious injuries or death.

IMPORTANT SAFETY INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY:

1 NEVER OPERATE THE SYSTEM ON WET

SURFACES OR TO PICK UP LIQUIDS.

2 DO NOT USE THE SYSTEM TO VACUUM UP

FLAMMABLE OR COMBUSTIBLE LIQUIDS

SUCH AS GASOLINE or use in areas where they

may be present.

3 Connect the power unit to a properly grounded

AC outlet only on a dedicated branch circuit.

4 Current‑carrying vacuum hose contains electrical

wires. DO NOT USE THE HOSE IF IT IS

DAMAGED, CUT, OR PUNCTURED. Avoid

vacuuming up sharp objects with the hose.

5 The AirVac system is not a toy. NEVER LET

CHILDREN OPERATE, OR PLAY WITH THE

AIRVAC SYSTEM.

6 Use only as described in the Owner’s Manual and

only with the manufacturer’s recommended

attachments.

7 Do not vacuum up anything that is burning or

smoking, such as cigarettes, matches, or hot

ashes.

8 Do not use without the dust bag (Platinum Series

only) and filters in place.

9 Keep hair, loose clothing, fingers, and all parts of

the body away from openings and moving parts.

10 Do not put any object into any of the wall inlet

valves or vacuum auxiliary air inlet. Do not use

the system with any vacuum opening blocked;

keep all ducting free of dust, lint, hair, or anything

that may reduce the air flow.

11 Turn off all controls before unplugging the power

unit.

12 Use extra care when cleaning stairs to prevent a

fall.

SAVE THESE INSTRUCTIONS.

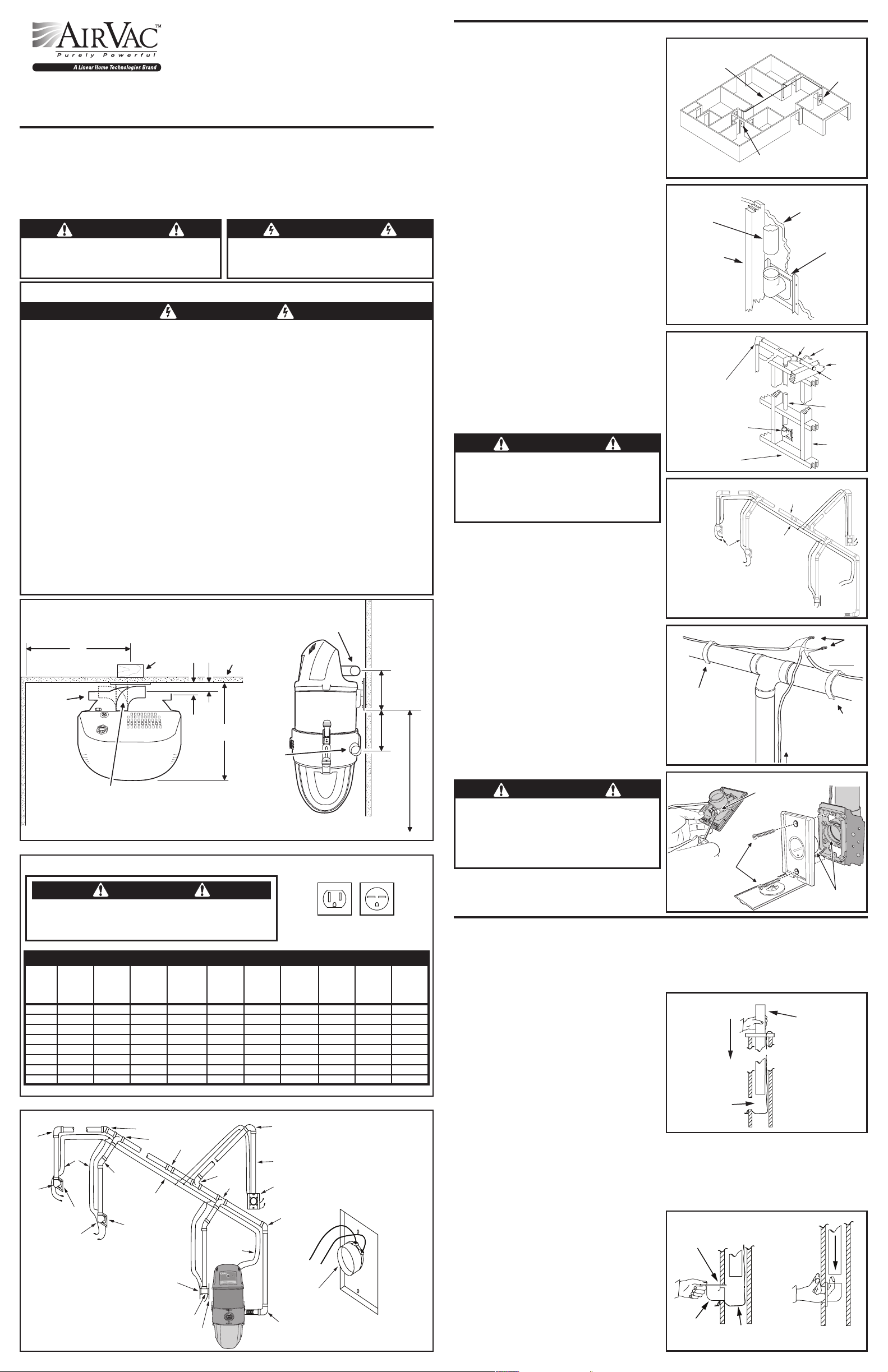

ARCHITECT’S SPECIFICATIONS

FOR LEFTWARD EXHAUST

INTAKE

(LEFT OR

RIGHT)

30"

MINIMUM

WALL STUD

EXHAUST

(LEFT, RIGHT OR VERTICAL)

DEPTH DIMENSIONS

(TOP VIEW)

SPECIFICATIONS

DRYWALL

1-1/4"

1-3/4"

16"

AC POWER

OUTLET MUST BE

WITHIN 5 FEET OF

POWER UNIT TOP

INTAKE

HEIGHT DIMENSIONS

EXHAUST

(SIDE VIEW)

120 VAC

NEMA 5-15R

INTAKE AND

EXHAUST

FROM BOTTOM

OF MOUNTING

BRACKET

8-3/4"

7-1/2"

40" TO

FLOOR

240 VAC

NEMA 6-15R

CAUTION

All circuit breakers must be SEPARATE and DEDICATED

as with any other major appliance. The electrical outlets

MUST match the plug WITHOUT USE OF ADAPTERS

POWER UNIT SPECIFICATIONS

VM103

WALL VALVE

BRACKET

VM241

HOUSE

CIRCUIT

BREAKER

SIZE

VM112

VM106

LOW VOLTAGE WIRES

WALL VALVE

BRACKET

VM241

VM109

DOUBLE-FLANGED

WALL TEE

RECEPTACLE

TYPE

VM102

AIRVAC

OPERATING

MODEL

AVR3000 120 VAC 13.5 AMPS 20 AMP TYPE 1 3000 150 FEET 6 GALLONS 537 PEAK 123” 118 CFM

AVR7500 120 VAC 13.5 AMPS 20 AMP TYPE 1 7500 200 FEET 6 GALLONS 551 PEAK 131” 118 CFM

AVR12000 120 VAC 13.5 AMPS 20 AMP TYPE 1 12000 350 FEET 6 GALLONS 570 PEAK 127” 122 CFM

AVR24000 240 VAC 7 AMPS 15 AMP TYPE 2 12000 500 FEET 6 GALLONS 627 PEAK 137” 124 CFM

AVP3000 120 VAC 13.5 AMPS 20 AMP TYPE 1 3000 150 FEET 5.2 GALLONS 537 PEAK 123” 118 CFM

AVP7500 120 VAC 13.5 AMPS 20 AMP TYPE 1 7500 200 FEET 5.2 GALLONS 551 PEAK 131” 118 CFM

AVP12000 120 VAC 13.5 AMPS 20 AMP TYPE 1 12000 350 FEET 5.2 GALLONS 570 PEAK 127” 122 CFM

AVP24000 240 VAC 7 AMPS 15 AMP TYPE 2 12000 500 FEET 5.2 GALLONS 627 PEAK 137” 124 CFM

VOLTAGE

OPERATING

CURRENT

TYPICAL VACUUM SYSTEM INSTALLATION

VM103

VM104

LOW

VOLTAGE

WIRES

WALL VALVE

BRACKET

VM241

VM104

LOW VOLTAGE WIRES

WALL VALVE

BRACKET

VM241

HOME

SQUARE

FOOTAGE

VM106

LOW

VOLTAGE

WIRES

VM106

MAXIMUM

DUCT

LENGTH

AIRVAC

POWER

UNIT

CAPACITY

VM103

VM101

WALL VALVE

BRACKET

VM241

VM103

VM103

DEBRIS

DO NOT CEMENT

THIS JOINT!

“TYPE 1”

RECEPTACLE

TYPES

AIR

WATTS

VM195 WALL INLET VALVES

TRIM OUT THE VM241 WALL

INLET VALVE BRACKETS

“TYPE 2”

WATER

LIFT

AIR

FLOW

VM195 WALL INLET

VALVE (BACK VIEW)

1 New Construction Vacuum Duct and Wall Inlet Valve Installation

Valve Brackets for Wall Inlet Valves

1 Locate the first valve bracket at a point the farthest

distance from the power unit. From this location,

select additional valve locations. Each location should

allow vacuuming in all corners of the room with a 30’

hose. Remember walls and furniture can shorten the

distance serviced by a valve in some areas, so be sure

to locate inlets with furniture and walls in mind.

2 Nail the valve brackets to the wall studs 12” to 15”

above the floor, usually the same distance from the

floor as electrical wall outlets. Alternate wall valve

bracket configurations are possible.

Vacuum Duct System

1 After the valve brackets are nailed in place, drill a

2‑9/16” diameter hole in the header plate directly

above each valve bracket. Cement a RISER tube from

the valve bracket, extending the tube through the hole

in the header plate for each valve.

2 Starting from the farthest valve bracket, lay tubing (cut‑

to‑length) on top of ceiling joist and work toward the

power unit location. All sweep fittings must curve

in the direction of air flow. Connect all risers from

valve brackets to the main duct line using only 90°

Sweep Tee Fittings (VM106) or 90° Sweep Fittings

(VM103). Cement all duct connections at the time

of installation. There cannot be any air leaks in the

duct systems. Testing of vacuum integrity with wall

inlet valves installed is highly recommended. Vacuum

leaks will affect system performance.

➤ NOTE: The use of nail guards (VM118) and plaster

guards (VM196) are highly recommended to protect

the wall valve brackets and vacuum duct system

during construction.

Low Voltage Vacuum Control Wiring

CAUTION

All wiring installation must conform to local

electrical codes. Wiring in the ground (soil)

must be in conduit. All wiring installation must

have a good, solid mechanical connection.

Protect all connections and/or splices against

short circuits using wire nuts.

1 Low voltage 18‑gauge, 2‑conductor cable connects all

inlet valves to the power unit. When a hose is inserted

into the wall inlet valve, the switch in the hose activates

the power unit automatically; turning the switch off or

removing the hose stops the power unit. Low voltage

cable follows the same route as the vacuum duct

system. Route the 2‑conductor cable from each valve

bracket, up the risers to the main duct line.

2 Splice each additional riser cable to the main duct cable

using wire nuts. All connections will be in PARALLEL.

3 Secure the wiring to the horizontal main line ducts with

tape or quick clips (VM450), but DO NOT TAPE THE

CABLE TO THE RISERS. Secure the loose cable end

at each valve bracket, allowing 6” of extra cable for

each inlet valve connection and 18” of extra cable at

the power unit location.

Wall Inlet Valve Trim-out

1 When the installation is ready for trim‑out, connect the

wires from a wall inlet valve to the cable that descends

from the riser at the valve bracket.

2 Slide the wall inlet valve into the fitting on the valve

bracket.

CAUTION

DO NOT CEMENT WALL INLET VALVES TO THE

VALVE BRACKET FITTING! Occasionally, wall

inlet valves require replacement due to leaky

gaskets or other damage. If the wall inlet valve

is cemented to the valve bracket fitting, the

wall inlet valve cannot be replaced.

3 Secure the wall inlet valve to the valve bracket with the

two wall plate screws.

4 Repeat steps for each wall inlet valve location.

TYPICAL WALL INLET VALVE LOCATIONS

MAIN VACUUM TUBE

FARTHEST WALL INLET

VALVE LOCATION

VALVE BRACKET INSTALLATION

RISER

TUBE

STUD

VIEW FROM

INSIDE OF

WALL

DUCT SYSTEM INSTALLATION

BE SURE ALL

SWEEP TEE FITTINGS

CURVE IN THE DIRECTION

OF THE AIR FLOW

CONTROL WIRE ROUTING

CONTROL WIRE SPLICING

WALL INLET VALVE TRIM-OUT

90˚ ELBOW

VALVE

BRACKET

PLATE

LOW

VOLTAGE

WIRES

ROUTE 2-CONDUCTOR WIRE

FROM EACH VALVE BRACKET

UP TO THE MAIN VACUUM TUBE

CABLE THAT LEADS TO THE

POWER UNIT LOCATION

VM450

QUICK

CLIP

DO NOT TAPE

CABLE TO RISER!

ATTACH WALL INLET

VALVE TO VALVE

BRACKET WITH

TWO SCREWS

MAIN VACUUM

TUBE CABLE

CONNECT CONTROL

WIRES TO WALL

INLET VALVE

MAIN VACUUM

TUBE

FROM VALVE

BRACKET

DRYWALL

SWEEP

TEE

TUBING STRAP

RISER

TUBE

POWER UNIT

LOCATION

SPLICE WIRES

IN

DO NOT CEMENT

THIS CONNECTION!

POWER

UNIT

VALVE

BRACKET

CEILING

JOIST

MAIN VACUUM

TUBE TO

POWER UNIT

STUD

AIRVAC

PARALLEL

VM450

QUICK

CLIP

WIRE

NUTS

2 Existing Construction Vacuum Duct Installation Techniques

Overhead Vacuum Duct Installation

Two people are normally required to perform overhead vacuum duct installations. Power unit installation

requirements are the same as in new construction. Wall inlet valves should be limited to interior walls. Exterior

walls contain insulation and are not normally accessible from inside the roof to drill holes for the vacuum duct.

1 After marking a wall valve location, check inside

the roof area to see if a hole can be drilled in the

header plate for the tubing. BEFORE DRILLING,

CHECK FOR ELECTRICAL WIRING. If there are no

obstructions, drill a 2‑9/16” diameter hole in the header

plate. It is possible that you will hit a fire block about

halfway down the wall. If this is the case, you must use

an extension drill and drill through the fire block. Make

sure the drill is straight up and down or you might

drill through the side of the wall!

2 After holes are drilled, lower tubing and the low‑voltage

control wire from inside the roof to the wall valve.

Seldom is the roof high enough to use a single length

of tubing. As the tube is dropped down the wall to the

valve location, several short lengths of tubing should be

cemented together with a straight coupling (VM102).

3 At the wall valve location, drill a 1” diameter hole in the

wall. Using a flashlight from the attic, check for hole

alignment. Then cut a rectangular hole 2‑½” horizontal

and 3‑½” vertically from the center of the 1” diameter

hole. This hole will allow an adapter (VM107) to make

contact with tubing inside the wall. CEMENT THE

ADAPTER TO THE TUBING.

4 Secure the adapter to the mounting bracket (VM142)

with screws. After the mounting bracket is attached to

the adapter, the completed assembly inside the wall is

ready for the inlet valve (VM195).

5 Connect the low‑voltage control wires and slide the

inlet valve into the fitting on the valve bracket. DO

NOT CEMENT THE INLET VALVE TO THE WALL

BRACKET FITTING. Tighten the valve against the

wall with screws to the mounting bracket.

OVERHEAD RISER INSTALLATION

LOWER RISER

TUBE DOWN

FROM ATTIC

1“ DIAMETER

WALL INLET VALVE

INSPECTION HOLE

ALIGNING THE WALL ADAPTER FITTING

CUT HOLE 2-1/2” WIDE BY

3-1/2” HIGH TO SLIP VM107

ADAPTER INSIDE WALL

VM107

ADAPTER

LOW VOLTAGE

CONTROL WIRE

(DO NOT TAPE TO RISER!)

RISER TUBE

BECAUSE OF LOW

ATTIC CLEARANCE

USE VM102 COUPLINGS

TO CONNECT SEVERAL

SHORT LENGHTS OF

TUBING

ALIGN WITH

FINGER WHILE

CEMENTING THE

FITTING TO THE

RISER TUBE

Page 2

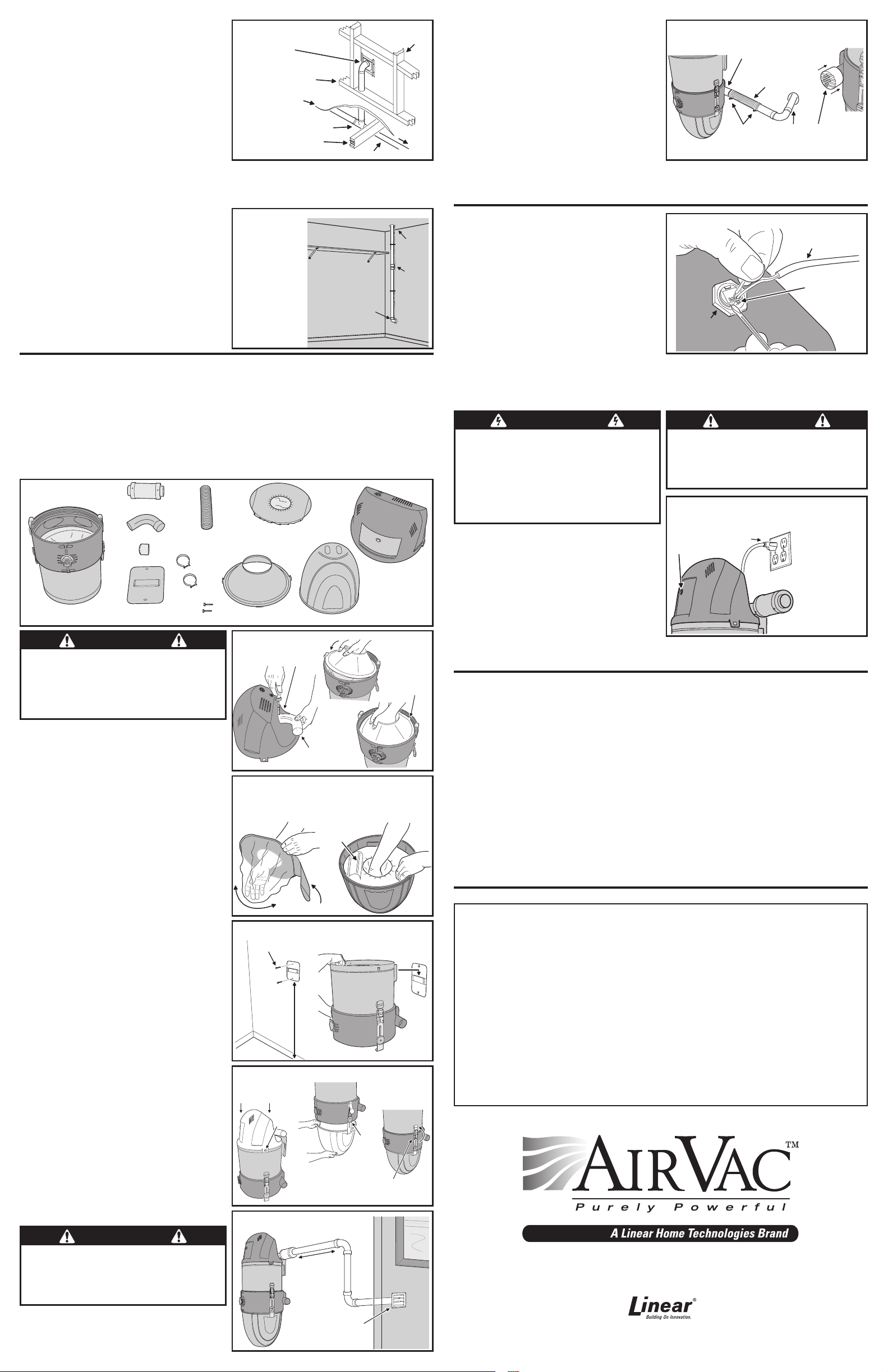

Overhead Vacuum Duct Installation (continued)

6 Secure the inlet valve to the valve bracket with the two

wall plate screws.

7 Repeat steps for each wall inlet valve location.

Under the Floor Installation

In homes with a pier and beam foundation or basement,

either the overhead or an under the floor installation can

UNDER FLOOR INSTALLATION

INSTALL

VALVE BRACKET

12" TO 15" ABOVE

FLOOR LEVEL

PLATE

FLOOR

STUD

be made. Sometimes under the floor installation is easier

in an existing home, especially if the roof has a low pitch

and clearances in the attic adds to the installation problem.

Under the floor installation also eliminates encountering

fire blocks in the wall. Shorter risers are also utilized,

VM106

SWEEP TEE

FLOOR

JOIST

FLOW

MAIN VACUUM TUBE

eliminating the longer tube drop from the attic.

1 Vacuum tubing should be secured to floor joist with

perforated nailing strips or tube straps.

2 Generally, follow the overhead installation steps, but

from below the floor, to install each wall inlet valve.

ALTERNATE DUCT RISER INSTALLATION

Alternate Vacuum Duct Riser Installation

An effective technique highly suitable for many types

of construction with adequate working room inside the

HOLE IN

CEILING

attic is to make drops to the wall inlet valves through the

ceiling, then route the tube through the wall at inlet level

for the inlet valve on the opposite side of the wall. If this

method is used, the drop from the inside of the attic for the

riser can be made in the corner of a closet, utility room,

etc. where the tubing is not visible or not objectionable

THE TUBING DROP

CAN BE INSIDE A CLOSET

THEN THROUGH THE

WALL TO THE WALL

VALVE INSIDE THE ROOM

TO WALL VALVE

ON OTHER SIDE

OF THE WALL

RISER AND

CONTROL

WIRE

to the Homeowner. On occasion this might be the only

alternative for placing an inlet valve in a desired location.

3 Power Unit Installation

Power Unit Unpacking and Pre-assembly

This AirVac power unit is packaged disassembled in a nested configuration which reduces the size of the shipping

carton and allows for much smaller shelf space requirements than previous AirVac models. The power unit must

be assembled during installation.

1 Carefully remove the nested vacuum from the box.

2 Separate each of the nested parts and place them

gently on the floor.

3 Refer to the parts identification figure below to

familiarize yourself with each of the parts.

VACUUM PARTS IDENTIFICATION

EXHAUST MUFFLER

SLIDE-GATE COLLAR BAG

(PLATINUM SERIES ONLY)

MOTOR HEAD

DUST CONE

(PLATINUM SERIES ONLY)

EXHAUST ELBOW & DUST CONE INSTALLATION

ATTACH THE EXHAUST

ELBOW TO THE MOTOR

HEAD WITH #4 SCREW

DUST BAG INSTALLATION (PLATINUM SERIES ONLY)

EXPAND THE DUST

BAG BEFORE PLACING

IT INTO THE DEBRIS BUCKET

HANGING THE MOUNTING BRACKET & MOUNTING THE VACUUM BODY

ATTACH MOUNTING BRACKET

TO WALL WITH TWO LAG SCREWS

SCREW TO

WALL STUD

BOTTOM

EDGE 40"

ABOVE

FLOOR

INSTALLING THE MOTOR HEAD AND DEBRIS BUCKET

SNAP MOTOR HEAD

ONTO VACUUM BODY

RETAINING

SNAP

OPTIONAL EXHAUST TUBING

DEBRIS BUCKET

DO NOT PRESS

CONE PAST THE

LARGE RIDGE

EXHAUST ELBOW

CAN POINT TO

LEFT, RIGHT OR VERTICAL

PLACE BAG'S

SLIDE-GATE

HERE

SLIDE-GATE COLLAR BAG

HANG DEBRIS

BUCKET ON BUCKET

SLIDE LATCHES

TIP DUST CONE

INTO VACUUM BODY

BOTTOM END

PRESS DUST CONE

IN UNTIL THE FOUR

TABS SNAP AGAINST

THE LARGE RIDGE

PLACE THE BAG INTO THE

DEBRIS BUCKET AND

EXPAND THE BAG AGAINST

THE DEBRIS BUCKET SIDES

HANG VACUUM BODY ON

MOUNTING BRACKET

BUCKET

SLIDE

LATCH

SWING THE TWO

BUCKET SLIDE

LATCHES UP

VACUUM BODY

EXHAUST ELBOW

INLET PLUG

MOUNTING

BRACKET

CAUTION

FLEXIBLE HOSE

HOSE

CLAMPS

LAG

SCREWS

Do not mount the motor head onto the vacuum

body until AFTER the vacuum body is hung on

the mounting bracket. Placing the motor head

on the vacuum body before mounting causes

the unit to be top heavy and may tip the vacuum

over, causing damage to the vacuum.

4 Connect the 90° steel exhaust elbow to the motor

head. The exhaust elbow can point to the left, right or

vertical depending on the installation requirements.

Secure the exhaust elbow to the motor head flange

with the #4 self‑tapping screw.

5 PLATINUM SERIES ONLY: Install the dust cone inside

the bottom end of the vacuum body as shown in the

figure. Be sure the cone snaps against the large ridge in

the vacuum body. DO NOT PUSH DUST CONE PAST

THE LARGE RIDGE!

6 PLATINUM SERIES ONLY: Install the slide‑gate collar

dust bag into the debris bucket. BE SURE TO FULLY

EXPAND THE BAG WITH YOUR HAND TO FILL THE

BUCKET.

Power Unit Mounting

1 Determine the mounting location for the power unit. Be

sure clearance dimensions are followed. The power

supply cord length is 5 feet. An AC power outlet of the

proper type on a dedicated circuit breaker must be

available within 5 feet so the power supply cord can be

directly plugged into the electrical outlet. DO NOT USE

AN EXTENSION CORD.

2 Use a stud finder to locate a wall stud for attaching the

mounting bracket. Mark the stud location.

3 Attach the mounting bracket to the wall, centered on the

marked stud, with the bottom edge 40" above the floor,

using the two 1/4" x 2" lag screws and a 7/16" socket.

4 Carefully hang the vacuum body by sliding the body’s

mounting tab into the mounting bracket slot.

5 Fit the motor head onto the vacuum body with the

controls facing forward latching the two locking snaps.

6 Hang the debris bucket on the two bucket slide latches.

Swing the two slide latch handles up to lock the debris

bucket into place.

7 Slide the exhaust muffler onto the exhaust elbow.

Optional Exhaust Tubing

The vacuum’s exhaust can be piped away from the

power unit if desired or required. The exhaust tubing

must vent to the outside of the house, NOT INTO THE

ATTIC. A louvered exhaust vent cap (VM136) is available

to terminate the exhaust tubing. Steel tubing is also

available for the exhaust tubing and may be required by

local building codes.

Vacuum Intake Connection

Depending on the requirements of the installation, the

main vacuum duct line can be connected to the left or

right side intake port of the power unit.

1 Cut a 4" piece of duct tubing.

2 Slide the tubing piece into the left or right power unit

VACUUM INTAKE CONNECTION

VACUUM

INTAKE PORT

FLEXIBLE

HOSE

THE UNUSED

INTAKE PORT

MUST BE SEALED!

intake port. DO NOT CEMENT TUBING.

3 Slide a hose clamp onto the flexible hose. Slide the

flexible hose onto the tubing piece. Tighten the hose

clamp.

4 Slide another hose clamp onto the flexible hose.

Connect the flexible hose to the drop from the main

HOSE

CLAMPS

MAIN

VACUUM

TUBE

INSERT THE INLET

PLUG ONTO THE

UNUSED VACUUM

INTAKE PORT

vacuum duct system line. Tighten the hose clamp.

5 The unused power unit intake port MUST be sealed,

slide the inlet plug onto the unused intake port.

4 Power Unit Electrical

Low Voltage Control Wire Connection

1 Strip back the insulation about 1/2" from the two‑

conductor low voltage control wire cable at the power

LOW VOLTAGE CONTROL WIRE CONNECTION

LOW VOLTAGE

CONTROL WIRE

FROM WALL VALVES

unit.

2 Using a small screwdriver or other object, press down

on one of the wire locks on the control wire connector

(top rear of motor head) while inser ting the wire

into the connector hole. Release the wire lock while

holding the wire in. Repeat with the other wire and the

other hole. Polarity is not important, either wire can be

connected to either hole.

LOW VOLTAGE

CONTROL WIRE

CONNECTOR

PUSH EACH WIRE

LOCK DOWN WHILE

INSERTING THE WIRE

INTO THE CONECTOR

HOLE

Grounding Instructions

This appliance must be grounded. If it should malfunction or breakdown, grounding provides a path of least

resistance for electrical current to reduce the risk of electrical shock. This appliance is equipped with a cord having

an equipment‑grounding conductor and grounding plug. The plug must be plugged into an appropriate outlet that

is properly installed and grounded in accordance with all local codes and ordinances.

WARNING

Improper connection of the equipment-grounding

conductor can result in risk of electric shock.

Check with a qualified electrician or service

person if you are in doubt as to whether the

outlet is properly grounded. Do not modify the

plug provided with the appliance - if it will not

fit the outlet, have a proper outlet installed by a

CAUTION

All circuit breakers must be SEPARATE and

DEDICATED as with any other major appliance.

The electrical outlets MUST match the plug

WITHOUT THE USE OF ADAPTERS. DO NOT USE

AN EXTENSION CORD.

AC POWER CONNECTION

qualified electrician.

Power Connection

1 BE SURE THE UNIT’S POWER SWITCH IS OFF.

Plug the line cord into the AC receptacle.

2 Verify that power is available to the vacuum by

BE SURE THE POWER

SWITCH IS OFF

PLUG THE POWER UNIT

INTO A

GROUNDED

AC OUTLET THAT IS

WIRED TO A DEDICATED

CIRCUIT BREAKER

switching the unit’s power on then off.

DO NOT USE AN

EXTENSION CORD

OR AN AC ADAPTER!

System Testing

The AirVac central vacuum system should be tested for good suction throughout the system. Use a vacuum gauge

(VM181) at each wall inlet valve location to measure the vacuum suction.

5 Troubleshooting

NOTE: NO USER SERVICEABLE PARTS INSIDE, DO NOT LUBRICATE MOTOR.

IF THE MOTOR FAILS TO OPERATE

1 Be sure the power unit is plugged into a working AC outlet.

2 Push breaker reset button on the power unit.

3 Check the panel circuit breaker that connects the power unit.

AFTER CHANGING OF THE BAG (PLATINUM SERIES ONLY)

1 Push down the RESET button for 7 seconds to reset the bag indicator.

IN CASE OF LOW VACUUM POWER

1 Be sure that the inlet plug is inserted into the unused power unit intake port.

2 Check that all wall valves are closed.

3 Check that all gaskets on wall valves are sealed.

4 Check to see if debris bucket or bag (Platinum Series only) needs emptying.

5 Check for obstructions in the hose, tools, or vacuum lines.

6 Check for any ruptures or breaks in the vacuum duct system.

If you are unable to resolve the operational problems, please contact AirVac technical support at (800) 421‑1587.

6 Limited Warranty

Linear LLC warrants AirVac Platinum Series power units to be free of defects for

10 years, and AirVac Red Series power units to be free of defects for 5 years.

The warranty period begins from either (1) the date of “first user” purchase of

this product or (2) the first close of escrow date on a residence in which this

new product was originally installed. This warranty extends to the original user

of the product and to each subsequent owner of the product during the term of

this warranty. Linear LLC will repair or replace, at its option, parts and materials

at no charge. Parts supplied under this warranty may be new or rebuilt at the

option of Linear LLC.

If, during the limited warranty period, it appears as though this product contains

a defect which is covered by this limited warranty, call our toll free service

number before dismantling the product (1-800-421-1587). Remember to

attain a Return Product Authorization number (RPA) before returning any

product to Linear LLC. Send this product freight pre-paid and insured

to our service center for warranty repair. You will be advised on shipping

instructions when you call the toll free service number. Linear LLC will return

the repaired product freight pre‑paid within the U.S.A. The installing dealer or

distributor may assist you, at your choice and expense, with returning product

for repair. Please include a brief description of the problem and a dated proof‑

of‑purchase receipt with any product that is retur ned for warranty repair. ANY

PRODUCT RETURNED WITHOUT A RETURN PRODUCT AUTHORIZATION

NUMBER WILL BE REFUSED.

THIS LIMITED WARRANTY IS IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR

OTHERWISE, AND OF ANY OTHER OBLIGATIONS OR LIABILITY ON THE

SELLER’S PART. THIS LIMITED WARRANTY DOES NOT COVER DAMAGE

CAUSED BY ACTS OF GOD, IMPROPER INSTALLATION, NORMAL

SYSTEM WEAR AND TEAR AS DEFINED BY THE MANUFACTURER, THE

VIOLATION OF APPLICABLE BUILDING OR ELECTRICAL CODES, OR

THE USE OF NON-AIRVAC WIRE, CABLE, OR WALL HOUSINGS. THIS

LIMITED WARRANTY APPLIES ONLY TO PRODUCTS INSTALLED IN A

PRIVATE RESIDENCE.

UNDER NO CIRCUMSTANCES SHALL THE SELLER BE LIABLE FOR

CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES ARISING IN

CONNECTION WITH USE, OR INABILITY TO USE THIS PRODUCT. IN

NO EVENT SHALL SELLER’S LIABILITY, FOR BREACH OF WARRANTY,

BREACH OF CONTRACT, NEGLIGENCE, OR STRICT LIABILITY, EXCEED

THE COST OF THE PRODUCT COVERED HEREBY. NO PERSON

IS AUTHORIZED TO ASSUME FOR US ANY OTHER LIABILITY IN

CONNECTION WITH THE SALE OF THIS PRODUCT.

Some states do not allow the exclusion or limitation of consequential, incidental

or special damages, so the above limitation or exclusion may not apply to you.

This limited warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

CAUTION

In order to avoid motor failure resulting from

excessive back pressure, DO NOT install more

than 30 feet of exhaust tubing and DO NOT

install any bends in the exhaust tubing closer

than 18" from the exhaust muffler.

1 Install any optional exhaust tubing following the

guidance above.

2 Connect the optional exhaust tubing to the muffler.

18" MINIMUM FROM

THE MUFFLER BEFORE

ANY BENDS IN THE

EXHAUST TUBING

EXHAUST TUBING

MUST VENT OUTSIDE

OF THE HOUSE

VM136

LOUVERED

EXHAUST

VENT CAP

OUTSIDE

WALL

www.purelypowerful.com

Manufactured by:

USA & Canada (800) 421-1587 & (800) 392-0123

(760) 438-7000 - Toll Free FAX (800) 468-1340

Copyright © 2010 Linear LLC 226529 B

www.linearcorp.com

Loading...

Loading...